The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Vehicle Valeting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Vehicle Valeting Interview

Q 1. What are the different types of car washes and their effectiveness?

Car washes come in various types, each with its own level of effectiveness. The most common are:

- Automatic Washes: These use automated brushes, rollers, or high-pressure sprays. While convenient, they can cause scratches and swirl marks, especially on delicate paint finishes. Their effectiveness varies greatly depending on the quality of the wash and the condition of the equipment.

- Touchless Washes: These use high-pressure water jets and specialized detergents instead of brushes. They minimize the risk of scratching but may not be as effective at removing stubborn dirt and grime, particularly in crevices.

- Self-Service Washes: These provide customers with various tools and options like high-pressure wands, foam brushes, and different detergents. This option offers more control but requires more time and effort. The effectiveness relies heavily on the user’s technique and the products used.

- Hand Washes: This is the most effective method, employing detailed hand washing and drying techniques with specialized tools and products. It minimizes the risk of damage and ensures thorough cleaning. This method requires more skill and time, hence its cost.

In summary, hand washing is the most effective method for thorough cleaning and preserving your car’s paint, while automatic washes offer convenience at the expense of potential damage. Touchless and self-service washes fall somewhere in between, offering a balance of convenience and effectiveness.

Q 2. Explain your experience with various detailing products (e.g., waxes, sealants).

My experience spans a wide range of detailing products. I’ve worked extensively with various waxes, from traditional carnauba waxes, offering a natural, deep shine and moderate protection, to synthetic waxes providing increased durability and water resistance. I also have in-depth knowledge of sealants, which offer a harder, more durable protective layer compared to waxes. These range from polymer-based sealants offering moderate protection and gloss, to ceramic coatings that provide the most durable and hydrophobic protection available – often lasting for years.

For example, I’ve found that using a high-quality sealant followed by a carnauba wax provides the ultimate combination of protection and stunning shine. The sealant provides the durable base coat against the elements while the carnauba adds depth and warmth to the finish. I carefully select products based on the client’s needs and the vehicle’s condition, considering factors such as paint type and desired level of protection and gloss.

Q 3. How do you remove different types of stains from car interiors?

Stain removal from car interiors requires a careful, tailored approach. The type of stain dictates the appropriate cleaning method.

- Spills (Coffee, Soda, Juice): These are generally addressed by immediate blotting (never rubbing) with a clean cloth or paper towel. A specialized interior cleaner may be used afterwards.

- Grease or Oil Stains: A degreasing agent, such as a diluted dish soap solution, followed by a thorough rinse and drying is usually effective.

- Ink Stains: These often require specialized stain removers or even professional cleaning, depending on the ink type and the material. Testing the cleaner on an inconspicuous area first is crucial.

- Mud or Dirt: Pre-vacuuming followed by gentle scrubbing with an appropriate cleaner and brush is typically sufficient.

It’s essential to always test any cleaning solution on an inconspicuous area first to ensure it doesn’t damage the material. For stubborn stains, professional detailing services might be necessary.

Q 4. Describe your process for cleaning and protecting leather car seats.

Cleaning and protecting leather car seats requires specialized products and techniques to maintain their supple texture and prevent cracking. My process involves:

- Thorough Cleaning: I begin by vacuuming the seats to remove loose dirt and debris. Then, I use a dedicated leather cleaner appropriate for the type of leather (e.g., aniline, semi-aniline, top-grain). I apply it with a soft brush and gently wipe away dirt and grime.

- Conditioning: After the leather is clean and dry, I apply a high-quality leather conditioner. This replenishes lost moisture, keeps the leather soft and supple, and helps prevent cracking. I apply it evenly using a soft cloth and allow it to absorb properly.

- Protection (Optional): Depending on the client’s needs, I might apply a leather protectant to create a barrier against spills and stains. This further enhances the lifespan and aesthetic appeal of the seats.

The key is to use products specifically designed for leather and to avoid harsh chemicals that can strip the leather of its natural oils.

Q 5. How do you handle scratches and minor paint damage?

Handling scratches and minor paint damage requires a careful assessment. Simple scratches can often be buffed out using rubbing compound and polishing compound, with the proper technique and tools. This involves using progressively finer grades of compound to remove the scratch and restore the shine. For deeper scratches or chips that reach the primer, professional paint repair or touch-up might be required to ensure the proper restoration of the paint’s integrity.

In more complex situations, such as deep gouges or significant damage, I advise the client to seek professional bodywork repair, as attempting DIY solutions may cause further damage.

Q 6. What are the steps involved in a complete exterior detail?

A complete exterior detail involves a methodical approach, typically including:

- Pre-wash: Removing loose dirt and debris with a pressure washer and specialized pre-wash solution. This minimizes scratching during the wash.

- Wash and Rinse: Using the two-bucket method (one with wash solution, one with clean water for rinsing the wash mitt) with a high-quality wash mitt or sponge and specialized car wash soap. This reduces the risk of introducing scratches during washing.

- Decontamination: Removing bonded contaminants like tar, tree sap, and iron particles. This typically involves specialized clay bar or iron remover products.

- Drying: Thoroughly drying the vehicle to prevent water spots with a high-quality drying towel or air blower.

- Polishing and Refinishing (optional): If the paint is dull or has imperfections, I use a polishing compound and a polishing pad to correct these imperfections and restore the shine.

- Waxing or Sealing: Applying a wax or sealant to protect the paint from the elements and enhance shine.

- Tire Cleaning and Dressing: Cleaning and applying a tire dressing to improve their appearance.

- Window Cleaning: Cleaning the interior and exterior windows for a clear view.

The order and specific products used may vary depending on the vehicle’s condition and the client’s preferences.

Q 7. What techniques do you use to achieve a swirl-free finish?

Achieving a swirl-free finish requires meticulous attention to detail and the right tools. The two-bucket method during washing is a key element, preventing the introduction of swirl marks from dirty wash mitts. However, the most important aspect is the polishing process. I utilize:

- High-quality polishing pads: Choosing the appropriate pad (foam, wool, etc.) depending on the severity of imperfections and the desired level of correction.

- Proper polishing technique: Using overlapping passes and minimal pressure to prevent creating new swirl marks.

- Dedicated polishing tools: Using dual-action or rotary polishers depending on the situation. Dual-action polishers are generally preferred for minimizing the risk of causing damage.

The goal is to remove imperfections without introducing new ones. Practice, attention to detail, and the right tools are vital for achieving a flawless, swirl-free finish.

Q 8. How do you clean and maintain car wheels and tires effectively?

Cleaning and maintaining car wheels and tires effectively involves a multi-step process. Think of it like giving your car’s shoes a spa day! First, you need to pre-wash the wheels to remove loose dirt and grime. A pressure washer is ideal for this, but be careful not to get too close to avoid damage. Next, use a dedicated wheel cleaner – these are formulated to break down brake dust and other stubborn contaminants. Apply it, let it dwell according to the product instructions, and then thoroughly scrub with a brush specifically designed for wheels (a stiff-bristled brush is best). Rinse again with the pressure washer. Finally, dress the tires with a tire shine product for UV protection and a glossy finish. This process prevents build-up of brake dust, which can damage the wheels over time and dull their appearance. Regular maintenance, even just a quick rinse after each drive in harsh conditions, significantly extends the life and beauty of your wheels.

Q 9. Describe your experience with using a pressure washer.

I have extensive experience using pressure washers, both hot and cold water models. I’m proficient in adjusting the pressure and nozzle to suit different surfaces and cleaning tasks. For example, I use a lower pressure and wider nozzle for delicate areas like paintwork, and a higher pressure with a concentrated nozzle for tackling stubborn dirt on wheels and undercarriage. Safety is paramount; I always wear appropriate protective gear, including eye protection and gloves, and ensure the area is clear of bystanders. I understand the potential for damage if used incorrectly, so I’m meticulous about technique and always test pressure in an inconspicuous area before applying it to the main surface. For instance, I once used a pressure washer on a classic car, taking extra precautions to avoid water ingress into the electrics. The result was a gleaming finish without any damage.

Q 10. Explain your knowledge of different types of car cleaning equipment.

My knowledge of car cleaning equipment is comprehensive. I’m familiar with a wide range of tools, from basic items like microfiber cloths and buckets to more specialized equipment. This includes: pressure washers (as discussed), various types of brushes (wheel brushes, detailing brushes), vacuum cleaners (wet/dry and shop vacs for interiors), steam cleaners (for upholstery and stubborn stains), rotary and dual-action polishers (for paint correction), and various detailing tools like clay bars and applicator pads. I understand the strengths and weaknesses of each piece of equipment and choose the appropriate tool for each job. For example, using a rotary polisher requires skill to avoid burning through the clear coat, unlike a dual-action polisher, which is safer for less experienced users.

Q 11. How do you handle difficult customers or challenging situations?

Handling difficult customers or challenging situations requires patience, empathy, and clear communication. I always strive to understand their concerns and address them directly. I listen actively, acknowledge their feelings, and then explain the process clearly and professionally. If there’s a misunderstanding, I try to clarify it with patience and offer solutions. For example, I once had a customer who was unhappy with a minor imperfection that I couldn’t fully remove, and I offered a discount on their next service. Open communication, combined with a willingness to find a fair resolution, is key to de-escalating any tense situation and maintaining a positive customer experience.

Q 12. What is your experience with applying paint protection film or ceramic coatings?

I have experience applying both paint protection film (PPF) and ceramic coatings. PPF is a clear urethane film that protects the paint from rock chips and other damage, creating a self-healing barrier. Ceramic coatings, on the other hand, form a hard, chemically bonded layer that protects against UV rays, water spots, and environmental contaminants. Both offer significant protection, but PPF is better at resisting physical damage, while ceramic coatings enhance shine and make cleaning easier. The application process for both requires meticulous preparation, including thorough cleaning and paint correction to ensure proper adhesion. I follow manufacturer instructions carefully to achieve optimal results. For instance, I recently applied a ceramic coating to a client’s brand-new sports car, protecting the paint and delivering an incredible glossy finish.

Q 13. Describe your experience with interior detailing, including vacuuming, shampooing, and leather conditioning.

Interior detailing is a crucial aspect of my work, encompassing a range of tasks to achieve a pristine interior. This starts with thorough vacuuming, removing all loose dirt and debris from carpets, upholstery, and crevices. Next, I may use a steam cleaner or interior detailing shampoo to clean upholstery and carpets, addressing any stains or spills. I use appropriate cleaning agents based on the material. Leather surfaces require specific conditioning products to maintain their suppleness and prevent cracking. I also clean and dress the dashboard, console, and other interior surfaces, using appropriate products to avoid damaging delicate materials. I often use specialized brushes and detailing tools to reach hard-to-clean areas, ensuring a comprehensive clean. It’s similar to spring cleaning your house, but with specialized tools and materials for a car’s delicate interior.

Q 14. What safety procedures do you follow when using detailing chemicals?

Safety is my top priority when working with detailing chemicals. I always read and follow the manufacturer’s instructions carefully before using any product. I wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator when necessary, particularly when working with strong or volatile chemicals. I work in a well-ventilated area, preferably outdoors or with good ventilation to minimize exposure to fumes. I store chemicals properly, away from heat and ignition sources, and never mix different chemicals without fully understanding the potential reactions. I also dispose of used chemicals responsibly, according to local regulations. For example, if working with a very strong cleaner I will always ensure proper ventilation and wear a respirator.

Q 15. How do you manage your time and prioritize tasks during a busy day?

Effective time management in valeting is crucial. I use a combination of techniques. Firstly, I always begin my day with a detailed plan, prioritizing tasks based on urgency and the time each will take. This might involve assessing the vehicles scheduled for the day and grouping similar jobs together – for example, all interior detailing followed by exterior work. This minimizes wasted time switching between tools and cleaning solutions. Secondly, I meticulously track my progress. If I find myself falling behind on schedule, I quickly re-evaluate and adjust my approach, possibly delegating tasks if working as part of a team. Think of it like a conductor orchestrating a symphony – every section needs careful timing to create a harmonious whole.

For example, if I have a particularly complex detail job alongside several quicker ones, I’ll strategically place the complex job to maximize workflow efficiency. Perhaps scheduling it for a quieter period, or breaking it into smaller, manageable segments interspersed with faster tasks. This keeps momentum going and avoids feeling overwhelmed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is paramount for efficiency and safety. My approach is multifaceted. Firstly, I have designated areas for different cleaning solutions and tools, clearly labeled to avoid confusion and accidental mixing. This is essential for safety and helps me locate items quickly. Regularly, I clean and disinfect all surfaces, including my workbenches and equipment. This prevents cross-contamination and maintains a professional image. A messy workspace equals a messy outcome – imagine trying to find a specific microfiber cloth in a chaotic environment! Finally, I implement a strict “clean as you go” policy, ensuring tools and materials are put away immediately after use. This prevents clutter and ensures I always have a clear workspace ready for the next task.

Q 17. What are the common signs of damage you look for during a pre-detail inspection?

A thorough pre-detail inspection is vital to avoid costly mistakes and unexpected issues. I systematically check for various types of damage, including:

- Scratches and swirl marks in the paintwork, noting their depth and location.

- Dents and dings, evaluating their size and impact on the overall aesthetic.

- Stone chips on the paintwork, which could require touch-up paint.

- Glass damage such as chips or cracks in the windshield or windows.

- Interior damage, such as tears in upholstery, stains on carpets, or broken components.

- Wheel damage including scuffs, scratches or curb rash.

I document all findings using photographic evidence, informing the customer before commencing any work. This ensures transparency and avoids misunderstandings regarding the condition of the vehicle before and after detailing.

Q 18. What are some common mistakes to avoid during vehicle valeting?

Several common mistakes can significantly compromise the quality of a vehicle valeting service. One major error is using the wrong cleaning products or techniques. Using abrasive cleaners or harsh chemicals on delicate surfaces can cause irreversible damage. For example, using a strong alkaline cleaner on a car’s paintwork can strip away the protective wax layer. Another frequent mistake is inadequate rinsing. Residual cleaning products can leave streaks and water spots, defeating the purpose of the detailing. Failing to dry the vehicle thoroughly after washing also risks water spotting and streaking, leaving a less-than-perfect finish. Finally, neglecting to protect the interior can lead to staining and damage. Using unsuitable upholstery cleaners or neglecting to protect delicate surfaces from harsh chemicals can significantly diminish the quality of the valet.

Q 19. How would you handle a situation where a customer is unhappy with the service?

Customer satisfaction is my top priority. If a customer expresses dissatisfaction, my first step is to listen attentively and empathize with their concerns. I would then thoroughly investigate the issue, identifying the root cause of their complaint. Perhaps a detail wasn’t completed to their satisfaction, or they noticed something overlooked. This could involve re-inspecting the vehicle together to understand their specific concerns. My goal is to understand their perspective and find a solution that meets their expectations. This could involve redoing the work, offering a partial refund, or providing a complimentary service to compensate for the issue. Maintaining calm, professional communication and a focus on problem-solving is key. My aim is to turn a negative experience into a positive one, showing them that we value their feedback and are committed to their satisfaction.

Q 20. What is your experience with steam cleaning?

I have extensive experience using steam cleaning in vehicle valeting. It offers several advantages. Steam effectively sanitizes surfaces by killing bacteria and viruses, making it ideal for interior detailing. It also loosens dirt and grime more effectively than traditional methods. This minimizes the need for harsh chemicals, making it an eco-friendly option. However, steam cleaning also presents challenges. High-pressure steam can damage delicate interior components if not used carefully. Certain materials, such as leather, require specific steam cleaning techniques to avoid damage. Therefore, training and understanding its application are vital. For instance, the distance of the steam nozzle from the surface, and the amount of dwell time is critical. Understanding these variables makes steam cleaning a very efficient tool in the valet process.

Q 21. What are your preferred methods for cleaning glass surfaces?

My preferred methods for cleaning glass surfaces prioritize streak-free results and long-lasting clarity. I typically start with a thorough pre-cleaning to remove loose dirt and debris. This may involve a simple rinse with water, followed by a high-quality glass cleaner applied with a microfiber cloth. I use a back-and-forth motion for initial cleaning, followed by a vertical wiping pass to remove any lingering residue. The key is to use clean microfiber cloths for each pass to prevent streaks. For stubborn stains or water spots, a dedicated glass cleaner may be required, ensuring careful and thorough rinsing to prevent residue. For optimal results, I always work in a shaded area to avoid sunlight interference during the process. Just like a painter needs the right lighting, I need to ensure ideal conditions for a sparkling finish.

Q 22. How do you deal with stubborn water spots on paintwork?

Stubborn water spots, also known as etching, are a common problem in vehicle valeting. They occur when mineral deposits in hard water dry on the paint surface, leaving behind unsightly marks. Dealing with them requires a multi-step approach, starting with assessment. The severity of the etching will dictate the method used.

- Mild Spots: These can often be removed with a thorough wash using a quality car wash soap, followed by a detail spray and a gentle wipe down with a microfiber towel. A dedicated water spot remover may also be effective here.

- Moderate Spots: More aggressive techniques are needed. This may involve using a dedicated water spot remover, followed by polishing with a fine-grade polish and a dual-action polisher (DA polisher). This is important to avoid burning through the clear coat.

- Severe Spots: For deep etching, compounding may be necessary. Compounding is more abrasive than polishing and removes a tiny layer of clear coat to level out the surface. This should only be done by experienced detailers as incorrect application can cause more harm than good. After compounding, polishing is always recommended to refine the finish.

It’s crucial to work in small sections, and always test any product on an inconspicuous area first. Remember, prevention is key! Regular washing and drying, preferably with a drying aid, is vital in preventing water spot formation.

Q 23. Describe your knowledge of different types of car fabrics and their cleaning methods.

Understanding car fabrics is critical for effective cleaning. Different materials require different cleaning methods to avoid damage.

- Leather: Leather is a durable material but sensitive to harsh chemicals. It should be cleaned using specialized leather cleaners, conditioned regularly to maintain its suppleness and protect against cracking, and protected with a leather sealant. I always advise against using household cleaners on leather.

- Fabric (Cloth): This is a very common upholstery material. Fabric upholstery requires a fabric cleaner specifically designed for automotive use. These cleaners typically come in spray bottles or foam applicators and should be agitated gently using a soft brush or detailing brush. Always follow the manufacturer’s instructions.

- Vinyl: Vinyl is a relatively low-maintenance material that can be cleaned with all-purpose cleaners or vinyl-specific cleaners. Avoid using abrasive cleaners, which can scratch the surface. A simple wipe down with a microfiber cloth often suffices.

- Suede/Alcantara: These materials are more delicate and require specialist cleaners. It’s best to test any cleaning product on a small, hidden area before applying it to the whole surface. Professional cleaning may be necessary for heavily soiled areas.

Vacuuming before cleaning is always recommended for all fabrics to remove loose dirt and debris. Always allow the fabric to dry completely after cleaning, ensuring good air circulation to prevent mildew or mold growth.

Q 24. What are your experience with engine bay cleaning?

Engine bay cleaning is a more advanced aspect of valeting, requiring care and precision to avoid damaging electrical components. My experience includes thorough degreasing, using specialized engine degreasers and high-pressure water, and careful rinsing to ensure complete removal of all residue.

I use a variety of brushes, including detail brushes and smaller brushes to reach tighter spaces. I meticulously protect sensitive electrical components with plastic sheeting and tape before starting. After degreasing and rinsing, I use a variety of specialized products to dress components like plastic and rubber, restoring their original appearance and protecting them from future degradation. The final step is to meticulously dry everything using compressed air, ensuring no moisture remains in the engine bay.

Safety is paramount in engine bay cleaning. I always ensure the engine is completely cool before I begin. I also take precautions with electrical components and avoid high-pressure water near sensitive electronics.

Q 25. How familiar are you with the use of polishing and compounding techniques?

Polishing and compounding are crucial for paint correction and enhancing a vehicle’s shine. Compounding uses more abrasive materials to remove imperfections like scratches and swirl marks, effectively removing a microscopic layer of paint. Polishing, on the other hand, refines the surface, leaving a smooth, glossy finish.

I have extensive experience using both rotary and dual-action polishers, understanding the nuances of each and the techniques needed to achieve professional-level results. Selecting the right compound and polish based on the paint condition is critical, and my knowledge encompasses a range of products to suit various paint types and defects. I’m also proficient in techniques like paint depth measurement to ensure I don’t remove too much clear coat.

For example, I might use a more aggressive compound with a rotary polisher for deeper scratches, followed by a finer polish with a dual-action polisher for a flawless finish. Always protecting the surrounding areas with painter’s tape before starting ensures a clean and precise outcome.

Q 26. What are your salary expectations for this role?

My salary expectations are in line with the industry standard for experienced vehicle detailers with my skillset and experience. Considering my proven expertise in paint correction, engine bay detailing, and upholstery cleaning, I am seeking a competitive salary package that reflects my value.

I am open to discussing a specific figure after learning more about the complete compensation and benefits package offered.

Q 27. Are you comfortable working independently and as part of a team?

I am entirely comfortable working both independently and collaboratively. My experience in this industry has honed my ability to manage my workload effectively and meet deadlines while working solo. I can equally contribute effectively within a team environment, sharing knowledge and supporting colleagues.

I’m a strong believer in team synergy, and I actively seek opportunities to learn from and share expertise with others. I’m adept at adapting my work style depending on the task and team dynamics.

Q 28. What are your long-term career goals in the vehicle valeting industry?

My long-term career goals in the vehicle valeting industry include achieving a level of mastery and expertise that allows me to become a mentor and trainer for others in the field. I envision contributing to the continued improvement of techniques and standards within the industry.

I am particularly interested in exploring opportunities to specialize further in paint correction and advanced detailing techniques. Eventually, I aspire to manage a team of detailers and contribute to the success of a reputable and high-quality automotive detailing business.

Key Topics to Learn for Your Vehicle Valeting Interview

- Exterior Cleaning Techniques: Understanding different washing methods (two-bucket, foam cannon), appropriate cleaning agents for various surfaces (paint, glass, trim), and safe drying practices to avoid scratches.

- Interior Detailing: Mastering vacuuming techniques, upholstery cleaning (fabric and leather), stain removal, and odor elimination. Consider the practical application of different cleaning solutions and tools for various interior materials.

- Wheel and Tire Care: Proper wheel cleaning techniques to prevent damage, tire dressing application, and understanding the importance of maintaining tire pressure.

- Vehicle Protection: Knowledge of waxing, sealing, and polishing techniques to protect paintwork. Understanding the benefits and application of different protective coatings.

- Tools and Equipment: Familiarity with common valeting tools (e.g., pressure washers, steam cleaners, detailing brushes) and their safe and effective usage.

- Health and Safety: Understanding and adhering to health and safety regulations regarding the use of chemicals and equipment. Practical application of safe working practices.

- Customer Service: Demonstrating excellent communication skills and the ability to manage customer expectations. This includes addressing concerns professionally and efficiently.

- Time Management and Efficiency: Understanding how to prioritize tasks and complete valeting services within a reasonable timeframe. This includes estimating job durations and optimizing workflows.

Next Steps

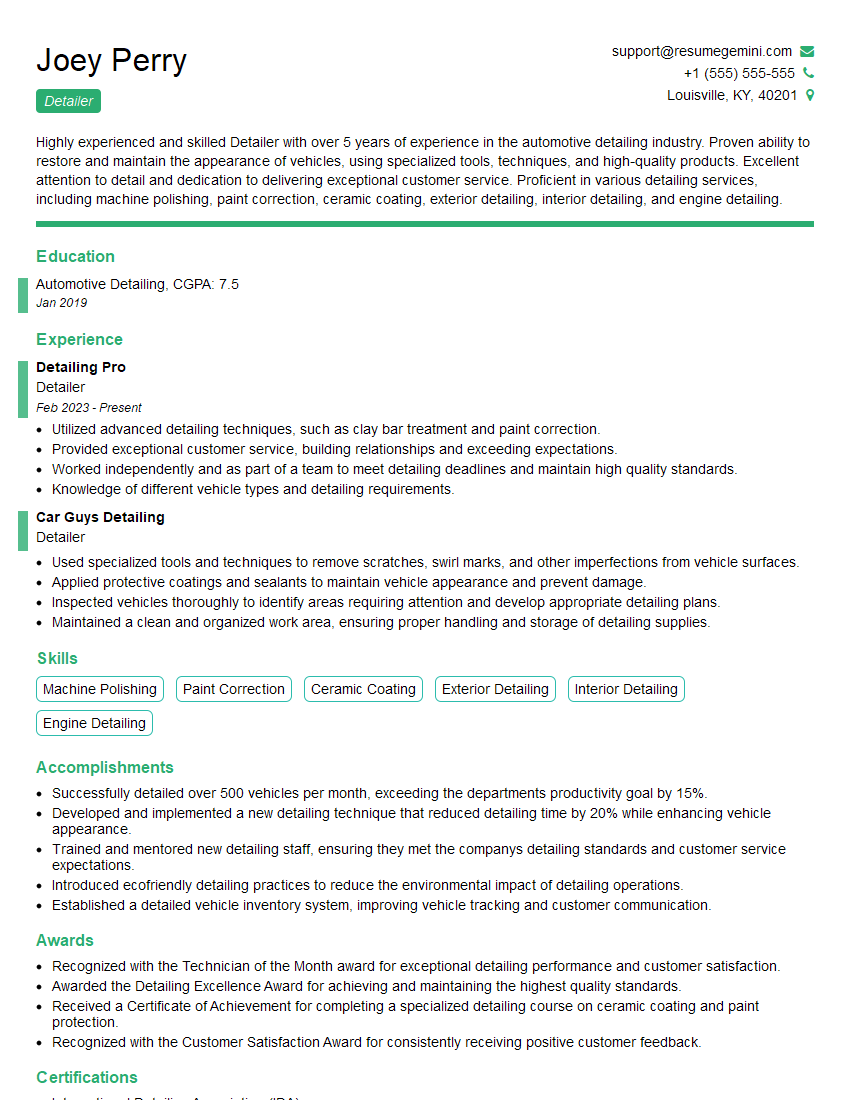

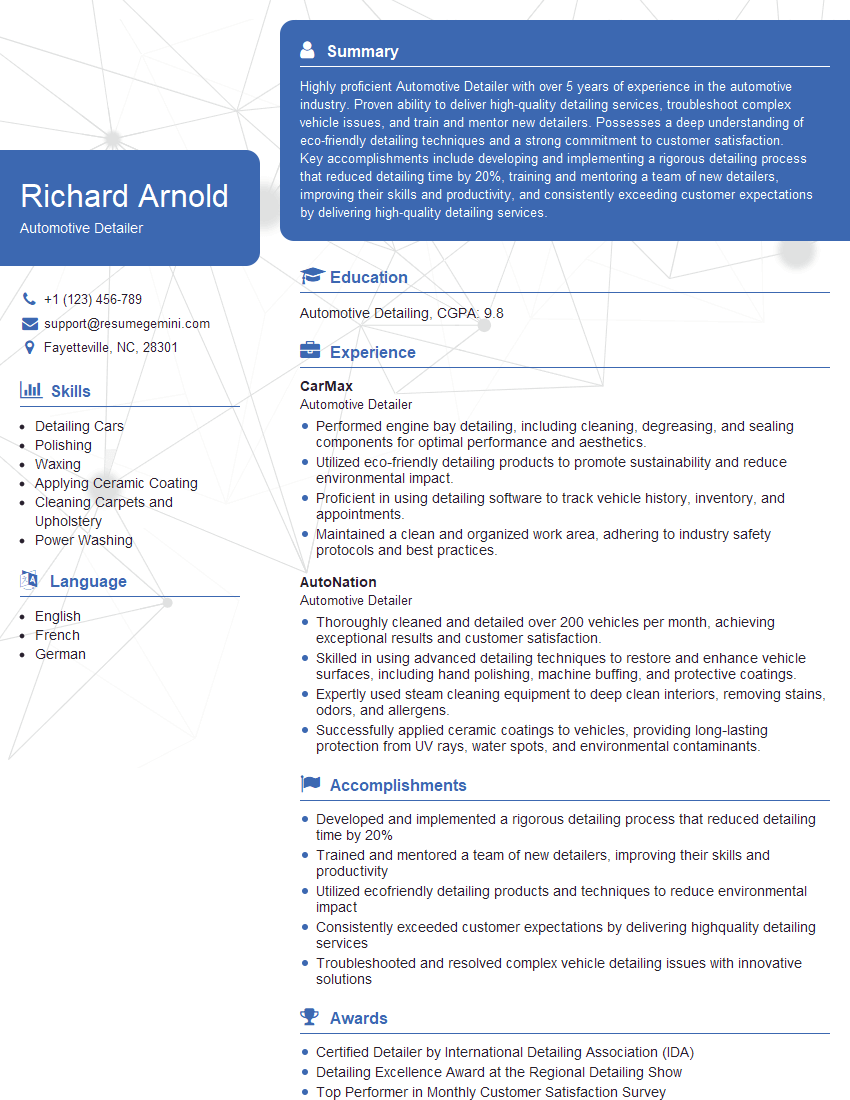

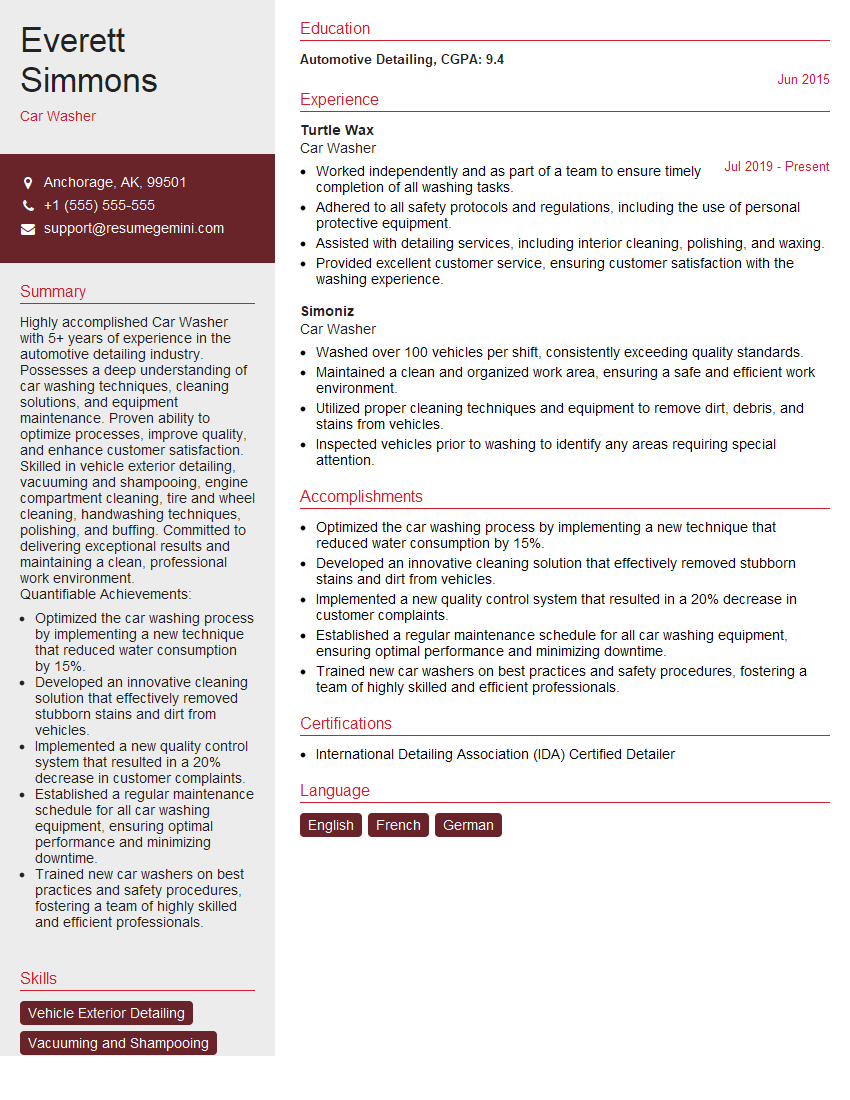

Mastering vehicle valeting opens doors to a fulfilling career with opportunities for advancement, from entry-level detailer to team leader or even business ownership. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. This ensures your application gets noticed by hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume that showcases your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the vehicle valeting industry to help you get started. Invest the time in crafting a compelling resume – it’s your first impression and a key step toward your successful career in vehicle valeting.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO