The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Expertise in Automotive Mechanical Systems interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Expertise in Automotive Mechanical Systems Interview

Q 1. Explain the Otto cycle and its efficiency.

The Otto cycle is the thermodynamic cycle that describes the functioning of a typical spark-ignition internal combustion engine. It’s a four-stroke cycle, meaning it completes one cycle over four piston strokes (two revolutions of the crankshaft). Think of it like this: the engine breathes in, compresses, ignites, and then exhales.

- Intake Stroke: The piston moves down, drawing a mixture of air and fuel into the cylinder.

- Compression Stroke: The piston moves up, compressing the air-fuel mixture, increasing its temperature and pressure. This is crucial for efficient combustion.

- Power Stroke: The spark plug ignites the compressed mixture, causing rapid expansion and pushing the piston down. This is where the engine’s power is generated.

- Exhaust Stroke: The piston moves up, pushing the spent gases out of the cylinder through the exhaust valve.

The efficiency of the Otto cycle is limited by the compression ratio (the ratio of the cylinder volume at the bottom dead center to the volume at the top dead center) and the specific heat ratio of the air-fuel mixture. Higher compression ratios generally lead to higher efficiency, but there are practical limitations due to factors like detonation (uncontrolled combustion).

The thermal efficiency (η) of an ideal Otto cycle can be calculated using the formula: η = 1 - (1 / r^(γ-1)), where ‘r’ is the compression ratio and ‘γ’ is the specific heat ratio. In reality, the actual efficiency of an Otto engine is significantly lower due to friction, heat losses, and incomplete combustion.

Q 2. Describe the different types of automotive transmissions and their applications.

Automotive transmissions are crucial for matching the engine’s speed and torque to the vehicle’s driving conditions. Different types cater to varying performance and efficiency needs.

- Manual Transmission: The driver manually selects gears using a clutch and gear shift lever. This offers maximum control and efficiency but requires driver skill.

- Automatic Transmission: A complex system of planetary gears and hydraulic controls automatically shifts gears based on engine speed, throttle position, and vehicle speed. Offers convenience but may be less efficient than a manual transmission.

- Continuously Variable Transmission (CVT): Uses two pulleys and a belt to provide a continuously variable gear ratio. This allows the engine to always operate at its optimal speed, maximizing fuel efficiency, but can sometimes feel less responsive.

- Automated Manual Transmission (AMT): Combines the efficiency of a manual transmission with the convenience of automatic shifting. An actuator controls the clutch and shifting, eliminating the need for a clutch pedal.

- Dual-Clutch Transmission (DCT): Uses two clutches to control odd and even gears simultaneously. This allows for extremely fast gear changes, enhancing performance.

The choice of transmission depends on factors such as vehicle type, intended use, and target market. For example, sports cars might favor DCTs for their performance, while fuel-efficient city cars often use CVTs. Trucks and SUVs might utilize heavy-duty automatic transmissions designed for towing and hauling.

Q 3. What are the key components of a modern braking system?

Modern braking systems are sophisticated safety mechanisms designed to bring a vehicle to a controlled stop. Key components include:

- Brake Pedal: The primary input device.

- Master Cylinder: A hydraulic pump that converts pedal pressure into hydraulic pressure.

- Brake Lines: Tubes carrying hydraulic pressure to the wheels.

- Wheel Cylinders/Calipers: Hydraulic actuators that translate hydraulic pressure into mechanical force on the brake pads.

- Brake Pads/Shoes: Friction material that presses against the brake rotors/drums.

- Brake Rotors/Drums: Rotating components that are slowed by friction from the brake pads/shoes.

- Brake Booster: Amplifies the driver’s pedal pressure, making braking easier.

- Anti-lock Braking System (ABS): Prevents wheel lockup during braking, maintaining steering control.

- Electronic Stability Control (ESC): Helps prevent loss of control by selectively applying brakes to individual wheels.

These components work together to convert the driver’s input into a controlled deceleration of the vehicle. A failure in any of these components can significantly compromise braking performance and safety.

Q 4. Explain the principles of vehicle suspension systems and their impact on handling.

Vehicle suspension systems are crucial for providing a comfortable ride while maintaining good handling and stability. They act as a buffer between the vehicle’s chassis and the road, absorbing shocks and vibrations.

Suspension systems typically consist of springs (coil springs, leaf springs, torsion bars), dampers (shock absorbers), and linkages. Springs absorb the impact of bumps and irregularities in the road surface, while dampers control the oscillations of the springs, preventing excessive bouncing. The linkages connect the suspension components to the chassis and wheels, guiding their movement.

Different suspension designs (e.g., MacPherson strut, double wishbone, multi-link) offer varying levels of comfort, handling, and control. A well-designed suspension system minimizes body roll during cornering, improves traction, and reduces the impact of road imperfections on the vehicle’s occupants. Poor suspension can lead to a harsh ride, poor handling, and reduced tire life. For example, a sports car may prioritize handling by employing a stiff suspension system, while a luxury vehicle will opt for a softer system that prioritizes comfort.

Q 5. Discuss the function of a catalytic converter and its environmental importance.

A catalytic converter is an exhaust emission control device that reduces toxic gases and pollutants in exhaust fumes from internal combustion engines. It uses a catalyst, typically platinum, palladium, and rhodium, to convert harmful substances into less harmful ones.

The main pollutants reduced by a catalytic converter include:

- Carbon Monoxide (CO): A highly toxic gas. The converter oxidizes CO to carbon dioxide (CO2).

- Unburned Hydrocarbons (HC): Partially burned fuel. The converter oxidizes HC to CO2 and water (H2O).

- Nitrogen Oxides (NOx): Greenhouse gases that contribute to acid rain and smog. The converter reduces NOx to nitrogen (N2) and oxygen (O2).

The environmental importance of the catalytic converter is immense. It significantly reduces air pollution from vehicles, improving air quality and public health. This has had a substantial positive impact on reducing respiratory illnesses and other health problems associated with air pollution.

Q 6. How does an anti-lock braking system (ABS) work?

An Anti-lock Braking System (ABS) is a safety feature that prevents wheel lockup during hard braking. Wheel lockup reduces steering control, potentially leading to skidding and loss of control. ABS uses sensors to monitor wheel speed, and if a wheel starts to lock up, the system momentarily reduces braking pressure to that wheel, allowing it to regain rotation. This process happens rapidly and repeatedly, resulting in a pulsing feeling in the brake pedal during hard braking.

Here’s how it works:

- Wheel Speed Sensors: Monitor the rotational speed of each wheel.

- Electronic Control Unit (ECU): Processes the sensor data and determines if a wheel is locking up.

- Hydraulic Control Unit: Modulates brake pressure to individual wheels, preventing lockup.

By preventing wheel lockup, ABS helps maintain steering control during emergency braking, significantly improving safety and reducing the risk of accidents.

Q 7. Describe different types of engine cooling systems.

Engine cooling systems are essential for maintaining the optimal operating temperature of an internal combustion engine. Overheating can lead to serious engine damage. Different types exist, each with its advantages and disadvantages:

- Air Cooling: Uses air to cool the engine. Simpler and lighter but less effective than liquid cooling, particularly at high loads.

- Liquid Cooling: Uses a coolant (typically water mixed with antifreeze) circulated through passages in the engine block and cylinder head. More efficient than air cooling, allowing for higher engine power and efficiency.

- Liquid Cooling with Radiator: The most common liquid cooling system. The hot coolant is circulated through a radiator, where heat is transferred to the air. A fan often aids in this process.

- Liquid Cooling with Oil Cooler: Some high-performance engines utilize oil coolers as an additional cooling mechanism for the engine oil, which also contributes significantly to heat dissipation.

The choice of cooling system depends on factors like engine size, power output, intended use, and cost considerations. For instance, air cooling is often found in smaller engines like motorcycles and some lawnmowers, while liquid cooling is standard for most passenger cars and larger engines due to its superior cooling efficiency.

Q 8. Explain the operation of a fuel injection system.

A fuel injection system precisely delivers fuel to an internal combustion engine’s cylinders. Unlike older carburetor systems, which rely on air pressure to atomize and mix fuel, fuel injection uses electronically controlled injectors to spray a metered amount of fuel directly into the intake manifold (port injection) or cylinder (direct injection). This provides better control over the air-fuel mixture, leading to improved engine efficiency, power, and reduced emissions.

Operation: The system starts with an Engine Control Unit (ECU), a computer that monitors various engine sensors (like air flow, temperature, and engine speed). Based on this data, the ECU calculates the required amount of fuel. This information is then sent to the fuel injectors, which are precisely timed to open and close, releasing the calculated fuel quantity at high pressure. The fuel is then mixed with air and ignited in the combustion chamber.

Types: There are various types of fuel injection systems, including:

- Multi-point Fuel Injection (MPFI): One injector per cylinder, delivering fuel into the intake port.

- Direct Injection (DI): Fuel is injected directly into the combustion chamber, allowing for more precise control and improved combustion efficiency.

- Sequential Fuel Injection: Injectors operate in a specific sequence, corresponding to the firing order of the cylinders, for optimized fuel delivery.

Example: Imagine a car accelerating uphill. The ECU, sensing the increased load, instructs the injectors to deliver more fuel, providing the extra power needed to maintain speed. This precise control, impossible with a carburetor, makes fuel injection far more efficient and responsive.

Q 9. What are the factors affecting engine performance?

Engine performance is a complex interplay of factors, ultimately determining power, fuel economy, and emissions. Key factors include:

- Air-Fuel Mixture: The correct ratio is crucial. Too lean (too much air) leads to incomplete combustion and reduced power, while too rich (too much fuel) wastes fuel and increases emissions.

- Ignition System: A properly functioning ignition system ensures the air-fuel mixture ignites at the optimal time. Problems with spark plugs, ignition coils, or the timing can significantly impact performance.

- Compression Ratio: The ratio of the cylinder’s volume at the bottom of the stroke to its volume at the top. A higher ratio generally means more power, but also increased stress on engine components.

- Engine Condition: Worn piston rings, valve seals, or bearings reduce compression and power. Accumulated carbon deposits can foul spark plugs and disrupt combustion.

- Engine Lubrication: Proper lubrication reduces friction and wear, ensuring smooth operation. Using the wrong oil or insufficient oil levels leads to damage and decreased performance.

- Environmental Factors: Altitude, temperature, and humidity affect air density, influencing combustion and performance. Higher altitudes lead to reduced power due to less oxygen.

Example: A car experiencing sluggish acceleration could be due to a faulty oxygen sensor providing incorrect readings to the ECU, leading to an improperly adjusted air-fuel mixture. Diagnosing performance issues requires a systematic approach, checking each of these factors.

Q 10. What are common causes of engine overheating?

Engine overheating is a serious issue that can cause significant damage if not addressed promptly. Several factors can contribute to this:

- Coolant System Issues: Low coolant levels, leaks in the radiator or hoses, a faulty water pump, or a clogged radiator can prevent proper heat dissipation.

- Thermostat Problems: A malfunctioning thermostat can prevent the coolant from circulating properly. A stuck-closed thermostat prevents coolant flow, while a stuck-open one can cause the engine to run too cool.

- Faulty Radiator Fan: The radiator fan is crucial for drawing air through the radiator to cool the coolant. A malfunctioning fan, especially in hot conditions, can cause overheating.

- Head Gasket Failure: A blown head gasket allows coolant to leak into the cylinders or oil, causing overheating and potentially irreparable engine damage.

- Clogged Cooling System: Deposits and scale build-up can restrict coolant flow, hindering heat transfer and causing overheating.

- Insufficient Airflow: Debris blocking the front of the radiator can reduce airflow and lead to overheating.

Example: If you notice your engine temperature gauge rising unexpectedly, the first step should be checking the coolant level. If low, adding coolant may solve the immediate problem, but a leak needs to be identified and fixed. Ignoring overheating can lead to warped cylinder heads, cracked engine blocks, and major repair bills.

Q 11. Describe the different types of automotive lubricants and their functions.

Automotive lubricants are essential for reducing friction and wear within the engine and other components. Different lubricants serve different purposes, each with specific properties:

- Engine Oil: The most critical lubricant, engine oil reduces friction between moving parts, lubricates, cools, and cleans. It’s graded by viscosity (thickness) and performance standards (like SAE and API).

- Transmission Fluid: Lubricates and cools the transmission, enabling smooth gear shifting. Different types exist for automatic and manual transmissions, each with specific characteristics.

- Differential Fluid: Lubricates the differential gears, facilitating smooth power transfer to the wheels. The type of fluid depends on the differential design and operating conditions.

- Brake Fluid: Hydraulic fluid used in the braking system. It transmits pressure from the brake pedal to the calipers or wheel cylinders, stopping the vehicle.

- Power Steering Fluid: Lubricates and hydraulically assists the steering system, making it easier to turn the wheels.

- Grease: A thick lubricant used in bearings, joints, and other moving parts where continuous lubrication is needed but oil wouldn’t stay in place effectively.

Example: Using the wrong viscosity engine oil in cold weather can result in poor lubrication at start-up, leading to increased wear and damage. Regular oil changes and using the correct type of lubricant are vital for extending the life of your vehicle’s components.

Q 12. How does a differential work in a vehicle?

A differential is a gear mechanism that allows the wheels on an axle to rotate at different speeds. This is crucial for vehicles navigating turns, as the outer wheel travels a greater distance than the inner wheel. Without a differential, both wheels would be forced to rotate at the same speed, causing excessive tire wear and making turning difficult.

Operation: The differential consists of a ring gear, pinion gear, side gears, and a differential case. The pinion gear is driven by the driveshaft, transferring power to the ring gear. The ring gear meshes with the side gears, which in turn drive the axles. The side gears are able to rotate relative to each other, allowing the wheels to turn at different speeds.

Types: There are various types of differentials, including:

- Open Differential: The simplest type, allowing the wheels to rotate at different speeds. It has a tendency to send power to the wheel with the least traction.

- Limited-Slip Differential (LSD): Restricts the difference in speed between the two wheels, improving traction, especially on slippery surfaces.

- Locking Differential: Forces both wheels to rotate at the same speed. Useful in off-road conditions, but can reduce handling on paved roads.

Example: When turning a corner, the outer wheel needs to rotate faster than the inner wheel. The differential allows this to happen smoothly, preventing tire scrubbing and ensuring optimal handling.

Q 13. Explain the concept of vehicle dynamics and stability control.

Vehicle dynamics refers to how a vehicle behaves in motion, considering factors like acceleration, braking, steering, and handling. Stability control systems aim to enhance vehicle stability and safety by intervening when the vehicle’s behavior deviates from the driver’s intentions.

Key aspects of Vehicle Dynamics:

- Steering Response: How quickly and accurately the vehicle responds to steering inputs.

- Handling: The vehicle’s ability to maintain control during turns and maneuvers.

- Braking Performance: The effectiveness and stability of the braking system.

- Traction: The grip between the tires and the road surface.

Stability Control Systems: These systems use sensors (like wheel speed sensors, steering angle sensors, and yaw rate sensors) to monitor the vehicle’s movement and compare it to the driver’s intended direction. If a loss of traction or instability is detected, the system intervenes by reducing engine power and selectively applying brakes to individual wheels to maintain control. This prevents skidding, spinning, and rollover accidents.

Example: Imagine driving on a slippery road and suddenly braking hard. An Electronic Stability Control (ESC) system would detect the impending skid, reduce engine power, and apply brakes to individual wheels to maintain stability and prevent the vehicle from losing control. This system is a crucial safety feature in modern vehicles.

Q 14. What are common diagnostic tools used for automotive systems?

Modern automotive diagnostics rely on a range of tools, providing insights into various vehicle systems:

- OBD-II Scanners: These plug into the vehicle’s On-Board Diagnostics (OBD-II) port and retrieve diagnostic trouble codes (DTCs) from the ECU. These codes indicate potential problems within various systems.

- Digital Multimeters (DMMs): Used to measure voltage, current, and resistance in electrical circuits, helping to diagnose faulty sensors, wiring, and other electrical components.

- Oscilloscope: Provides a visual representation of electrical signals, allowing technicians to analyze waveforms and identify issues in electrical systems, such as ignition timing or sensor signals.

- Specialized Scan Tools: Manufacturer-specific scan tools offer more in-depth diagnostics and programming capabilities beyond the basic functionality of OBD-II scanners.

- Pressure Gauges: Used to measure fuel pressure, oil pressure, and other pressures within the engine and associated systems.

- Compression Testers: Measure the compression pressure within each cylinder, helping diagnose problems like worn piston rings or leaking valves.

Example: If a car’s check engine light illuminates, an OBD-II scanner can read the DTCs, providing clues about the underlying problem. A technician might then use a DMM to check the voltage at a suspect sensor or an oscilloscope to analyze the signal, confirming the diagnosis and guiding repairs.

Q 15. Discuss the impact of electric vehicles on automotive mechanical systems.

The rise of electric vehicles (EVs) significantly impacts automotive mechanical systems, primarily by drastically reducing or eliminating the need for many traditional components.

Internal Combustion Engine (ICE) Removal: The most impactful change is the absence of the ICE, its associated subsystems (fuel system, exhaust system, cooling system), and the complex mechanical transmission. This simplifies the powertrain significantly, reducing weight and maintenance needs.

Transmission Changes: EVs typically use simpler single-speed transmissions or even direct drive systems, replacing complex gearboxes. This reduces mechanical complexity, friction losses, and improves efficiency.

Increased Electrical Complexity: While mechanical complexity decreases, the electrical and electronic systems become considerably more complex. This includes battery management systems (BMS), electric motors, power inverters, and sophisticated control units. These components require specialized expertise and maintenance procedures.

For example, a conventional vehicle’s repair might involve replacing a worn clutch or adjusting valve clearances; in an EV, the focus shifts to battery health monitoring, motor control diagnostics, or power electronics repair. The shift is towards more software-defined functionality and electrical diagnostics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with finite element analysis (FEA) in automotive applications.

I have extensive experience using Finite Element Analysis (FEA) for various automotive applications, primarily focusing on structural integrity and durability. I’ve utilized FEA software such as ANSYS and ABAQUS to model and analyze components ranging from engine mounts and chassis structures to crashworthiness simulations.

For instance, in one project, I used FEA to optimize the design of a new suspension component, reducing its weight by 15% while maintaining structural strength and stiffness under various load conditions. This was achieved by iterative simulations, modifying the geometry and material properties based on the stress and strain analysis provided by the FEA software. We also employed modal analysis to predict the natural frequencies of the component and prevent potential resonance issues. This process ensured both performance and longevity of the component.

Further, I’ve contributed to crash simulations, using FEA to model impact scenarios and evaluate the effectiveness of safety features. Analyzing the stress distribution during a virtual crash test helps in optimizing the design for better passenger protection. This is a crucial part of ensuring vehicles meet strict safety regulations.

Q 17. Explain the principles of vehicle aerodynamics and its influence on fuel efficiency.

Vehicle aerodynamics studies how air flows around a vehicle. The shape and surface features significantly impact air resistance (drag), lift, and downforce. Minimizing drag is crucial for fuel efficiency because drag increases exponentially with speed, meaning higher speeds require exponentially more power to overcome.

Drag Reduction: Streamlined body shapes, reduced frontal area, and aerodynamic aids like spoilers and underbody panels help minimize drag. Features like air curtains, which channel air through carefully designed openings, further enhance airflow and reduce drag.

Lift and Downforce: Lift (upward force) reduces traction, while downforce (downward force) improves handling, especially at high speeds. The balance between lift and downforce is crucial for vehicle stability.

Consider a car with a boxy shape versus a sleek, aerodynamic one. The boxy car will experience significantly higher drag, consuming more fuel at any given speed compared to the streamlined vehicle. Aerodynamic design improvements can yield substantial gains in fuel economy, potentially improving miles per gallon (mpg) by 10-15% or more.

Q 18. How do you troubleshoot a malfunctioning engine management system?

Troubleshooting a malfunctioning engine management system (EMS) requires a systematic approach using diagnostic tools and a thorough understanding of the system’s components and their interactions.

Retrieve Diagnostic Trouble Codes (DTCs): The first step involves using an OBD-II scanner to retrieve DTCs stored by the EMS. These codes provide clues to the specific malfunction.

Analyze DTCs: Each DTC points towards a specific sensor, actuator, or system malfunction. Consult the vehicle’s service manual to understand the meaning of the codes and their potential causes.

Visual Inspection: Inspect related components for obvious issues such as damaged wiring, loose connections, or leaks. This could involve examining the sensors, wiring harnesses, and actuators.

Sensor Testing: Using a multimeter or specialized sensor testing equipment, verify the functionality of suspected faulty sensors such as the MAF sensor (mass airflow sensor), oxygen sensor (O2 sensor), or throttle position sensor (TPS).

Actuator Testing: Test the operation of actuators like injectors, ignition coils, and the throttle body, often by observing their response to commands from the EMS.

Data Logging: Using advanced diagnostic tools, record real-time sensor data to identify patterns or inconsistencies that may not be indicated by DTCs.

Component Replacement: Based on the diagnosis, replace faulty components, one at a time if multiple are suspected, and retest the system after each replacement.

For example, a lean condition indicated by DTCs might point to a failing oxygen sensor or a vacuum leak. By systematically testing each component, the root cause can be identified and resolved.

Q 19. Describe different types of sensors used in modern vehicles.

Modern vehicles employ a wide array of sensors to monitor various parameters and ensure optimal performance and safety. Here are some key examples:

Speed Sensors: Measure wheel speed and vehicle speed (often using ABS sensors).

Temperature Sensors: Monitor coolant temperature, oil temperature, intake air temperature, etc.

Pressure Sensors: Measure fuel rail pressure, oil pressure, tire pressure, and manifold absolute pressure (MAP).

Position Sensors: Include throttle position sensor (TPS), crankshaft position sensor (CKP), camshaft position sensor (CMP).

Oxygen Sensors (O2 Sensors): Measure the oxygen content in the exhaust to monitor the air/fuel ratio.

Mass Airflow Sensor (MAF Sensor): Measures the amount of air entering the engine.

Knock Sensors: Detect engine knocking (uncontrolled combustion).

Acceleration Sensors: Detect vehicle acceleration and deceleration, used in safety systems like airbags.

These sensors provide crucial information to the vehicle’s Engine Control Unit (ECU) and other control modules enabling precise control over engine operation, transmission shifting, safety systems, and more.

Q 20. Explain the operation of a turbocharger or supercharger.

Both turbochargers and superchargers are forced induction systems that increase the amount of air entering the engine’s cylinders, leading to increased power output. The key difference lies in how they achieve this:

Turbocharger: Uses exhaust gas energy to drive a turbine, which in turn spins a compressor. The compressor forces more air into the engine’s intake manifold. Because it uses exhaust gas, it has no parasitic power loss from the engine itself; however, it has a lag time before boost is generated.

Supercharger: Is mechanically driven by the engine’s crankshaft via a belt. This provides immediate boost but at the cost of some engine power (parasitic loss) because it directly uses engine power to compress air.

Think of a turbocharger as a wind turbine powering a fan; the exhaust gases spin the turbine (windmill) driving the compressor (fan) that pushes more air into the engine. A supercharger is more like a mechanically powered fan directly connected to the engine. Both increase the air density in the intake manifold, allowing the engine to burn more fuel and thus generate more power.

Q 21. What are common methods for reducing vehicle emissions?

Reducing vehicle emissions involves a multifaceted approach targeting various pollutants. Common methods include:

Exhaust Gas Recirculation (EGR): Recirculates a portion of the exhaust gas back into the intake manifold, reducing combustion temperatures and the formation of nitrogen oxides (NOx).

Three-Way Catalytic Converter (TWC): Converts harmful pollutants like NOx, carbon monoxide (CO), and unburnt hydrocarbons (HC) into less harmful substances (N2, CO2, H2O).

Selective Catalytic Reduction (SCR): Injects a reducing agent (like urea) into the exhaust stream to further reduce NOx emissions. Common in diesel engines.

Particulate Filters (DPF): Trap soot particles from diesel exhaust, reducing particulate matter emissions.

Improved Combustion Control: Precisely controlling the air/fuel mixture and ignition timing optimizes combustion efficiency, minimizing unburnt hydrocarbons and CO.

Electric and Hybrid Vehicles: EVs produce zero tailpipe emissions, while hybrids significantly reduce emissions compared to conventional gasoline vehicles.

For example, stricter emission regulations often necessitate the use of both TWCs and SCR systems in modern diesel engines to meet increasingly stringent standards. The transition to electric and hybrid vehicles represents a significant step towards achieving cleaner transportation and significantly reducing greenhouse gas emissions.

Q 22. Describe your experience with designing or testing automotive components.

Throughout my career, I’ve been extensively involved in both the design and testing phases of various automotive components. For instance, I led a project designing a new lightweight suspension system for a compact SUV. This involved using finite element analysis (FEA) software to simulate stress and strain under various load conditions, ensuring optimal performance and durability. We iterated through several design prototypes, constantly refining the geometry and material selection based on simulation results and physical testing. In another project, I was responsible for the testing and validation of a newly developed engine cooling system. This included rigorous environmental testing—high and low temperatures, humidity, and vibration—to ensure the system’s reliability under diverse operating conditions. We used data acquisition systems to monitor key parameters like coolant temperature, pressure, and flow rate, comparing the results against predefined specifications. This ensured the system’s compliance with industry standards and met performance targets.

Q 23. What are the key considerations for selecting materials for automotive parts?

Selecting materials for automotive parts is a critical process, balancing numerous competing factors. The primary considerations include:

- Strength and Durability: The material must withstand significant stress and strain during operation, resisting fatigue and wear. For example, engine blocks often use cast iron for its high strength and heat resistance.

- Weight: Lighter materials improve fuel efficiency and vehicle performance. Aluminum alloys are frequently used for body panels and engine components due to their lightweight nature and good strength-to-weight ratio.

- Cost: The material’s cost impacts the overall vehicle price. Engineers often strive to find a balance between performance requirements and economic viability.

- Corrosion Resistance: Automotive parts are exposed to various environmental factors, so corrosion resistance is vital. Galvanized steel and stainless steel are popular choices to combat rust.

- Manufacturing Process Compatibility: The selected material should be easily and cost-effectively processed using available manufacturing techniques, such as casting, forging, or stamping.

- Thermal Properties: For components exposed to high temperatures, thermal conductivity and resistance are key considerations. For instance, the selection of materials for exhaust manifolds is crucial for efficient heat dissipation.

The selection process often involves extensive material testing and simulations to verify performance and ensure the chosen material meets all design requirements.

Q 24. Explain the principles of combustion in an internal combustion engine.

Combustion in an internal combustion engine (ICE) is a complex process involving the controlled explosion of a fuel-air mixture. The four strokes of a four-stroke engine illustrate this:

- Intake Stroke: The piston moves downward, drawing a mixture of air and fuel into the cylinder.

- Compression Stroke: The piston moves upward, compressing the fuel-air mixture, increasing its temperature and pressure. This increases efficiency.

- Power Stroke: The compressed fuel-air mixture is ignited by a spark plug (in gasoline engines) or by the heat of compression (in diesel engines). The resulting explosion forces the piston downward, generating power.

- Exhaust Stroke: The piston moves upward, expelling the burned gases from the cylinder.

The efficiency of combustion depends on factors such as the air-fuel ratio, the timing of ignition, and the design of the combustion chamber. Optimizing these factors is crucial for maximizing engine power and fuel efficiency while minimizing emissions. For example, using advanced combustion strategies like direct injection improves fuel efficiency and reduces emissions compared to older port fuel injection systems.

Q 25. Describe your experience working with CAD software in an automotive context.

I have extensive experience with various CAD software packages, including CATIA, SolidWorks, and NX. In automotive design, CAD is indispensable for creating and visualizing complex three-dimensional models. For instance, I used CATIA to design a new engine mount, ensuring proper clearance with surrounding components and optimizing its stiffness and damping characteristics. We utilized simulation tools integrated within the CAD software to evaluate stress and vibration patterns under various load cases. Further, I have used SolidWorks to model and simulate the performance of various braking systems, analyzing brake pad wear and rotor temperature. The ability to easily iterate designs and analyze their performance virtually significantly reduces development time and cost. The accurate digital models are crucial for generating manufacturing drawings and facilitating seamless collaboration with manufacturing teams.

Q 26. How do you ensure the quality and reliability of automotive systems?

Ensuring the quality and reliability of automotive systems is paramount. My approach involves a multi-faceted strategy:

- Design for Reliability (DFR): Integrating reliability considerations from the initial design phase, using techniques like fault tree analysis and failure mode and effects analysis (FMEA) to identify potential failure points and mitigate risks.

- Rigorous Testing: Conducting comprehensive testing throughout the development cycle, encompassing environmental testing, durability testing, and performance testing, using various methods such as vibration testing, thermal cycling, and endurance runs.

- Quality Control (QC): Implementing robust QC procedures during manufacturing to ensure that parts meet specifications and that assembly processes are consistent and reliable. This often involves statistical process control (SPC) methodologies.

- Continuous Improvement: Regularly reviewing performance data and feedback from the field to identify areas for improvement and enhance system reliability. This is achieved through data analysis, root cause analysis, and corrective actions.

For example, during the development of an advanced driver-assistance system (ADAS), we implemented rigorous software testing procedures, including unit testing, integration testing, and system testing, to validate the software’s functionality and reliability. The goal is to minimize defects and produce high-quality, reliable systems that meet and exceed customer expectations.

Q 27. Discuss the challenges of designing for both performance and fuel efficiency.

Balancing performance and fuel efficiency presents a significant challenge in automotive design. Higher performance usually requires larger engines, more powerful components, and less focus on aerodynamic drag reduction, all of which impact fuel consumption negatively. However, several strategies can help mitigate this conflict:

- Lightweighting: Using lightweight materials reduces vehicle mass, improving both performance and fuel economy.

- Aerodynamic Optimization: Designing aerodynamically efficient body shapes minimizes drag, enhancing fuel efficiency.

- Engine Downsizing: Utilizing smaller, more efficient engines with technologies like turbocharging and supercharging to maintain performance while reducing fuel consumption.

- Hybrid and Electric Powertrains: Integrating hybrid or electric powertrains enhances fuel efficiency and reduces emissions, while also offering improved performance in certain scenarios.

- Advanced Combustion Strategies: Employing advanced combustion strategies to optimize fuel-air mixing and improve combustion efficiency, thereby enhancing fuel economy.

The optimal solution often involves a combination of these strategies, carefully balancing the competing demands of performance and fuel efficiency based on the target vehicle specifications and market requirements. Finding this sweet spot is a critical part of the design process.

Q 28. Explain your experience with various testing methodologies in the automotive industry.

My experience encompasses a wide range of automotive testing methodologies. These include:

- Environmental Testing: Exposing components and systems to extreme temperatures, humidity, and vibration to assess their durability and reliability under various operating conditions. This often involves climatic chambers and vibration shakers.

- Durability Testing: Simulating real-world driving conditions to evaluate the lifespan and performance degradation of components, frequently using road simulators and highly controlled test tracks.

- Performance Testing: Measuring key performance indicators such as horsepower, torque, fuel efficiency, and braking distance using dynamometers and track testing.

- NVH (Noise, Vibration, and Harshness) Testing: Assessing the noise and vibration levels of the vehicle and its components to identify and resolve issues affecting passenger comfort. This often involves sophisticated instrumentation and acoustic chambers.

- Emission Testing: Measuring the exhaust emissions of vehicles to ensure compliance with environmental regulations. This requires specialized emission analyzers and test procedures.

I’m proficient in using data acquisition systems to collect and analyze test data, ensuring objective evaluation and informed decision-making. Furthermore, understanding statistical analysis techniques is vital for interpreting test results and drawing meaningful conclusions from them. This allows for data-driven optimization and refinement of designs.

Key Topics to Learn for Expertise in Automotive Mechanical Systems Interview

- Internal Combustion Engines (ICE): Understanding engine cycles (Otto, Diesel), fuel systems (injection, carburetion), emission control systems, and engine diagnostics.

- Powertrain Systems: Knowledge of transmissions (manual, automatic, CVT), drivetrain components (axles, differentials), and their interactions within the vehicle’s power delivery system. Practical application: troubleshooting drivetrain issues based on symptoms.

- Chassis and Suspension Systems: Familiarization with suspension types (MacPherson strut, double wishbone), steering systems (rack and pinion, power steering), braking systems (ABS, ESP), and their impact on vehicle handling and safety. Problem-solving approach: diagnosing suspension component failures based on observed vehicle behavior.

- Vehicle Dynamics and Control: Understanding concepts like stability control, traction control, and their underlying principles. Application: analyzing vehicle response to different driving conditions and maneuvers.

- Automotive Materials and Manufacturing: Knowledge of materials used in automotive components (metals, composites, polymers) and manufacturing processes (casting, forging, machining). This allows you to discuss material selection for specific applications and their influence on performance and durability.

- Electrified Powertrains: Understanding Hybrid and Electric Vehicle architectures, including battery systems, electric motors, power electronics, and their integration into the vehicle. This is crucial for understanding the future of automotive technology.

- Troubleshooting and Diagnostics: Develop your ability to systematically approach problems, identify root causes, and implement effective solutions using diagnostic tools and techniques.

Next Steps

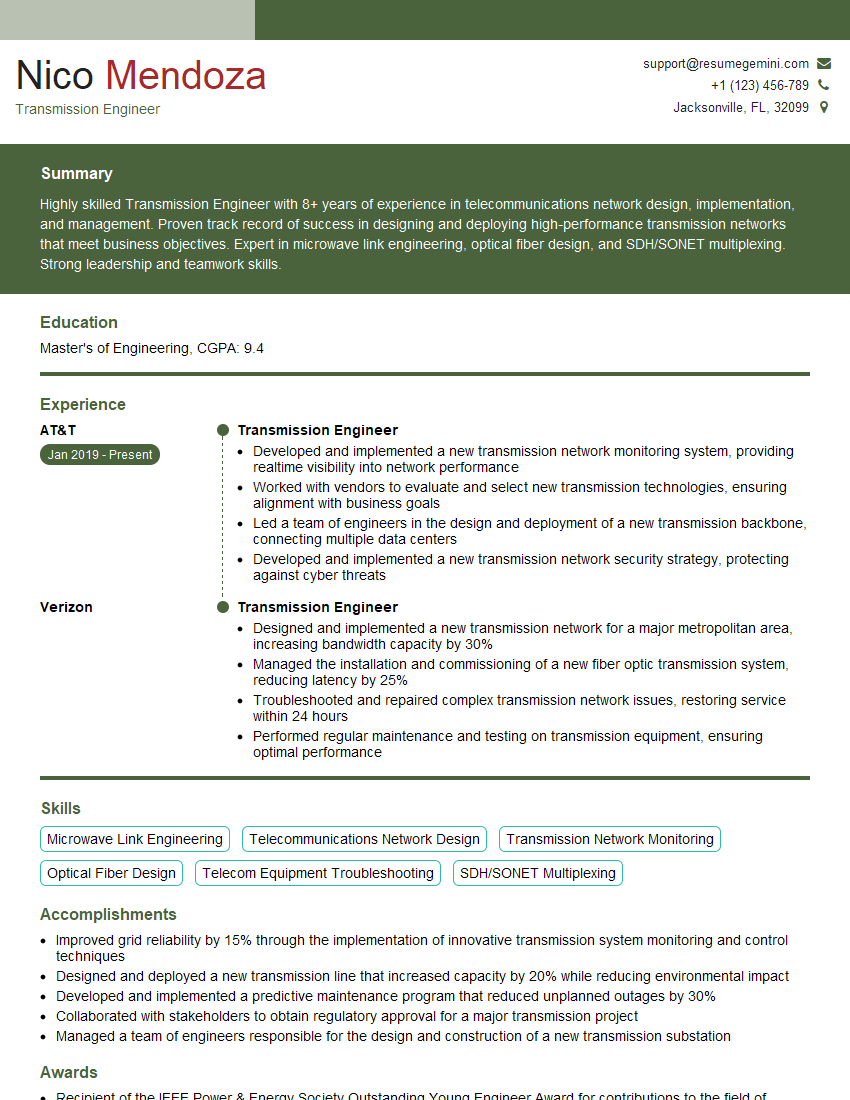

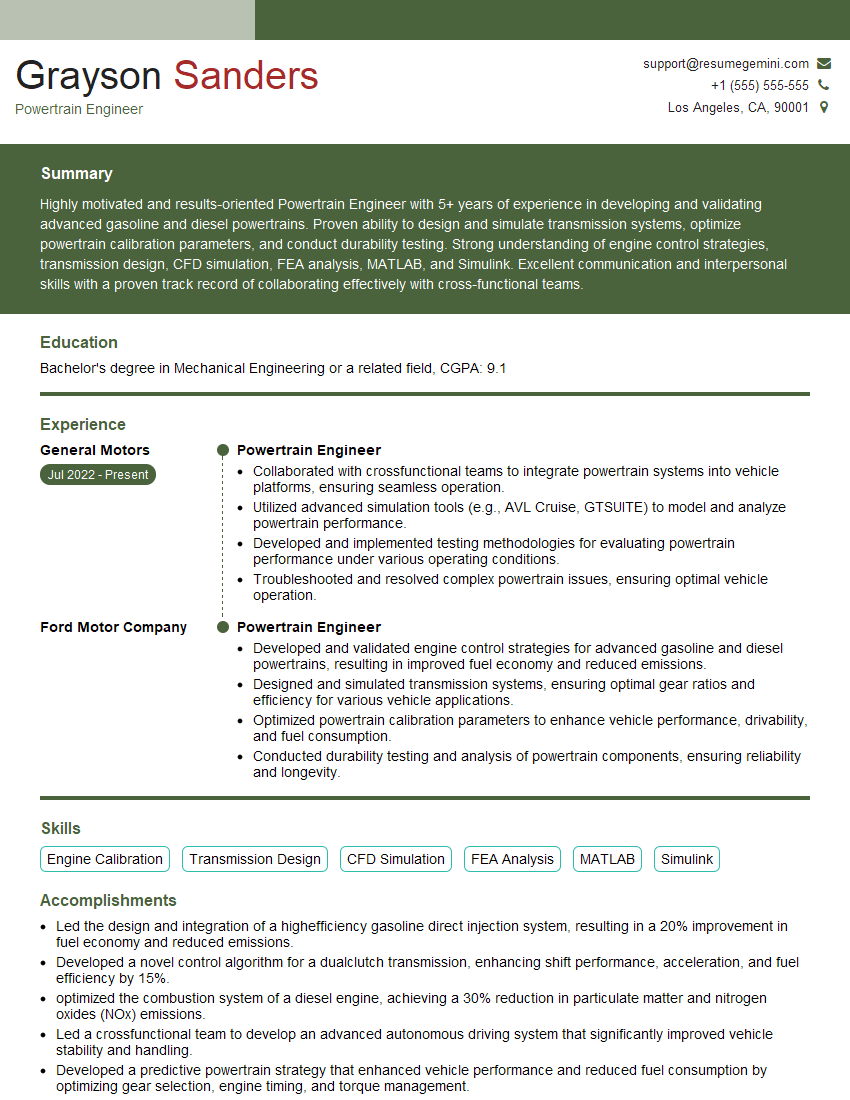

Mastering Expertise in Automotive Mechanical Systems opens doors to exciting career opportunities in research, development, manufacturing, and service within the automotive industry. A strong understanding of these systems significantly enhances your employability and allows you to pursue advanced roles. To maximize your job prospects, focus on creating an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your expertise. Examples of resumes tailored to Expertise in Automotive Mechanical Systems are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO