Cracking a skill-specific interview, like one for Use surface grinders, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Use surface grinders Interview

Q 1. Explain the different types of surface grinders.

Surface grinders are categorized primarily by the way the workpiece is held and the type of grinding wheel movement. The most common types are:

- Horizontal-spindle surface grinders: These are the workhorses of many shops. The workpiece is typically held on a magnetic chuck and the wheel rotates horizontally, traversing across the part. They’re excellent for flat surfaces and offer good accessibility for larger parts.

- Vertical-spindle surface grinders: In these machines, the wheel rotates vertically, and the worktable moves under the wheel. They’re often preferred for intricate shapes or higher precision work due to the wheel’s orientation and reduced chance of wobble.

- Rotary surface grinders: These use a rotating wheel that grinds the workpiece on its edge. They’re specialized for cylindrical parts or creating specific profiles.

- Planer-type surface grinders: These use a reciprocating motion for the table, moving back and forth beneath a stationary grinding wheel. They’re capable of handling large workpieces.

- Jig grinders: This type offers high accuracy with specific work holding and wheel movements to tackle complicated or highly precise grinding tasks. Often used for specialized applications.

The choice of grinder depends heavily on the part size, material, required precision, and production volume. For example, a small shop might opt for a versatile horizontal-spindle grinder while a high-volume manufacturing plant may require a more automated vertical-spindle or even a rotary type.

Q 2. Describe the process of setting up a surface grinder for a specific job.

Setting up a surface grinder involves a meticulous process to ensure accuracy and prevent damage. It starts with understanding the job specifications – drawing, material, tolerances and surface finish requirements. Here’s a step-by-step guide:

- Workpiece mounting: Securely clamp the workpiece onto the magnetic chuck, ensuring proper alignment and even contact. For non-magnetic materials, use suitable fixtures or vises.

- Wheel selection and mounting: Choose a wheel appropriate for the material and finish required (discussed in more detail later). Mount the wheel correctly, ensuring it’s concentric and securely fastened.

- Wheel balancing: It’s crucial to balance the wheel to minimize vibrations during operation. An unbalanced wheel will not only reduce accuracy, but may damage the machine.

- Table alignment: Precisely align the table using the machine’s alignment indicators. This ensures that the workpiece is consistently presented to the wheel throughout the grinding cycle. Any misalignment directly translates to an inaccurate finish.

- Initial cut (roughing): Start with a light initial cut to remove stock evenly. Always use proper safety glasses.

- Fine grinding: Gradually reduce the depth of cut and increase the traverse speed as the desired dimension is approached. Take frequent measurements with precision instruments.

- Finish grinding: Once the desired size is achieved, use progressively finer grinding wheels and lighter cuts for the final surface finish.

- Part Inspection: After grinding, it’s crucial to meticulously inspect the part using calibrated measuring tools to ensure it meets specifications. Any deviations should be noted and documented.

Remember, consistent monitoring and adjustments are key throughout the entire process. I’ve had instances where a seemingly minor misalignment at the beginning would cost hours of rework. Thoroughness pays off, particularly with tightly toleranced parts.

Q 3. How do you ensure the accuracy and precision of a surface grinding operation?

Accuracy and precision in surface grinding rely on a combination of factors:

- Proper machine maintenance: Regular lubrication, cleaning, and inspection are critical. A well-maintained machine is less prone to errors.

- Precise setup: Meticulous attention to detail during setup, from workpiece mounting to wheel alignment, is paramount. I often remind apprentices: ‘Measure twice, cut once’ applies tenfold in surface grinding.

- Wheel selection: Choosing the correct wheel for the material, surface finish, and desired stock removal rate directly affects accuracy.

- Consistent operating parameters: Maintaining consistent downfeed, traverse speed, and wheel speed is crucial for even material removal. Sudden changes can introduce errors.

- Regular wheel dressing and truing: This ensures a consistent and true grinding surface, minimizing inaccuracies caused by a worn or loaded wheel.

- Regular calibration: Regularly calibrate the machine’s measuring devices and alignment systems to maintain accuracy. It’s best practice to do this according to manufacturer recommendations, usually at least once a month for consistent accuracy.

- Proper coolant usage: Using the right coolant helps in minimizing heat buildup and maintains the life of the wheel, also improving accuracy.

Think of it like baking a cake: if the oven isn’t at the right temperature, or the ingredients aren’t properly measured, you won’t get the intended result. Similarly, neglecting any of these factors in surface grinding can compromise accuracy and precision.

Q 4. What are the common causes of surface grinder vibrations and how do you mitigate them?

Surface grinder vibrations significantly impact accuracy and surface finish. Common causes include:

- Unbalanced grinding wheel: This is a primary culprit. An unbalanced wheel causes significant vibrations. Regular wheel balancing is essential.

- Wear and tear in bearings and spindles: Worn bearings and spindles introduce play and vibrations into the system.

- Loose components: Loose fasteners, mounts, or other components can transmit vibrations.

- Foundation instability: A shaky or unstable foundation will resonate vibrations during operation. A robust, level base is critical.

- Improper workpiece clamping: Uneven workpiece clamping can also generate vibrations.

- High cutting speeds and feeds: Pushing the machine too hard can introduce excessive vibrations.

Mitigation strategies include:

- Regular maintenance: Addressing worn parts and ensuring proper lubrication will significantly reduce vibrations.

- Wheel balancing: Periodic balancing prevents the most common cause of vibrations.

- Foundation analysis: Examine the machine’s foundation for any instability and correct as needed.

- Proper cutting parameters: Avoid aggressive cutting to minimize vibrations.

- Correct clamping techniques: Ensure that the workpiece is securely clamped to prevent movement during operation.

Once, I diagnosed a persistent vibration issue to a loose bolt in the chuck mechanism. A simple fix, but the resulting improvement in surface finish was dramatic.

Q 5. How do you select the appropriate grinding wheel for a specific material?

Grinding wheel selection is crucial for achieving the desired surface finish and avoiding damage to the workpiece. Factors to consider include:

- Material being ground: Different materials require wheels with different abrasive types and grain sizes. Harder materials need harder wheels, and vice-versa.

- Desired surface finish: A finer grain size produces a smoother finish. A coarser grain size removes more material quickly but leaves a rougher finish.

- Stock removal rate: The desired stock removal rate affects the choice of grain size and bond type. A higher stock removal rate requires a more aggressive wheel.

- Bond type: The bond holds the abrasive grains together. Different bond types (vitrified, resinoid, etc.) have varying strengths and suit different materials and applications.

For instance, grinding hardened steel might necessitate a vitrified bond wheel with a silicon carbide abrasive and a relatively fine grain size for a precise finish. Conversely, rough grinding cast iron might use a resinoid bond wheel with an aluminum oxide abrasive and a coarser grain size for faster stock removal. The manufacturer’s specifications for the wheel should always be consulted. Selecting the incorrect wheel can lead to wheel failure, damage to the workpiece, or a poor surface finish.

Q 6. Explain the importance of wheel dressing and truing.

Wheel dressing and truing are essential maintenance procedures that ensure the grinding wheel remains sharp, true, and maintains its specified shape and size. Neglecting this step leads to poor surface finishes, uneven grinding, and reduced wheel life.

- Dressing: This removes the dull and loaded abrasive grains from the wheel’s surface. It sharpens the wheel, improving its cutting ability. Diamond dressers are commonly used for this.

- Truing: This process restores the wheel’s shape and size. Truing ensures a consistent and flat grinding surface, preventing uneven stock removal. Truing is also done using diamond dressers or other specialized tools.

Imagine a chisel with a dull edge – it wouldn’t cut cleanly. Similarly, a dull or misshapen grinding wheel will not produce an accurate or consistent surface. Regular dressing and truing maintain the wheel’s efficiency, prolong its lifespan, and are essential for consistent high-quality results. Proper dressing and truing techniques are vital to ensuring the wheel is consistently performing at its optimum capabilities.

Q 7. Describe the process of aligning a surface grinder.

Aligning a surface grinder is a critical step to ensure accurate and consistent grinding. The process involves several steps, depending on the machine’s specific design:

- Leveling the machine: Ensure the machine is level in both the X and Y axes using a level and shims. This forms the fundamental basis for all subsequent alignments.

- Spindle alignment: Align the grinding wheel spindle’s axis to be perfectly perpendicular to the table’s surface. The spindle must be aligned for the wheel to run correctly and prevent non-uniform grinding.

- Table alignment: Ensure the table moves perfectly parallel to the grinding wheel. Any misalignment will translate to uneven grinding.

- Cross-feed alignment: Check that the cross-feed mechanism is properly aligned with both the spindle and the table. It is important to check alignment perpendicular to the direction of the table movement.

- Use of alignment indicators: Modern machines have built-in alignment indicators to assist with the process. I would always follow the manufacturer’s specific instructions here. Sometimes these involve dial indicators or electronic alignment tools.

Accurate alignment is fundamental to precision surface grinding. I’ve witnessed countless instances where poor alignment led to wasted material and hours of rework. Taking the time to perform a thorough alignment procedure is an investment that pays off in both quality and efficiency.

Q 8. How do you measure the flatness and parallelism of a workpiece after grinding?

Measuring the flatness and parallelism of a workpiece after surface grinding is crucial for ensuring the part meets specifications. We primarily use precision measuring instruments like surface plates and dial indicators.

For flatness, we place the workpiece on a surface plate, which is a highly accurate reference plane. Then, using a dial indicator, we measure the distance between the workpiece surface and the surface plate at multiple points across the workpiece. Any deviation from a perfect zero reading indicates a departure from flatness, and the magnitude of that deviation indicates the degree of flatness error. We typically aim for tolerances specified on the blueprint, which are usually in micrometers or ten-thousandths of an inch.

For parallelism, we check the flatness of two opposing faces. For instance, we’d check the parallelism between the top and bottom faces of a rectangular part. This involves measuring the distance between the two surfaces at several locations along the length and width using dial indicators or a combination square and height gauge. Maintaining parallelism ensures consistent dimensional accuracy and prevents warping or misalignment in subsequent assembly operations.

Imagine trying to stack perfectly flat pancakes; any lack of flatness results in a wobbly stack. Similarly, a workpiece lacking flatness and parallelism won’t fit precisely in an assembly, causing problems and potential failures.

Q 9. What are the safety precautions you take while operating a surface grinder?

Safety is paramount when operating a surface grinder. Before starting, I always ensure the machine is properly grounded and the surrounding area is clean and free of obstructions. I wear appropriate safety gear including safety glasses, hearing protection, and a dust mask to protect against flying debris and airborne particles from the grinding process. Long hair is always tied back, and loose clothing is avoided.

The grinding wheel is handled with extreme care, avoiding sudden movements or impacts. I always inspect the wheel for cracks or damage before mounting, and ensure it’s properly secured and balanced on the spindle. I check the coolant system function to ensure efficient wheel cooling and chip evacuation, preventing overheating. Never reach into the moving parts of the grinder, only adjust settings or change components when the machine is turned off and completely stopped. Regular machine maintenance, such as checking for coolant leaks and vibrations, is part of my routine to prevent accidents.

Finally, I thoroughly understand the machine’s controls and emergency stop procedures before operating it. Regular safety training and a proactive mindset are essential for maintaining a safe working environment.

Q 10. How do you interpret surface grinder blueprints and drawings?

Surface grinder blueprints and drawings are interpreted using standard engineering drawing practices. I start by identifying the material to be ground, dimensions of the workpiece, including length, width, thickness, and tolerances. Tolerances define the permissible variations from the stated dimensions. Next, I examine the surface finish requirements (often specified as Ra or RMS values), and the flatness and parallelism tolerances. The drawings will also indicate the features to be ground— specific faces, edges, or angles — and often show the type and size of grinding wheel recommended for that operation.

For example, a drawing might show a rectangular block with specific dimensions (e.g., 100mm x 50mm x 25mm), tolerance (e.g., ±0.05mm), a surface roughness of 0.8µm Ra, and a flatness tolerance of 2µm. I pay close attention to callouts like ‘all over grind,’ ‘face grind’, or ‘angle grind’, providing precise instructions on what areas to focus on and which processes to follow.

Understanding engineering drawings is vital for producing a precision-machined component to the specifications requested by the client. The use of dimensions, tolerances and symbols allows us to communicate the technical requirements with accuracy, clarity, and consistency.

Q 11. Explain the concept of surface finish and its importance in grinding.

Surface finish refers to the texture of a machined surface. In grinding, it’s determined by the grinding wheel’s characteristics (grain size, bond type), the feed rate, the depth of cut, and the type of grinding fluid used. A smoother surface finish generally implies a lower surface roughness, indicated by parameters like Ra (average roughness) or Rz (maximum roughness height).

The importance of surface finish is multifaceted. In applications requiring high precision, like optical components or bearings, a very smooth finish is essential to reduce friction, wear, and improve performance. Conversely, rougher surfaces might be preferred in situations where high friction or better paint adhesion is desired. Surface finish significantly impacts the component’s functionality, aesthetic appeal, and fatigue life. For example, a rough surface on a bearing might cause rapid wear and failure, while a smooth surface on a mirror is critical for optical clarity.

Q 12. Describe different grinding fluids and their applications.

Various grinding fluids are used in surface grinding, each offering specific advantages. Water-based fluids are commonly used due to their low cost, ease of disposal, and good cooling properties. They prevent wheel glazing and help to wash away swarf. Oil-based fluids provide superior lubrication, which is beneficial for grinding hard and brittle materials. They also suppress the generation of sparks. Synthetic fluids offer a compromise between water-based and oil-based, providing good cooling and lubrication properties with improved environmental compatibility.

The selection of the grinding fluid depends on the material being ground, the grinding wheel’s bond and type, and the desired surface finish. For example, grinding hardened steel often requires an oil-based fluid to prevent excessive wheel wear and chipping. For aluminum, a water-based fluid might be sufficient due to aluminum’s relative softness and better heat conductivity.

Q 13. How do you identify and address common grinding wheel problems?

Identifying and addressing grinding wheel problems is a crucial aspect of efficient and safe surface grinding. Glazing, characterized by a shiny, smooth surface on the wheel, reduces grinding efficiency and can lead to poor surface finish. It’s usually caused by insufficient coolant or a wheel speed that’s too slow. The solution is to dress the wheel (using a dressing tool to remove the glazed layer) or switch to a different wheel.

Loading, where the wheel becomes clogged with workpiece material, similarly degrades performance. This happens when grinding soft metals or with inadequate coolant. To resolve this, you may need to dress the wheel, adjust the coolant flow, increase wheel speed, or change to an open-structured wheel.

Cratering, which occurs when the wheel develops pits or cavities, may indicate incorrect wheel selection or overloading. Choosing the right wheel for the workpiece material and avoiding excessive grinding pressure helps to prevent this issue. A cracked or damaged wheel requires immediate replacement for safety reasons. Regular inspection is crucial to identify and address problems promptly and prevent further damage and potential accidents.

Q 14. What are the different types of grinding wheel bonds?

Grinding wheel bonds are the materials that hold the abrasive grains together. The bond type significantly influences the wheel’s performance and application. Common types include:

- Vitrified bonds: Made from ceramic materials, they are strong, durable, and resistant to heat, suitable for grinding a wide range of materials.

- Silicate bonds: These offer good strength and are commonly used for wheels requiring high sharpness. They are more susceptible to heat and moisture degradation than vitrified bonds.

- Resinoid bonds: These bonds, made from synthetic resins, are flexible and used for high-speed grinding and cutting wheels. They are less resistant to heat.

- Shellac bonds: Used for extremely fine grinding operations.

- Rubber bonds: Offer flexibility and are used for honing and finishing operations.

Choosing the right bond type depends on the specific grinding application and the properties of the material being ground. For example, a vitrified bond is often preferred for general-purpose grinding due to its versatility and durability, while a resinoid bond might be used for high-speed cutting or shaping operations.

Q 15. How do you calculate the infeed rate for surface grinding?

Calculating the infeed rate for surface grinding is crucial for achieving the desired surface finish and preventing damage to the workpiece or grinding wheel. It’s essentially how much material you remove with each pass of the wheel. The calculation depends on several factors:

- Material Removal Rate (MRR): This is the volume of material removed per unit time. It’s influenced by the wheel’s characteristics (type, grit, bond), the workpiece material, and the desired surface finish. A harder material requires a slower infeed rate.

- Wheel Speed: A faster wheel speed generally allows for a slightly higher infeed rate, but this needs to be balanced against the risk of wheel glazing or burning the workpiece.

- Workpiece Material: Harder materials like hardened steel require a much slower infeed rate than softer materials like aluminum. This prevents damage to the wheel or burning the workpiece.

- Depth of Cut (Downfeed): This is the total amount of material you want to remove in a single grinding operation. You divide this by the number of passes to get the infeed rate per pass.

Example: Let’s say you need to remove 0.010 inches of material from a steel workpiece, and you’ve decided on 5 passes. Your infeed rate would be 0.010 inches / 5 passes = 0.002 inches per pass.

It’s important to start with a conservative infeed rate and gradually increase it as you assess the results and the condition of the wheel and workpiece. Always monitor for signs of wheel loading, burning, or excessive vibration.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of workpiece clamping and fixturing.

Proper workpiece clamping and fixturing are absolutely paramount in surface grinding. Without them, you risk inaccurate grinding, damage to the workpiece, and even accidents. Think of it like trying to carve a perfect sculpture with unstable material – it’s impossible!

- Accuracy: Secure clamping ensures the workpiece remains perfectly flat and stable during grinding, minimizing variations in the final surface finish. Any movement leads to inconsistencies.

- Safety: Improper fixturing can lead to the workpiece shifting during grinding, causing potential injury to the operator or damage to the machine.

- Repeatability: Consistent clamping methods ensure that subsequent grinding operations produce identical results, crucial for mass production.

- Surface Finish: Secure clamping avoids vibrations that can lead to chatter marks or other undesirable surface defects.

Example: For a complex part, you might use a combination of magnetic chucks, vacuum chucks, and precision vises with appropriate clamping jaws to secure it firmly, maintaining parallelism and squareness.

Choosing the right fixturing method depends entirely on the workpiece’s shape, size, and material. A simple part might just need a magnetic chuck, while complex parts will require a more sophisticated setup.

Q 17. How do you troubleshoot common surface grinder malfunctions?

Troubleshooting surface grinder malfunctions requires a systematic approach. I always follow a step-by-step process to isolate and fix the problem:

- Safety First: Always disconnect power before performing any maintenance or troubleshooting.

- Visual Inspection: Look for obvious problems like loose components, damaged parts, or unusual wear patterns on the wheel or workpiece.

- Check the Basics: Verify that coolant flow is adequate, the wheel is properly dressed, and that there is no excessive vibration in the machine.

- Systematic Elimination: If the issue persists, systematically check each component. Start with the simplest elements like the power supply, coolant system, and wheel alignment, progressing to more complex aspects like the hydraulics or control systems.

- Listen for Unusual Sounds: Grinding noises can help identify problems like wheel imbalance, bearing wear, or a malfunctioning spindle.

- Consult Manuals & Documentation: Manufacturers’ manuals often contain troubleshooting guides with specific error codes and solutions.

Example: If the surface finish is poor, the causes could range from a dull grinding wheel, improper infeed rate, excessive vibration, or a problem with the machine’s alignment. A systematic approach helps isolate the correct cause.

Experience is key in this area. After years of working with these machines, I can often diagnose problems quickly by recognizing the specific sounds or patterns of the malfunctions.

Q 18. What is the difference between plunge grinding and traverse grinding?

Plunge grinding and traverse grinding are two fundamental methods used in surface grinding, each with its own applications:

- Plunge Grinding: In plunge grinding, the grinding wheel is fed downwards into the workpiece at a constant rate, removing material until the desired depth is achieved. It’s ideal for operations requiring a consistent depth of cut across a relatively small area, like finishing a flat surface or removing a small amount of material from the entire workpiece surface.

- Traverse Grinding: In traverse grinding, the grinding wheel moves across the workpiece while simultaneously being fed downwards. This allows for the removal of material over a larger area, and is useful for grinding longer, narrower parts and achieving a consistent surface finish over the whole length. The table moves back and forth under the rotating grinding wheel.

Key Differences: Plunge grinding is simpler and faster for localized material removal, while traverse grinding is more suitable for large surface areas requiring uniform material removal. The choice depends on the specific application requirements.

Example: Plunge grinding might be used to quickly and precisely remove a small amount of material from a flat surface while traverse grinding would be used to surface grind a long rectangular part.

Q 19. How do you perform a surface grinder maintenance routine?

A regular maintenance routine is essential for keeping a surface grinder in top condition and preventing costly repairs. My routine typically includes:

- Daily Inspection: Check for coolant levels, wheel condition (wear, glazing, cracks), and overall cleanliness of the machine. Also, listen for any unusual noises.

- Weekly Cleaning: Thoroughly clean the machine, removing any accumulated chips or debris from the worktable, ways, and other components. Pay particular attention to the coolant system.

- Monthly Maintenance: Check and adjust the machine’s alignment, lubricate moving parts (ways, slides), and inspect the spindle bearings for wear. This often includes checking and cleaning the coolant system filter.

- Periodic Wheel Dressing: Dress the grinding wheel regularly to maintain its sharpness and profile. This will vary depending on usage and the type of wheel.

- Regular Calibration: Periodically calibrate the machine’s measuring systems (e.g., dial indicators) to ensure accuracy.

Importance: Regular maintenance not only extends the lifespan of the machine but also ensures the quality and consistency of the work produced. Ignoring this can lead to unexpected downtime, inaccurate parts, and safety hazards.

Q 20. Describe your experience with different types of grinding wheels (e.g., vitrified, resinoid).

I have extensive experience working with various grinding wheel types, each with its own strengths and weaknesses:

- Vitrified Wheels: These are the most common type, known for their durability, high-speed capability, and good wear resistance. They are ideal for a wide range of materials, but their relatively rigid structure can lead to some surface imperfections if not handled correctly.

- Resinoid Wheels: Resinoid-bonded wheels are known for their flexibility and ability to produce fine finishes. They’re often preferred for grinding softer materials or producing intricate shapes. However, they are generally less durable than vitrified wheels and are not as well suited for heavy stock removal.

- Other Bonds: I’ve also worked with wheels using rubber, silicate, and metal bonds, each offering different characteristics in terms of strength, cutting ability, and finish.

Wheel Selection: The choice of grinding wheel depends on many factors including the workpiece material, the desired surface finish, the amount of material to be removed, and the specific grinding operation. Incorrect wheel selection can lead to poor results, wheel damage, or even workpiece damage.

Example: For high-precision grinding of hardened steel, a vitrified wheel with a fine grit would be ideal, whereas a resinoid wheel with a coarser grit might be preferable for deburring softer aluminum parts.

Q 21. What is your experience with CNC controlled surface grinders?

I possess significant experience operating CNC-controlled surface grinders, which offer significant advantages over manual machines. These machines provide:

- Increased Accuracy and Precision: CNC control eliminates many sources of human error, resulting in more consistent and precise results.

- Improved Efficiency: Automated operation allows for unattended grinding operations, improving efficiency and throughput.

- Complex Part Capabilities: CNC machines are capable of handling complex part geometries and intricate grinding operations that would be difficult or impossible on a manual machine.

- Repeatability: CNC programs can be saved and reused, ensuring that identical parts can be produced repeatedly.

Programming and Operation: I’m proficient in programming CNC surface grinders using various programming languages like G-code. This includes setting up tooling, workpiece fixturing, and monitoring the grinding process.

Example: I’ve used CNC surface grinders to produce high-precision parts with intricate features, including complex shapes that require multiple passes and varied feed rates.

My expertise with CNC machines has been instrumental in many projects requiring superior accuracy and efficiency in surface grinding operations.

Q 22. How do you handle out-of-tolerance workpieces?

Handling out-of-tolerance workpieces requires a systematic approach. First, I’d meticulously analyze the deviation from the specifications, identifying the type and magnitude of the error. Is it a dimensional issue, surface finish problem, or both? Then, I determine the root cause. Was it due to improper setup, worn tooling, incorrect grinding parameters (feed rate, depth of cut, wheel speed), or a workpiece defect?

Once the root cause is identified, corrective actions are implemented. This might involve adjusting the machine settings, replacing worn components (like the grinding wheel or magnetic chuck), or re-evaluating the fixturing. For example, if the workpiece is consistently too large, I might reduce the depth of cut or adjust the workhead position. If the surface finish is rough, I might need to change to a finer grit wheel or optimize the coolant flow. Careful documentation of the problem, the corrective actions, and the resulting improvements is crucial for preventing recurrence.

In cases where the workpiece is significantly out-of-tolerance and beyond correction, I would consult with the engineering team to assess the feasibility of rework or scrap. The decision will depend on the cost of rework versus scrap, the severity of the deviation, and the customer’s requirements.

Q 23. Explain your experience with different types of workholding devices.

My experience encompasses a wide range of workholding devices used in surface grinding, each suited for specific workpiece geometries and material properties. I’m proficient with magnetic chucks, both permanent and electromagnetic, which are ideal for ferrous materials. I understand the importance of proper magnetization, ensuring uniform holding power across the workpiece surface to avoid warping or chatter. I’ve also worked extensively with vacuum chucks, particularly useful for non-ferrous materials and delicate parts. These require careful attention to surface cleanliness and vacuum pressure to maintain a secure grip.

Furthermore, I have experience using various jigs and fixtures for complex shapes or those requiring precise location. These custom-designed holders are crucial for achieving repeatable accuracy and minimizing setup time. For intricate parts or those with delicate features, soft jaws or specialized clamping mechanisms may be necessary to prevent damage. Choosing the right workholding device directly impacts the quality, efficiency, and safety of the grinding operation. For instance, a poorly chosen chuck could lead to workpiece movement, resulting in inaccurate dimensions or surface damage.

Q 24. Describe your experience with surface roughness measurement techniques.

Surface roughness measurement is paramount in achieving the desired surface finish. I’m experienced with various techniques, including using a surface roughness tester (profilometer). This instrument measures the surface texture using a stylus that traverses the surface, generating a profile that quantifies parameters like Ra (average roughness) and Rz (maximum peak-to-valley height). I understand the significance of these parameters and how they relate to the application requirements of the finished part.

Besides profilometry, I can also visually assess surface quality under magnification, looking for imperfections like scratches, digs, or burn marks. This visual inspection complements the quantitative data provided by the profilometer, giving a complete picture of surface finish quality. The chosen technique depends on the required level of accuracy and the complexity of the surface. For instance, a simple visual inspection might be sufficient for some applications, while a precise profilometer measurement is crucial for others, such as highly polished surfaces or parts with tight tolerance requirements. Correct calibration of instruments and adherence to established standards are vital for ensuring accurate and reliable results.

Q 25. How do you ensure the quality and consistency of your work?

Ensuring quality and consistency is a core principle in my work. This begins with meticulous planning and preparation. I always verify the workpiece material, dimensions, and surface finish requirements before commencing the operation. Precise machine setup is critical; this involves carefully aligning the workpiece, selecting the appropriate grinding wheel, and setting the correct parameters like feed rate, depth of cut, and wheel speed.

Throughout the grinding process, I monitor the machine’s performance and the workpiece’s progress. Regular checks of the wheel wear, coolant flow, and workpiece dimensions are essential. I use appropriate measuring tools like calipers, micrometers, and optical comparators to ensure dimensional accuracy. A systematic approach, careful attention to detail, and adherence to established procedures are key to maintaining consistent quality. For example, I use a surface grinder setup sheet which I complete for each job, documenting all the parameters used, allowing consistency between jobs and troubleshooting if a problem occurs.

Q 26. How do you document your work and maintain records?

Documentation and record-keeping are vital aspects of my work. For each job, I maintain detailed records including the workpiece material, dimensions, surface finish specifications, machine settings (wheel type, speed, feed rate, depth of cut), and the date and time of the operation. This is typically documented on a job sheet or within a company database. I also include any deviations from the standard procedure, corrective actions taken, and the results obtained.

Measurements taken during and after the grinding process, including both dimensional checks and surface finish measurements, are meticulously documented, often with accompanying photographs or sketches. This comprehensive documentation serves multiple purposes: it ensures traceability, facilitates quality control, aids in troubleshooting future problems, and enables continuous improvement efforts. A well-maintained record system also simplifies audits and ensures compliance with industry standards.

Q 27. Describe a time you had to troubleshoot a complex problem on a surface grinder.

One time, I encountered a persistent chatter problem on a surface grinder that was proving difficult to resolve. The workpiece, a hardened steel plate, was producing unacceptable surface roughness despite adjustments to the feed rate and depth of cut. I systematically investigated the possible causes. I checked the wheel dressing, which was found to be adequate. I inspected the machine’s foundation for vibrations, which were within acceptable limits. I examined the workpiece for any imperfections, and found nothing unusual.

Eventually, I discovered the issue stemmed from the magnetic chuck itself. Although visually it appeared fine, a section of the chuck had lost some of its magnetic strength causing uneven workpiece clamping. Replacing the magnetic chuck with a new one immediately resolved the chatter problem, resulting in a significantly improved surface finish. This experience emphasized the importance of thoroughly investigating all potential causes when troubleshooting complex problems and not prematurely ruling out seemingly minor details.

Q 28. What are your strategies for continuous improvement in surface grinding operations?

My strategies for continuous improvement in surface grinding operations focus on several key areas. First, I continuously seek ways to optimize the grinding process, aiming for higher efficiency, improved surface finish, and reduced cycle times. This includes exploring new wheel types and dressing techniques, analyzing the effects of different coolants, and experimenting with varied grinding parameters.

Secondly, I prioritize regular maintenance of the surface grinder. Preventive maintenance minimizes downtime and ensures optimal machine performance. I also keep abreast of the latest advancements in surface grinding technology and techniques through professional development and industry publications. Finally, I actively participate in team discussions on process improvements, sharing my experiences and contributing to problem-solving initiatives. This collaborative approach fosters a culture of continuous learning and innovation.

Key Topics to Learn for Use Surface Grinders Interview

- Machine Operation and Setup: Understanding the various controls, safety procedures, and setup processes for different surface grinding applications. This includes pre-grinding checks and calibrations.

- Wheel Selection and Dressing: Knowing how to choose the appropriate grinding wheel based on material properties and desired surface finish. Mastering wheel dressing techniques for optimal performance and longevity.

- Workpiece Fixturing and Clamping: Securely and accurately clamping workpieces to ensure precise grinding and prevent damage. Understanding different fixturing methods for various workpiece shapes and sizes.

- Grinding Parameters and Adjustments: Knowing how to adjust parameters like feed rate, depth of cut, and wheel speed to achieve desired tolerances and surface finishes. Understanding the impact of each parameter.

- Quality Control and Inspection: Performing accurate measurements and inspections to ensure the workpiece meets specifications. Understanding common quality control methods and using measuring instruments effectively.

- Troubleshooting and Maintenance: Identifying and resolving common issues encountered during surface grinding operations. Performing basic preventative maintenance tasks to ensure machine uptime.

- Safety Regulations and Procedures: Adhering to all safety regulations and procedures to prevent accidents and injuries. Understanding the use of personal protective equipment (PPE).

- Material Science Basics: Understanding the properties of common materials that are surface ground and how those properties affect the grinding process.

Next Steps

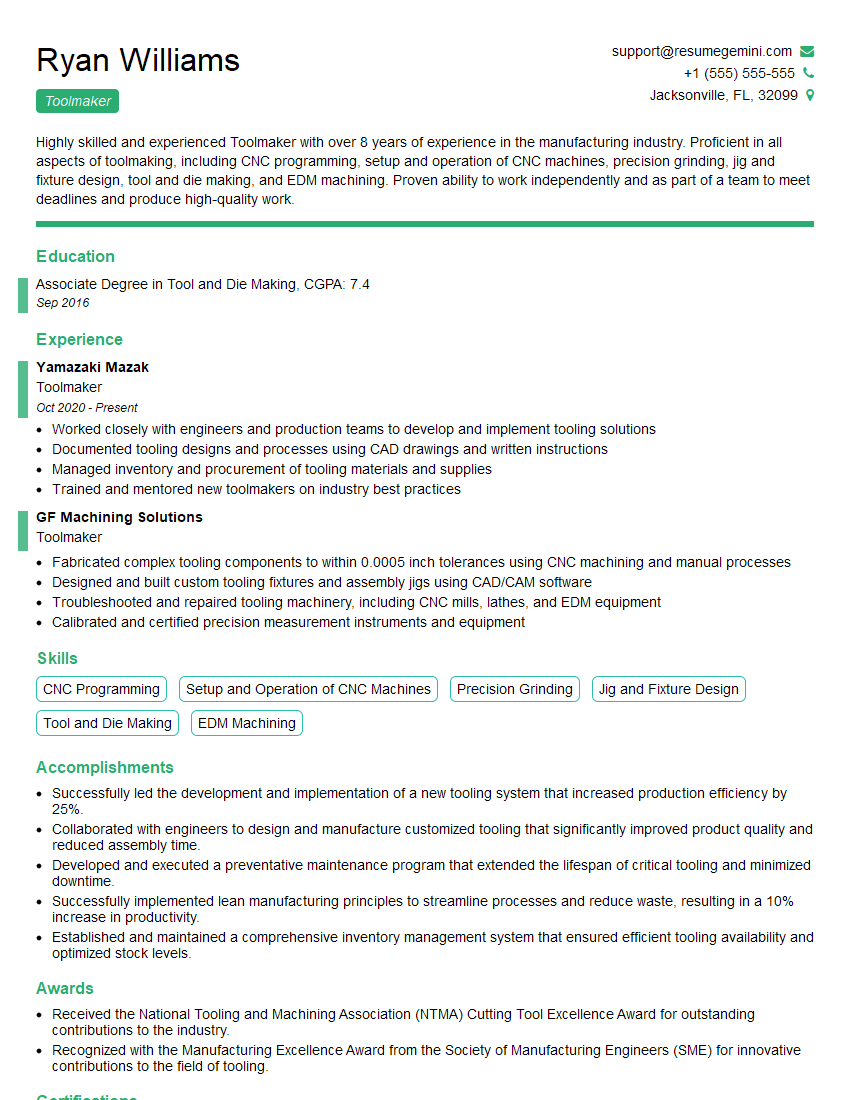

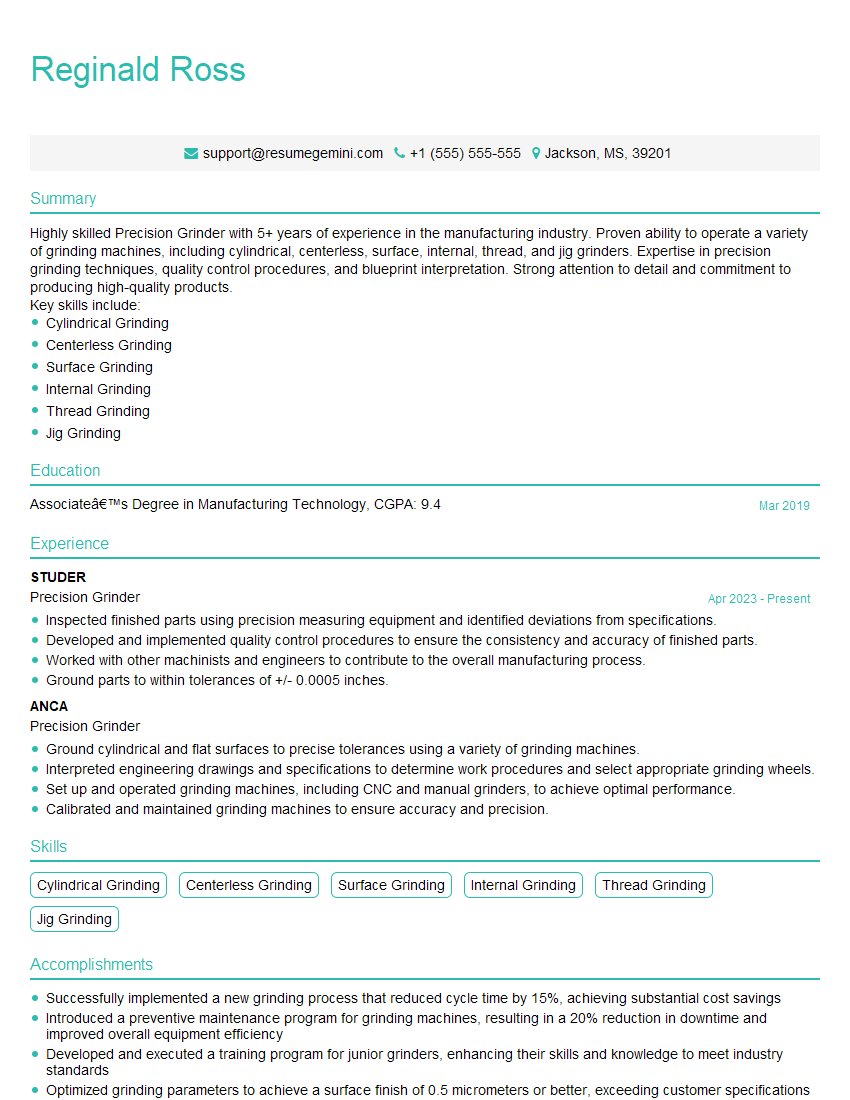

Mastering the use of surface grinders opens doors to rewarding careers in manufacturing and precision engineering. These skills are highly sought after, offering opportunities for growth and specialization. To maximize your job prospects, it’s crucial to present your qualifications effectively. Crafting an ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to highlight your surface grinding expertise. Examples of resumes tailored to surface grinding professionals are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO