The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Safe Handling of Flammable Materials interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Safe Handling of Flammable Materials Interview

Q 1. What are the classes of flammable materials?

Flammable materials are classified into different categories based on their flash points and how easily they ignite. These classifications help determine appropriate handling and storage procedures. Common classes include:

- Class IA: Liquids with a flash point below 73°F (23°C) and a boiling point below 100°F (38°C). These are extremely volatile and pose a significant fire hazard. Think of gasoline or ether.

- Class IB: Liquids with a flash point below 73°F (23°C) and a boiling point at or above 100°F (38°C). These are also highly flammable, but slightly less volatile than Class IA. Examples include acetone and ethyl acetate.

- Class IC: Liquids with a flash point at or above 73°F (23°C) and below 100°F (38°C). These are less volatile than Class IA and IB but still require careful handling. Examples include some alcohols.

- Class II: Liquids with a flash point at or above 100°F (38°C) and below 140°F (60°C). These are considered moderately flammable. Examples include kerosene.

- Class IIIA: Liquids with a flash point at or above 140°F (60°C) and below 200°F (93°C). These are considered combustible.

- Class IIIB: Liquids with a flash point at or above 200°F (93°C). These have a higher ignition temperature.

- Combustible Solids: Materials that can burn, but generally not as readily as liquids. Examples include wood, paper, and some plastics.

- Flammable Gases: Gases that easily ignite and burn in air. Examples include propane and methane.

Understanding these classifications is critical for selecting appropriate safety measures.

Q 2. Explain the fire triangle and how it relates to flammable materials.

The fire triangle illustrates the three elements necessary for a fire to occur: fuel, heat, and an oxidizing agent (usually oxygen). Flammable materials provide the fuel source. A sufficient heat source, such as a spark, flame, or hot surface, initiates the combustion process. The oxidizing agent, typically oxygen from the air, supports the burning process. Remove any one of these elements, and the fire will be extinguished.

For example, a gasoline spill (fuel) on a hot engine (heat) in the presence of air (oxygen) will result in a fire. Extinguishment strategies focus on removing one or more of these elements: using a fire extinguisher to cool the fuel (removing heat), smothering the fire with a blanket to cut off the oxygen supply (removing the oxidizing agent), or preventing the spread of flammable liquids (removing fuel).

Q 3. Describe different methods for extinguishing flammable material fires.

Different methods are used to extinguish flammable material fires, depending on the type and size of the fire. These include:

- Water: Effective for cooling many flammable materials, but not suitable for flammable liquids lighter than water (they can float on the surface and spread), or materials that react violently with water (such as alkali metals).

- Foam: Creates a layer that separates the fuel from the oxygen, preventing further combustion. This is especially useful for flammable liquid fires.

- Dry Chemical Powder: Disrupts the chemical chain reaction of the fire and interrupts the combustion process. It’s versatile and effective for various flammable materials.

- Carbon Dioxide (CO2): Displaces oxygen, suffocating the fire. It’s clean and leaves no residue, but it’s less effective on large fires.

- Halon (in specific situations): Although largely phased out due to ozone depletion concerns, it’s still used in some specialized applications where its effectiveness is critical.

The choice of extinguishing method should always align with the specific flammable material involved. Improper use can worsen the situation.

Q 4. What are the proper procedures for storing flammable materials?

Proper storage of flammable materials is crucial for preventing fires and ensuring workplace safety. Key aspects include:

- Designated Storage Areas: Flammable materials should be stored in designated areas, away from ignition sources such as heat, sparks, and open flames. These areas should be well-ventilated and preferably fire-resistant.

- Approved Containers: Always use approved, properly labeled containers designed for flammable materials. Improper containers can leak or break, increasing fire risk.

- Quantity Limits: Storage quantities should be kept to a minimum, complying with relevant regulations and guidelines. Large quantities increase the potential damage in case of a fire.

- Separation and Compatibility: Incompatible materials should be stored separately to prevent reactions that could ignite or create hazardous fumes. Check compatibility charts before mixing.

- Bonding and Grounding (for liquids): For conductive containers, bonding and grounding are essential to prevent static electricity buildup, which can ignite flammable vapors.

- Temperature Control: Store flammable materials within recommended temperature ranges specified by the manufacturer.

Remember: Regular inspections are vital to maintain a safe storage environment.

Q 5. What safety equipment is required when handling flammable materials?

The specific safety equipment needed depends on the nature of the flammable material being handled, but essential items include:

- Fire Extinguishers: The appropriate type and size should be readily accessible and regularly inspected.

- Safety Glasses or Goggles: Protect eyes from splashes and fumes.

- Gloves: Choose gloves appropriate for the specific material to prevent skin contact and absorption.

- Respiratory Protection: A respirator might be needed when dealing with vapors or fumes.

- Protective Clothing: Flame-resistant clothing can offer additional protection in case of fire.

- Spill Kits: These kits contain materials for quickly and safely containing and cleaning up spills.

- Emergency Showers and Eyewash Stations: These should be easily accessible for immediate first aid in case of contact.

Training on the correct use of safety equipment is mandatory.

Q 6. How do you identify and interpret safety data sheets (SDS) for flammable materials?

Safety Data Sheets (SDS), formerly known as Material Safety Data Sheets (MSDS), provide comprehensive information about the hazards and safe handling of chemicals. For flammable materials, the SDS will detail:

- Flammability Hazards: Flash point, autoignition temperature, flammable limits, and any special fire hazards.

- Health Hazards: Toxicity, potential health effects from inhalation, ingestion, or skin contact.

- Physical and Chemical Properties: Boiling point, melting point, density, and other relevant properties.

- Handling and Storage Recommendations: Specific instructions for safe handling, storage, and disposal.

- Fire Fighting Measures: Suitable extinguishing agents and special fire-fighting procedures.

- Personal Protection Equipment (PPE): Recommended PPE for safe handling.

Always thoroughly review the SDS before working with any flammable material. The information contained within is vital for safe operations. Look for sections specifically addressing flammability and fire safety procedures.

Q 7. Explain the importance of proper ventilation when working with flammable materials.

Proper ventilation is essential when working with flammable materials because it prevents the buildup of flammable vapors or fumes. Flammable vapors, when mixed with air at the right concentration, can create explosive mixtures. Good ventilation ensures that the concentration of these vapors remains below the lower explosive limit (LEL). Inadequate ventilation can lead to:

- Fire Hazards: A build-up of flammable vapors increases the risk of ignition from even a small spark.

- Explosion Hazards: Reaching the LEL and UEL (upper explosive limit) can lead to devastating explosions.

- Health Hazards: Inhaling flammable vapors can cause a range of health problems, from headaches and dizziness to more serious conditions.

Ventilation strategies can range from simple natural ventilation (opening windows and doors) to more sophisticated mechanical systems. The specific ventilation requirements depend on factors such as the quantity and type of flammable material, the size of the workspace, and the nature of the work being done.

Always ensure adequate ventilation is in place before commencing any work involving flammable materials.

Q 8. Describe the different types of fire suppression systems used for flammable materials.

Fire suppression systems for flammable materials vary depending on the type of material, the size of the area, and the potential hazards. Here are some common types:

- Water-based systems: These are effective for Class A fires (ordinary combustibles) and can sometimes be used on Class B fires (flammable liquids) if the liquid isn’t miscible with water and the application is controlled. However, water can be ineffective or even worsen some flammable liquid fires. Think of trying to put out a grease fire with water – it can cause a dangerous splatter.

- Foam systems: These are specifically designed for Class B fires. Foam creates a layer on the surface of the burning liquid, suppressing the vapors and preventing oxygen from reaching the fuel. Different types of foam exist, each suited for particular flammable liquids.

- Dry chemical systems: These systems use dry chemicals, like sodium bicarbonate or potassium bicarbonate, to interrupt the combustion process. They’re effective on Class B and C fires (flammable liquids and electrical fires) and are relatively easy to deploy.

- Carbon dioxide (CO2) systems: CO2 systems displace oxygen, suffocating the fire. They’re suitable for Class B and C fires, especially in areas where water damage is undesirable, such as computer rooms. However, CO2 can displace oxygen in an enclosed space and pose an asphyxiation risk.

- Halon alternatives: These are gaseous extinguishing agents designed to replace halons, which have been phased out due to their ozone depletion potential. They’re effective on Class A, B, and C fires but can be more expensive than other options.

The choice of system is crucial and depends on a thorough risk assessment. A professional fire protection engineer is typically involved in selecting and designing the appropriate fire suppression system.

Q 9. What are the emergency procedures in case of a flammable materials spill?

Emergency procedures for a flammable materials spill must be swift and methodical to minimize risks. They generally follow these steps:

- Evacuate the area: Immediately clear the area of all personnel, ensuring a safe distance. This prevents exposure to fumes and potential fire.

- Alert emergency services: Contact your local emergency services (fire department, HAZMAT team) immediately. Provide accurate details about the location, the substance spilled, and the estimated quantity.

- Contain the spill: If safe to do so, and with proper personal protective equipment (PPE), attempt to contain the spill using absorbent materials like sand, vermiculite, or specialized spill kits. This prevents the spread and reduces the contact area.

- Prevent ignition sources: Eliminate any potential ignition sources in the vicinity, such as sparks, flames, or even static electricity. This is paramount in preventing a fire.

- Ventilate the area: If possible, increase ventilation to dissipate flammable vapors and reduce the risk of explosion.

- Follow emergency response plan: Your facility should have a detailed emergency response plan that outlines specific steps to be taken for different types of spills. Follow this plan meticulously.

Remember, personal safety is paramount. Do not attempt to handle a spill without appropriate training and protective equipment. The emergency response plan should outline procedures for PPE selection and use.

Q 10. How do you conduct a risk assessment for handling flammable materials?

A risk assessment for handling flammable materials is a crucial step in ensuring workplace safety. It involves a systematic identification and evaluation of hazards associated with these materials. Here’s a structured approach:

- Identify hazards: This involves listing all potential hazards associated with the flammable materials, including fire, explosion, toxicity, and health effects. Consider the properties of each flammable material (flash point, ignition temperature, etc.).

- Identify who might be harmed and how: Determine who might be exposed to the hazards (workers, visitors, the public) and how they might be harmed (burns, respiratory problems, etc.).

- Evaluate the risks and decide on precautions: Analyze the likelihood and severity of each hazard. This helps prioritize risks and determine the level of control measures needed. For instance, a high-likelihood, high-severity hazard requires stringent controls.

- Record findings and implement control measures: Document the identified hazards, risks, and chosen control measures. Implement the control measures (engineering controls, administrative controls, PPE) to mitigate identified risks.

- Review the assessment and update as needed: Regularly review and update the risk assessment to reflect changes in processes, materials, or regulations. This ensures that the assessment remains relevant and effective.

For example, in a lab setting, a risk assessment might involve evaluating the flammability of solvents used in experiments, the potential for ignition sources (Bunsen burners, hot plates), and identifying appropriate PPE (lab coats, safety glasses, gloves). This might even extend to the location of fire extinguishers and emergency exits.

Q 11. What are the regulations and standards related to the safe handling of flammable materials in your region?

Regulations and standards for safe handling of flammable materials vary by region. However, many jurisdictions adopt or adapt international standards. Specific regulations would need to be checked at a regional or national level. Generally, these regulations cover:

- Storage requirements: Regulations often dictate specific storage conditions for different classes of flammable materials, including temperature control, ventilation, and separation from incompatible materials.

- Handling procedures: Safe handling procedures, including the use of proper equipment and personal protective equipment (PPE), are often mandated.

- Labeling and signage: Clear and standardized labeling and signage are crucial for identifying flammable materials and warning of potential hazards. This is often dictated by nationally recognized standards.

- Emergency response planning: Facilities handling flammable materials are usually required to have comprehensive emergency response plans, including spill response procedures and training for personnel.

- Training requirements: Workers handling flammable materials often require specific training to ensure they understand the associated hazards and safe handling procedures.

- Permitting and inspections: In some jurisdictions, permits may be required for handling specific quantities of flammable materials, and regular inspections might be conducted to ensure compliance.

Consulting with local authorities and relevant safety organizations is crucial to ensure complete compliance with applicable regulations.

Q 12. Explain the concept of flash point and its significance.

The flash point of a flammable liquid is the lowest temperature at which it can form an ignitable mixture in air near the surface of the liquid. In simpler terms, it’s the temperature at which the vapor produced by the liquid will ignite if exposed to an ignition source. This is incredibly significant for safety reasons.

For example, a liquid with a low flash point (like gasoline, which has a flash point below 0°C) presents a much higher fire hazard than a liquid with a high flash point (like kerosene, with a flash point around 38°C). Understanding the flash point allows for appropriate handling, storage, and safety precautions. Liquids with low flash points require more stringent safety measures and storage in designated areas to minimize the risk of ignition. This is a fundamental piece of data used in any risk assessment concerning flammable liquids.

Q 13. What is the difference between flammable and combustible liquids?

The distinction between flammable and combustible liquids lies primarily in their flash points:

- Flammable liquids: Have a flash point below 37.8°C (100°F). They readily ignite at or near room temperature and present a significant fire hazard.

- Combustible liquids: Have a flash point at or above 37.8°C (100°F). They require a higher temperature to ignite and generally present a lower fire risk compared to flammable liquids. However, this doesn’t mean they are safe; they still pose a significant fire hazard if heated to their flash point or above.

Both types require careful handling, appropriate storage, and adherence to safety regulations. The difference in flash point dictates the level of precaution required; flammable liquids need far more rigorous control measures.

Q 14. What are the precautions to take when working with flammable gases?

Working with flammable gases necessitates rigorous safety precautions due to their potential for rapid ignition and explosion. Key precautions include:

- Proper ventilation: Ensure adequate ventilation to prevent the buildup of flammable gas concentrations. This is crucial to prevent the formation of explosive mixtures.

- Leak detection and prevention: Regularly check for leaks using appropriate detection equipment. Prevent leaks through proper maintenance of equipment and connections.

- Ignition source control: Eliminate all potential ignition sources, such as flames, sparks, and static electricity. This includes grounding equipment and using explosion-proof electrical devices.

- Personal protective equipment (PPE): Use appropriate PPE, including safety glasses, gloves, and respiratory protection, depending on the specific gas and potential hazards.

- Storage and handling procedures: Follow strict procedures for the storage, handling, and transportation of flammable gases. This includes using appropriate containers, valves, and pressure relief devices.

- Emergency response plan: Develop and practice an emergency response plan for gas leaks or fires. This plan should address evacuation, containment, and notification of emergency services.

Remember, flammable gases are particularly dangerous due to their rapid dispersion and the potential for invisible leaks. Methane, propane, and acetylene are examples of common flammable gases each requiring different handling procedures based on their properties.

Q 15. Describe the proper use of personal protective equipment (PPE) when handling flammable materials.

Proper Personal Protective Equipment (PPE) is paramount when handling flammable materials. It forms the first line of defense against potential injury from fire, burns, or exposure to hazardous fumes. The specific PPE required depends on the material’s flammability and the task, but generally includes:

- Flame-Resistant Clothing: This includes coveralls, lab coats, or other garments made from inherently flame-resistant fabrics. Think of it as a protective shield against direct flames.

- Safety Glasses or Goggles: These protect your eyes from splashes of flammable liquids, sparks, or flying debris. Imagine trying to work with highly volatile solvents without eye protection – it’s a recipe for disaster!

- Gloves: The type of glove depends on the specific chemical. Some materials might require specialized chemical-resistant gloves that are also flame-resistant. Gloves are your hands’ best friend in preventing chemical burns and exposure.

- Respiratory Protection: For volatile or potentially toxic fumes, a respirator might be needed, chosen based on the specific hazard. This could be a simple dust mask for some scenarios or a more sophisticated respirator for others. Remember, protecting your breathing is crucial.

- Safety Shoes: Steel-toe safety shoes protect your feet from falling objects and potential spills.

Example: When working with ethanol, safety glasses, flame-resistant gloves, and a lab coat are minimum requirements. If you are using large quantities or performing actions that could lead to significant splashing, a face shield should also be used.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you conduct a fire safety inspection related to flammable materials?

A fire safety inspection concerning flammable materials is a systematic process aimed at identifying and mitigating potential fire hazards. It should be conducted regularly and involve a thorough check of storage areas, workspaces, and equipment. The inspection process should cover:

- Storage Areas: Check for proper storage of flammable materials, including compliance with regulations regarding separation distances, segregation of incompatible materials, and adequate ventilation. Look for any signs of leaks or spills. Are materials properly labeled and stored in approved containers?

- Workspaces: Examine the work area for potential ignition sources such as open flames, hot surfaces, static electricity, and sparks. Are proper electrical installations and grounding practices in place? Is there sufficient ventilation to disperse flammable vapors?

- Equipment: Inspect machinery and equipment for proper maintenance and operation, paying attention to potential leaks or ignition sources. Are there proper shut-off procedures in place? Does the equipment meet safety standards?

- Spill Control: Check for the availability and functionality of spill kits and absorbent materials. Ensure personnel are trained in proper spill response procedures. This is about being prepared for the unexpected.

- Emergency Procedures: Verify the presence and readability of emergency exit routes, fire extinguishers, and fire alarm systems. Ensure emergency contacts and response plans are readily accessible.

Practical Application: Documenting all findings from the inspection is essential. Any deficiencies identified must be addressed immediately to prevent fire hazards. A checklist is helpful in ensuring a consistent and thorough inspection process.

Q 17. What is the role of grounding and bonding in preventing fires involving flammable materials?

Grounding and bonding are critical safety measures that prevent the build-up of static electricity, a major ignition source for flammable materials. They work together to provide a path for static electricity to discharge safely to the earth, preventing sparks that could ignite flammable vapors or liquids.

- Grounding: Connecting a conductive object (e.g., a metal container or equipment) to the earth through a low-resistance path. This provides a route for static charges to dissipate.

- Bonding: Connecting two or more conductive objects together to equalize their electrical potential. This prevents a potential difference that could lead to a spark between objects.

Example: A flammable liquid transfer operation requires both grounding the container and bonding it to the receiving tank. This ensures that any static electricity generated during the transfer process is safely discharged to the ground, preventing the possibility of an ignition.

Why is this important? The energy from a static discharge can easily exceed the ignition energy of many flammable materials, leading to a fire or explosion. Grounding and bonding are essential safety practices in industries that handle flammable liquids and gases.

Q 18. Explain the importance of proper labeling and signage for flammable materials.

Proper labeling and signage are crucial for the safe handling of flammable materials. They serve as a visual warning system, communicating the hazards associated with the material and providing instructions for its safe handling and storage. Clear and consistent labeling ensures that everyone handling these materials understands the potential risks.

- Labels: Must include the name of the material, its hazard classification (e.g., flammability rating), and any specific safety precautions. Labels must be durable and clearly visible.

- Signage: Provides warnings and instructions related to fire prevention and emergency procedures within a specific area. Signage could include ‘No Smoking,’ ‘Flammable Materials,’ ‘Fire Extinguisher Location,’ or specific instructions for emergency procedures.

Example: A container of acetone must be clearly labeled with the name ‘Acetone,’ its flammability rating, and a warning indicating its potential health hazards. The storage area might also have signage indicating ‘Flammable Materials – No Open Flames.’

Consequences of Inadequate Labeling: Failure to properly label and sign can lead to accidents, injuries, and potentially catastrophic fires. It also places the responsibility squarely on the individual or company responsible for the inadequate labeling/signage.

Q 19. Describe different types of flammable material containers and their safety features.

Flammable material containers are designed with various safety features to minimize the risk of leakage, spills, and fires. Different container types are selected based on the material’s properties and the intended application.

- Safety Cans: Designed for dispensing small quantities of flammable liquids. They have a flame arrestor to prevent the ignition of vapors and a spring-loaded spout to prevent spills. Think of them as a mini, extra-safe container.

- Drums: Used for larger quantities of flammable liquids. Often made of steel or plastic, with tight-fitting lids and sometimes equipped with ground connections. These require careful handling due to their size and weight.

- Compressed Gas Cylinders: Specialized containers for storing and transporting compressed gases. They have pressure relief valves to prevent over-pressurization. These must be secured and managed very carefully.

- Carboys: Glass or plastic containers, usually encased in protective crates, for storing and transporting large volumes of flammable liquids. They usually need special handling to avoid breakage.

Safety Features: Common safety features include UN ratings (for transport), self-closing lids, pressure relief valves, spill containment trays, and grounding provisions. The specific features will depend on the nature and quantity of the material being stored or transported.

Q 20. How do you manage waste generated from flammable materials?

Managing waste from flammable materials requires careful planning and adherence to regulations. The approach depends on the nature of the waste. Improper waste disposal can lead to serious environmental and safety hazards.

- Segregation: Flammable waste must be separated from other types of waste to prevent accidental ignition or reactions.

- Containerization: Use appropriate containers, often marked with hazard labels, for collecting flammable waste.

- Treatment/Neutralization: Some flammable wastes may require treatment or neutralization before disposal. This is very dependent on the material in question.

- Disposal: Flammable waste should be disposed of according to local, regional and national regulations. In many cases, special waste disposal facilities are required for such material.

Example: Used solvent rags should be kept in a designated, sealed metal container, away from other materials. They must be disposed of via a licensed hazardous waste disposal service.

Important Note: Always refer to local and national regulations for the appropriate disposal methods for flammable materials.

Q 21. What are the common causes of fires involving flammable materials?

Fires involving flammable materials typically stem from a combination of factors: the presence of a flammable substance, an ignition source, and an oxidizing agent (usually oxygen in the air).

- Ignition Sources: These include open flames, sparks (from welding or electrical equipment), hot surfaces, static electricity, and friction. Often, these ignition sources are preventable.

- Flammable Materials: Liquids, gases, and solids with low flash points present the highest risk. This includes solvents, fuels, aerosols, and many other common materials.

- Insufficient Ventilation: Poor ventilation can lead to the accumulation of flammable vapors, creating a combustible atmosphere.

- Improper Storage: Incorrect storage of flammable materials, including proximity to ignition sources or incompatible materials, is a major cause of fires.

- Human Error: Negligence, lack of training, or failure to follow safety procedures can result in ignition and fires.

Example: A fire might erupt when a worker sparks a cigarette near a container of gasoline that has accumulated vapors, causing a flash fire. This highlights the importance of safe work practices and attention to detail when handling flammable substances.

Q 22. Explain the process of conducting a spill response plan drill.

Conducting a spill response plan drill involves a simulated scenario to test the effectiveness of our established procedures. It’s not just about reading a plan; it’s about putting it into action and identifying weaknesses.

- Scenario Development: We begin by defining a realistic spill scenario – perhaps a leak from a storage tank containing a specific flammable liquid, considering factors like the quantity spilled and environmental conditions.

- Team Briefing: The team involved in the response, including safety officers, emergency responders, and potentially even neighboring facility personnel, receives a brief outlining the scenario and their assigned roles.

- Drill Execution: The drill unfolds according to the chosen scenario. This involves containment, cleanup, and reporting steps. Observers monitor the team’s performance, noting response times, effectiveness of techniques, and adherence to safety protocols.

- Debriefing and Improvement: Following the drill, a thorough debriefing session is critical. We analyze the response, identify areas where the plan worked well, and more importantly, where improvements are needed. This could range from refining communication procedures to improving equipment deployment.

For example, in a past drill simulating a methanol spill, we discovered a communication bottleneck between the initial responders and the cleanup crew. This was quickly addressed by implementing a more streamlined reporting system using dedicated radios.

Q 23. How do you ensure compliance with all relevant safety regulations?

Ensuring compliance is an ongoing process, not a one-time task. It involves a multifaceted approach:

- Staying Updated: We regularly review and update our safety procedures and training materials to align with the latest versions of NFPA, OSHA, and other relevant regulations. Changes in technology and best practices require constant vigilance.

- Regular Inspections: Thorough and frequent inspections of storage areas, equipment, and workspaces are essential to identify potential hazards and ensure equipment is functioning correctly and safely. This includes checking for leaks, proper ventilation, and appropriate signage.

- Documentation: Meticulous record-keeping is vital. This includes maintaining accurate inventories of flammable materials, training records for employees, inspection reports, and incident reports. This documentation serves as evidence of our commitment to compliance and can be essential in the event of an audit or investigation.

- Employee Training: Comprehensive and regularly updated training programs for all personnel who handle flammable materials is crucial. This includes proper handling procedures, emergency response protocols, and the use of personal protective equipment (PPE).

- Third-Party Audits: Periodically, we engage third-party safety consultants to conduct independent audits. This provides an objective assessment of our safety program and identifies areas for improvement, ensuring we maintain the highest standards.

Q 24. Describe your experience with using different fire suppression equipment.

My experience with fire suppression equipment includes:

- Class B Fire Extinguishers: I’m proficient in using various types of Class B extinguishers (CO2, dry chemical, foam) suitable for flammable liquid fires. This includes knowing the proper operating procedures, limitations, and the importance of aiming at the base of the fire.

- Fire Hydrants and Hose Systems: I’m trained in connecting and operating fire hydrants and hose systems, understanding water pressure and stream control techniques. This is vital for larger-scale fires.

- Fixed Suppression Systems: I’m familiar with various fixed suppression systems, including sprinkler systems and foam deluge systems, and understand their activation mechanisms and limitations. Understanding these systems is critical for effective fire prevention and response planning.

For example, during a training exercise simulating a large-scale solvent spill fire, I successfully deployed a foam deluge system, effectively containing and extinguishing the blaze. This showcased the practical application of theoretical knowledge and the importance of knowing how to operate this type of equipment safely and effectively.

Q 25. Explain how you would train employees on safe handling practices for flammable materials.

Training employees on safe handling practices involves a multi-stage approach:

- Initial Training: New employees receive comprehensive training covering the properties of flammable materials, the hazards associated with them, and the proper handling and storage procedures. This includes practical demonstrations and hands-on exercises.

- Regular Refresher Training: Regular refresher training sessions reinforce previously learned knowledge and address any updates to regulations or best practices. These sessions help to maintain consistent safe practices.

- On-the-Job Training: Experienced personnel provide on-the-job training to new employees, ensuring they apply their knowledge in real-world settings under supervision. This practical approach enhances understanding.

- Hazard Communication: Clear and concise hazard communication is essential. Safety Data Sheets (SDS) for all flammable materials are readily available, and employees are trained to understand and interpret this vital information.

- Emergency Response Training: Employees are trained in emergency procedures, including spill response, use of fire suppression equipment, and evacuation protocols. Regular drills ensure preparedness.

We use a combination of classroom instruction, videos, interactive modules, and hands-on exercises to cater to different learning styles. Practical application through simulations and real-world scenarios significantly boosts understanding and retention.

Q 26. What is your understanding of NFPA standards related to flammable materials?

My understanding of NFPA standards related to flammable materials is comprehensive. NFPA (National Fire Protection Association) publishes numerous standards relevant to the safe handling, storage, and use of flammable and combustible materials. Key standards include:

- NFPA 30: Flammable and Combustible Liquids: This is a cornerstone standard covering the storage, handling, and use of flammable and combustible liquids. It details requirements for storage tanks, containers, and safety precautions.

- NFPA 497: Hazardous Materials Management: This standard provides guidelines for the management of hazardous materials throughout their lifecycle, including flammable materials, addressing storage, handling, transportation, and emergency response.

- NFPA 704: Standard System for the Identification of the Hazards of Materials for Emergency Response: This provides the familiar diamond-shaped hazard identification system used on labels and placards, conveying crucial information about the flammability and other hazards of a material.

Understanding these standards is fundamental to ensuring compliance and mitigating risks. We utilize these standards as the basis for our safety programs and training materials.

Q 27. Describe a situation where you had to address a safety concern related to flammable materials. What was your approach?

In a previous role, we identified a safety concern involving improper storage of highly flammable solvents in an area with inadequate ventilation. This posed a significant fire hazard.

- Assessment: I first conducted a thorough assessment of the situation, documenting the location, type and quantity of solvents, ventilation levels, and proximity to ignition sources. This included taking photos and measurements.

- Immediate Action: To mitigate the immediate risk, I immediately restricted access to the area, relocating any unnecessary personnel. I also initiated the process of moving the solvents to a designated and appropriately ventilated storage area.

- Corrective Actions: I developed a plan outlining corrective actions, including improved storage practices, enhanced ventilation in the original storage area, and additional employee training on proper solvent handling and storage. I ensured the implementation of these changes was tracked and verified.

- Reporting and Documentation: The entire incident, including the assessment, actions taken, and corrective measures, was thoroughly documented and reported to relevant authorities and management. This documentation ensures accountability and helps to prevent similar incidents in the future.

This situation highlighted the importance of proactive hazard identification and the need for consistently applying safety protocols. The quick response and subsequent corrective actions prevented a potential accident.

Key Topics to Learn for Safe Handling of Flammable Materials Interview

- Flammable Material Classification: Understanding the different classes of flammable materials (liquids, solids, gases) and their associated hazards. This includes learning about flash points, autoignition temperatures, and flammability limits.

- Storage and Handling Procedures: Safe storage practices, including proper container selection, segregation of incompatible materials, and ventilation requirements. Practical application includes understanding the use of safety data sheets (SDS) and implementing appropriate spill response procedures.

- Personal Protective Equipment (PPE): Identifying and using appropriate PPE such as gloves, eye protection, respirators, and flame-resistant clothing based on the specific hazard presented. This includes understanding when and why specific PPE is necessary.

- Fire Prevention and Suppression: Understanding the fire triangle and methods for preventing fires involving flammable materials. This involves knowing how to use different types of fire extinguishers and emergency shutdown procedures.

- Emergency Response Procedures: Developing a clear understanding of emergency procedures, including evacuation plans, alarm systems, and the proper use of emergency equipment. This also includes knowing how to react to different types of flammable material incidents.

- Regulatory Compliance: Familiarity with relevant safety regulations and standards related to the handling and storage of flammable materials. This includes understanding the importance of documentation and record-keeping.

- Risk Assessment and Mitigation: Conducting thorough risk assessments to identify potential hazards and developing effective mitigation strategies to minimize the risk of incidents. This involves practical problem-solving skills.

Next Steps

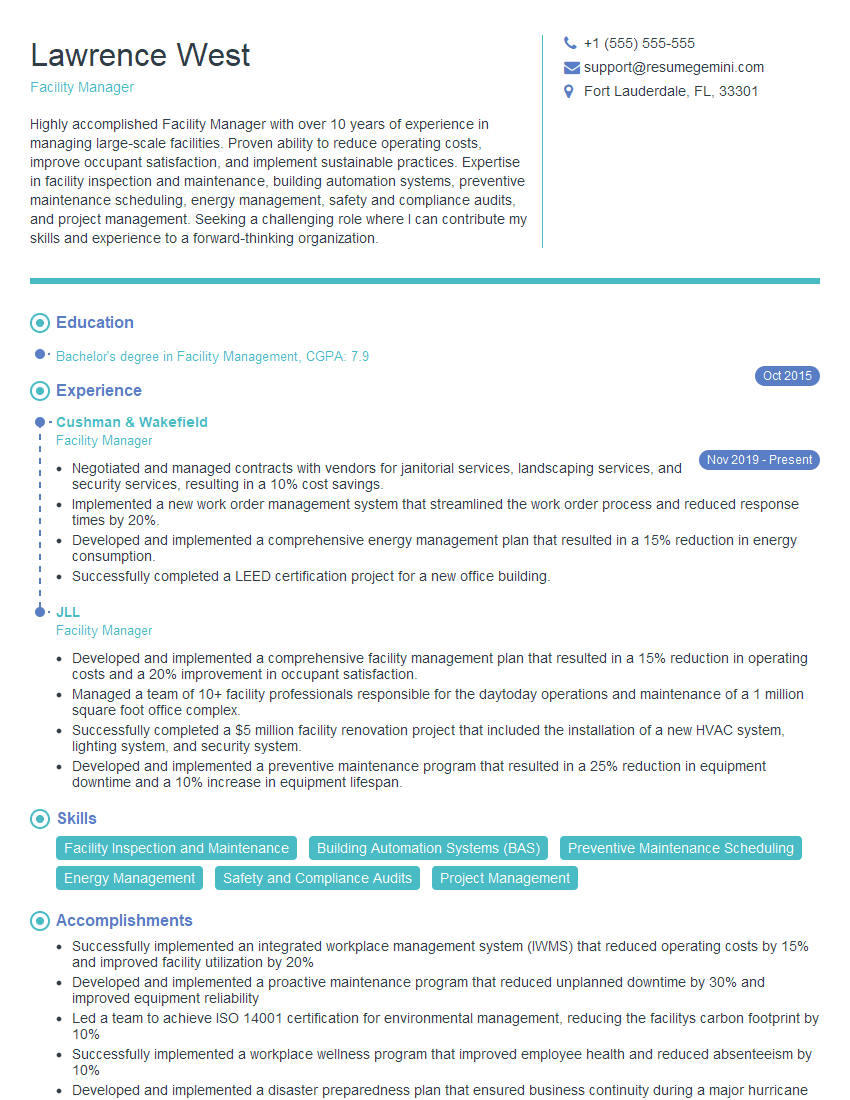

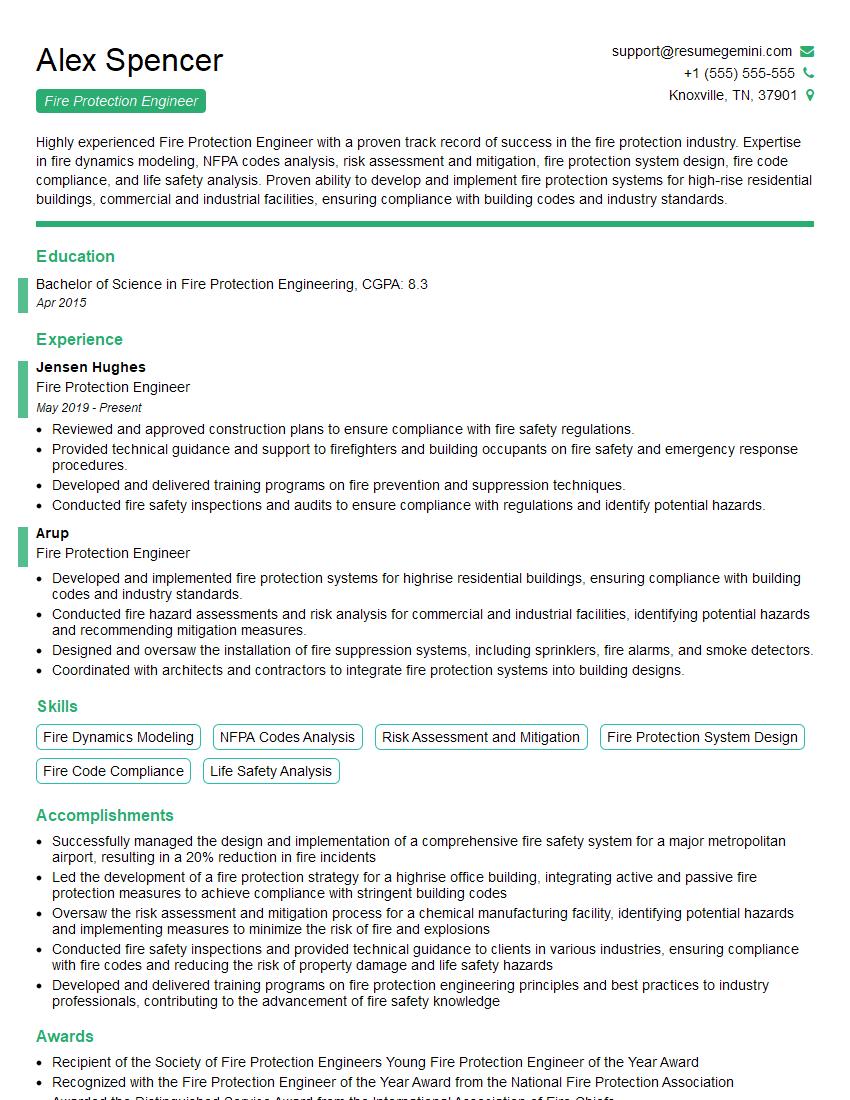

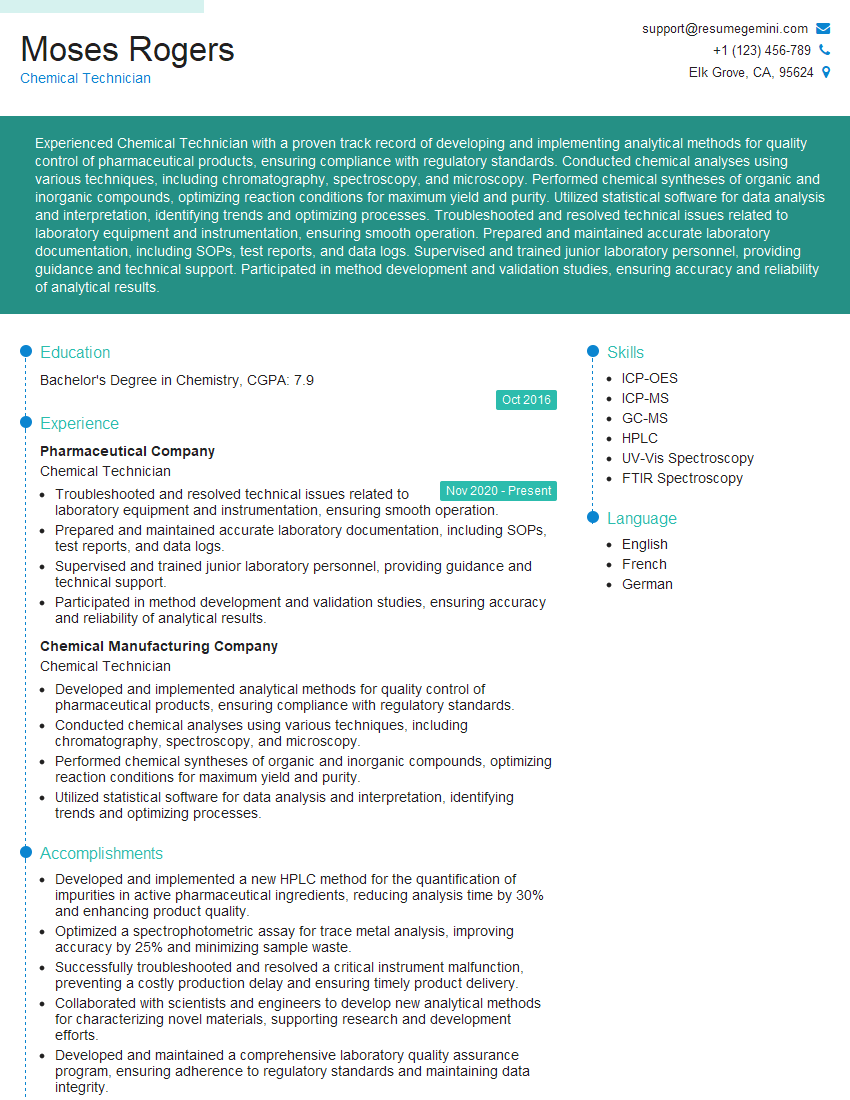

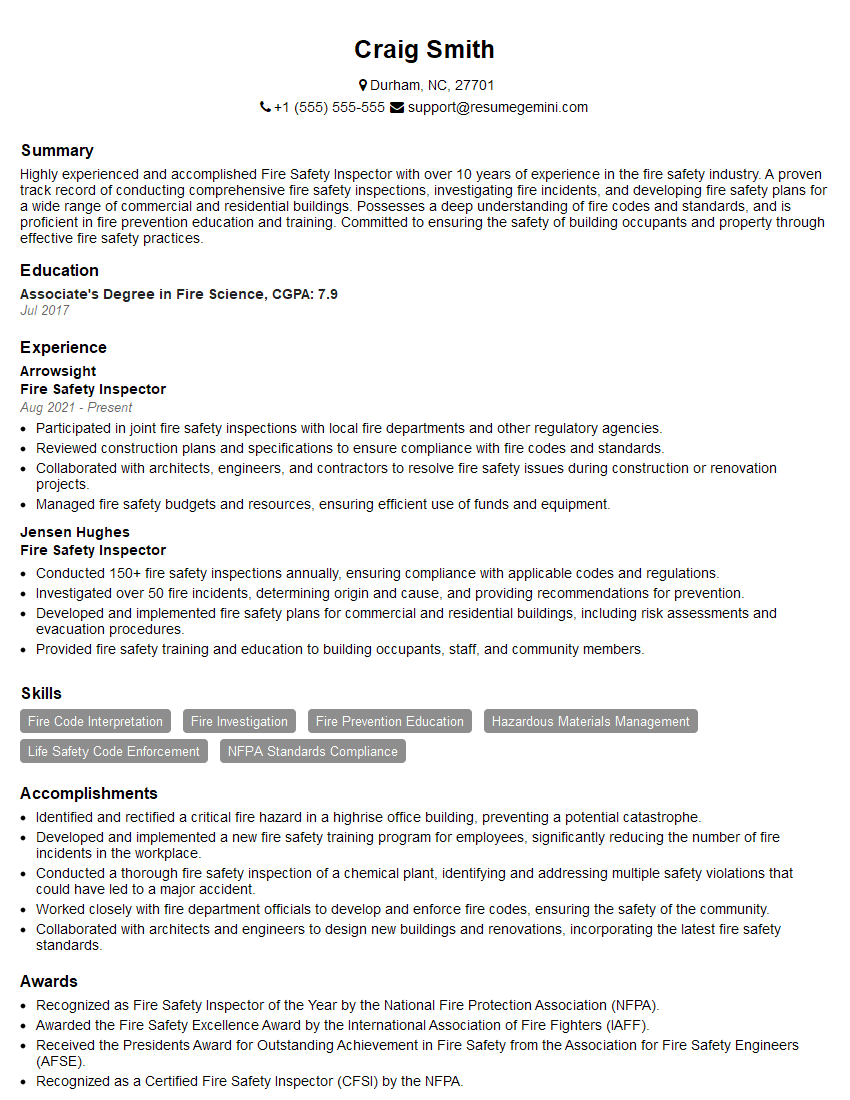

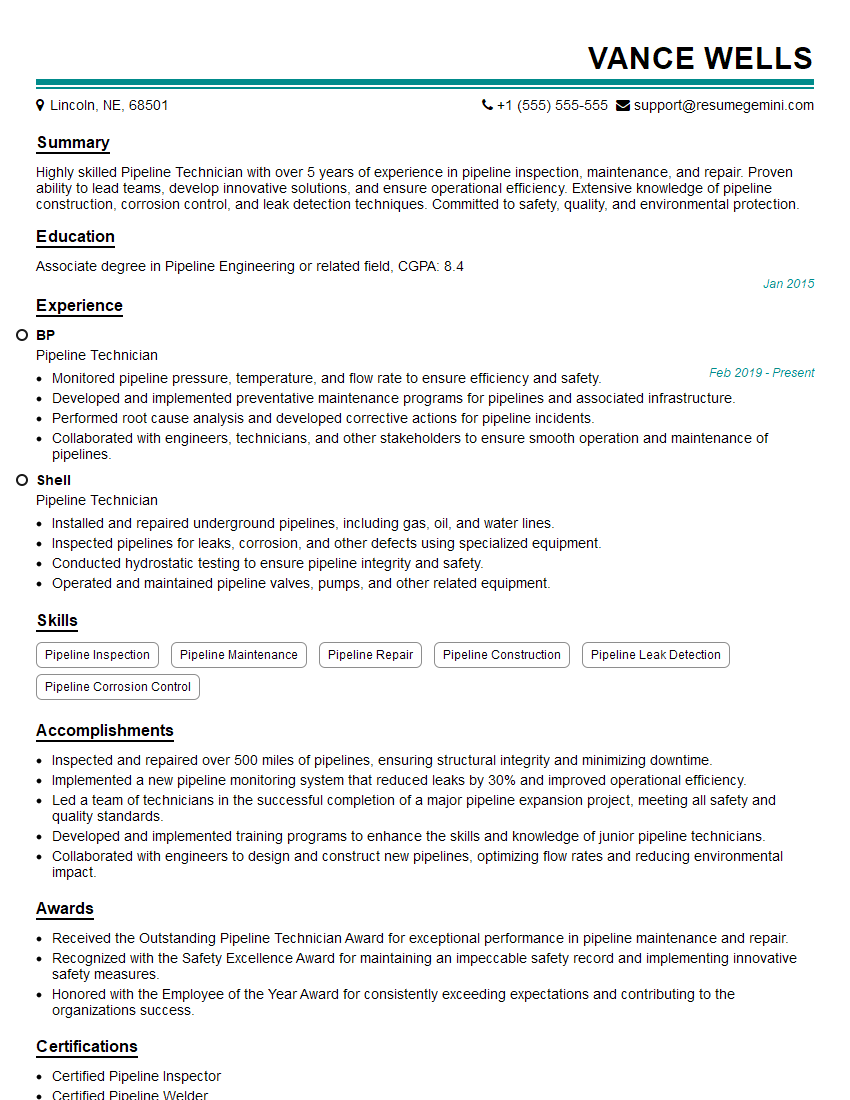

Mastering safe handling of flammable materials is crucial for career advancement in many industries. Demonstrating a deep understanding of these procedures is highly valued by employers and significantly increases your job prospects. To showcase your expertise effectively, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience. We provide examples of resumes tailored to the Safe Handling of Flammable Materials field to guide you. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO