Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Use diagnostic equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Use diagnostic equipment Interview

Q 1. Describe your experience troubleshooting malfunctioning diagnostic equipment.

Troubleshooting malfunctioning diagnostic equipment involves a systematic approach. I begin by gathering information: What is the specific issue? When did it start? Were there any preceding events? Then, I visually inspect the equipment for obvious problems like loose connections, damaged cables, or physical obstructions. Next, I consult the equipment’s troubleshooting manual and error codes. This often provides clues about the source of the malfunction. If the problem persists, I’ll employ more advanced techniques like checking power supply voltages, testing signal paths with multimeters, and potentially running diagnostic software. For instance, I once had to troubleshoot a malfunctioning hematology analyzer that was producing inaccurate results. Through systematic testing, I identified a faulty sensor that was causing inconsistent measurements. Replacing the sensor resolved the problem completely.

My approach emphasizes a methodical process of elimination, starting with the simplest possibilities and progressing to more complex ones. This approach minimizes downtime and ensures a swift resolution.

Q 2. Explain the process of calibrating a specific type of diagnostic equipment.

Let’s take the calibration of a blood gas analyzer as an example. Calibration is crucial to ensure accurate measurements. The process usually involves using standardized gas mixtures with known concentrations of oxygen, carbon dioxide, and pH. First, the analyzer is powered on and allowed to warm up to its operating temperature. Then, I follow the manufacturer’s instructions meticulously, typically involving a series of steps: inserting the calibration gas cartridges, running the calibration routine via the software interface, and entering the known gas values. The analyzer then performs internal adjustments to align its readings with the known standards. During this process, I monitor the calibration values closely for any inconsistencies or drift. This often includes visual inspection of calibration curves generated by the equipment and ensuring they fall within the manufacturer-specified tolerances.

Following the calibration, a verification step is usually performed with a different set of calibration standards, verifying the accuracy and reliability of the calibration process. Detailed records of all calibration steps and results, including date, time, calibration gas lot numbers and technician ID, must be documented for quality assurance.

Q 3. How do you ensure the safety and regulatory compliance of diagnostic equipment?

Ensuring safety and regulatory compliance is paramount when working with diagnostic equipment. This involves adherence to safety protocols and guidelines provided by regulatory bodies like the FDA (Food and Drug Administration) and relevant national standards organizations. This includes routine safety checks, proper grounding, and the use of personal protective equipment (PPE) as needed. For example, regular inspection of electrical wiring and ensuring equipment is properly grounded helps prevent electrical shocks. We must follow all manufacturer’s guidelines and maintain detailed logs of all maintenance and calibration activities which are reviewed by a qualified supervisor. Furthermore, regular training for technicians on safety procedures and updates to regulations is key. Equipment needs to be regularly inspected and serviced according to a schedule which often reflects the level of risk the equipment is used for and it’s regulatory compliance mandates. Failure to comply with these regulations could lead to inaccurate results, equipment malfunction, or even patient harm.

Q 4. What preventative maintenance procedures are crucial for diagnostic equipment?

Preventative maintenance is critical for extending the lifespan and ensuring the accuracy of diagnostic equipment. Crucial procedures include regular cleaning and disinfection (following manufacturer’s recommended procedures and disinfectants), checking and replacing filters, lubricating moving parts as necessary, and conducting thorough inspections for any signs of wear and tear. Regular calibration is also crucial, as outlined previously. For instance, in an ultrasound machine, regular checks of transducer functionality and cleaning are essential to maintain image quality and prevent cross-contamination. A preventative maintenance schedule should be developed based on the manufacturer’s recommendations and the frequency of use of the equipment, and these activities should always be documented.

Q 5. What are the common causes of failure in [specific type of diagnostic equipment]?

Let’s consider common causes of failure in an X-ray machine. Failures can range from minor to major. Some common issues include: problems with the high-voltage generator (leading to decreased output or complete failure), malfunctions in the X-ray tube (due to filament burnout or anode damage), issues with the control system (affecting image acquisition), or problems with the cooling system (leading to overheating). Other issues could arise from problems with the image intensifier and associated circuitry. Wear and tear on mechanical parts, like the collimator, are also significant concerns. Regular preventative maintenance, including testing and replacement of aging components, can significantly reduce the likelihood of these issues.

Q 6. How do you interpret diagnostic equipment readings and identify anomalies?

Interpreting diagnostic equipment readings and identifying anomalies requires a strong understanding of the equipment’s principles and the expected ranges of normal values. I use a combination of visual inspection of waveforms, numerical data analysis, and comparison against reference ranges. For example, in an electrocardiogram (ECG), I look for characteristic patterns and deviations from the norm. An abnormal rhythm, elevated ST segments, or inverted T waves could indicate cardiac issues. In blood gas analysis, I would compare the measured values of pH, pCO2, and pO2 against the reference intervals to identify acidosis, alkalosis, or other respiratory or metabolic problems. Software associated with the equipment often highlights potential anomalies and provides automated interpretations, but clinical judgement and consideration of the patient’s clinical presentation is critical in the final assessment.

Q 7. Describe your experience with repairing or replacing components in diagnostic equipment.

My experience encompasses both minor repairs and component replacements in various diagnostic equipment. I have replaced faulty sensors, repaired broken circuits, and replaced damaged circuit boards. I’ve also handled the replacement of high-voltage cables in X-ray equipment and maintained ultrasound transducers. For example, in one instance, I repaired a malfunctioning centrifuge by replacing its worn-out motor brushes. This involved carefully disassembling the unit, identifying the faulty component, sourcing a replacement part, and carefully reassembling the equipment while observing all necessary safety protocols. Before and after the repair, the device needs to be tested and verified. More complex repairs often involve collaborating with specialized technicians or engineers or potentially sending the equipment to a specialized repair facility. Throughout the process, detailed documentation is kept.

Q 8. Explain the importance of documentation in the maintenance and repair of diagnostic equipment.

Meticulous documentation is the cornerstone of effective diagnostic equipment maintenance and repair. It ensures traceability, accountability, and facilitates efficient troubleshooting in the future. Think of it like a medical chart for your equipment – it records its entire history.

Preventive Maintenance Logs: These document scheduled checks, calibrations, and cleaning procedures, helping predict potential failures and extend the lifespan of the equipment.

Repair Records: These detail any repairs performed, including the nature of the malfunction, parts replaced, and the steps taken to resolve the issue. This is crucial for warranty claims and future troubleshooting. For instance, if a specific component keeps failing, this data helps identify a pattern.

Calibration Certificates: These are legal documents confirming the accuracy and reliability of the equipment’s measurements. They are essential for ensuring the quality of patient care and complying with regulatory standards.

Software Updates and Firmware Versions: Recording software and firmware versions ensures compatibility and enables quick restoration to a known working state if problems arise.

Without thorough documentation, troubleshooting becomes a guessing game, repairs are less efficient, and potential safety hazards might be overlooked. It’s simply best practice for responsible equipment management.

Q 9. How do you handle a situation where a diagnostic equipment malfunction affects patient care?

A malfunction affecting patient care is a critical situation demanding immediate action. My priority is always patient safety.

Immediate Actions: First, I’d immediately inform the appropriate personnel – clinicians, supervisors, and potentially the patient’s family. The severity of the malfunction dictates the urgency of this notification.

Mitigation: If the malfunction compromises a life-critical function, I’d work to find an immediate alternative solution, whether it involves using a backup device or employing alternative diagnostic methods. For example, if an X-ray machine fails, I’d ensure access to a backup machine or suggest alternative imaging options like ultrasound, depending on the clinical situation.

Troubleshooting: Once patient care is secured, I would begin a thorough investigation of the equipment failure, carefully documenting all steps taken. This includes reviewing maintenance logs and error messages to pinpoint the root cause.

Reporting: A detailed report needs to be filed to detail the incident, the corrective actions, and any preventative measures that can be implemented to prevent recurrence. This is necessary for internal quality control and potential regulatory reporting.

Preventative Measures: Implementing preventative strategies, such as enhanced preventative maintenance schedules or improved staff training, may help to avert similar incidents in the future.

Q 10. What are the different types of diagnostic equipment you are familiar with?

My experience encompasses a wide range of diagnostic equipment, including:

Imaging Systems: X-ray machines (both general radiography and fluoroscopy), CT scanners, MRI scanners, Ultrasound machines, and Mammography units. I understand their operational principles, image acquisition, and image processing techniques.

Hematology Analyzers: These automated systems analyze blood samples, providing crucial information about blood cell counts, hemoglobin levels, and other hematological parameters.

Chemistry Analyzers: These perform biochemical analyses on patient samples, measuring various metabolites, enzymes, and electrolytes essential for diagnosis and treatment monitoring.

Electrocardiography (ECG) Machines: These record the electrical activity of the heart, providing valuable data for cardiac diagnosis.

Patient Monitors: I’m familiar with various patient monitoring systems that track vital signs like heart rate, blood pressure, oxygen saturation, and respiratory rate.

My expertise extends to both the hardware and software aspects of these systems.

Q 11. How do you stay up-to-date with the latest advancements in diagnostic equipment technology?

Staying current in this rapidly evolving field requires a multifaceted approach.

Professional Organizations: Active membership in organizations like the American College of Radiology (ACR) or the Association for Medical Instrumentation (AMI) provides access to continuing education opportunities, conferences, and peer-reviewed journals.

Manufacturer Training: Many manufacturers offer extensive training programs on their equipment, keeping me updated on new features, troubleshooting techniques, and safety protocols.

Industry Publications and Journals: Regularly reading publications like Radiology, Medical Physics, and Clinical Chemistry provides insights into the latest technological advancements and research findings.

Webinars and Online Courses: Numerous online resources offer webinars and continuing education courses that cover various aspects of diagnostic equipment technology.

Networking: Engaging with colleagues and attending conferences allows for the exchange of knowledge and experiences.

This continuous learning ensures that I remain proficient in the use, maintenance, and troubleshooting of the latest diagnostic equipment.

Q 12. Describe your experience with different diagnostic equipment manufacturers and their products.

I have experience working with a range of manufacturers, including:

GE Healthcare: I’m proficient with their MRI and CT systems, understanding their image reconstruction algorithms and quality assurance procedures.

Siemens Healthineers: I’ve worked extensively with their ultrasound and X-ray equipment, familiar with their diagnostic software and preventative maintenance protocols.

Philips Healthcare: I have experience with their patient monitoring systems and their data management capabilities.

Abbott Diagnostics: My experience with their hematology and chemistry analyzers includes troubleshooting, calibration, and preventative maintenance.

This broad experience allows me to appreciate the strengths and weaknesses of different manufacturers’ products and choose the most appropriate equipment for specific clinical needs. It also allows for more effective troubleshooting as I am familiar with common issues across various brands.

Q 13. What safety precautions do you take when working with diagnostic equipment?

Safety is paramount when working with diagnostic equipment. My safety protocols include:

Radiation Safety: When working with X-ray or CT equipment, I strictly adhere to ALARA (As Low As Reasonably Achievable) principles. This involves minimizing exposure time, maximizing distance, and utilizing appropriate shielding. I always wear a radiation dosimeter to monitor personal radiation levels.

Electrical Safety: I ensure all equipment is properly grounded and use appropriate personal protective equipment (PPE), including insulated gloves and safety glasses, when necessary. Regular safety checks of electrical cords and connections are essential.

Laser Safety: When working with equipment that utilizes lasers (some laser-based imaging systems), I wear appropriate laser safety eyewear and follow established laser safety protocols.

Magnetic Resonance Safety: When working near MRI scanners, I adhere to strict safety protocols to avoid the risks posed by the strong magnetic fields. This includes removing any ferromagnetic materials from the vicinity.

Infection Control: I strictly follow infection control procedures, including hand hygiene and the proper cleaning and disinfection of equipment to minimize the risk of cross-contamination.

Regular safety training and adherence to established protocols are essential for maintaining a safe working environment.

Q 14. How do you handle complex troubleshooting scenarios involving multiple components?

Troubleshooting complex scenarios involving multiple components requires a systematic and logical approach.

Gather Information: First, I would gather as much information as possible regarding the malfunction, including any error messages, observations from users, and any recent maintenance or repairs performed. Think of it like detective work – you need to gather all the clues first.

Isolate the Problem: Based on the information gathered, I would systematically test individual components to isolate the faulty part. This could involve checking connections, power supplies, and individual modules.

Component-Level Diagnostics: This stage might involve using specialized diagnostic tools such as oscilloscopes, multimeters, or logic analyzers to perform detailed testing of individual circuits and components.

Schematic Diagrams and Service Manuals: These are crucial resources to understand the equipment’s functionality and aid in tracing signal paths and isolating faulty components. They are the ‘maps’ guiding me through the system.

Documentation: Accurate and thorough documentation of every step taken, including test results and observations, is crucial for efficient troubleshooting and future reference.

Consult Expertise: If I encounter problems I can’t resolve independently, I would consult with colleagues, manufacturers, or other experts to get their input.

This structured approach allows for efficient troubleshooting, minimizing downtime and ensuring the equipment is restored to full functionality as quickly and safely as possible.

Q 15. Explain your experience with diagnostic equipment software and related applications.

My experience with diagnostic equipment software spans a wide range of applications, from basic troubleshooting tools to sophisticated image processing and analysis software. I’m proficient in using software for various modalities, including ultrasound, X-ray, MRI, and CT scanners. This includes understanding the software’s workflow, interpreting displayed data, adjusting parameters for optimal image acquisition, and troubleshooting software malfunctions. For example, I’ve used PACS (Picture Archiving and Communication System) software extensively to manage and archive medical images, ensuring secure access and efficient retrieval for clinicians. I’m also familiar with DICOM (Digital Imaging and Communications in Medicine) standards, which are crucial for interoperability between different imaging systems. In one instance, I resolved a recurring software glitch in an ultrasound machine that prevented the storage of patient data by identifying a conflict with a recently updated system driver. This involved meticulously reviewing system logs, testing different driver versions, and ultimately resolving the issue, ensuring uninterrupted workflow.

Beyond image processing, I have experience using software for equipment calibration, quality control, and preventative maintenance. This includes running automated tests, analyzing results, and generating reports to track the performance of the equipment and ensure it remains within regulatory guidelines.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize repair tasks when multiple pieces of diagnostic equipment are malfunctioning?

Prioritizing repair tasks for multiple malfunctioning diagnostic equipment requires a systematic approach. I use a prioritization matrix considering factors like the urgency of the repair (impact on patient care), the equipment’s criticality (number of patients affected), and the estimated repair time. For instance, a broken CT scanner, vital for emergency trauma cases, would take precedence over a malfunctioning ultrasound machine used for routine checkups.

- Criticality: How essential is the equipment to daily operations and patient care?

- Urgency: How quickly does the equipment need to be repaired to avoid significant disruption?

- Repair Time: How long is the estimated repair time, considering parts availability and technical complexity?

I document each repair request, its priority level, and the assigned technician. This ensures accountability and efficient allocation of resources. Regular monitoring and communication with the clinical staff are vital to ensure that the prioritization aligns with their needs.

Q 17. What are the key performance indicators (KPIs) you monitor for diagnostic equipment?

Key Performance Indicators (KPIs) for diagnostic equipment are crucial for assessing operational efficiency, quality of care, and identifying potential issues. I regularly monitor:

- Uptime: Percentage of time the equipment is operational and available for use. This reflects on equipment reliability and minimizes patient delays.

- Mean Time Between Failures (MTBF): The average time between equipment failures, indicating equipment reliability and the effectiveness of preventive maintenance.

- Mean Time To Repair (MTTR): The average time it takes to repair a malfunctioning piece of equipment. A shorter MTTR demonstrates efficiency in troubleshooting and repair.

- Image Quality Metrics: Parameters such as contrast, resolution, and noise levels, assessed through routine quality control tests, are critical for ensuring accurate diagnosis. Examples include spatial resolution, contrast-to-noise ratio (CNR), and uniformity for imaging modalities.

- Test Accuracy: For automated testing systems, the percentage of correct readings helps measure reliability and identify potential calibration issues.

By monitoring these KPIs, I can identify trends, predict potential failures, and implement proactive measures to improve equipment performance and reduce downtime.

Q 18. Describe your experience working with electronic schematics and diagrams.

I have extensive experience interpreting and working with electronic schematics and diagrams. This is crucial for troubleshooting complex equipment malfunctions. My understanding extends to various types of diagrams, including block diagrams, circuit diagrams, and wiring schematics. For example, I can trace signals through a circuit, identify components, and understand their function to diagnose problems down to the component level. I regularly use these schematics in conjunction with diagnostic software and multimeters to identify faulty components and implement repairs. Recently, I successfully repaired a malfunctioning X-ray generator by using the schematic to trace a faulty connection within the high-voltage circuit, avoiding unnecessary replacement of parts.

Schematic interpretation skills are also vital for modifying existing equipment or integrating new components. A strong understanding of electrical engineering principles is crucial for making modifications safely and effectively.

Q 19. How do you identify and address potential hazards associated with diagnostic equipment?

Identifying and addressing potential hazards associated with diagnostic equipment is paramount for both patient and staff safety. This involves a multi-faceted approach:

- Regular Safety Inspections: Conducting routine inspections to identify and address frayed wires, exposed components, or any other potential hazards.

- Radiation Safety Procedures: Following strict protocols for radiation safety, including proper shielding, ALARA (As Low As Reasonably Achievable) principles for radiation exposure, and ensuring the correct functioning of radiation safety interlocks.

- Electrical Safety: Adhering to electrical safety regulations, using proper grounding techniques, and implementing lockout/tagout procedures during repairs to prevent electrical shocks.

- Proper Equipment Handling: Training staff on the correct handling and usage of equipment, including proper transportation and positioning to avoid damage or injury.

- Emergency Procedures: Establishing and practicing emergency procedures in case of equipment malfunctions or accidents.

Beyond these, I always emphasize a proactive approach, ensuring equipment is regularly serviced, and that staff are properly trained on safe operating procedures. This reduces the likelihood of accidents and minimizes risks.

Q 20. What is your experience with different types of diagnostic imaging modalities?

My experience with diagnostic imaging modalities is quite comprehensive, encompassing:

- X-ray: Including both general radiography and fluoroscopy, understanding image acquisition parameters and quality control procedures.

- Computed Tomography (CT): Familiar with CT scanner operation, image reconstruction techniques, and radiation safety protocols.

- Magnetic Resonance Imaging (MRI): Proficient in MRI principles, sequence selection, image acquisition, and artifact identification.

- Ultrasound: Experienced in various ultrasound applications, including abdominal, cardiovascular, and obstetric ultrasound, and adept at selecting appropriate transducers and image optimization techniques.

- Nuclear Medicine: While not directly involved in the operation of these systems, I understand the principles of nuclear imaging and have worked with the related data and image processing software.

This diverse experience allows me to effectively troubleshoot issues across various modalities and collaborate effectively with technicians and clinicians specializing in specific areas.

Q 21. How do you ensure the accuracy and reliability of diagnostic equipment readings?

Ensuring the accuracy and reliability of diagnostic equipment readings is crucial for accurate diagnoses and patient care. This involves a combination of strategies:

- Regular Calibration and Quality Control: Performing routine calibrations and quality control tests according to manufacturer’s recommendations and regulatory guidelines. This involves using standardized phantoms and testing equipment to verify image quality and accuracy.

- Preventive Maintenance: Regular preventative maintenance schedules minimize equipment malfunctions and ensure optimal performance. This includes cleaning, lubrication, and inspections.

- Software Updates: Keeping software up-to-date to benefit from bug fixes, improved algorithms, and enhanced performance.

- Phantom Testing: Using standardized phantoms (test objects with known characteristics) to regularly verify the accuracy of the equipment readings. These phantoms provide a baseline against which the performance can be measured.

- Quality Assurance Programs: Participation in quality assurance programs helps identify and resolve systemic issues and ensure the equipment continually meets quality standards.

By combining these techniques, I can assure consistent and reliable performance, building confidence in the diagnostic results generated by the equipment.

Q 22. What are your troubleshooting strategies for resolving intermittent equipment failures?

Troubleshooting intermittent equipment failures requires a systematic approach. It’s like detective work – you need to gather clues to pinpoint the root cause. My strategy begins with careful observation of the symptoms. When does the failure occur? Under what conditions? Is there a pattern? This helps narrow down potential causes.

- Detailed Documentation: I meticulously document each instance of failure, noting the exact time, error messages (if any), and any preceding events. This helps identify trends and recurring issues.

- Environmental Checks: I check for environmental factors like power fluctuations, temperature extremes, or electromagnetic interference (EMI) that might be affecting the equipment.

- Component Testing: Once environmental factors are ruled out, I systematically test individual components of the equipment. This often involves using specialized tools and test equipment, checking connections, and performing calibration procedures.

- Software Updates & Configurations: For equipment with software components, I check for the latest updates and ensure proper software configurations. Outdated software or incorrect settings are common causes of intermittent failures.

- Escalation: If the problem persists after thorough investigation, I escalate the issue to the manufacturer or a higher-level technician for expert assistance.

For example, I once dealt with an intermittent failure of an ultrasound machine. By carefully documenting the timing of the failures and observing that they often occurred after a specific sequence of scans, I traced the issue to a faulty internal memory module. Replacing the module resolved the problem.

Q 23. Explain your experience with using diagnostic equipment manuals and technical documentation.

Diagnostic equipment manuals and technical documentation are my bible. They’re essential for understanding the equipment’s functionality, troubleshooting procedures, and safety protocols. My experience spans various manufacturers and models, requiring proficiency in interpreting diverse documentation formats.

- Navigating Manuals: I’m adept at quickly finding relevant information within extensive manuals, using indices, tables of contents, and search functions efficiently. I understand the importance of following safety precautions and warnings outlined in the documentation.

- Troubleshooting Guides: I utilize troubleshooting flowcharts and diagrams to systematically identify potential causes of equipment malfunctions. These guides help me eliminate possible causes one by one, leading to quicker diagnosis.

- Schema & Diagrams: I am familiar with understanding electrical schematics, block diagrams, and wiring diagrams to trace signal paths and identify potential points of failure within the equipment.

- Calibration Procedures: I regularly follow calibration and preventative maintenance procedures as outlined in the manuals to ensure the accuracy and reliability of the equipment.

For instance, when working with a new MRI machine, I thoroughly studied its service manual to understand its complex cooling system. This knowledge was crucial when I later had to troubleshoot a temperature-related alarm.

Q 24. How do you collaborate with other healthcare professionals when dealing with equipment malfunctions?

Collaboration is crucial when dealing with equipment malfunctions. It’s a team effort. I effectively communicate with biomedical engineers, clinicians, and IT staff to ensure timely resolution and minimize disruption to patient care.

- Clear Communication: I communicate clearly and concisely about the nature of the problem, the steps I’ve taken, and any potential solutions. I use clear and non-technical language when speaking with clinicians.

- Information Sharing: I share relevant diagnostic data and findings with the appropriate personnel. I might provide clinicians with workarounds if immediate repairs aren’t possible.

- Joint Troubleshooting: I collaborate with biomedical engineers for complex issues, leveraging their specialized knowledge and expertise. For software related issues, I collaborate closely with the IT department.

- Feedback & Reporting: I provide feedback to manufacturers regarding recurring issues or design flaws to improve the reliability of future equipment.

For instance, during a power outage that affected a critical cardiac monitor, I worked closely with the IT team to restore power and with the clinicians to ensure patient safety using backup equipment while coordinating repairs.

Q 25. Describe a time when you had to deal with a critical diagnostic equipment failure.

I once encountered a critical failure of a CT scanner during a busy emergency department shift. The scanner suddenly stopped functioning mid-scan, leaving a patient halfway through a critical examination. This was a high-pressure situation, requiring quick thinking and decisive action.

- Immediate Actions: My first priority was patient safety and ensuring they weren’t in any danger. I coordinated with the radiology staff to move the patient to a safe location and informed the attending physician.

- Troubleshooting: I immediately checked for power supply issues, checked the error logs on the scanner, and followed the manufacturer’s troubleshooting guide. The problem pointed to a hardware failure within the scanner’s internal power supply.

- Contacting Support: Since I couldn’t resolve the issue myself, I contacted the manufacturer’s 24/7 support hotline. Their technicians guided me remotely through some diagnostics, eventually confirming the need for a replacement part.

- Alternative Arrangements: While waiting for the repair, I coordinated with other hospitals to arrange for the patient’s scan to be performed at an alternative facility to minimize the delay in care.

This experience highlighted the importance of thorough training, quick decision-making, and effective communication under pressure. The situation also emphasized the significance of having contingency plans in place to minimize disruption when critical equipment fails.

Q 26. How do you ensure the proper disposal of obsolete or damaged diagnostic equipment?

Proper disposal of obsolete or damaged diagnostic equipment is crucial for environmental and safety reasons. It’s not just about throwing things away; it’s about responsible management. My process adheres strictly to all local, regional and national regulations.

- Assessment & Decontamination: Before disposal, I ensure the equipment is properly decontaminated to prevent the spread of infectious agents. This often involves following specific protocols depending on the type of equipment and its potential exposure to biological hazards.

- Data Security: If the equipment contains sensitive patient data, I securely erase or destroy the data according to HIPAA or other relevant data privacy regulations. I verify data erasure using approved methods.

- Recycling & Disposal: I coordinate with certified medical waste disposal companies that specialize in the proper handling and recycling of electronic waste (e-waste). I ensure they have the necessary permits and certifications.

- Documentation: I maintain thorough records of the disposal process, including the date, method of disposal, the company handling the waste, and any special handling instructions.

This ensures compliance with environmental regulations and minimizes any potential health or environmental risks associated with improper disposal of medical equipment containing hazardous materials.

Q 27. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skills in this field, aligning with the industry standards for a specialist with my qualifications. I’m open to discussing a competitive compensation package that reflects the value I bring to this role.

Key Topics to Learn for Use Diagnostic Equipment Interview

- Equipment Operation & Maintenance: Understanding the functionality of various diagnostic equipment (e.g., X-ray machines, ultrasound machines, ECG machines), including routine maintenance procedures and troubleshooting common malfunctions.

- Safety Procedures & Regulations: Knowledge of relevant safety protocols, radiation safety, infection control, and adherence to regulatory guidelines (e.g., HIPAA, OSHA).

- Interpreting Diagnostic Data: Analyzing data obtained from diagnostic equipment, recognizing patterns, and identifying potential anomalies. This includes understanding the limitations and potential biases of each type of equipment.

- Quality Control & Calibration: Performing quality control checks, calibrating equipment accurately, and maintaining detailed records of these procedures. Understanding the importance of maintaining equipment accuracy for reliable results.

- Troubleshooting & Problem Solving: Identifying and resolving technical issues with diagnostic equipment, using systematic approaches to diagnose problems and implement effective solutions. This includes understanding basic electronic principles and mechanical components.

- Patient Interaction & Communication: Explaining procedures to patients, ensuring their comfort and understanding, and communicating effectively with colleagues and other healthcare professionals.

- Data Management & Record Keeping: Properly storing, managing, and retrieving patient data obtained from diagnostic equipment, adhering to data privacy and security regulations.

- Emerging Technologies & Advancements: Familiarity with new and emerging technologies in diagnostic imaging and their implications for patient care.

Next Steps

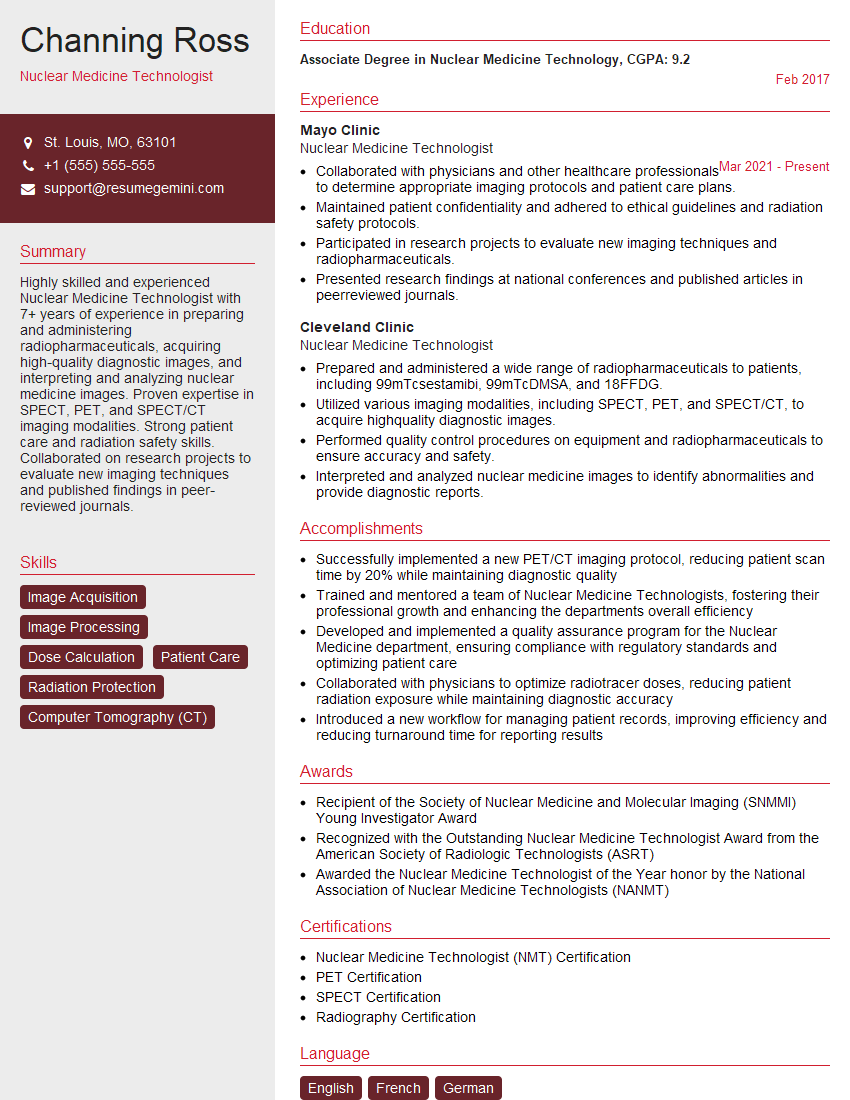

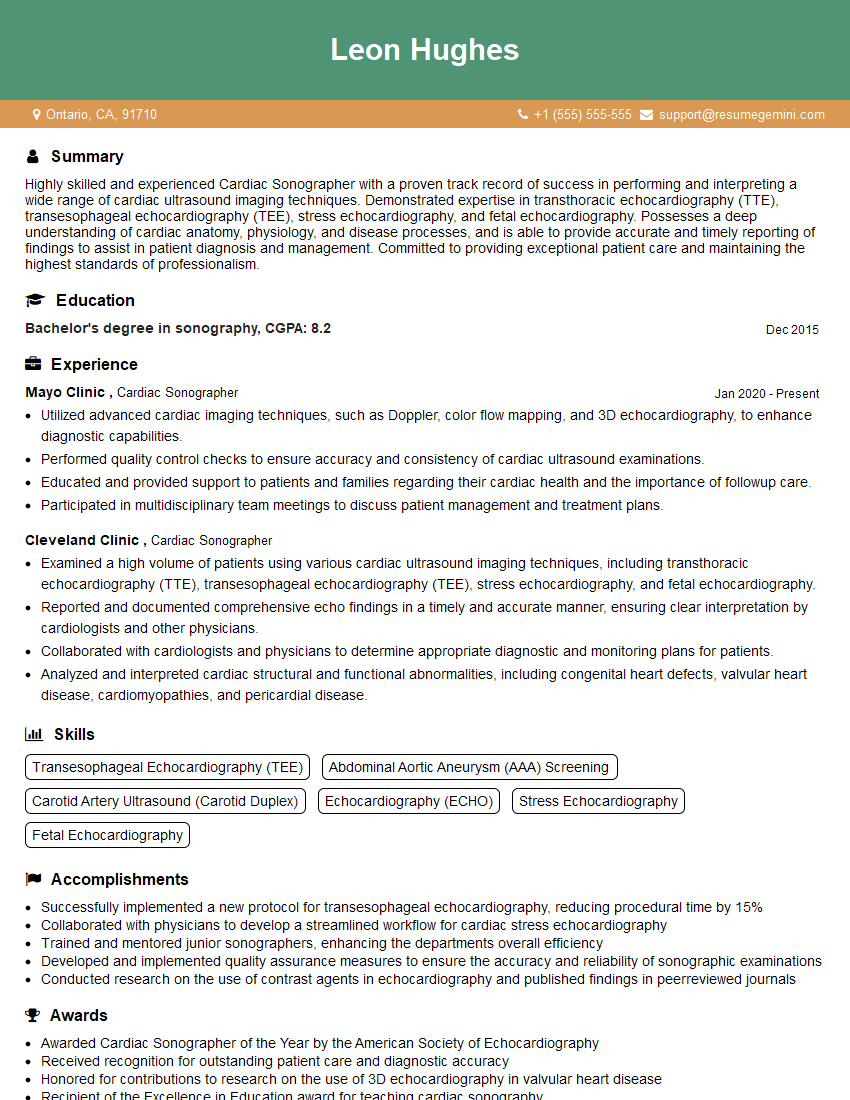

Mastering the use of diagnostic equipment is crucial for career advancement in healthcare. Proficiency in this area demonstrates technical expertise and commitment to patient well-being, opening doors to specialized roles and increased responsibility. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to using diagnostic equipment are provided to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO