Cracking a skill-specific interview, like one for CTP Platemaking, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in CTP Platemaking Interview

Q 1. Explain the CTP platemaking process from start to finish.

The CTP (Computer-to-Plate) platemaking process revolutionized the printing industry by eliminating the need for film. It’s a fully digital workflow, resulting in increased efficiency and accuracy. Here’s a step-by-step breakdown:

- Design and Prepress: The printing job begins with the design and layout. This is typically done using software like Adobe InDesign or Illustrator. The final files need to be carefully prepared for platemaking, ensuring correct color profiles and resolution.

- RIP Processing: The prepared files are then sent to a Raster Image Processor (RIP). The RIP converts the vector-based design into a raster image (bitmap) suitable for the CTP imager. It also applies color separations (CMYK) and creates the image data that will expose the plate.

- Plate Imaging: The RIP’s output is sent to the CTP imager. This machine uses a laser to expose the photosensitive plate material. Different imagers utilize various technologies, such as thermal or violet lasers, each with its own strengths and weaknesses.

- Plate Processing: After imaging, the plate needs to be processed to develop the image. This involves washing away the unexposed areas, leaving behind a hardened image that will transfer the ink during printing. The specific processing steps depend on the plate type (e.g., thermal, violet).

- Plate Mounting: Once processed, the plate is mounted onto a printing press cylinder, ensuring proper alignment and registration. This is a critical step for accurate printing.

- Printing: Finally, the mounted plate is ready for the printing process. Ink is applied to the exposed areas of the plate, transferred to the substrate (paper, etc.), and then the printed product is ready.

Imagine it like baking a cake: the design is the recipe, the RIP is the preparation, the imager is the oven, processing is the cooling, mounting is the presentation, and printing is the delicious result!

Q 2. What are the different types of CTP plates and their applications?

CTP plates come in various types, each with specific properties and applications:

- Thermal Plates: These plates are exposed using a thermal laser, which heats the plate to trigger a chemical change. They are generally known for their cost-effectiveness and ease of use. However, they might have a slightly shorter lifespan compared to violet plates. Often preferred for smaller print runs and applications where speed is prioritized.

- Violet Plates: These utilize a violet laser for exposure. They are known for their high resolution, improved image quality, and longer plate life. They are a preferred choice for high-quality printing, long print runs, and applications requiring fine details. These plates are generally more expensive.

- UV Plates: UV (Ultraviolet) plates use a UV laser. They offer advantages similar to violet plates but with even higher sensitivity, often used in high-speed printing environments. The cost tends to be at the higher end.

The choice of plate type depends on factors like budget, print quality requirements, print run length, and the type of printing press used. For instance, a high-volume commercial printer might opt for violet plates for their durability and high resolution, while a smaller shop focusing on short-run, quick-turnaround jobs might choose thermal plates.

Q 3. Describe the role of a RIP in CTP workflow.

The RIP (Raster Image Processor) is the brain of the CTP workflow. It acts as the translator between the digital design files and the CTP imager. Its key roles include:

- Rasterization: Converting vector-based artwork (lines, curves, text) into a raster image (pixels) that the imager can understand. This is crucial as the imager only works with pixel data.

- Color Separation: Separating the design into its four process colors (CMYK: Cyan, Magenta, Yellow, and Black). Each color requires its own plate, which the RIP creates individually.

- Image Processing: Enhancing the image quality, adjusting color profiles, and ensuring proper screen ruling for optimal print results. The RIP can also apply various image processing techniques to improve clarity and sharpness.

- Plate Exposure Data Generation: The RIP creates the exact data that dictates how the laser will expose the plate, ensuring the correct positioning and intensity of the laser for each pixel.

Think of the RIP as a skilled chef who takes raw ingredients (design files) and expertly prepares them (processes and rasterizes) to create a perfect recipe (plate exposure data) that the imager (oven) can execute flawlessly.

Q 4. How do you ensure proper plate registration?

Accurate plate registration is essential for perfect color alignment and overall print quality. Misregistration leads to blurry images and color shifts. Several techniques ensure proper registration:

- Precise Plate Mounting: Using specialized mounting equipment that ensures the plate is accurately positioned on the printing cylinder. This often involves fiducial marks on the plate and corresponding sensors on the mounting equipment.

- Fiducial Marks: Tiny marks printed on the plate itself act as reference points during mounting and printing. The printing press utilizes these marks to automatically adjust the plate position for perfect registration.

- Pre-Press Software: The pre-press software helps ensure the design is correctly set up for accurate registration. This includes proper imposition (arrangement of pages on the sheet) and careful attention to margins and bleeds.

- Regular Calibration: Regularly calibrating the CTP imager and printing press is crucial for maintaining consistent registration. This involves checking and adjusting the mechanical parts to ensure accuracy.

Imagine building a Lego castle; without proper alignment (registration), the different parts won’t fit together correctly, leading to an imperfect structure. Similarly, proper registration in CTP ensures all the colored plates align flawlessly during printing.

Q 5. What are the common causes of plate defects and how do you troubleshoot them?

Plate defects can significantly impact print quality. Some common causes and troubleshooting steps include:

- Scratches or Debris: These can be caused by handling the plate improperly. Solution: Careful handling and regular cleaning of the plate processing equipment. Inspect plates before and after processing.

- Incomplete Exposure: This may result from improper laser power settings or plate material issues. Solution: Check laser settings and power, ensure the plate is fresh and within its shelf life. Re-expose the plate if necessary.

- Dust or Particles: Dust or debris on the plate during processing can cause defects. Solution: Work in a clean environment, utilize dust covers for the plates and equipment, and filter the processing chemicals regularly.

- Chemical Imbalance: Incorrect chemical concentrations during processing can also lead to defects. Solution: Carefully follow the manufacturer’s instructions for chemical mixing and maintenance, regularly test and calibrate the processing solutions.

- Improper Plate Mounting: Incorrectly mounted plates cause registration issues. Solution: Use proper mounting equipment and follow established procedures. Verify plate alignment before printing.

Troubleshooting often involves a systematic approach: identifying the defect, isolating the potential cause through visual inspection and testing, and then implementing corrective actions. Keeping detailed records of plate production is crucial for identifying recurring issues.

Q 6. Explain the importance of image resolution in CTP platemaking.

Image resolution is paramount in CTP platemaking. It directly affects the final print quality. Higher resolution means more detail and sharpness in the printed image. The resolution is expressed in dots per inch (dpi) or lines per inch (lpi).

Insufficient resolution leads to a pixelated or blurry image, especially noticeable in areas of fine detail or sharp lines. It is important to match the resolution of the design to the capabilities of the imager and the printing press. Overly high resolutions might not improve the quality significantly while increasing processing times and file sizes.

For example, a standard resolution for high-quality printing might be around 2400 dpi for the plate but the screen ruling on the press might be 150-175 lpi. The RIP software often handles this interaction by resampling the data to a suitable value. The resolution choice is a balance between image quality, file size, and processing time.

Q 7. How do you manage color consistency in CTP plate production?

Maintaining color consistency in CTP production is crucial for achieving accurate color reproduction across different print runs. This is achieved through:

- Color Management System (CMS): Implementing a robust CMS throughout the workflow, from design to printing, ensures color profiles are consistent across all devices. This involves using calibrated monitors, accurate color profiles for the RIP and imager, and consistent press settings.

- Regular Color Calibration: Periodically calibrating all equipment involved in the workflow, including monitors, RIP, imager, and printing press, ensures accuracy and minimizes color drift. This might involve using color targets and specialized software for calibration.

- Standard Operating Procedures (SOPs): Establishing and consistently following SOPs ensures all operators utilize the same settings and workflows, reducing the chances of variability in color reproduction.

- Proofing: Using accurate soft proofing and hard proofing methods allows for verification of color accuracy before platemaking and printing, identifying discrepancies and making corrections early in the workflow.

Consistency is akin to a conductor leading an orchestra: each musician (device or step) must play in harmony (accurate color) to produce a beautiful symphony (accurate print). Proper color management is the conductor’s baton, ensuring every element works together seamlessly.

Q 8. Describe your experience with different types of plate imagers.

Throughout my career, I’ve had extensive experience with various types of plate imagers, ranging from older thermal platesetters to the latest generation of violet laser imagers. My experience encompasses both internal drum and external drum systems. For instance, I’ve worked extensively with Creo/Kodak platesetters, utilizing both their thermal and violet laser technologies. I’m also familiar with the Agfa platesetters, particularly their chemistry-free options which offer significant environmental and cost advantages. The key differences I’ve observed lie in resolution, speed, plate type compatibility, and overall cost of operation. Thermal imagers, while simpler and sometimes cheaper to purchase, offer lower resolution and tend to be slower. Violet laser imagers, on the other hand, provide much higher resolution, faster processing speeds, and superior image quality, making them ideal for high-end printing applications requiring fine details and consistent results. My expertise extends to understanding the strengths and limitations of each type, allowing me to select the optimal imager for any given job based on factors such as deadline, print quality requirements, and budget.

I’m proficient in operating and maintaining these machines, troubleshooting issues, and ensuring optimal performance. This includes understanding the importance of laser power calibration, plate-to-plate consistency, and regular preventative maintenance to minimize downtime and maximize the lifespan of the equipment.

Q 9. What are the safety precautions you take while handling CTP plates and chemicals?

Safety is paramount in CTP platemaking. Handling CTP plates and chemicals requires meticulous attention to detail and adherence to strict safety protocols. I always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat, when handling chemicals. This prevents skin irritation and eye damage from exposure to developer, fixer, and other chemicals. Proper ventilation is crucial; I ensure the processing area is well-ventilated to minimize inhalation of fumes. I handle plates carefully to avoid cuts from sharp edges or breakage. The proper disposal of used chemicals is vital. I am trained on and follow the prescribed methods for neutralizing and discarding waste according to environmental regulations. I regularly check for leaks and spills, immediately cleaning up any incidents with appropriate absorbent materials. Furthermore, I meticulously follow the manufacturer’s instructions for handling both plates and chemicals, ensuring the safety of myself and my colleagues.

Q 10. How do you perform quality control checks on CTP plates?

Quality control is an integral part of the CTP process, ensuring consistent and high-quality prints. My QC process begins with visual inspection of the plates for any defects, like scratches, pinholes, or uneven exposure. This is followed by a densitometer reading to measure the density of different areas on the plate. This helps determine if the exposure is consistent across the plate. Furthermore, I use a microscope to examine the dot sizes and shapes to verify if they’re within the acceptable parameters for the specific print job. A significant aspect is checking the plate for correct registration, which ensures proper alignment of colours when multiple plates are used. This is often done using a registration target or a dedicated registration system integrated with the platesetter. For critical jobs, I might even produce a test print to verify the overall quality and make adjustments if necessary. All this data is meticulously documented, contributing to a comprehensive quality record.

Q 11. Explain the concept of dot gain and how it affects print quality.

Dot gain refers to the increase in the size of a printed dot compared to the size of the corresponding dot on the plate. Think of it like this: you intend to print a tiny dot, but after the printing process, it’s slightly larger. This happens due to several factors like ink spread, paper absorption, and the printing pressure. Excessive dot gain leads to poor image sharpness, muddy colours, and a loss of fine detail. It can make images appear darker and less vibrant than intended. Conversely, insufficient dot gain can result in images that look thin and lacking in density. Controlling dot gain is critical to achieving the desired print quality. This involves careful calibration of the printing press, selection of appropriate paper and inks, and precise dot size control during platemaking. Accurate profile creation and colour management systems are vital to minimizing undesirable dot gain and achieving consistent results. For example, a halftone screen’s angle and frequency, along with the chosen printing method, all have a significant impact on dot gain.

Q 12. What software are you proficient in for prepress workflow?

My prepress workflow proficiency includes a wide range of software. I’m adept at using Adobe Creative Suite (Photoshop, Illustrator, InDesign) for image preparation and page layout. I am experienced in using Esko’s suite of prepress software, including ArtiosCAD for packaging design and preflighting, and Color Engine for color management. I also have significant experience in workflow automation software like Kodak Prinergy and Agfa Apogee, which are essential for streamlining the entire prepress process from design to platemaking. Furthermore, I’m familiar with various RIP (Raster Image Processor) software packages, allowing me to process high-resolution images efficiently and accurately for different printing processes. This software expertise enables me to optimize image quality, handle complex files, and efficiently manage the prepress workflow for optimal productivity.

Q 13. How do you handle plate jams or other equipment malfunctions?

Handling plate jams or equipment malfunctions requires a systematic approach. First, I ensure the machine is safely powered down to prevent further damage or injury. Then, I carefully diagnose the problem, referring to the equipment’s manual and troubleshooting guides. Common issues include paper jams, sensor malfunctions, and laser issues. For minor jams, I carefully remove the obstruction following the manufacturer’s instructions. For more complex issues, I first try basic troubleshooting steps such as checking power supply, connections, and software settings. If the problem persists, I contact the manufacturer’s technical support for assistance. Throughout the troubleshooting process, I maintain detailed records of the problem, the steps taken, and the outcome to improve future problem-solving and prevent recurring issues. Proactive maintenance, like regular cleaning and preventative measures, significantly reduces the likelihood of malfunctions.

Q 14. What is your experience with different plate processing chemistries?

My experience encompasses various plate processing chemistries, including traditional wet processing methods and newer process-free technologies. I’m proficient in using different types of developers and fixers for traditional thermal and violet plates. I understand the importance of maintaining optimal chemical concentrations and temperatures to ensure consistent processing results. I’m also well-versed in the chemistry-free or ‘waterless’ plate processing technologies, which offer significant environmental and cost advantages by eliminating the need for traditional wet processing chemicals. These systems often involve utilizing specialized plates and processing techniques that utilize UV light or thermal energy for imaging and development. Understanding the specific requirements and characteristics of each chemistry allows me to optimize plate processing for efficiency, quality, and environmental responsibility. This includes being aware of the specific health and safety regulations associated with each chemistry type.

Q 15. Describe your experience with plate cleaning and maintenance.

Plate cleaning and maintenance are crucial for consistent print quality and the longevity of your CTP (Computer-to-Plate) system. Think of it like regularly servicing your car – neglecting it leads to problems down the line. My experience encompasses both manual and automated cleaning processes. For manual cleaning, I utilize specialized cleaning solutions and cloths, carefully removing any residual developer, ink, or debris from the plate surface. This prevents build-up which can affect image sharpness and lead to printing inconsistencies. I always follow the manufacturer’s recommendations for cleaning agents to avoid damaging the plate. For automated systems, I regularly check the cleaning solution levels, monitor the cleaning cycle, and perform preventative maintenance such as replacing worn brushes or rollers. A key aspect of my process is meticulous inspection after cleaning; I check for any residual contaminants that might be missed by the automated system. I’ve found that a combination of careful manual checks and efficient automated cleaning ensures optimal plate cleanliness and extends the life of the plates significantly.

- Regular cleaning prevents build-up of chemicals and debris.

- Proper cleaning solution selection is critical to avoid plate damage.

- Automated cleaning systems require routine maintenance.

- Visual inspection is essential for quality assurance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain the accuracy of color profiles in your workflow?

Maintaining accurate color profiles is paramount in CTP workflow. Inconsistent color reproduction can lead to costly reprints and dissatisfied clients. My approach involves a multi-stage process starting with proper color calibration of all devices in the workflow, including the RIP (Raster Image Processor), the CTP imager, and the printing press. I use colorimetric devices, like spectrophotometers, to measure and profile each component. We create ICC (International Color Consortium) profiles and meticulously check for any color shifts during the imaging and printing processes. Regular color profile updates are essential, especially if changes are made to any equipment or consumables. A practical example: Recently we changed our printing plates supplier; this slight alteration in plate material necessitated a complete re-profiling of the entire workflow to ensure accurate and consistent color across all our jobs. To monitor long-term accuracy, we regularly print color test charts and compare them to the target values. This ensures early detection of color drift and allows for timely corrections. This proactive approach is much more cost-effective than reacting to discovered problems on press.

Q 17. Explain the importance of proper plate storage.

Proper plate storage is vital for preventing plate degradation and ensuring consistent print quality. Think of it like storing valuable documents – you wouldn’t leave them out in the sun, would you? Exposed plates are susceptible to damage from moisture, dust, scratches, and static electricity. This could result in poor image quality, reduced plate lifespan, and ultimately, costly production delays. My workflow prioritizes storing plates in a clean, dark, and dry environment, ideally in a climate-controlled room. Plates are kept flat, protected from any kind of physical damage, and stored in protective sleeves. I meticulously label all plates to ensure easy identification. We use a FIFO (First In, First Out) system to rotate the plates and prevent them from expiring before they can be used. We also maintain strict temperature and humidity levels within the storage area, typically within 20-22°C and 45-55% RH. Adherence to these measures significantly extends plate life and guarantees that the plates are in optimal condition when used, minimizing waste and downtime.

Q 18. What is your experience with different plate materials (e.g., aluminum, polyester)?

My experience spans various plate materials, each with its strengths and weaknesses. Aluminum plates are the industry standard due to their affordability, durability, and excellent image quality. However, they are susceptible to scratches and require careful handling. Polyester plates, on the other hand, are more flexible and easier to handle, suitable for smaller format or specialized printing. I have worked extensively with both, understanding their unique properties and application-specific advantages. For example, for high-volume, demanding jobs requiring durability, I prefer aluminum plates. However, for applications requiring greater flexibility or handling ease, polyester plates are a preferred choice. The choice depends on the job’s requirements, production volume, and budget considerations. I also have experience with different plate coatings and thicknesses, tailoring the selection to achieve the best results for specific printing applications. For instance, thicker plates provide better stability for long runs, while thinner plates can offer better fine detail resolution for certain applications.

Q 19. How do you identify and resolve issues related to plate exposure?

Plate exposure issues can manifest in various ways, from poor image density to complete plate failure. Identifying and resolving these issues requires a systematic approach. I start by analyzing the printed output – looking for issues like ghosting, poor dot reproduction, or uneven density. Then, I examine the CTP workflow, checking the exposure settings on the imager, the quality of the plates themselves, and the condition of the imaging laser. Incorrect exposure settings are a common culprit; this often involves fine-tuning the exposure time and laser power based on the plate type and RIP settings. I use test plates to check the exposure settings, and I regularly calibrate the imager to ensure consistent results. For instance, if I observe poor dot reproduction on the final output, I would first check for any misalignment issues in the imager and then adjust the laser power to optimize the dot shape. Similarly, if I observe uneven density, I’d examine the laser’s power distribution and consider whether there’s a problem with the laser itself or the plate surface. Each step involves carefully documenting the findings and adjustments made. This methodical approach ensures that the problems are thoroughly addressed and the risk of recurrence is minimized.

Q 20. Describe your experience with different plate developing systems.

I have experience with various plate developing systems, including processors employing different chemistries and automation levels. This includes both thermal and processless plates, along with their associated developers. Thermal plates eliminate the need for a separate developing process, simplifying operations and reducing processing time and waste. Processless plates also simplify things, but offer a different set of image characteristics. Process developers, on the other hand, offer a greater degree of control over the final image, but require careful monitoring of chemical concentrations and regular maintenance. I understand the specific requirements of each system, including the proper chemical handling, maintenance schedules, and waste disposal procedures. This knowledge enables me to troubleshoot problems efficiently, selecting the appropriate developing process based on the type of plate used and the desired outcome. For instance, a thermal developer requires less attention to chemical mixing but necessitates precise temperature control. Meanwhile, a process developer demands strict adherence to mixing ratios and careful monitoring of the developer’s pH and lifespan. My experience allows me to select the best option based on the specific requirements of each job, optimizing the throughput and minimizing any potential problems.

Q 21. What is your experience with automated plate handling systems?

Automated plate handling systems significantly enhance efficiency and productivity in CTP platemaking. My experience encompasses various automated systems, from simple plate loading and unloading devices to fully automated lines incorporating plate processing, imaging, and cleaning. These systems increase throughput, reduce manual handling errors, and improve overall process consistency. However, automated systems require regular maintenance and calibration to ensure proper functioning. I am proficient in troubleshooting and performing preventative maintenance on these systems, identifying and resolving problems such as jams, misalignments, or sensor malfunctions. For instance, I’ve worked with systems that employ robotic arms for handling plates; understanding the programming and error codes for these robots is crucial to swiftly addressing malfunctions. I believe that a combination of skilled human oversight and robust automation is essential for optimal productivity and quality control. The automated systems free up time for the technicians to concentrate on quality control and other crucial tasks, making the process more efficient and less prone to human error.

Q 22. How do you ensure the longevity and stability of your plates?

Plate longevity and stability are paramount in CTP (Computer-to-Plate) platemaking for consistent print quality and minimized waste. We achieve this through a multi-pronged approach.

Proper Plate Storage: Plates are stored in a climate-controlled environment, away from direct sunlight and extreme temperatures. This prevents warping, cracking, and oxidation, all of which degrade plate performance.

Careful Handling: Plates are handled with care to avoid scratches or damage that could lead to printing inconsistencies. We use anti-static gloves and protective sleeves during the process.

Optimized Processing Parameters: The exposure and processing times and chemicals used in the CTP imager and processor are meticulously controlled and regularly calibrated. Incorrect parameters can shorten plate life and reduce print quality. For example, over-exposure can lead to premature plate degradation.

High-Quality Plates and Chemistry: We source plates and processing chemicals from reputable manufacturers, ensuring they meet or exceed industry standards for quality, durability, and compatibility with our CTP system. This choice impacts the lifespan and print quality significantly.

Regular Maintenance of CTP Equipment: Preventative maintenance on our CTP imager and processor is crucial. This includes regular cleaning, calibration, and part replacement as needed. A well-maintained machine ensures consistent, high-quality imaging and processing, extending plate life.

Q 23. How do you handle discrepancies between the digital file and the final plate?

Discrepancies between the digital file and the final plate are meticulously investigated to ensure print quality. Our process involves a systematic approach:

Verification of the Digital File: The digital file undergoes a preflight check to verify its integrity, including resolution, color profiles, and overall structure. We use software designed to detect potential issues before imaging.

RIP Settings Review: We review the RIP (Raster Image Processor) settings to ensure that they match the requirements of both the digital file and the plate type. Incorrect settings can lead to mismatches between the digital and physical output.

Plate Inspection: After the plate is processed, a visual inspection is conducted to identify any obvious defects, such as scratches, streaks, or pinholes. We also perform a print test to verify the accuracy of the imaging and the absence of artifacts.

Troubleshooting: If discrepancies are identified, a systematic investigation is carried out. This could involve reviewing the digital file again, checking the RIP settings, investigating the CTP imager’s exposure settings, or examining the plate processing parameters. We use a combination of software analysis and manual inspection to isolate the root cause.

Corrective Action: Once the source of the error is determined, corrective actions are implemented, and the platemaking process is repeated. This often involves retraining on a procedure or addressing potential equipment issues.

Q 24. What are the key performance indicators (KPIs) for a CTP platemaker?

Key Performance Indicators (KPIs) for a CTP platemaker focus on efficiency, quality, and cost-effectiveness. These include:

Platemaking Speed: The number of plates produced per hour or per day, reflecting the efficiency of the process.

Plate Quality: Measured by the percentage of plates deemed acceptable after inspection and print testing; a high percentage indicates fewer rejects and waste.

Throughput: The total number of jobs completed within a given timeframe, showing overall productivity.

Waste Reduction: The percentage of plates that are scrapped due to defects or errors, reflecting the cost-effectiveness of the platemaking process. Lower waste reduces costs and environmental impact.

Downtime: The amount of time the CTP system is unavailable due to maintenance or malfunctions. Minimizing downtime maximizes productivity and reduces delays.

Cost Per Plate: This metric helps track the overall cost-effectiveness of plate production, including consumables and labor.

Q 25. How do you stay updated with the latest advancements in CTP technology?

Staying updated on CTP technology advancements is crucial for maintaining competitiveness and efficiency. My approach involves:

Industry Publications and Websites: I regularly read trade publications and visit websites that focus on printing and prepress technologies, staying informed about new equipment, software, and techniques. This keeps me abreast of current trends.

Industry Conferences and Trade Shows: Attending industry conferences and trade shows allows me to see new technologies firsthand, network with colleagues, and learn from industry experts. This provides invaluable real-world insights.

Manufacturer Training Programs: Participating in training programs offered by the manufacturers of our CTP equipment ensures I am proficient in operating and maintaining our systems, utilizing the latest functionalities.

Online Courses and Webinars: I actively seek online courses and webinars from industry professionals, keeping my skills current and broadening my knowledge base on new advancements.

Networking with Colleagues: Regular communication and collaboration with other CTP operators and technicians within the industry fosters knowledge sharing and helps expose me to new methodologies and best practices.

Q 26. Describe your experience with workflow optimization and automation.

Workflow optimization and automation are crucial for improving efficiency and reducing errors in CTP platemaking. My experience includes:

Implementing JDF/JMF workflows: I have experience integrating Job Definition Format (JDF) and Job Management Format (JMF) standards to automate the flow of jobs through the prepress system, improving overall efficiency and reducing manual intervention.

Automating Plate Processing: I have worked with automated plate processors, optimizing parameters to reduce processing time and improve consistency. This involves the programming and adjustment of the plate processor to reduce manual steps.

Integrating prepress software: I am proficient in utilizing different prepress software packages for tasks such as color management, proofing, and imposition to streamline the workflow and improve overall efficiency.

Lean methodologies: I am familiar with implementing lean methodologies to identify and eliminate waste in the platemaking process, optimizing workflows and reducing lead times. This involves analyzing each step to remove non-value-added processes.

Q 27. How do you contribute to a team environment in a fast-paced printing environment?

In a fast-paced printing environment, teamwork is essential. I contribute by:

Proactive Communication: I maintain open communication with my team members, keeping them informed of any potential delays or issues that might arise. This ensures everyone is informed and can adapt quickly.

Problem-Solving Collaboration: I actively participate in problem-solving sessions, contributing my expertise and collaborating with others to find effective solutions. We encourage a team-based approach to solving problems.

Mentoring and Training: I’m happy to mentor and train junior team members, sharing my knowledge and experience to improve the overall skills of the team.

Flexibility and Adaptability: I understand that in a fast-paced environment, priorities can shift rapidly, and I am adaptable to changes and willing to help wherever needed.

Maintaining a Positive Attitude: I strive to maintain a positive and collaborative work environment, even under pressure, promoting teamwork and a supportive atmosphere.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of [Insert Salary Range], depending on the specifics of the position and benefits package. I am open to discussing this further based on a more detailed understanding of the role and responsibilities.

Key Topics to Learn for Your CTP Platemaking Interview

- CTP Platemaking Processes: Understanding the different types of CTP (Computer-to-Plate) technologies (thermal, violet, UV), their respective workflows, and advantages/disadvantages. This includes a thorough grasp of the chemical and physical processes involved.

- Plate Handling and Processing: Familiarize yourself with plate preparation, including cleaning, imaging, processing, and quality control procedures. Consider the practical implications of different plate types and their impact on print quality.

- Troubleshooting and Maintenance: Develop a strong understanding of common CTP platemaking issues, such as image defects, plate registration problems, and equipment malfunctions. Practice diagnosing and resolving these issues efficiently.

- RIP Software and Color Management: Gain proficiency in using RIP (Raster Image Processor) software, including color profile management, screening techniques, and dot gain compensation. Understanding how these impact the final print output is crucial.

- Prepress Workflow Integration: Understand how CTP platemaking integrates with the overall prepress workflow, including file preparation, imposition, and proofing. This demonstrates your awareness of the bigger picture.

- Safety and Environmental Considerations: Be prepared to discuss safety protocols related to chemical handling and waste disposal in a CTP environment. Familiarity with environmentally friendly practices is increasingly important.

- Quality Control and Metrics: Understand the key metrics used to assess the quality of CTP plates and the printed output. This might include density, dot gain, and registration accuracy.

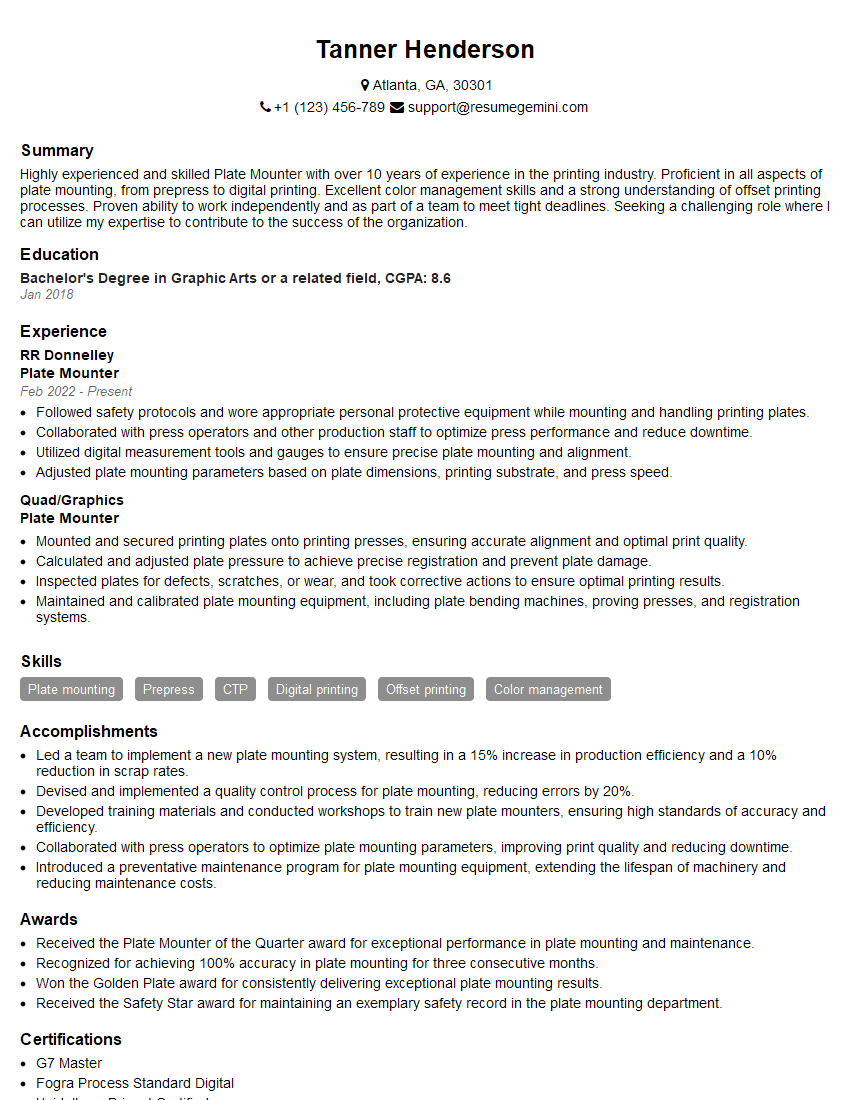

Next Steps: Level Up Your Career

Mastering CTP platemaking opens doors to exciting opportunities in the printing industry, offering potential for advancement and higher earning potential. To maximize your job prospects, crafting a compelling and ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. We provide examples of resumes tailored specifically to CTP Platemaking to give you a head start. Take the next step towards your dream job – create a resume that makes a lasting impression.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO