Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Proven Ability to Meet Production Goals interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Proven Ability to Meet Production Goals Interview

Q 1. Describe a time you exceeded production goals. What strategies did you employ?

One time, we faced a significant increase in demand for our flagship product, exceeding our projected production goals by 30%. To meet this challenge, we implemented a multi-pronged strategy. First, we analyzed the production process meticulously, identifying bottlenecks in the assembly line. We streamlined the process by reorganizing workstations and implementing a lean manufacturing approach, eliminating unnecessary steps. Second, we optimized resource allocation. We cross-trained employees to handle multiple tasks, ensuring flexibility and reducing downtime. Third, we leveraged technology. We implemented a new scheduling software that allowed us to monitor progress in real-time and adjust our production plan accordingly. Finally, we fostered a culture of collaboration and open communication, ensuring every team member was aware of the goal and their role in achieving it. This comprehensive approach enabled us not only to meet but surpass the increased demand, demonstrating the effectiveness of proactive planning and team collaboration.

Q 2. How do you prioritize tasks to ensure on-time production completion?

Prioritizing tasks for on-time production completion requires a structured approach. I typically utilize a combination of methods, including the Eisenhower Matrix (urgent/important), which helps categorize tasks based on their urgency and importance. This allows me to focus on critical tasks first, preventing delays and ensuring project milestones are met. Beyond that, I use project management software to track deadlines, dependencies, and resource allocation. This provides a clear visual representation of the project timeline, and I regularly review and adjust priorities as needed, adapting to changing circumstances and unexpected delays. Regular team meetings and clear communication are crucial for keeping everyone informed and aligned with priorities.

Q 3. What metrics do you use to track production efficiency?

Tracking production efficiency involves a multifaceted approach encompassing several key metrics. I routinely monitor output, calculating units produced per hour or per employee to assess productivity. Defect rates are crucial; a high defect rate points to issues in the production process needing attention. We also track lead times – the time it takes to complete a product from start to finish – to pinpoint areas for improvement and ensure efficient workflow. Finally, we analyze resource utilization – how effectively equipment and personnel are employed. This comprehensive approach provides a holistic picture of production efficiency, guiding our improvement efforts.

Q 4. Explain your experience with production planning and scheduling software.

I have extensive experience with various production planning and scheduling software, including ERP systems (Enterprise Resource Planning) and specialized manufacturing execution systems (MES). I’m proficient in using these systems to create detailed production schedules, manage inventory, track materials, and monitor progress in real-time. For instance, in my previous role, we used an ERP system to integrate production planning with supply chain management, optimizing inventory levels and minimizing waste. I understand how to configure these systems to align with specific production requirements and use their reporting capabilities to identify areas for improvement and make data-driven decisions. My skills extend to utilizing specialized modules for capacity planning and resource optimization, ensuring efficient allocation of resources and preventing bottlenecks.

Q 5. How do you handle unexpected production delays or setbacks?

Unexpected delays or setbacks are inevitable in production. My approach involves a swift and systematic response. First, I immediately identify the root cause of the delay. This often involves collaborating with the team, examining production logs, and assessing equipment performance. Once the root cause is identified, I develop a contingency plan, which might involve adjusting the production schedule, reassigning resources, or seeking alternative solutions. Open communication is vital during this phase; I keep all stakeholders informed about the delay, potential impact, and the steps being taken to mitigate the problem. Finally, we conduct a post-incident review to understand what went wrong and prevent similar issues from occurring in the future. This approach ensures that we are not only reactive but also proactive in minimizing disruptions to our production process.

Q 6. Describe your approach to identifying and resolving production bottlenecks.

Identifying and resolving production bottlenecks requires a methodical approach. I begin by analyzing production data, looking for areas where throughput is significantly lower than other stages. Visual tools like flowcharts or process maps can help visualize the production process and identify the bottleneck visually. Techniques like Value Stream Mapping can help identify non-value-added activities that are contributing to the bottleneck. Once the bottleneck is pinpointed, the solutions can vary, ranging from investing in new equipment or software to improving employee training or simply reorganizing the workflow to optimize efficiency. A key aspect is using data-driven decision making throughout this process, ensuring that the implemented solutions are effective and sustainable.

Q 7. How do you motivate your team to achieve production targets?

Motivating a team to achieve production targets is about creating a positive and collaborative environment. This starts with clear communication of goals and expectations. Everyone needs to understand their role and how their contribution contributes to the overall goal. Regular feedback, both positive and constructive, is essential. I believe in celebrating successes, recognizing individual and team achievements to boost morale. Furthermore, providing opportunities for professional development and advancement helps foster employee engagement and commitment. Finally, ensuring a safe and supportive work environment is paramount; feeling valued and respected is a key motivator for any employee. A combination of these approaches builds a high-performing team committed to reaching and exceeding production targets.

Q 8. What is your experience with Lean Manufacturing principles?

Lean Manufacturing is a philosophy focused on eliminating waste and maximizing value in production. It’s all about streamlining processes to deliver the highest quality product at the lowest cost with minimal waste. My experience encompasses implementing several Lean principles, including:

- Value Stream Mapping: I’ve led numerous value stream mapping exercises, identifying bottlenecks and areas for improvement in production flows. For instance, in a previous role, we mapped the assembly process for a key product, revealing a significant delay at the quality inspection stage. By reorganizing the inspection process and implementing a faster defect identification system, we reduced lead time by 15%.

- 5S Methodology: I’ve implemented 5S (Sort, Set in Order, Shine, Standardize, Sustain) to create a more organized and efficient work environment. This resulted in a reduction in errors and improved worker safety. In one project, implementing 5S in a warehouse reduced search time for parts by 30%, directly impacting production throughput.

- Kanban: I’ve successfully used Kanban systems to visualize workflow and limit work in progress (WIP). This helped us better manage resources and prevent overproduction. In a fast-paced manufacturing environment, using Kanban reduced inventory holding costs and improved responsiveness to customer demand.

My experience with Lean principles consistently translates to improved efficiency, reduced costs, and enhanced product quality.

Q 9. How familiar are you with Six Sigma methodologies?

Six Sigma is a data-driven methodology focused on improving processes by reducing defects and variability. My familiarity with Six Sigma extends to applying DMAIC (Define, Measure, Analyze, Improve, Control) methodology across various projects.

- Define: Clearly defining the problem and project goals. For example, in one project, our goal was to reduce the defect rate in a specific component to below 0.1%.

- Measure: Gathering data to understand the current process and identify key metrics. We collected data on defect rates, cycle times, and other relevant factors.

- Analyze: Identifying the root causes of defects using statistical tools. Root Cause Analysis (RCA) techniques, such as the 5 Whys, were employed to pinpoint the sources of variability.

- Improve: Implementing solutions to address the root causes and improve the process. This involved process redesign, operator training, and equipment upgrades.

- Control: Monitoring the improved process to ensure sustained improvements. Control charts and other monitoring techniques were implemented to track the performance of the improved process.

Through the application of Six Sigma, I have consistently delivered significant improvements in quality, efficiency, and cost reduction. I’m proficient in using statistical software and tools to analyze data and drive process improvements.

Q 10. Explain your experience with Kaizen or other continuous improvement initiatives.

Kaizen, or continuous improvement, is a cornerstone of my approach to manufacturing. It’s a philosophy that encourages small, incremental improvements over time. I’ve participated in and led numerous Kaizen events, involving teams in identifying and eliminating waste and inefficiencies.

For example, in one instance, our team noticed a recurring issue with a particular machine constantly jamming. Through a Kaizen event, we systematically analyzed the problem, involving operators, maintenance personnel, and engineers. We discovered that minor adjustments to the machine’s settings and a change in the material handling process significantly reduced jamming incidents, leading to improved uptime and output.

My approach to Kaizen isn’t limited to structured events. I actively encourage a culture of continuous improvement where every team member is empowered to suggest and implement improvements to their processes. This fosters a proactive environment where even small improvements accumulate to significant gains over time.

Q 11. How do you ensure quality control while maintaining production speed?

Balancing quality control and production speed requires a strategic approach. It’s not a compromise, but rather a synergy.

- Proactive Quality Control: Implementing robust quality checks at each stage of the production process, rather than relying solely on end-of-line inspection. This includes using Statistical Process Control (SPC) charts to monitor key parameters in real-time and identify potential problems before they escalate.

- Automation: Automating repetitive and error-prone tasks, reducing human error and increasing consistency. This frees up human resources to focus on higher-level tasks like process improvement and problem-solving.

- Employee Training: Investing in training and empowering employees to identify and solve quality issues promptly. A well-trained workforce is crucial in ensuring consistent quality and efficient production.

- Preventive Maintenance: Regularly maintaining equipment to prevent breakdowns and downtime, minimizing production interruptions and maintaining consistent quality.

By integrating quality control into the entire production process, we achieve higher quality products without sacrificing speed. It’s a proactive, rather than reactive, approach.

Q 12. How do you balance cost-effectiveness with production efficiency?

Balancing cost-effectiveness and production efficiency is a critical aspect of successful manufacturing. It requires a holistic view of the entire production system.

- Process Optimization: Identifying and eliminating waste in the production process. This involves analyzing each step to identify areas for improvement, such as reducing material usage, minimizing energy consumption, and streamlining workflows.

- Technology Investment: Investing in appropriate technology to enhance efficiency and reduce costs in the long run. This could include automation, advanced manufacturing techniques, or improved data analysis tools.

- Supplier Relationship Management: Collaborating with suppliers to ensure a reliable and cost-effective supply chain. This may involve negotiating better prices, improving delivery times, and ensuring consistent quality.

- Inventory Management: Implementing effective inventory control systems to minimize storage costs and avoid stockouts or overstocking. Techniques like Just-in-Time (JIT) manufacturing can help optimize inventory levels.

The key is to find the optimal balance between upfront investment and long-term cost savings. A well-planned strategy will ensure that efficiency improvements generate a positive return on investment.

Q 13. Describe a time you had to adapt your production strategy to changing market demands.

In a previous role, we experienced a sudden surge in demand for a particular product due to a competitor’s recall. Our existing production strategy was not designed for such a rapid increase.

To adapt, we quickly implemented several measures:

- Overtime and Shift Adjustments: We implemented overtime shifts to increase production capacity immediately.

- Supplier Collaboration: We worked closely with our suppliers to secure additional raw materials and expedite deliveries.

- Production Line Reorganization: We reorganized the production line to optimize the flow of materials and maximize output.

- Temporary Workforce: We hired temporary workers to augment our existing workforce and manage the increased workload.

This quick response allowed us to meet the increased demand and prevent significant losses. It showcased the importance of having a flexible production strategy and strong relationships with suppliers.

Q 14. How do you utilize data analysis to improve production outcomes?

Data analysis plays a crucial role in improving production outcomes. I utilize data from various sources, including production tracking systems, quality control reports, and machine sensor data.

- Key Performance Indicators (KPIs): I define and track relevant KPIs to monitor production performance, such as output, defect rates, cycle times, and equipment uptime. This provides valuable insights into areas for improvement.

- Statistical Process Control (SPC): I employ SPC techniques to monitor process variability and identify potential problems before they escalate. Control charts help visualize trends and identify deviations from expected performance.

- Predictive Maintenance: Analyzing machine sensor data to predict equipment failures and schedule preventative maintenance proactively. This minimizes downtime and prevents production interruptions.

- Root Cause Analysis (RCA): Utilizing data to identify the root causes of defects and inefficiencies. This allows for targeted interventions to address the underlying problems and prevent recurrence.

By leveraging data-driven insights, I can make informed decisions to optimize production processes, improve quality, and increase efficiency. Data analysis is not just about collecting numbers; it’s about using them to drive meaningful change.

Q 15. What is your approach to managing inventory to support production needs?

Managing inventory effectively is crucial for meeting production goals. My approach is multifaceted and relies on a robust system incorporating forecasting, real-time tracking, and proactive adjustments. It’s like running a well-oiled machine where every part is accounted for and readily available.

- Demand Forecasting: I leverage historical data and market trends to predict future demand. This helps determine optimal stock levels, preventing both shortages and excessive inventory.

- Just-in-Time (JIT) Inventory: Where appropriate, I implement JIT principles to minimize storage costs and reduce the risk of obsolescence. This involves procuring materials only when they are needed for production.

- Real-Time Tracking: Utilizing inventory management software, I maintain a constant, accurate view of stock levels. This allows for immediate identification of low-stock items and prompt reordering.

- Regular Inventory Audits: Physical audits are conducted to reconcile system data with physical inventory. This helps identify discrepancies and improve the accuracy of forecasting.

- Vendor Relationships: Strong relationships with reliable suppliers are key to ensuring timely delivery of materials.

For example, in my previous role, implementing a new inventory management system reduced our lead times by 15% and lowered storage costs by 10%.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with safety regulations in a production environment?

Safety is paramount in any production environment. My approach to ensuring compliance involves a proactive, multi-layered strategy that encompasses training, regular inspections, and continuous improvement.

- Comprehensive Safety Training: All employees receive thorough training on relevant safety regulations, including the use of personal protective equipment (PPE) and emergency procedures. This training is regularly reviewed and updated.

- Regular Safety Inspections: I conduct or oversee regular inspections of the production facility to identify potential hazards. This proactive approach allows for swift remediation of any safety issues before accidents occur.

- Incident Reporting and Investigation: A robust system for reporting and investigating incidents is crucial for identifying root causes and implementing corrective actions. This is key to preventing recurrence.

- Emergency Preparedness: We regularly practice emergency drills to ensure employees are prepared to respond effectively in the event of an accident or emergency.

- Compliance Audits: Regular audits are conducted to ensure ongoing compliance with all relevant safety regulations.

In one instance, by implementing a new safety protocol for machine operation, we reduced workplace injuries by 20% in a single quarter.

Q 17. What are some key performance indicators (KPIs) you track in production?

Key Performance Indicators (KPIs) are essential for tracking progress towards production goals. My focus is on a balanced scorecard approach, tracking both efficiency and quality metrics.

- Production Output: Units produced per hour/day/week, measuring overall productivity.

- Defect Rate: Percentage of defective products, indicating quality control effectiveness.

- On-Time Delivery Rate: Percentage of orders delivered on time, reflecting reliability.

- Inventory Turnover Rate: How quickly inventory is used and replenished, indicating efficiency.

- Overall Equipment Effectiveness (OEE): A composite metric combining availability, performance, and quality.

- Labor Productivity: Output per labor hour, assessing workforce efficiency.

By monitoring these KPIs, I can identify areas for improvement and make data-driven decisions to optimize production processes. For instance, a consistently high defect rate might highlight the need for retraining or equipment upgrades.

Q 18. How do you handle conflicting priorities among various production tasks?

Conflicting priorities are inevitable in a production setting. My approach involves a structured prioritization framework based on urgency, importance, and impact on overall production goals.

- Prioritization Matrix: I utilize a matrix that categorizes tasks based on urgency and importance (e.g., Eisenhower Matrix). This allows for a clear understanding of which tasks need immediate attention and which can be delegated or rescheduled.

- Resource Allocation: Once priorities are established, I allocate resources (personnel, materials, equipment) accordingly. This ensures that the most critical tasks receive the necessary support.

- Communication and Collaboration: Open communication with all stakeholders is essential. This includes clearly explaining the prioritization rationale and obtaining buy-in from the team. This fosters a collaborative environment where everyone understands the objectives.

- Flexibility and Adaptability: The production environment is dynamic, so I maintain flexibility to adapt to unexpected changes and re-prioritize as needed.

For instance, if an urgent customer order conflicts with a planned maintenance schedule, I would prioritize the order, rescheduling maintenance to minimize disruption.

Q 19. Describe your experience with implementing new technologies to improve production.

Implementing new technologies is crucial for staying competitive and improving production efficiency. My experience includes the successful integration of several technologies, focusing on thorough planning and employee training.

- Automated Manufacturing Systems (AMS): I’ve overseen the implementation of robotic systems and automated assembly lines, leading to significant improvements in throughput and consistency.

- Enterprise Resource Planning (ERP) Systems: I have experience with deploying and optimizing ERP systems to streamline processes, improve data management, and enhance communication across departments.

- Data Analytics Tools: I leverage data analytics tools to analyze production data, identify bottlenecks, and make informed decisions to optimize efficiency.

- Project Management Methodology: I use a structured approach such as Agile or Scrum to manage the implementation of new technologies, ensuring projects are completed on time and within budget.

In a previous role, implementing a new automated packaging system increased our packaging speed by 30% and reduced labor costs by 15%. Success involved careful planning, thorough employee training, and addressing initial resistance to change.

Q 20. How do you delegate tasks effectively to achieve production targets?

Effective delegation is crucial for achieving production targets. My approach focuses on selecting the right person for the task, providing clear instructions, and offering appropriate support.

- Task Matching: I assess each team member’s skills and experience to assign tasks that align with their strengths. This ensures that tasks are completed efficiently and effectively.

- Clear Communication: I provide clear and concise instructions, outlining expectations, deadlines, and required resources. This leaves no room for ambiguity.

- Authority and Accountability: I delegate not only tasks but also the authority to make decisions related to those tasks. This fosters ownership and responsibility.

- Regular Check-ins: I maintain regular communication with team members, providing support and addressing any challenges they may encounter. This ensures tasks remain on track.

- Feedback and Recognition: I provide timely feedback and recognize accomplishments to motivate the team and encourage continued high performance.

For example, by delegating tasks effectively, I enabled my team to handle a 20% increase in production volume without additional staffing.

Q 21. What is your experience with managing budgets in a production setting?

Managing production budgets requires careful planning, monitoring, and control. My approach involves a combination of forecasting, tracking expenses, and identifying areas for cost optimization.

- Budget Forecasting: I develop detailed budget forecasts based on production plans, material costs, labor costs, and overhead expenses. This provides a baseline for tracking performance.

- Expense Tracking: I implement a system for meticulously tracking all expenses, comparing actual expenditures to the budgeted amounts. This helps identify any deviations from the plan.

- Cost Control Measures: I proactively identify areas where costs can be reduced without compromising quality or production output. This includes negotiating better prices with suppliers, optimizing material usage, and improving efficiency.

- Variance Analysis: I perform regular variance analyses to understand the reasons for any discrepancies between the budgeted and actual expenses. This enables corrective actions.

- Regular Reporting: I provide regular budget reports to management, highlighting performance against budget and any potential risks or opportunities.

In a previous role, by implementing cost-saving measures, I managed to stay within budget despite a 15% increase in raw material prices.

Q 22. How do you handle employee performance issues that impact production?

Addressing employee performance issues impacting production requires a multi-faceted approach focused on understanding the root cause, providing support, and implementing corrective actions. It’s crucial to remember that addressing performance issues is about helping the employee succeed, not about punishment.

- Identify the Problem: Start with a detailed assessment. Is the issue skill-based, motivational, or stemming from external factors? For example, a consistently missed deadline might indicate a lack of time management skills, insufficient resources, or an unclear project scope.

- Documentation is Key: Thoroughly document all performance-related conversations, including dates, specific instances, and agreed-upon action plans. This protects both the employee and the company.

- Performance Improvement Plan (PIP): If the issue is recurring, a formal PIP might be necessary. This outlines specific, measurable, achievable, relevant, and time-bound (SMART) goals for improvement. Regular check-ins are crucial to track progress.

- Training and Support: Offer appropriate training, mentorship, or additional resources to help the employee improve. Perhaps they need training on a new software or better project management techniques.

- Consequences: If the employee fails to meet the goals outlined in the PIP, despite support, then more serious consequences, such as disciplinary action, may be necessary. This should always be a last resort and should be documented meticulously.

Example: In a previous role, a team member consistently missed deadlines on their assigned tasks. After careful observation and discussion, we discovered they were struggling with time management and prioritizing tasks effectively. We implemented a training program on project management, provided them with additional resources, and set clear expectations with regular check-ins. Their performance improved significantly, and the team’s overall productivity increased.

Q 23. Describe a time you had to make a difficult decision to meet production goals.

One challenging decision involved prioritizing tasks during a critical product launch. We were facing significant pressure to meet a tight deadline, and we discovered a critical bug in the software just days before the launch. We had two options: release the product with the bug and risk reputational damage, or delay the launch, potentially impacting revenue and investor confidence.

After a thorough risk assessment involving the entire team, we opted to delay the launch by a week. This allowed us to fix the bug and ensure a high-quality product release. While the delay was difficult, it ultimately prevented a far more costly and damaging scenario. Transparency with stakeholders was key to managing expectations during this stressful period. We explained the situation clearly, highlighting the potential risks of an immediate release versus the benefits of a slightly delayed, bug-free launch.

This taught me the importance of making data-driven decisions, even under intense pressure. The short-term pain of a delayed launch was far outweighed by the long-term benefits of maintaining product quality and customer trust.

Q 24. How familiar are you with different production methodologies (e.g., Agile, Waterfall)?

I’m proficient in both Agile and Waterfall methodologies, understanding their strengths and weaknesses in various contexts.

- Waterfall: This is a sequential approach where each phase (requirements, design, implementation, testing, deployment) must be completed before the next begins. It’s well-suited for projects with stable requirements and a clear scope. However, it’s less adaptable to changing requirements.

- Agile: This iterative and incremental approach emphasizes flexibility and collaboration. Development happens in short cycles (sprints), allowing for frequent feedback and adjustments. It’s ideal for projects with evolving requirements or a high degree of uncertainty. Examples include Scrum and Kanban.

My experience has shown that the best approach often involves a hybrid model, leveraging the strengths of both methodologies depending on the project’s specific needs. For example, a large-scale project might use a Waterfall framework for the overall project plan, but employ Agile principles within individual phases to enhance flexibility and responsiveness.

Q 25. What steps do you take to proactively prevent production problems?

Proactive prevention of production problems relies on meticulous planning, consistent monitoring, and a culture of continuous improvement. My approach includes:

- Regular Risk Assessments: Identifying potential bottlenecks and challenges early in the project lifecycle allows for proactive mitigation strategies. This might include reviewing past projects for common issues, analyzing potential dependencies, and forecasting resource needs.

- Process Optimization: Continuously analyzing production processes to identify inefficiencies and areas for improvement. Lean manufacturing principles, such as eliminating waste and streamlining workflows, can be highly effective.

- Preventive Maintenance: Regularly scheduling equipment maintenance, software updates, and other preventative measures minimizes the risk of unexpected breakdowns. This includes both hardware and software aspects of the production system.

- Team Training and Development: Ensuring the team possesses the necessary skills and knowledge to effectively handle their responsibilities minimizes errors and ensures consistent performance.

- Data Analysis and Monitoring: Using key performance indicators (KPIs) and real-time data to track production progress, identify potential issues early, and make necessary adjustments. This could involve dashboards and automated alerts that provide insights into productivity and any potential problems.

Q 26. How do you communicate production progress and challenges to stakeholders?

Communicating production progress and challenges effectively involves transparency, consistent updates, and tailored messaging for different stakeholders. My strategy focuses on:

- Regular Reporting: Providing concise and informative reports on production metrics, including progress towards goals, identified challenges, and mitigation plans. This can involve weekly or daily updates depending on the project’s complexity and urgency.

- Visualizations: Using charts, graphs, and dashboards to effectively communicate key data points to both technical and non-technical audiences. This improves understanding and speeds up information transfer.

- Tailored Communication: Adapting the level of detail and terminology to suit the audience. A technical report for engineering might include detailed performance data, while an executive summary would focus on high-level progress and key milestones.

- Proactive Communication: Addressing potential problems before they escalate by promptly notifying stakeholders of any significant issues. Transparency about challenges is more effective than delivering bad news unexpectedly.

- Open Communication Channels: Establishing clear and accessible channels for stakeholders to ask questions, provide feedback, and request information. This promotes collaboration and ensures everyone is kept informed.

Q 27. Describe your experience with using project management tools for production tracking.

I have extensive experience using various project management tools for production tracking, including Jira, Asana, and MS Project. My proficiency includes:

- Task Management: Creating and assigning tasks, tracking progress, and managing dependencies between tasks.

- Resource Allocation: Optimizing resource allocation to maximize efficiency and productivity.

- Progress Monitoring: Using dashboards and reports to track progress against deadlines and identify potential delays.

- Collaboration: Facilitating collaboration among team members through shared workspaces and communication tools.

- Reporting: Generating reports to communicate progress to stakeholders and identify areas for improvement.

Example: In a previous role, we used Jira to manage the development lifecycle of a complex software project. Jira allowed us to track individual tasks, manage sprints, and generate reports on progress, bugs, and overall velocity. This provided real-time visibility into the project’s status, enabling us to identify and address potential bottlenecks promptly.

Q 28. How do you measure the success of your production strategies?

Measuring the success of production strategies requires a multi-dimensional approach, focusing on both quantitative and qualitative metrics. My approach includes:

- On-Time Delivery: Meeting project deadlines consistently indicates efficient planning and execution. Measuring the percentage of projects delivered on time is a key indicator.

- Within Budget: Staying within allocated budgets demonstrates effective resource management.

- Quality: Producing high-quality output, measured through defect rates, customer satisfaction surveys, or other relevant metrics.

- Efficiency: Tracking metrics such as production output per unit of time or per employee to gauge overall efficiency. This can be further analyzed by identifying and optimizing bottlenecks.

- Employee Satisfaction: A happy and engaged team is more productive and innovative. This can be assessed through surveys or regular feedback sessions.

Combining these metrics provides a comprehensive view of production success. Regularly reviewing these metrics and making adjustments to strategies based on data insights is critical for continuous improvement.

Key Topics to Learn for Proven Ability to Meet Production Goals Interview

- Understanding Production Goals: Defining and clarifying expectations, understanding key performance indicators (KPIs), and aligning personal goals with overall team objectives.

- Time Management & Prioritization: Strategies for effective task management, prioritizing tasks based on urgency and importance, and utilizing productivity tools to optimize workflow.

- Resource Allocation & Optimization: Identifying and utilizing available resources effectively, optimizing processes to minimize waste and maximize output, and adapting to changing resource availability.

- Problem-Solving & Adaptability: Identifying and addressing roadblocks proactively, implementing solutions to overcome challenges, and adapting strategies in response to unexpected issues or changing priorities.

- Data Analysis & Performance Tracking: Monitoring progress against goals, analyzing data to identify trends and areas for improvement, and using data-driven insights to refine strategies and improve performance.

- Communication & Collaboration: Effectively communicating progress and challenges to team members and stakeholders, collaborating effectively to achieve shared goals, and seeking support when needed.

- Continuous Improvement & Learning: Identifying areas for personal and team growth, actively seeking opportunities to enhance skills and knowledge, and implementing learned best practices to continually improve production efficiency.

Next Steps

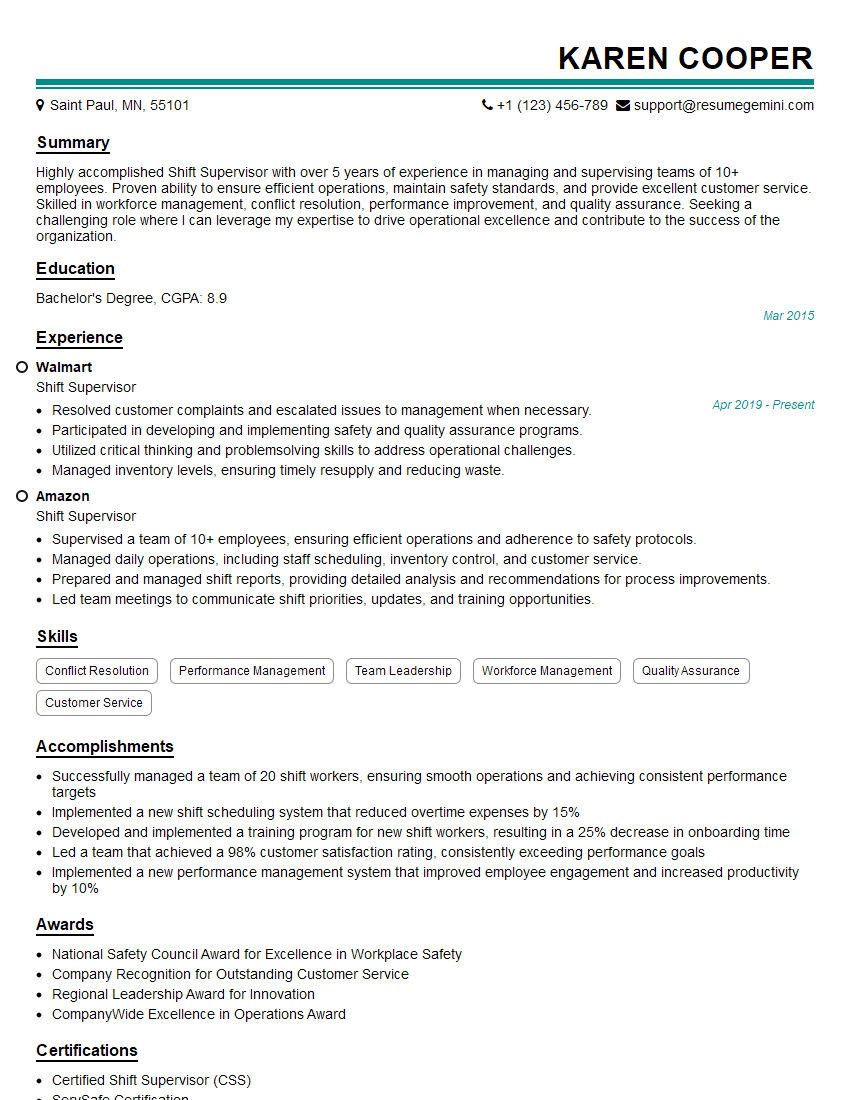

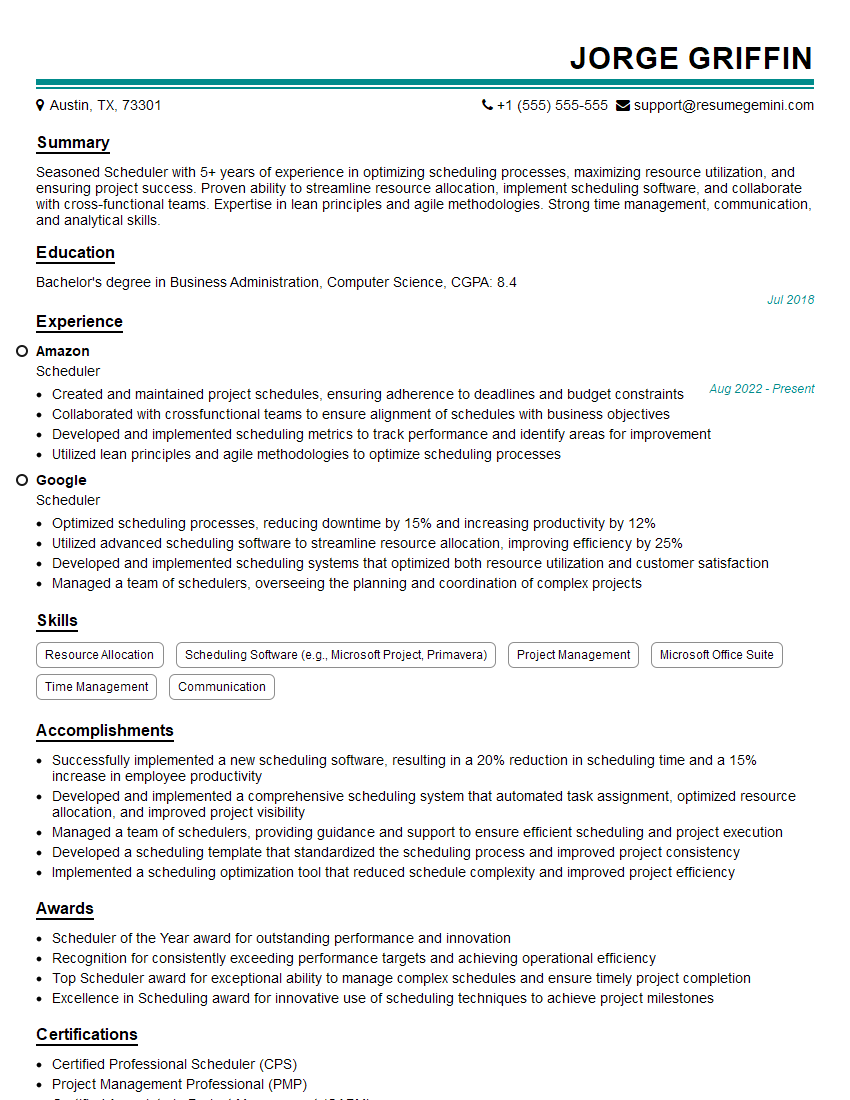

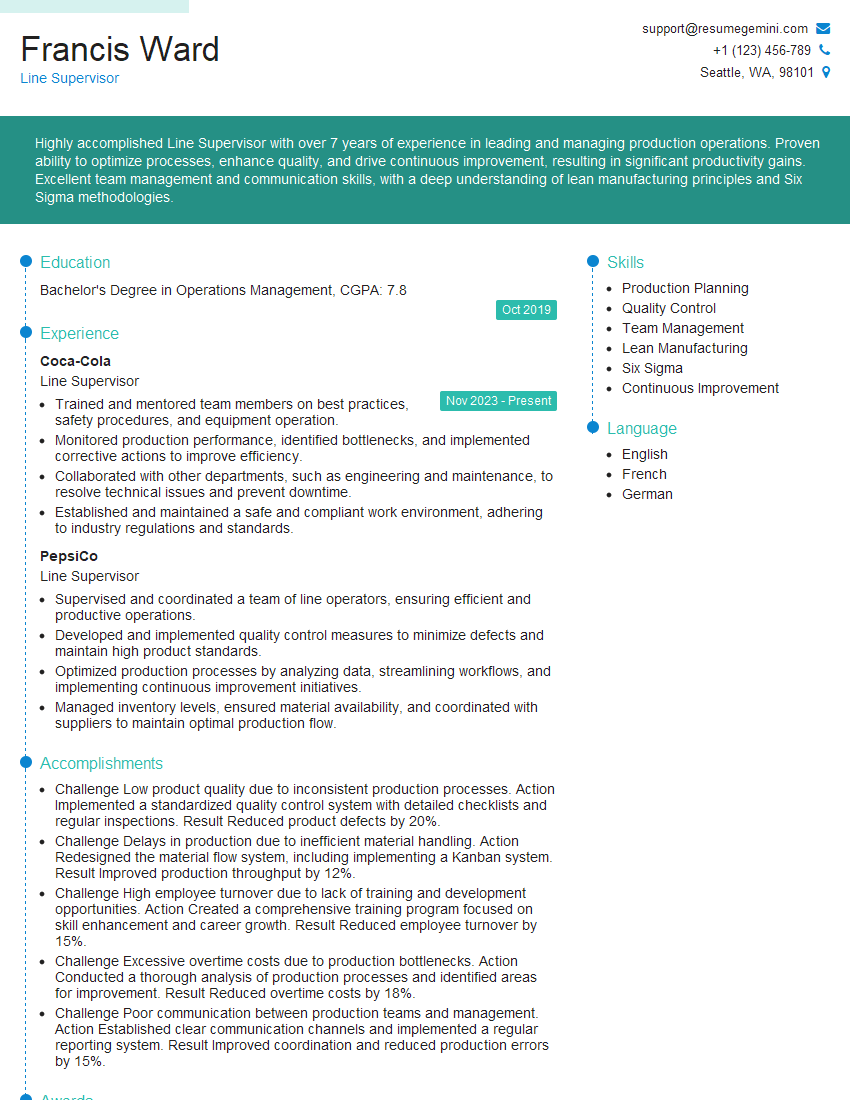

Mastering the ability to meet production goals is crucial for career advancement. Demonstrating this skill consistently opens doors to higher-level positions and increased responsibilities. To showcase your capabilities effectively, create an ATS-friendly resume that highlights your achievements and quantifies your contributions. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. Examples of resumes tailored to showcasing Proven Ability to Meet Production Goals are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO