Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Knowledge of public transportation maintenance and repair procedures interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Knowledge of public transportation maintenance and repair procedures Interview

Q 1. Describe your experience with preventative maintenance schedules for buses.

Preventative maintenance schedules for buses are crucial for ensuring operational efficiency and safety. They’re essentially a roadmap outlining regular inspections and servicing to prevent major breakdowns. These schedules are typically based on mileage, hours of operation, or a combination of both.

My experience involves developing and implementing these schedules, considering factors like the bus model, operating environment (city vs. highway), and manufacturer recommendations. A typical schedule might include daily checks of fluids (oil, coolant, brake fluid), tire pressure, and lights, weekly checks of the braking system and steering components, and monthly inspections of the engine, transmission, and electrical systems. Every few months or every few thousand miles, more extensive servicing, such as oil changes, filter replacements, and lubrication, is required. Annual inspections are comprehensive, involving a thorough examination of every system and component.

For example, I once worked on optimizing a preventative maintenance schedule for a fleet of hybrid buses. By analyzing operational data and incorporating predictive maintenance techniques, we were able to reduce unexpected downtime by 15% and improve fuel efficiency.

Q 2. How do you diagnose electrical problems in a transit vehicle?

Diagnosing electrical problems in a transit vehicle requires a systematic approach. It starts with a thorough visual inspection, checking for loose wires, damaged insulation, corrosion, or burned connectors. Next, I use a multimeter to check voltage, current, and resistance at various points in the electrical system. This helps identify faulty components like batteries, alternators, starters, or wiring harnesses.

Specific diagnostic tools, such as a scan tool capable of reading the vehicle’s onboard diagnostic (OBD) system codes, can provide crucial information about electrical faults. For example, a code might indicate a problem with a specific sensor or control module. Troubleshooting often involves systematically isolating the problem area by following wiring diagrams and using continuity tests to check for broken circuits. I always prioritize safety, ensuring the vehicle’s power is disconnected before undertaking any repairs.

I recall an instance where a bus experienced intermittent lighting issues. By meticulously tracing the wiring harness and utilizing a multimeter, I discovered a corroded connection at a junction box, which was causing the problem. A simple cleaning and secure reconnection resolved the issue, preventing further electrical damage and ensuring passenger safety.

Q 3. Explain your troubleshooting process for a malfunctioning engine in a rail car.

Troubleshooting a malfunctioning engine in a rail car is a complex process demanding a methodical approach. It begins with gathering information – the symptoms, when the problem started, and any preceding events.

The next step usually involves using diagnostic tools like onboard computers and fault code readers to identify potential issues. Then, a visual inspection is conducted, checking for obvious problems like leaks, loose connections, or damaged components. Further diagnosis might involve checking engine compression, testing fuel pressure and delivery, analyzing exhaust gases, and inspecting the engine’s cooling system. Specific tools like compression gauges, fuel pressure testers, and exhaust gas analyzers are essential.

My approach always prioritizes safety, and I’ll isolate the affected area before proceeding with detailed examination. For example, if there’s a suspected fuel leak, I’ll ensure proper ventilation before working on the fuel system. The troubleshooting process often requires a deep understanding of diesel engine operation, fuel injection systems, and electronic control units (ECUs).

I remember an incident with a rail car experiencing reduced power. Through a systematic approach involving the onboard computer diagnostics and physical examination, we identified a faulty fuel injector. Replacing the injector promptly restored the engine’s performance, preventing costly delays.

Q 4. What are the common causes of brake failure in public transportation vehicles?

Brake failure in public transportation vehicles is a serious safety concern, and several factors can contribute to it. Common causes include:

- Wear and tear: Brake pads, rotors, and drums wear out over time, reducing braking effectiveness.

- Fluid leaks: Leaks in the brake lines or master cylinder can lead to a loss of brake pressure.

- Air in the brake lines: Air in the hydraulic brake system can compromise braking performance.

- Malfunctioning components: Faulty brake calipers, wheel cylinders, or master cylinder can cause brake failure.

- Improper maintenance: Neglecting regular inspections and maintenance is a significant factor.

- Contamination: Brake fluid contamination can lead to corrosion and component failure.

Regular inspections and timely replacement of worn components are crucial in preventing brake failure. Proper maintenance practices, including regular fluid changes and air bleeding, are essential.

Q 5. How do you handle emergency repairs on the road?

Handling emergency repairs on the road requires quick thinking, resourcefulness, and a strong understanding of safety protocols. My approach is based on a priority system – first, ensuring the safety of passengers and the public.

Then, I assess the situation, determining the nature and severity of the problem. If the vehicle is immobilized, I coordinate with dispatch to arrange for a tow truck and replacement vehicle. For minor repairs, like a flat tire or a minor electrical fault, I’ll conduct temporary repairs ensuring safety and functionality until professional repair can be completed. Safety is paramount, and I would never attempt a repair that compromises safety.

Documentation is essential; I always create detailed records of the incident, the temporary repairs made, and any further actions taken. For instance, if a bus breaks down due to a flat tire, I’ll securely place warning triangles to alert other drivers before changing the tire. If the issue is more serious, I’ll evacuate passengers safely and contact emergency services if needed. My training emphasizes efficient communication and collaboration to minimize disruption and maintain public safety.

Q 6. Describe your experience with hydraulic systems in transit vehicles.

Hydraulic systems are essential in many transit vehicles, powering braking systems, steering, and sometimes suspension. My experience involves maintaining and repairing these systems, which requires specialized knowledge of hydraulic fluids, pumps, valves, and cylinders.

Regular maintenance includes checking fluid levels, inspecting for leaks, and ensuring proper operation of hydraulic components. Troubleshooting often involves pressure testing, checking for leaks using fluorescent dye, and systematically inspecting individual components for faults. Specialized tools are needed for working with hydraulic systems, including pressure gauges, hydraulic jacks, and leak detection equipment. Safety is extremely important due to the high pressure involved; proper safety precautions must always be taken when dealing with hydraulic components.

I once worked on a case of a bus with a malfunctioning hydraulic braking system. Using pressure gauges and a systematic approach, I identified a faulty brake valve, which was replaced effectively restoring the braking system to its proper function.

Q 7. What safety procedures do you follow when working on public transportation equipment?

Safety is my absolute top priority when working on public transportation equipment. My procedures consistently follow these guidelines:

- Lockout/Tagout (LOTO): I always use LOTO procedures to de-energize equipment before starting any work, preventing accidental activation.

- Personal Protective Equipment (PPE): I wear appropriate PPE, including safety glasses, gloves, and protective clothing, depending on the task.

- Proper Lifting Techniques: I use correct lifting techniques to avoid injuries when handling heavy components.

- Working Area Safety: I ensure the work area is well-lit, free of obstructions, and properly ventilated.

- Following Manufacturer’s Specifications: I strictly adhere to manufacturer’s repair manuals and procedures.

- Regular Inspections: I conduct routine safety inspections of tools and equipment before beginning any work.

Furthermore, I always follow any specific safety regulations and procedures mandated by the transit authority and/or the company. Safety is a continuous process, and I am always aware of potential risks and take steps to mitigate them.

Q 8. Explain your experience with diagnostic tools and equipment.

My experience with diagnostic tools and equipment is extensive. I’m proficient in using a wide range of tools, from basic multimeters and diagnostic scanners to advanced computerized systems like those found on modern electric and hybrid buses. For example, I’m skilled in using OBD-II scanners to troubleshoot engine control modules (ECMs) in diesel vehicles, identifying fault codes, and using data logs to pinpoint intermittent issues. With electric vehicles, I’m adept at using specialized diagnostic software to analyze battery health, motor performance, and power electronics. This often involves interpreting complex data streams to isolate the root cause of a malfunction. I also regularly use infrared thermometers for quick checks of overheating components and ultrasonic leak detectors to find hidden problems in hydraulic or pneumatic systems. Beyond electronic tools, I’m proficient with mechanical diagnostic techniques, such as using compression testers to assess engine health, or employing visual inspection to identify wear and tear on mechanical components like brakes and suspension systems.

Q 9. How do you prioritize maintenance tasks in a high-pressure environment?

Prioritizing maintenance tasks in a high-pressure environment requires a systematic approach. I utilize a combination of methods, including a criticality assessment based on safety, operational impact, and regulatory compliance. For example, a brake system failure poses a significant safety risk and would immediately take priority over a minor cosmetic issue. I employ a computerized maintenance management system (CMMS) to schedule preventive maintenance, track repairs, and generate work orders. This allows for efficient task assignment and resource allocation. The CMMS also provides insights into the failure history of components, helping me proactively address potential problems before they escalate into major breakdowns. Furthermore, I constantly communicate with operators to identify emerging issues and adjust priorities as needed. Think of it like a triage system in a hospital – we address the most critical issues first to ensure safe and reliable service.

Q 10. What is your experience with different types of transit vehicle engines (diesel, electric, hybrid)?

My experience spans various transit vehicle engine types, including diesel, electric, and hybrid systems. With diesel engines, I’m experienced in troubleshooting fuel systems, performing engine overhauls, and repairing emissions control systems. I understand the intricacies of diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems. With electric vehicles, my expertise includes diagnosing battery issues, working with high-voltage systems (always following strict safety protocols), and repairing electric motors and power inverters. I’ve worked on various battery chemistries, understanding the differences in their maintenance requirements and failure modes. Hybrid systems require a unique blend of expertise, combining knowledge of both diesel/gasoline engines and electric components. I’m proficient in diagnosing interactions between the internal combustion engine and the electric motor, and troubleshooting the complex control systems that manage power flow.

Q 11. How familiar are you with relevant safety regulations and compliance standards?

Safety is paramount in public transportation. I’m thoroughly familiar with relevant safety regulations and compliance standards, including those set by the Federal Transit Administration (FTA) and local authorities. This includes adhering to strict safety protocols when working with high-voltage systems in electric vehicles, maintaining detailed documentation for all repairs, and ensuring that all maintenance work is performed according to manufacturer’s specifications. I understand the importance of regular inspections, preventative maintenance schedules, and thorough documentation to ensure compliance. For example, I’m well-versed in the regulations surrounding brake system inspections and repairs, ensuring that vehicles meet minimum safety standards. I stay updated on changes in regulations and industry best practices through professional development courses and participation in industry forums.

Q 12. Describe your experience with repairing air conditioning and heating systems in transit vehicles.

I have significant experience repairing air conditioning and heating systems in transit vehicles. This involves diagnosing refrigerant leaks using specialized equipment, replacing compressors, condensers, and evaporators, and troubleshooting electrical components such as blower motors and control units. In older vehicles, I am experienced in repairing the more mechanical aspects, such as vacuum-operated actuators and blend doors. I’m also familiar with different refrigerant types and the environmentally responsible disposal procedures. Troubleshooting these systems often involves systematically checking components, such as ensuring proper airflow, verifying electrical connections, and checking for leaks. It’s crucial to ensure passenger comfort and a safe environment, especially in extreme temperatures, and addressing HVAC issues quickly helps maintain efficient transit operations.

Q 13. How do you manage inventory and ordering of spare parts?

Managing inventory and ordering spare parts efficiently is crucial for minimizing downtime. I use a CMMS to track parts usage, monitor stock levels, and generate automated re-order points. This system allows me to anticipate potential shortages and proactively order parts, preventing delays in repairs. I’m skilled in negotiating with suppliers to secure competitive pricing and ensure timely delivery. The CMMS also allows for the analysis of parts failure rates, enabling me to optimize our inventory strategy and identify potential areas for improvement, such as replacing parts that frequently fail with more robust alternatives. Effectively managing our parts inventory involves balancing the need to have readily available parts with the cost of storing excessive quantities.

Q 14. What is your experience with welding and fabrication?

I possess a working knowledge of welding and fabrication techniques, which are often necessary for repairs that involve damaged metal parts. I’m proficient in various welding methods, including MIG and TIG welding, allowing me to repair or fabricate parts as needed. This skill is particularly useful for repairing damaged body panels, chassis components, or custom-fabricating parts where replacements are unavailable or cost-prohibitive. For example, I’ve used welding to repair cracked exhaust systems, fabricate custom brackets, and even create temporary repairs to keep a vehicle operational until a replacement part arrives. Safety is paramount when performing welding, and I meticulously follow all safety protocols to protect myself and others.

Q 15. How do you ensure the accuracy of maintenance records?

Maintaining accurate maintenance records is crucial for ensuring the safety and reliability of public transportation. Inaccuracy can lead to costly repairs, delays, and even accidents. We achieve accuracy through a multi-pronged approach:

- Digitalization: We utilize computerized maintenance management systems (CMMS) to eliminate manual errors and ensure data consistency. Every repair, inspection, and part replacement is digitally recorded, timestamped, and linked to the specific vehicle.

- Double-checking and Verification: A system of checks and balances is in place. For example, a mechanic’s work is often reviewed by a supervisor, and critical repairs require additional authorization.

- Standardized Procedures: We adhere to strict, documented procedures for all maintenance tasks. These procedures specify the information that must be recorded, ensuring consistency across the entire fleet.

- Regular Audits: We conduct regular audits of our maintenance records to identify any inconsistencies or areas for improvement. These audits help us maintain data integrity and identify potential issues before they escalate.

- Training: Our mechanics receive comprehensive training on the proper use of the CMMS and the importance of accurate record-keeping. This ensures that everyone understands their responsibility in maintaining accurate data.

For example, if a brake pad replacement is performed, the CMMS would record the date, time, mechanic’s ID, part number, and mileage. This detailed information allows us to easily track the lifespan of brake pads and schedule future maintenance accordingly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with working on different types of transmissions.

My experience encompasses a wide range of transmissions used in public transport, from automatic transmissions in buses to the more complex systems found in modern light rail vehicles. I’ve worked on:

- Automatic Transmissions (Buses): I’m proficient in diagnosing and repairing common issues such as faulty solenoids, worn clutches, and transmission fluid leaks. I understand the importance of proper fluid levels and regular filter changes in maintaining optimal performance.

- Manual Transmissions (Older Buses and some Rail Cars): While less common now, I possess expertise in troubleshooting clutch problems, gear shifting issues, and synchronizer problems in manual transmissions.

- Electric Transmissions (Trams and Light Rail): With the increasing adoption of electric vehicles, I’ve gained experience in maintaining and repairing electric motor controllers, regenerative braking systems, and power inverters. This includes diagnostics using specialized equipment and software.

- Hydrostatic Transmissions (Specialised Vehicles): I have worked on some specialized vehicles that utilize hydrostatic transmissions, understanding their unique characteristics and troubleshooting techniques.

For instance, in one instance, I diagnosed a complex issue with a bus’s automatic transmission that involved a faulty shift solenoid. By systematically testing the various components and using diagnostic tools, I identified the problem quickly and avoided a lengthy, costly breakdown.

Q 17. Describe a time you had to quickly resolve a critical maintenance issue.

During a severe winter storm, a critical section of overhead power lines supplying electric trams failed. This resulted in several trams becoming stranded, causing significant disruption. I was part of the team tasked with resolving the issue quickly.

Our first step was to ensure passenger safety and evacuation. Simultaneously, we assessed the extent of the damage, determining that a major section of the power line needed replacement. Working collaboratively with the power supply company and fellow technicians, we prioritized the repair and replacement of the affected lines. We utilized specialized equipment and worked through the night, prioritizing safety, efficiency, and communication across the team.

While challenging, we successfully restored power within 10 hours, minimizing passenger inconvenience and avoiding major service disruptions. This was a testament to our team’s ability to respond effectively under pressure and highlights the importance of well-defined emergency procedures and strong teamwork in resolving critical maintenance issues.

Q 18. What are the common causes of wheel and axle problems in rail cars?

Wheel and axle problems are a significant concern in rail car maintenance. Common causes include:

- Wheel Wear and Flat Spots: This can result from excessive braking, track irregularities, or metal fatigue. Regular wheel profile checks are crucial to prevent this.

- Axle Fatigue and Cracking: This is often due to stress from heavy loads, repeated impacts, and material defects. Regular ultrasonic inspection is vital.

- Bearing Failure: Bearing failures can stem from inadequate lubrication, contamination, or excessive wear, leading to overheating and potential derailment. Regular lubrication and condition monitoring are key.

- Wheel Mounting Issues: Improper wheel mounting can lead to imbalance and premature wear. Strict adherence to mounting procedures is essential.

- Track Interaction: Interactions between the wheels and tracks, such as flange wear due to track gauge discrepancies, can contribute to axle problems.

Think of it like a car tire: uneven wear indicates problems with alignment or tire pressure. Similarly, unusual wear patterns on rail wheels signify issues with the track, axles, or braking systems.

Q 19. How familiar are you with different types of braking systems?

I’m familiar with a variety of braking systems used in public transport, including:

- Air Brakes: This is the most common type, using compressed air to activate the brake shoes or discs. I’m experienced in troubleshooting leaks, inspecting air compressors, and testing the overall system integrity. I understand the safety-critical nature of this system and the importance of regular inspections.

- Disc Brakes: These are increasingly used in modern trains and light rail vehicles offering superior stopping power and better heat dissipation than traditional systems. I understand their maintenance, including pad replacement and caliper servicing.

- Regenerative Braking (Electric Vehicles): This system uses the electric motor to slow the vehicle down, converting kinetic energy back into electricity. My experience includes understanding the complexities of these systems and their interactions with other components.

- Hydraulic Brakes: Less common but still used in some applications, hydraulic brakes rely on hydraulic fluid to transmit braking force. I am familiar with their maintenance requirements, including fluid changes and leak detection.

Each system requires a different approach to maintenance and repair, and it’s vital to understand their specific functionalities and potential points of failure.

Q 20. How do you perform a pre-trip inspection on a bus or train?

A pre-trip inspection is a crucial safety check performed before each journey. The specific steps vary slightly depending on the vehicle (bus or train), but the general approach remains consistent. Here’s an example for a bus:

- Exterior Check: Inspect tires for wear and damage, check lights, wipers, mirrors, and signals. Ensure that doors and windows operate correctly and that emergency exits are clear.

- Engine Compartment: Check fluid levels (engine oil, coolant, brake fluid, power steering fluid), inspect belts and hoses for wear and tear, and check the battery connections.

- Interior Check: Verify that the seating is secure, emergency equipment (fire extinguisher, first-aid kit) is in place and accessible, and that there are no obstructions in the aisles or emergency exits.

- Brakes and Steering: Test the brakes for responsiveness and check for any unusual noises or vibrations. Inspect the steering for proper function and check for any play or looseness.

- Operational Systems: Verify that the air conditioning, heating, and other onboard systems are functional and safe to operate.

For trains, the inspection would be more extensive, involving a more detailed check of the coupling systems, pantographs (for overhead line power), and additional safety systems. A checklist is used to ensure that all aspects are covered, and any issues are properly documented.

Q 21. Describe your experience with computerized maintenance management systems (CMMS).

I have extensive experience with computerized maintenance management systems (CMMS). These systems are vital for efficient and effective maintenance operations. My experience includes:

- Data Entry and Management: I’m proficient in accurately recording maintenance activities, scheduling preventative maintenance, and tracking parts inventory within CMMS platforms.

- Work Order Management: I’m familiar with creating and managing work orders, assigning tasks to technicians, and tracking progress.

- Report Generation: I utilize CMMS reports to analyze maintenance trends, identify areas for improvement, and support decision-making in resource allocation.

- Preventative Maintenance Scheduling: I use CMMS to schedule and track preventative maintenance tasks, ensuring that vehicles are maintained proactively to prevent breakdowns and maximize their lifespan.

- Integration with Other Systems: I’ve worked with CMMS systems that integrate with other systems, such as GPS tracking and diagnostic tools, allowing for better real-time vehicle monitoring and data analysis.

For example, I’ve used CMMS to analyze brake pad replacement data, which showed a pattern of premature wear on a specific bus model. This data allowed us to identify a potential issue with the braking system design and initiate a fleet-wide investigation and rectification.

Q 22. Explain your knowledge of different types of suspension systems.

Public transportation vehicles utilize various suspension systems to ensure passenger comfort and vehicle stability. The choice depends on factors like vehicle type, weight, and operational environment. Common types include:

- Leaf Spring Suspension: This older system uses steel leaf springs to absorb shocks. It’s simple, robust, and relatively inexpensive, often found in older buses. Think of it like a giant, flexible ruler supporting the vehicle.

- Coil Spring Suspension: This system uses individual coil springs at each wheel, offering better ride comfort and handling than leaf springs. Most modern buses and many light rail vehicles use this system. It’s like having individual shock absorbers at each wheel.

- Air Suspension: This sophisticated system uses air bags or bellows to control ride height and damping. It provides excellent ride comfort and can automatically adjust for varying loads. High-speed trains and some luxury buses use this, offering a smoother, more stable ride. Imagine it as a vehicle ‘floating’ on a cushion of air.

- Hydro-pneumatic Suspension: This system uses hydraulic fluid and pressurized gas to control suspension. It’s known for exceptional ride quality and self-leveling capabilities, though it’s more complex and requires specialized maintenance. Some high-end coaches and rail cars might employ this advanced system.

Understanding the nuances of each system is critical for effective maintenance and repair, as each has unique failure points and maintenance schedules.

Q 23. How do you stay up-to-date with the latest technologies and best practices in public transportation maintenance?

Staying current in this rapidly evolving field requires a multi-pronged approach. I actively participate in industry conferences and workshops, such as those hosted by the American Public Transportation Association (APTA), to learn about new technologies and best practices. I also subscribe to relevant trade publications and online journals, keeping abreast of the latest research and innovations in areas like predictive maintenance and alternative fuel systems. Furthermore, I actively participate in professional development courses focused on new diagnostic tools and repair techniques, ensuring my skills remain sharp and my knowledge base is updated regularly. Finally, networking with other maintenance professionals through online forums and local chapters of professional organizations allows me to share experiences and learn from others’ successes and challenges.

Q 24. How do you ensure the efficient use of resources and minimize downtime?

Efficient resource utilization and minimizing downtime are paramount. I achieve this through several strategies. Firstly, I employ a robust preventative maintenance schedule, identifying potential problems before they cause major failures. This includes regular inspections, lubrication, and component replacement based on manufacturer recommendations and historical data. Secondly, I utilize computerized maintenance management systems (CMMS) to track parts inventory, schedule maintenance activities, and analyze repair history. This allows for proactive ordering of parts and optimized scheduling, minimizing delays. Thirdly, I leverage diagnostic tools, such as onboard diagnostic systems (OBD) and specialized scanners, to quickly identify and address issues, reducing repair times. Finally, I champion continuous improvement initiatives, regularly evaluating maintenance processes and implementing modifications based on data analysis to enhance efficiency and reduce downtime. For example, we implemented a new lubrication system that reduced maintenance time by 15%.

Q 25. Describe your experience working with a team to complete a complex maintenance project.

During my time at [Previous Company Name], our team undertook a major overhaul of the light rail vehicle braking systems. This project involved coordinating the efforts of mechanics, electricians, and engineers, requiring precise scheduling and seamless communication. I spearheaded the development of a detailed project plan, outlining tasks, timelines, and resource allocation. We utilized daily stand-up meetings to address immediate challenges and track progress against the plan. Open communication and clear roles were crucial. We encountered unforeseen complications with a specific part’s availability, but by proactively contacting alternative suppliers and creatively adapting our workflow, we completed the project ahead of schedule and within budget. This experience highlighted the importance of strong teamwork, meticulous planning, and adaptability in complex maintenance undertakings.

Q 26. What are the common causes of door malfunctions in transit vehicles?

Door malfunctions are a frequent issue in transit vehicles, often impacting service reliability and passenger safety. Common causes include:

- Mechanical failures: Worn-out hinges, broken linkages, jammed actuators, or damaged seals can all prevent doors from opening or closing properly. Think of a door as a complex system of interconnected parts, any of which can fail.

- Electrical issues: Faulty wiring, malfunctioning control units, or damaged sensors can disrupt the door’s electrical operation, leading to malfunction. A simple short circuit can have significant consequences.

- Pneumatic problems: In vehicles using pneumatic door systems (air pressure), leaks, faulty air compressors, or blocked air lines can cause doors to malfunction. It’s like having a flat tire in the door system.

- Environmental factors: Ice, snow, or debris can obstruct door mechanisms. Extreme temperatures can also affect components, such as seals and actuators. The climate can significantly affect door performance.

Diagnosing the root cause requires systematic troubleshooting, which typically involves visual inspection, electrical testing, and checking pneumatic pressure (if applicable).

Q 27. How do you deal with difficult or demanding customers or supervisors?

Dealing with demanding customers or supervisors requires a calm, professional demeanor and effective communication. I prioritize active listening, trying to understand their concerns and perspective. I clearly explain the situation, including technical details in layman’s terms where necessary. I focus on solutions, rather than dwelling on problems. If I can’t immediately resolve an issue, I provide realistic timelines and keep the customer or supervisor updated on progress. In situations where immediate resolution isn’t possible, I clearly explain the reasons for any delays, emphasizing safety and regulatory compliance. Empathy and a proactive approach to problem-solving are key to maintaining positive working relationships. For example, once I faced a furious passenger whose trip was delayed by a mechanical failure. By apologizing sincerely and promptly arranging alternative transportation, I defused the situation, converting an angry customer into a satisfied one.

Q 28. Describe your experience with working on various types of transit vehicles (buses, trains, light rail, etc.)

Throughout my career, I’ve gained extensive experience maintaining a wide variety of transit vehicles, including buses (both diesel and electric), light rail vehicles, and commuter trains. My experience encompasses both preventative maintenance tasks, such as regular inspections and oil changes, as well as complex repairs involving engine overhauls, brake system replacements, and electrical system troubleshooting. While the specific systems and components vary across vehicle types, the underlying principles of mechanical and electrical operation remain consistent. For instance, troubleshooting a door malfunction on a bus involves a similar diagnostic process as on a light rail vehicle, even though the specific components may differ. This broad experience allows me to quickly adapt to new challenges and effectively maintain a diverse fleet of vehicles.

Key Topics to Learn for Public Transportation Maintenance & Repair Procedures Interviews

- Preventive Maintenance Schedules & Techniques: Understanding the importance of regular inspections, lubrication, and component replacements to prevent major breakdowns and extend the lifespan of vehicles.

- Diagnostic Procedures: Mastering the use of diagnostic tools and techniques to identify malfunctions in various systems (e.g., braking, electrical, engine). Practical application includes troubleshooting common issues and isolating faulty components.

- Repair & Replacement Procedures: Knowing the steps involved in repairing or replacing damaged parts, including proper safety procedures and the use of specialized tools. This includes understanding component functionality and their interdependencies.

- Safety Regulations & Compliance: Familiarity with industry safety standards, regulations, and best practices related to public transportation maintenance. This includes understanding the implications of non-compliance.

- Hydraulic & Pneumatic Systems: Understanding the principles of operation, maintenance, and troubleshooting of hydraulic and pneumatic systems commonly found in public transportation vehicles.

- Electrical Systems: Knowledge of electrical schematics, wiring diagrams, and troubleshooting techniques for electrical components and systems. This includes understanding voltage, amperage, and safety precautions.

- Diesel Engine Maintenance: For diesel-powered vehicles, a thorough understanding of engine maintenance, repair procedures, and troubleshooting techniques is essential.

- Record Keeping & Documentation: Understanding the importance of accurate and detailed record-keeping for maintenance activities, including compliance with regulatory requirements.

- Problem-Solving & Critical Thinking: Applying logical reasoning and analytical skills to diagnose complex mechanical issues and develop effective repair strategies.

Next Steps

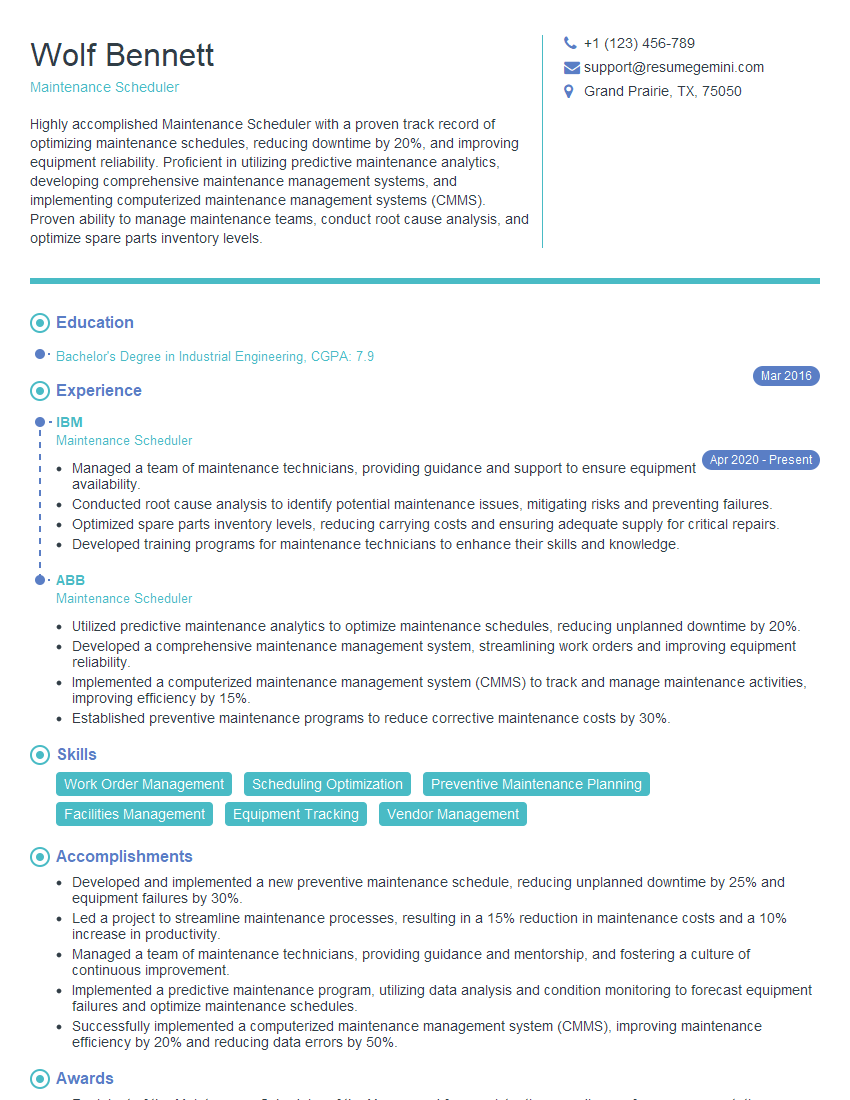

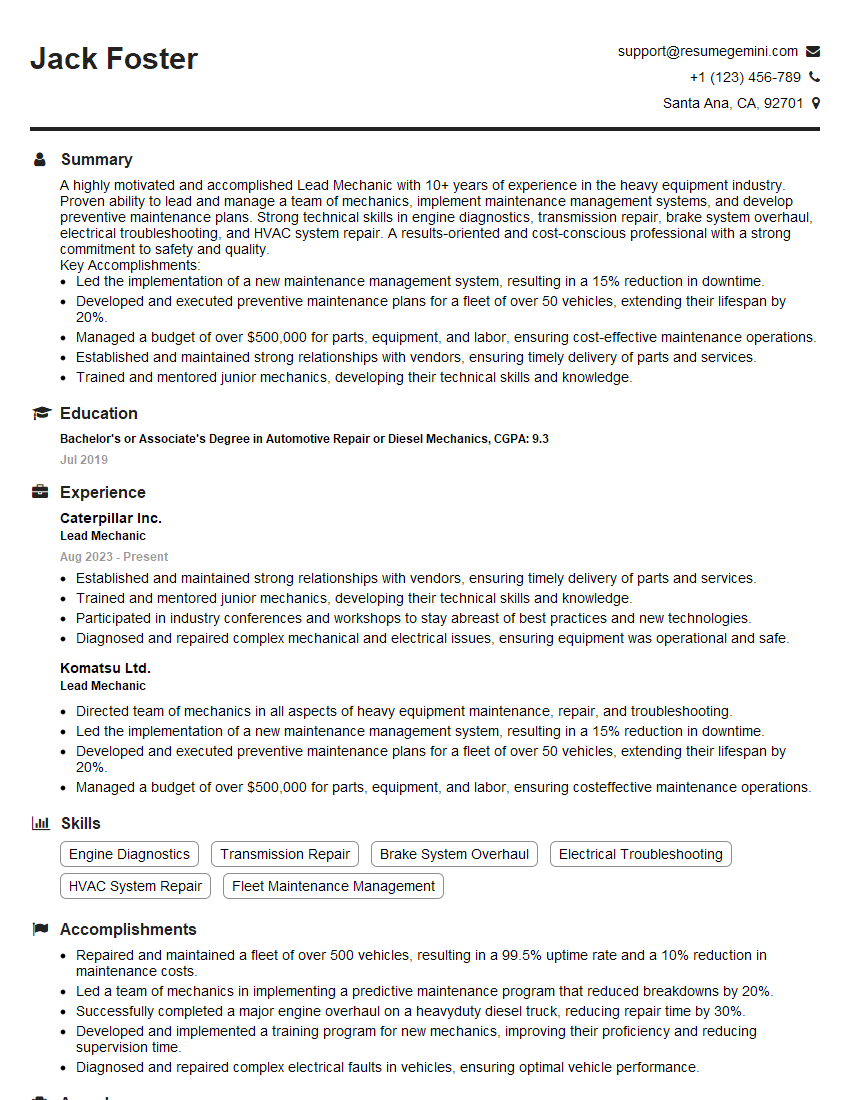

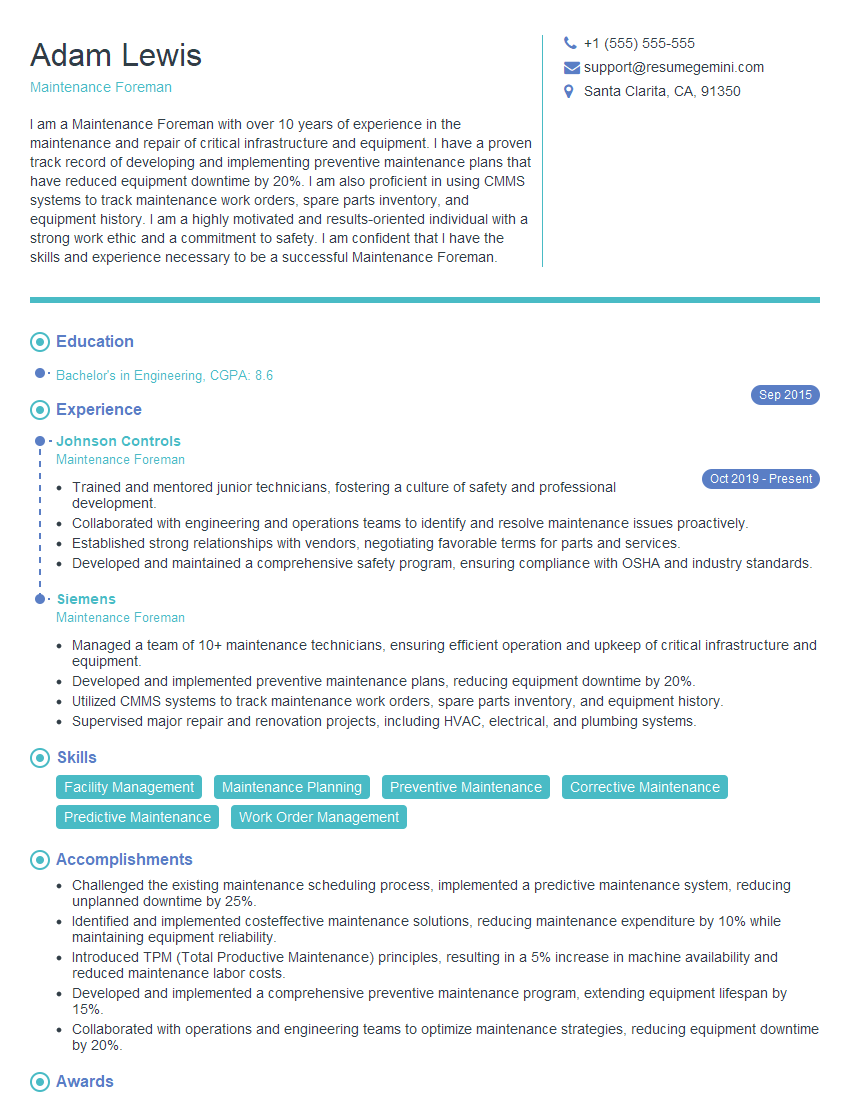

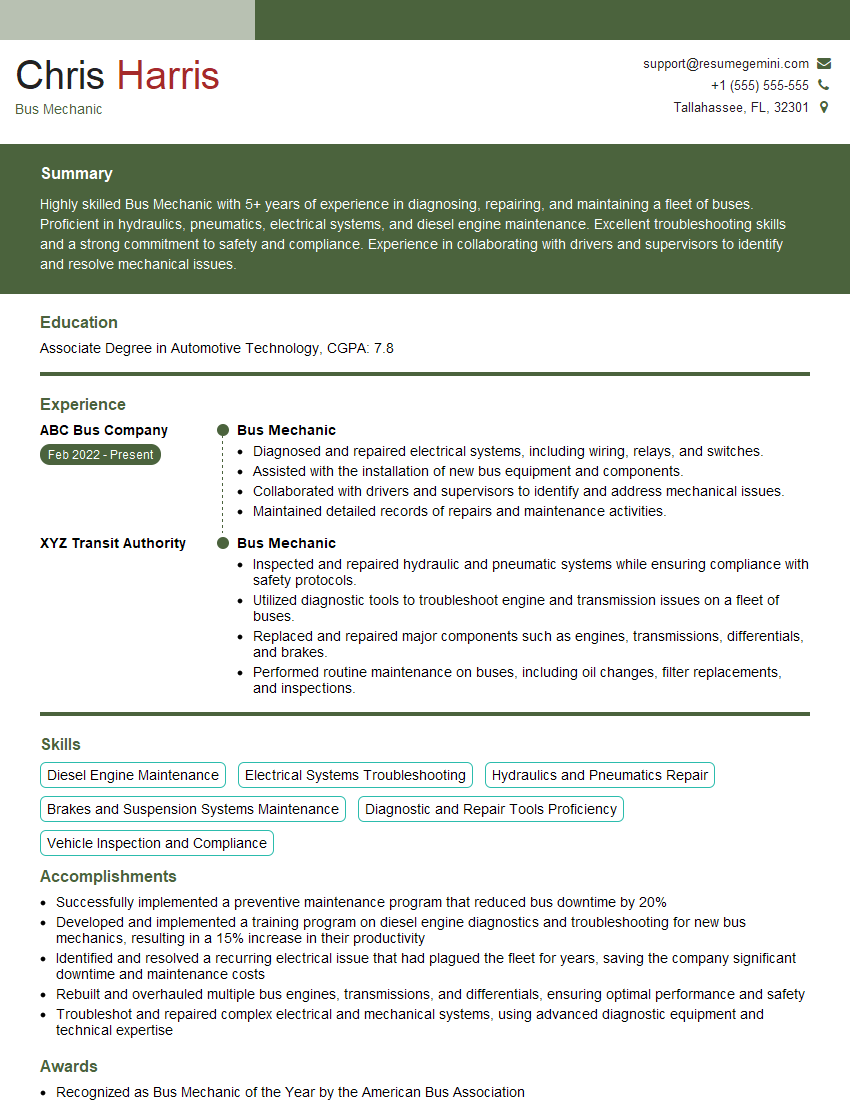

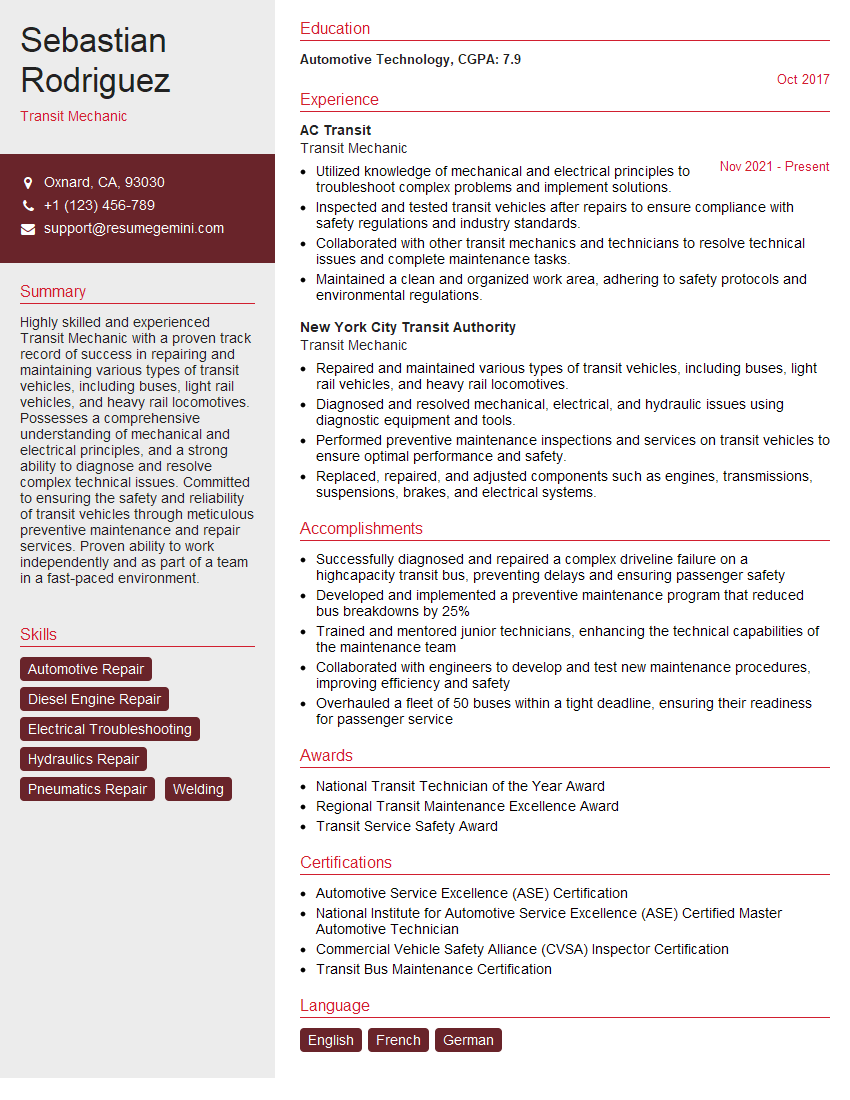

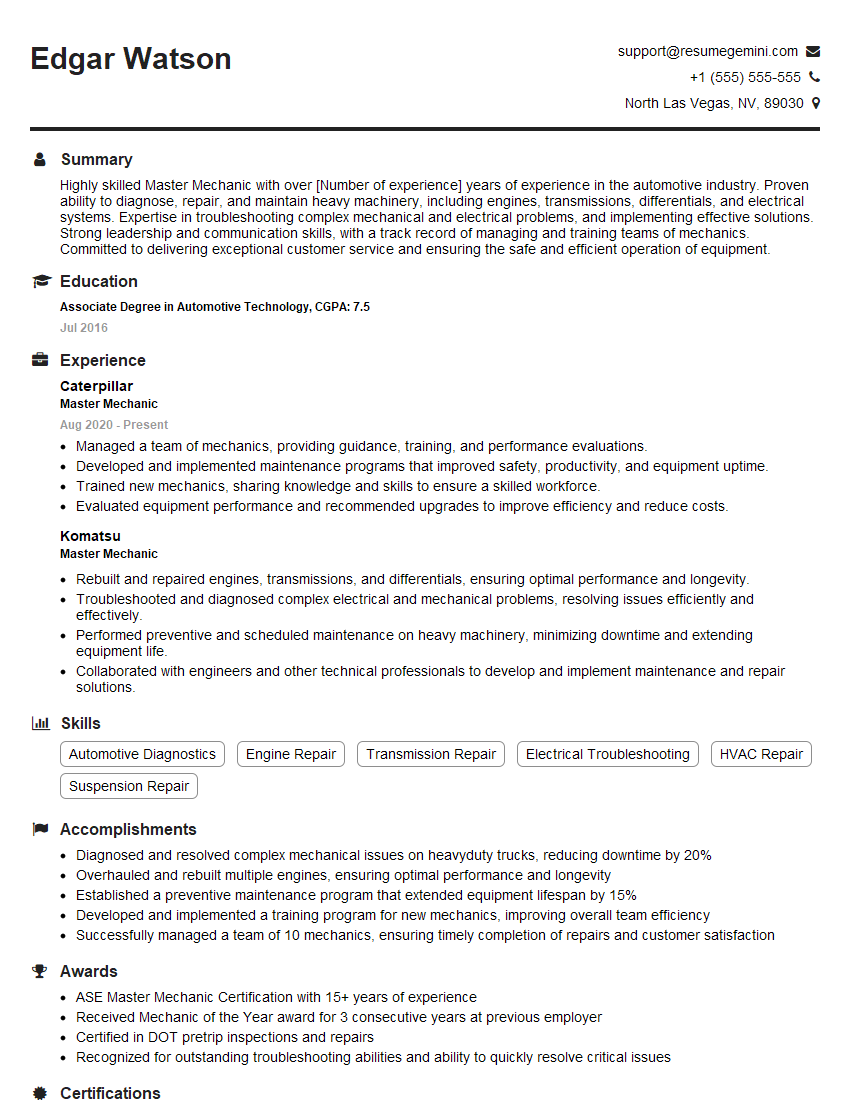

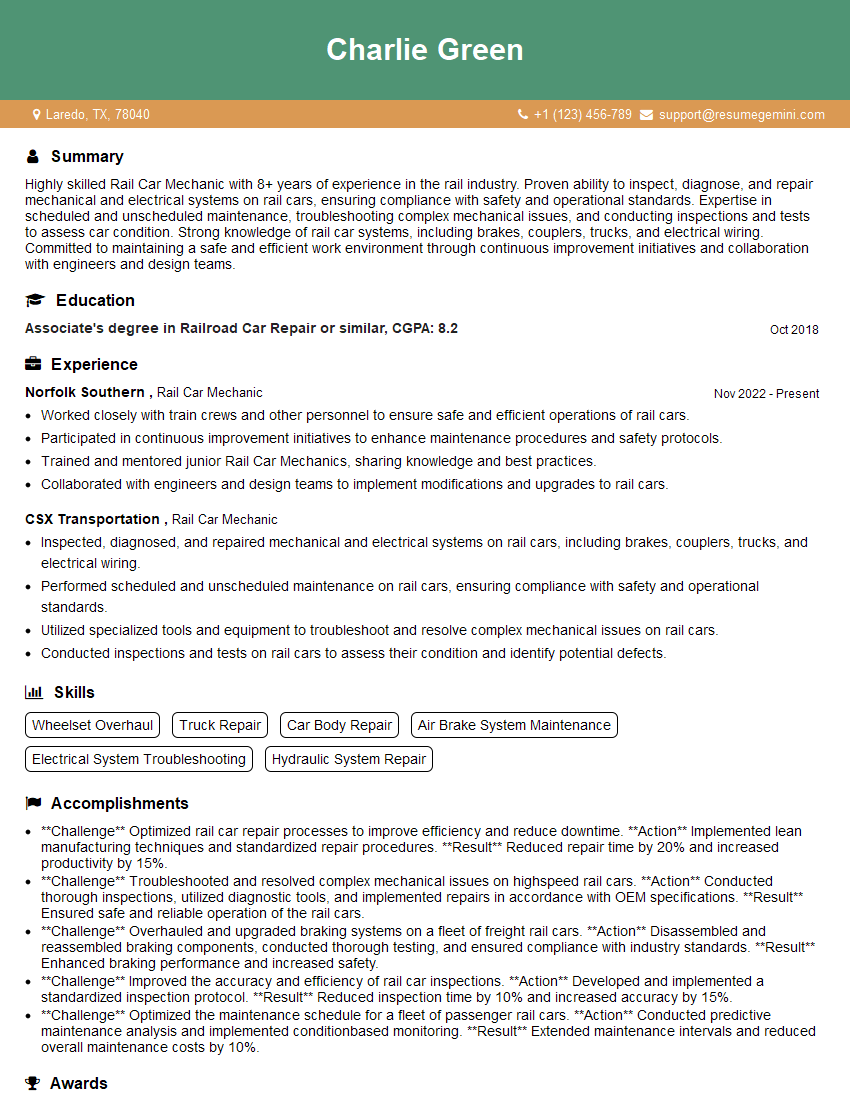

Mastering public transportation maintenance and repair procedures is crucial for career advancement in this vital industry. Demonstrating this expertise through a strong resume is key to securing your dream role. An ATS-friendly resume is essential for getting past applicant tracking systems and into the hands of hiring managers. To create a compelling and effective resume that highlights your skills and experience, we strongly encourage you to use ResumeGemini. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to public transportation maintenance and repair procedures, helping you showcase your qualifications effectively. Invest time in crafting a professional and impactful resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO