Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Loading and Unloading Machines interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Loading and Unloading Machines Interview

Q 1. Describe your experience operating different types of loading and unloading machines.

My experience encompasses a wide range of loading and unloading machines, from basic forklifts and pallet jacks to advanced automated guided vehicles (AGVs) and gantry cranes. I’ve operated both internal combustion engine (ICE) and electric-powered forklifts, proficiently navigating diverse warehouse layouts and handling various cargo types, including pallets, crates, drums, and loose materials. My experience with AGVs includes programming and troubleshooting their navigation systems to optimize efficiency. Working with gantry cranes required meticulous attention to detail and precise control, ensuring the safe lifting and placement of heavy loads. I’ve also worked with conveyor systems, understanding their configuration and maintenance for smooth material flow. Each machine demands a unique skill set, and my adaptability allows me to quickly learn and master new equipment.

For example, during a project involving the unloading of oversized machinery components, I utilized my experience with gantry cranes to safely manage the delicate lifting and positioning required, preventing any damage to the equipment or the surrounding environment.

Q 2. Explain the safety procedures you follow when operating loading and unloading equipment.

Safety is paramount in my work. Before operating any equipment, I always conduct a thorough pre-operational inspection, checking for any mechanical faults, fluid leaks, or damaged components. This includes verifying the functionality of safety features like brakes, horns, and emergency stops. I adhere strictly to the manufacturer’s operating instructions and any site-specific safety regulations. Personal protective equipment (PPE) such as safety boots, gloves, high-visibility vests, and hard hats are always worn. I also maintain a safe operating distance from other personnel and equipment, communicate clearly with colleagues, and follow traffic management plans within the warehouse or loading dock. I’m certified in safe forklift operation and regularly participate in refresher training to ensure my skills are up-to-date and my awareness of potential hazards remains sharp.

For instance, when working near other workers or vehicles, I make eye contact and give a clear signal before starting any lifting or moving operation. If I encounter an unexpected issue, I immediately stop the machine and report the problem to my supervisor before resuming any work.

Q 3. How do you ensure the efficient and safe loading and unloading of goods?

Efficient and safe loading and unloading requires careful planning and execution. This begins with understanding the cargo, its dimensions, weight, and fragility. Proper load securing methods are crucial to prevent damage during transit. I utilize different techniques based on the goods – for example, using straps, shrink wrap, or dunnage for securing pallets. Load planning optimizes space utilization within the vehicle and ensures weight distribution is balanced to prevent instability or damage. This also involves coordinating with drivers and warehouse personnel to ensure a smooth workflow and minimizing idle time. I regularly review and refine loading/unloading procedures to identify and address bottlenecks or potential risks. This might include optimizing routes or implementing improved load securing techniques.

For example, I once streamlined a particularly slow unloading process by implementing a new system of pallet staging, which reduced unnecessary movement and sped up the whole operation by approximately 20%.

Q 4. What are the common causes of equipment malfunctions in loading and unloading operations?

Common equipment malfunctions in loading and unloading operations often stem from inadequate maintenance, operator error, or environmental factors. Mechanical issues include hydraulic leaks, worn brake pads, engine problems (in ICE machines), and faulty electrical systems. Tire problems, such as punctures or uneven wear, can also significantly impact machine performance and safety. Environmental factors such as extreme temperatures, dust, or moisture can accelerate wear and tear and lead to malfunctions. Operator error can contribute to problems through incorrect operation, overloading equipment, or neglecting routine checks.

- Hydraulic Leaks: Can lead to reduced lifting capacity and potential safety hazards.

- Worn Brake Pads: Compromises braking effectiveness, posing a serious safety risk.

- Electrical Faults: Can cause unexpected shutdowns or malfunctioning of critical components.

- Improper Maintenance: Leads to premature wear and tear, increasing the frequency of breakdowns.

Q 5. How do you troubleshoot common issues with loading and unloading machines?

Troubleshooting involves a systematic approach. I begin with a visual inspection to identify any obvious problems. Then, I consult the equipment’s operation manual to diagnose possible causes based on error codes or observed symptoms. Simple issues, such as low hydraulic fluid, can be addressed immediately. For more complex problems, I might use diagnostic tools to pinpoint faulty components. If I’m unable to resolve the issue, I contact a qualified mechanic or report the problem to my supervisor. Safety is always prioritized. If a machine is unsafe to operate, it is immediately taken out of service.

For instance, if a forklift experiences a sudden loss of power, I’d first check the battery level (if electric) or fuel level (if ICE). I would then check the circuit breakers and fuses. If the problem persists, I would call for maintenance support.

Q 6. What are the different types of loading and unloading equipment you are familiar with?

My experience covers a wide variety of loading and unloading equipment. This includes:

- Forklifts (various capacities and types): Counterbalance, reach truck, order picker, sit-down, stand-up.

- Pallet Jacks/Hand Trucks: Manual and powered.

- Conveyors: Belt conveyors, roller conveyors, chain conveyors.

- Gantry Cranes: For heavy lifting and placement.

- Automated Guided Vehicles (AGVs): For automated material handling in warehouses.

- Loading Docks and Ramps: Experience in safe loading and unloading practices.

- Strapping and Securing Equipment: Hand tools and power tools for secure load handling.

Q 7. Describe your experience with inventory management in relation to loading and unloading.

Inventory management is intrinsically linked to loading and unloading efficiency. Accurate inventory tracking ensures that the right goods are loaded and unloaded at the right time. This involves using inventory management systems (WMS) to track goods, manage stock levels, and optimize storage space. Real-time data on incoming and outgoing goods allows for better planning and reduces delays. I’ve used various WMS systems, providing updates on load completion, and reporting discrepancies. This ensures efficient order fulfillment and prevents stock-outs or overstocking. Knowing what’s being loaded and unloaded, and when, helps with coordinating resources and scheduling warehouse activities effectively.

In one instance, by integrating real-time inventory data with our loading schedules, we managed to reduce loading times by 15% and minimize storage errors.

Q 8. How do you maintain accurate records of loading and unloading activities?

Maintaining accurate records of loading and unloading activities is crucial for efficiency, accountability, and regulatory compliance. We use a multi-pronged approach:

Digital Tracking Systems: We utilize Warehouse Management Systems (WMS) and Transportation Management Systems (TMS) to record every detail—from the type and quantity of goods to the time of loading/unloading, vehicle information, and the personnel involved. These systems often integrate with barcode or RFID scanners for automated data entry, minimizing human error.

Manual Checklists and Logs: While digital systems are preferred, physical checklists and logs act as backups and provide a readily available audit trail. These are especially important when dealing with less-technological processes or during system outages.

Third-Party Verification: In certain high-stakes situations (e.g., transporting hazardous materials), we engage independent third-party auditors to verify the accuracy of our loading and unloading records and procedures. This ensures compliance with regulations and provides an unbiased assessment.

Regular Audits: Internal audits of our record-keeping processes are conducted routinely to identify any weaknesses or inconsistencies in our documentation and to ensure that our systems are functioning correctly and efficiently.

Imagine a situation where a shipment is damaged. Accurate records help pinpoint the source of the damage—was it during loading, transit, or unloading? This helps in claim processing, damage prevention, and improved procedures.

Q 9. Explain your understanding of weight and balance considerations during loading and unloading.

Weight and balance considerations are paramount for safety and efficient operations. Incorrect weight distribution can lead to vehicle instability, accidents, and damage to goods. We adhere to strict protocols:

Precise Weighing: All shipments are accurately weighed using certified scales. This ensures that we don’t exceed the vehicle’s weight limits, which is critical for road safety and avoiding hefty fines.

Load Planning Software: We utilize software to simulate load configurations and optimize weight distribution. This helps us to avoid overloading specific axles or areas of the vehicle, ensuring stability and safety.

Center of Gravity Calculation: Understanding the center of gravity of the load is essential. Heavy items should be placed lower and closer to the center to prevent tipping. Imagine loading a truck with all the heavy boxes stacked high at the rear – this is a recipe for disaster.

Securement Methods: Proper load securing is key. We use straps, chains, and other methods to prevent shifting during transit. This not only safeguards the cargo but also enhances safety.

For example, transporting oversized or oddly shaped goods requires even more careful planning and securement to ensure a stable and safe journey. This might involve using specialized equipment or techniques.

Q 10. What are the key performance indicators (KPIs) you track in loading and unloading operations?

Key Performance Indicators (KPIs) allow us to measure the efficiency and effectiveness of loading and unloading operations. We track:

Loading/Unloading Time: This measures the time taken to complete loading or unloading a vehicle. Reducing this time improves operational efficiency and reduces costs.

Throughput: The number of units or pallets processed per hour or day, reflecting overall efficiency.

Damage Rate: Percentage of damaged goods, indicating the effectiveness of handling procedures and load securing techniques. A higher rate indicates potential problems requiring attention.

On-Time Performance: Percentage of shipments loaded and unloaded within the scheduled timeframe. This is crucial for meeting deadlines and maintaining customer satisfaction.

Labor Productivity: Units handled per worker-hour, assessing the effectiveness of staffing levels and training.

Safety Incidents: Number of accidents or near misses, highlighting safety risks and indicating areas needing improvement.

By consistently monitoring these KPIs, we can identify bottlenecks, optimize processes, and enhance overall performance.

Q 11. How do you prioritize tasks during peak loading and unloading periods?

Prioritizing tasks during peak periods requires a systematic approach. We use a combination of strategies:

Pre-Planning and Scheduling: Prioritize shipments based on urgency, delivery deadlines, and product characteristics (e.g., perishable goods). We often use advanced scheduling software to optimize loading and unloading sequences.

First-In, First-Out (FIFO): This inventory management principle ensures that older goods are shipped out first, reducing storage costs and minimizing the risk of spoilage.

Emergency Protocols: Establishing clear protocols for handling unexpected surges or urgent shipments is crucial. This might involve assigning additional personnel or re-prioritizing tasks.

Communication: Excellent communication among the loading/unloading team, dispatchers, and drivers is crucial to keep things running smoothly under pressure.

Cross-Training: Cross-trained staff allow for greater flexibility in response to changing demands.

Imagine a sudden influx of orders before a major holiday. A well-defined prioritization system, coupled with clear communication, will be essential to avoid delays and customer dissatisfaction.

Q 12. Describe your experience with different types of pallets and their handling.

Experience with various pallet types is vital for efficient handling. We regularly work with:

Standard Pallets: These are the most common and readily available, making them easy to handle with standard equipment. We use them for most shipments.

Block Pallets: These have a solid base and are often used for heavier or more fragile goods needing extra support.

Half-Pallets: Smaller pallets used for lighter loads or smaller shipments.

Slip Sheets: These are used as a substitute for pallets, reducing overall weight and increasing storage efficiency. They require specialized equipment to handle.

Each type requires consideration of its dimensions, weight capacity, and suitability for the goods being handled. Improper pallet selection can lead to damage, inefficiency, and safety hazards. For example, using a standard pallet for very heavy items might lead to structural failure.

Q 13. How do you adapt your techniques for loading and unloading different types of goods?

Adaptability is key when handling diverse goods. We adjust our techniques based on several factors:

Fragility: Fragile items require extra care and protection, potentially needing specialized packing, handling equipment, and gentler loading methods.

Weight and Size: Heavy items often require the use of forklifts or other specialized equipment. Oversized goods might need specialized vehicles or handling methods.

Temperature Sensitivity: Perishable goods require refrigerated transport and handling to maintain quality and prevent spoilage. This might involve using specialized trailers and loading procedures.

Shape and Configuration: Oddly shaped items often necessitate custom packing and careful placement within the vehicle to optimize space and avoid damage.

Imagine loading a shipment containing both delicate glassware and heavy machinery on the same truck. Careful planning and prioritization of the loading sequence are essential to ensure both arrive at their destination safely and without damage. We might load the machinery first and then carefully place the glassware on top, padded and secured.

Q 14. What is your experience with loading and unloading hazardous materials?

Handling hazardous materials requires meticulous adherence to safety regulations and specialized training. Our experience includes:

Specialized Equipment: We use appropriate containers, equipment, and personal protective equipment (PPE) designed for specific hazardous materials.

Detailed Documentation: We meticulously document every aspect of handling hazardous materials, including the type of material, quantity, safety procedures followed, and any incidents encountered. This is crucial for regulatory compliance and incident investigation.

Emergency Response Plans: We have established comprehensive emergency response plans to handle potential spills or accidents. This includes training personnel in emergency procedures and maintaining readily available emergency equipment.

Regulatory Compliance: We ensure full compliance with all relevant local, national, and international regulations governing the transportation and handling of hazardous materials.

For example, transporting flammable liquids requires specialized tanks, careful loading procedures to prevent static electricity build-up, and appropriate labeling and documentation. Any deviation from the prescribed safety protocols can lead to serious accidents and legal repercussions.

Q 15. How do you ensure the security of goods during loading and unloading?

Ensuring the security of goods during loading and unloading is paramount. It involves a multi-faceted approach encompassing proper handling techniques, secure storage, and meticulous documentation. Think of it like building a strong, protective shield around your cargo.

Proper Packaging: Using appropriate packaging materials – like sturdy crates, protective wraps, and shock absorbers – is the first line of defense against damage. For instance, fragile items need extra cushioning, while heavier goods might require reinforced pallets.

Secure Loading Techniques: Loading methods must prevent shifting or falling during transit. This includes using appropriate restraints like straps, dunnage (protective material used to fill empty spaces), and blocking (wedging materials to prevent movement). I’ve personally overseen the securement of heavy machinery using specialized straps and customized load-bearing structures.

Inventory Management and Tracking: Accurate tracking from the moment goods arrive until they are unloaded prevents theft and misplacement. This often involves barcodes, RFID tags, and robust inventory management software. I have extensive experience using these technologies to maintain complete visibility of goods throughout the entire process. For example, I once used RFID technology to track high-value electronics during a cross-country shipment, which eliminated several potential loss events.

Environmental Protection: Protection from the elements – rain, sun, extreme temperatures – is crucial, especially for sensitive cargo. This includes using tarpaulins, climate-controlled vehicles, and storage facilities. During a particularly heavy storm, I managed to safeguard a shipment of delicate medical equipment by utilizing specialized waterproof containers and repositioning them to avoid water pooling.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your proficiency in using warehouse management systems (WMS).

My proficiency in Warehouse Management Systems (WMS) extends beyond basic operation; I’m adept at utilizing them for optimization and problem-solving. I’m familiar with various systems, including SAP EWM, Oracle WMS, and Blue Yonder. I can confidently perform tasks such as inventory management, order fulfillment, and labor management.

Inventory Control: I utilize WMS to monitor stock levels in real-time, ensuring accuracy and preventing stockouts or overstocking. For instance, I’ve integrated WMS data with sales forecasts to proactively manage inventory and reduce storage costs.

Order Fulfillment: I leverage WMS to streamline the picking, packing, and shipping processes, optimizing routes for efficiency and reducing order fulfillment time. Through my experience, I have developed strategies for reducing errors and improving order accuracy.

Reporting and Analysis: I’m proficient in using WMS reports to identify bottlenecks and areas for improvement in loading and unloading efficiency. For example, I used WMS data to analyze loading dock congestion and implement a new scheduling system that reduced loading times by 15%.

Q 17. How do you ensure compliance with safety regulations during loading and unloading operations?

Safety is my top priority. Compliance with safety regulations involves a rigorous approach, encompassing worker training, equipment maintenance, and adherence to established protocols. This isn’t just about following rules; it’s about creating a culture of safety.

Training and Certification: I ensure all team members undergo comprehensive training on safe loading and unloading procedures, including hazard identification and risk mitigation. This includes training on the safe operation of forklifts, pallet jacks, and other equipment, along with proper lifting techniques to prevent injury.

Equipment Maintenance: Regular maintenance of all loading and unloading equipment is crucial. This includes regular inspections, preventative maintenance schedules, and immediate repair of any malfunctions. I personally oversaw a program that reduced equipment downtime by 20% through preventative maintenance.

Adherence to Regulations: Thorough understanding and strict adherence to all relevant safety regulations, including OSHA (Occupational Safety and Health Administration) guidelines, are mandatory. We maintain detailed records of all safety inspections and training to ensure compliance.

Hazard Identification and Mitigation: Proactive identification and mitigation of potential hazards – such as uneven surfaces, unstable stacks, and blind spots – are key to preventing accidents. I’ve implemented strategies like improved lighting and designated pedestrian walkways to enhance safety.

Q 18. Explain your experience working with various types of packaging materials.

My experience encompasses a broad range of packaging materials, from simple cardboard boxes to specialized containers designed for hazardous materials. Understanding the properties of each material is key to ensuring the safe and efficient handling of goods.

Cardboard Boxes: I’m proficient in handling various sizes and types of cardboard boxes, understanding their limitations and ensuring proper stacking and securing.

Pallets: I’m experienced with different pallet types (wood, plastic, etc.) and their load-bearing capacities. Safe and efficient pallet handling is crucial for preventing damage and optimizing space.

Crates: I’m skilled in using and inspecting crates, understanding the significance of proper construction and secure fastening for fragile goods. I’ve worked extensively with customized crates for oversized or oddly shaped items.

Specialized Containers: I’ve worked with containers designed for specific goods, including those requiring temperature control or protection from moisture. For example, I’ve managed the loading and unloading of refrigerated containers for pharmaceuticals and food products.

Q 19. How do you handle damaged or defective goods during loading and unloading?

Handling damaged or defective goods requires a systematic approach, combining immediate documentation, careful segregation, and efficient communication. The goal is to minimize further damage, ensure accurate reporting, and facilitate efficient claims processing.

Immediate Documentation: Thorough documentation of the damage, including photographic evidence and detailed descriptions, is the first step. This provides irrefutable proof for insurance claims.

Segregation: Damaged goods need to be clearly separated from undamaged items to prevent further contamination or damage. This often involves using designated areas or specialized containers.

Reporting: A comprehensive report is filed, detailing the extent of the damage, potential causes, and any actions taken to mitigate further damage. This report serves as a record for insurance claims and internal analysis to prevent future occurrences.

Disposal or Return: Depending on the extent of the damage and the nature of the goods, they might be disposed of according to regulations or returned to the supplier for replacement or credit.

Q 20. What is your experience with loading and unloading in different weather conditions?

Experience handling loading and unloading operations in various weather conditions is crucial. Adapting to these conditions requires specialized equipment and procedures to ensure safety and prevent damage. Think of it as preparing for a challenging outdoor expedition.

Extreme Temperatures: In extreme heat, measures to prevent overheating of goods and personnel are vital (e.g., scheduling work during cooler parts of the day, providing adequate hydration). In cold weather, specialized equipment for maintaining product temperatures might be necessary (e.g., heated trucks and warehouses).

Precipitation: Rain, snow, or ice require protective measures like tarpaulins to prevent water damage. Safety procedures need to adjust to account for slippery surfaces.

Wind: High winds can cause instability and damage. Securing loads with extra care using robust straps and weights is necessary to counteract strong winds.

Equipment Adaptation: Specialized equipment – such as enclosed loading docks, heated trailers, and waterproof packaging – often becomes necessary to manage the challenges of adverse weather.

Q 21. How do you work effectively as part of a team during loading and unloading operations?

Effective teamwork during loading and unloading is critical for efficiency and safety. It relies on clear communication, shared responsibility, and mutual respect. Imagine a well-orchestrated symphony, where each instrument plays its part harmoniously.

Clear Communication: Open and clear communication is key. This includes using hand signals, radios, or other communication tools to coordinate tasks and ensure everyone is aware of the plan.

Delegation and Coordination: Efficient delegation of tasks ensures that everyone has a clear role, promoting efficiency and preventing confusion. This often involves a designated team leader to coordinate operations.

Mutual Support: Team members need to support each other, helping with tasks as needed and ensuring everyone’s safety. A sense of camaraderie is crucial to preventing accidents and maintaining morale.

Problem Solving as a Team: When challenges arise, collaborative problem-solving is essential. Brainstorming solutions as a team often leads to quicker and more effective solutions.

Q 22. Describe your experience with different types of loading docks and their configurations.

My experience encompasses a wide range of loading dock configurations, from basic level-loading docks to more sophisticated designs incorporating hydraulic levelers, dock seals, and shelters. Level-loading docks are the most common, ensuring a smooth transition between the truck bed and the warehouse floor. However, the efficiency and safety of these docks greatly depend on their design and maintenance.

- Hydraulic Levelers: These automatically adjust to the height of the truck, minimizing the gap and improving safety for workers. I’ve worked with various brands, each with unique maintenance requirements which I’m well-versed in.

- Dock Seals and Shelters: These are crucial for environmental control and preventing energy loss. I have experience with inflatable, rigid, and fabric seals, understanding the impact of different materials on lifespan and effectiveness. I’ve overseen installations and repairs to ensure optimal performance and longevity.

- Vehicle Restraint Systems: Ensuring truck stability is paramount. I’ve worked extensively with different types of wheel chocks and interlocking systems to prevent accidental movement during loading and unloading. Proper use and regular inspections are key to preventing accidents.

In one project, we improved efficiency by replacing an aging dock system with a modernized hydraulic leveler and improved sealing system. This reduced loading times by 15% and significantly decreased energy costs by minimizing drafts.

Q 23. How do you utilize technology to optimize loading and unloading processes?

Technology plays a pivotal role in optimizing loading and unloading processes. I utilize Warehouse Management Systems (WMS) to manage inventory, schedule deliveries, and track shipments in real-time. This allows for proactive planning and efficient resource allocation.

- WMS Integration: I’ve successfully integrated WMS with various loading dock equipment, including conveyors and automated guided vehicles (AGVs), to streamline workflows and reduce manual intervention. This results in fewer errors and faster turnaround times.

- Real-time Tracking: Using RFID tags and barcode scanners, I’ve improved accuracy in tracking goods throughout the loading and unloading process. This data feeds directly into the WMS, providing valuable insights for process improvement.

- Predictive Analytics: Analyzing historical data from the WMS helps predict peak periods and potential bottlenecks. This allows for preemptive scheduling adjustments and resource allocation, maximizing efficiency and minimizing delays.

For instance, by implementing a real-time tracking system in a previous role, we were able to reduce order fulfillment time by 20% by optimizing route planning and minimizing unnecessary movement of goods.

Q 24. What is your experience with preventive maintenance for loading and unloading equipment?

Preventive maintenance is crucial for extending the lifespan and ensuring the safe operation of loading and unloading equipment. My approach involves a comprehensive schedule that includes regular inspections, lubrication, and part replacements as needed.

- Regular Inspections: I conduct daily and weekly inspections of all equipment, checking for wear and tear, leaks, and any potential safety hazards. I document all findings and follow up with necessary repairs or replacements.

- Lubrication Schedules: Regular lubrication of moving parts is vital for preventing friction and extending the lifespan of equipment. I follow manufacturer recommendations and maintain detailed records of lubrication schedules.

- Predictive Maintenance: Utilizing data from equipment sensors and operational history, I can predict potential failures before they occur. This allows for proactive maintenance, minimizing downtime and unexpected repairs.

In one instance, we implemented a predictive maintenance program for our forklifts, which led to a 30% reduction in unexpected downtime and significant cost savings by preventing major repairs.

Q 25. How do you identify and report potential safety hazards related to loading and unloading?

Identifying and reporting safety hazards is a top priority. My approach involves regular safety audits, employee training, and a robust reporting system.

- Safety Audits: I conduct regular walkthroughs of the loading dock area, identifying potential hazards such as damaged equipment, blocked walkways, or inadequate lighting. These audits are documented and corrective actions are implemented immediately.

- Employee Training: Regular safety training is crucial to ensure employees are aware of potential hazards and follow safe work practices. Training covers topics like proper forklift operation, safe lifting techniques, and emergency procedures.

- Incident Reporting: A comprehensive system is in place for reporting any near misses or incidents. This allows for prompt investigation and corrective actions to prevent similar events in the future.

For example, during a safety audit, we identified a potential tripping hazard due to uneven pavement. Immediate repairs were made, preventing a potential accident.

Q 26. Explain your experience with different types of conveyors and their operations.

My experience includes working with various types of conveyors, each with its own operational characteristics and applications.

- Belt Conveyors: These are commonly used for moving goods over long distances. I have experience with different belt materials and drive systems, understanding the importance of proper tensioning and alignment for optimal performance and safety.

- Roller Conveyors: These are simple and cost-effective for moving goods over shorter distances. I’ve worked with gravity-fed and powered roller conveyors, understanding the importance of incline and decline angles for smooth operation.

- Chain Conveyors: These are used for heavier loads and more complex movements. I have familiarity with different types of chain drives and attachments, ensuring proper lubrication and maintenance to prevent damage.

In one project, we implemented a system of interconnected belt and roller conveyors to optimize the movement of goods from the loading dock to different areas of the warehouse, dramatically increasing throughput.

Q 27. How do you handle discrepancies between inventory counts and loading/unloading records?

Discrepancies between inventory counts and loading/unloading records necessitate a thorough investigation to pinpoint the source of the error.

- Verification Process: I initiate a verification process that involves double-checking the physical inventory against the loading/unloading records. This often involves using barcode scanners to verify items against the system.

- Data Analysis: If discrepancies persist, I analyze the data to identify patterns or potential causes. This may include examining loading/unloading logs for errors, checking for damage or loss, or investigating potential issues with the inventory management system.

- Corrective Actions: Once the cause is identified, corrective actions are implemented to prevent future discrepancies. This may involve improving data entry procedures, enhancing inventory management processes, or improving communication between different teams.

In a previous role, we discovered a systematic error in our inventory management system. By identifying and correcting this error, we significantly improved the accuracy of our inventory counts and reduced discrepancies.

Q 28. Describe your experience with the use of barcode scanners and other relevant technologies in a warehouse environment.

Barcode scanners are essential tools in a warehouse environment, improving accuracy and efficiency in various operations.

- Inventory Management: Barcode scanners are used to accurately track inventory levels, reducing the risk of stockouts or overstocking. This improves the accuracy of picking, packing, and shipping.

- Loading/Unloading: Scanners ensure accurate tracking of goods during loading and unloading, minimizing errors and improving inventory reconciliation. This data is crucial for real-time monitoring of warehouse operations.

- Data Integration: Barcode scanner data seamlessly integrates with the WMS, providing real-time updates on inventory levels and movement of goods. This helps managers make informed decisions about resource allocation and workflow optimization.

Using barcode scanners, we significantly reduced human error in picking and packing, leading to a substantial improvement in order accuracy and customer satisfaction.

Key Topics to Learn for Loading and Unloading Machines Interview

- Machine Operation & Safety: Understanding the mechanics of various loading and unloading machines (conveyors, cranes, forklifts, etc.), including their operational procedures and safety protocols. This includes pre-operational checks and emergency procedures.

- Material Handling Techniques: Efficient and safe handling of diverse materials, considering factors like weight, size, fragility, and hazardous materials. Practical application includes optimizing loading patterns for maximum efficiency and minimizing damage.

- Maintenance & Troubleshooting: Basic understanding of preventative maintenance schedules, common malfunctions, and simple troubleshooting techniques. This includes recognizing signs of wear and tear and reporting issues promptly.

- Productivity & Efficiency: Strategies for optimizing loading and unloading processes to maximize throughput and minimize downtime. This involves understanding workflow optimization and utilizing available technology.

- Regulations & Compliance: Familiarity with relevant safety regulations and industry best practices related to loading and unloading operations. This includes understanding weight limits, load securing techniques, and relevant certifications.

- Technological Advancements: Awareness of modern technologies used in loading and unloading, such as automated systems, robotics, and advanced materials handling equipment. This could include understanding the basic principles of operation and potential benefits.

Next Steps

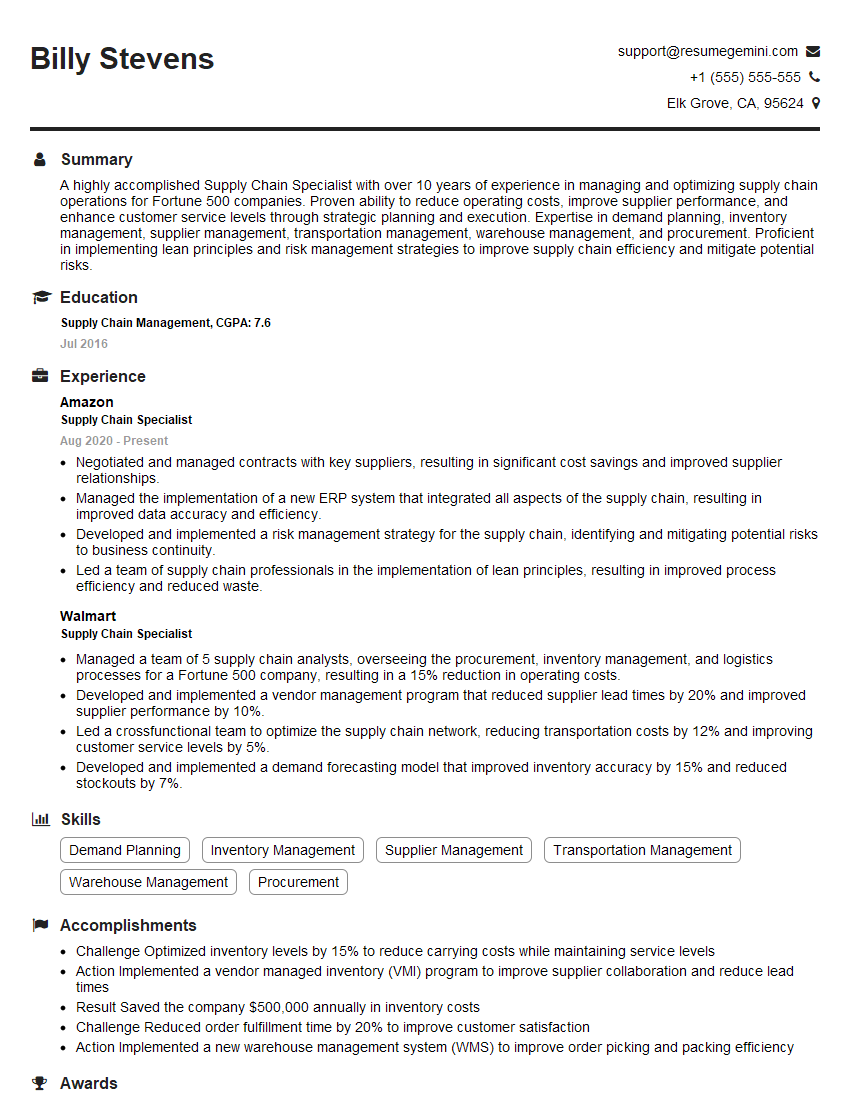

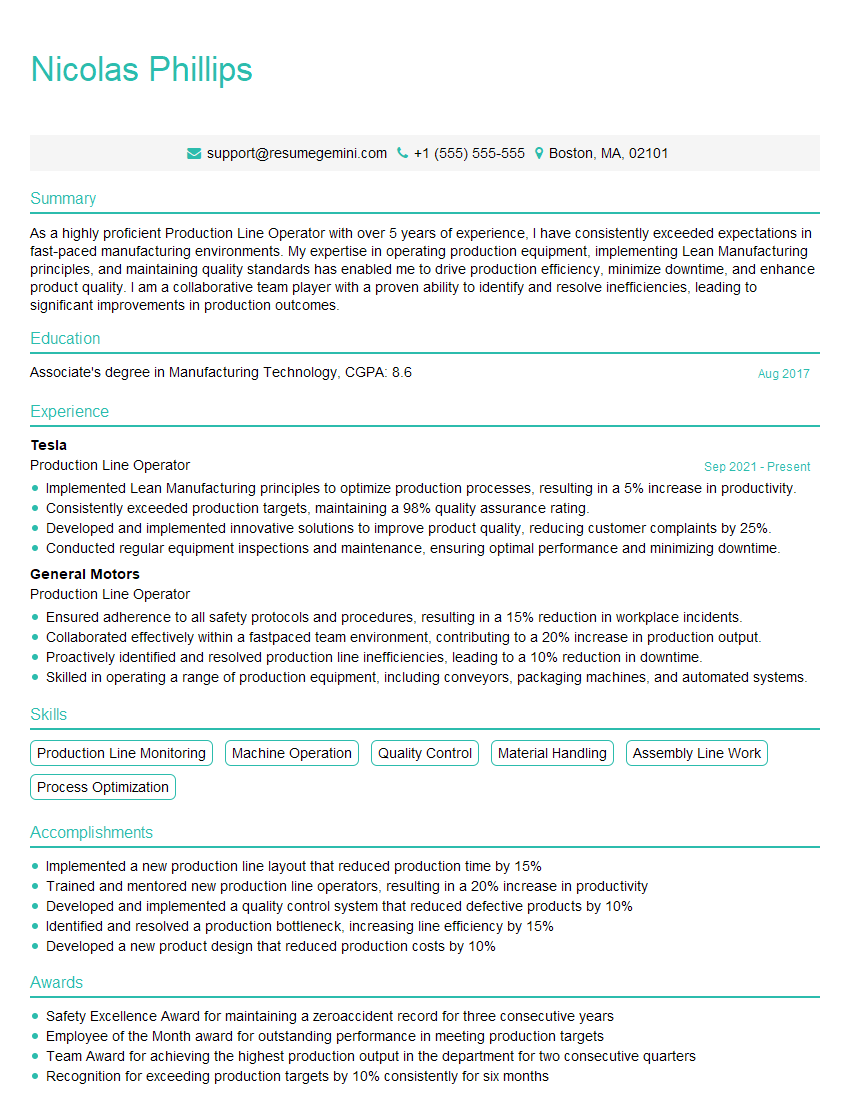

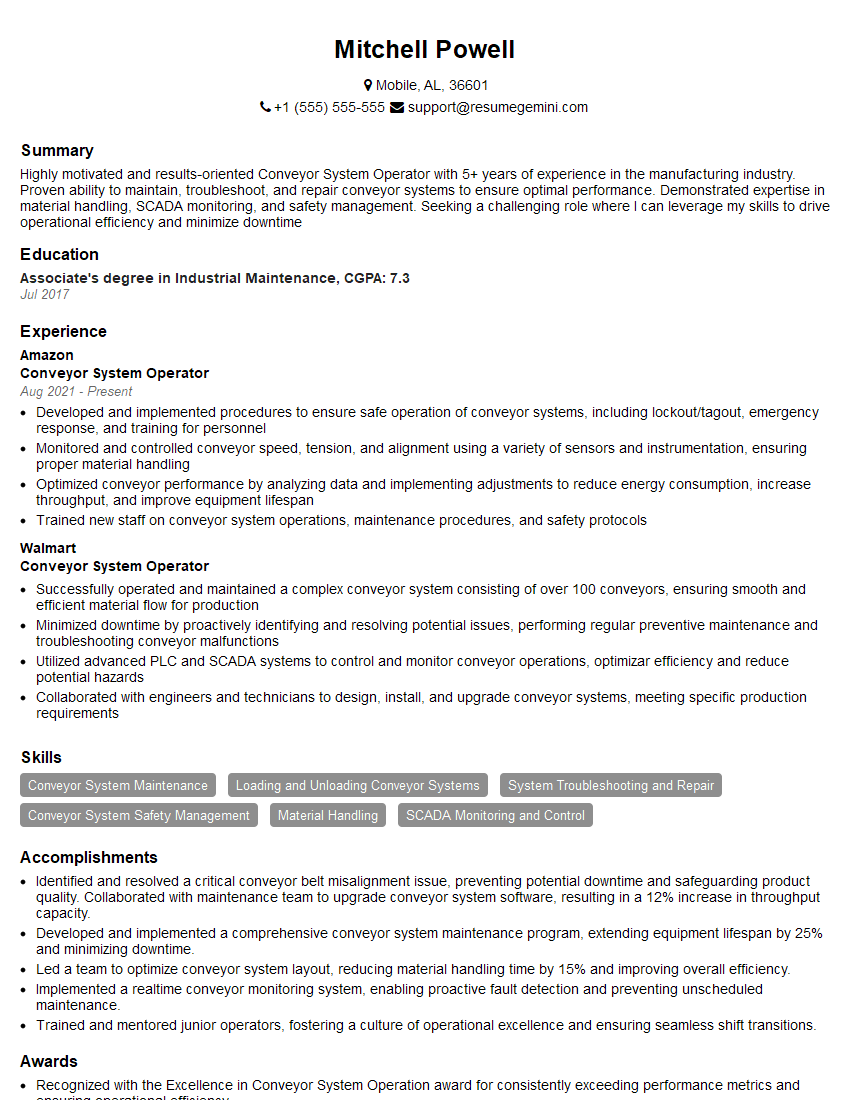

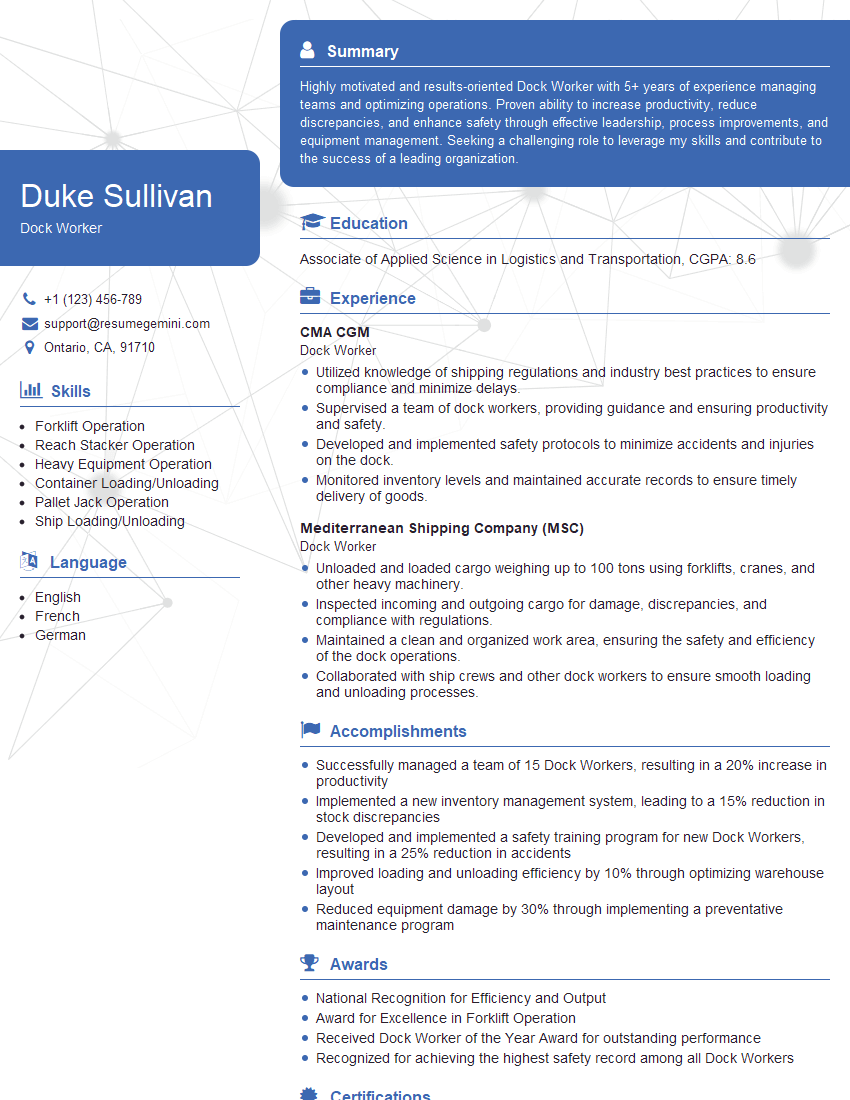

Mastering the intricacies of loading and unloading machines opens doors to rewarding careers in logistics, manufacturing, and warehousing. These roles are vital to efficient supply chains, offering opportunities for growth and specialization. To significantly boost your job prospects, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. We provide examples of resumes tailored specifically to Loading and Unloading Machines roles to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO