Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Proofing and Make-Ready Techniques interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Proofing and Make-Ready Techniques Interview

Q 1. Explain the difference between color proofing and soft proofing.

Color proofing and soft proofing are both crucial stages in the pre-press process, ensuring the final printed product matches the client’s expectations, but they differ significantly in their methods and capabilities.

Color Proofing involves creating a physical representation of the final printed piece using specialized printing techniques. This might involve technologies like inkjet proofing, dye-sublimation proofing, or even a small-scale run on the actual printing press. Color proofing offers a highly accurate visual representation of the final print, taking into account the specific paper stock, inks, and printing process. It’s the gold standard for color accuracy, especially for critical projects like packaging or high-end brochures.

Soft Proofing, on the other hand, is a digital representation of the print displayed on a calibrated monitor. It’s faster and cheaper than color proofing, relying on software to simulate the appearance of the print. While convenient, soft proofing’s accuracy depends heavily on the calibration of the monitor and the color profiles used. It’s perfectly suitable for less critical projects or as a preliminary check, but for critical color matching, a physical color proof is essential. Imagine trying to match a paint color on a phone screen versus viewing a physical paint sample – the physical sample offers far greater accuracy.

In essence, color proofing provides a physical representation for precise color matching, while soft proofing offers a quick, cost-effective digital preview.

Q 2. Describe the process of making ready a printing press for a specific job.

Making ready a printing press is a meticulous process that ensures the press is optimally configured for the specific job. It’s akin to tuning a high-precision instrument before a concert. Here’s a breakdown:

- Paper Selection and Setup: The correct paper stock is loaded onto the press, ensuring proper alignment and feeding. The paper’s characteristics (weight, texture, moisture content) significantly impact print quality.

- Ink Setup and Adjustment: The correct inks are selected and loaded into the press. Each ink’s viscosity is adjusted to achieve the desired color density and consistency. This stage might involve initial test prints to fine-tune ink values.

- Plate Mounting and Registration: Printing plates are carefully mounted onto the press cylinders. Precise registration is crucial – ensuring that all colors align perfectly to prevent misregistration (colors being slightly off-register from one another). This is often achieved through careful adjustments using registration marks on the printing plates.

- Press Adjustments: The press operator adjusts various parameters to optimize print quality. This includes things like ink-water balance, impression pressure (how hard the plate presses against the paper), and blanket pressure. These adjustments are fine-tuned using test prints.

- Test Prints and Adjustments: A series of test prints are produced to evaluate color accuracy, density, dot gain, and registration. Based on these test prints, further adjustments are made to the press until the desired print quality is achieved. This is an iterative process; several test prints are usually required.

- Waste Run: Before starting the main print run, a short waste run is conducted. This removes any remaining debris and ensures that the press is producing consistent, high-quality prints.

The entire make-ready process requires a deep understanding of printing technology and a keen eye for detail. A skilled press operator can significantly impact the final print quality.

Q 3. What are the key elements of a thorough pre-press checklist?

A thorough pre-press checklist is the cornerstone of a successful print job. It’s a systematic approach to identifying and preventing potential problems before they reach the printing press. Key elements include:

- File Integrity and Format: Verification of the file’s resolution, color mode (CMYK for print), and correct file format (PDF is usually preferred).

- Color Management: Confirmation that the correct color profiles are embedded and applied throughout the workflow.

- Image Resolution and Sharpness: Ensuring that images are adequately sharp and have sufficient resolution for the intended print size.

- Font Embedding and Outlines: Ensuring that all fonts used are either embedded in the PDF or converted to outlines to prevent font substitution issues.

- Bleed and Trim Marks: Verification that bleed (extra space around the image for trimming) and trim marks are correctly positioned.

- Proof Approval: Confirmation of client approval on a final proof, ideally a color proof.

- Paper Stock Verification: Checking the paper stock’s weight, type, and suitability for the intended printing process.

- Imposition Check: Verification that pages are correctly imposed according to the printing requirements (e.g., how pages are arranged on a press sheet).

- Barcode/Variable Data Check (If Applicable): For jobs with variable data, ensuring that the data is accurately integrated and the barcodes are functional.

A well-executed checklist prevents costly errors and ensures smooth production.

Q 4. How do you identify and correct common prepress errors?

Identifying and correcting prepress errors requires a systematic approach. Let’s look at some common errors and their solutions:

- Low-Resolution Images: Identified by pixelation or blurriness in the soft proof. Solution: Replace with high-resolution images.

- Missing Fonts: Results in font substitution during printing. Solution: Embed fonts or convert text to outlines.

- Incorrect Color Mode: Printing with RGB instead of CMYK will lead to inaccurate colors. Solution: Convert to CMYK using a proper color management workflow.

- Misregistration: Colors are misaligned. Solution: Check plate alignment and make adjustments on the press.

- Color Shifts: Differences between soft proof and printed output. Solution: Recalibrate monitors, check color profiles, and make adjustments on the press.

- Missing Bleed or Trim Marks: Results in unwanted white edges or incorrect trimming. Solution: Correct the design file before proceeding.

Using a combination of proofing methods and a keen eye for detail helps prevent these problems. A preflight check within the prepress software also helps to catch many errors before they escalate.

Q 5. What are the different types of proofing methods and when would you use each?

Several proofing methods cater to different needs and budgets:

- Soft Proof: A digital proof displayed on a calibrated monitor, suitable for early design reviews and less critical projects. Cost-effective and fast.

- Digital Proof (Hard Copy): High-resolution inkjet or laser proofs printed on media similar to the final print stock. More accurate than soft proofs but less accurate than press proofs.

- Contract Proof: A proof produced on a proofing press simulating the final print process closely. Provides high accuracy and is often required for critical color matching. More expensive than digital proofs.

- Press Proof: A small test run on the actual printing press, ensuring the highest level of accuracy. Most expensive and time-consuming but guarantees the final print will match.

The choice depends on the project’s criticality, budget, and time constraints. For high-stakes jobs, a press proof is usually the best option. For less sensitive projects, a digital or soft proof might suffice.

Q 6. Explain the importance of color management in prepress.

Color management is paramount in prepress, ensuring consistent color reproduction throughout the entire workflow, from design to printing. Without it, the colors on your screen will likely differ significantly from the final printed piece. This is because different devices (monitors, printers, scanners) interpret and display colors differently.

Effective color management relies on using industry-standard color profiles (ICC profiles) that define how a particular device handles color. By embedding these profiles in files and managing the workflow through a color management system (CMS), we aim to ensure that the color intent from design remains consistent through different stages. It’s about translating color information from one device’s color space to another consistently. Imagine trying to translate a language without a dictionary – color management is that dictionary for colors.

Failing to manage color effectively can lead to significant color shifts and inconsistencies, potentially resulting in costly reprints and client dissatisfaction.

Q 7. How do you handle a discrepancy between a proof and the final printed piece?

Discrepancies between proofs and final prints are unfortunately not uncommon. Handling these requires a methodical approach:

- Identify the Source: First, pinpoint the discrepancy’s root cause. Is it a problem with the proof, the printing process, the file, or the press settings? Often, a visual comparison of the proof and the printed sheet, alongside examining the test prints from the press make-ready stage, is helpful.

- Analyze the Difference: Quantify the discrepancy. How much does the color differ? Is it a consistent shift, or are there localized variations? This often involves using a spectrophotometer to measure color values accurately.

- Investigate the Press Settings: If the printing is at fault, review the press settings – ink-water balance, impression pressure, and other parameters. It is possible to reproduce the press test and assess if the discrepancies exist from the outset.

- Check the Files: If the issue isn’t press-related, thoroughly examine the design files. Are the color profiles correctly embedded? Are there any anomalies in the file itself?

- Communicate with the Client: Clearly explain the issue to the client, outlining potential causes and proposed solutions. Negotiate a resolution, which may involve reprints or minor adjustments.

Preventing discrepancies is always preferable, achieved through meticulous prepress practices and the use of appropriate proofing methods. But when they do occur, a calm, systematic approach is crucial.

Q 8. What are your preferred methods for ensuring accurate color reproduction?

Accurate color reproduction is paramount in printing. My approach involves a multi-stage process, starting with careful profile creation. I use color management software like X-Rite i1Profiler to create ICC profiles for both the input device (scanner or camera) and the output device (printer or press). This ensures that the colors intended are accurately translated across the workflow.

Next, I rely heavily on soft proofing. I utilize dedicated software such as Adobe Acrobat Pro with its proofing features and other professional RIP software (Raster Image Processor) offering soft proofing capabilities. These tools allow me to simulate the final printed output on screen, checking for accurate color representation and identifying potential issues before committing to the expensive process of plate making.

Finally, I always produce hard proofs – physical prints from a proof printer calibrated to match the printing press profile. This provides a crucial visual reference and accounts for minor variations inherent in different printing technologies. Hard proofs allow for final client approval and provide a critical check against the soft proofs. Comparing soft and hard proofs helps catch any discrepancies early in the process.

Q 9. Describe your experience with different types of printing plates.

My experience encompasses a wide range of printing plates, from traditional methods to the latest digital technologies. I’m proficient with:

- Conventional Plates: I’ve worked extensively with film-based plates such as CTP (Computer-to-Plate) plates – specifically using different types like thermal and violet plates. My understanding extends to the various plate materials (aluminum, polyester) and their impact on print quality and longevity. The choice depends on print volume, press type and budget considerations.

- Digital Plates: I am experienced with direct-to-plate technologies, which eliminate the film stage, increasing speed and efficiency. I’m familiar with various plate types like those used in inkjet and laser technologies. These methods often result in higher quality and sharper details.

My expertise includes understanding the platemaking process, including plate exposure, processing, and cleaning – ensuring optimal plate quality and avoiding issues like poor ink transfer or unwanted scumming.

Q 10. How familiar are you with imposition software and techniques?

Imposition is crucial for efficient printing and minimizing waste. I’m highly proficient in using imposition software such as Esko ArtiosCAD and other industry standard applications. These programs allow me to create precise layouts, ensuring that pages are arranged optimally for printing on sheets or rolls. I understand various imposition techniques including:

- Sheetfed Imposition: For sheet-fed printing, I use imposition software to optimize sheet layout, accounting for bleed, margins, and the number of pages per sheet. I’m skilled in creating different imposition schemes depending on the press configuration and print size.

- Roll-fed Imposition: For web-fed presses, I create layouts suitable for continuous printing. This requires understanding the web path, print repeat, and other factors affecting the final output.

- Gang Run Imposition: I’m experienced in combining multiple jobs onto a single sheet or roll, minimizing makeready time and material costs, particularly useful for small-run printing.

My skills also encompass understanding and optimizing imposition for different finishing requirements, like folding, cutting and binding.

Q 11. How do you ensure the proper alignment and registration of print materials?

Precise alignment and registration are fundamental to high-quality printing. I use a combination of pre-press and press-side techniques. Pre-press includes meticulous attention to detail during file preparation and imposition, ensuring all elements are correctly positioned.

On the press, my approach utilizes the press’s built-in registration systems. This often involves making fine adjustments using the press controls. I also use registration marks on the printed sheets as a visual reference. I use various methods to control registration such as adjusting the gripper, sidelays, and other press settings.

Regular monitoring during the print run and regular quality checks help to catch registration problems early before they impact a significant number of prints. I’m proficient in troubleshooting issues such as incorrect plate mounting, stretching or shrinking of the substrate during the print process, and problems with the press mechanics itself.

Q 12. What are some common causes of print defects and how do you troubleshoot them?

Print defects can stem from various sources. Here are some common ones and my troubleshooting strategies:

- Color Issues: These include inaccurate color reproduction, banding, and mottling. Troubleshooting involves checking color profiles, ink densities, and press settings. I may conduct color tests and adjustments during the press run to maintain color consistency.

- Registration Problems: Misalignment of colors or images. This is addressed by checking the press registration, plate mounting, and substrate handling. Precise adjustments and re-registration of plates might be required.

- Dot Gain: Excessive spreading of ink dots, leading to darker areas. I’d investigate the ink viscosity, press speed, and screen ruling. Possible solutions involve adjusting ink settings or applying specialized coatings.

- Hickeys: Small blemishes from foreign objects. This necessitates a thorough cleaning of the press and careful material handling.

- Paper Problems: Issues with paper quality, such as wrinkles, tears, or inconsistent thickness will disrupt the print process. Thorough substrate inspection and potential replacement is needed.

My approach is systematic. I begin by closely examining the defect, isolating the possible causes, and systematically checking the various stages of the printing process to identify the root cause. Documentation is vital – recording all changes, adjustments and results allows for effective troubleshooting and improvements in future jobs.

Q 13. Explain your experience with different types of paper stocks and their impact on print quality.

Paper selection significantly influences print quality. I have extensive experience with various paper stocks, including:

- Coated Papers: Offer excellent color reproduction and sharpness but might have limitations in terms of texture and environmental impact.

- Uncoated Papers: Provide a more natural feel and are often preferred for applications requiring a less glossy finish. However, they may present challenges with ink absorption and sharpness.

- Specialty Papers: Include textured papers, metallic papers, and recycled papers, each with unique properties influencing the final outcome.

For every project, I carefully consider the paper’s weight, finish, brightness, and opacity. The choice depends on the project requirements, desired aesthetic, and the printing method used. For instance, heavier stocks often necessitate adjustments to the press settings to prevent issues like paper jams. The choice of coated vs uncoated paper affects ink absorption, dot gain and overall color vibrancy. I work closely with clients to select the most suitable paper that meets their budget and visual requirements. I would always provide samples and discuss the impact of paper choice on the final printed output.

Q 14. How do you manage and resolve client feedback on proofs?

Managing client feedback on proofs is a crucial aspect of the job. My approach focuses on clear communication and collaboration. I start by thoroughly explaining the proofing process and its limitations, ensuring the client understands what can and cannot be achieved with the chosen printing techniques.

I actively listen to the client’s concerns and address each point individually. If adjustments are feasible, I provide detailed estimates of the time and cost implications, keeping the client informed throughout the process. Sometimes, it might involve adjustments to the artwork itself, which will require close collaboration with the designer.

For example, if a client finds a color slightly off, I may conduct a color analysis, checking if a small adjustment is possible without affecting the entire print run. If color correction necessitates a full reprint, I carefully explain the associated costs and implications. In cases where the client’s expectations are unrealistic given the chosen printing method or materials, I explain the limitations and offer alternative solutions. My goal is always to deliver a product that satisfies the client while maintaining the highest standards of quality and efficiency. Maintaining detailed records of all client communication and changes made ensures a smooth and efficient workflow.

Q 15. What software are you proficient in for prepress work (e.g., Adobe Acrobat, InDesign, etc.)?

My prepress workflow heavily relies on the Adobe Creative Suite. I’m highly proficient in Adobe InDesign for page layout and design, Acrobat Pro for PDF manipulation and preflighting, and Photoshop for image editing and retouching. I also have experience with other relevant software such as Illustrator for vector graphics and Color Management tools like X-Rite i1Profiler for ensuring color accuracy across different devices and printing processes. For example, in a recent project involving a multi-page brochure, I utilized InDesign’s advanced features for master pages and styles to maintain consistency, ensuring efficient design updates and reducing errors. Acrobat Pro was crucial for creating optimized, print-ready PDFs, including preflight checks to identify potential issues before sending to print.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of printing presses (e.g., offset, digital).

I have extensive experience with both offset and digital printing presses. Offset printing is my primary expertise, having worked extensively with Heidelberg and Komori presses. I understand the intricacies of sheetfed and web offset, including the setup, color management, and troubleshooting involved. My digital printing experience involves various high-volume Xerox and HP Indigo presses, enabling me to choose the best technology for specific projects based on factors like print volume, quality requirements, and turnaround time. For instance, a large-scale magazine would ideally utilize an offset press for cost-effectiveness and high-quality results, while a smaller, time-sensitive project might benefit from the speed and versatility of a digital press.

Q 17. How do you calculate the necessary amount of ink and paper for a specific job?

Calculating ink and paper requirements involves a multi-step process. First, the total area to be printed is calculated, considering the dimensions and quantity of printed pieces. For paper, this is straightforward: multiply the area per sheet by the number of sheets needed. Ink calculation is more complex. It depends on the paper stock, ink coverage (percentage of the area covered by ink), and ink density. We typically use industry-standard estimations based on past projects and press calibrations. For example, a 1000-piece brochure with 50% ink coverage on a particular paper type will require a specific ink volume, which I’d determine using established formulas and historical data. Overestimation is always preferred to avoid running short, as production delays are costly.

Q 18. What are your experience levels with different finishing techniques (e.g., cutting, binding, etc.)?

My experience in finishing techniques is comprehensive, encompassing various cutting, binding, and other post-press operations. I’m proficient in die-cutting, creasing, scoring, perfect binding, saddle-stitching, wire-O binding, and various folding techniques. I understand the different types of finishing equipment and their capabilities, enabling me to specify the optimal technique for a given project. For instance, a high-end corporate report would benefit from perfect binding for a sophisticated look, while a simple leaflet might just require folding and saddle-stitching for cost efficiency.

Q 19. Describe your process for quality control throughout the prepress and printing process.

Quality control is paramount throughout the entire process. It begins with rigorous preflighting of the digital files in Acrobat Pro, checking for resolution, color profiles, fonts, and bleeds. During the printing process, I conduct regular checks of color accuracy, registration, and print quality. This involves analyzing test prints and making adjustments as needed. Post-press quality control involves inspecting the finished product for any defects like miscuts, misalignment, or inconsistencies in binding. Documentation of each stage is vital for tracking and traceability. A robust quality control system ensures we meet the highest standards and avoid costly reprints.

Q 20. How do you ensure the accuracy of barcodes and other critical data in print materials?

Ensuring barcode accuracy is critical. I use specialized barcode verification software to check for proper symbology, quiet zones, and checksums. This software ensures the barcodes are scannable and meet industry standards, minimizing potential issues at the point of sale or distribution. For critical data, I implement a verification system, including multiple checks and approvals before sending the files to print. This could involve comparing the final design against the original client-approved artwork. Double-checking data entry is also crucial to avoid costly errors.

Q 21. What is your approach to managing tight deadlines and high-volume print jobs?

Managing tight deadlines and high-volume jobs requires meticulous planning and efficient resource allocation. This involves breaking down the project into smaller, manageable tasks with clearly defined timelines. I prioritize tasks based on their criticality and dependencies. Effective communication with the client and print production team is essential. If necessary, I would explore options like overtime or additional resources to ensure timely completion. Utilizing automation tools wherever possible, such as automated preflighting and imposition, streamlines the process and minimizes errors. Prioritization and proactive problem-solving are key for successful high-volume projects under pressure.

Q 22. Explain your understanding of color profiles and their importance.

Color profiles are essentially sets of data that describe how a particular device—like a monitor, printer, or scanner—reproduces color. They’re crucial because different devices interpret and display colors differently. Without color profiles, the colors you see on your screen might not accurately reflect the printed output, leading to significant discrepancies. Think of it like translating languages; a color profile is the dictionary ensuring accurate communication between your digital design and the final printed piece.

For example, an sRGB profile is a standard for web display, while CMYK is used for printing. If you’re designing a print piece and only use an sRGB profile, the colors will likely be significantly off when printed because printers use a subtractive color model (CMYK) while screens use an additive model (RGB).

The importance lies in color accuracy and consistency. Accurate color profiles ensure that the client receives the intended colors, avoiding costly reprints and ensuring client satisfaction. Choosing the correct profile at each stage – design, proofing, and printing – is paramount for successful color management.

Q 23. How do you maintain a clean and organized workspace in a high-pressure print environment?

In a high-pressure print environment, a clean and organized workspace is not just about aesthetics; it’s about efficiency and preventing errors. My approach involves a multi-pronged strategy: First, I meticulously organize my digital files using a clear naming convention and folder structure, making it easy to find specific files quickly. This saves considerable time during the make-ready process. Second, my physical workspace follows a similar principle—I have dedicated areas for different tasks, like proofing materials, prepress files, and inks. Third, I maintain a rigorous cleanup routine at the end of each day, discarding unnecessary materials and ensuring all equipment is properly stored and maintained. This prevents accidents and speeds up the next day’s work.

Think of it like a surgeon preparing for an operation: a sterile, organized environment is crucial to avoid errors and ensure the best possible outcome. This level of preparedness minimizes stress and maximizes productivity, especially under pressure.

Q 24. Describe a time you had to troubleshoot a complex prepress or printing issue.

During a large-scale poster printing project, we encountered a significant color banding issue. The posters, printed using a high-speed press, showed distinct horizontal bands of color variation. Initially, we suspected an issue with the ink supply, but after thorough inspection, the problem was traced to the press’s ink rollers. We discovered that one of the rollers wasn’t distributing ink evenly, leading to the banding effect. This was confirmed by test prints from other rollers, leading us to change the roller.

Troubleshooting involved a systematic approach: first, eliminating potential issues such as ink consistency and file preparation, and then focusing on the mechanical aspects of the printing press. We utilized a process of elimination, conducting test prints after each adjustment until the issue was solved. The solution required a quick replacement of the problematic roller and recalibration of the press, minimizing production downtime and preventing significant financial losses.

Q 25. What are some common challenges in prepress and how do you overcome them?

Common prepress challenges include color discrepancies, file preparation errors, and font issues. Color discrepancies can stem from incorrect color profiles or inconsistencies between the monitor and the printing press. File preparation errors can include low-resolution images, missing fonts, or incorrect bleed settings. Font issues often arise from using unsupported or missing fonts in the design files.

I overcome these challenges by implementing robust quality checks at every stage. This includes careful color profile management, high-resolution image verification, comprehensive font checking, and rigorous proofreading before sending files to the press. Using color management software and automated preflight checks helps identify and resolve many of these potential problems early in the process, preventing costly mistakes later. Proactive communication with clients and designers throughout the process also contributes to successful project completion. I see this as problem prevention rather than problem-solving; the goal is to anticipate and avoid issues before they occur.

Q 26. How do you stay up-to-date with the latest technology and trends in print production?

Staying current in the rapidly evolving field of print production requires a multi-faceted approach. I regularly attend industry conferences and workshops, which offer invaluable insights into new technologies and best practices. I also subscribe to industry publications and online resources that keep me abreast of the latest trends. In addition to this, I actively participate in online forums and communities, engaging in discussions with fellow professionals and experts. I believe continuous learning is paramount, particularly in a field that constantly incorporates advancements.

Furthermore, I actively seek out opportunities to experiment with new technologies and software in my work. Hands-on experience is invaluable for truly understanding the capabilities and limitations of new equipment and processes, and I’m always eager to incorporate new tools that improve efficiency and quality.

Q 27. What are your salary expectations for this role?

Based on my experience and the requirements of this role, my salary expectations are in the range of [Insert Salary Range]. This range is reflective of my expertise in proofing and make-ready techniques, my proven track record of success in high-pressure environments, and my commitment to continuous professional development.

Q 28. Why are you interested in this position?

I’m highly interested in this position because it offers an excellent opportunity to leverage my extensive knowledge and experience in proofing and make-ready techniques within a dynamic and challenging environment. I’m particularly drawn to [Mention specific aspects of the company or role that interest you, e.g., the company’s reputation for quality, the opportunity to work on innovative projects, the chance to mentor junior staff]. The chance to contribute to a successful team and contribute to high-quality print production is incredibly appealing.

Key Topics to Learn for Proofing and Make-Ready Techniques Interview

- Color Management: Understanding color profiles (CMYK, RGB), color consistency across different media, and troubleshooting color discrepancies. Practical application: Explaining your process for ensuring accurate color reproduction in print.

- Prepress Quality Control: Identifying and correcting errors in artwork, such as trapping issues, missing fonts, low-resolution images, and incorrect bleeds. Practical application: Describing your methodology for a thorough preflight check and how you handle identified errors.

- Imposition and Plate Making: Knowledge of different imposition techniques for various print formats, understanding imposition software, and familiarity with platemaking processes. Practical application: Explaining how you would set up an imposition for a specific print job, considering factors like sheet size and finishing requirements.

- File Formats and Conversions: Expertise in handling various file formats (PDF, TIFF, EPS, etc.), understanding color space conversions, and resolving compatibility issues between different software applications. Practical application: Detailing your experience with converting files for optimal print quality and explaining how you handle file format challenges.

- Print Finishing Techniques: Familiarity with various print finishing options, such as cutting, folding, binding, and laminating. Understanding how these techniques affect the final product and their impact on the overall workflow. Practical application: Discussing how you would specify finishing requirements based on the project needs and budget.

- Troubleshooting and Problem-Solving: Ability to diagnose and solve common prepress problems, such as registration issues, ink density problems, and other print-related defects. Practical application: Providing examples of how you’ve successfully troubleshot a complex prepress issue.

Next Steps

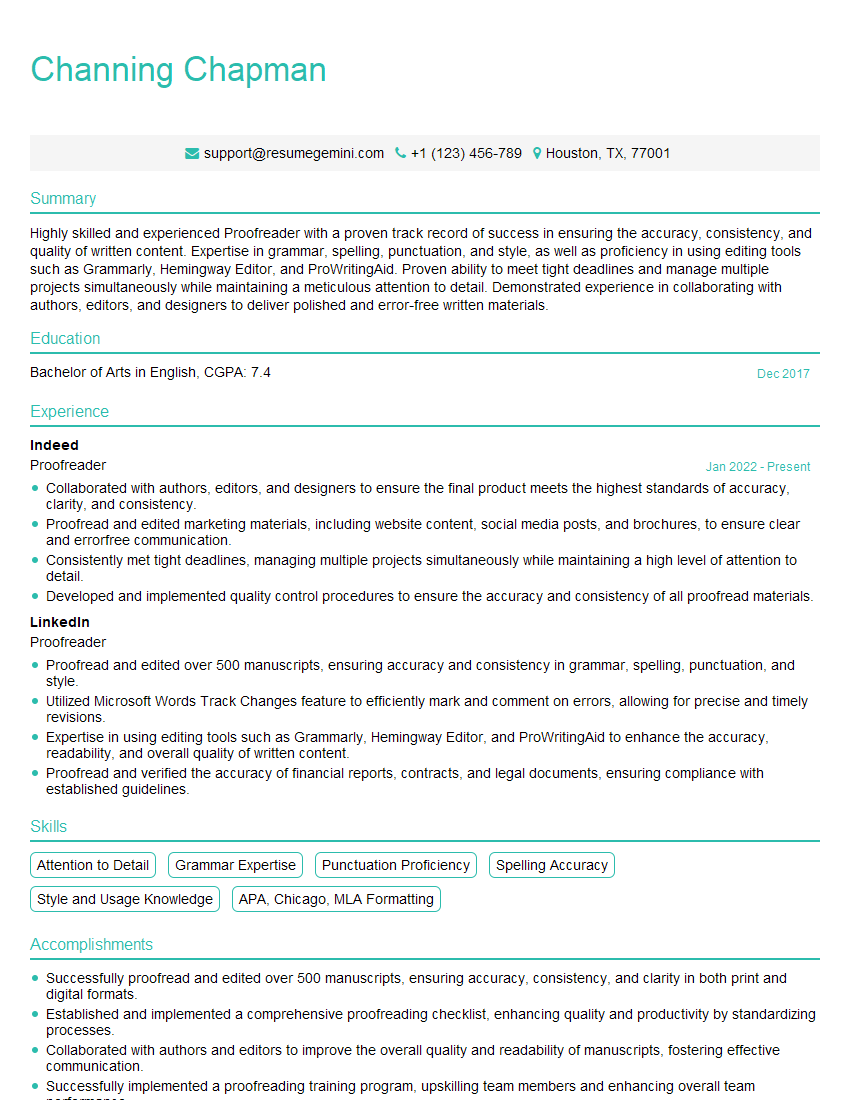

Mastering Proofing and Make-Ready Techniques is crucial for career advancement in the printing industry. A strong understanding of these techniques opens doors to higher-paying roles and more challenging projects. To enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills effectively. Examples of resumes tailored to Proofing and Make-Ready Techniques are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO