Are you ready to stand out in your next interview? Understanding and preparing for Inspection and Maintenance of Airport Infrastructure interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Inspection and Maintenance of Airport Infrastructure Interview

Q 1. Describe your experience with runway surface inspections.

Runway surface inspections are crucial for ensuring the safety and efficiency of air operations. My experience encompasses a wide range of techniques, from visual inspections using standardized forms and checklists to advanced technologies like laser profilometers and ground-penetrating radar. Visual inspections involve systematically traversing the runway, carefully examining the surface for any signs of distress, such as cracks, potholes, foreign object debris (FOD), and surface irregularities. I’m proficient in identifying the severity of these defects based on established standards like FAA guidelines. For example, a small crack might be deemed minor, requiring monitoring, while a large, transverse crack could necessitate immediate repair to prevent further damage and ensure safe aircraft operations. Advanced technologies provide quantitative data on pavement condition, allowing for more precise assessment and predictive maintenance planning.

During my time at [Previous Employer Name], I was responsible for leading inspections on a major international airport’s runways, covering over 100 acres of pavement. My team and I implemented a comprehensive inspection program, resulting in a 15% reduction in runway-related maintenance delays.

Q 2. Explain the different types of pavement used on airport runways and taxiways.

Airport runways and taxiways utilize several types of pavement, each chosen based on factors like traffic volume, climate, and soil conditions. Common types include:

- Portland Cement Concrete (PCC): Durable and high-strength, offering excellent load-bearing capacity and long lifespan. Think of it as the concrete you see on highways, but designed to withstand the extreme forces of aircraft landings and takeoffs.

- Asphaltic Concrete (AC): A more flexible and less expensive option than PCC, consisting of aggregates bound together by bitumen. It’s easier to repair but may require more frequent maintenance than PCC. Think of the common asphalt used on roads.

- Jointless Concrete Pavement (JCP): Designed to minimize cracking by using specialized construction techniques and materials. It’s particularly advantageous in areas with high temperature fluctuations and expansive soils.

The choice between these pavement types is a complex engineering decision involving cost-benefit analysis, considering factors like initial construction, long-term maintenance, and life cycle costs.

Q 3. How do you identify and assess pavement distress?

Identifying and assessing pavement distress requires a keen eye and understanding of common defects. My approach combines visual inspection with data from specialized equipment. Visual inspection involves looking for:

- Cracking: Longitudinal, transverse, alligator, and map cracking are all indicators of pavement weakening and potential failure.

- Rutting: Depression or deformation of the pavement surface, typically caused by heavy loads.

- Pot Holes/Ravelling: Loss of aggregate and binder material, creating holes in the pavement surface.

- Spalling: Breaking or chipping of the pavement surface.

- Bleeding/Shoving: Excess bitumen rising to the surface, creating a slippery film.

Severity assessment uses established standards and scales (e.g., the PCI – Pavement Condition Index). I’d use a scoring system to categorize the distress, factoring in size, severity, and distribution of the damage. This allows for prioritizing repairs and planning maintenance effectively. For instance, a small crack might receive a low score requiring monitoring, while a large pothole disrupting the runway’s surface requires immediate attention.

Q 4. What are the common causes of pavement deterioration?

Pavement deterioration results from a complex interplay of factors. Some common causes are:

- Environmental Factors: Temperature changes (freeze-thaw cycles), moisture ingress (water damage), and UV radiation degrade the pavement materials over time. For example, repeated freezing and thawing can cause cracking in concrete pavements.

- Traffic Loads: Heavy aircraft loads cause stress and fatigue in the pavement structure, accelerating deterioration. The sheer weight and repetitive loading significantly contribute to rutting and cracking.

- Poor Construction Practices: Inadequate compaction, improper material selection, or insufficient base preparation can lead to premature failure. This highlights the importance of strict quality control during construction.

- Chemical Attack: De-icing salts, fuels, and oils can chemically react with pavement materials, causing damage. Runways in colder climates face a significant challenge from de-icing salt application, necessitating careful maintenance.

Understanding these causes helps in implementing preventive maintenance strategies and selecting appropriate materials for construction and repairs.

Q 5. What are your methods for documenting pavement inspection findings?

My methods for documenting pavement inspection findings involve a combination of visual recording, detailed reports, and digital data capture. This ensures comprehensive and reliable records for future reference and decision-making. My process includes:

- Visual Documentation: High-resolution photographs and videos of pavement defects, clearly showing the location, size, and type of damage.

- Detailed Reports: Formal reports that include location data, GPS coordinates, defect descriptions (using standardized terminology), severity assessments, and recommended maintenance actions. These are often integrated into a comprehensive database for trend analysis.

- Digital Data Capture: Data from laser profilometers and other specialized equipment provide quantitative measurements of pavement roughness, rutting, and other parameters. This data is crucial for objective assessment and predictive modeling.

- GIS Integration: Geo-spatial data integration allows for the precise mapping of defects, enabling efficient planning of repairs and tracking progress over time.

This multi-faceted approach allows for effective communication, accurate record-keeping, and informed decision-making related to maintenance and repair planning.

Q 6. Explain the importance of regular airport lighting system inspections.

Regular inspections of the airport lighting system are paramount for ensuring safe and efficient air operations, especially during low-visibility conditions. These inspections cover all aspects of the system, from runway lights, taxiway lights, and approach lighting systems to signage and obstruction lights. The goal is to identify and address any malfunctions promptly, preventing accidents and disruptions.

For example, a faulty approach light could compromise a pilot’s ability to safely land an aircraft, especially in inclement weather. Similarly, malfunctioning taxiway lights could lead to collisions between aircraft on the ground. Inspections typically include checks for burned-out bulbs, damaged components, and inadequate illumination levels. Functional testing ensures proper operation of the system, including the intensity and timing of lights. Modern lighting systems often include automated monitoring systems, providing real-time alerts of any issues. Maintenance actions range from simple bulb replacements to major system overhauls. Comprehensive documentation is essential to ensure compliance with regulations and track the overall condition of the lighting system.

Q 7. How do you inspect and maintain airport drainage systems?

Airport drainage systems are crucial for preventing water accumulation on runways, taxiways, and aprons. Poor drainage can lead to pavement damage, hydroplaning hazards, and disruptions to air operations. My inspection and maintenance approach is multifaceted:

- Visual Inspection: Regular visual checks of all drainage components, including inlets, pipes, culverts, and outfalls. This involves assessing the condition of the infrastructure for any blockages, damage, or erosion.

- Flow Assessment: Assessing the capacity of the drainage system to handle water runoff, using flow measurements and inspections of water levels during rainfall events.

- Debris Removal: Regular cleaning of inlets and pipes to remove sediment, leaves, and other debris that can obstruct water flow. This often involves specialized equipment like vacuum trucks or high-pressure water jets.

- Structural Repairs: Addressing any damage to the drainage infrastructure, including cracks in pipes, damaged inlets, or erosion of embankments. This may require excavation, pipe replacement, or other repair works.

- Maintenance Schedule: Developing and adhering to a regular maintenance schedule that encompasses all aspects of the drainage system. This proactive approach minimizes the risk of failure and ensures optimal performance.

Maintaining a well-functioning drainage system is a crucial component of preventive maintenance, ensuring both the safety and smooth operation of the airport.

Q 8. Describe your experience with airport electrical system inspections.

My experience with airport electrical system inspections spans over a decade, encompassing various roles from junior inspector to lead supervisor. I’ve worked on both large international airports and smaller regional facilities. Inspections aren’t simply about visually checking wires; they require a deep understanding of electrical schematics, load calculations, and safety regulations. We use a combination of visual inspections, infrared thermography to detect overheating, and specialized testing equipment to verify proper grounding, insulation resistance, and circuit functionality. For example, at one airport, we discovered a critical grounding issue in the runway lighting system during a routine inspection using infrared thermography. This prevented a potential catastrophic failure and ensured the safety of aircraft landings. My work also includes assessing the condition of transformers, switchgear, and emergency power systems, ensuring their compliance with stringent FAA regulations and airport-specific requirements. We meticulously document all findings and create comprehensive reports, recommending necessary repairs or upgrades. The goal is not only to identify immediate problems, but also to predict potential future failures to prevent costly downtime and safety risks.

Q 9. What are the safety regulations related to airport infrastructure maintenance?

Safety regulations governing airport infrastructure maintenance are paramount and incredibly stringent, prioritizing the safety of both personnel and the traveling public. These regulations are multifaceted and involve several agencies, primarily the FAA (Federal Aviation Administration) in the US, but also encompass OSHA (Occupational Safety and Health Administration) standards for worker safety and local fire codes. Key aspects include:

- Lockout/Tagout Procedures: Strict adherence to lockout/tagout procedures is mandatory before performing any electrical or mechanical work to prevent accidental energization. We use clearly marked tags and lockout devices to ensure circuits and equipment are completely de-energized.

- Personal Protective Equipment (PPE): Appropriate PPE is essential and varies based on the task. This includes safety glasses, hard hats, high-visibility vests, arc flash suits (for electrical work), and hearing protection.

- Confined Space Entry: Many maintenance tasks require entering confined spaces, such as manholes or underground tunnels. These entries must be meticulously planned and overseen with appropriate permits, atmospheric monitoring, and rescue plans in place.

- Emergency Response Planning: Detailed emergency response plans must be in place for any potential incident, including fire, electrical shock, or equipment failure. This includes designated personnel, emergency communication systems, and clearly marked emergency exits and assembly points.

Failure to comply with these regulations can lead to serious injuries, operational disruptions, and significant fines. Safety is always the top priority.

Q 10. How do you handle emergency situations during maintenance?

Emergency situations during maintenance are handled with a pre-defined, well-rehearsed protocol. Our procedures emphasize rapid response and effective communication. For example, if a fire breaks out during an electrical system repair, the first step is to immediately evacuate personnel to a safe location, then activate the airport emergency response system (often a direct connection to the airport fire department). Simultaneously, we will use fire extinguishers to contain the fire until professional firefighters arrive, prioritizing the safety of personnel and the prevention of further damage. If there’s a power outage impacting critical systems, our established procedures immediately shift to backup systems. We have rigorous testing and maintenance schedules for backup power generators to ensure their reliability. Detailed incident reports are then filed, documenting the cause, actions taken, and any lessons learned to prevent future occurrences. Regular emergency drills help our team to quickly adapt to unexpected events.

Q 11. Explain the process for obtaining necessary permits and approvals for maintenance work.

Obtaining permits and approvals for airport maintenance work is a multi-step process requiring meticulous documentation and adherence to strict guidelines. It typically involves:

- Submitting a detailed work request: This outlines the scope of work, specific location, required materials, and the planned schedule.

- Airport Operations review and approval: The work request is reviewed by airport operations personnel to ensure it doesn’t interfere with normal airport operations or pose safety hazards.

- FAA Notification (if necessary): For certain types of work impacting critical safety systems, notification to the FAA might be required to receive their approval.

- Obtaining necessary permits: This could include permits for confined space entry, hot work (welding or cutting), or work near runways.

- Scheduling work: The work is scheduled to minimize disruption to airport operations. This often involves coordination with other maintenance teams and airport stakeholders.

Proper documentation is key to a smooth process. We utilize a computerized maintenance management system (CMMS) to track permit applications, approvals, and ensure all necessary documentation is readily available for audits.

Q 12. Describe your experience with airport security system inspections.

My experience with airport security system inspections focuses on ensuring the continued effectiveness and reliability of these critical systems. This involves detailed inspections of various security components, such as:

- CCTV systems: We verify camera functionality, image quality, recording capabilities, and network connectivity. This includes checking for blind spots and ensuring adequate coverage of critical areas.

- Access control systems: We inspect access card readers, door locks, and the overall access control system database. This includes testing access protocols and ensuring security breaches are minimized.

- Intruder detection systems: Inspection includes testing sensors, alarm systems, and monitoring central station connectivity. Regular testing verifies the effectiveness of these systems in identifying potential threats.

- Perimeter security: We review fencing, lighting, and any other physical security measures to ensure they are functioning properly and deter unauthorized access.

These inspections aren’t simply about checking that things are ‘on’; they involve rigorous testing and analysis to confirm effectiveness and identify any vulnerabilities. We utilize specialized testing equipment and follow standardized procedures to ensure comprehensive coverage.

Q 13. How do you ensure compliance with FAA regulations during maintenance?

Ensuring compliance with FAA regulations is an integral part of every maintenance activity. We use a multi-pronged approach to ensure adherence:

- Regular training: All maintenance personnel undergo regular training on the latest FAA regulations and best practices. This training covers both theoretical knowledge and practical application.

- Detailed documentation: We maintain meticulously detailed records of all maintenance activities, including inspections, repairs, and modifications. This documentation must be readily accessible for FAA audits.

- Standard Operating Procedures (SOPs): We follow strict SOPs for all maintenance tasks, ensuring consistency and compliance. These SOPs are regularly reviewed and updated to reflect any changes in FAA regulations or best practices.

- Quality control checks: We implement rigorous quality control checks at every stage of the maintenance process, ensuring work is performed to the highest standards.

- FAA audits: We actively participate in FAA audits to demonstrate compliance and address any identified deficiencies.

Compliance is not just a checkbox exercise; it’s a fundamental part of our commitment to safety and operational excellence. Regular proactive steps are crucial to maintaining our FAA certification.

Q 14. What are your methods for managing maintenance schedules and prioritizing tasks?

Managing maintenance schedules and prioritizing tasks requires a structured and proactive approach. We utilize a computerized maintenance management system (CMMS) that allows us to:

- Track equipment: The CMMS provides a central database of all airport infrastructure equipment, including its maintenance history and criticality.

- Schedule preventive maintenance: The system automatically generates preventive maintenance schedules based on manufacturer recommendations and historical data.

- Prioritize tasks: Tasks are prioritized based on factors such as criticality, potential safety risks, and operational impact. Emergency repairs always take precedence.

- Track work orders: The system tracks work orders from inception to completion, ensuring accountability and efficient resource allocation.

- Generate reports: The CMMS generates reports on maintenance activities, providing valuable data for performance analysis and improvement.

In addition to the CMMS, regular meetings with the maintenance team and airport operations personnel ensure we align our schedules with airport needs and identify any emerging issues.

Q 15. How do you manage a team of maintenance personnel?

Managing a maintenance team at an airport requires a blend of leadership, technical expertise, and strong communication. I approach it through a structured, collaborative model. First, I clearly define roles and responsibilities, ensuring each team member understands their contribution to the overall maintenance plan. This includes individual performance goals aligned with the airport’s operational needs. Regular one-on-one meetings allow me to offer personalized feedback, address concerns, and track progress. Secondly, I foster a culture of open communication and teamwork. This means encouraging feedback, actively listening to suggestions, and creating a safe space for discussion. I also utilize team-building activities to improve collaboration and morale. Finally, I believe in empowering my team. I delegate tasks appropriately, providing the necessary training and support to ensure success. This approach fosters ownership and professional growth within the team.

For example, during a recent runway resurfacing project, I delegated specific tasks – from scheduling equipment to managing materials – to different team members based on their expertise. Regular progress updates ensured the project stayed on schedule and within budget, showcasing the effectiveness of this delegation strategy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle conflicts or disagreements within the maintenance team?

Conflicts are inevitable in any team environment. My approach emphasizes proactive conflict resolution. I initiate open and honest conversations with the involved parties, encouraging them to express their perspectives clearly and respectfully. I act as a neutral facilitator, helping to identify the root cause of the disagreement. The focus is always on finding a solution that benefits the team and the airport’s operations, not on assigning blame. Sometimes, this involves mediation; other times, it might require setting clear expectations or adjusting work processes. For particularly persistent conflicts, I involve HR to ensure a fair and impartial resolution process.

For instance, a disagreement arose between two technicians about the best method for repairing a damaged taxiway light. Instead of imposing a solution, I facilitated a discussion where both technicians presented their approaches. We evaluated the pros and cons of each method, ultimately selecting a solution incorporating the best aspects of both, strengthening team collaboration.

Q 17. Describe your experience with budgeting and resource allocation for maintenance projects.

Budgeting and resource allocation are crucial for effective maintenance. My experience involves a three-step process: First, I carefully assess the airport’s infrastructure, identifying potential maintenance needs and prioritizing them based on safety, regulatory compliance, and operational impact. This typically involves a detailed inspection and analysis of current infrastructure condition. Second, I develop a comprehensive budget proposal, detailing the costs associated with each maintenance project, considering materials, labor, equipment rental, and potential unforeseen expenses. Third, I meticulously track expenses throughout the project, ensuring accountability and efficient resource utilization. I regularly monitor budget progress against projections and adjust accordingly, leveraging data analysis to identify areas for potential cost savings or improved efficiency.

In a recent project involving the rehabilitation of airport taxiways, I successfully allocated resources by prioritizing critical repairs first, while strategically phasing less urgent work to spread the financial burden effectively. This allowed us to complete the essential repairs on time and under budget, optimizing resource utilization.

Q 18. What software or tools do you use for managing maintenance records and data?

Efficient maintenance record-keeping is essential for safety and compliance. I have extensive experience with Computerized Maintenance Management Systems (CMMS). These software solutions allow for centralized storage and management of all maintenance-related data, including work orders, inspection reports, repair history, and inventory tracking. We use a CMMS that provides real-time dashboards showing the status of various maintenance tasks, allowing for proactive scheduling and efficient resource allocation. The system also generates comprehensive reports, which are vital for auditing and regulatory compliance. Some specific examples of CMMS software I’ve utilized include IBM Maximo and Fiix.

For example, our CMMS provides automated alerts for impending maintenance deadlines, allowing us to schedule preventative maintenance before issues escalate into more costly repairs.

Q 19. Explain your knowledge of different types of airport markings and signage.

Airport markings and signage are critical for safe and efficient aircraft operations. My knowledge encompasses various types, including:

- Runway markings: These include runway centerline markings, edge markings, threshold markings, and runway numbers, all crucial for aircraft navigation and landing.

- Taxiway markings: Taxiway centerlines, edges, holding positions, and signage direct aircraft movement on the ground.

- Approach and departure markings: Visual aids guiding pilots during approach and departure procedures.

- Signage: This includes various types of signs providing instructions and information to pilots and ground personnel, such as speed limits, taxi instructions, and emergency information.

Compliance with ICAO standards (International Civil Aviation Organization) is paramount, ensuring uniformity and clear communication across airports globally. Any deviation from these standards must be well-justified and approved by the relevant regulatory bodies.

Q 20. How do you ensure the accuracy of inspection reports?

Ensuring the accuracy of inspection reports is paramount for airport safety. My approach involves a multi-layered system. First, the inspectors are highly trained and certified, possessing a thorough understanding of inspection procedures and relevant regulations. Second, a standardized checklist is used for all inspections, promoting consistency and reducing the likelihood of errors. Third, regular quality control checks and audits are performed to ensure the accuracy and completeness of the reports. This includes random spot-checks and comparisons to previous inspections to identify any discrepancies. Finally, the reports undergo a final review before being submitted, ensuring that all findings are accurately documented and that any necessary corrective actions are clearly identified.

For example, we use digital inspection software, which captures photos and videos of the inspected areas, providing visual evidence to support the written report and further enhancing accuracy.

Q 21. Describe your experience with using specialized inspection equipment.

I have experience using a range of specialized inspection equipment. This includes:

- Ground Penetrating Radar (GPR): Used to detect subsurface anomalies such as voids or cracks in pavements.

- Infrared Thermography Cameras: Detect temperature variations, helping to identify potential problems like faulty wiring or insulation issues.

- Crack Measurement Gauges: Precisely measure the width and depth of cracks in runways and taxiways.

- Ultrasonic testing equipment: Detects internal flaws in concrete structures.

Regular calibration and maintenance of this equipment are crucial to ensure accuracy and reliable results. Proper training and certification are essential for operating and interpreting the data generated by this specialized equipment.

Q 22. What are the environmental considerations involved in airport maintenance?

Environmental considerations in airport maintenance are paramount, impacting not only the immediate surroundings but also the broader ecosystem. We must minimize our carbon footprint and adhere to strict regulations.

- Noise Pollution: Maintenance activities, especially those involving heavy machinery, generate significant noise. Mitigation strategies include using quieter equipment, scheduling noisy tasks during less sensitive hours, and implementing noise barriers. For example, using electric ground support equipment instead of diesel-powered ones significantly reduces noise pollution.

- Air Quality: Exhaust fumes from vehicles and equipment contribute to air pollution. Regular maintenance of this equipment, using low-emission fuels, and implementing effective ventilation systems are crucial. We regularly monitor air quality during maintenance operations and ensure compliance with emission standards.

- Water Management: Run-off from de-icing fluids used on aircraft during winter can contaminate water sources. Proper collection and treatment systems are essential. We use environmentally friendly de-icing fluids whenever possible and carefully manage the disposal of used fluids.

- Waste Management: Proper disposal of hazardous waste, such as used oil, batteries, and chemicals, is critical. We adhere strictly to waste management protocols and work with licensed disposal companies to ensure responsible handling.

- Wildlife Protection: Airports are habitats for various species. Maintenance activities should minimize disruption to their natural environment. We carefully plan work around nesting seasons and implement measures to protect wildlife during operations.

Failing to address these environmental concerns can lead to significant fines, reputational damage, and harm to the surrounding ecosystem. A comprehensive environmental management plan is essential for sustainable airport maintenance.

Q 23. Explain your knowledge of different types of airport ground support equipment.

Airport ground support equipment (GSE) is diverse and crucial for efficient airport operations. It can be broadly categorized as follows:

- Towing and Pushback Tractors: These powerful vehicles move aircraft from gates to runways and vice versa. Different sizes cater to various aircraft types. Regular inspections of their braking systems and steering mechanisms are vital for safety.

- Baggage Handling Equipment: This includes conveyor belts, baggage carts, and loading systems. Proper maintenance prevents breakdowns and ensures efficient baggage handling. We perform regular lubrication, belt alignment checks, and inspections of electrical components.

- Passenger Boarding Bridges (Jet Bridges): These connect aircraft to terminals, facilitating passenger boarding and disembarking. Regular inspections of hydraulic systems, safety sensors, and moving parts are essential.

- Aircraft Servicing Vehicles: These include fuel trucks, lavatory service units, and catering trucks. Regular maintenance ensures the safe and efficient delivery of services to aircraft. We implement strict safety protocols for handling fuel and other hazardous materials.

- De-icing Equipment: These vehicles spray de-icing fluids onto aircraft during winter conditions to prevent ice buildup. Proper maintenance and calibration of spray systems are crucial for effective de-icing and preventing environmental damage.

The specific types and quantity of GSE depend on the airport’s size and operations. Effective maintenance management ensures operational reliability, minimizes downtime, and ensures passenger and staff safety.

Q 24. How do you coordinate maintenance activities with airport operations?

Coordinating maintenance with airport operations requires meticulous planning and effective communication. Disruptions to ongoing operations must be minimized.

- Scheduling: We meticulously plan maintenance activities to avoid peak operating hours. This often involves working overnight or during periods of low air traffic.

- Communication: Open communication channels with air traffic control, airline ground handlers, and other stakeholders are vital. We provide timely updates on planned work and potential delays.

- Permitting: For major maintenance projects, we obtain necessary permits and approvals well in advance. This ensures compliance and minimizes potential disruptions.

- Risk Assessment: Prior to any maintenance, a thorough risk assessment is performed to identify potential hazards and develop mitigation strategies. This includes evaluating the impact on ongoing operations.

- Contingency Planning: We have contingency plans in place to handle unexpected delays or issues. This ensures minimal disruption to airport operations.

Effective coordination ensures safe and efficient maintenance without significantly impacting airport functionality. A collaborative approach involving all stakeholders is essential.

Q 25. How do you ensure the safety of maintenance personnel and the public during maintenance work?

Ensuring safety is our top priority. We implement a multi-layered approach:

- Safety Training: All maintenance personnel undergo regular safety training covering hazard identification, risk assessment, and the use of personal protective equipment (PPE).

- Permit-to-Work System: A formal permit-to-work system is used for high-risk tasks. This involves detailed risk assessments, safety briefings, and authorizations before commencing work.

- Lockout/Tagout Procedures: Strict lockout/tagout procedures are followed to prevent accidental activation of equipment during maintenance.

- Emergency Response Plan: A comprehensive emergency response plan is in place, including emergency communication protocols and evacuation procedures.

- Site Security: Secure work zones are established to protect maintenance personnel and the public from hazards. Signage, barriers, and traffic control measures are employed.

- PPE: Appropriate PPE, such as hard hats, safety glasses, high-visibility clothing, and hearing protection, is mandatory for all personnel.

Regular safety inspections and audits ensure our safety protocols are effective and up-to-date. A proactive approach to safety minimizes risks and ensures a safe working environment for both personnel and the public.

Q 26. Describe your experience with conducting risk assessments for maintenance tasks.

Risk assessment is a critical part of our process. We use a systematic approach based on industry best practices:

- Hazard Identification: We identify potential hazards associated with each maintenance task, considering factors such as equipment, environment, and personnel.

- Risk Evaluation: We assess the likelihood and severity of each identified hazard, using a standardized risk matrix. This helps prioritize risks.

- Risk Control Measures: We develop and implement control measures to mitigate identified risks. These can include engineering controls (e.g., guarding machinery), administrative controls (e.g., work permits), and personal protective equipment (PPE).

- Documentation: All risk assessments are documented and reviewed regularly. This ensures that risks are appropriately managed and updated as needed.

- Example: For a runway resurfacing project, we would assess risks associated with heavy machinery operation, working near active runways, and potential exposure to hazardous materials. Control measures would include traffic management plans, use of safety barriers, and provision of appropriate PPE.

Our risk assessments are tailored to each specific task, ensuring that appropriate safety measures are implemented to minimize the potential for accidents and injuries.

Q 27. How do you stay up-to-date on the latest advancements in airport infrastructure maintenance?

Staying up-to-date is crucial in this rapidly evolving field. We utilize various methods:

- Industry Publications and Journals: We regularly read industry publications and journals to stay informed about the latest advancements in airport infrastructure and maintenance techniques. Examples include Airport World and various aviation engineering journals.

- Conferences and Workshops: Attending industry conferences and workshops provides valuable insights into new technologies and best practices. Networking with peers helps share knowledge and experiences.

- Professional Organizations: Membership in professional organizations, such as the American Association of Airport Executives (AAAE), provides access to resources, training, and networking opportunities.

- Manufacturer Training: We participate in manufacturer training programs to learn about the latest equipment and maintenance procedures. This ensures we are proficient in using the most advanced technologies.

- Online Resources: We leverage online resources, such as webinars and online courses, to learn about new technologies and best practices.

Continuous learning ensures that we are equipped with the knowledge and skills to implement the most efficient and effective maintenance strategies.

Q 28. Describe your experience with using Computerized Maintenance Management Systems (CMMS).

Computerized Maintenance Management Systems (CMMS) are essential for efficient airport maintenance management. We utilize a CMMS to:

- Work Order Management: We use the CMMS to create, track, and manage work orders for all maintenance activities. This improves workflow and ensures accountability.

- Inventory Management: The CMMS helps us manage our inventory of spare parts and supplies, reducing downtime due to lack of materials.

- Preventative Maintenance Scheduling: The CMMS enables us to schedule and track preventative maintenance tasks, extending the lifespan of equipment and reducing unexpected failures. This includes setting up reminders and alerts for upcoming maintenance.

- Reporting and Analytics: The CMMS provides valuable reports and analytics on maintenance costs, equipment performance, and workforce productivity. This information aids in decision-making and resource allocation.

- Data Analysis: We use the data from the CMMS to identify trends and patterns in equipment failures, allowing us to implement proactive maintenance strategies and improve overall reliability.

Our CMMS is integral to our operations, improving efficiency, reducing costs, and enhancing safety. It provides a centralized platform for managing all aspects of airport infrastructure maintenance.

Key Topics to Learn for Inspection and Maintenance of Airport Infrastructure Interview

- Airport Pavement Management: Understanding pavement design, material properties, and deterioration mechanisms. Practical application includes assessing runway conditions for safety and identifying areas requiring repair or resurfacing.

- Airfield Lighting Systems: Knowledge of different lighting systems (e.g., runway lights, taxiway lights, approach lights), their maintenance, and troubleshooting common failures. Practical application involves performing inspections, identifying faulty components, and ensuring compliance with regulations.

- Drainage Systems: Understanding the design and function of airport drainage systems, including storm drains, culverts, and ditches. Practical application includes inspecting for blockages, erosion, and ensuring proper drainage to prevent water damage to infrastructure.

- Structural Inspection of Airport Buildings and Terminals: Familiarity with building materials, structural components, and common deterioration processes. Practical application includes identifying cracks, corrosion, and other structural deficiencies.

- Safety Regulations and Compliance: Thorough understanding of relevant safety regulations (FAA, ICAO) and best practices related to airport infrastructure maintenance. Practical application involves ensuring all maintenance activities adhere to safety protocols and regulatory requirements.

- Asset Management and Predictive Maintenance: Knowledge of asset management principles and the application of predictive maintenance techniques to optimize maintenance schedules and reduce downtime. Practical application includes using data analysis to predict potential failures and schedule preventative maintenance.

- Environmental Considerations: Understanding environmental regulations and their impact on airport infrastructure maintenance, including waste management and the use of environmentally friendly materials.

- Problem-solving and Reporting: Ability to effectively identify, analyze, and document maintenance issues, and to communicate findings clearly and concisely in reports.

Next Steps

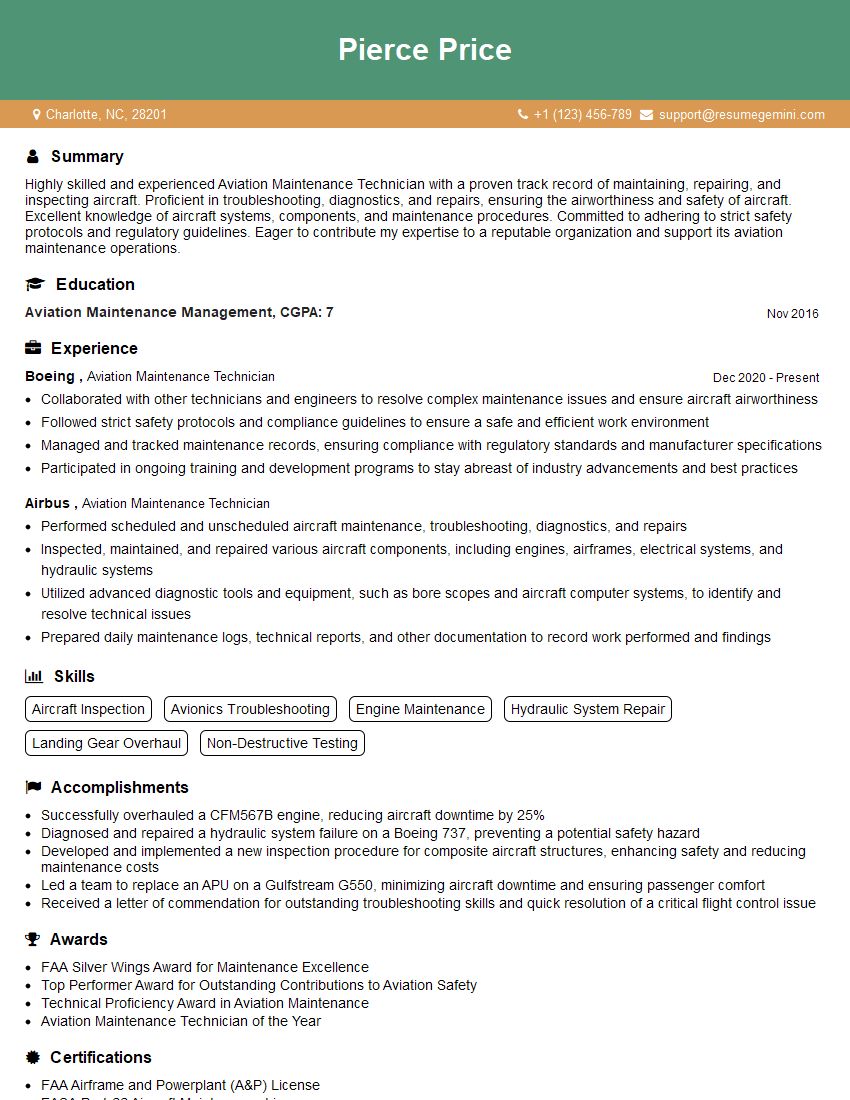

Mastering Inspection and Maintenance of Airport Infrastructure opens doors to a rewarding career with excellent growth potential within the aviation industry. Your expertise in ensuring the safe and efficient operation of airports is highly valued. To significantly improve your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Inspection and Maintenance of Airport Infrastructure to guide you in creating your own compelling application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO