The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Chemical Use and Safety interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Chemical Use and Safety Interview

Q 1. Describe your experience with SDS (Safety Data Sheets).

Safety Data Sheets (SDSs) are crucial documents providing comprehensive information about the hazards and safe handling of chemical products. My experience with SDSs encompasses their interpretation, utilization in risk assessments, and ensuring their accessibility to all personnel. I’ve used SDSs extensively to identify potential hazards like flammability, toxicity, and reactivity, allowing for the implementation of appropriate control measures. For instance, when working with a new solvent, I would first consult its SDS to understand its flash point (flammability), health hazards (toxicity), and recommended personal protective equipment (PPE). This ensures safe handling and prevents accidents. I’m also experienced in ensuring SDSs are updated, readily available, and easily understood by the workforce, using training and clear labeling systems.

In previous roles, I’ve been responsible for managing a library of SDSs, ensuring they are kept current and readily available in both physical and digital formats. I’ve also incorporated SDS information into training programs to educate workers on chemical hazards and safe practices.

Q 2. Explain the hierarchy of hazard controls.

The hierarchy of hazard controls prioritizes eliminating hazards, then substituting them, engineering controls, administrative controls, and finally, personal protective equipment (PPE). Think of it like a ladder of safety; you should always aim for the highest rung possible.

- Elimination: The best way – removing the hazard entirely. For example, replacing a hazardous solvent with a less toxic one.

- Substitution: Replacing a hazardous substance with a less hazardous alternative. For instance, switching from a highly volatile solvent to a less volatile one.

- Engineering Controls: Implementing physical changes to the work environment, such as ventilation systems to remove airborne hazards or enclosed systems to prevent spills.

- Administrative Controls: Changes to work practices, such as limiting exposure time, using standard operating procedures, providing training, and implementing safe work permits.

- Personal Protective Equipment (PPE): The last line of defense, providing personal protection such as gloves, respirators, and eye protection. While necessary, PPE is not a substitute for proper hazard controls at higher levels in the hierarchy.

For example, if a process generates harmful fumes, the ideal approach would be to eliminate the process altogether or substitute it with a fume-free alternative. If that isn’t feasible, engineering controls like a ventilation system would be the next step. Administrative controls like limiting exposure time would follow, and finally, respirators would be used as a last resort.

Q 3. How do you conduct a risk assessment for chemical handling?

A risk assessment for chemical handling involves a systematic process to identify potential hazards associated with the chemicals used and evaluate the likelihood and severity of potential harm. It follows a structured approach:

- Identify the hazards: This involves reviewing SDSs, understanding chemical properties, and considering potential exposure routes (inhalation, ingestion, skin contact).

- Identify who might be harmed and how: This step considers the workers involved, visitors, and the surrounding environment. Identify potential routes of exposure.

- Evaluate the risks and prioritize: Assessing the likelihood of exposure and the severity of potential harm. This often involves a risk matrix considering the probability and severity of incidents.

- Record the findings: Documenting the assessment, including identified hazards, risk levels, and control measures. This ensures accountability and allows for future review and updates.

- Review and update: Regularly reviewing and updating the risk assessment as new information becomes available or the process changes.

Example: In a laboratory setting, handling concentrated acids would involve identifying hazards (corrosiveness, potential for burns), identifying who might be harmed (lab personnel), evaluating the risks (high likelihood of splashes, severe burns), implementing controls (fume hoods, proper PPE, emergency eyewash stations), recording the findings, and regularly reviewing the assessment to ensure effectiveness.

Q 4. What are the key regulations concerning chemical storage and disposal?

Regulations concerning chemical storage and disposal vary by region but generally focus on preventing environmental contamination, protecting human health, and ensuring safe handling. Key aspects often include:

- Storage: Chemicals must be stored according to their properties (flammability, reactivity, toxicity). Incompatible chemicals should be segregated to prevent reactions. Proper labeling and clear signage are crucial. Storage areas may require specific features, such as ventilation, fire suppression systems, and spill containment.

- Disposal: Disposal methods depend on the chemical’s characteristics and local regulations. Many jurisdictions have specific regulations for hazardous waste disposal, requiring proper labeling, packaging, and transportation to licensed facilities. Improper disposal can lead to severe fines and environmental damage.

For example, in the US, OSHA and EPA regulations govern chemical storage and disposal, often requiring detailed record-keeping, employee training, and compliance with specific standards for hazardous waste management. Similar regulations exist in other countries, often based on international guidelines like those from the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

Q 5. Describe your experience with emergency response procedures involving chemical spills.

My experience with emergency response procedures for chemical spills involves both preventative measures and reactive actions. I’ve participated in training programs covering spill response plans, including knowing what to do before, during, and after a spill. This encompasses:

- Pre-spill preparedness: Developing and regularly practicing emergency response plans, ensuring readily available spill kits containing appropriate absorbents, and designating trained personnel.

- Spill response: Containing the spill to prevent further spread, using proper PPE, notifying appropriate authorities, and following established procedures for cleanup and waste disposal. This usually involves evacuation of the area if necessary.

- Post-spill actions: Documenting the incident, evaluating the effectiveness of the response, and implementing corrective actions to prevent future occurrences.

In a past incident involving a small acid spill, I quickly contained the spill using spill kits, notified the emergency response team, and evacuated the area. We used neutralization procedures, followed by proper disposal of the contaminated materials according to established protocols. This demonstrates the importance of training, well-defined procedures, and access to appropriate resources for effective spill management.

Q 6. Explain the difference between acute and chronic toxicity.

Acute toxicity refers to the adverse effects occurring relatively soon after exposure to a chemical, typically within a short time frame (hours to days). Chronic toxicity, on the other hand, refers to adverse effects that manifest over a longer period, often after repeated or prolonged exposure (weeks, months, or years).

Acute toxicity examples include immediate skin irritation after contact with a strong acid or respiratory distress following inhalation of a toxic gas. Chronic toxicity examples include liver damage after long-term exposure to certain solvents or the development of cancer after prolonged exposure to carcinogens. The difference lies primarily in the timing and duration of exposure and the subsequent onset of effects. Acute effects are typically immediate and severe, while chronic effects develop gradually and may be subtle initially.

Q 7. How do you ensure compliance with OSHA regulations (or relevant regional regulations)?

Ensuring compliance with OSHA (or relevant regional) regulations requires a multifaceted approach that incorporates training, documentation, and ongoing monitoring.

- Training: Providing comprehensive training to all personnel involved in chemical handling on hazard identification, safe practices, emergency response procedures, and relevant regulations.

- Documentation: Maintaining detailed records of chemical inventories, SDSs, risk assessments, training records, and any incidents. This ensures traceability and accountability.

- Monitoring and Audits: Regularly monitoring work practices, conducting safety inspections, and performing internal audits to identify and correct any non-compliance issues. This can also involve using monitoring equipment to measure air quality or employee exposure levels.

- Hazard Communication Program: Implementing a comprehensive hazard communication program that provides workers with information about chemical hazards and how to protect themselves. This typically includes labeling, SDSs, and employee training.

I have experience with implementing and maintaining such programs, ensuring compliance with regulations, and fostering a proactive safety culture within the workplace. This includes staying current with changes in regulations and best practices to ensure continued compliance.

Q 8. What are the different types of personal protective equipment (PPE) used in chemical handling?

Personal Protective Equipment (PPE) is crucial for safeguarding individuals from chemical hazards. The type of PPE required depends entirely on the specific chemicals being handled and the potential risks involved. It’s never a one-size-fits-all approach.

- Respiratory Protection: This includes respirators, ranging from simple dust masks to sophisticated air-purifying respirators and supplied-air respirators. The choice depends on the airborne concentration and toxicity of the chemical. For example, a painter might use a simple dust mask for low-level dust, whereas a worker handling highly volatile organic compounds would need a full-face respirator with appropriate cartridges.

- Eye Protection: Safety glasses, goggles, and face shields protect the eyes from splashes, fumes, and dust. Chemical splash goggles are a must when handling corrosive or irritating chemicals. Imagine the devastating consequences of a corrosive chemical splashing into someone’s eyes without proper protection.

- Skin Protection: Gloves are essential, and the material must be compatible with the chemical being handled. Different glove materials offer varying degrees of resistance to different chemicals. For example, nitrile gloves are commonly used for many chemicals, but neoprene or butyl rubber might be necessary for highly aggressive substances. Likewise, protective clothing like lab coats, aprons, and coveralls offer additional protection for the skin.

- Foot Protection: Chemical-resistant boots protect the feet from spills and splashes. Steel-toe boots might also be required depending on the work environment.

Remember, proper training on the correct use and limitations of PPE is paramount. A seemingly protective glove may be useless if improperly worn or if it’s compromised.

Q 9. Explain the concept of Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon system designed to bring consistency and clarity to the classification and communication of chemical hazards. Before GHS, labeling and hazard communication varied widely across countries, leading to confusion and potential safety risks. GHS aims to standardize this, improving safety worldwide.

The system uses standardized hazard pictograms (symbols), signal words (danger or warning), hazard statements (describing the nature of the hazard), and precautionary statements (describing how to minimize the risk). This information is prominently displayed on chemical labels and Safety Data Sheets (SDS).

For example, a flammable chemical might have a flame pictogram, the signal word ‘Danger’, a hazard statement like ‘Highly flammable liquid and vapor’, and precautionary statements such as ‘Keep away from heat/sparks/open flames/hot surfaces’.

This harmonization simplifies communication regarding chemical hazards across international borders, greatly improving worker safety and facilitating better risk management in both production and usage.

Q 10. How do you handle incompatible chemicals?

Incompatible chemicals are substances that react dangerously when mixed, potentially creating heat, fire, explosions, or toxic gases. Handling them requires extreme caution and specific procedures. The key is to prevent contact between them.

- Segregation: Store incompatible chemicals in separate areas, using appropriate cabinets or storage systems. Consider factors like the reactivity of the chemicals and their physical states (solid, liquid, gas).

- Labeling: Clearly label all containers with the chemical name, hazards, and any special handling requirements. This reduces the chance of accidental mixing.

- Material Compatibility: Ensure that all containers and equipment (e.g., pumps, transfer lines) are compatible with the chemicals being handled. Some chemicals can degrade or react with certain materials.

- Personal Protective Equipment (PPE): Always wear the appropriate PPE for handling the specific chemicals. This often means using multiple layers of protection if handling multiple substances.

- Emergency Procedures: Develop and regularly practice emergency procedures in case of accidental mixing or spills.

A classic example of incompatible chemicals is mixing strong acids (like sulfuric acid) and strong bases (like sodium hydroxide). This reaction produces a significant amount of heat, potentially causing burns or even boiling over.

Q 11. Describe your experience with chemical waste management and disposal.

Chemical waste management is a critical aspect of chemical safety. My experience includes developing and implementing waste management plans, complying with all relevant regulations, and working directly with waste disposal companies.

The process typically involves:

- Waste Characterization: Identifying the chemical composition and hazards of the waste.

- Segregation: Separating incompatible waste streams to prevent reactions.

- Containerization: Using appropriate containers to prevent spills and leaks.

- Labeling: Clearly labeling containers with the contents and hazards.

- Disposal: Engaging licensed hazardous waste disposal companies to ensure proper and environmentally sound disposal, following all relevant local, state, and federal regulations.

- Record Keeping: Maintaining detailed records of waste generation, handling, and disposal.

I have experience with various waste streams, including solvents, acids, bases, heavy metals, and other hazardous chemicals. Proper management minimizes environmental impact and protects human health.

Q 12. Explain the process of conducting a chemical inventory.

A chemical inventory is a detailed list of all chemicals present in a facility. It’s a fundamental part of chemical safety management. The process involves a systematic approach to locate, identify, and quantify each chemical.

- Physical Inventory: Walk through the facility, physically checking each storage location and recording the chemical name, quantity, location, and date of inventory.

- Data Collection: Gather information from purchase orders, receiving documents, and Material Safety Data Sheets (MSDS).

- Database Management: Organize the inventory data in a database or spreadsheet for easy access and tracking.

- Regular Updates: The inventory should be updated regularly to account for new chemicals, used chemicals, and disposal of chemicals.

- Verification: Periodically verify the accuracy of the inventory.

The inventory helps to identify potential hazards, track chemical usage, and ensure compliance with regulations. It is a critical input for risk assessments and emergency response planning. Regular updates are vital to ensure the data reflects current conditions.

Q 13. How do you identify and mitigate potential hazards associated with chemical use?

Identifying and mitigating potential hazards associated with chemical use is a proactive process. It requires a multi-faceted approach.

- Hazard Identification: Using Safety Data Sheets (SDS) and other resources to understand the physical, health, and environmental hazards of each chemical.

- Risk Assessment: Evaluating the likelihood and severity of potential incidents, considering factors like the amount of chemical used, the frequency of handling, and the effectiveness of existing controls.

- Engineering Controls: Implementing engineering controls to minimize exposure, such as enclosed systems, ventilation, and process modifications. These controls physically remove or reduce the hazard.

- Administrative Controls: Developing standard operating procedures (SOPs), providing training to personnel, establishing emergency response plans, and implementing safety programs. These are focused on managing worker behavior and activities.

- Personal Protective Equipment (PPE): Providing and ensuring proper use of PPE as a last line of defense.

For example, in a laboratory setting, a risk assessment might identify the risk of chemical splashes. Mitigation strategies could involve using a fume hood, providing eye protection, and having a spill kit readily available.

Q 14. What are your methods for preventing chemical exposure incidents?

Preventing chemical exposure incidents requires a layered approach that combines engineering controls, administrative controls, and PPE. It’s about creating a safety culture.

- Engineering Controls: Implementing systems to eliminate or minimize exposure, such as enclosed systems, local exhaust ventilation, and automated processes.

- Administrative Controls: Developing and enforcing standard operating procedures (SOPs), providing comprehensive safety training, implementing a robust permit-to-work system for hazardous tasks, and establishing regular safety audits and inspections.

- Personal Protective Equipment (PPE): Ensuring employees are trained on the selection, proper use, maintenance, and limitations of the appropriate PPE for each task. Regular inspections of PPE are vital.

- Emergency Response Planning: Developing and regularly practicing emergency response plans for chemical spills, leaks, or fires, ensuring readily accessible emergency equipment and trained personnel.

- Communication and Training: Open communication about safety concerns and providing comprehensive safety training to all employees involved in chemical handling.

For instance, a company might implement a strict lockout/tagout procedure for equipment maintenance to prevent accidental exposure to chemicals during repair or cleaning. Regular safety training and communication keep safety at the forefront.

Q 15. Describe your experience with incident investigation and reporting.

Incident investigation and reporting are crucial for preventing future accidents. My approach involves a systematic process, starting with securing the scene and ensuring the safety of all personnel. This is followed by a thorough fact-finding process, gathering evidence like witness statements, equipment logs, and chemical analysis reports. I utilize root cause analysis techniques like the ‘5 Whys’ to delve deeper than surface-level observations and identify the underlying causes of the incident. For example, in one case involving a chemical spill, initial investigation showed human error in handling. However, the ‘5 Whys’ revealed inadequate training and a lack of clear safety protocols as the root causes. The final report documents findings, contributing factors, and recommendations for corrective actions and preventative measures. This report is then used to improve safety procedures, update training materials, and enhance overall chemical safety management within the organization. I also ensure compliance with all relevant regulations and reporting requirements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper training for employees handling chemicals?

Ensuring proper chemical handling training is paramount. My approach is multifaceted and includes a combination of classroom instruction, hands-on practical training, and regular refresher courses. Classroom instruction covers relevant regulations (like OSHA’s HAZCOM standard), chemical properties, hazard identification, safe handling procedures, and emergency response protocols. Hands-on training allows employees to practice safe handling techniques using mock scenarios in a controlled environment. We emphasize the practical application of the learned knowledge, addressing potential challenges and questions directly. Regular refresher courses reinforce training and keep employees updated on changes in procedures or regulations. For instance, we might conduct a scenario-based exercise simulating a chemical spill, prompting employees to demonstrate their understanding of spill response procedures and the use of PPE. Regular competency assessments are also implemented to verify the employees’ understanding and skill level.

Q 17. Explain your understanding of the various chemical hazard classes.

Chemical hazard classes categorize chemicals based on their inherent dangers. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized framework. Key hazard classes include:

- Flammable solids: Substances that can easily ignite.

- Oxidizers: Substances that readily release oxygen and enhance combustion.

- Toxic substances: Chemicals that can cause death or serious health effects through ingestion, inhalation, or skin contact.

- Corrosive substances: Chemicals that destroy living tissue through chemical reaction.

- Irritants: Substances that cause inflammation or irritation upon contact.

- Carcinogens: Substances capable of causing cancer.

- Sensitizers: Substances that cause allergic reactions upon repeated exposure.

- Reproductive toxins: Chemicals that can harm reproductive organs or impair fertility.

Understanding these classes is critical for selecting appropriate PPE, handling procedures, and storage requirements. For example, a corrosive substance requires specialized protective clothing and handling with extreme caution, unlike a less hazardous irritant.

Q 18. Describe your experience with respiratory protection programs.

Respiratory protection programs are crucial when dealing with airborne hazards. My experience encompasses developing and implementing comprehensive programs that include:

- Hazard assessment: Identifying airborne hazards and assessing the risk level.

- Respirator selection: Choosing appropriate respirators based on the specific hazard (e.g., air-purifying respirators for specific contaminants or supplied-air respirators for oxygen-deficient environments).

- Fit testing: Ensuring a proper seal to prevent leakage.

- Training: Educating employees on respirator use, maintenance, and limitations.

- Medical evaluations: Ensuring employees are medically fit to wear respirators.

- Record keeping: Maintaining detailed records of training, fit testing, and medical evaluations.

In one instance, we implemented a comprehensive respiratory protection program for workers exposed to silica dust, resulting in a significant reduction in respiratory illnesses.

Q 19. How do you select appropriate PPE for specific chemical hazards?

Selecting appropriate PPE is based on a thorough hazard assessment. This involves identifying the specific chemicals involved, their physical and chemical properties, and the potential exposure routes (inhalation, skin contact, ingestion). We then select PPE that offers sufficient protection against these hazards. For example:

- Acids: Require chemical-resistant gloves, aprons, and eye protection.

- Flammable liquids: Often necessitate flame-resistant clothing and gloves.

- Toxic substances: May require respirators and protective suits, depending on the toxicity level.

The selection process follows a hierarchy of controls, prioritizing engineering controls (e.g., ventilation) and administrative controls (e.g., work practices) before resorting to PPE as the last line of defense. Training on correct PPE use and maintenance is essential to ensure its effectiveness.

Q 20. Explain your knowledge of confined space entry procedures involving chemicals.

Confined space entry involving chemicals demands a stringent, multi-step process. This includes:

- Permit-required confined space program: Establishing a formal program outlining procedures and responsibilities.

- Atmospheric monitoring: Testing the atmosphere for oxygen deficiency, flammability, and toxic substances before entry.

- Ventilation: Ensuring adequate ventilation to remove hazardous atmospheres.

- Lockout/Tagout: Isolating energy sources to prevent accidental activation of equipment.

- Rescue plan: Having a well-defined rescue plan in place.

- Entry and exit procedures: Establishing clear procedures for entry, monitoring, and exit from the confined space.

- PPE selection: Utilizing appropriate PPE based on the identified hazards.

Failure to follow these procedures can lead to serious injury or death. Each step must be meticulously documented.

Q 21. What are your experiences with Lockout/Tagout procedures?

Lockout/Tagout (LOTO) procedures are essential for preventing accidental energy release during maintenance or repair work. My experience involves developing and implementing LOTO programs that comply with OSHA standards. This includes:

- Energy isolation: Identifying and isolating all energy sources (electrical, mechanical, hydraulic, pneumatic).

- Lockout devices: Using appropriate lockout devices to prevent the re-energization of equipment.

- Tagout devices: Utilizing tags to provide clear warnings.

- Training: Providing thorough training to employees on LOTO procedures.

- Audits: Regularly auditing LOTO procedures to ensure compliance.

We use a step-by-step checklist to ensure each step is consistently followed, reducing the risk of accidental starts and ensuring worker safety. Ignoring LOTO procedures can lead to serious injuries or fatalities.

Q 22. Describe your experience with conducting safety audits.

Conducting safety audits involves a systematic evaluation of chemical handling practices to identify potential hazards and ensure compliance with regulations. My approach is thorough and multi-faceted, beginning with a review of existing Safety Data Sheets (SDS) for all chemicals used. This is followed by a physical inspection of the workspace, including storage areas, laboratories, and any areas where chemicals are handled or processed. I look for things like proper labeling, containment procedures, emergency equipment accessibility (eyewash stations, spill kits), and adherence to established standard operating procedures (SOPs).

During the audit, I interview personnel to assess their understanding of safety protocols and their competency in handling hazardous materials. I also observe their work practices to identify any unsafe behaviors. For example, I might witness improper disposal of waste chemicals, inadequate personal protective equipment (PPE) use, or failure to follow proper ventilation procedures. I document all findings, both positive and negative, and provide a comprehensive report with recommendations for improvement, prioritizing critical hazards and offering specific corrective actions.

A recent example involved auditing a pharmaceutical manufacturing facility. I discovered a deficiency in their spill response plan, particularly concerning a highly reactive chemical. My report led to immediate implementation of improved containment procedures and enhanced employee training, mitigating a significant potential risk.

Q 23. How do you implement and maintain a chemical management program?

Implementing and maintaining a robust chemical management program requires a structured approach encompassing several key areas. First, a comprehensive inventory of all chemicals used, including SDSs, is crucial. This allows for accurate risk assessment. Secondly, clearly defined Standard Operating Procedures (SOPs) for handling, storage, and disposal of each chemical must be developed and implemented. This includes proper labeling, segregation of incompatible chemicals, and use of appropriate PPE.

Regular training for all personnel involved in chemical handling is essential. Training should cover hazard identification, risk mitigation, emergency procedures, and proper use of equipment. The program should also incorporate a system for tracking chemical usage, ensuring compliance with inventory control and waste management regulations. Periodic safety audits, as discussed earlier, are essential to identify areas for improvement and to ensure continued compliance. Finally, the program needs a system for recording and managing incidents, learning from mistakes, and refining safety procedures.

Imagine a small laboratory. A well-managed program would involve a clearly marked chemical storage area with appropriate labeling, a readily available SDS binder, regularly scheduled training on safe handling of acids and bases, and a designated area for safe disposal of chemical waste. Regular inspections and a system for reporting any incidents complete the picture.

Q 24. Explain your understanding of different types of chemical reactions and their safety implications.

Chemical reactions, broadly classified into several types, each presents unique safety implications. For example, exothermic reactions, which release heat, can cause fires or explosions if not properly controlled. Examples include the reaction of sodium metal with water or the combustion of organic solvents. Safety precautions involve careful control of reaction conditions, using appropriate cooling systems, and ensuring adequate ventilation.

Endothermic reactions absorb heat and are generally less hazardous but still require attention. For instance, the dissolution of certain salts can cause a significant drop in temperature, posing a risk of frostbite. Redox reactions, involving electron transfer, can be highly reactive and may lead to ignition or explosions if oxidizers and reducers are mixed inappropriately. Examples include reactions involving strong oxidizing agents like potassium permanganate or strong reducing agents like lithium aluminum hydride.

Acid-base reactions can be exothermic and produce corrosive byproducts. Improper handling of strong acids or bases can cause severe burns or injuries. Finally, polymerization reactions can be highly exothermic and, if uncontrolled, can lead to runaway reactions resulting in explosions. Always refer to the SDS for specific safety information relevant to the particular reaction and chemicals involved.

Q 25. How do you ensure the accuracy of chemical measurements and calculations?

Accuracy in chemical measurements and calculations is paramount in ensuring safety and experimental reproducibility. This begins with using calibrated equipment like analytical balances, volumetric glassware, and pipettes. Regular calibration and maintenance of this equipment are crucial to maintain accuracy. Proper techniques in using these instruments are essential; for instance, using the correct technique for weighing chemicals, ensuring proper meniscus reading in volumetric glassware, and avoiding parallax errors.

Furthermore, meticulous record-keeping is crucial. All measurements and calculations should be clearly documented, including units and significant figures. Using appropriate calculation methods, including error propagation techniques, ensures the reliability of results. For complex calculations, specialized software can help avoid manual errors. Regularly checking calculations against known standards or expected results is also helpful. In a real-world example, an inaccurate measurement of a highly reactive chemical in a synthesis could lead to a dangerous deviation from the intended reaction stoichiometry, potentially causing an explosion.

Q 26. Describe your experience with using various laboratory equipment safely.

My experience with laboratory equipment encompasses a wide range of instruments, from basic glassware like beakers and flasks to more sophisticated equipment like centrifuges, spectrophotometers, and rotary evaporators. Safe operation of each piece requires specific knowledge and adherence to SOPs. Before using any equipment, I always ensure that I have received appropriate training and understand the operating procedures and safety precautions. This includes understanding any potential hazards associated with the equipment, like electrical shocks, moving parts, or exposure to hazardous materials.

For example, when using a centrifuge, I ensure that the tubes are properly balanced to prevent vibrations and potential breakage. When working with heating equipment, I use appropriate heat-resistant gloves and safety glasses to prevent burns. I always follow the manufacturer’s instructions and safety guidelines, and I regularly inspect equipment for any signs of damage or malfunction. Furthermore, understanding the principles behind equipment operation helps in preventative maintenance and troubleshooting.

Q 27. How do you communicate chemical safety information to different audiences?

Communicating chemical safety information effectively requires tailoring the message to the audience’s level of understanding and their specific needs. For scientists and laboratory personnel, communication can involve detailed discussions of hazards, risk assessments, and specific safety procedures. This often involves technical jargon and detailed protocols. For non-scientific personnel, such as janitorial staff or security personnel, communication needs to be simpler and more focused on the potential hazards and basic safety procedures.

Visual aids such as labels, pictograms, and safety signs are particularly effective in communicating hazards broadly. Training programs, incorporating both written materials and hands-on demonstrations, are crucial for imparting practical knowledge. Furthermore, emergency response plans should be clearly communicated and regularly practiced. For instance, a safety training program for laboratory personnel might include detailed discussions of SDSs and proper use of PPE, whereas a safety briefing for building maintenance staff might focus on recognizing chemical hazard labels and how to respond to spills.

Q 28. Explain your familiarity with different types of ventilation systems and their applications in chemical handling.

Ventilation systems play a critical role in maintaining a safe working environment when handling chemicals. Different types of systems cater to various needs. Local exhaust ventilation (LEV) systems, such as fume hoods and benchtop extractors, remove hazardous fumes and vapors directly at their source, providing the most effective protection. These are essential for working with volatile or toxic chemicals.

General dilution ventilation relies on air exchange to dilute and disperse airborne contaminants throughout the entire workspace. While less effective than LEV for localized hazards, it’s important for overall air quality. Specialized ventilation systems, such as those used in cleanrooms or specialized containment facilities, are designed to maintain extremely high levels of air purity. The choice of ventilation system depends on the specific chemicals being handled, the concentration of airborne contaminants, and the potential for exposure.

For example, a laboratory working with volatile organic solvents would need LEV systems like fume hoods to protect the user from inhalation exposure, while a larger industrial facility might use a combination of LEV and general dilution ventilation systems to manage air quality. Proper maintenance and regular testing of all ventilation systems are crucial to ensure their effectiveness.

Key Topics to Learn for Chemical Use and Safety Interview

- Hazard Communication: Understand OSHA’s Hazard Communication Standard (HCS), including the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), Safety Data Sheets (SDS), and proper labeling procedures. Consider practical applications like interpreting SDS information and implementing control measures based on hazard classifications.

- Personal Protective Equipment (PPE): Learn about selecting, using, and maintaining appropriate PPE (e.g., respirators, gloves, eye protection) for various chemical hazards. Think about scenarios requiring different PPE combinations and the limitations of each type.

- Risk Assessment and Control: Master the process of identifying, evaluating, and controlling chemical hazards in the workplace. This includes understanding different control hierarchies (elimination, substitution, engineering controls, administrative controls, PPE) and their practical applications.

- Spill Response and Emergency Procedures: Familiarize yourself with procedures for handling chemical spills, including containment, cleanup, and reporting. Consider the specific protocols for different types of chemicals and the importance of emergency response training.

- Waste Management: Understand regulations and best practices for the proper handling, storage, and disposal of chemical waste. This includes identifying different waste streams and complying with relevant environmental regulations.

- Regulatory Compliance: Be familiar with relevant regulations and standards (e.g., OSHA, EPA) related to chemical use and safety. Consider how these regulations impact workplace practices and the consequences of non-compliance.

- Chemical Reactivity and Compatibility: Understand the principles of chemical reactivity and the importance of storing incompatible chemicals separately to prevent dangerous reactions. Explore practical examples of incompatible chemical pairings.

Next Steps

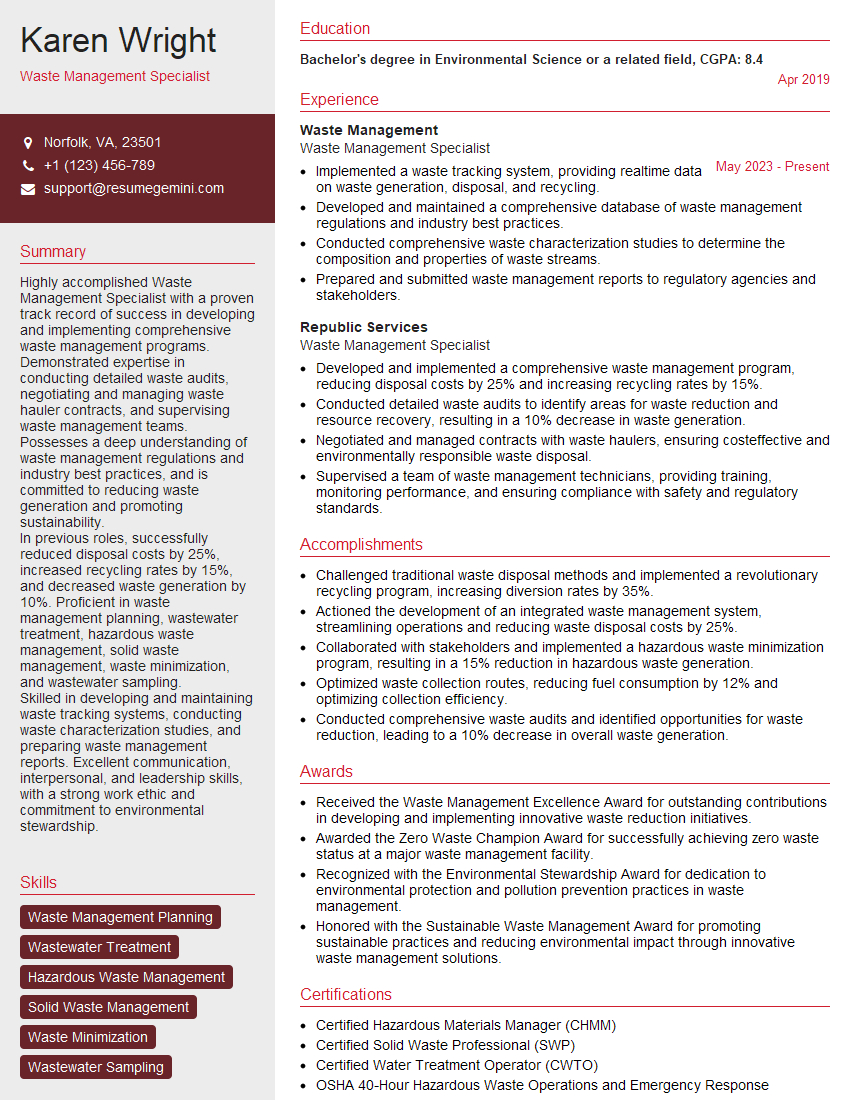

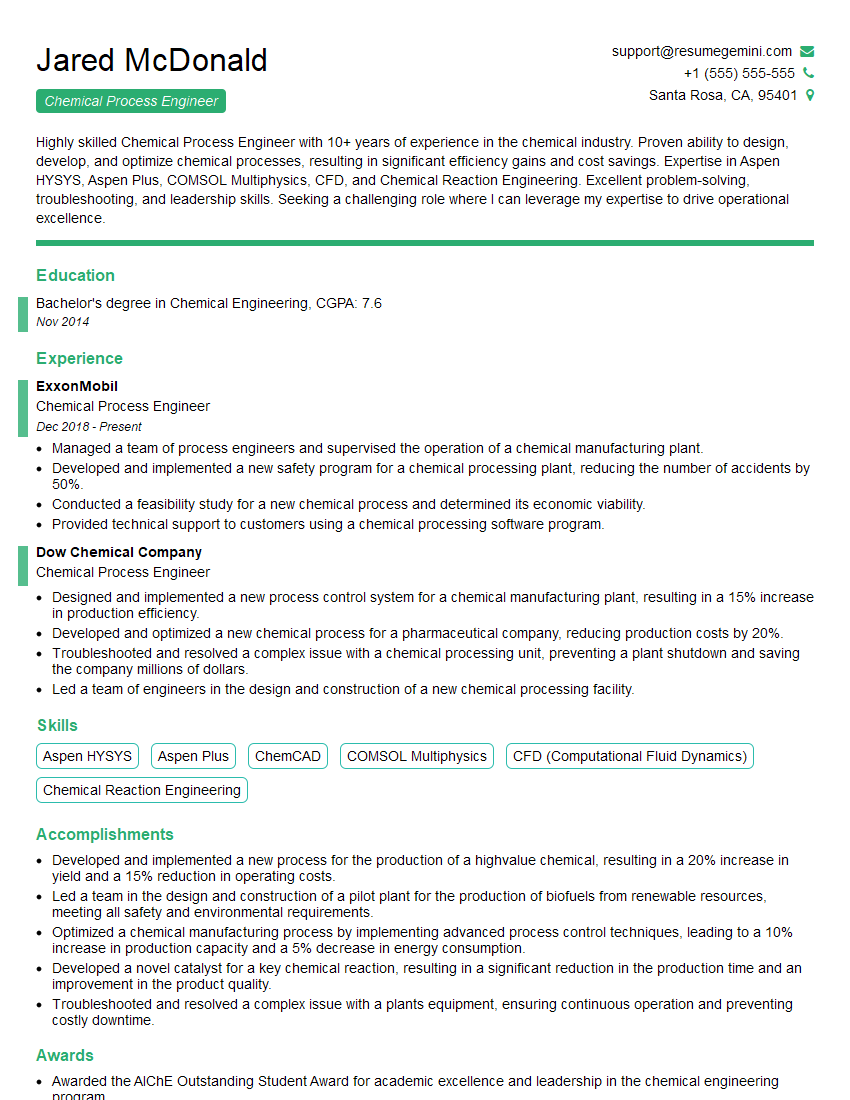

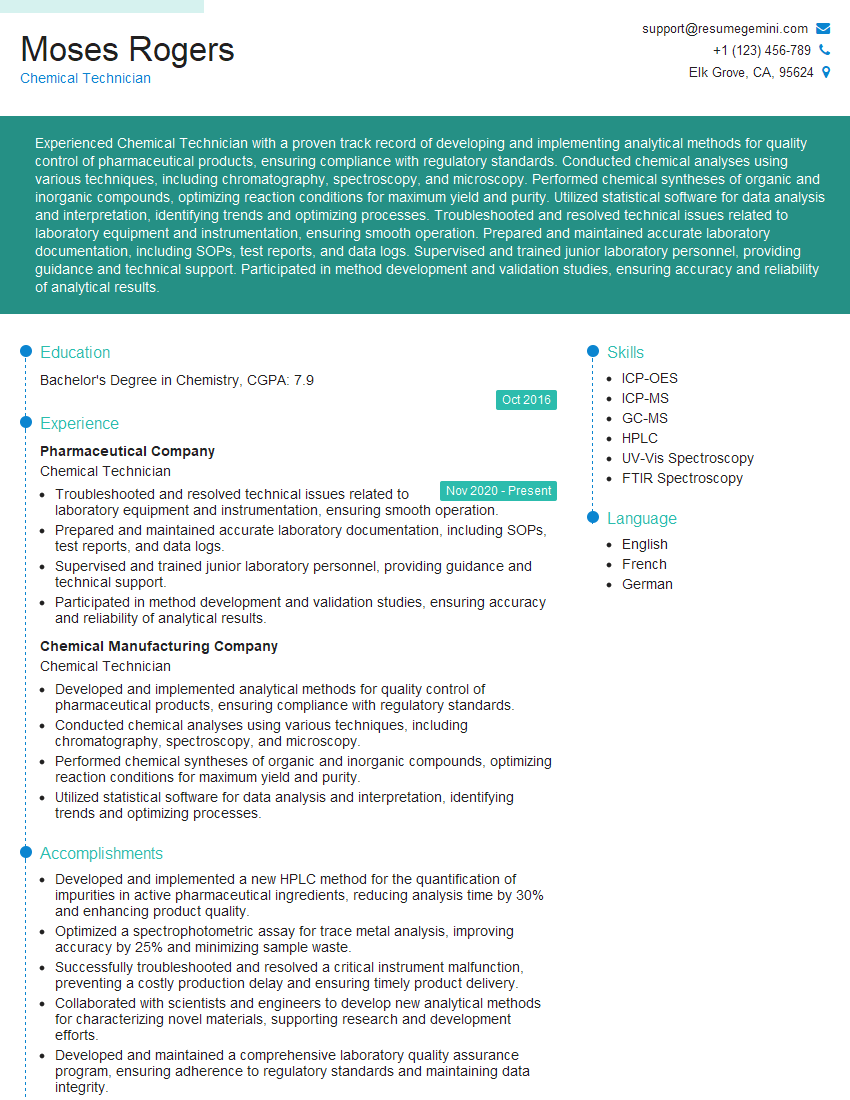

Mastering Chemical Use and Safety is crucial for career advancement in many industries. A strong understanding of these principles demonstrates your commitment to workplace safety and your ability to contribute to a safe and productive work environment. To significantly boost your job prospects, creating an ATS-friendly resume is vital. ResumeGemini is a trusted resource that can help you build a professional and effective resume, ensuring your skills and experience are highlighted effectively. Examples of resumes tailored to Chemical Use and Safety are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO