Are you ready to stand out in your next interview? Understanding and preparing for Rigging and Handling interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Rigging and Handling Interview

Q 1. Explain the different types of rigging hardware and their applications.

Rigging hardware encompasses a wide array of components crucial for safe and efficient lifting operations. Understanding their individual strengths and limitations is paramount. Here are some key types:

- Shackles: These are U-shaped pieces of metal with a pin through the bow, used to connect different rigging components. They come in various strengths and types (bow, screw pin, etc.), each suitable for specific applications. For instance, a screw pin shackle offers better pin security than a bow shackle.

- Slings: These are flexible load-bearing components, typically made of wire rope, synthetic fiber (e.g., polyester, nylon), or chain. Wire rope slings are durable and suitable for heavy loads but require regular inspection for damage. Synthetic slings are lighter but may degrade under UV exposure or chemical contact. Chain slings are strong and resistant to abrasion but can suffer from wear and tear at links.

- Hooks: These are critical load-bearing attachments, typically found on cranes and hoists. They must be inspected regularly for cracks, deformation, or wear. Different hook types exist, such as grab hooks and clevis hooks, each with its specific purpose.

- Turnbuckles: These are adjustable devices used to tighten or loosen slings or other rigging components, ensuring proper tension and load distribution. They’re vital for leveling loads and fine-tuning rigging setups.

- Eye Bolts: These are threaded bolts with an eye at the end, used to provide a secure attachment point for slings or other rigging components. They should be correctly rated for the load and installed perpendicularly to avoid bending stresses.

The selection of appropriate hardware depends heavily on the load characteristics, the environment, and the specific lifting operation. Always refer to manufacturer’s specifications and relevant safety standards.

Q 2. Describe the process of calculating safe working loads (SWLs).

Calculating Safe Working Loads (SWLs) is crucial for preventing accidents. It involves determining the maximum load a piece of rigging equipment can safely support under specific conditions. This isn’t a simple calculation; it requires careful consideration of several factors:

- Manufacturer’s Rated Capacity: The most critical piece of information. This is the maximum load the equipment can handle as per the manufacturer’s testing and specifications.

- Angle of Lift: Lifting at angles reduces the effective load capacity. The SWL decreases significantly as the angle deviates from vertical. Many rigging charts and calculators help determine the reduced SWL at various angles.

- Environmental Factors: Temperature extremes, corrosion, and exposure to chemicals can weaken rigging equipment. These factors reduce the SWL and should be considered.

- Wear and Tear: Regularly inspect rigging for signs of damage, such as fraying (in slings), bending (in shackles), or deformation (in hooks). Damaged equipment should be immediately removed from service.

- Safety Factor: A safety factor is usually applied (often 5:1 or 6:1) to the manufacturer’s rated capacity, providing a buffer for unforeseen circumstances.

Example: A sling has a manufacturer’s rated capacity of 10,000 lbs. With a 5:1 safety factor, the SWL is 2,000 lbs (10,000 lbs / 5). If lifted at a 30-degree angle, a rigging chart would further reduce this SWL. Always use a documented and verified calculation method. Using manufacturer SWL charts and angle reduction factors is the best method.

Q 3. What are the key safety regulations and standards relevant to rigging?

Rigging safety is governed by a multitude of regulations and standards, varying slightly by location. However, some common themes prevail globally. These include:

- OSHA (Occupational Safety and Health Administration) in the US: Sets comprehensive standards for workplace safety, including detailed regulations on rigging equipment inspection, safe lifting practices, and training requirements.

- ASME (American Society of Mechanical Engineers): Develops standards for various aspects of lifting and rigging equipment, covering design, manufacturing, testing, and inspection.

- National and International Standards: Many countries have their own national standards (e.g., CSA in Canada, BS in the UK), and international organizations like ISO publish global standards for rigging equipment and practices.

- Employer-Specific Safety Programs: Companies operating lifting equipment usually have their internal safety programs and guidelines, often exceeding the minimum legal requirements.

Adherence to these regulations is not merely a matter of compliance; it’s a commitment to worker safety and preventing costly accidents. Staying updated on the latest standards and undergoing regular training are essential.

Q 4. How do you select the appropriate rigging equipment for a specific lift?

Selecting the right rigging equipment is a critical decision that requires a systematic approach. It’s not simply about choosing the strongest equipment; it’s about choosing the most appropriate equipment for the specific task. This involves:

- Load Characteristics: Determine the weight, dimensions, and center of gravity of the load. An unevenly distributed load requires careful consideration of sling angles and attachment points.

- Lift Environment: Consider the space available, potential obstacles, environmental conditions (wind, temperature), and the presence of any hazardous materials.

- Lifting Equipment Capabilities: Ensure that the crane or hoist has the capacity to lift the calculated SWL, taking into account any limitations due to reach, angle, or other factors.

- Rigging Hardware Selection: Choose the appropriate slings, shackles, hooks, and other hardware based on the load weight, material, and the required working angle. Always use equipment with a sufficient safety factor.

- Inspection and Maintenance: Only use equipment that has been inspected and is in good working order. Never use damaged equipment.

Example: Lifting a heavy, oddly shaped steel component might require multiple slings arranged at specific angles to distribute the load evenly, combined with shackles and a strong hook capable of withstanding the force. A thorough pre-lift plan is essential to detail this.

Q 5. Explain the importance of pre-lift planning and risk assessment.

Pre-lift planning and risk assessment are not optional extras; they are fundamental to ensuring a safe and efficient lift. They involve a detailed analysis of the entire lifting operation, identifying and mitigating potential hazards.

- Site Survey: Assess the work area for obstacles, access points, ground conditions, and potential hazards.

- Load Analysis: Determine the weight, dimensions, and center of gravity of the load, as well as the required rigging configuration.

- Equipment Selection: Choose appropriate lifting equipment and rigging hardware, ensuring adequate capacity and suitability for the task.

- Lifting Plan Development: Outline the steps involved in the lift, including the sequence of operations, communication protocols, and emergency procedures.

- Risk Assessment: Identify potential hazards and develop mitigation strategies to address each risk.

- Team Briefing: Conduct a thorough briefing with all personnel involved in the lift, ensuring they understand their roles and responsibilities.

A well-executed pre-lift plan minimizes the risks involved and ensures a smoother, safer lift. Skipping this step can have severe consequences.

Q 6. Describe your experience with different types of lifting equipment (cranes, hoists, etc.).

My experience encompasses a wide range of lifting equipment, from small chain hoists to large crawler cranes. I’m proficient in the operation and maintenance of various types of cranes (tower, mobile, overhead), hoists (electric, pneumatic, manual), and associated rigging equipment. I have hands-on experience with:

- Overhead Cranes: Experience operating, inspecting, and maintaining various types of overhead cranes in industrial settings, including bridge cranes, gantry cranes, and jib cranes. I understand the importance of load charts and safe load limits.

- Mobile Cranes: Proficient in working with different types of mobile cranes, including rough-terrain cranes, all-terrain cranes, and truck-mounted cranes, understanding their specific operational limitations and safety requirements.

- Tower Cranes: I’m familiar with the unique safety protocols and operational procedures associated with tower cranes, particularly in high-rise construction environments.

- Hoists: Experienced with a range of electric and manual hoists, understanding their lifting capacities, limitations, and safety features. I have been involved in both the installation and maintenance of hoisting systems.

Through this experience, I have developed a deep understanding of the capabilities and limitations of various lifting equipment and can effectively select the most suitable equipment for any given task. I always prioritize safety and efficiency in my approach.

Q 7. How do you communicate effectively with crane operators and other team members during a lift?

Effective communication is paramount during a lift. Miscommunication can lead to serious accidents. My approach to communication involves:

- Pre-lift Briefing: A clear and concise briefing with the crane operator and team outlining the lift plan, including load details, rigging configuration, hand signals, and emergency procedures.

- Standardized Hand Signals: Utilizing universally recognized hand signals to direct the crane operator, ensuring clear and unambiguous instructions, even in noisy environments.

- Two-Way Communication: Maintaining constant visual contact and using clear, concise verbal communication with the crane operator to confirm instructions and acknowledge progress.

- Emergency Procedures: Establishing clear emergency procedures and communication protocols to ensure a rapid and coordinated response in case of unexpected events.

- Documentation: Maintaining detailed records of the lift, including the load weight, rigging configuration, personnel involved, and any incidents or near misses.

For instance, a simple hand signal indicating the exact lifting height, combined with verbal confirmation, prevents misinterpretations and ensures a safe lift. Consistent, clear communication is the bedrock of safe rigging practices.

Q 8. What are the different types of slings and their limitations?

Slings are the crucial components connecting the load to the lifting equipment. Several types exist, each with specific strengths and weaknesses. Choosing the right sling is paramount for safety and efficiency.

- Polyester Slings: Strong, lightweight, and relatively inexpensive. They are resistant to rot and mildew but can be susceptible to UV degradation over prolonged exposure to sunlight. Their stretch is also slightly higher than other options which needs to be considered for precise lifting.

- Nylon Slings: Similar to polyester in many ways, nylon slings offer excellent shock absorption. This makes them suitable for situations where there might be sudden load shifts. However, they are prone to abrasion.

- Wire Rope Slings: Extremely strong and durable, ideal for heavy lifting. They can withstand high temperatures and abrasive environments better than synthetic slings. However, they are heavier, can be more difficult to handle, and are prone to damage from corrosion if not properly maintained.

- Chain Slings: Known for their exceptional strength and resistance to abrasion and sharp edges. They are suitable for heavy and abrasive applications, particularly those involving high temperatures. Careful inspection is needed, as kinks or damage can weaken them significantly.

Limitations: Each sling type has limitations. Synthetic slings (polyester and nylon) have reduced strength when exposed to chemicals or extreme temperatures. Wire rope slings are susceptible to damage from kinking and corrosion. Chain slings, while durable, can be heavy and stiff, making them less maneuverable.

Q 9. Explain the concept of load distribution and its importance in rigging.

Load distribution refers to how the weight of a lifted object is spread across the lifting points and the supporting rigging components. Proper load distribution is crucial for preventing overload and ensuring the safety of the equipment and personnel. Imagine trying to lift a heavy sofa by only one leg – it’s likely to break. Similarly, uneven load distribution during rigging can lead to sling failure or damage to the load.

Importance: Effective load distribution minimizes stress on individual sling legs and other components. By distributing the load evenly, we ensure that no single point experiences excessive force that could cause failure. This prevents accidents, saves money on repairs/replacements, and protects personnel from harm. Techniques like using multiple slings in a bridle configuration help achieve even weight distribution. The choice of sling type and rigging method itself is a direct consequence of the need for proper load distribution.

Q 10. How do you inspect rigging equipment for damage or wear?

Rigging equipment inspection is a critical safety procedure that should be performed before every lift. It’s a methodical process, and thoroughness is essential. I usually follow a checklist, which includes the following:

- Visual Inspection: Look for any signs of wear and tear, such as fraying, cuts, burns, or kinks in slings. Inspect hooks, shackles, and other hardware for cracks, deformation, or excessive wear. Examine the connections between components carefully.

- Load Chart Verification: Double-check the Working Load Limit (WLL) of each component. Ensure the total weight of the load does not exceed the safe working load of any single component in the system.

- Testing (if applicable): Certain critical lifts might require load testing to ensure all components meet their specified strength ratings.

- Documentation: All inspection findings are meticulously documented, including date, time, and any identified defects or repairs. This documentation helps track equipment condition and identifies potential maintenance needs.

Any questionable items are immediately tagged and removed from service. A sling showing even minor damage is immediately replaced—safety is never compromised.

Q 11. What actions do you take if you identify a safety hazard during a rigging operation?

Safety is paramount. If I identify a hazard during a rigging operation, my immediate priority is to stop the operation and correct the issue.

- Identify and Assess: Clearly define the hazard, determining its potential impact on safety.

- Isolate the Hazard: Take steps to isolate the hazardous condition, preventing access to it or preventing further unsafe conditions.

- Communicate: Immediately inform all relevant personnel, including the crane operator and any other workers in the area, about the hazard.

- Correct the Hazard: Depending on the nature of the hazard, this might involve replacing damaged equipment, adjusting the rigging setup, or seeking expert advice.

- Reinspect: After correcting the hazard, I’d conduct a thorough reinspection to confirm its elimination before resuming the operation.

- Report: The entire incident, including the hazard’s nature, corrective actions, and any near misses, would be documented and reported in accordance with company protocols.

I firmly believe that a proactive approach towards safety minimizes risks and prevents accidents. Safety is never a compromise.

Q 12. Describe your experience with various rigging techniques (e.g., choker hitches, bridle slings).

I have extensive experience with various rigging techniques. For instance, I’ve frequently used:

- Choker Hitches: These are simple yet effective for lifting cylindrical or uniformly shaped objects. It’s crucial to understand the angle of the sling, as the load bearing capacity is reduced significantly as the angle increases. I always ensure a proper choke hitch placement and avoid over-tightening to prevent damage to the sling or the load.

- Bridle Slings: These are commonly employed to distribute the load across multiple sling legs, creating a more stable and safer lift, especially for heavy or awkwardly shaped objects. The key here is calculating the correct angle between the sling legs to evenly distribute the weight. I’ve utilized bridle slings extensively in lifting large equipment and machinery.

- Vertical Lifts: Straightforward vertical lifts are common. The focus here is ensuring the load is properly centered and balanced to avoid any swinging or instability during the lift.

My experience includes working with a variety of loads, from delicate components to heavy machinery, always adhering to safe rigging practices. Proper planning and understanding of load distribution principles are fundamental to selecting and implementing the correct rigging technique for any situation.

Q 13. How do you handle unexpected situations or emergencies during a lift?

Handling unexpected situations requires quick thinking and decisive action. My approach involves:

- Assess the Situation: Quickly determine the nature of the emergency and its potential consequences.

- Prioritize Safety: The immediate priority is always the safety of personnel. Initiate emergency procedures as needed, which may include halting the lift and evacuating the area.

- Communicate Effectively: Clearly communicate with all involved parties, including the crane operator and other crew members, to coordinate actions.

- Take Corrective Action: Implement appropriate corrective actions to address the situation. This might involve adjusting the rigging configuration, securing the load, or seeking external assistance.

- Document Everything: Maintain a detailed record of the event, including the circumstances, actions taken, and any resulting damage.

Experience teaches you to react calmly and efficiently under pressure, leveraging training and knowledge to mitigate risks and resolve unexpected events. A pre-lift safety briefing also plays a significant role in ensuring preparedness for potential issues.

Q 14. Explain your understanding of load charts and their use in rigging.

Load charts are essential documents providing vital information about the safe working load limits (SWL) of rigging hardware. They typically specify the maximum load a particular sling, hook, shackle, or other component can handle under various conditions (e.g., different sling angles).

Use in Rigging: Before any lift, I meticulously review the load charts for all components involved. This ensures that the selected equipment is suitable for the weight and nature of the load. It is crucial to understand that SWLs are often affected by factors such as sling angles and the type of hitch used. For instance, a sling’s capacity decreases considerably as its angle from the vertical increases. Load charts help avoid exceeding the SWL, which would lead to potential catastrophic failures.

I ensure all team members understand and use the load charts properly. These charts are not just documents; they’re essential tools for ensuring a safe lifting operation. I always cross-reference the load chart specifications against the actual load weight and rigging configuration to prevent accidents.

Q 15. What is your experience with different types of knots and their applications in rigging?

Knots are fundamental in rigging, providing secure connections and crucial load-bearing capabilities. My experience encompasses a wide range, including the Bowline (a reliable slip knot ideal for loops), the Clove Hitch (quick and easy for temporary attachments), the Figure Eight (a secure stopper knot), and the Shackle (used to connect wire rope and chains). The choice of knot depends entirely on the specific application and the type of load.

- Bowline: I’ve used this extensively for creating a secure loop in a rope’s end, essential for attaching to lifting points or creating a running loop that won’t slip. Imagine attaching a load to a crane hook – a well-tied Bowline ensures a secure connection.

- Clove Hitch: This is my go-to for temporary attachments, like securing a rope to a post during setup. It’s quick to tie and easy to untie, crucial for speed and efficiency in various situations.

- Figure Eight: This is an important stopper knot, preventing a rope from running through a pulley or a block. I use it frequently to ensure that the rope remains securely in place and doesn’t slip under load.

- Shackles: These are vital connectors for joining wire rope or chain to other rigging components. They allow quick connections and disconnections, a huge time saver when dealing with multiple lifts. I always meticulously inspect shackles for any signs of wear or damage before use.

Selecting the right knot is critical for safety. Improper knot selection can lead to slippage, failure, and potentially serious accidents. My expertise lies in choosing the appropriate knot for the specific load, material, and environmental conditions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the stability and balance of a load during lifting and moving?

Ensuring load stability and balance during lifting is paramount for safety. This involves several key steps. Firstly, accurately determining the load’s center of gravity (CG) is essential. This is the point where the weight of the load is evenly distributed. Misjudging the CG can lead to imbalance and dangerous swinging of the load. Secondly, proper rigging techniques come into play, using appropriate slings, shackles, and other hardware to distribute the weight evenly and securely. Finally, careful control of the lift itself, with smooth and controlled movements, prevents sudden shifts or unintended swings.

For example, lifting a large, irregularly shaped object, I would first identify its approximate center of gravity by visual inspection and potentially using measuring tools. Then, I’d use multiple slings or a spreader beam to create multiple lifting points evenly distributed around the CG. This ensures the weight is balanced, minimizing the chances of it tipping or swinging during the lift. Constant communication with the crane operator is also crucial to ensure synchronized and controlled lifting movements.

Q 17. Describe your experience with rigging in confined spaces or challenging environments.

Rigging in confined spaces or challenging environments demands extra caution and specialized techniques. My experience includes working in tight ship holds, confined spaces within industrial plants, and even on uneven terrain. In such environments, maneuverability and precise control are crucial. I adapt my rigging techniques by using smaller, more maneuverable equipment and employing specialized slings and rigging hardware tailored to the confined environment. Risk assessments are even more crucial; we might use extra safety lines or smaller capacity cranes to prevent damage and ensure safety within the limited space.

One memorable project involved lifting a large component into a tightly packed factory space. The space was narrow, and there were several obstacles. I developed a rigging plan that involved using a smaller crane with exceptional maneuverability and lightweight yet robust rigging materials. A carefully orchestrated lift, with clear communication amongst the team, made it possible to avoid collisions with surrounding equipment.

Q 18. Explain your understanding of center of gravity and its importance in rigging.

The center of gravity (CG) is the point at which the weight of an object is balanced. In rigging, understanding and accounting for the CG is absolutely critical for safe and efficient lifting operations. An unbalanced load is much more likely to swing unpredictably or tip during lifting, leading to accidents and potential damage to equipment or injury to personnel.

Consider lifting a long steel beam. Its CG is at its midpoint. If we only lift it from one end, the beam will likely rotate unpredictably and may fall. However, by using multiple slings positioned correctly around the CG or by using a spreader beam, we distribute the load evenly and prevent unwanted swinging. Accurate CG determination may involve measuring the object’s dimensions and weight distribution, or using specialized software or even a visual assessment if it is of simple geometry. Knowing the CG allows for a balanced lift, and I always ensure its consideration in my rigging plans.

Q 19. How do you manage potential risks associated with weather conditions during rigging operations?

Weather conditions pose significant risks during rigging operations. High winds, rain, snow, and even extreme temperatures can all impact the safety and feasibility of a lift. My approach to managing these risks involves careful monitoring of weather forecasts before, during, and after operations. We might delay the lift entirely if weather conditions pose an unacceptable risk. In other cases, we might adjust the rigging plan to mitigate the risks. For instance, wind speed greatly affects load stability; at high wind speeds, we might use additional counterweights or reduce the lift’s height to minimize swinging or collapse. Rain can reduce visibility or make the load slippery, whereas ice buildup adds significant weight and can alter the CG, so adjustments may be necessary to ensure safe lifting. I always prioritize safety and won’t proceed if the risks are deemed too high.

Q 20. What are your methods for documenting rigging procedures and inspections?

Documentation is crucial for maintaining safety and accountability. Rigging procedures and inspections are meticulously documented to provide a comprehensive record of the operations. This includes pre-lift inspections of all equipment, a detailed rigging plan outlining the procedure, and a post-lift inspection to check for any damage or issues.

I utilize a combination of digital and physical documentation. Digital records often involve photos, videos, and electronic checklists documenting inspections and signoffs, along with the details of the lifting plan, crane specifications, and weather conditions. These are saved in a secure database or shared drive for easy access and auditability. Physical documentation includes hard copies of inspection reports, signed work permits, and any necessary certifications, stored securely onsite and offsite. This comprehensive approach ensures a full audit trail of all the rigging operation, essential for safety and regulatory compliance.

Q 21. Describe your proficiency in using rigging software or calculation tools.

Proficiency with rigging software and calculation tools is essential for optimizing safety and efficiency. I’m experienced in using various software programs for load calculations, stress analysis, and CG determination. These tools help in creating accurate rigging plans, determining safe working loads, and optimizing sling angles and configurations. This minimizes risks and ensures the lift is executed efficiently.

For example, I use software to model complex lifts involving multiple points and varying load characteristics. The software allows me to simulate different scenarios, ensuring the lift is safe and feasible before execution. This is particularly important in projects with significant weight or complex geometry. I also use calculation tools to verify the structural integrity of rigging equipment under different load conditions, ensuring we are always within safe working limits.

Q 22. Explain your experience with different types of anchors and their applications.

Anchors are the foundation of any rigging operation, providing a secure point of attachment for lifting equipment. The type of anchor chosen depends critically on the load, the environment, and the substrate. My experience encompasses a wide range, including:

Deadmen: These are buried anchors, often used in soil or earth for temporary applications. I’ve used them extensively on construction sites where we needed a reliable anchor point for tensioning cables or supporting temporary structures. Their effectiveness relies heavily on proper soil analysis and installation depth.

Steel plate anchors: These offer significant holding power when bolted to concrete or steel structures. I’ve used them in numerous industrial settings, specifically for heavy-duty lifting operations where maximum security is paramount. The bolt size and embedment depth are crucial factors in their design and application.

Screw anchors: These are easily installed and offer excellent holding power in many materials. I’ve found them particularly useful in applications where quick setup and dismantling is required. Selection depends on the specific material (wood, concrete, masonry) and the intended load.

Foundation anchors: These are permanently embedded in a structure’s foundation and provide exceptionally high holding capacity. These are common in industrial settings where the rigging system needs to be in place for extended periods, such as crane installations.

Selecting the right anchor involves a rigorous risk assessment, considering factors like load capacity, environmental conditions (weather, temperature, corrosion), and the duration of the operation. Incorrect anchor selection can lead to catastrophic failures, so meticulous planning and selection are absolutely essential.

Q 23. How do you plan for and execute a complex multi-lift operation?

Planning a multi-lift operation is a complex process that requires meticulous planning and flawless execution. It’s not simply lifting multiple objects; it’s about coordinating the movements of multiple cranes, loads, and personnel. My approach involves these key steps:

Detailed Load Analysis: This includes determining the weight, center of gravity, and dimensions of each load. We use specialized software to simulate the lift and identify potential points of failure.

Crane Selection and Placement: Careful consideration is given to crane capacity, reach, and stability. We conduct thorough site surveys to identify suitable crane locations and ensure sufficient clearance.

Rigging Plan Development: This involves selecting appropriate lifting equipment (slings, shackles, hooks), calculating sling angles, and determining the sequence of lifts. Detailed diagrams and simulations are created to visualize the lift.

Risk Assessment and Mitigation: A comprehensive risk assessment identifies potential hazards, such as collisions, structural failure, and environmental factors. Mitigation strategies are developed to minimize risk.

Communication Plan: Establishing clear communication channels among crane operators, riggers, and spotters is crucial. We use hand signals, radios, and a designated communication coordinator to ensure everyone is synchronized.

Rehearsal and Execution: A thorough rehearsal, using dummy loads if necessary, helps identify any unforeseen issues. The actual lift is executed precisely according to the plan, with constant monitoring and communication.

For example, in a recent project involving the lift of several large transformers, we used 3D modeling software to simulate the lift, ensuring that there was adequate clearance and that no obstacles were in the way. The rehearsal with the client and the crew greatly reduced the risks involved. This meticulous planning resulted in a successful and safe operation.

Q 24. What are your strategies for effective communication and teamwork in a rigging crew?

Effective communication and teamwork are absolutely crucial for safety and efficiency in rigging. My strategies focus on:

Pre-lift Briefing: A thorough briefing before every lift ensures that everyone understands the plan, their roles, and potential hazards. This includes reviewing the rigging plan, discussing communication protocols, and identifying emergency procedures.

Clear Communication Protocols: We use a combination of hand signals, radio communication, and designated communication coordinators to ensure clear and unambiguous instructions. Everyone on the crew is trained in standard hand signals and radio etiquette.

Respectful and Collaborative Environment: I foster a team environment where everyone feels comfortable voicing concerns or asking questions. Open communication is essential for identifying and resolving potential problems.

Regular Check-ins: During the lift, regular check-ins between team members ensure that everything is proceeding as planned and that no unforeseen issues have arisen.

Post-lift Debriefing: A post-lift debriefing allows the team to review the operation, identify areas for improvement, and share lessons learned. This ensures continuous improvement and enhances safety.

For instance, during one particularly complex lift, a team member noticed a slight anomaly with a sling angle. By openly voicing their concern, we were able to adjust the plan before it became a safety issue. This highlighted the importance of open communication and collective problem-solving within the team.

Q 25. Describe your experience with troubleshooting rigging equipment malfunctions.

Troubleshooting rigging equipment malfunctions requires a systematic approach, combining practical knowledge, problem-solving skills and a keen eye for detail. My experience has taught me to:

Identify the Problem: Begin by precisely identifying the nature of the malfunction. Is it a mechanical issue, a wear-and-tear problem, or something else?

Safety First: Immediately secure the load and isolate the faulty equipment. This is non-negotiable – safety always takes priority.

Visual Inspection: Carefully inspect the affected equipment for visible damage, such as cracks, bends, or wear. Check for proper function of safety mechanisms.

Component Testing: If possible, test individual components to isolate the root cause of the failure. For example, we might test the load capacity of a sling using calibrated load cells.

Consult Manuals and Specifications: Refer to the manufacturer’s manuals and specifications for guidance on troubleshooting and repair procedures.

Replacement or Repair: Depending on the nature and severity of the malfunction, the equipment may need to be replaced or repaired. Replacements should always meet or exceed the original specifications.

Once, a wire rope sling showed signs of significant wear during a visual inspection. It was immediately replaced, preventing a potential catastrophic failure. This highlights the importance of regular inspection, proactive maintenance and swift action when issues are identified.

Q 26. How do you ensure compliance with all relevant health and safety regulations?

Compliance with health and safety regulations is paramount in rigging. My approach involves:

Thorough Risk Assessments: Conducting comprehensive risk assessments for each project, identifying potential hazards, and implementing control measures to mitigate risk.

Regular Inspections: Regular inspections of all rigging equipment, including slings, chains, hooks, and anchors, to ensure they are in good working order and meet safety standards. We maintain detailed inspection records.

Proper Training and Certification: Ensuring all crew members are properly trained and certified to operate rigging equipment and follow safety procedures. We maintain up-to-date records of training and certifications.

Adherence to Regulations: Strict adherence to all relevant national and international health and safety regulations, including OSHA (or equivalent) guidelines.

Emergency Procedures: Developing and practicing emergency procedures for various scenarios, including equipment failure and accidents. This includes evacuation plans and emergency contact information.

Documentation: Maintaining meticulous documentation of all inspections, training, and incident reports. This provides a comprehensive record of our safety practices.

For example, we use a specialized software to manage our equipment inspections, which helps ensure that we comply with manufacturer’s recommendations and regulatory requirements. This proactive approach ensures compliance and minimizes safety risks.

Q 27. Explain your experience with different types of lifting points and their selection criteria.

Lifting points are critical for safe and efficient lifting. The selection of appropriate lifting points depends on several factors, and my experience encompasses a variety of types:

Eye Bolts: These are commonly used for relatively lightweight loads and are suitable for many applications. However, their load capacity is limited and they can be subject to damage if improperly used.

Lifting Rings: These offer superior strength and are particularly suitable for heavier loads. Their design provides a better load distribution compared to eye bolts.

Welded Lifting Points: These are often integrated into the design of a load, providing a strong and secure lifting point. Their design and welding procedure must meet stringent standards.

Shackles: These are used to connect slings to lifting points and allow for changes in direction. The choice of shackle type and capacity is critical based on the load and application.

The selection criteria involve considering the load’s weight, shape, and material, the type of lifting equipment used, and the environment. For instance, when lifting a large steel beam, welded lifting points are preferable for their superior strength and load distribution. In other cases, strategically placed eye bolts might suffice. It’s vital to always calculate the load and choose lifting points with sufficient capacity for the job. Improper selection can result in catastrophic failures.

Q 28. How do you stay updated on the latest best practices and advancements in rigging technology?

Staying updated on best practices and advancements in rigging technology is essential for maintaining competency and ensuring safety. My approach involves:

Professional Development Courses: Regular participation in industry-recognized training courses and workshops to learn about new techniques, technologies, and regulations.

Industry Publications and Journals: Subscribing to and reading industry publications and journals to stay informed about the latest research, developments, and best practices.

Trade Shows and Conferences: Attending industry trade shows and conferences to network with peers, learn about new products, and see demonstrations of new technologies.

Manufacturer Websites and Training Materials: Consulting the websites and training materials of leading equipment manufacturers to learn about new products and their capabilities.

Networking with Peers: Maintaining a network of colleagues and professionals in the rigging industry to exchange ideas, best practices, and experiences.

For example, I recently completed a course on advanced rigging techniques for heavy lifting, which included training on the latest software for load calculations and risk assessment. These continuous learning initiatives help ensure that I stay at the forefront of the industry, employing the latest and safest techniques in my work.

Key Topics to Learn for Your Rigging and Handling Interview

- Load Calculations and Weight Distribution: Understanding principles of center of gravity, load limits, and safe working loads. Practical application: Calculating the safe lifting capacity for a specific load and rigging configuration.

- Rigging Hardware and Equipment: Familiarity with various types of slings, shackles, hooks, wire rope, and their appropriate applications. Practical application: Selecting the correct hardware for a given lifting task, considering factors like load capacity, material compatibility, and environmental conditions.

- Knots and Hitches: Mastering essential knots and hitches used in rigging, understanding their strengths and limitations. Practical application: Demonstrating the ability to tie various knots securely and efficiently.

- Inspection and Maintenance: Procedures for inspecting rigging equipment for wear and tear, damage, and proper maintenance schedules. Practical application: Identifying potential hazards and recommending appropriate actions.

- Safety Regulations and Procedures: Knowledge of relevant safety standards, regulations, and best practices related to rigging and handling. Practical application: Applying safety protocols to minimize risks during lifting operations.

- Lifting Techniques and Procedures: Understanding different lifting methods and techniques, including crane operation, hand rigging, and specialized lifting equipment. Practical application: Developing safe and efficient lifting plans for various scenarios.

- Troubleshooting and Problem-Solving: Identifying and resolving common issues during rigging operations. Practical application: Developing effective strategies for handling unexpected challenges and maintaining safety.

- Communication and Teamwork: Effective communication with team members and supervisors during rigging operations. Practical application: Demonstrating leadership and collaboration skills in a team environment.

Next Steps

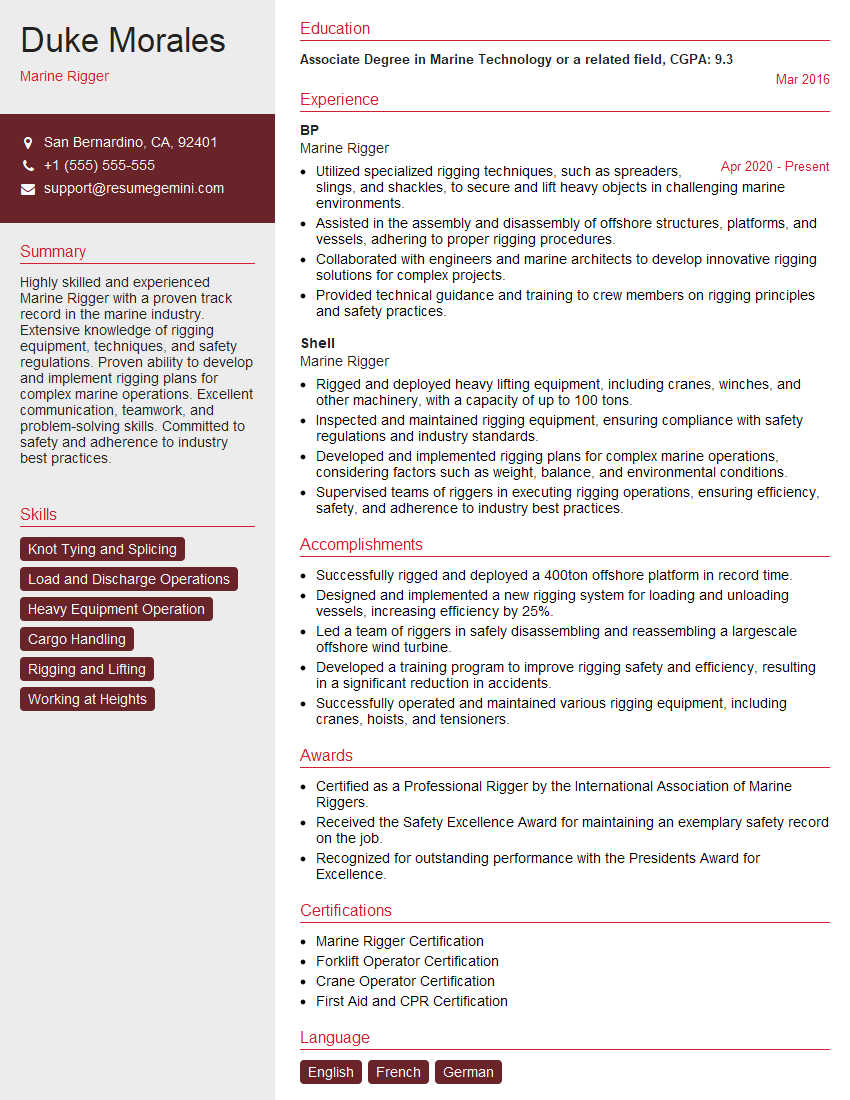

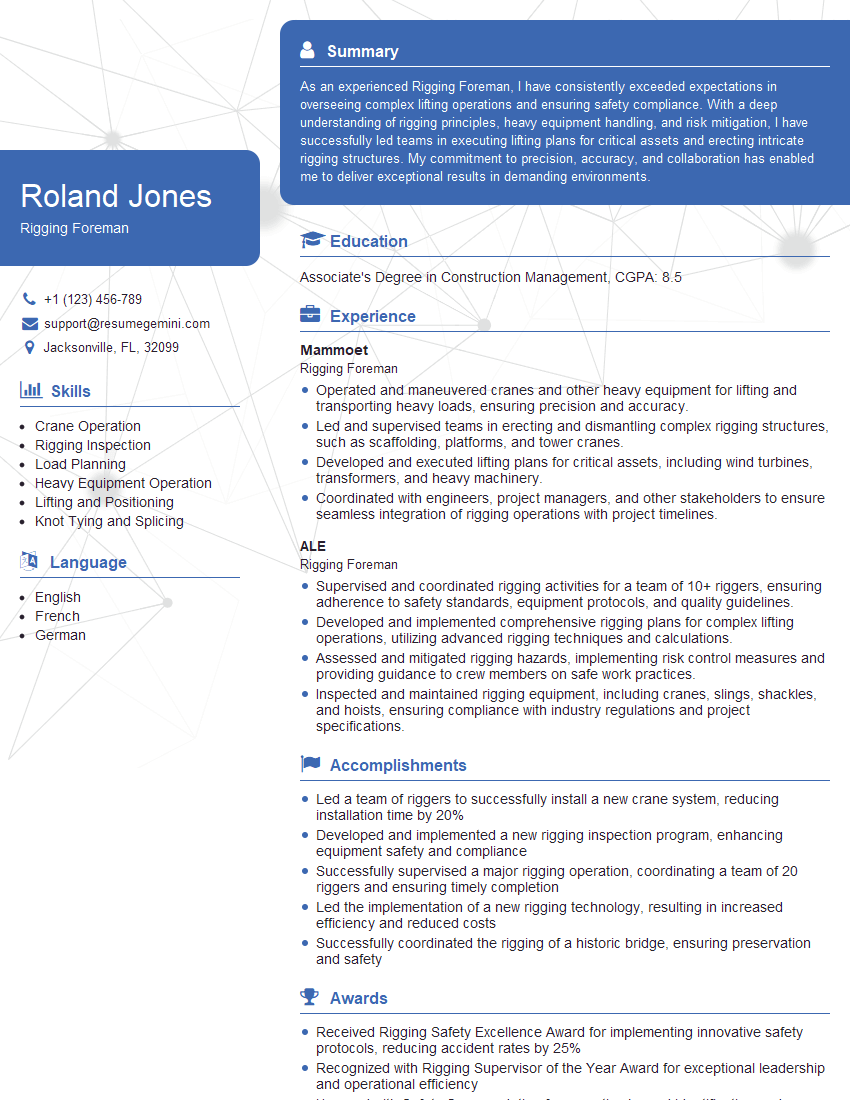

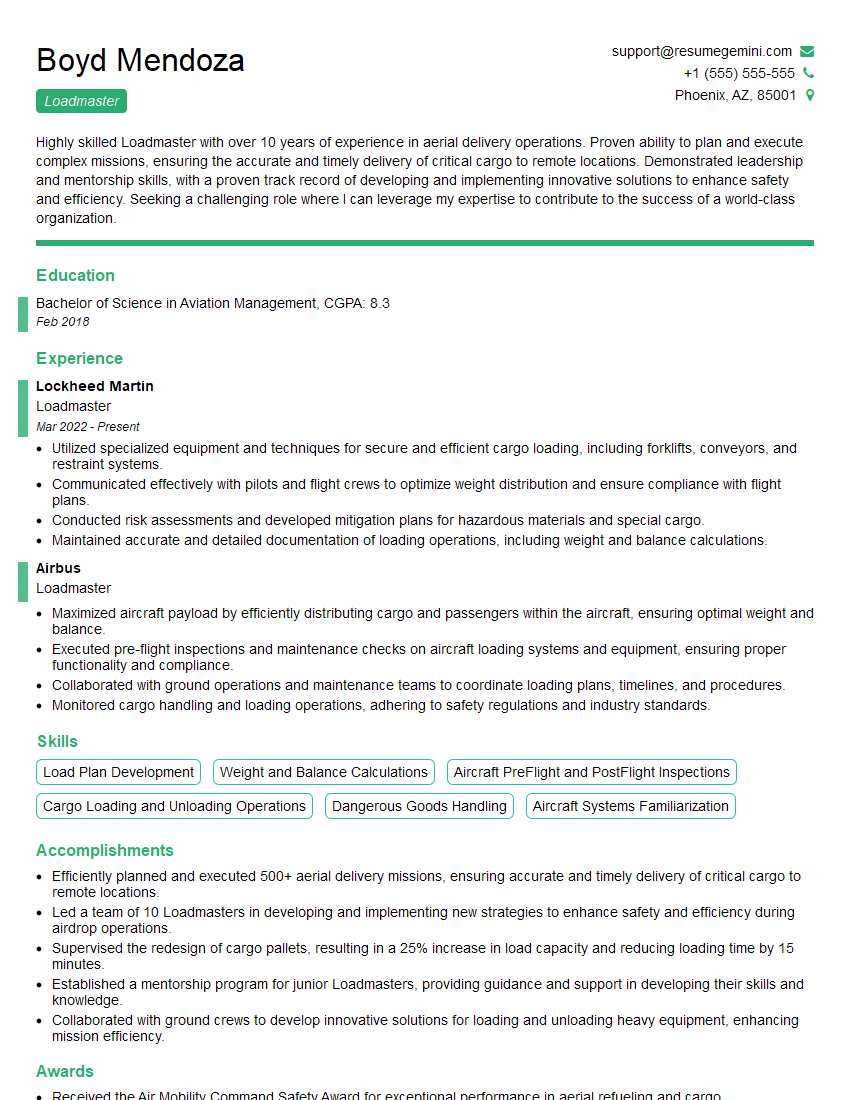

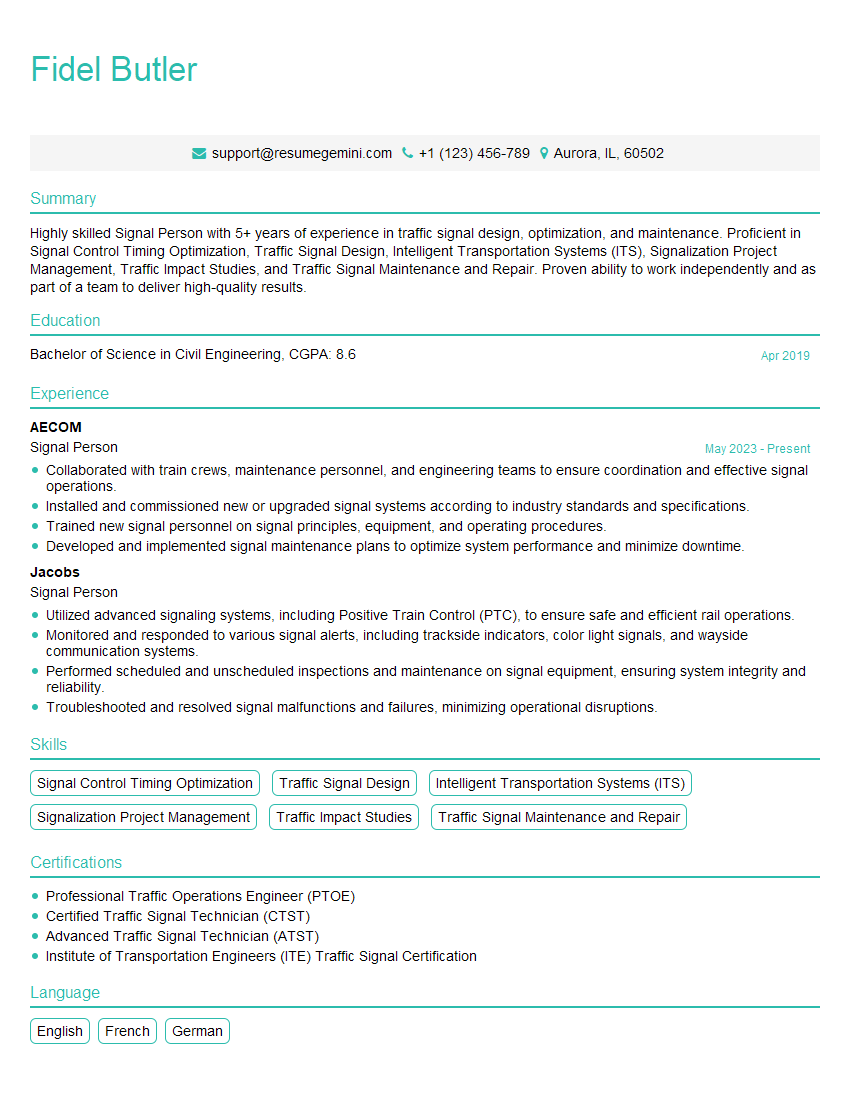

Mastering Rigging and Handling is crucial for career advancement in this demanding field. It demonstrates a commitment to safety, efficiency, and technical proficiency, opening doors to more challenging and rewarding roles. To enhance your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to help you craft a compelling document, and examples of resumes tailored to Rigging and Handling are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO