Are you ready to stand out in your next interview? Understanding and preparing for Safe Crane Operation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Safe Crane Operation Interview

Q 1. What are the different types of cranes and their applications?

Cranes are essential lifting machines categorized by their design and application. Several types exist, each suited to specific tasks and environments.

- Tower Cranes: Tall, freestanding cranes used extensively in high-rise construction projects. Their ability to lift heavy loads to significant heights makes them indispensable in building skyscrapers and large structures.

- Mobile Cranes: These are versatile cranes mounted on a chassis, offering mobility and adaptability across various sites. They are commonly employed for general construction, industrial applications, and infrastructure projects where moving the crane is required.

- Overhead Cranes: These are typically found in factories and warehouses. They run on tracks along the ceiling, providing efficient lifting and movement of materials within a confined area. Think of the overhead cranes you see in auto manufacturing plants.

- Crawler Cranes: Known for their stability, crawler cranes use tracks for movement and are ideal for heavy lifting in challenging terrains or confined spaces. They are often used in heavy construction, like bridge building.

- Gantry Cranes: Similar to overhead cranes but instead of running on a ceiling track, they run on ground-level tracks. They’re used for heavier loads and where ceiling mounting isn’t feasible.

- Floating Cranes: These are specialized cranes mounted on barges or ships, used for lifting and placing heavy equipment in marine environments, such as during offshore construction or ship repair.

The choice of crane depends heavily on the specific project requirements, including lifting capacity, reach, height, and terrain.

Q 2. Explain the safe operating procedures for a tower crane.

Safe tower crane operation requires strict adherence to established procedures. Ignoring these procedures can lead to catastrophic accidents.

- Pre-operational checks: Thorough inspection of all components, including the structure, hoisting mechanism, brakes, and safety devices, is crucial before commencing any operation.

- Load Capacity: Never exceed the crane’s rated load capacity. The load chart must be consulted for safe working limits.

- Wind Conditions: Operating in high winds is incredibly dangerous. Wind speeds must be within the crane’s specified limits. Most cranes are equipped with anemometers to monitor wind speeds.

- Proper Signaling: Clear and consistent hand signals or radio communication between the crane operator and the signal person are essential to ensure safe lifting and movement of the load.

- Proper Load Securing: Ensuring the load is properly secured and balanced is critical. Using appropriate lifting gear and slings is paramount.

- Emergency Procedures: Operators must be fully trained in emergency procedures, including how to handle power failures, load malfunctions, or other unforeseen issues.

- Regular Maintenance: Scheduled maintenance and inspections are paramount to prevent equipment failures.

Following these procedures minimizes the risk of accidents and ensures the safety of workers and the surrounding environment.

Q 3. Describe the pre-operational checks you perform before operating a crane.

Pre-operational checks are non-negotiable for safe crane operation. Think of it as a thorough health check for the crane before it starts work.

- Visual Inspection: Carefully examine all structural components for any signs of damage, wear, or corrosion. Look for cracks, loose bolts, or damaged cables.

- Mechanical Check: Test all braking systems, hoisting mechanisms, and slew drives to ensure smooth and reliable operation. Check for any unusual noises or vibrations.

- Electrical Check: Verify the proper functioning of all electrical systems, including power supply, control circuits, and safety devices. Check for any exposed wiring or faulty connections.

- Safety Devices: Ensure that all safety devices, such as limit switches, overload protection, and emergency stops, are functioning correctly.

- Load Chart Verification: Confirm the crane’s load chart is readily available and accessible to the operator.

- Documentation: Complete all necessary pre-operational checklists and logbooks, recording any observations or issues.

This systematic approach ensures that the crane is in optimal condition and ready for safe operation. Skipping these checks is a recipe for disaster.

Q 4. How do you identify and mitigate potential hazards during crane operations?

Hazard identification and mitigation are critical throughout the entire crane operation process. A proactive approach is always better than a reactive one.

- Site Survey: Before starting work, conduct a thorough site survey to identify any potential hazards, such as overhead power lines, obstructions, unstable ground, or nearby traffic.

- Risk Assessment: Based on the site survey, perform a risk assessment to evaluate the likelihood and severity of each potential hazard. This helps prioritize mitigation efforts.

- Safe Working Zones: Establish clear and well-defined safe working zones around the crane to prevent unauthorized access and ensure the safety of personnel.

- Communication Protocols: Implement clear communication protocols between the crane operator and other workers on the site to prevent misunderstandings and accidents.

- Emergency Procedures: Develop and practice emergency procedures for various scenarios, such as equipment failure, power outages, or medical emergencies.

- Personal Protective Equipment (PPE): Ensure that all personnel involved in crane operations wear appropriate PPE, including hard hats, safety glasses, and high-visibility clothing.

By systematically addressing potential hazards, you minimize risks and create a safer working environment.

Q 5. What are the limitations and capacities of different crane types?

Crane types have varying limitations and capacities, dictated by their design and intended use. Understanding these limitations is crucial for safe operation.

- Lifting Capacity: This varies significantly among crane types and models, ranging from a few tons to hundreds of tons. Always refer to the manufacturer’s load chart for specific capacities.

- Reach: The horizontal distance a crane can reach with a load also differs widely. A tower crane has a long reach, whereas an overhead crane has a more limited reach.

- Height: The maximum height to which a crane can lift a load is another crucial factor. Tower cranes excel in lifting to great heights, while other types have more limited vertical reach.

- Stability: Some cranes, like crawler cranes, are designed for excellent stability in challenging terrain, while others, such as mobile cranes, may require more careful placement.

- Mobility: Mobile cranes offer excellent mobility, while tower cranes and gantry cranes are stationary.

Knowing these limitations helps in selecting the appropriate crane for a specific job and ensures safe and efficient operation.

Q 6. Explain the importance of load charts and how to interpret them.

Load charts are indispensable for safe crane operation. They provide critical information on the crane’s lifting capacity under various conditions.

A typical load chart shows the maximum safe load the crane can lift at different radii (distances from the crane’s center) and boom angles. It also indicates restrictions based on factors like wind speed and ground conditions. Interpreting the chart is crucial to avoid overloading the crane, which could lead to catastrophic failure.

How to Interpret a Load Chart:

- Identify the boom angle: Locate the boom angle that matches your lifting configuration.

- Find the radius: Determine the distance between the crane’s center and the load’s position.

- Locate the intersection: Find the point where the boom angle and radius intersect on the chart.

- Read the maximum load: The value at this intersection represents the maximum load you can safely lift under those specific conditions.

Always work below the indicated maximum safe load. Remember, load charts are essential for preventing accidents and should always be followed meticulously.

Q 7. What are the different types of crane signals and how are they used?

Crane signals are vital for effective and safe communication between the crane operator and the signal person (or rigger) during lifting operations. Misunderstandings can have serious consequences.

- Hand Signals: Standard hand signals, as defined by relevant safety regulations, are often used. These signals indicate hoisting, lowering, swinging, and other crane movements.

- Radio Communication: Radio communication is increasingly common, especially on larger construction sites. This allows for clear and concise communication, even in noisy environments.

- Visual Signals: Sometimes, simple visual signals like lights or flags can be used to complement hand signals or radio communication.

Regardless of the signaling method used, the key is clarity, consistency, and proper training for all personnel involved. Operators should be proficient in understanding and responding to all types of signals, and signal persons must be thoroughly trained to give clear and unambiguous instructions.

Example of a Hand Signal: A closed fist raised slowly indicates a gradual lowering of the load; an open hand with fingers spread wide and moving slowly would signal to slowly raise the load. Detailed signal charts are always available for reference.

Q 8. How do you ensure the stability of a crane during operation?

Ensuring crane stability is paramount for safe operation. It involves a multi-faceted approach focusing on the crane itself, the load, and the environment. Think of it like balancing a seesaw – you need to distribute the weight evenly to prevent tipping.

- Proper Load Distribution: The load’s center of gravity must be accurately determined and positioned within the crane’s safe operating limits. Incorrectly distributing weight can lead to instability, especially with uneven or oddly shaped loads.

- Ground Conditions: The ground beneath the crane must be firm and level. Soft or uneven ground can cause the crane to sink or tilt, compromising stability. Outriggers, when available, should be fully extended and firmly seated on a stable surface.

- Crane Condition: Regular inspections are crucial. Any mechanical issues, such as worn components or hydraulic leaks, can directly impact stability. Always ensure the crane is properly leveled and calibrated before lifting.

- Wind Speed: High winds create significant forces that can affect stability. Crane operators must adhere to wind speed limitations outlined in the crane’s operating manual. In extreme wind conditions, operation should cease.

- Swing Radius: Operators should be mindful of the crane’s swing radius to prevent collisions or imbalances. Maintaining a safe distance from obstructions and other equipment is vital.

For example, I once worked on a project where the ground was unexpectedly soft. By carefully assessing the situation and using additional ground mats, we ensured the crane remained stable, preventing a potentially dangerous incident.

Q 9. Describe your experience with different lifting techniques and rigging procedures.

My experience encompasses a variety of lifting techniques and rigging procedures, ranging from simple lifts to complex multi-lift operations. Proper rigging is as critical as the crane itself; it’s the link between the crane and the load.

- Basic Lifting: This includes using slings (chain, wire rope, or synthetic) and shackles to lift simple, well-balanced loads. I’m proficient in calculating the required sling angles to distribute the load evenly and avoid excessive stress on any single sling.

- Specialized Lifting: I have experience with more complex techniques such as using spreader beams for wide or awkward loads, and employing specialized rigging equipment like vacuum lifters or magnetic lifters for delicate or sensitive items. Knowing the limitations of each tool and choosing the right one is key.

- Multi-Lift Operations: Coordinating multiple cranes, or a crane and other lifting equipment, demands precise communication, planning, and execution to prevent collisions and ensure synchronized movements.

- Load Securing: I’m versed in various techniques for securing loads, preventing movement or shifting during the lift. Proper load securing involves selecting appropriate equipment, such as chains, straps, and nets, depending on the load’s size, shape, and characteristics.

One project involved lifting a large, irregularly shaped transformer using a specially designed spreader beam. Precise calculations of load center and careful rigging were critical to prevent damage or accidents.

Q 10. What are the emergency procedures in case of a crane malfunction?

Emergency procedures for crane malfunctions are crucial and must be practiced regularly. They prioritize the safety of personnel and the prevention of further damage.

- Immediate Shutdown: In case of a malfunction, the first step is to immediately shut down the crane using the emergency stop mechanism. This prevents further damage and potential accidents.

- Evacuation: Clear the immediate area surrounding the crane, ensuring all personnel are a safe distance away. Establish a perimeter to prevent unauthorized access.

- Assessment: Once the area is secure, assess the nature of the malfunction. Determine if the issue is mechanical, electrical, or related to the load. Consider the stability of the crane and the load.

- Reporting: Report the incident immediately to the appropriate supervisor and safety personnel. Document the incident, including details of the malfunction, the actions taken, and any injuries or damages.

- Repair and Investigation: Do not attempt to restart the crane or repair the malfunction without proper authorization and qualified personnel. A thorough investigation will be necessary to identify the root cause and implement preventative measures.

For example, a sudden hydraulic failure requires immediate shutdown, evacuation, and a call to maintenance to assess the leak and pressure issues before resuming operation.

Q 11. How do you handle unexpected situations or emergencies during crane operation?

Handling unexpected situations requires quick thinking, decisive action, and adherence to safety protocols. My approach is based on a systematic problem-solving process.

- Assess the Situation: Quickly and calmly analyze the unexpected event. Identify any immediate hazards, such as a shifting load, a malfunction, or an environmental factor like sudden strong winds.

- Prioritize Safety: The priority is always the safety of personnel and the prevention of further damage. Implement immediate safety measures, such as shutting down the crane or evacuating the area.

- Communicate: Maintain clear communication with the ground crew, other operators, and supervisors. Relay information about the situation and the actions being taken.

- Problem-Solve: Based on the assessment, determine the appropriate course of action. This may involve using alternative lifting techniques, requesting additional equipment, or seeking expert advice.

- Document: Thoroughly document the incident, including the details, actions taken, and outcome. This information is crucial for future incident analysis and prevention.

One time, I encountered a sudden power outage. I immediately secured the load, communicated with the ground crew, and followed the emergency power-down procedure. After a thorough assessment of the power situation, we safely lowered the load and waited for power restoration before resuming operation.

Q 12. What are the regulations and standards related to safe crane operation in your region?

(Note: This answer will vary depending on the region. Replace the example below with the relevant regulations and standards for your specific location.)

In my region, safe crane operation adheres to [Insert relevant regional or national safety standards, e.g., OSHA regulations in the USA, or equivalent standards in other countries. Mention specific regulations regarding crane inspections, operator certification, load capacity, and safety procedures]. These regulations cover various aspects of crane operation, including:

- Operator Certification: Operators must possess the necessary training and certification to operate cranes. This ensures a minimum competency level.

- Regular Inspections: Cranes undergo regular inspections to identify any potential issues before they lead to accidents. These inspections can be daily, weekly, or monthly depending on the type of crane and intensity of usage.

- Load Capacity Limits: Regulations specify load capacity limits for different cranes, ensuring they are not overloaded. Exceeding load capacity puts enormous stress on the crane structure and is highly dangerous.

- Safety Procedures: Strict safety procedures must be followed during every operation. This includes pre-lift inspections, signal communication, and emergency protocols.

Strict adherence to these regulations is crucial for preventing accidents and creating a safe working environment.

Q 13. Explain your understanding of load-bearing capacity and stress factors.

Understanding load-bearing capacity and stress factors is fundamental to safe crane operation. It’s about ensuring the crane and its components can handle the forces involved in lifting.

- Load-Bearing Capacity: This refers to the maximum weight a crane can safely lift under specific conditions. It’s usually specified in the crane’s operating manual and is influenced by factors like boom length, radius, and load configuration.

- Stress Factors: Several factors can increase stress on the crane, reducing its effective load-bearing capacity. These include wind speed, uneven load distribution, and the condition of the crane itself. Even seemingly minor damage or wear can significantly weaken the structure.

- Stress Calculations: Determining the appropriate load-bearing capacity often involves complex calculations taking into account the above factors. It is recommended to consult the crane’s load chart, which provides this information for different configurations.

- Safety Margin: A safety margin is always incorporated into calculations. This means the crane’s actual capacity should significantly exceed the expected load to account for unexpected stress factors and uncertainties.

Ignoring load capacity and stress factors can lead to catastrophic failures, like structural collapse or component breakage, causing significant damage and potential injuries.

Q 14. Describe the process for conducting a thorough pre-lift inspection.

A thorough pre-lift inspection is a non-negotiable step in every crane operation, analogous to a pre-flight checklist for an airplane. It ensures the crane is in safe working condition before any load is lifted.

- Visual Inspection: This involves a visual check of the entire crane, including the boom, hoist, cables, wires, outriggers, and all safety devices. Look for any obvious damage, wear, or loose parts. Check for wear, corrosion, and deformation on critical components.

- Mechanical Checks: Inspect the brakes, hoisting mechanisms, and other moving parts. Confirm that all functions operate smoothly and effectively, without any binding, unusual noises, or excessive play.

- Hydraulic System: Inspect the hydraulic system for any leaks or damage. Ensure the hydraulic fluid level is within the acceptable range. Check for proper functioning of hydraulic cylinders and valves.

- Electrical System: Check electrical wiring for damage or fraying. Inspect all switches, controls, and indicators. Ensure the crane’s electrical system is properly grounded.

- Load Chart and SWL: Verify that the crane’s load chart is accessible and that the Safe Working Load (SWL) for the intended lift is understood. Always compare the intended load weight against the crane’s rated capacity, accounting for variables like boom length, radius, and wind speed.

- Documentation: Record the findings of the inspection and any necessary maintenance or repairs. Signature confirmation by the inspector and the operator is crucial for accountability.

Skipping this critical step can lead to equipment malfunction, injuries, and potentially disastrous consequences. A systematic pre-lift inspection helps prevent these dangerous situations.

Q 15. How do you communicate effectively with the ground crew during lifting operations?

Effective communication with the ground crew is paramount for safe crane operations. It’s not just about shouting instructions; it’s about clear, concise, and unambiguous communication using a standardized system. Think of it like conducting an orchestra – everyone needs to be on the same page, understanding their role and the conductor’s cues.

- Pre-lift Briefing: Before any lift commences, a thorough briefing should occur. This clarifies the lift plan, hand signals, potential hazards, and emergency procedures. Each team member should understand their responsibilities and communication protocols.

- Hand Signals: We use a standardized set of hand signals, ensuring everyone understands the meaning of each gesture. This is particularly important in noisy environments where verbal communication might be difficult. For instance, a slow, deliberate hand signal to the crane operator might indicate a gradual lowering of the load.

- Two-Way Radios: Two-way radios are essential for continuous communication, especially in large-scale projects. This allows for immediate feedback, updates on the load’s position, and any immediate adjustments needed.

- Clear Terminology: Using consistent and unambiguous terminology avoids confusion. For example, instead of saying ‘move it over there,’ a clear instruction like ‘move the load five feet to the east’ is preferred.

- Confirmation: Always ensure instructions are understood and confirmed by the receiving party before proceeding. This simple step prevents miscommunication and potential accidents.

For instance, during a recent project involving the placement of prefabricated sections of a building, a clear pre-lift briefing identifying the exact positioning required, along with the use of two-way radios, ensured a smooth and safe lift of multiple components, without incident.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of crane accidents and how can they be prevented?

Crane accidents stem from various factors, often stemming from a combination of human error, inadequate equipment maintenance, and insufficient safety procedures. Think of it like a chain – if one link is weak, the entire chain can fail.

- Human Error: This accounts for the majority of accidents. Examples include inadequate training, ignoring safety procedures, rushing the job, improper load handling, and operating equipment while under the influence of drugs or alcohol.

- Inadequate Equipment Maintenance: Regular inspections and maintenance are crucial. Faulty brakes, worn cables, or damaged components can lead to catastrophic failures. Imagine driving a car with faulty brakes – the consequences are equally severe with a crane.

- Insufficient Safety Procedures: Lack of proper risk assessments, inadequate safety protocols, and insufficient training for personnel are significant contributors. A solid safety program must be more than just a checklist; it needs to be ingrained in the culture of the operation.

- Environmental Factors: Adverse weather conditions, such as strong winds or heavy rain, can negatively impact crane stability and visibility.

- Improper Load Handling: Incorrectly calculating the load weight, improper load securing, and exceeding the crane’s capacity are common issues.

Prevention: Implementing robust safety protocols including thorough operator training, comprehensive equipment inspections, and stringent adherence to safety regulations are essential. Regular safety meetings, proactive risk assessments, and the use of technology like load moment indicators (LMIs) which prevent overloading help minimize risk. For example, ensuring that crane operators receive regular refresher training and complete pre-operation checks prevents many accidents related to human error and equipment malfunction.

Q 17. What is your experience with different types of crane hooks and attachments?

My experience encompasses a wide range of crane hooks and attachments, each tailored to specific lifting requirements. Choosing the right attachment is as important as choosing the right crane itself.

- Standard Hooks: These are the most common and used for general lifting tasks. Different sizes cater to varying load capacities.

- Clevis Hooks: These offer greater strength and security than standard hooks, particularly for heavier loads.

- Grab Hooks: Used for grabbing and lifting materials, such as logs or scrap metal.

- Spreader Beams: Distribute the weight of a load across multiple hook points, ideal for handling large, unwieldy objects.

- Magnetic Lifters: Used for lifting ferrous materials.

- Vacuum Lifters: Suitable for lifting smooth, non-porous materials.

- Other Specialized Attachments: This includes shackles, slings, and various other custom attachments to handle specific materials or configurations.

The selection of a particular hook and attachment depends on various factors, including the weight, shape, and material of the load, as well as the environment. For instance, during a project involving the installation of large glass panels, we used vacuum lifters to handle them safely and efficiently without risk of damage.

Q 18. Explain your understanding of swing radius and its importance in crane operation.

The swing radius represents the horizontal distance from the crane’s center of rotation to the furthest point reached by the load. It’s a critical factor in ensuring safe operation and preventing accidents. Think of it as the ‘reach’ of the crane.

Understanding the swing radius is essential for several reasons:

- Obstacle Avoidance: It helps determine the safe working area, allowing operators to avoid collisions with nearby structures, equipment, or personnel. Failing to account for the swing radius can lead to catastrophic collisions.

- Stability: Exceeding the crane’s rated capacity within a specific swing radius can compromise stability, potentially leading to tipping.

- Load Capacity: The crane’s lifting capacity often decreases as the swing radius increases. Operators must check load charts and adjust their operations accordingly.

- Planning and Site Survey: Accurate determination of the swing radius is crucial during the planning phase of a project to ensure a safe and efficient operation. Careful site surveys are crucial to identify potential obstructions and plan a lifting scheme accordingly.

For example, in a recent construction project, careful calculation of the swing radius and the placement of the crane allowed us to avoid the risk of the crane boom colliding with an adjacent building while lifting large steel beams.

Q 19. How do you manage the risks associated with working at heights with a crane?

Working at heights with a crane presents significant risks, including falls from the crane itself, falling objects, and the potential for crane instability. Mitigating these risks requires a multi-faceted approach.

- Fall Protection: All personnel working on the crane must use appropriate fall protection equipment, such as harnesses and lifelines, ensuring proper anchoring points.

- Proper Training: Crane operators and ground crew personnel must receive comprehensive training in safe work practices at heights, including the proper use of fall protection equipment.

- Regular Inspections: Regular inspections of all fall protection equipment and the crane structure itself are crucial to ensure everything is in good working order.

- Exclusion Zones: Establishing clearly marked exclusion zones around the crane’s operating area prevents unauthorized personnel from entering hazardous areas.

- Wind Speed Monitoring: Crane operations should cease if wind speeds exceed the crane’s operational limits. Continuously monitoring wind speed conditions is essential for safety.

- Emergency Procedures: Detailed and well-rehearsed emergency procedures must be in place to deal with potential falls or accidents.

For instance, during the erection of a wind turbine, we implemented strict fall protection measures for workers on the tower, ensuring they were always secured with appropriate harnesses and lifelines. We also utilized specialized rigging techniques to minimize the risk of falling components.

Q 20. What are your experience with maintaining crane log books and documentation?

Maintaining accurate and comprehensive crane log books and documentation is crucial for ensuring compliance with regulations and preventing accidents. These records provide a detailed history of the crane’s operation and maintenance. Think of it as a meticulous health record for the crane.

- Daily Inspections: Daily pre-operational inspections are meticulously recorded, documenting the crane’s condition, any observed defects, and the operator’s signature. Any defects identified are immediately reported and rectified.

- Maintenance Records: Detailed records of all maintenance activities, including servicing schedules, repairs, and component replacements are carefully documented, along with the names of technicians and relevant dates.

- Operator Certification: Records of all crane operators’ certifications, training, and experience levels are maintained to confirm their competency.

- Load Records: Records of each lift, including the date, time, load weight, height, and swing radius, are carefully logged.

- Incident Reporting: Any accidents or near misses are promptly reported and thoroughly investigated, with detailed reports added to the logbook.

This detailed documentation allows for a clear audit trail and helps identify potential safety issues and trends. The data provided aids proactive maintenance to prevent future problems and provides evidence of compliance with regulatory requirements. We utilize a digital logbook system, enhancing ease of access and record-keeping.

Q 21. Describe the process of selecting the appropriate crane for a specific job.

Selecting the appropriate crane for a job requires a thorough assessment of several factors. It’s not just about lifting capacity; it’s about the right tool for the right job.

- Load Capacity: The crane’s capacity must exceed the weight of the heaviest load to be lifted. Always include a safety factor.

- Lifting Height and Radius: The crane’s reach and height must accommodate the job’s requirements. Remember the swing radius – it’s a critical consideration.

- Site Conditions: Consider ground conditions, available space, and potential obstacles. A larger crane might be needed in confined spaces compared to an open area.

- Load Configuration: The shape, size, and stability of the load must be considered when choosing the appropriate crane and attachments.

- Weather Conditions: Wind speeds and precipitation can affect crane stability and operational limits.

- Crane Type: Various crane types (tower cranes, mobile cranes, overhead cranes, etc.) are suited for different applications. The choice depends on the job and site conditions.

A thorough risk assessment should precede crane selection. For example, in a project involving the construction of a tall building, the selection of a suitable tower crane with sufficient reach and capacity is crucial for lifting heavy building materials to significant heights. On the other hand, a mobile crane might be the better choice for lifting equipment in a smaller site.

Q 22. How do you ensure the safety of personnel working in the vicinity of a crane?

Ensuring personnel safety around a crane involves a multi-layered approach, prioritizing proactive measures and strict adherence to regulations. Think of it like creating a protective bubble around the crane’s operational area.

Designated Exclusion Zones: Establishing clearly marked and enforced exclusion zones around the crane’s swing radius is paramount. These zones prevent unauthorized personnel from entering areas where falling objects or swinging loads pose a risk. Imagine a painted circle on the ground – that’s your exclusion zone.

Signage and Warning Systems: Visible and audible warning systems are crucial. This could include flashing lights, audible alarms, and clear signage indicating restricted areas and potential hazards. Think of it like a loud and clear warning system before a train crosses.

Crane Operator Communication: The crane operator must maintain clear communication with ground personnel using hand signals, radios, or other designated communication systems. Miscommunication is a major hazard, so clear and concise communication is vital.

Personnel Training and Awareness: Rigorous training programs for all personnel working near cranes are indispensable. This includes understanding hand signals, recognizing potential hazards, and knowing emergency procedures. It’s like teaching someone to drive safely – you need to understand the rules of the road.

Regular Site Inspections: Conducting regular site inspections to identify and rectify any potential hazards before work commences is critical. This could involve checking for obstructions, ensuring proper signage, and verifying the crane’s stability.

Q 23. Explain your experience with different types of crane controls (e.g., radio remote).

My experience encompasses a range of crane controls, from traditional lever and pedal systems to modern radio remote controls. Each type presents unique safety considerations.

Lever and Pedal Controls: These are often found in older cranes and require the operator to be physically positioned in the crane cab. The advantage is direct tactile feedback, but they limit the operator’s visibility. I have extensive experience operating these, understanding the importance of precise movements and careful control.

Radio Remote Controls: These provide greater flexibility, allowing the operator to control the crane from a safe distance. However, they rely on radio signals, which can be susceptible to interference or malfunctions. I’ve worked extensively with these, understanding the need for regular testing and backup communication systems. We regularly check signal strength and have established protocols for troubleshooting signal loss.

Joystick Controls: Many modern cranes use joystick controls for precise movements. These offer ergonomic advantages but require proper training to avoid jerky movements and accidents. The precision required is similar to piloting an aircraft, requiring a steady hand and good judgment.

In every case, my priority is always safe operation. I meticulously follow established safety protocols and undergo regular training updates to ensure proficiency with all control types.

Q 24. What are the procedures for disconnecting a load safely?

Disconnecting a load safely is a critical procedure requiring precision and awareness. A sudden or uncontrolled release can cause serious accidents. Think of it like carefully unplugging a high-voltage device – you need to follow a precise sequence.

Lower the Load Slowly and Carefully: Gently lower the load to the designated area, ensuring it’s stable and won’t shift or roll.

Engage Safety Mechanisms: If the crane has a load-holding brake, engage it before releasing the load completely. This prevents the load from unexpectedly dropping.

Check for Obstructions: Ensure the area is clear of obstacles and personnel before releasing the load completely.

Visual Confirmation: After the hook is released, visually confirm the load is safely on the ground and stable before moving the crane.

Post-Disconnect Check: After the load has been disconnected, it is essential to conduct a post-disconnect check. This includes inspecting the hook and rigging for damage, ensuring all safety mechanisms are functioning correctly, and confirming the area is secure.

Q 25. How do you handle weather-related challenges during crane operation?

Weather significantly impacts crane operation, posing potential hazards such as strong winds, rain, ice, and lightning. Therefore, weather-related challenges necessitate careful planning and immediate response. It’s like preparing for a storm – you need to anticipate the conditions and take precautions.

Wind Speed Monitoring: Wind speed is a crucial factor. Most cranes have operational wind speed limits; exceeding these limits is extremely hazardous. Regular monitoring, often with an anemometer, is necessary.

Rain and Ice: Rain and ice can reduce visibility and make the load slippery. Specialized equipment and procedures may be required to ensure safe operation under these conditions. It’s important to assess the load’s condition and any potential for shifting or slippage.

Lightning: Operations must cease immediately during lightning storms. The crane itself can act as a lightning rod, presenting a severe electrocution hazard. Immediate shutdown and evacuation are essential.

Weather Forecasting: Regular weather forecasts and warnings allow for proactive planning and can prevent operation under unsafe conditions.

In all cases, the safety of personnel and the structural integrity of the crane are top priorities. If conditions are hazardous, crane operation must cease.

Q 26. Describe your experience with different types of crane foundations and anchoring.

Crane foundations and anchoring are critical for stability and safety. A poorly designed or installed foundation can lead to catastrophic crane failure. Think of it as the building’s foundation – it needs to support the weight and withstand stress.

Concrete Foundations: These are the most common, providing excellent stability for most crane types. The design must account for the crane’s weight, load capacity, and potential ground conditions. The concrete must be properly cured and inspected for flaws.

Steel Bases and Anchors: These are often used for temporary or mobile cranes. The steel base must be properly anchored to the ground to prevent movement. This usually involves embedded bolts or tie-downs.

Pile Foundations: In areas with poor soil conditions, pile foundations provide the necessary support. These involve driving long piles deep into the ground to create a stable base.

My experience involves assessing site conditions, reviewing foundation designs, and ensuring proper installation. Safety inspections are essential throughout the process, and I’m familiar with industry standards and regulations to assure structural integrity.

Q 27. How familiar are you with the use of load moment indicators (LMIs)?

Load Moment Indicators (LMIs) are essential safety devices that measure the load’s weight and the crane’s radius, calculating the potential overturning moment. It’s like having a built-in warning system to prevent overloading. An LMI will prevent the crane operator from placing the crane in a dangerous condition.

I am highly familiar with LMIs. I understand their functionality, limitations, and regular maintenance requirements. I know how to interpret the readings and take appropriate action if the indicator suggests an unsafe situation. My experience includes working with different types of LMIs, from simple analog gauges to advanced digital systems with real-time load monitoring and alerts.

Q 28. Describe your experience with conducting and recording crane inspections.

Regular crane inspections are paramount for safety. It’s like a routine medical checkup for your crane – identifying potential problems before they become major issues.

My experience involves conducting both pre-operational and periodic inspections, documenting findings meticulously and adhering to industry best practices. Inspections include:

Visual Inspection: Thoroughly checking all components for signs of wear, damage, or corrosion.

Functional Testing: Testing all mechanical and electrical components to ensure proper operation.

Load Testing: Periodically testing the crane’s capacity with a calibrated load.

Documentation: Maintaining detailed records of inspections, including dates, findings, and corrective actions.

I use checklists and standardized forms to ensure thoroughness and consistency. Any defects identified are immediately reported and rectified before operation resumes. Safety is my top priority in every inspection.

Key Topics to Learn for Safe Crane Operation Interview

- Crane Types and Capabilities: Understanding the differences between various crane types (tower, mobile, overhead) and their operational limitations is crucial. Be prepared to discuss specific examples and their suitability for different lifting tasks.

- Load Chart Interpretation and Calculations: Demonstrate your ability to interpret load charts accurately and perform necessary calculations to ensure safe lifting practices. Practice applying this knowledge to hypothetical scenarios.

- Rigging and Signaling: Master the principles of proper rigging techniques, including selecting the appropriate slings and hardware. Familiarize yourself with standard hand signals and their importance in clear communication between crane operators and riggers.

- Safety Regulations and Procedures: Thorough knowledge of OSHA (or relevant regional) regulations and safe operating procedures is paramount. Be ready to discuss specific regulations and how they apply in real-world situations.

- Pre-Operational Inspections and Maintenance: Explain the importance of conducting thorough pre-operational inspections and identifying potential hazards. Discuss routine maintenance procedures and their impact on crane safety.

- Emergency Procedures: Outline your understanding of emergency procedures, including what to do in case of equipment malfunction, load instability, or other unforeseen circumstances. Highlight your problem-solving skills in these high-pressure situations.

- Environmental Awareness: Demonstrate understanding of how environmental factors (wind, weather) can impact crane operation and the necessary safety precautions.

- Communication and Teamwork: Effective communication is essential in crane operation. Be prepared to discuss how you would coordinate with other workers on a job site to ensure everyone’s safety.

Next Steps

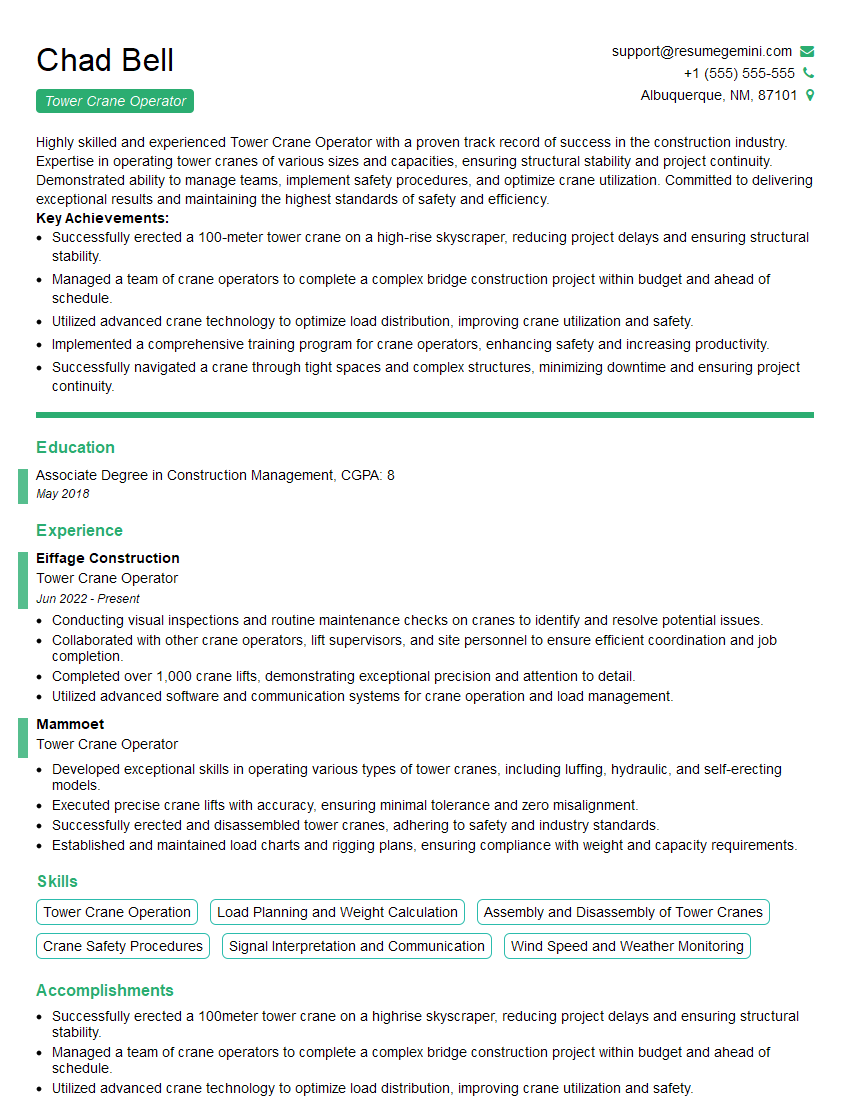

Mastering safe crane operation is vital for career advancement in the construction, manufacturing, and logistics industries, opening doors to higher-paying roles and increased responsibility. To stand out to potential employers, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your qualifications and experience. Examples of resumes tailored to Safe Crane Operation are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO