Cracking a skill-specific interview, like one for Operating and maintaining core drying equipment, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Operating and maintaining core drying equipment Interview

Q 1. Explain the different types of industrial dryers and their applications.

Industrial dryers come in various types, each suited for specific applications. The choice depends on the material being dried, its properties, the desired final moisture content, and production scale.

- Rotary Dryers: These are large cylindrical drums that rotate, tumbling the material and exposing it to hot gases for efficient drying. They’re ideal for large-scale drying of granular materials like grains, ores, and cement.

- Fluidized Bed Dryers: These dryers use a stream of hot air to suspend the material, creating a fluidized bed. This ensures excellent heat transfer and uniform drying, suitable for powders and granules that are sensitive to heat. I’ve used these extensively in pharmaceutical applications where delicate powders need careful drying.

- Spray Dryers: A liquid feed is atomized into a hot gas stream, causing rapid evaporation and producing a dry powder. This method is used for producing powdered milk, coffee, and various chemicals. The key is controlling the atomization and gas flow for consistent particle size and moisture content.

- Conveyor Dryers: These utilize a moving conveyor belt to transport the material through a heated chamber. They are suitable for continuous drying of sheet materials, films, or other materials that can be easily conveyed. I remember working on a project where we used a conveyor dryer for drying lumber before finishing, ensuring consistent moisture levels across the boards.

- Vacuum Dryers: These dryers operate under reduced pressure, allowing for drying at lower temperatures. This is crucial for heat-sensitive materials, as it prevents degradation while still achieving the desired dryness. I’ve seen these in use for drying pharmaceuticals and other temperature-sensitive products.

The selection process often involves considering factors like throughput, energy efficiency, and the specific characteristics of the material. For instance, a material prone to clumping would necessitate a dryer that minimizes agglomeration, like a fluidized bed dryer.

Q 2. Describe the safety procedures for operating drying equipment.

Safety is paramount when operating drying equipment. A comprehensive safety program must be in place and strictly adhered to. This includes:

- Lockout/Tagout Procedures: Before any maintenance or repair, the dryer must be completely shut down and locked out to prevent accidental start-up. This is a non-negotiable safety protocol.

- Personal Protective Equipment (PPE): Appropriate PPE, including heat-resistant gloves, safety glasses, and respirators (depending on the material being dried), must be worn at all times. We always emphasize the importance of proper PPE usage during our safety briefings.

- Fire Prevention: Many dryers utilize high temperatures and flammable materials. Fire extinguishers must be readily available and personnel trained in their use. Regular inspections of the fire suppression systems are mandatory.

- Ventilation and Exhaust: Adequate ventilation is crucial to remove dust, fumes, and excess moisture to prevent fire hazards and ensure a safe working environment. Regularly checking exhaust systems for blockages is part of our standard operating procedure.

- Emergency Shutdown Procedures: Everyone operating the equipment should be familiar with the location and operation of emergency shut-off switches and emergency procedures. We conduct regular drills to reinforce this knowledge.

- Regular Inspections: Frequent inspections of the dryer and its components, including wiring, piping, and safety devices, are essential for identifying potential hazards before they lead to accidents.

Safety isn’t just a set of rules; it’s a mindset. A culture of safety, where everyone takes ownership of their safety and the safety of others, is critical in preventing accidents.

Q 3. How do you troubleshoot a malfunctioning drying system?

Troubleshooting a malfunctioning drying system requires a systematic approach. I usually follow these steps:

- Identify the Problem: Begin by clearly defining the malfunction. Is the dryer failing to reach the desired temperature? Is the drying time too long? Is the final product moisture content too high? Accurate observation is the first step.

- Check Basic Operations: Verify that power, fuel supply, and airflow are functioning correctly. Simple issues like a tripped breaker or a clogged filter can often be the cause.

- Review Process Parameters: Check the settings of the dryer’s control system. Are the temperature, airflow, and drying time set correctly? Even small deviations can significantly affect drying efficiency.

- Inspect Sensors and Instrumentation: Ensure that temperature sensors, flow meters, and other instruments are functioning accurately. Faulty sensors can lead to incorrect control actions, resulting in inefficient drying or even product damage.

- Check for Mechanical Issues: Inspect moving parts for wear and tear. Problems like a malfunctioning motor or a damaged conveyor belt can significantly impact the drying process. I always recommend a visual inspection before diving into more complex issues.

- Examine the Material: Sometimes, the problem isn’t with the equipment but with the material being dried. Changes in material composition or moisture content can affect drying performance.

- Consult Operating Logs: Review the dryer’s operating logs to identify any trends or patterns that might indicate a recurring problem.

If the problem persists after these steps, it might require more specialized expertise, possibly involving a vendor or a qualified technician.

Q 4. What are the common causes of reduced drying efficiency?

Reduced drying efficiency can stem from several factors:

- Insufficient Airflow: Inadequate airflow limits the heat transfer rate, resulting in longer drying times and increased energy consumption. This can be caused by clogged filters, ductwork issues, or a malfunctioning fan.

- Low Inlet Air Temperature: If the inlet air temperature is too low, the material won’t dry efficiently. This could be due to problems with the heating system, fuel supply issues, or inadequate insulation.

- High Moisture Content in the Inlet Air: High humidity in the incoming air reduces the drying capacity. A dehumidification system might be necessary in such cases.

- Poor Material Distribution: Uneven distribution of the material within the dryer leads to uneven drying, resulting in some parts being under-dried while others are over-dried. Improved material handling or the dryer’s design might be needed.

- Fouling or Scaling: Buildup on heat transfer surfaces reduces the efficiency of heat transfer, prolonging drying times. Regular cleaning is essential.

- Equipment Wear and Tear: Worn or damaged components, such as seals, bearings, or heating elements, reduce overall efficiency. Preventative maintenance is key to avoid this.

Addressing these issues requires careful diagnosis and appropriate corrective actions. For example, a clogged filter might require simple cleaning, while a worn-out heating element might need replacement. Understanding the root cause is crucial for effective remediation.

Q 5. Explain the importance of preventative maintenance for drying equipment.

Preventative maintenance is crucial for maximizing the lifespan, efficiency, and safety of drying equipment. It’s far more cost-effective to prevent problems than to fix them after they occur. A well-structured preventative maintenance program includes:

- Regular Inspections: Routine inspections to check for wear and tear, leaks, corrosion, and other potential problems. We often use checklists to ensure nothing is missed.

- Scheduled Cleaning: Regular cleaning of the dryer, including the interior surfaces, filters, and exhaust system, to prevent fouling and maintain optimal airflow.

- Lubrication: Regular lubrication of moving parts to reduce wear and tear and extend the life of the equipment. We follow manufacturer recommendations for lubrication schedules and types.

- Component Replacement: Proactive replacement of parts that show signs of wear or are nearing their end-of-life, preventing unexpected failures.

- Calibration: Regular calibration of sensors and instrumentation to ensure accurate measurements and control.

- Safety Checks: Regular inspection of safety devices, such as emergency shutdown systems, to ensure their proper functioning.

A well-documented maintenance program, with records of all inspections, repairs, and replacements, is essential for tracking performance and identifying potential issues early on. It is also helpful in planning future maintenance needs.

Q 6. How do you monitor and control the temperature and humidity within a dryer?

Monitoring and controlling temperature and humidity within a dryer involves a combination of sensors, control systems, and actuators. Temperature is typically monitored using thermocouples or RTDs (Resistance Temperature Detectors) strategically placed within the dryer. Humidity is often measured using sensors that measure the dew point or relative humidity.

These sensors feed data to a control system, which can be a simple PID (Proportional-Integral-Derivative) controller or a more sophisticated system like a PLC (Programmable Logic Controller) or DCS (Distributed Control System). The control system compares the measured values to the setpoints and adjusts the actuators to maintain the desired conditions. These actuators might include heating elements, fans, dampers, or humidification/dehumidification systems.

For example, if the temperature falls below the setpoint, the control system will increase the heat input by activating the heating elements. Similarly, if the humidity is too high, the control system might activate a dehumidification system or adjust the airflow to reduce the moisture content. Modern dryers often use advanced control algorithms for precise and efficient control of temperature and humidity.

Q 7. Describe your experience with different types of dryer controls (e.g., PLC, DCS).

I have extensive experience with various dryer control systems, including PLCs and DCSs. PLCs are commonly used in smaller-scale dryers, offering programmable logic and precise control over various parameters. I’ve worked with Allen-Bradley and Siemens PLCs in several projects, programming them to manage temperature, airflow, and other crucial parameters.

Example PLC Code (Illustrative): // Check temperature sensor IF Temp < Setpoint THEN //Increase heating element output END_IF

For larger, more complex drying systems, DCSs provide a more centralized and integrated control approach, allowing for better monitoring and management of multiple dryers and other associated equipment. I've worked with Honeywell and Emerson DCS systems, managing large-scale drying operations in various industries. These systems offer advanced features like SCADA (Supervisory Control and Data Acquisition) for real-time monitoring and data analysis, which is vital for optimizing energy efficiency and maintaining consistent product quality. The advanced capabilities of DCS systems allow for seamless integration with other plant systems, which is crucial for large-scale manufacturing operations.

Q 8. How do you ensure the quality of the dried product?

Ensuring the quality of the dried product involves a multifaceted approach, starting even before the drying process begins. It's crucial to have high-quality raw materials with consistent properties. During drying, we monitor key parameters like temperature, airflow, and humidity to prevent degradation or uneven drying. We employ various techniques like regular sampling and analysis of moisture content, using tools such as moisture meters or Karl Fischer titrators to ensure the product meets predefined specifications. For example, in food drying, exceeding the optimal temperature can lead to nutrient loss and color changes, affecting the final product's quality. In pharmaceutical drying, precise control is essential to prevent degradation of active ingredients and maintain product potency. Post-drying, quality checks are performed on the final product, assessing factors like color, texture, and particle size to ensure consistency and meet quality standards.

Regular calibration and maintenance of all measuring instruments are paramount. We keep detailed records of each batch, including all parameters, to track trends and identify potential quality issues early on. This data-driven approach allows for continuous improvement and ensures consistent high-quality output.

Q 9. What are the potential hazards associated with operating drying equipment?

Operating drying equipment presents several potential hazards. High temperatures pose a burn risk to personnel, requiring careful attention to safety protocols and the use of appropriate personal protective equipment (PPE), such as heat-resistant gloves and clothing. Moving parts, like conveyor belts and fans, create a risk of entanglement or crushing injuries. Regular safety checks and proper machine guarding are essential. Many dryers use flammable or combustible materials. This necessitates stringent fire safety measures, including proper ventilation, fire suppression systems, and adherence to strict procedures regarding the handling of these materials. Furthermore, the release of dust from certain products can create a risk of explosions if not properly controlled. This is mitigated through appropriate dust collection and explosion-prevention systems. Finally, electrical hazards from faulty wiring or equipment can pose significant risks. Regular electrical inspections and proper grounding are essential.

Q 10. How do you perform a routine inspection of a dryer?

A routine dryer inspection is a systematic process encompassing visual checks and functional tests. The visual inspection focuses on identifying any signs of wear and tear, such as cracks in the dryer shell, damaged seals, or loose components. We carefully check for leaks or blockages in the system, assessing the integrity of pipes, valves, and filters. For example, a visual inspection of a conveyor belt might reveal wear or damage that needs immediate attention. The functional tests involve checking the heating system's efficiency, ensuring the correct temperature and airflow are maintained. We verify the proper functioning of the control system and alarms. This includes checking if the temperature sensors accurately measure and control the temperature within the set parameters. We also check the efficiency of the exhaust system and any dust collection systems. Proper documentation of all findings during the inspection is crucial for maintenance planning and safety records. This prevents problems from escalating and minimizes downtime.

Q 11. Explain the process of cleaning and maintaining a dryer.

Cleaning and maintaining a dryer is crucial for ensuring its efficiency and longevity. The process typically begins with a shutdown and cooling down period to prevent accidents. The dryer is then thoroughly cleaned. Depending on the type of dryer and the material being processed, this may involve vacuuming, brushing, or pressure washing. For example, a spray dryer would require different cleaning procedures than a rotary dryer. Any accumulated material is removed, and all surfaces are cleaned and sanitized, paying particular attention to areas prone to fouling, such as heating elements, filter screens and conveyors. Maintenance includes lubricating moving parts, inspecting and replacing worn-out components like belts, bearings and seals. We also check and clean filters and sensors, and we perform a thorough inspection of all safety systems and components. A detailed log documenting all maintenance activities, including parts replaced and any anomalies noted, is essential for tracking maintenance history and future decision making. Preventative maintenance schedules help minimize downtime and extend the life of the equipment.

Q 12. Describe your experience with different types of dryer components (e.g., heaters, fans, conveyors).

My experience encompasses a wide range of dryer components. I've worked extensively with different types of heaters, including electric resistance heaters, gas-fired heaters, and steam heaters, each with its own advantages and drawbacks in terms of efficiency, cost, and maintenance. I am also familiar with various fan types, from centrifugal fans to axial fans, understanding their impact on airflow patterns and energy consumption. My expertise extends to conveyor systems, including belt conveyors, screw conveyors, and fluidized bed conveyors, which are selected based on the characteristics of the material being processed. I've also worked with various control systems, ranging from simple on-off controls to advanced PLC-based systems that offer precise control over drying parameters like temperature, airflow, and humidity. For instance, in one project, we upgraded from an older resistance heating system to a more efficient gas-fired system, significantly reducing energy costs and improving process control. I also have experience troubleshooting problems with individual components, such as identifying and fixing a faulty bearing on a conveyor belt, or replacing a malfunctioning temperature sensor.

Q 13. How do you handle emergencies related to drying equipment malfunctions?

Handling emergencies related to drying equipment malfunctions requires a swift and systematic approach. The first step involves activating the emergency shutdown procedures, ensuring the safety of personnel and preventing further damage to the equipment. We then assess the situation, identifying the source of the malfunction and its potential impact. This involves checking safety systems, including alarms and sensors. Based on the nature of the malfunction, we either take immediate corrective action, such as replacing a blown fuse or resetting a tripped circuit breaker, or we contact qualified technicians for assistance. We also engage in the appropriate reporting procedures, documenting the incident, the steps taken to resolve it, and any damage incurred. Depending on the severity of the malfunction, this might involve reporting to a supervisor or relevant safety authorities. Following a thorough investigation into the cause of the malfunction, we implement preventive measures to avoid similar incidents in the future. This could include replacing a worn-out component, or adjusting operational parameters.

Q 14. What are the key performance indicators (KPIs) for a drying process?

Key Performance Indicators (KPIs) for a drying process are crucial for evaluating efficiency and quality. These include:

- Moisture Content: This is the most critical KPI, measuring the final moisture level in the dried product. Targets are set based on product specifications and quality requirements.

- Drying Rate: This indicates the speed at which moisture is removed, influencing throughput and productivity. A faster drying rate, without compromising quality, is generally desirable.

- Energy Consumption: This measures the energy used per unit of product dried, a key factor in operational cost. Reducing energy consumption is a continual goal.

- Throughput: This represents the amount of product processed per unit of time, reflecting the dryer's productivity.

- Product Quality: This encompasses various attributes, such as color, texture, and particle size, and depends on the specific product being dried.

- Downtime: The time the dryer is not operational due to maintenance or malfunctions affects productivity significantly. Minimizing downtime is essential.

Monitoring these KPIs provides insights into the drying process's performance, allowing for timely adjustments and improvements to maximize efficiency and product quality.

Q 15. How do you optimize a drying process for maximum efficiency?

Optimizing a drying process for maximum efficiency involves a multifaceted approach focusing on minimizing energy consumption, maximizing throughput, and maintaining product quality. Think of it like baking a cake – you want it perfectly done, in the shortest time, using the least amount of energy.

Improved airflow design: Ensuring uniform airflow distribution within the dryer prevents hot spots and ensures even drying. This can be achieved through optimized dryer design, baffles, and air distribution systems. For instance, in a rotary dryer, strategically placed vanes can significantly improve air mixing and reduce drying time.

Precise temperature and humidity control: Monitoring and controlling temperature and humidity are critical. Too high a temperature can degrade the product, while too low a temperature extends drying time unnecessarily. Advanced control systems, including PID controllers, can maintain optimal parameters. Consider a scenario where you're drying sensitive pharmaceuticals – precise control is crucial to prevent degradation.

Material handling optimization: The way material is fed into and discharged from the dryer impacts efficiency. A consistent feed rate, preventing clogging or bridging, is essential. For example, using vibratory feeders for consistent material flow can significantly improve throughput.

Regular maintenance: Regular maintenance, including cleaning of the dryer, replacement of worn components (like fans or filters), and calibration of sensors, prevents unexpected downtime and ensures optimal performance. Preventive maintenance is significantly cheaper than emergency repairs.

Process monitoring and data analysis: Implementing a robust data acquisition system allows for continuous monitoring of key process parameters. Analyzing this data helps identify areas for improvement and optimize the drying process further. Think of it like having a dashboard providing real-time feedback on your drying process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini's guide. Showcase your unique qualifications and achievements effectively.

- Don't miss out on holiday savings! Build your dream resume with ResumeGemini's ATS optimized templates.

Q 16. Explain the concept of heat and mass transfer in drying.

Heat and mass transfer are fundamental to the drying process. Imagine drying wet clothes – heat is transferred to the clothes, causing water to evaporate (mass transfer). Heat transfer is the movement of thermal energy from a higher temperature region (the drying medium) to a lower temperature region (the wet material). This can occur through conduction, convection, and radiation.

Conduction: Heat transfer through direct contact, like heat transfer from a hot plate to a pan.

Convection: Heat transfer through the movement of fluids (like air or steam), carrying thermal energy away from the surface of the material.

Radiation: Heat transfer through electromagnetic waves, like heat from the sun.

Mass transfer, on the other hand, involves the movement of water vapor from the wet material into the drying medium. This occurs through diffusion (water vapor moving from high concentration to low concentration) and convection (water vapor being carried away by the drying medium).

The rate of drying depends on the combined effect of heat and mass transfer. Efficient dryers are designed to maximize both processes.

Q 17. Describe your experience with different types of drying media (e.g., air, steam).

My experience encompasses various drying media, each with its own advantages and limitations. I've extensively worked with air, steam, and indirectly heated systems.

Air drying: This is the most common method, often using hot air to evaporate moisture. I've used this extensively in spray dryers and fluidized bed dryers, and I'm familiar with controlling parameters such as air temperature, humidity, and flow rate to optimize drying. Air drying is versatile and relatively inexpensive, but can be slower for some materials.

Steam drying: Direct steam injection or indirect steam heating is used for faster drying, particularly for materials sensitive to high temperatures. In indirect steam heating, steam heats a surface which in turn transfers heat to the material. Direct steam injection can be more efficient but requires careful control to prevent product degradation. I've used this in vacuum dryers and some rotary dryers, particularly when working with food products needing gentle drying.

Indirectly heated systems: These use conduction or radiation to transfer heat. Examples include ovens and vacuum dryers using heated plates or walls. The heat transfer rate is generally slower but provides better control, particularly for materials sensitive to high temperatures. I have worked with infrared drying systems which provide even and rapid heating.

Choosing the right drying medium depends on factors like material properties, desired product quality, energy efficiency, and cost considerations. I always carefully evaluate these aspects to make informed decisions.

Q 18. How do you interpret drying curves and charts?

Drying curves and charts are graphical representations of the moisture content of a material over time. They are essential for understanding and optimizing the drying process. They typically show a decreasing moisture content curve as drying progresses.

Interpreting these charts involves identifying key stages in the drying process, such as the constant rate period (where the drying rate is constant) and the falling rate period (where the drying rate decreases). The shape of the curve provides insights into the drying kinetics and can help identify potential problems.

For instance, a plateau in the curve might indicate insufficient heat transfer or air circulation, while a very steep initial slope could mean excessive drying conditions. Analyzing multiple curves for different parameters (e.g., temperature, airflow) allows one to determine optimal settings for maximum efficiency and product quality. I regularly use these charts to identify areas for improvement in drying cycles and fine-tune parameters for specific products.

Q 19. What are the regulatory requirements related to operating drying equipment?

Regulatory requirements for operating drying equipment vary depending on the industry and the material being processed. However, some common regulations include:

Occupational Safety and Health Administration (OSHA) regulations: These cover aspects like safety guards, emergency shut-off systems, proper ventilation to prevent the build-up of flammable vapors or dust, personal protective equipment (PPE), and training for personnel.

Environmental Protection Agency (EPA) regulations: These address emissions to the atmosphere, particularly volatile organic compounds (VOCs) or hazardous air pollutants (HAPs). Some dryers require permits and monitoring of emissions. Proper scrubbing systems are often required for these emissions.

Industry-specific regulations: For example, the Food and Drug Administration (FDA) sets standards for food processing equipment, ensuring safe and hygienic practices. In pharmaceuticals, Good Manufacturing Practices (GMP) heavily influence the design and operation of drying equipment.

Compliance is crucial. I always make sure all equipment operates within the confines of relevant regulations and maintain all necessary documentation to ensure compliance.

Q 20. Describe your experience with different types of dryer automation systems.

I have experience with a variety of dryer automation systems, ranging from simple programmable logic controllers (PLCs) to sophisticated distributed control systems (DCSs). My experience includes:

PLC-based systems: These offer good control and monitoring for simpler dryers. I’ve used these systems in smaller-scale operations and for specific unit control like conveyor belts or material handling.

DCS-based systems: These are more complex systems offering centralized control and monitoring of multiple dryers and associated equipment. I’ve used these in large-scale industrial settings, allowing for automated control of many parameters, such as temperature, humidity, airflow, and material feed rate. The central monitoring capabilities were critical for overall optimization.

Supervisory Control and Data Acquisition (SCADA) systems: These provide real-time monitoring and data analysis capabilities, enabling proactive problem-solving and improved process optimization. Data visualization and reporting features were helpful in generating performance metrics.

The choice of automation system depends on the scale and complexity of the drying process. I carefully assess these factors to recommend the most suitable solution.

Q 21. How do you troubleshoot problems with dryer sensors and instrumentation?

Troubleshooting dryer sensors and instrumentation is a crucial part of my work. My approach is systematic and involves a combination of observation, diagnostics, and testing. I start by carefully examining the problem, collecting data, and then working through possible causes.

Step-by-step troubleshooting approach:

Identify the problem: What exactly isn't working? Is the sensor reading incorrect, or is there a fault in the associated control loop?

Gather data: Check sensor readings, historical data, and any relevant alarm logs. Look for patterns or trends that might indicate the cause of the problem.

Verify sensor calibration: Incorrect calibration is a common source of errors. Calibrate sensors using appropriate procedures and traceable standards.

Check wiring and connections: Loose or damaged wiring can lead to incorrect readings or system failures. Visually inspect wiring and connections.

Test the sensor: Use a multimeter or other test equipment to verify the sensor is functioning correctly. Compare readings against known good sensors.

Check the control system: If the sensor is working fine, the issue might be in the PLC, DCS, or other control system. Investigate the control logic and look for programming errors or faults.

Consult technical documentation: Refer to manufacturer's manuals, schematics, and other relevant documentation to understand the system and troubleshoot effectively.

By following a structured approach, I can quickly identify the root cause of sensor issues and implement the necessary repairs or replacements. I always prioritize safety when dealing with electrical systems and follow the appropriate lockout/tagout procedures.

Q 22. Explain the principles of material handling in relation to drying.

Material handling in drying is crucial because it directly impacts drying efficiency and product quality. It encompasses all aspects of moving the material to be dried – from its initial source to the dryer inlet, through the dryer itself, and finally to its storage or further processing. Inefficient handling can lead to uneven drying, product degradation, and increased energy consumption.

- Feeding the Dryer: The method of feeding – whether it's a conveyor belt, screw feeder, or pneumatic system – needs to be matched to the material's properties and the dryer's design. For instance, delicate materials might require gentle pneumatic conveying to prevent damage, while bulk materials can use robust conveyor systems.

- Material Flow Inside the Dryer: The internal design of the dryer influences the material's movement. Rotary dryers use tumbling action, fluidized bed dryers use upward airflow, and spray dryers atomize the material. Understanding this flow is essential for achieving uniform drying.

- Discharge and Post-Drying Handling: The discharge system needs to remove the dried material without causing damage or re-wetting. This might involve conveyors, chutes, or specialized discharge mechanisms tailored to the final product form.

For example, in a food processing plant drying coffee beans, a gentle conveyor system would be used to prevent bean breakage. In contrast, a cement plant might use heavy-duty belt conveyors to handle large volumes of material.

Q 23. Describe your experience with process improvement initiatives in a drying environment.

In my previous role at a pharmaceutical manufacturing plant, we implemented a process improvement initiative focused on optimizing the spray dryer's performance. Our analysis revealed that uneven atomization was leading to inconsistent drying and increased waste. We addressed this by:

- Upgrading the atomizer nozzles: We replaced the older nozzles with new, high-precision ones, ensuring a more uniform spray pattern.

- Optimizing air flow parameters: We fine-tuned the inlet air temperature, flow rate, and distribution to enhance drying uniformity.

- Implementing a real-time monitoring system: This allowed for continuous monitoring of key parameters like temperature, humidity, and pressure, enabling immediate adjustments to maintain optimal conditions.

These improvements resulted in a 15% increase in production efficiency, a 10% reduction in waste, and a significant improvement in product quality as measured by a more consistent particle size and moisture content.

Q 24. How do you ensure compliance with environmental regulations related to drying emissions?

Compliance with environmental regulations is paramount in industrial drying. This typically involves minimizing emissions of volatile organic compounds (VOCs), particulate matter (PM), and other pollutants. My approach involves a multi-faceted strategy:

- Regular monitoring of emissions: Continuous monitoring using appropriate equipment is crucial to track emissions and ensure compliance with permitted limits.

- Implementing appropriate control technologies: This could include scrubbers, filters, or thermal oxidizers to remove or reduce pollutants before they are released into the atmosphere. The specific technology depends on the type of emissions and the regulatory requirements.

- Maintaining thorough records: Detailed records of emissions monitoring, maintenance activities, and any corrective actions taken are essential for audits and compliance demonstrations.

- Staying up-to-date with regulations: Environmental regulations can change, so staying informed about the latest requirements is crucial for maintaining compliance.

For instance, in a plant processing solvents, we installed a thermal oxidizer to combust VOCs before they are released, ensuring we met the strict emission standards set by the Environmental Protection Agency.

Q 25. What is your experience with energy efficiency measures for drying equipment?

Energy efficiency is a major concern in industrial drying, as it significantly impacts operating costs and environmental footprint. I have extensive experience implementing several energy-saving measures:

- Heat recovery systems: Implementing heat exchangers to recover waste heat from the dryer's exhaust and reuse it for preheating the inlet air can significantly reduce energy consumption.

- Improved insulation: Adding insulation to the dryer and its associated piping minimizes heat loss, leading to improved thermal efficiency.

- Process optimization: Optimizing operating parameters such as air flow, temperature, and residence time can reduce energy consumption without compromising product quality.

- Variable speed drives: Using variable speed drives on motors and fans allows for precise control of airflow and speed, adapting to changing process needs and optimizing energy use.

In one project, we achieved a 20% reduction in energy consumption by implementing a heat recovery system and optimizing the dryer's operating parameters.

Q 26. Describe a time you had to solve a complex problem related to drying equipment.

In a previous role, we experienced unexpected downtime on a rotary dryer due to a persistent bearing failure. The initial troubleshooting pointed to a lubrication issue, but replacing the lubricant didn't resolve the problem. After systematically investigating, we discovered that the issue wasn’t the lubricant itself but the alignment of the rotary drum. A slight misalignment was causing excessive stress on the bearings.

My approach involved:

- Precise alignment check: We performed a meticulous alignment check using laser alignment tools to precisely adjust the drum's position.

- Bearing replacement and inspection: We replaced the damaged bearings and thoroughly inspected the remaining components to identify any other potential issues.

- Implementing a preventative maintenance schedule: To prevent future occurrences, we developed a comprehensive preventative maintenance schedule that included regular alignment checks and lubrication procedures.

This systematic approach resolved the issue, restoring dryer functionality and preventing further downtime and production losses.

Q 27. How do you stay up-to-date with the latest technologies in industrial drying?

Staying current with the latest drying technologies is essential. My methods include:

- Attending industry conferences and trade shows: This provides opportunities to learn about new technologies and network with other professionals.

- Reading industry publications and journals: Staying informed about the latest research and developments in drying technology.

- Participating in online forums and professional organizations: Connecting with peers and experts in the field.

- Continuous professional development: Taking courses and workshops to enhance my knowledge and skills.

I also actively seek out information on emerging technologies like microwave drying, infrared drying, and advanced process control systems that are improving efficiency and sustainability in industrial drying.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of $100,000 to $120,000 per year, depending on the full benefits package and overall compensation structure. This is based on my experience, skills, and the market rate for similar roles with comparable responsibilities.

Key Topics to Learn for Operating and Maintaining Core Drying Equipment Interviews

- Understanding Drying Principles: Grasp the fundamental theories behind different drying methods (e.g., convective, conductive, radiative) and their application to various materials.

- Equipment Operation: Become proficient in the safe and efficient operation of specific drying equipment, including start-up procedures, parameter adjustments (temperature, airflow, humidity), and shutdown protocols. Familiarize yourself with different types of dryers (e.g., rotary dryers, spray dryers, fluid bed dryers).

- Maintenance Procedures: Learn about preventative maintenance schedules, troubleshooting common malfunctions, and performing routine inspections. Understand the importance of safety procedures and proper handling of chemicals and materials.

- Process Optimization: Explore strategies for improving drying efficiency, reducing energy consumption, and enhancing product quality. This includes understanding the impact of process variables on the final product.

- Quality Control and Monitoring: Learn how to monitor drying processes, analyze data (e.g., temperature profiles, moisture content), and implement corrective actions to maintain consistent product quality. Understand relevant quality control metrics and standards.

- Safety Regulations and Compliance: Familiarize yourself with relevant safety regulations and industry best practices for operating and maintaining drying equipment. This includes understanding lockout/tagout procedures and personal protective equipment (PPE) requirements.

- Troubleshooting and Problem-Solving: Develop your ability to diagnose equipment malfunctions, identify root causes, and implement effective solutions. Practice your analytical and problem-solving skills in a simulated environment.

Next Steps

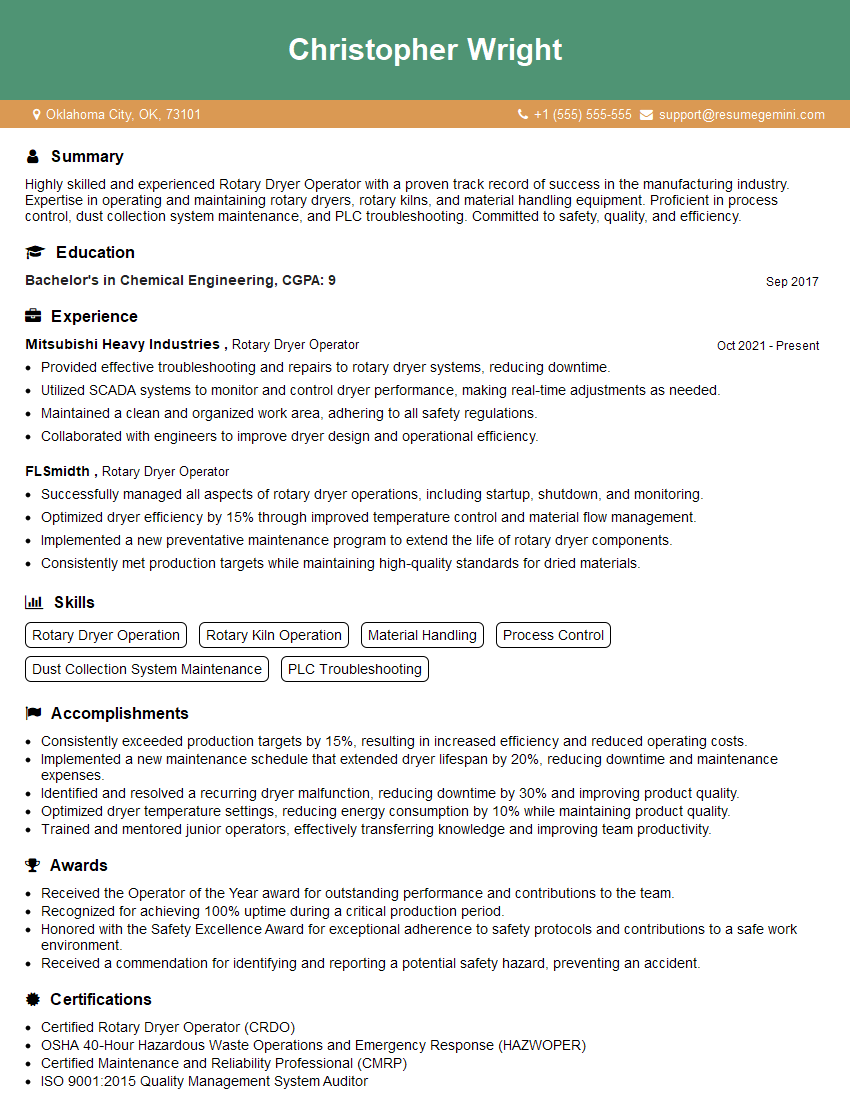

Mastering the operation and maintenance of core drying equipment opens doors to exciting career advancements and higher earning potential within the manufacturing and processing industries. A strong understanding of these principles is highly sought after by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of this field. Examples of resumes tailored to Operating and maintaining core drying equipment are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO