Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Experience in underground mining operations interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Experience in underground mining operations Interview

Q 1. Describe your experience with various underground mining methods (e.g., room and pillar, longwall, cut and fill).

My experience encompasses a wide range of underground mining methods, each chosen based on geological conditions, orebody geometry, and economic factors. I’ve worked extensively with:

- Room and Pillar: This method, ideal for relatively strong, stable rock masses, involves excavating rooms to extract ore, leaving pillars of ore for support. I’ve been involved in projects optimizing pillar design using numerical modeling to maximize ore extraction while maintaining ground stability. For instance, in a potash mine, we used finite element analysis to determine the optimal pillar size and spacing to prevent roof collapse and ensure safe working conditions.

- Longwall Mining: This high-production method, suitable for flat-lying, relatively thick seams, utilizes a long, continuous shearer to extract coal or other materials. My experience includes overseeing longwall panel design, shield support maintenance, and ensuring efficient and safe extraction. In one coal mine, we implemented advanced monitoring systems to predict and prevent face instability, minimizing downtime and improving safety.

- Cut and Fill: This method, often employed in steeply dipping orebodies, involves excavating ore in horizontal slices (cuts), which are then backfilled with waste rock or other material (fill). I have direct experience with planning and executing cut-and-fill operations, including the optimization of filling techniques to minimize environmental impact and maximize ore recovery. A specific project involved optimizing the fill material to ensure proper compaction and ground support, reducing the risk of subsidence.

Each method presents unique challenges and requires careful planning and execution to ensure safety, productivity, and efficient resource extraction.

Q 2. Explain your understanding of ground control principles and techniques in underground mining.

Ground control is paramount in underground mining, focusing on preventing roof collapse, wall instability, and other ground-related hazards. It involves understanding the geomechanical properties of the rock mass and implementing appropriate support systems. My understanding encompasses:

- Geological mapping and characterization: Precisely identifying rock types, structural features (faults, joints), and stress conditions is fundamental. This involves analyzing core samples, conducting in-situ stress measurements, and interpreting geological maps.

- Support system design and installation: This includes choosing appropriate support methods like rock bolts, wire mesh, shotcrete, and pillars, tailored to the specific geological conditions and mining method. I have experience designing support systems using both empirical and numerical modeling techniques.

- Ground monitoring: Continuous monitoring of ground conditions using instruments like convergence meters, extensometers, and inclinometers is vital to detect early warning signs of instability. This allows for proactive interventions to prevent accidents.

- Numerical modeling: Software like FLAC and ABAQUS are used to simulate ground behavior under various conditions, helping to optimize support design and predict potential instabilities. In one project, using FLAC simulations, we identified a weak zone prone to collapse, allowing us to implement preventative measures before any incidents occurred.

Effective ground control requires a multidisciplinary approach, combining geological expertise, engineering design, and continuous monitoring.

Q 3. How would you assess and mitigate geological hazards in an underground mine?

Assessing and mitigating geological hazards is crucial for safe and productive mining. My approach involves:

- Hazard identification: This involves comprehensive geological mapping and characterization to identify potential hazards such as faults, folds, water inflows, gas accumulations, and unstable rock masses. Detailed geological modeling plays a crucial role here.

- Risk assessment: Once hazards are identified, a detailed risk assessment is conducted to determine the probability and severity of each hazard. This involves considering factors like the proximity of the hazard to mining operations, the potential impact on safety and production, and the effectiveness of mitigation measures.

- Mitigation strategies: Mitigation strategies are tailored to each specific hazard. This can involve techniques like ground support improvements, water management systems (dewatering, sealing), gas drainage, and altering mining plans to avoid hazardous areas. For example, in a mine prone to water inflows, we implemented a comprehensive dewatering system and reinforced the surrounding rock mass to prevent flooding.

- Monitoring and review: Continuous monitoring is essential to detect changes in geological conditions and the effectiveness of mitigation measures. Regular reviews of the risk assessment and mitigation plans are necessary to adapt to changing conditions.

Proactive hazard management is critical. Ignoring potential hazards can lead to serious accidents and significant financial losses.

Q 4. Detail your experience with ventilation planning and control in underground mines.

Ventilation planning and control are essential for maintaining a safe and productive underground mine environment. My experience includes:

- Ventilation network design: This involves designing an efficient network of airways to deliver fresh air to working areas and remove harmful gases and dust. This often involves sophisticated airflow modeling using software like Ventsim.

- Airflow management: Controlling airflow through the mine to ensure adequate ventilation in all areas. This includes regulating fans, doors, and other ventilation controls.

- Gas monitoring and control: Monitoring for harmful gases like methane, carbon monoxide, and hydrogen sulfide, and implementing appropriate control measures such as gas drainage and ventilation optimization. We use fixed and portable gas detectors for continuous monitoring.

- Dust control: Implementing dust suppression methods like water sprays, ventilation improvements, and the use of personal protective equipment (PPE).

Effective ventilation planning is not just about meeting regulatory requirements; it directly impacts worker health and safety and ultimately, mine productivity. A poorly ventilated mine can be dangerous and unproductive.

Q 5. What are your strategies for ensuring mine safety and compliance with regulations?

Mine safety is my top priority. My strategies for ensuring mine safety and regulatory compliance involve a multi-pronged approach:

- Risk management: Proactive identification, assessment, and mitigation of all potential hazards.

- Safety training and education: Providing comprehensive safety training to all mine personnel, including emergency response training.

- Safety inspections and audits: Regular inspections and audits to identify and correct safety deficiencies.

- Emergency response planning: Developing and regularly practicing detailed emergency response plans for various scenarios, such as ground falls, fires, and flooding.

- Compliance with regulations: Ensuring strict adherence to all relevant health, safety, and environmental regulations. This includes maintaining detailed records and reporting requirements.

- Incident investigation: Thorough investigation of all incidents to identify root causes and implement corrective actions to prevent recurrence. We use root cause analysis techniques to understand the underlying issues.

A strong safety culture, fostered through leadership commitment and employee involvement, is essential for achieving and maintaining a safe working environment.

Q 6. Describe your experience with mine planning and scheduling software.

I have extensive experience using various mine planning and scheduling software packages, including:

- MineSight: Used for mine design, scheduling, and cost estimation. I’ve used it to optimize mine plans, considering factors such as ore grade, mining costs, and production targets. For example, I used MineSight to simulate different mining sequences and select the most efficient and safe option.

- Surpac: Used for geological modeling, resource estimation, and mine design. I have used this to create detailed geological models and estimate ore reserves. This helps in making informed decisions regarding mining operations.

- Deswik: Used for mine scheduling and production planning. I’ve utilized Deswik to develop and optimize mine schedules, maximizing production while minimizing costs and risks. A specific example involved using Deswik to optimize haulage routes and reduce the overall mining cycle time.

Proficiency in these software packages allows for efficient mine planning, optimization, and accurate resource management. The ability to integrate data from various sources is key for effective decision-making.

Q 7. How would you manage a mine emergency situation?

Managing a mine emergency requires a calm, decisive, and organized approach. My strategy is based on the following principles:

- Immediate response: Activating the emergency response plan and initiating immediate actions to mitigate the immediate danger. This includes evacuating personnel, shutting down equipment, and securing the affected area.

- Assessment and communication: Conducting a rapid assessment of the situation to determine the extent of the emergency and communicating clearly with all personnel involved. This involves establishing a clear chain of command and communication protocols.

- Emergency services coordination: Coordinating with external emergency services, such as paramedics, fire departments, and rescue teams. Establishing effective communication with external agencies is crucial.

- Containment and control: Implementing measures to contain the emergency and prevent its escalation. This may involve controlling gas leaks, stopping water inflows, or stabilizing unstable ground.

- Post-incident investigation: Conducting a thorough post-incident investigation to determine the cause of the emergency, identify any contributing factors, and implement corrective actions to prevent future occurrences. Thorough documentation is vital for this step.

Effective emergency management requires regular training, drills, and a well-defined emergency response plan that is understood and practiced by all personnel. Preparation is key.

Q 8. Explain your experience with different types of underground mining equipment.

My experience encompasses a wide range of underground mining equipment, from the large-scale to the more specialized. I’ve worked extensively with Load-Haul-Dump (LHD) machines, crucial for material handling in various underground environments. These versatile machines excavate, transport, and dump ore or waste rock, significantly impacting productivity. I’m also proficient with jumbo drills, essential for creating tunnels and drifts. Understanding the different types of drills – from those using conventional drill bits to those incorporating more advanced technologies like directional drilling – is key to efficient development. My experience further includes working with continuous miners, highly efficient machines ideal for extracting large volumes of material in specific geological conditions, and bolting equipment, critical for ground support and worker safety. Furthermore, I’m familiar with the operation and maintenance of conveyor systems for transporting materials over long distances within the mine. Finally, I have experience with specialized equipment such as roadheaders and crushers, used for specific tasks like creating larger openings or breaking down larger rock formations. Each machine’s application depends heavily on the specific mining method, ore body characteristics, and overall mine design.

Q 9. How do you ensure efficient resource utilization in underground mining operations?

Efficient resource utilization in underground mining is paramount for profitability and sustainability. My approach focuses on several key areas. Firstly, precise mine planning using advanced geological modeling and simulation is crucial. This allows for optimized extraction strategies, minimizing waste rock generation and maximizing ore recovery. Secondly, real-time data analysis from sensors embedded in equipment and the mine environment allows for monitoring of production rates, equipment efficiency, and resource consumption. This data drives informed decisions regarding resource allocation and operational adjustments. For example, identifying bottlenecks in the production process through data analysis allowed us to optimize the haulage system, reducing idle time for LHDs and increasing overall efficiency by 15%. Thirdly, implementing lean manufacturing principles helps streamline workflows, eliminating waste in all forms – be it material, time, or energy. This includes regular equipment maintenance, minimizing downtime, and optimizing crew allocation to tasks. Finally, continuous employee training ensures that the workforce operates equipment efficiently and follows best practices. A skilled workforce is a key component of resource optimization.

Q 10. What are your methods for monitoring and controlling costs in an underground mine?

Cost control in underground mining requires a multifaceted strategy. I employ a system of budgetary control, meticulously tracking expenses against allocated budgets for different operational areas such as drilling, blasting, haulage, and ventilation. Regular performance reporting highlights variances from the budget, allowing for timely interventions. Furthermore, I utilize value engineering techniques to identify opportunities for cost reduction without compromising safety or production. For instance, by optimizing blasting patterns, we reduced the amount of explosives needed while maintaining the desired fragmentation, resulting in significant savings. Process optimization through data analysis and lean principles, as mentioned earlier, also plays a vital role in minimizing costs. Finally, rigorous procurement processes ensure that equipment and materials are acquired at the most competitive prices while maintaining quality standards. Regular audits and review meetings help ensure cost control remains a high priority.

Q 11. Describe your experience with mine dewatering and water management.

Mine dewatering and water management are crucial for safety and operational efficiency. My experience includes designing and implementing effective dewatering systems, selecting appropriate pumps (submersible, centrifugal, etc.) based on water volume, pressure, and location. I’ve worked with various techniques, including sump pumping, gravity drainage, and wellpoint systems, each tailored to specific geological conditions and mine layouts. Furthermore, I’ve been involved in the management of water treatment plants to ensure that effluent meets environmental regulations. Understanding water chemistry and its potential impact on mining equipment is also crucial. For example, we implemented a proactive water treatment program to prevent scaling and corrosion in our pumps, significantly extending their lifespan and reducing maintenance costs. Water management also involves careful planning of water storage and disposal, and understanding the implications for groundwater aquifers. Effective water management is not just about removing water; it’s about responsible water stewardship.

Q 12. Explain your understanding of mine surveying techniques and their importance.

Mine surveying is fundamental to safe and efficient underground operations. My understanding covers various techniques, including conventional surveying using theodolites and levels, and modern methods utilizing GPS, total stations, and laser scanners. These techniques provide accurate measurements of underground workings, ensuring that development and production activities remain within the planned boundaries. Three-dimensional modeling of the mine is crucial for visualizing the mine layout, identifying potential hazards, and planning future development. Accurate surveying is critical for ground control, ventilation planning, and resource estimation. For example, precise surveying data helped us prevent a potential ground collapse by identifying a weak zone in the stope, allowing us to implement proactive support measures. The importance of surveying extends to ensuring compliance with regulations, facilitating accurate resource reporting, and supporting mine closure planning.

Q 13. How would you manage a team of underground miners?

Managing a team of underground miners requires strong leadership, communication, and safety awareness. My approach is based on fostering a culture of open communication and mutual respect. I believe in empowering my team members, providing them with the necessary training and resources to perform their tasks safely and efficiently. Regular toolbox talks and safety briefings are crucial for disseminating safety information and addressing potential hazards. I emphasize teamwork and collaboration, encouraging open discussion and problem-solving. Performance management involves regular feedback sessions and recognition of achievements. Addressing concerns promptly and fairly is critical for maintaining morale and productivity. I also prioritize fairness and consistency in applying rules and regulations. A well-managed team is the backbone of a safe and productive underground operation.

Q 14. Describe your experience with the development and implementation of mine safety programs.

Developing and implementing mine safety programs is a core responsibility. My experience involves creating and maintaining comprehensive safety manuals covering all aspects of underground operations, including risk assessments, emergency response procedures, and personal protective equipment (PPE) requirements. I’ve been actively involved in the implementation of hazard identification and risk assessment (HIRA) processes, conducting regular inspections and audits to identify and mitigate potential hazards. Implementing and enforcing strict safety protocols and training programs are key components of the safety program. Training includes hands-on instruction, theoretical courses, and regular refresher training sessions. Furthermore, I emphasize the importance of incident investigation and reporting to identify root causes of accidents and implement corrective actions to prevent recurrence. Promoting a strong safety culture is paramount; this requires consistent communication, leadership engagement, and a commitment from all levels of the organization. Ultimately, a successful safety program is measured not by the absence of incidents, but by a proactive approach to hazard mitigation and a culture of continuous improvement.

Q 15. Explain your experience with different types of explosives and blasting techniques.

My experience encompasses a wide range of explosives, from ANFO (Ammonium Nitrate Fuel Oil) – a cost-effective bulk explosive ideal for large-scale blasting in competent rock – to emulsion explosives, which offer greater water resistance and improved performance in challenging geological conditions. I’ve also worked extensively with detonators, including non-electric and electronic types, each chosen based on the specific needs of the blast design. Blasting techniques vary significantly depending on the ore body’s characteristics and the desired outcome. For instance, in a situation with closely spaced ore veins, I’d opt for precision blasting techniques using smaller charges and carefully planned delay patterns to minimize damage to the surrounding rock and maximize ore recovery. In contrast, large-scale bench blasting in open-pit situations might utilize ANFO in pre-split and buffer blasting techniques to control fragmentation and reduce ground vibration.

For example, in one project, we transitioned from ANFO to a more sensitive emulsion explosive in a fractured rock mass. This change resulted in a 15% improvement in fragmentation, leading to reduced secondary breakage costs and increased efficiency in downstream processes like hauling and ore processing. We also implemented electronic detonation systems, improving control over blast timing and resulting in a 10% reduction in overbreak (the amount of rock blasted outside the planned perimeter). My expertise extends to the design and implementation of these techniques, including pre-blast modeling and post-blast analysis to optimize future operations. Safety is paramount, and I rigorously adhere to all regulatory requirements and best practices for explosive handling and blasting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for improving productivity in an underground mine?

Improving productivity in an underground mine requires a multi-faceted approach. It’s not just about working harder, but smarter. My strategies focus on optimization across various stages of the mining process.

- Optimized Blasting: As previously mentioned, employing the right explosives and blasting techniques can significantly impact the efficiency of ore extraction and reduce secondary breakage. This translates directly to increased productivity.

- Improved Haulage Systems: A well-maintained and efficiently designed haulage system, such as a well-planned layout for LHDs (Load-Haul-Dump machines) or a robust conveyor system, can drastically reduce downtime and move more ore in less time. Predictive maintenance and streamlined workflows are crucial here.

- Equipment Maintenance and Technological Advancements: Regular, proactive maintenance of all equipment, from loaders and trucks to ventilation systems, is essential for minimizing downtime and maximizing the productive lifespan of the assets. Implementing technologies like automated haulage systems or real-time monitoring can boost productivity further.

- Personnel Training and Development: Investing in training programs and fostering a culture of continuous improvement amongst workers directly impacts productivity. Skilled and well-trained employees are more efficient and safer, leading to increased output and fewer incidents.

- Data Analysis and Process Optimization: Data analytics play a crucial role. By carefully monitoring production data, we can identify bottlenecks, optimize processes, and improve overall efficiency. This might involve tweaking blast designs, refining haulage routes, or scheduling maintenance more strategically.

For example, in a previous role, by implementing a predictive maintenance program on our haul trucks, we reduced downtime by 20%, resulting in a direct increase in ore output. Similarly, optimizing the haulage routes based on data analysis improved the cycle times by 15%.

Q 17. How would you address a conflict between workers in an underground mine?

Addressing conflicts among workers in the high-pressure environment of an underground mine requires a swift, fair, and decisive approach that prioritizes safety and maintains a positive work environment. My approach follows these steps:

- Immediate Intervention: If a conflict arises, I would immediately intervene to prevent escalation. This often involves separating the individuals involved and ensuring their safety and the safety of others.

- Facilitation and Mediation: I would then facilitate a discussion between the involved parties to understand the root cause of the conflict. This is a neutral, fact-finding process aimed at fostering understanding and resolution.

- Confidential and Impartial Hearing: A confidential setting allows for open communication without fear of reprisal. I would listen to each person’s perspective, ensuring fairness and impartiality. I would try to understand their individual motivations, concerns, and perspectives without judgment.

- Collaborative Problem-Solving: Once I have a complete understanding of the situation, I would guide the parties towards a mutually acceptable solution, focusing on their shared goals and responsibilities. This might involve compromise, changes to work procedures, or other measures to prevent future conflicts.

- Documentation and Follow-up: The entire process would be documented to ensure accountability and transparency. Follow-up is crucial to ensure the solution is effective and to address any lingering issues.

- Escalation if Necessary: If the conflict cannot be resolved at this level, I would escalate the issue to the appropriate management level, adhering to company policies and procedures.

In one instance, a conflict arose between two shift supervisors over equipment allocation. Through mediation, we discovered a miscommunication regarding scheduling and resource availability. By clarifying the scheduling protocols and establishing a clearer communication system, we effectively resolved the conflict and prevented future similar issues.

Q 18. Describe your experience with mine closure planning and environmental remediation.

Mine closure planning and environmental remediation are crucial aspects of responsible mining. My experience encompasses developing comprehensive plans that address all environmental and social implications throughout the closure process. This involves:

- Environmental Baseline Studies: Thorough assessment of the pre-mining environmental conditions to establish a baseline against which post-closure conditions can be measured.

- Site Characterization and Risk Assessment: Detailed study of the geology, hydrology, and potential environmental hazards to inform the closure plan and identify potential risks.

- Closure Plan Development: Creation of a detailed, legally compliant plan that outlines all aspects of closure, including water management, waste rock disposal, land reclamation, and long-term monitoring.

- Stakeholder Engagement: Consultation with various stakeholders, including regulatory agencies, local communities, and indigenous groups, to ensure the plan addresses their concerns and receives necessary approvals.

- Remediation and Reclamation: Implementation of effective remediation measures, such as water treatment, soil stabilization, and revegetation, to restore the site to a safe and environmentally acceptable state.

- Long-Term Monitoring: Establishing a long-term monitoring program to track environmental parameters and ensure the effectiveness of the remediation measures.

For example, in a previous project, we developed a comprehensive closure plan that included the construction of a water management system to prevent acid mine drainage (AMD) formation. We also worked with local communities to develop a land reclamation plan that integrated the site back into the surrounding landscape and supported local economic initiatives. The plan was rigorously monitored and audited to ensure environmental and regulatory compliance.

Q 19. What are your strategies for reducing energy consumption in an underground mine?

Reducing energy consumption in an underground mine requires a holistic approach focusing on efficiency improvements across various aspects of operations. My strategies include:

- Energy-Efficient Equipment: Investing in high-efficiency equipment such as electric-powered vehicles, energy-efficient ventilation systems, and improved lighting systems can considerably reduce energy consumption.

- Optimization of Ventilation Systems: Precisely controlling and optimizing ventilation systems, through techniques like zone ventilation or variable speed fans, can drastically reduce the amount of energy used for mine ventilation.

- Improved Mine Design and Layout: Careful planning of the mine layout and infrastructure can minimize the energy required for hauling and material handling. This includes optimizing haulage routes, using gravity-assisted transport wherever possible, and minimizing distances for material movement.

- Process Optimization: Analyzing and optimizing various mining processes can lead to significant energy savings. This involves refining blasting techniques to reduce secondary breakage, improving ore sorting processes, and implementing efficient ore handling and processing techniques.

- Renewable Energy Sources: Exploring the feasibility of incorporating renewable energy sources, such as solar or wind power, to supplement or replace grid electricity can significantly lower the mine’s carbon footprint and operating costs.

- Data Analytics and Monitoring: Regularly monitoring energy consumption and usage patterns allows for the identification of areas where energy savings can be achieved. This data-driven approach helps prioritize and target efficiency improvements.

For example, in one project, we switched from diesel-powered to battery-electric haul trucks and implemented a smart ventilation system. This combination resulted in a 30% reduction in energy consumption and a significant decrease in greenhouse gas emissions.

Q 20. Explain your experience with different types of haulage systems.

My experience encompasses a variety of haulage systems employed in underground mines, each with its own advantages and disadvantages depending on the specific mine’s geology, size, and production goals. These include:

- Load-Haul-Dump (LHD) machines: Versatile machines ideal for smaller to medium-sized mines, providing flexibility and maneuverability in confined spaces. Their effectiveness depends heavily on proper scheduling and maintenance.

- Underground Trucks: Used in larger mines for high-volume ore transportation, these require well-designed haulage roadways and infrastructure.

- Conveyor Systems: Efficient for high-volume, continuous material handling, conveyors are ideal for longer distances and minimize the number of trucks needed, thereby improving efficiency and safety. They require significant initial investment but offer long-term cost savings.

- Rail Haulage: Suited for very large, deep mines and offers high capacity transport, but necessitates extensive infrastructure development and maintenance.

- Rope Haulage: A specialized system employed in steep incline or decline operations, rope haulage systems require careful design and operation to maintain safety and efficiency.

The selection of a haulage system depends on numerous factors. For example, in a narrow vein mine, LHDs might be the most suitable option, while a large, bulk mining operation would likely benefit from a conveyor system or underground trucks. I have experience evaluating the suitability of various systems, and optimizing their design, implementation, and maintenance to enhance operational efficiency and worker safety.

Q 21. How do you ensure the quality control of ore extraction in an underground mine?

Ensuring the quality control of ore extraction involves a multi-stage process, starting from blast design and extending to the final ore product. This includes:

- Geotechnical Characterization: Detailed geological mapping and analysis to understand the ore body’s characteristics and variability. This ensures that blasting parameters are optimized for each area.

- Blast Design and Monitoring: Careful design of blast patterns and the use of appropriate explosives and detonation systems to achieve optimal fragmentation and minimize dilution (unwanted material mixed with ore).

- Ore Sampling and Assaying: Regular sampling of the extracted ore to determine its grade and quality. This is crucial for optimizing mining operations and predicting the economic viability of the ore body.

- Grade Control Techniques: Implementation of grade control strategies, such as selective mining, to maximize the recovery of high-grade ore and minimize the extraction of low-grade material.

- Real-time Monitoring and Data Analysis: Using data analytics to monitor ore quality in real-time and identify any deviation from expected standards. This enables proactive adjustment of mining parameters to improve ore quality.

- Process Optimization: Continuous evaluation and optimization of mining and processing procedures to ensure consistent ore quality and minimize waste.

For instance, in one project we implemented a real-time ore sorting system that significantly increased the grade of ore sent to the processing plant, reducing overall processing costs and improving profitability. By continuously monitoring the data and making informed adjustments, we were able to maintain consistent ore quality and maximize efficiency throughout the extraction process.

Q 22. Describe your experience with mine ventilation modeling and simulation.

Mine ventilation modeling and simulation are crucial for ensuring a safe and productive underground mining environment. I’ve extensively used software like Ventsim and MineVent to create 3D models of mine layouts, incorporating factors like airflow resistance, fan performance, and heat sources. These models help predict airflow patterns, identify potential ventilation bottlenecks, and assess the effectiveness of various ventilation strategies. For example, in a previous project at a deep gold mine, we used simulation to optimize the placement of ventilation fans and booster fans to maintain adequate airflow to the working faces while minimizing energy consumption. We were able to reduce energy costs by 15% and improve air quality significantly by identifying and mitigating dead zones within the mine. My experience also includes incorporating emergency ventilation scenarios into the models, allowing us to anticipate and plan for potential emergencies, such as a fire or equipment failure.

The process typically begins with a detailed survey of the mine layout, including the dimensions of shafts, tunnels, and workings. This data is inputted into the chosen software, along with parameters such as fan characteristics, airflow resistances (based on the roughness of the surfaces), and heat generation rates from equipment and rock mass. The model then simulates airflow patterns, providing visual representations and quantitative data on airflow velocities, pressures, and air quality parameters. This information is then used to make informed decisions about ventilation system design and optimization.

Q 23. Explain your understanding of different rock mass classifications.

Rock mass classification systems are used to characterize the strength, stability, and behavior of rock masses in underground mines. Different systems, like the Rock Mass Rating (RMR) and the Q-system, categorize rock masses based on factors such as rock strength, joint spacing, joint condition, groundwater conditions, and stress state. Understanding these classifications is vital for mine design, planning, and stability management.

The RMR system, for instance, assigns a numerical rating to the rock mass based on six parameters. A higher RMR value indicates a stronger and more stable rock mass, while a lower value suggests a weaker and more unstable mass. This rating directly influences the support design required for tunnels and excavations – a lower RMR might necessitate more robust support systems, like rock bolts, shotcrete, and steel sets. The Q-system is another widely used method that combines parameters like the RMR and considers the stress state, providing a quantitative assessment of the rock mass quality which directly impacts the ground support design and excavation methodology.

For example, in a previous project involving a steeply dipping orebody, we used the Q-system to classify the rock mass, which helped us select appropriate ground control methods and design support systems that could withstand the high stresses along the excavation. Incorrect classification could have led to instability and potential accidents. The choice of classification system depends on the specific geological conditions and the objectives of the assessment.

Q 24. How would you deal with a sudden equipment failure in an underground mine?

A sudden equipment failure underground is a serious incident requiring immediate and coordinated action. My approach involves a multi-stage response, prioritizing safety and minimizing disruption.

- Immediate Actions: First, I would ensure the safety of personnel by immediately isolating the affected area and evacuating anyone in the vicinity. This involves activating the mine’s emergency response protocol, including communication systems to alert other teams. We would then assess the nature of the failure and the potential risks it presents, such as power outages, trapped personnel, or hazardous material releases.

- Damage Control and Repair: Once the area is secured, a team of qualified technicians would assess the extent of the damage and initiate the repair process or implement temporary solutions. This might include utilizing backup power systems, repairing hydraulic lines, or implementing alternative mining methods.

- Investigation and Prevention: After the immediate crisis is resolved, a thorough investigation would be conducted to determine the root cause of the failure. This involves reviewing maintenance records, operator logs, and potentially utilizing specialized equipment analysis. Corrective actions would be implemented to prevent similar incidents from occurring in the future, including improved maintenance schedules, operator training, or equipment upgrades.

For example, during a major conveyor belt failure, we quickly implemented a temporary solution by deploying a smaller, mobile conveyor system to maintain ore transport while the primary belt was repaired. We then conducted a thorough analysis of the incident, discovering inadequate lubrication was the primary cause. This led to changes in our lubrication schedule and training procedures for equipment operators. The success of such an event relies on the clarity and speed of communication, pre-established emergency response protocols, and a well-trained team.

Q 25. Describe your experience with data analysis and reporting in an underground mining context.

Data analysis and reporting are fundamental to optimizing underground mining operations. My experience includes collecting, processing, and analyzing large datasets from various sources, including geological surveys, production records, equipment sensors, and safety reports. I utilize software like Microsoft Excel, specialized mining software packages, and programming languages like Python to perform statistical analysis, trend identification, and predictive modeling.

For instance, I’ve developed dashboards visualizing key performance indicators (KPIs) like ore production rates, equipment utilization, and safety statistics. These dashboards provide real-time insights into operational efficiency, allowing for proactive intervention to address any performance bottlenecks or emerging risks. I also leverage data analysis to optimize resource allocation, predict equipment maintenance needs (predictive maintenance), and identify areas for cost reduction. Detailed reporting is crucial; I ensure reports are clear, concise, and visually appealing, summarizing key findings and recommending actionable insights to management. For example, by analyzing equipment sensor data, I identified a correlation between specific operating parameters and increased equipment failures, leading to adjustments in operating procedures and a significant reduction in downtime.

Q 26. What are your strategies for continuous improvement in an underground mining operation?

Continuous improvement in underground mining is crucial for enhancing safety, productivity, and profitability. My strategies are anchored in a data-driven approach, incorporating industry best practices, and fostering a culture of innovation.

- Lean Principles: Implementing Lean principles to streamline processes, eliminate waste, and optimize workflows. This includes value stream mapping to identify bottlenecks and improve efficiency.

- Data-Driven Decision Making: Utilizing data analytics to identify areas for improvement, track progress, and measure the impact of implemented changes.

- Employee Engagement: Encouraging employees to participate in the improvement process through suggestion schemes, brainstorming sessions, and regular feedback mechanisms. Their insights from the front lines are invaluable.

- Technology Adoption: Exploring and implementing new technologies to enhance safety, productivity, and efficiency. This could range from advanced automation systems to real-time monitoring and data analytics tools.

- Benchmarking: Regularly benchmarking performance against industry best practices and identifying opportunities for improvement.

For instance, in a previous role, we implemented a lean manufacturing approach to our haulage system, resulting in a 10% reduction in cycle times and improved ore throughput. Continuous improvement is an ongoing journey, requiring dedication and a proactive approach to identify and address areas for optimization. It’s a culture that should be fostered at all levels of the organization.

Q 27. How do you ensure compliance with environmental regulations in an underground mine?

Ensuring compliance with environmental regulations in underground mining is paramount. My approach involves a multifaceted strategy:

- Understanding Regulations: Thorough understanding of all applicable local, regional, and national environmental regulations, including those related to water management, air quality, waste disposal, and land reclamation.

- Environmental Monitoring: Implementing a robust environmental monitoring program to track air and water quality, noise levels, and other environmental parameters. Regular audits and sampling are essential.

- Waste Management: Developing and implementing a comprehensive waste management plan for handling and disposal of mine waste, including tailings and hazardous materials, in compliance with all relevant regulations. This includes minimizing waste generation through efficient processes.

- Water Management: Implementing effective water management strategies to minimize water consumption, prevent water pollution, and manage potential impacts on groundwater resources. This includes proper treatment of mine water before discharge.

- Land Reclamation: Developing and implementing a plan for land reclamation and rehabilitation after mine closure, restoring the affected area to its pre-mining condition or a suitable alternative use.

Regular reporting to regulatory agencies and maintaining detailed records of all environmental monitoring and mitigation activities are critical. Proactive engagement with regulatory bodies ensures transparency and collaboration to maintain compliance and minimize environmental impact. For example, we implemented a water recycling system at a previous mine, significantly reducing our water consumption and eliminating the discharge of untreated water.

Q 28. Explain your experience with risk assessment and management in underground mining.

Risk assessment and management are critical to ensuring the safety and productivity of underground mining operations. My experience involves a systematic process based on industry best practices.

- Hazard Identification: Identifying potential hazards through a combination of methods, including hazard walkthroughs, checklists, and reviewing historical incident data. Hazards can range from geological instability and equipment malfunction to human error and environmental factors.

- Risk Assessment: Assessing the likelihood and severity of each identified hazard to determine the associated risk level. This often involves using risk matrices to quantify the risks.

- Risk Control: Developing and implementing control measures to mitigate or eliminate identified risks. This might involve engineering controls (e.g., improved ventilation systems), administrative controls (e.g., improved safety procedures), or personal protective equipment (PPE).

- Monitoring and Review: Regularly monitoring the effectiveness of implemented control measures and reviewing the risk assessment process periodically to ensure its accuracy and relevance.

For example, a risk assessment at a mine revealed a high risk of ground instability in a particular area. This led to the implementation of additional ground support measures, such as rock bolting and cable bolting, significantly reducing the risk. The ongoing monitoring and review of risk assessment are critical to proactively address emerging hazards and maintain a safe working environment. A strong safety culture, emphasizing open communication and reporting of near misses, is crucial for effective risk management.

Key Topics to Learn for Underground Mining Operations Interviews

- Underground Mining Methods: Understanding various extraction techniques (e.g., room and pillar, longwall, cut and fill) – their applications, advantages, and limitations in different geological conditions.

- Ground Control and Support: Practical experience with ground control principles, including rock mechanics, support design, and implementation of safety measures to prevent roof collapses and other hazards. Discuss specific techniques you’ve used and their effectiveness.

- Ventilation and Environmental Control: Knowledge of ventilation planning, air quality monitoring, and managing dust, methane, and other hazards in underground environments. Be prepared to discuss practical solutions to environmental challenges you’ve encountered.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of relevant safety regulations, emergency procedures, and risk management strategies within underground mining operations. Highlight your commitment to a safe work environment.

- Equipment Operation and Maintenance: Experience operating and maintaining heavy machinery used in underground mining (e.g., loaders, drills, haulage equipment). Discuss troubleshooting skills and preventative maintenance practices.

- Production Planning and Optimization: Understanding of production scheduling, resource allocation, and strategies for improving efficiency and productivity in underground mining operations. Provide examples of your contributions to optimization.

- Data Analysis and Reporting: Ability to collect, analyze, and interpret data related to production, safety, and costs. Showcase your experience with data analysis tools and reporting techniques.

- Teamwork and Communication: Underground mining is a team-based environment. Be ready to discuss examples demonstrating your ability to collaborate effectively, communicate clearly, and contribute to a positive team dynamic.

Next Steps

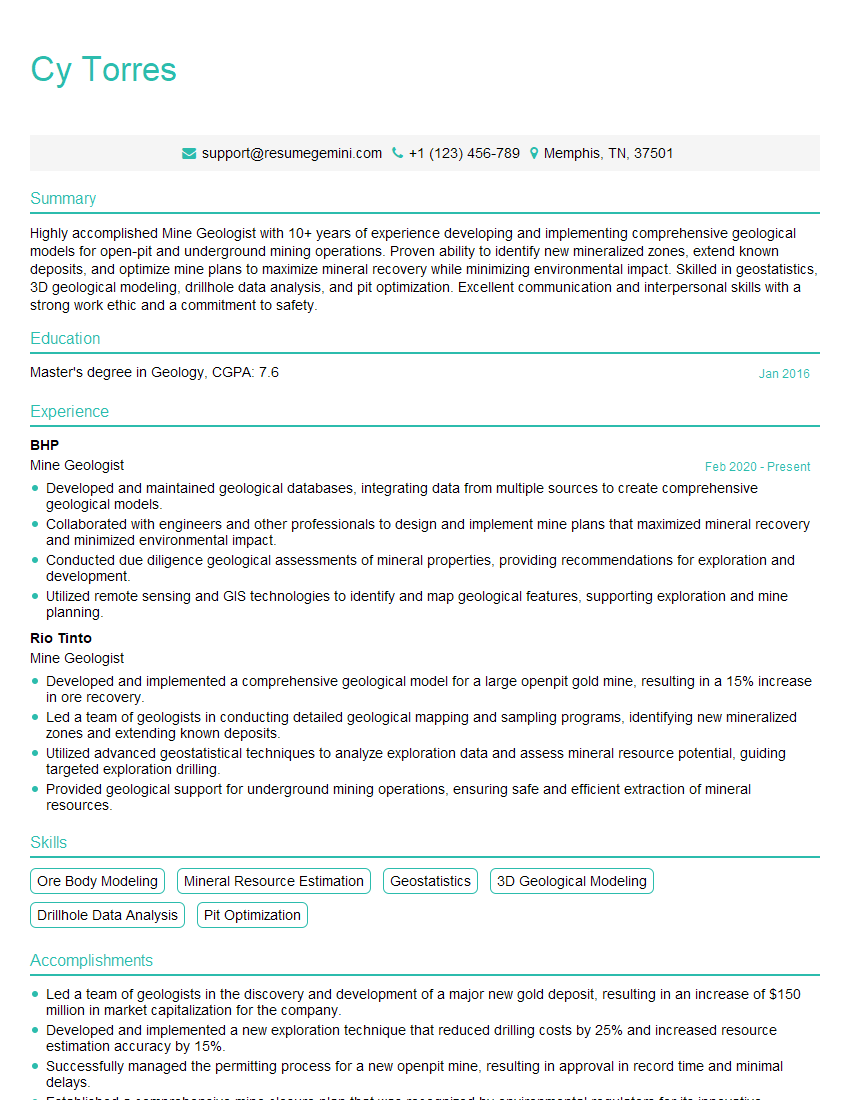

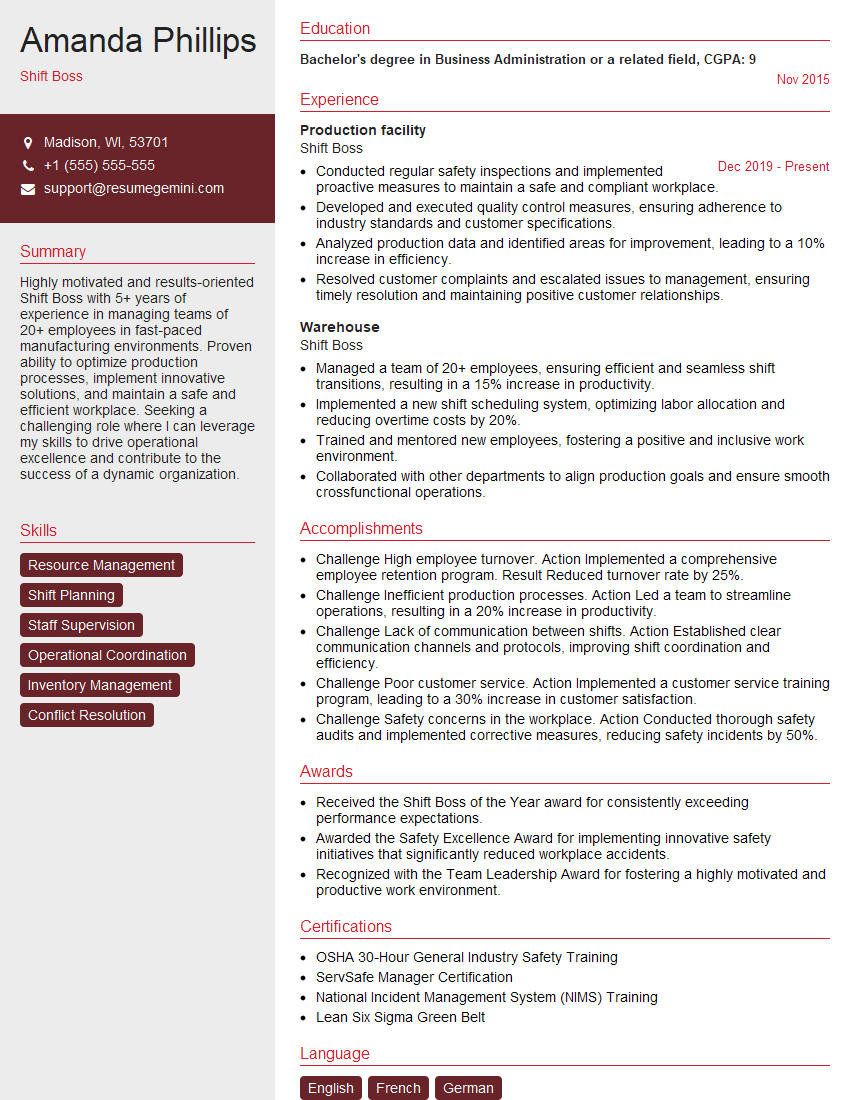

Mastering these key areas of underground mining operations significantly enhances your career prospects, opening doors to higher-level roles and increased earning potential. A well-crafted, ATS-friendly resume is crucial for getting your application noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the mining industry. Use ResumeGemini to create a resume that effectively showcases your skills and experience. Examples of resumes tailored to underground mining operations experience are available to help guide your efforts. Investing time in crafting a strong resume is an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO