The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience in operating heavy machinery interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience in operating heavy machinery Interview

Q 1. Describe your experience operating an excavator.

My excavator experience spans over eight years, encompassing various models and applications. I’ve operated everything from compact excavators for delicate landscaping work to larger, heavy-duty machines for demolition and large-scale earthmoving projects. I’m proficient in various techniques, including trenching, digging foundations, loading trucks, and working with specialized attachments like rippers and hydraulic hammers. For example, on one project, I used a 30-ton excavator to excavate a complex series of trenches for a large pipeline installation, requiring precise control to avoid damaging existing underground utilities. My experience also includes working in confined spaces and varying soil conditions, adapting my technique as needed to ensure both efficiency and safety.

Q 2. Explain the pre-operational checks you perform on a bulldozer.

Pre-operational checks on a bulldozer are crucial for safety and equipment longevity. My routine involves a thorough visual inspection, followed by functional tests. The visual inspection includes checking fluid levels (engine oil, hydraulic fluid, coolant), tire pressure, and the condition of tracks and undercarriage for any damage or wear. I also carefully examine the blade, ripper, and other attachments for any damage or loose components. The functional tests include starting the engine and checking for unusual noises or vibrations. I then test the steering, blade control, and ripper function, ensuring smooth and responsive operation. I always document any issues found, no matter how minor, reporting them to my supervisor before starting work. Think of it like a pilot’s pre-flight checklist – it’s a systematic approach ensuring everything’s in perfect working order before embarking on the operation.

Q 3. What safety procedures do you follow when operating heavy machinery?

Safety is paramount when operating heavy machinery. My safety procedures begin with a thorough understanding of the site’s layout and potential hazards. This includes identifying areas with underground utilities, potential drop-offs, and other obstacles. Before starting, I always ensure the area is clear of personnel and that all safety devices – seatbelts, emergency shut-offs, and warning lights – are functioning correctly. I maintain a safe operating speed, avoiding sudden movements that could cause loss of control. Communication is key – I use hand signals and two-way radios to communicate with spotters and other personnel on the site. I also follow all company safety regulations and wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and high-visibility clothing. Regular training and refresher courses keep my safety knowledge up-to-date. For example, I recently completed a course on confined-space operation, which significantly enhanced my skills and awareness in that specific environment.

Q 4. How do you handle unexpected equipment malfunctions?

Unexpected malfunctions require a calm and systematic response. My first step is to immediately shut down the equipment and activate the emergency brakes. I then assess the situation, identifying the nature of the malfunction and its potential consequences. If it’s a minor issue, like a hydraulic leak, I might attempt a temporary fix, following established procedures. However, for more serious problems – loss of steering control, engine failure, etc. – I prioritize safety and immediately report the problem to my supervisor, ensuring the area is secured. I never attempt repairs beyond my expertise or without proper authorization. My goal is to prevent further damage and ensure the safety of myself and others. I document all malfunctions and their resolution, helping to improve maintenance and prevent future incidents.

Q 5. Describe your experience with different types of loaders.

My experience with loaders includes wheel loaders, skid steer loaders, and backhoe loaders. Wheel loaders are excellent for moving large quantities of material over longer distances, typically used in construction and mining. I’ve used them extensively for loading trucks with aggregate and moving earth. Skid steer loaders are more versatile and maneuverable in confined spaces, perfect for smaller construction sites and landscaping tasks. Their compact size allows for precision work. Backhoe loaders are particularly useful for digging trenches and foundations, and they combine the digging capabilities of an excavator with the loading capabilities of a front loader. Each type has its specific strengths and applications, and choosing the right machine for the job is crucial for efficiency and productivity. For instance, on a recent road construction project, we used wheel loaders to move tons of gravel, while a skid steer loader was used to fine-grade the edges.

Q 6. What are the different types of cranes and their applications?

Cranes come in various types, each suited for specific applications. Tower cranes are tall, stationary cranes typically used in high-rise construction. Mobile cranes are self-propelled and highly versatile, suitable for a wide range of projects. Overhead cranes are found in factories and warehouses for lifting and moving materials. Floating cranes are used for underwater construction and salvage operations. The choice depends on the load capacity, reach, and the specific environment. For example, a tower crane’s height allows for lifting materials high up in a skyscraper construction, while a mobile crane’s mobility allows for efficient material handling across a large construction site. Each crane type has different safety protocols and operational procedures.

Q 7. Explain your understanding of load capacity and stability.

Understanding load capacity and stability is fundamental for safe operation. Load capacity refers to the maximum weight a machine can lift or carry safely. Exceeding this limit risks structural failure and accidents. Stability depends on factors such as the machine’s weight distribution, the ground conditions, and the location of the load. An uneven load or soft ground can drastically reduce stability, increasing the risk of tipping. Always check the machine’s specifications to determine its load capacity, and use appropriate lifting techniques to maintain stability. Operators should always be aware of their surroundings and adjust their operating techniques to avoid overloading or unstable conditions. For example, when using a forklift, I always assess the ground’s stability and ensure the load is distributed evenly to prevent tipping, keeping in mind the weight capacity and center of gravity.

Q 8. How do you ensure the safety of yourself and others on a job site?

Safety on a job site is paramount, and it’s a priority I address proactively, not reactively. My approach is multi-faceted and begins before I even start the engine. It involves a thorough pre-operation inspection of the machine, checking for any mechanical faults, fluid leaks, or damaged parts. Think of it like a pre-flight checklist for a plane – crucial for a safe flight, just as it’s crucial for a safe operation of heavy machinery.

Beyond the machine itself, I meticulously assess the work area. This includes identifying potential hazards like uneven terrain, overhead power lines, nearby personnel or other equipment, and ensuring adequate signage is in place. I always maintain a safe distance from other workers and communicate clearly using hand signals or radios to coordinate movements.

Finally, I always wear the appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, high-visibility clothing, and hearing protection. Safety isn’t just a checklist; it’s a mindset. I’m constantly vigilant and aware of my surroundings and the actions of others. Once, on a road construction project, I noticed a worker inadvertently walking into my blind spot while backing up a grader. I immediately stopped and communicated with him, preventing a potential accident. This highlights the importance of constant awareness and communication.

Q 9. What is your experience with GPS-guided heavy machinery?

I have extensive experience with GPS-guided heavy machinery, specifically using systems like Topcon and Trimble. These systems significantly enhance precision and efficiency in tasks like grading, excavation, and land leveling. Imagine trying to perfectly level a large area using only your eyesight and experience – it’s incredibly time-consuming and prone to errors. GPS guidance eliminates much of that guesswork.

I’m proficient in setting up and calibrating these systems, understanding the different correction signals (like RTK or DGPS) and their accuracy levels. I’ve used GPS-guidance on various projects, ranging from highway construction to utility trenching. The GPS allows for accurate adherence to design plans, minimizing rework and material waste. For instance, on a recent project building a retaining wall, GPS guidance ensured the precise placement of each layer of fill, leading to a structurally sound and aesthetically pleasing finished product. The benefits extend beyond accuracy; it also increases productivity by speeding up the work process.

Q 10. How do you maintain accurate records of equipment usage and maintenance?

Maintaining accurate equipment records is crucial for both preventative maintenance and compliance. I typically use a combination of digital and physical methods. I use digital logs which are accessible remotely, for fuel consumption, operating hours, maintenance schedules, and any repairs performed. These logs are often integrated with the machine’s onboard computer system. Then, I maintain a detailed physical logbook stored on-site or in the equipment shed. This manual log helps keep track of minor issues that may not be reflected in the digital logs.

For example, I’ll note things like the condition of tires, any unusual noises, or minor adjustments made during operation. This dual approach ensures a complete and reliable record of equipment usage and maintenance. This approach is especially important when submitting documentation for insurance purposes or during audits. The thoroughness of my records has been commended by supervisors in the past, leading to increased efficiency and less downtime.

Q 11. Describe your experience working with different types of terrain.

My experience encompasses a wide variety of terrain, from flat, stable surfaces to challenging, unpredictable conditions. I’ve worked on rocky terrain, soft soils, steep inclines, and areas with limited accessibility. Each terrain type requires a different operating technique and understanding of machine capabilities.

For instance, operating on steep slopes necessitates careful maneuvering to prevent rollovers or slides. Working with soft soils demands an awareness of potential ground instability and the use of appropriate ground-engaging tools to avoid getting stuck. On rocky terrain, the challenge lies in avoiding damage to the machine’s undercarriage and using appropriate techniques to break up or move rocks effectively. I’ve also encountered challenging conditions involving marshland and areas requiring careful consideration of environmental impact.

Adaptability and experience are crucial in handling diverse terrain. One memorable experience involved working on a mountainous region where I had to carefully navigate narrow, winding paths using a smaller excavator, while being mindful of the environment and protecting native vegetation. Understanding the unique challenges of different terrain types and adapting my operating techniques accordingly has been key to my success.

Q 12. How do you manage fuel efficiency while operating heavy machinery?

Fuel efficiency is a major concern in operating heavy machinery. It’s both economically and environmentally responsible to minimize fuel consumption. My approach focuses on several key areas. Firstly, I follow the manufacturer’s recommendations for proper machine operation, avoiding unnecessary idling. Excessive idling can dramatically increase fuel use. Think of it like leaving your car running unnecessarily – a significant waste of fuel.

Secondly, I ensure that the machine is properly maintained. A well-maintained machine operates more efficiently, translating to reduced fuel consumption. This includes regular checks on engine performance, proper lubrication, and timely servicing. Thirdly, I adapt my operating techniques to suit the task at hand. Smooth and controlled movements, rather than jerky operations, minimize fuel waste. Finally, I’m aware of the terrain and adjust my approach accordingly, avoiding unnecessary strain on the machine. By implementing these techniques, I have consistently demonstrated a commitment to fuel efficiency, resulting in lower operational costs and a smaller environmental footprint.

Q 13. What are the common causes of equipment breakdowns and how do you troubleshoot them?

Equipment breakdowns can be caused by a variety of factors, ranging from mechanical failures to operator error. Common issues include hydraulic leaks, engine problems (like fuel or air filter issues), electrical malfunctions, and wear and tear on components.

My troubleshooting approach is systematic. First, I perform a thorough visual inspection, checking for any obvious problems. Then, I’ll consult the machine’s operational manual and check diagnostic codes if the machine has an onboard computer system. I have experience using various diagnostic tools to isolate the root cause. I prioritize safety first. If a repair is beyond my expertise or involves a significant safety risk, I immediately shut down the machine and report the issue to my supervisor.

For example, I once experienced a sudden loss of hydraulic pressure. Through systematic troubleshooting, I identified a leak in a hydraulic hose. I carefully repaired the leak with a temporary solution, allowing me to complete the task safely before getting the hose properly replaced. This systematic approach ensures a safe and efficient resolution of equipment problems, minimizing downtime and maintaining productivity.

Q 14. Explain your understanding of different types of attachments for excavators.

Excavators are incredibly versatile machines due to their wide range of attachments. My experience includes working with many common attachments like different types of buckets (narrow, wide, ditch-cleaning), rippers for breaking up hard ground, augers for drilling holes, hydraulic hammers for demolition, and grapple buckets for handling materials like scrap metal or logs.

Each attachment has a specific purpose and is chosen based on the job requirements. A narrow bucket might be used for precision work in tight spaces, while a wide bucket is ideal for moving larger volumes of material quickly. A hydraulic hammer might be used for demolition, while an auger would be used for installing posts or utility lines. The choice of attachment is crucial for both efficiency and safety. Incorrect attachment selection can lead to damage to the machine or equipment, or even unsafe working conditions. I always ensure the attachment is correctly connected and secured before operation and follow safety protocols for operating each specific attachment. My experience includes training in using all of these attachments and adapting to using different brands of machinery.

Q 15. Describe your experience with working at heights using heavy machinery.

Working at heights with heavy machinery demands meticulous attention to safety. My experience includes operating cranes, aerial lifts, and excavators on construction sites and industrial projects where significant elevation was involved. Before commencing any operation, a thorough risk assessment is crucial. This involves checking the stability of the ground, inspecting the machinery for any defects (especially concerning the braking system and safety harnesses), and understanding wind conditions. For example, when operating a crane at a significant height, I always ensure the load is properly secured and the crane’s capacity is not exceeded. I also verify the functionality of the emergency shutdown systems and have a clear communication plan with ground crew. If working with an aerial lift, I always ensure the outriggers are properly deployed and the platform is level before any movement. Safety harnesses and fall protection systems are always double-checked and appropriately used.

One instance I recall involved placing prefabricated building sections onto high-rise scaffolding using a crane. The wind picked up unexpectedly. Instead of continuing, I immediately halted operations, secured the load, and waited for conditions to improve, even though this resulted in some delay in the project schedule. Safety always supersedes speed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks while operating multiple pieces of equipment?

Prioritizing tasks while operating multiple pieces of equipment requires a structured approach. I typically employ a system based on urgency and dependency. I begin by identifying tasks that are time-sensitive or have downstream dependencies. For example, if I’m using a bulldozer to clear land and an excavator to dig foundations, the land clearing must precede the excavation, creating a clear sequence. I then break down complex tasks into smaller, manageable steps. I also create a visual checklist or schedule to track progress and stay organized.

Real-time adjustments are crucial. Unforeseen issues, such as equipment malfunction or unexpected changes in site conditions, demand immediate adaptation. In such scenarios, I would quickly reassess the situation, re-prioritize tasks, and communicate any changes to the team. Communication is key to preventing conflicts or delays when working with multiple equipment pieces and personnel simultaneously.

Q 17. What is your experience with preventative maintenance on heavy machinery?

Preventative maintenance is critical for the longevity and safe operation of heavy machinery. My experience encompasses daily, weekly, and monthly checks, encompassing visual inspections, fluid level checks (hydraulic oil, engine oil, coolant), lubrication of moving parts, and functional testing of key systems. I maintain detailed logs of all maintenance activities. I also know how to interpret manufacturer’s manuals and perform more complex tasks, like changing filters and belts, when necessary. For example, I meticulously inspect hydraulic lines for leaks and ensure proper pressure. Neglecting preventative maintenance can lead to costly repairs and downtime, not to mention increased safety risks. Regular maintenance is about safeguarding both the equipment and the operator.

I always adhere to the manufacturer’s recommended maintenance schedule and keep detailed records. Proactive maintenance prevents catastrophic failures and reduces the risk of accidents.

Q 18. Describe your experience with working under pressure and tight deadlines.

Working under pressure and tight deadlines is a common aspect of my job. I handle these situations effectively by remaining calm and methodical. My approach involves breaking down large tasks into smaller, more manageable steps, setting realistic timelines, and prioritizing activities strategically. Open communication with supervisors and team members is crucial to manage expectations and ensure everyone is informed of potential delays or challenges.

For example, during a recent project where we had to complete earthmoving work before a scheduled storm, I calmly organized the team, optimized equipment usage, and coordinated our efforts efficiently. We completed the work safely and within the deadline, thanks to careful planning and teamwork. While speed is important, safety always comes first.

Q 19. How do you ensure compliance with all relevant safety regulations?

Safety is paramount in my work. I ensure compliance with all relevant safety regulations by undergoing regular safety training, participating in toolbox talks, and strictly adhering to site-specific safety procedures. I am familiar with OSHA regulations (or equivalent regional regulations) and understand the importance of personal protective equipment (PPE), such as hard hats, safety glasses, high-visibility clothing, and hearing protection. I always ensure the equipment is properly inspected before operation, and I never compromise on safety procedures, even if it means slightly extending the timeline.

If I observe any unsafe practices, I immediately report them to my supervisor. My commitment to safety isn’t just a matter of compliance; it’s a reflection of my personal responsibility and commitment to the well-being of myself and my colleagues.

Q 20. What is your experience with hydraulic systems in heavy machinery?

Hydraulic systems are fundamental to the operation of most heavy machinery. My experience encompasses understanding the basic principles of hydraulics, including pressure, flow, and power transmission. I’m familiar with common hydraulic components, such as pumps, valves, cylinders, and motors. I can troubleshoot basic hydraulic problems, such as identifying leaks, diagnosing faulty valves, and recognizing issues with fluid contamination.

For instance, I’ve successfully resolved issues with slow response times in an excavator’s hydraulic system by identifying a leak in a hose and replacing it. I also understand the importance of regularly checking hydraulic fluid levels, ensuring proper filtration, and recognizing the signs of overheating or other malfunctions. Understanding hydraulic systems ensures efficient and safe operation of heavy machinery.

Q 21. Explain your understanding of different types of soil and their impact on machinery operation.

Different soil types significantly impact heavy machinery operation. For example, sandy soil offers less resistance but can be unstable, leading to equipment sinking or becoming stuck. Clay soil is highly cohesive when wet, creating increased resistance and potentially damaging equipment. Rocky soil requires specialized tools and techniques to avoid damaging equipment. Understanding these soil properties is crucial for selecting the appropriate machinery and operating techniques.

When working on a site with various soil types, I always conduct a thorough site assessment to determine the appropriate machinery and operating procedures. I also adjust operating techniques based on soil conditions, such as reducing ground speed in challenging terrain to avoid damage to the equipment or the surrounding environment. Knowing and respecting the limitations of the equipment and the site conditions is pivotal for safety and efficiency.

Q 22. How do you handle difficult or challenging working conditions?

Handling challenging working conditions in heavy equipment operation requires a methodical approach. It’s not just about brute strength; it’s about strategic thinking and safety. My strategy involves a three-pronged approach: Preparation, Adaptability, and Safety First.

Preparation: Before starting any task, I thoroughly assess the site conditions. This includes checking the ground for instability, assessing weather forecasts for potential hazards like rain or strong winds, and verifying the equipment’s operational status and ensuring all safety mechanisms are functioning correctly. For instance, working on a steep slope necessitates additional caution and careful planning of the load path.

Adaptability: Unexpected situations are common. If I encounter a problem, like a sudden equipment malfunction or a change in weather, my response is guided by prioritizing safety and adapting my plan accordingly. I wouldn’t hesitate to halt operations and contact my supervisor to discuss alternative approaches or request assistance if needed. For example, if visibility is reduced due to fog, I’d delay work until conditions improve.

Safety First: This is paramount. No job is worth risking injury. I meticulously follow all safety protocols, using appropriate personal protective equipment (PPE) like hard hats, safety glasses, and high-visibility clothing. I routinely inspect the equipment before operation and report any deficiencies immediately. If I feel unsafe under any conditions, I’ll stop work and address the concerns before proceeding.

Q 23. Describe your experience working as part of a team.

Teamwork is fundamental in heavy equipment operation. I’ve been part of several teams, ranging from small crews on construction sites to larger teams involved in infrastructure projects. My role always involves clear communication, mutual respect, and a focus on collaborative problem-solving.

Communication: I actively participate in pre-job briefings, ensuring I understand my role and how it integrates with the overall plan. I communicate clearly and promptly with my team members, alerting them to any potential hazards or changes in the work plan. On a recent project, I successfully coordinated with the excavator operator and truck driver to ensure a smooth and efficient material-handling process.

Mutual Respect: I value each team member’s input and expertise. We all have different skills and responsibilities, and effective teamwork depends on recognizing and respecting those differences. I contribute by sharing my knowledge and assisting my colleagues whenever possible.

Problem-Solving: Challenges arise frequently, so proactive problem-solving is key. I approach challenges collaboratively, suggesting solutions and working with my team to implement effective strategies. For instance, when encountering a difficult terrain, we collectively evaluated the options and chose the most efficient and safest approach, successfully avoiding potential delays and accidents.

Q 24. How do you communicate effectively with supervisors and colleagues?

Effective communication is essential for safety and efficiency. I prioritize clear, concise, and respectful communication.

With Supervisors: I maintain open communication with my supervisors, regularly updating them on progress, reporting any issues promptly, and seeking clarification when necessary. I use appropriate channels, such as radio communication on site and written reports after completing tasks. This ensures everyone is informed and can make informed decisions.

With Colleagues: I use a variety of methods to communicate with colleagues, including verbal instructions, hand signals (especially important in noisy environments), and radio communication. I ensure that my instructions are understood and I actively listen to my colleagues’ concerns. I always adhere to the principle of clear and respectful communication, aiming for mutual understanding and collaboration.

Q 25. What are your salary expectations?

My salary expectations are in line with the industry standards for experienced heavy equipment operators with my skill set and years of experience. I’m flexible and open to discussing a competitive compensation package that reflects my value and contributions to the company. I would appreciate a detailed breakdown of the compensation and benefits offered for this role.

Q 26. What are your long-term career goals?

My long-term career goals involve continued professional development and advancement within the heavy equipment operation field. I aim to become a highly skilled and versatile operator, capable of handling a wide range of equipment and tasks. Ideally, I see myself progressing to a supervisory role, where I can mentor and train other operators while contributing to the safety and efficiency of large-scale projects. I am also keen to pursue certifications and training to enhance my expertise and expand my capabilities.

Q 27. What are your strengths and weaknesses as a heavy equipment operator?

My strengths lie in my precision, safety consciousness, and problem-solving abilities. I’m adept at operating various types of heavy equipment, consistently delivering high-quality work within deadlines. My meticulous approach ensures projects are completed to exacting standards while maintaining optimal safety. For example, my experience with precise grading work on a recent highway project resulted in significant time savings and reduced material waste.

A weakness I’m actively working on is delegation. While I enjoy taking ownership of tasks, I’m learning to trust and delegate effectively to maximize team efficiency. I’ve started implementing strategies like better task breakdown and clearer communication to improve this area.

Q 28. Do you have any questions for me?

Yes, I have a few questions. First, what opportunities are there for professional development and advancement within the company? Second, can you describe the typical projects this role will be involved in? And finally, what are the company’s safety procedures and protocols?

Key Topics to Learn for Heavy Machinery Operation Interviews

- Machine Operation Fundamentals: Understanding the theoretical principles behind operating various heavy machinery types (e.g., excavators, bulldozers, loaders). This includes knowledge of hydraulics, engine mechanics, and safety systems.

- Practical Application & Skill Demonstration: Be prepared to discuss your experience with specific machines, outlining your proficiency in tasks like digging, loading, grading, and material handling. Quantify your accomplishments whenever possible (e.g., “Increased efficiency by 15% by optimizing loading procedures”).

- Safety Procedures & Regulations: Demonstrate a thorough understanding of relevant safety protocols, including pre-operation checks, hazard identification, and emergency procedures. Knowledge of OSHA regulations (or equivalent in your region) is crucial.

- Maintenance & Troubleshooting: Discuss your experience with routine maintenance tasks, minor repairs, and troubleshooting common mechanical issues. Highlight your ability to identify problems quickly and efficiently.

- GPS & Technology Integration: If applicable, showcase your experience with GPS-guided machinery and other technological advancements in heavy equipment operation.

- Job Site Management & Teamwork: Discuss your ability to work effectively in a team environment, coordinate with other operators and crew members, and adhere to project timelines and specifications.

- Problem-Solving & Adaptability: Prepare examples showcasing your ability to solve unexpected problems on the job site, adapt to changing conditions, and make sound decisions under pressure.

Next Steps

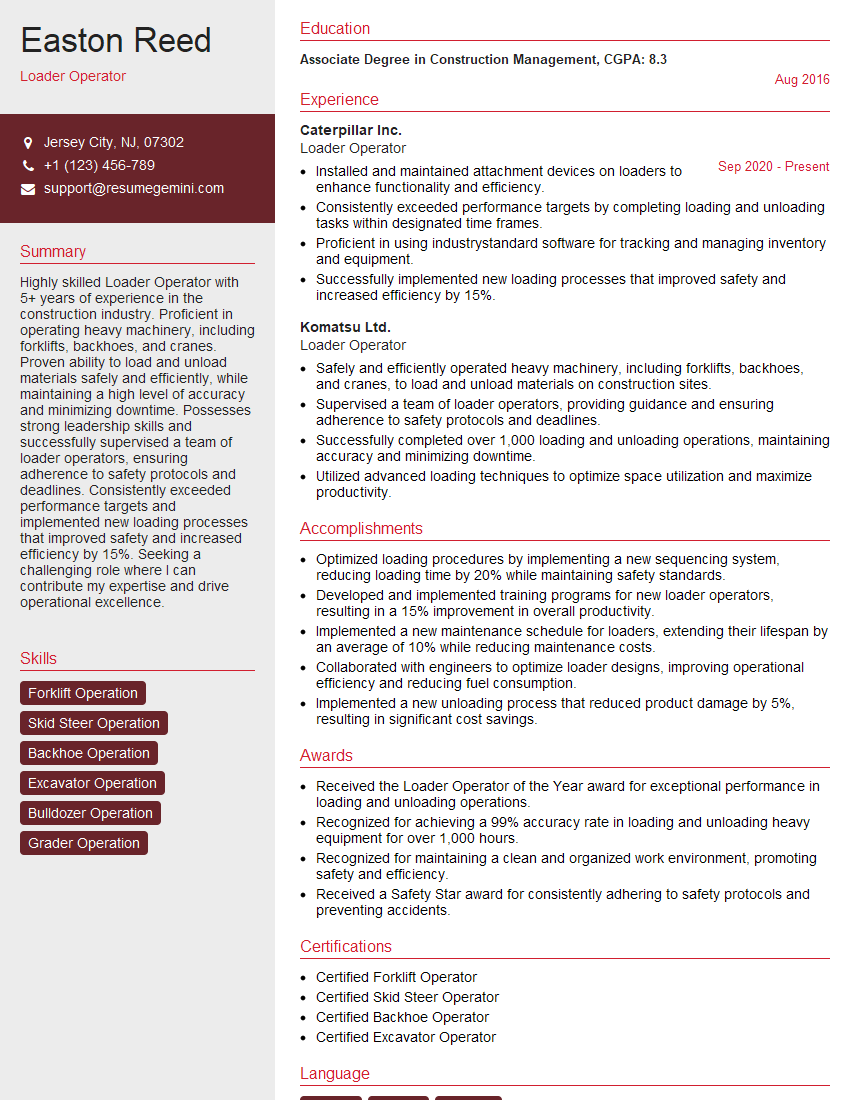

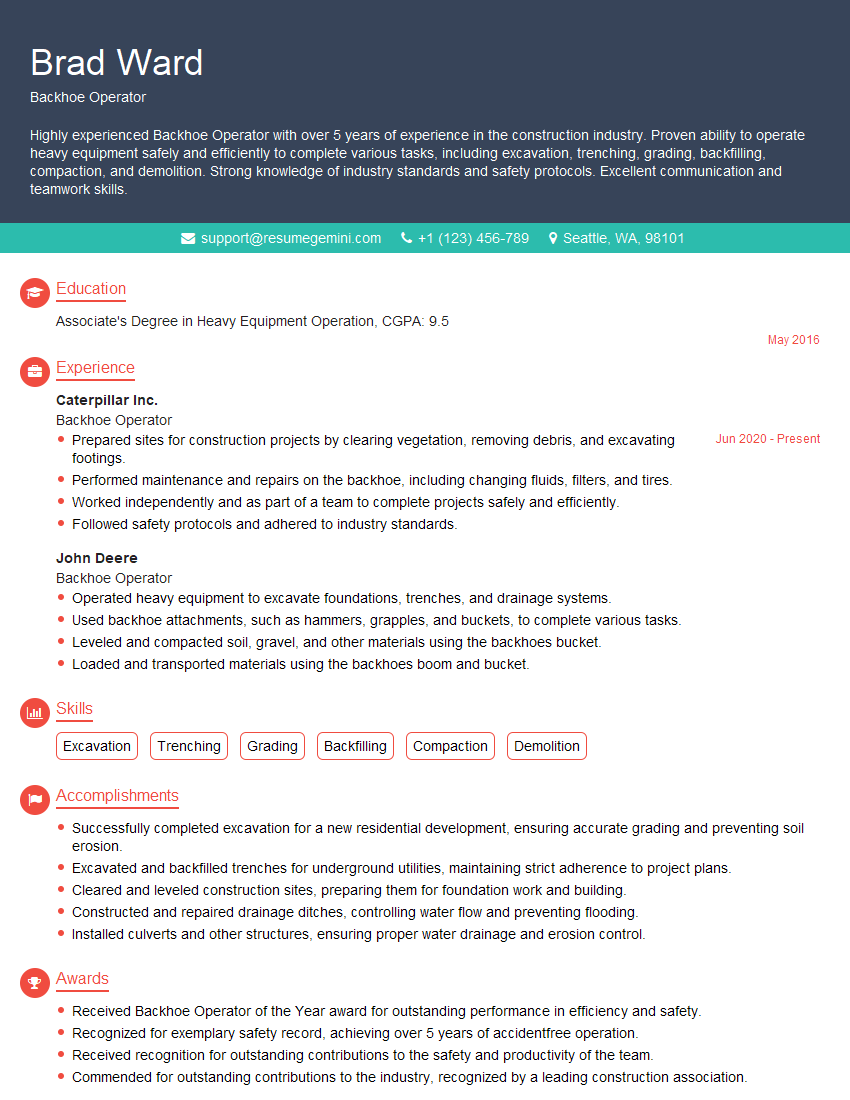

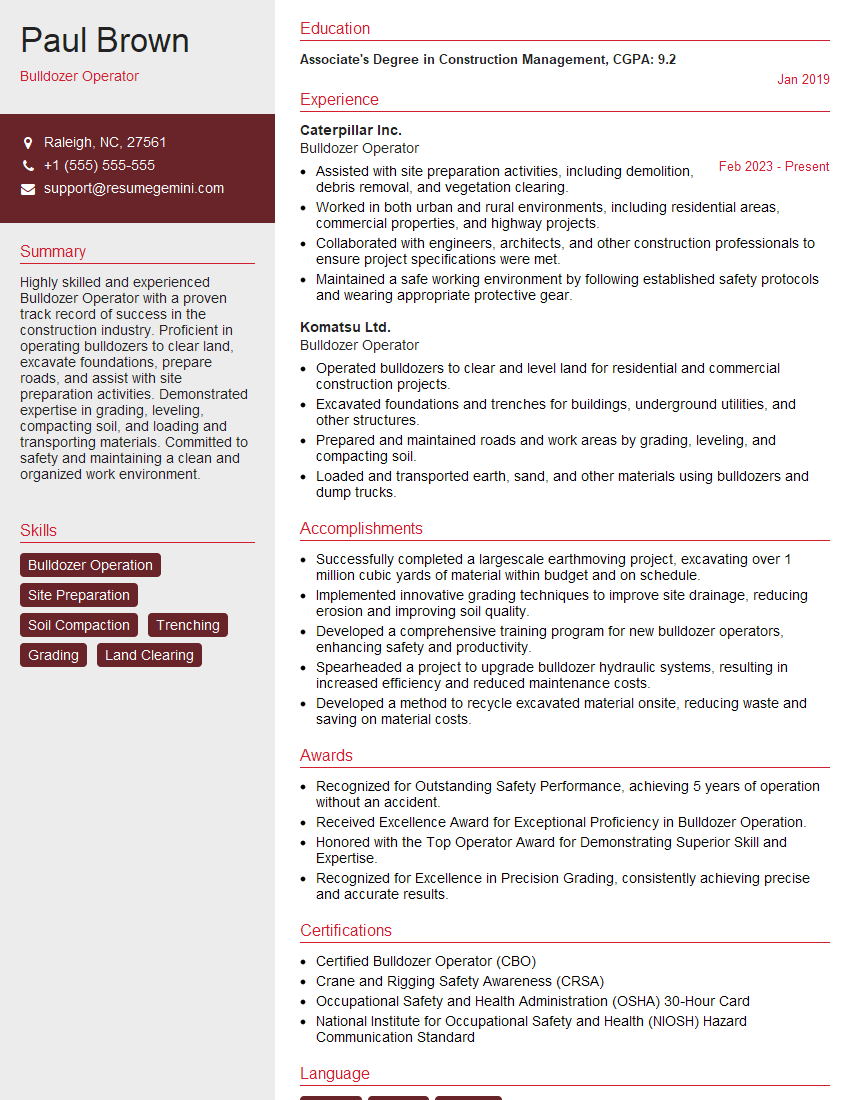

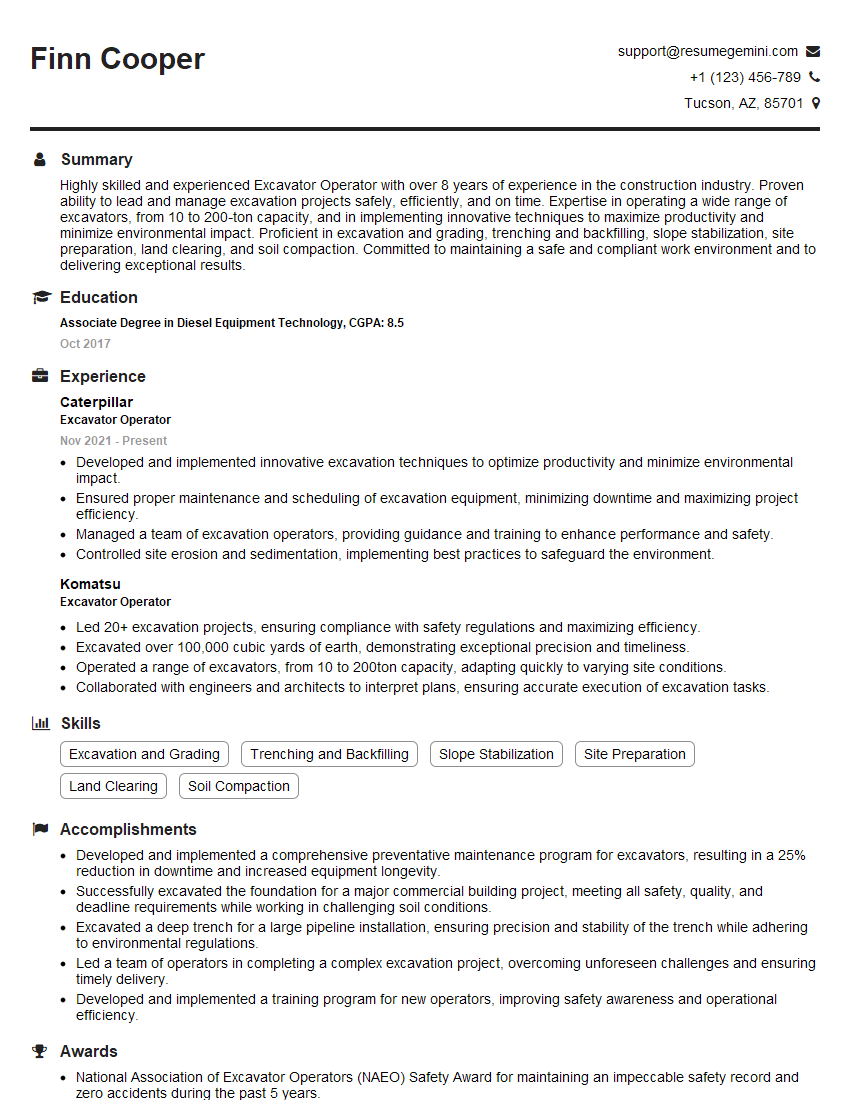

Mastering heavy machinery operation opens doors to rewarding and high-demand careers with excellent earning potential. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini can help you build a professional and impactful resume that showcases your skills and experience effectively. We provide examples of resumes tailored to heavy machinery operation experience to guide you through the process. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO