Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Water Treatment and Filtration interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Water Treatment and Filtration Interview

Q 1. Explain the difference between coagulation and flocculation in water treatment.

Coagulation and flocculation are two crucial steps in water treatment aimed at removing suspended solids. Think of it like cleaning a muddy pond: coagulation is like adding a special ingredient to clump the mud together, while flocculation is gently stirring to form larger clumps.

Coagulation involves adding a chemical coagulant (like alum or ferric chloride) to destabilize the negatively charged particles in the water. This destabilization causes the particles to collide and begin to clump together, forming microflocs. It’s a rapid process, happening within seconds or minutes.

Flocculation is the subsequent slow mixing process that encourages these microflocs to grow larger, forming larger, heavier flocs. These larger flocs are then easier to remove through sedimentation or filtration. This slow mixing usually lasts for 20-40 minutes. The gentle stirring helps to promote collisions between the microflocs, allowing them to aggregate into larger, more easily settleable particles.

In short: Coagulation destabilizes particles, while flocculation encourages their aggregation into larger, removable flocs. They are sequential processes, with coagulation preceding flocculation.

Q 2. Describe the process of reverse osmosis (RO) and its applications.

Reverse Osmosis (RO) is a water purification technology that uses a semipermeable membrane to remove ions, molecules, and larger particles from water. Imagine a sieve so fine it only lets water molecules through. That’s essentially what an RO membrane does.

The process involves applying pressure to the water, forcing it through the membrane. The dissolved salts, minerals, and other contaminants are left behind, resulting in purified water. This process is highly effective at removing a wide range of pollutants, including dissolved salts, heavy metals, bacteria, and viruses.

Applications of RO:

- Drinking water production: Producing high-quality drinking water from seawater, brackish water, or contaminated sources.

- Industrial processes: Providing ultrapure water for various industrial applications, such as pharmaceuticals, electronics, and power generation.

- Wastewater treatment: Removing contaminants from wastewater before discharge or reuse.

- Medical applications: Producing sterile water for dialysis and other medical uses.

While incredibly effective, RO systems can be energy-intensive and produce a significant amount of wastewater (the brine stream containing the concentrated contaminants).

Q 3. What are the different types of filtration membranes used in water treatment?

Various filtration membranes are used in water treatment, each with its unique characteristics and applications. The choice depends on the specific contaminants to be removed and the desired level of purification.

Common types include:

- Microfiltration (MF): Removes larger particles like suspended solids, bacteria, and protozoa. Pore sizes range from 0.1 to 10 microns.

- Ultrafiltration (UF): Removes smaller particles such as viruses, colloids, and dissolved organic matter. Pore sizes are typically 0.01 to 0.1 microns.

- Nanofiltration (NF): Removes multivalent ions, organic molecules, and some dissolved salts. Pore sizes are in the nanometer range.

- Reverse Osmosis (RO): Removes virtually all dissolved salts, minerals, and other contaminants. Membrane pore size is extremely small, only allowing water molecules to pass.

The choice of membrane depends on the specific treatment goals. For example, MF might suffice for removing bacteria from surface water, while RO is needed for desalination or producing ultrapure water.

Q 4. How do you determine the optimal dosage of coagulants for effective water treatment?

Determining the optimal coagulant dosage is critical for effective water treatment. An insufficient dosage won’t remove enough contaminants, while excessive dosage can lead to residual coagulant in the treated water, potentially causing taste and odor problems or harming aquatic life.

The optimal dosage is determined through jar testing. This laboratory procedure involves mixing several samples of the raw water with varying concentrations of the coagulant. The samples are then stirred (simulating coagulation and flocculation) and allowed to settle. The jar showing the best floc formation and the clearest supernatant (the liquid on top) indicates the optimal coagulant dose.

Steps involved in jar testing:

- Collect a representative sample of the raw water.

- Prepare a series of jars with different coagulant concentrations (e.g., 5, 10, 15, 20 mg/L).

- Add the coagulant to each jar and stir rapidly for a specified time (simulating coagulation).

- Reduce the stirring speed to a slower rate (simulating flocculation).

- Allow the samples to settle.

- Observe the floc formation and clarity of the supernatant in each jar.

- Select the jar with the best floc characteristics and clearest supernatant; this concentration represents the optimal coagulant dose.

Jar testing needs to be repeated regularly, as water quality can vary.

Q 5. Explain the significance of chlorine disinfection in water treatment and its limitations.

Chlorine disinfection is a widely used method for eliminating harmful microorganisms in water, making it safe for human consumption. It’s effective, relatively inexpensive, and readily available. Chlorine kills bacteria, viruses, and other pathogens by disrupting their cellular processes.

Significance: Chlorine disinfection has significantly reduced waterborne diseases worldwide, dramatically improving public health. It’s a critical component of water treatment ensuring safe drinking water.

Limitations:

- Formation of disinfection byproducts (DBPs): Chlorine can react with organic matter in the water to form DBPs, some of which are potentially carcinogenic or harmful to human health.

- Ineffective against some pathogens: Cryptosporidium and Giardia, for example, are more resistant to chlorine disinfection.

- Taste and odor issues: Chlorine can impart a noticeable taste and odor to water.

- Residual chlorine requirements: Maintaining a residual chlorine level throughout the distribution system is crucial, but it’s a challenge to maintain consistent levels across long distances.

Because of these limitations, many water treatment facilities are exploring alternative or supplemental disinfection methods, such as UV disinfection or ozonation.

Q 6. Describe the different types of water softeners and their working principles.

Water softeners remove hardness minerals (primarily calcium and magnesium ions) from water, preventing scale buildup in pipes and appliances. They primarily work using either ion exchange or other physical methods.

Types of water softeners:

- Ion-exchange softeners: These are the most common type. They use resin beads that contain sodium ions. When hard water passes through the resin bed, the calcium and magnesium ions are exchanged for sodium ions. The resin eventually becomes saturated with calcium and magnesium and needs to be regenerated by backwashing with a concentrated brine solution (saltwater). This process replaces the calcium and magnesium ions on the resin with sodium ions, making it ready for another cycle.

- Electromagnetic water softeners: These devices use electromagnetic fields to alter the crystalline structure of the minerals in the water, preventing them from forming scale. Their effectiveness is debated and is generally less reliable than ion exchange systems.

- Reverse osmosis (RO) systems: While primarily used for broader purification, RO systems are also highly effective at removing hardness minerals, as part of the overall purification process.

The choice of water softener depends on factors like water hardness, budget, and the desired level of softening.

Q 7. What are the common indicators of water quality and their significance?

Water quality indicators provide information about the suitability of water for different purposes (drinking, irrigation, industrial use, etc.). They are parameters measured to assess various aspects of water’s purity and health.

Common indicators and their significance:

- pH: Measures the acidity or alkalinity of water. A pH of around 7 is considered neutral. Extreme pH values can be corrosive or harmful to aquatic life.

- Turbidity: Measures the cloudiness of water caused by suspended particles. High turbidity indicates poor water quality and can harbor pathogens.

- Temperature: Affects dissolved oxygen levels and the metabolic rates of aquatic organisms. Elevated temperatures can stress or kill aquatic life.

- Dissolved oxygen (DO): Essential for aquatic life. Low DO levels indicate water pollution and can lead to fish kills.

- Total dissolved solids (TDS): Measures the total amount of dissolved minerals and salts in water. High TDS can make water taste salty or affect its suitability for drinking or industrial use.

- Bacterial contamination: Indicates the presence of harmful bacteria like E. coli, indicating fecal contamination and potential health risks.

- Heavy metals: The presence of heavy metals like lead, mercury, or arsenic can be toxic to humans and the environment.

Monitoring these indicators helps assess water quality, identify potential pollution sources, and ensure that water is safe for its intended use.

Q 8. Explain the concept of Total Dissolved Solids (TDS) and its impact on water quality.

Total Dissolved Solids (TDS) refers to the total amount of inorganic and organic minerals, salts, and metals dissolved in a given volume of water. It’s essentially a measure of the total concentration of dissolved solids. We measure TDS in milligrams per liter (mg/L) or parts per million (ppm). A higher TDS indicates more dissolved substances.

The impact on water quality is significant. High TDS can make water taste salty or metallic, affecting its palatability. It can also pose health risks depending on the specific dissolved substances. For example, high levels of certain minerals like arsenic or lead can be toxic. High TDS can also damage appliances such as water heaters and coffee makers through scaling (buildup of mineral deposits).

Think of it like this: imagine adding salt to a glass of water. The more salt you add, the higher the TDS. Eventually, the water becomes undrinkable. Similarly, high TDS in water sources can render them unsuitable for drinking or other purposes without treatment.

Q 9. How do you troubleshoot a malfunctioning water filter system?

Troubleshooting a malfunctioning water filter system requires a systematic approach. First, identify the specific problem: is the water flow reduced, is the water cloudy, is there a foul odor, or is the filter simply not working?

- Check the water pressure: Low water pressure can indicate a clogged pre-filter or a problem with the main water supply.

- Inspect the filter cartridges: Are they clogged? Replace them if necessary. Different filter types (sediment, carbon, etc.) have different lifespans and need to be changed according to the manufacturer’s recommendations.

- Check for leaks: Examine all connections for leaks and tighten them if necessary. Leaks can significantly reduce filter performance.

- Examine the bypass valve (if present): Ensure it’s in the correct position (usually switched to the ‘filter’ position).

- Test the water quality: After addressing the potential problems, test the water quality using a TDS meter or other appropriate tests to confirm that the filter is working correctly.

If you’ve checked all these points and the problem persists, it’s time to consult a professional for more in-depth diagnosis and repair.

Q 10. What are the safety precautions to be followed while working with water treatment chemicals?

Safety is paramount when handling water treatment chemicals. These chemicals can be corrosive, toxic, or otherwise hazardous. Always follow these precautions:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, safety goggles, and a lab coat or apron. The specific PPE depends on the chemical being used.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes. Consider using a respirator if necessary.

- Chemical Compatibility: Never mix chemicals together unless explicitly instructed to do so in the product’s safety data sheet (SDS). Mixing incompatible chemicals can create dangerous reactions.

- Proper Storage: Store chemicals in their original containers in a cool, dry, and secure location, away from incompatible materials and out of reach of children and unauthorized personnel.

- Spill Response: Have a spill response plan in place and know how to handle chemical spills safely. This includes having appropriate neutralizing agents and absorbent materials readily available.

- SDS Review: Always read and understand the SDS for each chemical before using it. The SDS contains vital information about its hazards and safe handling procedures.

Remember, safety is not just a guideline; it’s a responsibility. If you’re unsure about any aspect of chemical handling, seek expert guidance.

Q 11. Explain the concept of biological wastewater treatment.

Biological wastewater treatment uses microorganisms, primarily bacteria, to break down organic matter in wastewater. This process mimics natural decomposition processes but is optimized for efficiency and effectiveness. The goal is to remove pollutants and make the wastewater safe for discharge or reuse.

The process typically involves several stages:

- Primary Treatment: Physical processes like screening and sedimentation remove large solids and grit.

- Secondary Treatment: This is where the biological processes happen. Wastewater is aerated (introducing oxygen) to encourage aerobic bacteria to thrive. These bacteria consume the organic matter, converting it into simpler, less harmful substances like carbon dioxide and water. This often involves activated sludge processes or trickling filters.

- Tertiary Treatment (optional): This stage further refines the treated wastewater, often removing nutrients like nitrogen and phosphorus through processes like filtration or chemical treatment.

Think of it like composting: bacteria break down organic materials naturally, but in wastewater treatment, we carefully control the environment to maximize the process’s efficiency and effectiveness. The result is cleaner water that meets environmental standards.

Q 12. Describe the different types of water pumps used in water treatment plants.

Water treatment plants employ various pumps depending on the specific application and requirements. Some common types include:

- Centrifugal Pumps: These are the most common type, using rotating impellers to increase the water’s velocity and pressure. They’re versatile and can handle various flow rates and pressures.

- Submersible Pumps: These pumps are located directly within the water source, eliminating the need for suction lift. They are ideal for pumping from deep wells or reservoirs.

- Diaphragm Pumps: These pumps use a flexible diaphragm to move the water, making them suitable for handling slurries or fluids containing solids.

- Positive Displacement Pumps: These pumps move a fixed volume of water with each stroke, providing a consistent flow rate. They are often used for high-pressure applications.

- Progressive Cavity Pumps: These pumps use a rotating screw within a stationary stator to move the water. They are often used for high-viscosity fluids.

The choice of pump depends on factors such as the flow rate, head (pressure), the characteristics of the water being pumped (e.g., viscosity, presence of solids), and the overall plant design.

Q 13. What is the significance of pH control in water treatment?

pH control is crucial in water treatment because it significantly impacts the effectiveness of various treatment processes and the overall water quality. pH measures the acidity or alkalinity of water, with a scale from 0 to 14 (7 being neutral).

Optimal pH levels are needed for:

- Chemical coagulation and flocculation: These processes rely on specific pH ranges for efficient removal of suspended solids.

- Disinfection: The effectiveness of disinfectants like chlorine is significantly impacted by pH. Lower pH generally enhances disinfection.

- Corrosion control: Maintaining an appropriate pH prevents corrosion of pipes and equipment.

- Protecting aquatic life (in effluent discharge): Abrupt pH changes in discharged water can be harmful to aquatic ecosystems.

pH control is typically achieved using chemicals like acids (e.g., sulfuric acid) or bases (e.g., sodium hydroxide) to adjust the pH to the desired range. Continuous monitoring of pH is essential to ensure that the water remains within the acceptable limits.

Q 14. Explain the principles of UV disinfection in water treatment.

UV disinfection utilizes ultraviolet (UV) light to inactivate microorganisms in water by damaging their DNA, preventing them from reproducing and causing disease. UV light, specifically in the UVC range (200-280 nm), is highly effective in killing bacteria, viruses, and protozoa.

The process involves passing the water through a chamber containing UV lamps. The lamps emit UVC light, which irradiates the water, destroying the microorganisms’ genetic material. The intensity of the UV light and the exposure time are critical factors in determining the effectiveness of the disinfection process.

Key factors influencing UV disinfection efficacy include:

- Water turbidity: Suspended solids can block the UV light, reducing its effectiveness. Pre-filtration is often necessary to ensure sufficient UV penetration.

- UV lamp intensity: The intensity of the UV lamps diminishes over time, requiring regular monitoring and replacement.

- Flow rate: The flow rate of water through the UV chamber must be controlled to ensure sufficient exposure time.

UV disinfection is a chemical-free alternative to traditional disinfection methods like chlorination, making it environmentally friendly. However, it’s important to note that UV disinfection does not remove chemicals or other dissolved substances from the water.

Q 15. How do you perform a water quality analysis using standard laboratory techniques?

Water quality analysis involves a series of tests to determine the physical, chemical, and biological characteristics of water. It’s like giving water a thorough health checkup! We use standard laboratory techniques to identify contaminants and assess its suitability for different purposes, from drinking to industrial use.

A typical analysis might include:

- Physical parameters: Temperature, turbidity (cloudiness), color, odor, and pH are measured using instruments like thermometers, turbidity meters, and pH meters. For example, high turbidity indicates suspended solids, potentially affecting water clarity and taste.

- Chemical parameters: This involves determining the concentration of various dissolved substances. We test for things like dissolved oxygen (DO), chlorine, heavy metals (lead, mercury, etc.), nitrates, phosphates, and total dissolved solids (TDS). Techniques used include titrations, spectrophotometry, and atomic absorption spectroscopy. For instance, high nitrate levels can be harmful to human health.

- Biological parameters: This focuses on identifying and quantifying microorganisms like bacteria, viruses, and protozoa. Techniques like plate counts, membrane filtration, and polymerase chain reaction (PCR) are employed. Finding E. coli, for example, is a strong indicator of fecal contamination.

The specific tests performed depend on the intended use of the water and potential sources of contamination. Results are then compared to regulatory standards to determine water quality compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common operational problems encountered in water treatment plants?

Water treatment plants face several operational challenges. Think of it like running a complex machine – things can go wrong at various stages. Common problems include:

- Filter clogging: This reduces flow rates and treatment efficiency. Regular backwashing and proper pretreatment are crucial to prevent this. Imagine trying to filter sand through a clogged sieve – it won’t work efficiently.

- Chemical dosage control: Inaccurate chemical dosing can lead to under- or over-treatment, compromising water quality. Precise metering and regular monitoring are essential. Too little chlorine, for example, leaves the water vulnerable to contamination, while too much can be harmful.

- Equipment malfunction: Pumps, filters, and other equipment can break down, causing disruptions and affecting water quality. Regular maintenance and preventive measures are vital. A broken pump, for example, can halt the entire treatment process.

- Power outages: These can lead to temporary shutdowns, requiring backup power systems to maintain operations. This is critical, especially for emergency water supply.

- Influent water quality variations: Changes in the source water quality (e.g., increased turbidity during a storm) can stress the treatment process and require adjustments to operational parameters. This necessitates flexible treatment strategies.

Effective management involves proactive monitoring, predictive maintenance, and skilled operators capable of adapting to changing conditions.

Q 17. Explain the importance of regular maintenance in water treatment facilities.

Regular maintenance is paramount for ensuring safe, reliable, and efficient water treatment operations. It’s like a car needing regular servicing – neglecting it leads to bigger problems down the line.

Regular maintenance encompasses:

- Equipment inspections: Identifying and addressing potential problems before they escalate into major failures. This includes checking for wear and tear, leaks, and corrosion.

- Preventative maintenance: Scheduled cleaning, lubrication, and component replacements to extend equipment lifespan and prevent unexpected breakdowns. This could involve changing filters, cleaning membranes, or lubricating pump seals.

- Calibration and testing: Ensuring the accuracy of instruments and control systems. This means verifying the accuracy of pH meters, flow meters, and other critical monitoring devices.

- Operator training: Keeping staff updated on operational procedures, troubleshooting techniques, and safety protocols. Well-trained operators are the backbone of effective maintenance.

By implementing a comprehensive maintenance program, water treatment plants minimize downtime, reduce repair costs, ensure consistent water quality, and enhance overall operational efficiency and safety.

Q 18. How do you ensure the compliance of water treatment operations with regulatory standards?

Ensuring compliance with regulatory standards is crucial for protecting public health and the environment. We do this through a multi-pronged approach:

- Regular monitoring: Continuously collecting and analyzing water samples to ensure parameters meet regulatory limits set by agencies like the EPA. This involves testing for contaminants like bacteria, heavy metals, and chemicals.

- Record keeping: Maintaining detailed records of all operational data, including chemical usage, flow rates, maintenance activities, and test results. This documentation provides a clear audit trail for compliance verification.

- Compliance audits: Conducting internal and external audits to assess compliance with regulations. These audits identify areas for improvement and help ensure ongoing compliance.

- Operator certification: Ensuring that operators possess the necessary qualifications and training to operate and maintain the treatment plant according to regulations.

- Emergency response planning: Having protocols in place to deal with emergencies, such as equipment failures or spills, and to minimize their impact on water quality and public health.

By meticulously following these steps, we guarantee our water treatment operations consistently meet and exceed regulatory requirements, safeguarding public health and environmental protection.

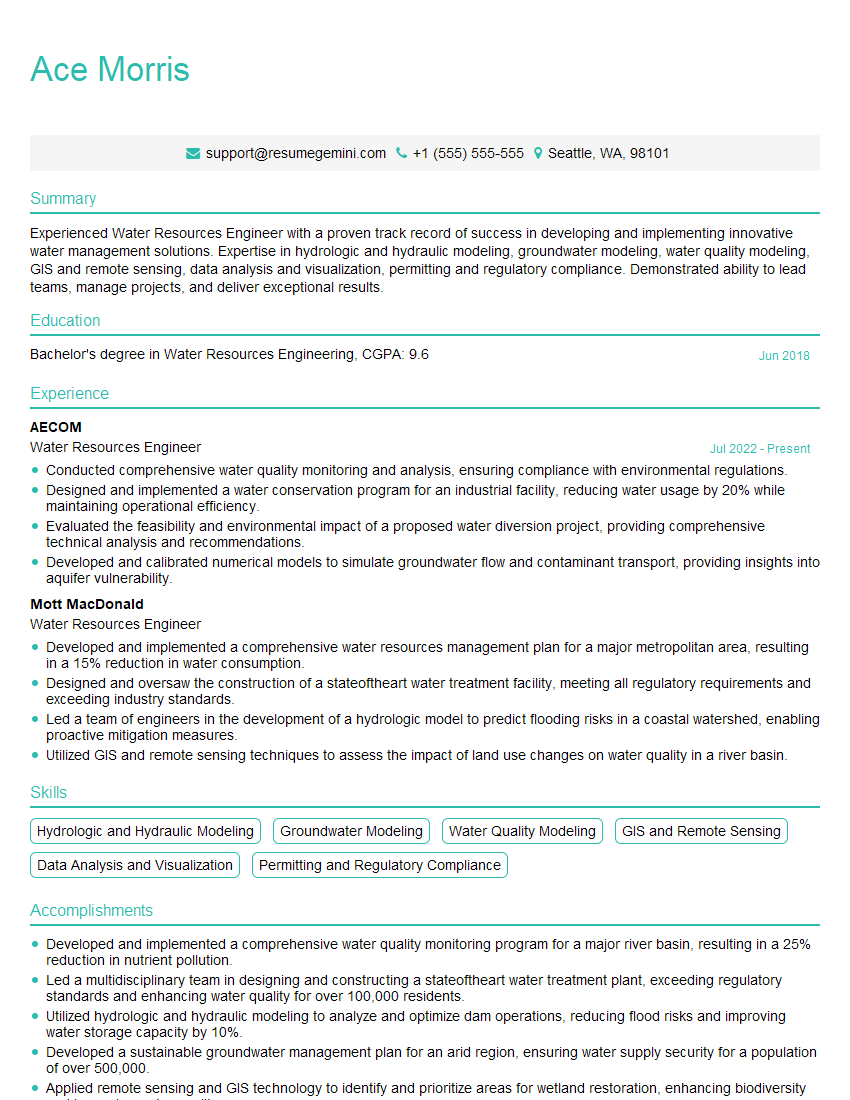

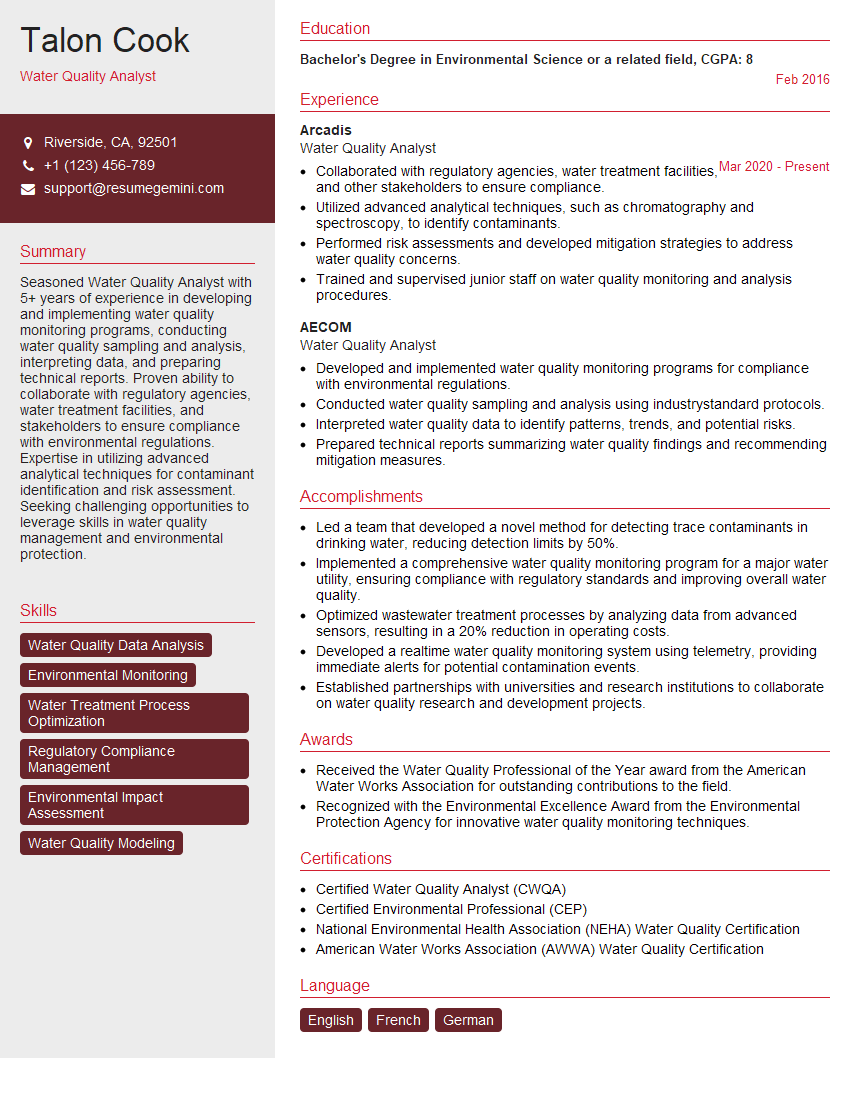

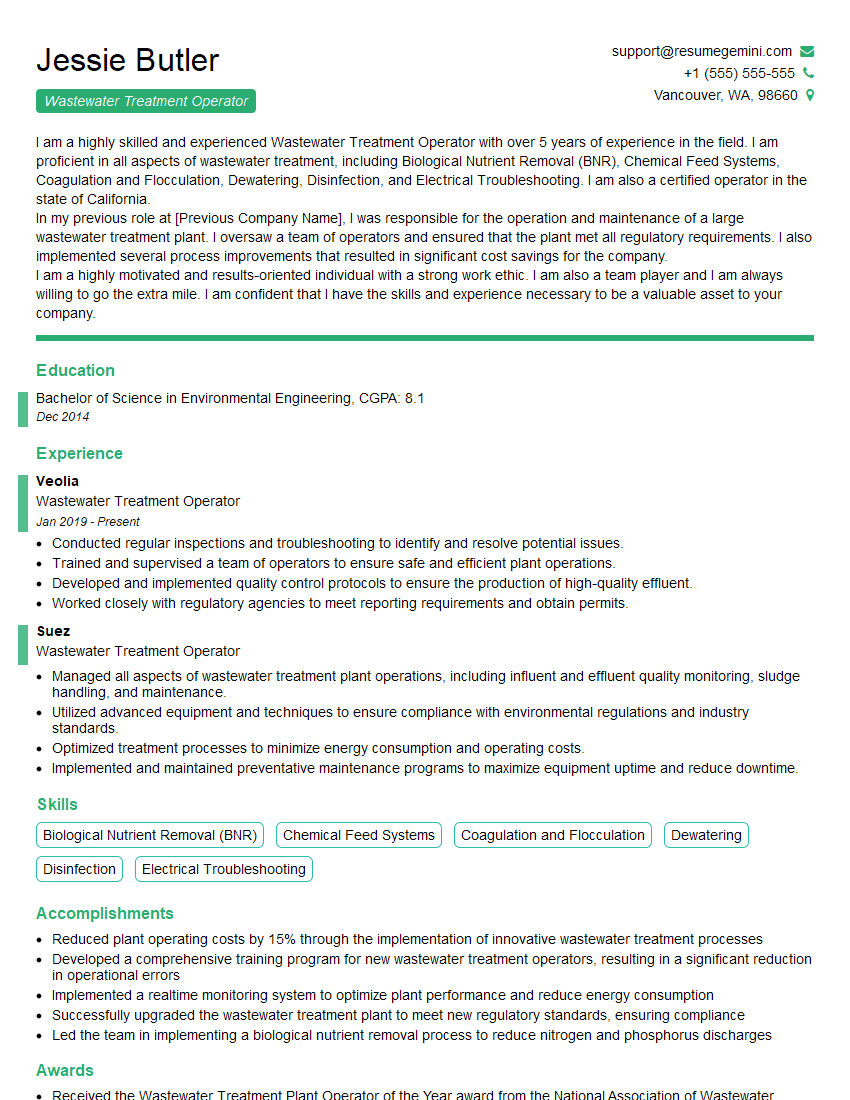

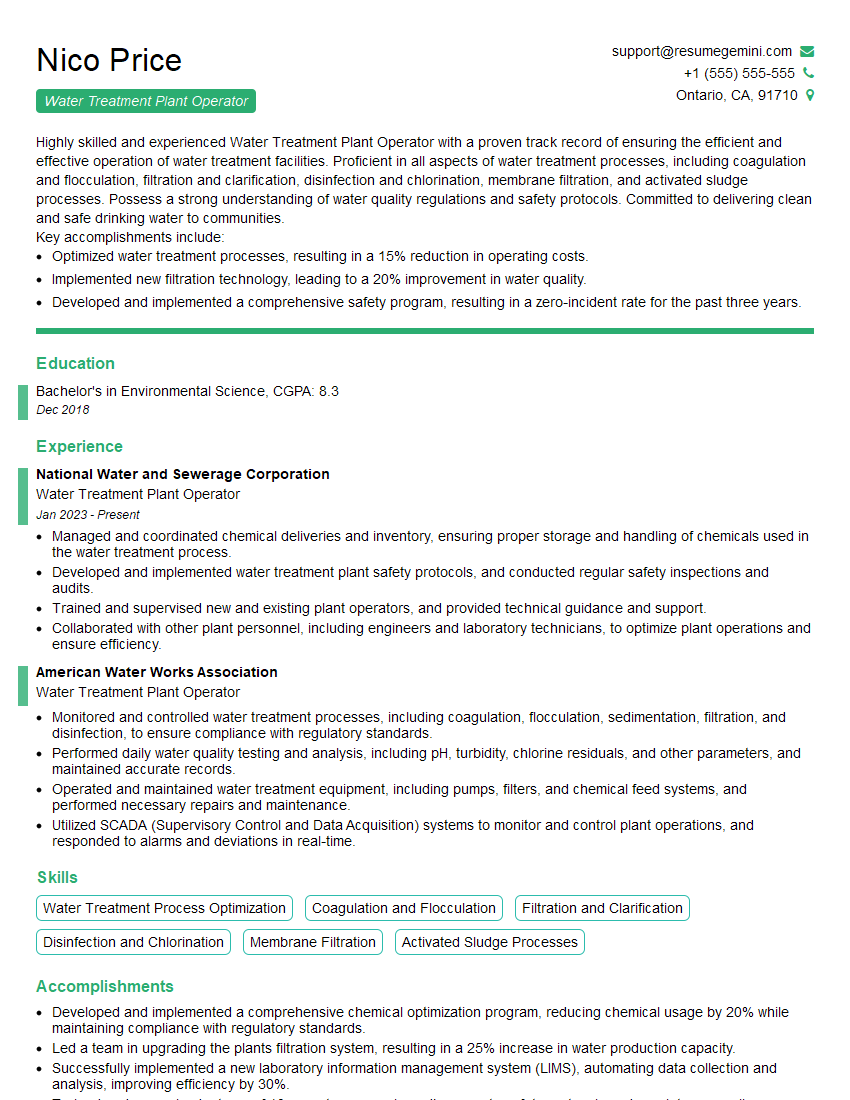

Q 19. Describe your experience with different types of water treatment processes.

My experience encompasses a broad range of water treatment processes, each tailored to address specific water quality issues. I’ve worked with:

- Conventional treatment: This includes coagulation, flocculation, sedimentation, filtration, and disinfection. I’ve overseen plants using this approach for municipal water supplies.

- Membrane filtration: Microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. I’ve been involved in projects using membrane technology for desalination and industrial wastewater treatment. For instance, reverse osmosis is excellent for removing dissolved salts from seawater.

- Advanced oxidation processes (AOPs): Such as ozonation and UV disinfection. I’ve applied these to remove persistent organic pollutants and inactivate pathogens resistant to conventional disinfection methods.

- Biological treatment: Utilizing microorganisms to remove organic matter and nutrients. I’ve worked on wastewater treatment plants employing activated sludge and other biological processes.

- Ion exchange: Used for removing specific ions, such as hardness minerals (calcium and magnesium). I’ve designed systems for softening water in industrial applications.

My experience spans diverse applications, from large-scale municipal water treatment to specialized industrial processes. I’m adept at selecting the optimal treatment strategy based on the specific water quality challenges and the desired outcome.

Q 20. Explain the concept of activated carbon filtration and its applications.

Activated carbon filtration is a powerful technique that uses porous carbon material to adsorb impurities from water. Imagine a sponge soaking up spills – activated carbon acts similarly, but at a molecular level. Its large surface area allows it to attract and bind various contaminants.

How it works: Activated carbon is produced by heating organic materials (like wood or coconut shells) under controlled conditions. This process creates a highly porous structure with a vast surface area. When water flows through a bed of activated carbon, contaminants such as chlorine, organic compounds, taste and odor compounds, and some heavy metals adhere to the surface of the carbon particles, effectively removing them from the water.

Applications:

- Municipal water treatment: Improving taste, odor, and color.

- Industrial wastewater treatment: Removing organic pollutants and improving discharge quality.

- Aquarium filtration: Removing impurities and maintaining water clarity.

- Air purification: Removing gaseous contaminants from air (though this is a different application of the same material).

The effectiveness of activated carbon filtration depends on several factors, including the type of activated carbon used, the contact time between the water and the carbon, and the concentration of the contaminants. Regeneration or replacement of the carbon is necessary once its adsorption capacity is exhausted.

Q 21. How do you calculate the hydraulic residence time in a water treatment reactor?

Hydraulic residence time (HRT) represents the average time water spends within a reactor. It’s crucial for designing and operating water treatment reactors effectively. Think of it as the average time a water molecule spends in a particular treatment step.

The calculation is straightforward:

HRT = Reactor Volume (V) / Flow Rate (Q)

Where:

Vis the volume of the reactor (typically in cubic meters or gallons).Qis the flow rate of water entering the reactor (typically in cubic meters per hour or gallons per minute).

Example: A reactor with a volume of 1000 cubic meters receives water at a flow rate of 50 cubic meters per hour. The HRT would be:

HRT = 1000 m³ / 50 m³/hr = 20 hours

This means the average water molecule spends 20 hours in this reactor. HRT is critical because it directly influences the effectiveness of the treatment process. A longer HRT typically allows more complete reaction or contact time for processes like coagulation, flocculation, or disinfection. However, excessively long HRTs can lead to undesirable side reactions or increased operational costs.

Q 22. What is your experience with SCADA systems used in water treatment plants?

SCADA, or Supervisory Control and Data Acquisition, systems are the nervous system of modern water treatment plants. They provide real-time monitoring and control of various processes, from chemical dosing and filtration to pump operations and water level management. My experience spans several years working with different SCADA platforms, including GE Proficy iFIX and Schneider Electric Wonderware InTouch. I’ve been involved in everything from initial system design and configuration to troubleshooting, upgrades, and operator training. For example, in one plant, we used SCADA to optimize the chlorine dosing process based on real-time water quality data, resulting in significant cost savings and improved disinfection efficacy. Another project involved integrating SCADA with a new reverse osmosis system, allowing for remote monitoring and automated control of the membrane cleaning cycles, minimizing downtime and maximizing efficiency.

My expertise includes developing custom SCADA applications tailored to specific plant requirements, integrating with other plant systems (like laboratory information management systems), and ensuring robust cybersecurity measures are in place to protect the plant’s operational data and control systems.

Q 23. Describe your experience with troubleshooting membrane fouling issues.

Membrane fouling is a common and costly problem in water treatment. It occurs when unwanted substances accumulate on the membrane surface, reducing its permeability and efficiency. My approach to troubleshooting membrane fouling involves a systematic process. First, I identify the type of fouling (organic, inorganic, biological). This often involves analyzing the fouled membrane and the feed water characteristics. For instance, if I see a slimy layer, it suggests biological fouling, while a hard scale suggests inorganic fouling.

Once the type of fouling is determined, I select the appropriate cleaning strategy. This might involve chemical cleaning using acids, bases, or oxidizing agents. For example, citric acid is effective for removing calcium carbonate scale, while sodium hypochlorite can effectively remove biological fouling. The choice of cleaning chemicals is critical and involves understanding their effectiveness, compatibility with the membrane material and environmental regulations. Physical cleaning methods, such as backwashing or air scouring, might also be employed. I always meticulously document the cleaning process, including the type and concentration of cleaning agents used, the cleaning duration and the results in terms of flux recovery. This data is crucial for developing a proactive fouling management plan to minimize the frequency and severity of future fouling events.

Q 24. Explain the principles of membrane separation processes.

Membrane separation processes utilize semi-permeable membranes to separate components of a liquid based on their size, charge, or other properties. Think of it like a very fine sieve. Different types of membranes exist, each suited to different applications.

- Microfiltration (MF): Removes larger particles like suspended solids and bacteria.

- Ultrafiltration (UF): Removes even smaller particles, including viruses and some dissolved organic matter.

- Nanofiltration (NF): Removes dissolved salts and multivalent ions, but some smaller molecules may pass through.

- Reverse Osmosis (RO): Removes almost all dissolved salts and other dissolved substances, producing highly purified water.

The driving force behind membrane separation can be pressure (as in microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) or an electric field (in electrodialysis). The principle always involves selectively allowing certain components to pass through the membrane while retaining others. For example, in a reverse osmosis system, high pressure forces water through a membrane, leaving behind dissolved salts and other impurities. Understanding the specific membrane characteristics, feed water quality, and operating parameters are critical for effective membrane separation.

Q 25. How do you manage and dispose of wastewater sludge?

Wastewater sludge management and disposal is a critical aspect of water treatment plant operations. The process begins with sludge thickening to reduce its volume and improve handling. This often involves gravity thickening or mechanical thickening methods. Then, the thickened sludge undergoes further treatment, which might include anaerobic digestion to reduce volume and produce biogas (a renewable energy source), aerobic digestion, or chemical stabilization. The choice of treatment method depends on factors such as sludge characteristics, energy costs, and local regulations.

Disposal methods vary, but common options include land application (if suitable and permitted), landfilling, incineration, or co-digestion with other organic waste streams. Strict adherence to environmental regulations is crucial throughout this process to prevent water and soil contamination. The entire process needs careful monitoring to ensure compliance and minimize environmental impact. For example, I’ve worked on projects where we optimized the anaerobic digestion process, resulting in a significant reduction in sludge volume and increased biogas production. This has positive implications for cost reduction and energy sustainability.

Q 26. What are the different types of water meters used in water distribution systems?

Water meters are essential for monitoring water consumption in distribution systems. Several types exist, each with its advantages and disadvantages:

- Positive Displacement Meters: These meters measure water volume directly by trapping a known volume of water and counting the number of times this volume is displaced. They offer high accuracy but are more prone to wear and tear.

- Velocity Meters: These meters measure the velocity of water flowing through a pipe using sensors. They are less expensive and have lower maintenance than positive displacement meters but generally have lower accuracy.

- Electromagnetic Meters: These meters use Faraday’s law of induction to measure water flow. They are highly accurate and can measure flow in both directions but are more expensive than other types of meters.

- Ultrasonic Meters: These meters use sound waves to measure the velocity of water in a pipe. They are non-invasive and can measure flow in pipes of various materials. They offer a good balance of accuracy, cost, and maintenance.

The choice of water meter depends on factors such as the required accuracy, pipe size, water pressure, and cost considerations.

Q 27. Describe your experience with different types of water storage tanks.

Water storage tanks are crucial for ensuring a reliable water supply and managing peak demands. Several types exist:

- Elevated Tanks: These tanks are elevated to provide pressure in the distribution system. They require significant structural support and can be expensive but offer excellent pressure management.

- Ground Storage Tanks: These tanks are located at ground level and require pumping to distribute water. They are generally less expensive than elevated tanks but may require more sophisticated pump systems.

- Standpipes: Tall, cylindrical tanks used to maintain pressure in water distribution systems. Often used as part of larger distribution network management strategies.

- Reservoirs: Large surface water storage facilities, typically for larger communities or municipalities. These are usually constructed of earth or concrete.

The selection of a water storage tank depends on factors such as the required storage capacity, pressure requirements, site conditions, and cost considerations. For example, I’ve been involved in projects where we assessed the need for upgrading aging ground storage tanks to improve their structural integrity and ensure compliance with safety regulations.

Q 28. Explain the principles of sedimentation in water treatment.

Sedimentation is a crucial step in water treatment where suspended solids settle out of the water due to gravity. Think of it like letting sand settle at the bottom of a glass of water. In water treatment plants, sedimentation occurs in large basins called clarifiers. The water flows slowly through these basins, allowing the heavier particles to settle to the bottom, forming a sludge layer. The clarified water then overflows from the top.

The effectiveness of sedimentation depends on several factors, including the residence time of the water in the clarifier (how long it stays there), the particle size and density, and the water’s flow rate. Improperly designed or operated clarifiers can lead to insufficient removal of suspended solids. Understanding these factors is critical for optimizing sedimentation efficiency. In practice, we use various design parameters, like the surface loading rate and the overflow rate, to ensure optimal sedimentation performance. The sludge accumulated at the bottom of the clarifier requires regular removal to maintain efficient operation.

Key Topics to Learn for Your Water Treatment and Filtration Interview

- Water Chemistry Fundamentals: Understanding pH, alkalinity, hardness, and their impact on treatment processes. Practical application: Troubleshooting issues related to scaling or corrosion in treatment plants.

- Coagulation and Flocculation: The principles behind removing suspended solids using chemical coagulants. Practical application: Optimizing coagulant dosage for effective removal of turbidity.

- Sedimentation and Filtration: Different types of filtration media (sand, anthracite, etc.) and their applications. Practical application: Analyzing filter performance and backwashing procedures.

- Disinfection Methods: Chlorination, UV disinfection, ozonation – their mechanisms and effectiveness. Practical application: Selecting the appropriate disinfection method based on water quality and regulatory requirements.

- Membrane Filtration (RO, UF, MF): Principles of membrane separation and their applications in advanced water treatment. Practical application: Troubleshooting membrane fouling and optimizing membrane performance.

- Water Quality Monitoring and Analysis: Standard water quality parameters and analytical techniques. Practical application: Interpreting water quality data to assess treatment effectiveness.

- Treatment Plant Operations and Maintenance: Understanding the operation of various treatment units and troubleshooting common problems. Practical application: Developing preventative maintenance schedules and responding to equipment malfunctions.

- Regulations and Compliance: Familiarize yourself with relevant environmental regulations and safety protocols. Practical application: Ensuring compliance with discharge permits and reporting requirements.

- Process Control and Automation: Understanding the role of SCADA systems and automated control strategies in water treatment plants. Practical application: Optimizing treatment processes through data analysis and process control adjustments.

Next Steps

Mastering Water Treatment and Filtration opens doors to a rewarding career with excellent growth potential. This field is vital for public health and environmental sustainability, offering diverse opportunities in plant operation, research, and engineering. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that stands out from the competition. We provide examples of resumes tailored specifically to the Water Treatment and Filtration industry to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO