Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Extrusion Blow Molding Machine Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Extrusion Blow Molding Machine Operation Interview

Q 1. Explain the extrusion blow molding process step-by-step.

Extrusion blow molding is a process that creates hollow plastic parts, like bottles or containers. It’s like making a balloon, but instead of your breath, we use compressed air.

- Extrusion: A heated plastic resin is melted and pushed through a die, creating a long, hollow tube called a parison. Think of it as squeezing toothpaste out of a tube.

- Parison Clamping and Inflation: The parison is clamped between two halves of a mold. The mold is designed to create the final shape of the product. Compressed air is then injected into the parison, inflating it to fill the mold cavity. It’s like blowing up a balloon inside a mold.

- Cooling and Demolding: The inflated parison is cooled until the plastic solidifies into the shape of the mold. Once cooled, the mold opens, releasing the finished blow-molded part.

- Trimming and Finishing: Any excess plastic is trimmed away, leaving the final, clean product ready for packaging or further processing.

For instance, making a plastic bottle involves extruding the parison, clamping it into a bottle-shaped mold, inflating it with air, cooling it down, and then trimming the excess plastic from the neck and base.

Q 2. Describe the different types of resins used in extrusion blow molding.

Many resins are suitable for extrusion blow molding, each with its own properties affecting the final product’s strength, flexibility, clarity, and cost.

- High-Density Polyethylene (HDPE): Commonly used for milk jugs and detergent bottles. Known for its strength, durability, and chemical resistance.

- Low-Density Polyethylene (LDPE): Often used for squeezable bottles and films. It’s flexible and has good impact resistance.

- Polyethylene Terephthalate (PET): Used for soda bottles and other food containers. Offers excellent clarity and barrier properties against gases and moisture.

- Polypropylene (PP): Suitable for containers needing heat resistance, often found in yogurt cups and microwaveable containers.

- Polyvinyl Chloride (PVC): Used less frequently now due to environmental concerns but offers good rigidity and chemical resistance.

The choice of resin depends on the final product’s requirements. For example, a bottle needing chemical resistance would use HDPE or PET, while a flexible squeeze bottle would likely use LDPE.

Q 3. How do you identify and troubleshoot common defects in blow molded parts?

Identifying defects requires a keen eye and understanding of the process. Troubleshooting involves systematically checking different parameters.

- Thin Walls/Thick Walls: Uneven wall thickness may be caused by improper parison programming, insufficient air pressure, or die issues. Adjust parameters accordingly.

- Sagging: Parison may sag before clamping, indicating improper parison programming or too long a parison hang time. Adjust extrusion rates or clamping timing.

- Wrinkles or Bubbles: These may result from insufficient air pressure, incorrect mold temperature, or low melt temperature. Check air pressure and mold temperatures and adjust accordingly.

- Flashing: Excess material squeezed out from between the mold halves usually means improper clamping force or mold misalignment. Check clamping pressure and mold alignment.

- Burn Marks: These are caused by high melt temperatures or too long residence time in the extruder. Reduce melt temperature or increase extrusion rate.

For instance, if you see significant sagging, you would first adjust the parison programming, perhaps lowering the extrusion rate or reducing the parison hang time, then monitor for improvement. Careful observation and record-keeping are crucial for effective troubleshooting.

Q 4. What are the key parameters you monitor during the extrusion blow molding process?

Monitoring key parameters is vital for consistent quality and efficient production. These include:

- Melt Temperature: Ensures proper plastic fluidity. Too low, and the plastic is too thick; too high, and it can degrade or burn.

- Extrusion Rate: Controls the parison’s dimensions. Improper rates can lead to thin or thick walls.

- Air Pressure: Determines how completely the parison fills the mold. Too low, and the part won’t be fully formed; too high, and it may burst.

- Clamping Force: Ensures a good seal between the mold halves. Inadequate clamping can lead to flashing.

- Mold Temperature: Affects cooling time and final part quality. Too low, and the part may be slow to cool and warp.

- Cycle Time: Determines overall production efficiency. Optimization of all other parameters can reduce cycle time.

We continuously monitor these parameters using sensors and control systems, making adjustments to maintain consistent product quality. Data logging and analysis help identify trends and prevent future issues.

Q 5. Explain the role of the parison in the extrusion blow molding process.

The parison is the crucial intermediary stage between the extruder and the finished product. It’s the hollow tube of molten plastic that forms the basis of the final part.

Its role is to provide the material that gets shaped by the mold and air pressure. The parison’s dimensions (diameter, wall thickness, length) directly influence the final product’s thickness and overall shape. Precise control over the parison is paramount for achieving high-quality blow-molded parts.

Think of it as a clay sculptor’s lump of clay: it’s the raw material that takes on its final shape through skillful manipulation (in our case, air pressure and the mold).

Q 6. How do you adjust the air pressure and clamping force during the blow molding cycle?

Adjusting air pressure and clamping force is crucial for producing quality parts. It’s a balancing act!

Air Pressure: This is adjusted using the machine’s control system, usually a PLC (Programmable Logic Controller). Increased pressure results in a more fully inflated parison, leading to thinner walls. However, too much pressure can cause the parison to burst. Lower pressure leads to thicker walls, potentially affecting the final part’s properties. The ideal air pressure is determined by experimentation and depends on the specific resin, mold design, and desired part wall thickness.

Clamping Force: This is controlled through the machine’s hydraulic system. Insufficient clamping force can lead to flashing (excess material escaping between mold halves). Excessive force can damage the mold or cause stress marks on the part. The optimal clamping force is determined by the mold size, the type of resin, and the material’s viscosity at the molding temperature. We typically start with manufacturer recommendations and fine-tune based on our experience.

I typically use a combination of automated controls and manual adjustments to achieve the optimal settings during the molding cycle.

Q 7. Describe your experience with different types of blow molding machines.

Throughout my career, I’ve worked with a variety of extrusion blow molding machines, from small, single-station machines ideal for prototyping and low-volume production to large, high-speed rotary machines capable of producing thousands of parts per hour. My experience encompasses:

- Single-station machines: These machines are simpler and easier to operate and maintain but have a lower output. They are ideal for small-batch production and testing new designs.

- Double-station machines: These offer higher output than single-station machines as they can produce two parts per cycle but require more space and are more complex.

- Rotary machines: These high-speed machines use a rotating carousel to carry multiple molds through the process simultaneously and boast very high production rates. They are commonly used in large-scale production environments.

Working with diverse machinery has equipped me with a broad understanding of various control systems, troubleshooting methods, and optimization techniques. I’m comfortable working on machines from various manufacturers and am proficient in maintaining and repairing common issues.

Q 8. How do you maintain and clean an extrusion blow molding machine?

Maintaining and cleaning an extrusion blow molding machine is crucial for optimal performance, product quality, and operator safety. It’s a multi-step process that needs to be performed regularly and meticulously.

- Regular Cleaning: After each production run, I’d thoroughly clean the die head, ensuring no residual plastic remains. This prevents build-up and ensures consistent parison formation. A specialized cleaning solution and appropriate brushes or tools are used to remove any plastic residue from the internal channels. Compressed air helps to reach hard-to-access areas.

- Scheduled Maintenance: Beyond daily cleaning, scheduled maintenance includes inspecting and lubricating moving parts like the clamping mechanism, extruder screw, and air ring. We’d also check for wear and tear on the die, and replace components as needed. This preventive maintenance prevents costly breakdowns and ensures consistent output.

- Die Maintenance: The die is a critical component. Regular inspections check for wear, damage, or leaks. Any signs of irregularity warrant immediate attention and potentially a professional assessment by a die technician.

- Safety First: Before any cleaning or maintenance, the machine must be completely shut down, and all power sources must be disconnected. Appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and potentially a respirator, must be worn.

- Documentation: I maintain detailed records of all maintenance and cleaning activities, including date, time, actions taken, and any problems encountered. This ensures traceability and helps to optimize maintenance schedules.

For example, during one production run, we discovered a minor build-up of resin in the die head, which was promptly addressed through cleaning. If left unchecked, this could have caused parison defects and decreased output. The detailed record helped us to adjust our cleaning procedures to prevent similar issues in the future.

Q 9. What safety precautions do you follow while operating an extrusion blow molding machine?

Safety is paramount when operating an extrusion blow molding machine. We adhere to a strict set of safety protocols to minimize risk.

- Lockout/Tagout Procedures: Before performing any maintenance or repair, the machine must be completely shut down, and the power source locked out and tagged out to prevent accidental start-up. This is a non-negotiable step.

- PPE: Personal Protective Equipment (PPE), including safety glasses, hearing protection, and heat-resistant gloves, is always worn. Depending on the specific task, additional PPE like a respirator may be necessary.

- Emergency Shutdown: Operators are thoroughly trained on the location and operation of emergency stop buttons and other safety mechanisms. Regular drills ensure everyone understands these procedures.

- Machine Guards: All moving parts of the machine are properly guarded to prevent accidental contact. These guards are regularly inspected to make sure they remain intact and effective.

- Material Handling: Proper procedures are followed for the safe handling and storage of resin pellets and finished products. This prevents spills and injuries.

- Hot Surfaces: Extrusion blow molding involves hot surfaces. Operators are trained to avoid contact with these surfaces, and appropriate safety precautions are taken to prevent burns.

One instance that reinforces the importance of safety procedures involved a minor malfunction. Because of our adherence to lockout/tagout procedures, we prevented a potentially serious accident during repair. The machine was completely isolated, allowing the technician to work safely without fear of unexpected startup.

Q 10. Explain the concept of parison programming.

Parison programming refers to the process of controlling the shape and dimensions of the plastic tube (parison) before it’s inflated to form the final product. It’s essentially tailoring the parison to achieve the desired final product’s shape and thickness.

This is achieved through controlling various parameters of the extrusion process. These include:

- Extrusion Screw Speed: Controls the melt flow rate.

- Die Head Geometry: Dictates the parison’s initial shape and dimensions.

- Parison Weight: Total amount of plastic in the parison.

- Die Lip Shape: Influences the wall thickness distribution.

- Mandrel Design: Determines the internal shape of the parison, if applicable.

- Parison Length: Influences the shape of the blown product.

Sophisticated control systems manage these parameters. Think of it like a 3D printer for plastic tubes, but instead of layers, we manipulate the melt flow to create a specific tube shape. Different products need different parison profiles; a thin-walled bottle requires a different parison than a thick-walled container.

Parison programming requires a deep understanding of material properties and processing parameters. Improper programming results in defects such as uneven wall thickness, weak points, or inadequate filling of the mold.

Q 11. How do you handle material changes during production?

Material changes during production require careful planning and execution to avoid defects and maintain product quality. It is a methodical process involving several steps.

- Thorough Cleaning: Before switching materials, the entire extrusion system must be completely cleaned to prevent contamination. This includes the hopper, extruder, die head, and all associated components. The cleaning process must use a resin compatible with the next material.

- Purge Material: A purge compound is usually used to remove residual material from the system efficiently. This ensures complete removal of the previous resin to minimize contamination.

- Parameter Adjustments: Different resins have different processing parameters (melt temperature, screw speed, back pressure). These parameters need to be carefully adjusted based on the new material’s properties. The machine’s control system is adjusted according to manufacturer recommendations and prior testing.

- Testing and Verification: After changing the material, we run test parts and visually inspect for any defects like discoloration, inconsistencies, or imperfections. Material properties tests (tensile strength, etc) might be conducted, depending on the requirements.

- Documentation: All changes made, including the new material’s properties and the adjusted parameters, are carefully documented. This is essential for process traceability.

For instance, when switching from a high-density polyethylene (HDPE) to a low-density polyethylene (LDPE), we’d need to lower the melt temperature and potentially adjust the screw speed and back pressure. Thorough purging is especially crucial in this scenario to avoid undesirable mixing of materials.

Q 12. Describe your experience with troubleshooting die issues.

Troubleshooting die issues is a critical skill in extrusion blow molding. It requires a systematic approach.

- Visual Inspection: The first step involves carefully inspecting the die for any obvious issues, such as leaks, damage to the mandrel or die lip, or signs of wear and tear. Checking the air flow for irregularities is also important.

- Pressure Readings: Checking the pressure readings throughout the system (melt pressure, air pressure, back pressure) helps to pinpoint where the problem may originate.

- Parison Analysis: Carefully examine the parison for inconsistencies such as uneven thickness, sagging, or tearing. This helps to understand the nature of the die issue.

- Melt Temperature: If the melt temperature isn’t optimal, it can affect the parison’s uniformity. Reviewing melt temperature readings helps identify this source of defects.

- Systematic Troubleshooting: If the problem isn’t readily apparent, a systematic approach is necessary. This could involve isolating sections of the die and verifying them independently. A process of elimination is essential.

- Expert Assistance: If necessary, I would consult with a die specialist or the equipment manufacturer to resolve more complex issues.

For instance, one time we encountered a parison sag. Through careful analysis, we discovered a slight misalignment in the die head causing uneven melt distribution. A minor adjustment resolved the issue. However, complex problems might require replacing worn parts or even sending the die for professional reconditioning.

Q 13. How do you ensure the quality of the blow molded parts?

Ensuring the quality of blow molded parts requires a multi-faceted approach, involving both process control and inspection.

- Process Control: Maintaining consistent melt temperature, pressure, and air ring settings is critical. These factors are strictly monitored and recorded throughout the production process.

- In-Process Monitoring: Regular inspections of the parison and the finished parts ensure early detection of defects.

- Dimensional Measurement: The dimensions (height, diameter, wall thickness) of the parts are routinely checked using calibrated measuring tools. This verifies that the manufactured products meet the specifications.

- Visual Inspection: A thorough visual inspection for any physical defects such as flash, sink marks, or uneven wall thickness is performed. This is where most common defects are identified.

- Statistical Process Control (SPC): SPC techniques help to identify trends and patterns in the production process. This allows for proactive adjustments and optimization, minimizing defects before they become major issues.

- Material Testing: Depending on the application, material testing such as tensile strength or impact resistance might be conducted to ensure the parts meet the required standards.

For example, regularly measuring wall thickness using a micrometer allows us to promptly address any discrepancies in the extrusion process. If the wall thickness consistently falls outside the specified range, we investigate the root cause. This could involve adjusting the die settings or checking the air pressure in the blowing stage.

Q 14. What is the significance of melt temperature control in extrusion blow molding?

Melt temperature control is critical in extrusion blow molding because it directly affects the plastic’s viscosity and flow characteristics, and thus, the quality of the final product.

Too low a melt temperature leads to:

- High viscosity: This results in insufficient flow, leading to incomplete filling of the mold and thin walls.

- Increased shear stress: This can damage the polymer chains, weakening the final product.

- Uneven parison formation: Resulting in inconsistent wall thickness in the finished part.

Too high a melt temperature leads to:

- Low viscosity: This can cause excessive sagging in the parison, leading to uneven wall thickness and defects such as warping.

- Degradation of the polymer: Excessive heat can break down the polymer chains, causing discoloration and reduced strength in the final product.

- Reduced melt strength: This leads to instability and potential collapsing of the parison during the blow molding process.

Precise melt temperature control, usually achieved through sophisticated control systems, ensures the plastic is at its optimal viscosity for consistent extrusion, resulting in high-quality, defect-free parts. This requires careful calibration and monitoring. Each polymer resin has its specific optimal temperature range which must be adhered to.

Q 15. How do you address issues related to uneven wall thickness in blow molded parts?

Uneven wall thickness in blow molded parts is a common problem, often stemming from inconsistencies in the extrusion process, mold design, or air pressure distribution. Addressing this requires a systematic approach. First, we analyze the part itself to pinpoint the areas of unevenness. This is often done visually, sometimes aided by precise measurement tools like calipers or even 3D scanning for complex shapes. Then we move to the root cause.

Parison Issues: Uneven parison (the extruded tube before inflation) often leads to uneven wall thickness. This might be due to inconsistent melt flow, die design flaws, or extruder screw issues. We would check extruder settings (temperature, screw speed, back pressure), the die itself (for wear, damage, or improper design), and the material’s melt index for consistency.

Air Ring Problems: The air ring distributes air pressure to inflate the parison. A poorly functioning air ring, perhaps with clogged orifices or uneven air distribution, can cause variations in wall thickness. We’d inspect the air ring carefully, cleaning or replacing components as needed, and we’d check air pressure regulation and the consistency of its delivery.

Mold Design Flaws: The mold itself can contribute to uneven wall thickness. Issues like improper venting, uneven cooling, or poor mold design can all play a role. This is often addressed by modifying the mold or working with the mold maker to redesign critical areas.

Material Issues: Inconsistent material properties, such as inconsistent melt viscosity, can lead to uneven wall thickness. We’d perform checks on the resin supplier’s consistency and potentially test the material itself for its melt flow index (MFI) and other relevant properties.

Addressing uneven wall thickness requires a thorough investigation, often combining adjustments to the process parameters, mold maintenance, and close collaboration with material suppliers.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with preventative maintenance procedures.

Preventative maintenance is crucial for maximizing uptime and producing high-quality parts. My experience involves a structured approach that combines daily, weekly, and monthly checks, tailored to the specific machine and its components.

Daily Checks: These focus on quick visual inspections, such as checking for leaks in the air and hydraulic systems, lubricant levels, and the condition of the tooling. I make sure to log all readings and observations.

Weekly Checks: These involve more in-depth inspections, including cleaning the air ring, checking the extruder screws for wear, and lubricating moving parts more thoroughly. I’d also review process control charts for any developing trends.

Monthly Checks: This level involves more extensive checks, like calibrating sensors, checking the clamping pressure on the mold, and inspecting the heating elements in the extruder. We often conduct more thorough cleaning and lubrication at this stage.

I also meticulously document all maintenance activities, including replacement of parts and any necessary adjustments, to build a comprehensive history of the machine’s health. This proactive maintenance approach allows us to predict potential failures and prevent costly downtime.

Q 17. How do you interpret process control charts and identify trends?

Process control charts are vital for monitoring the stability and consistency of a blow molding process. I’m experienced in reading and interpreting various charts, including X-bar and R charts, and individual and moving range charts. These charts visualize parameters like wall thickness, cycle time, and melt temperature over time.

Identifying trends involves looking for patterns in the data points. For example, a consistent upward or downward trend suggests a gradual shift in the process, possibly due to tool wear or material degradation. Points consistently outside the control limits indicate potential problems that demand immediate attention. I would then investigate these patterns and determine root causes using techniques like the 5 Whys or Fishbone diagrams. For example, a gradual increase in cycle time might indicate increasing friction in a moving part, whereas erratic data points may signal a malfunctioning sensor.

Once a trend is identified, appropriate corrective actions are implemented and their effectiveness monitored through the process control charts. This iterative approach ensures a consistent and high-quality output.

Q 18. Describe your experience with different types of molds used in blow molding.

My experience encompasses a variety of molds used in blow molding, each designed for specific applications and part geometries.

Single-cavity molds: These are the simplest, producing one part per cycle. They’re efficient for high-volume production of simple parts.

Multi-cavity molds: These produce multiple parts simultaneously, significantly increasing output. They are cost-effective for high-volume production of simpler parts.

Stack molds: These are more complex, stacking multiple cavities vertically to increase output, commonly used for high-volume applications of smaller parts.

Rotary molds: These use a rotating mechanism to cycle multiple cavities, leading to high production rates. These are more complex and best suited for complex part geometries and high production demands.

Extrusion blow molds for different materials: I’ve worked with molds designed for a variety of materials, each requiring specific design considerations, like those adapted for HDPE, PET, PVC and others.

Selecting the right mold is critical for efficiency and product quality, requiring careful consideration of part complexity, production volume, and material properties. Often, the choice involves a trade-off between initial cost and long-term production efficiency.

Q 19. How do you calculate the cycle time for a blow molding operation?

Calculating cycle time in blow molding involves summing the time for each step in the process. The individual steps and their durations vary significantly depending on the part design, machine specifications, and material used.

A typical breakdown includes:

Extrusion time: Time taken to extrude the parison.

Clamping time: Time for the mold to close and clamp the parison.

Inflation time: Time for inflating the parison with air.

Cooling time: Time for the part to cool and solidify within the mold.

Ejection time: Time for the finished part to be ejected from the mold.

For example, consider a simple HDPE bottle: Extrusion might take 2 seconds, clamping 1 second, inflation 3 seconds, cooling 10 seconds, and ejection 2 seconds, totaling a cycle time of 18 seconds. However, for more complex parts with longer cooling requirements, or higher-viscosity materials, the cycle time can extend significantly. Accurate cycle time calculation is crucial for optimizing production efficiency and planning output.

Q 20. How do you ensure the proper functioning of the air ring system?

The air ring system is vital in blow molding, responsible for evenly distributing air pressure to inflate the parison and create the desired part shape. Ensuring its proper functioning is crucial for consistent wall thickness and part quality. Regular maintenance is key.

Air pressure regulation: The air pressure must be precisely regulated to control the inflation process. Maintaining the appropriate pressure is crucial for achieving the desired wall thickness and shape. I would ensure accurate calibration and regular monitoring of the pressure gauge and regulators.

Air ring cleanliness: The orifices in the air ring can easily clog with material splatter or debris. Regular cleaning and inspection are crucial to ensure that air distributes evenly. I would use compressed air and specialized cleaning tools.

Air ring alignment: The air ring must be precisely aligned with the mold and parison to ensure even inflation. Improper alignment leads to inconsistent wall thickness. This requires careful visual inspection and adjustments as necessary.

Air ring wear and tear: Over time, the air ring components may wear or suffer damage. Regular inspection for signs of wear and timely replacement of damaged components are vital to prevent uneven inflation. I’d check for cracks, warping, or excessive wear.

Addressing issues with the air ring requires a combination of meticulous cleaning, precise alignment, and careful monitoring of air pressure. A properly functioning air ring is paramount for consistent and high-quality parts.

Q 21. Describe your experience with automated blow molding systems.

My experience includes working with various automated blow molding systems, ranging from semi-automatic to fully automated lines. These systems significantly enhance production efficiency and consistency.

Semi-automatic systems: These systems automate some processes, such as mold clamping and parison extrusion, but still require manual intervention for tasks like part ejection. These are cost effective for medium volume production.

Fully automated systems: These systems fully automate all aspects of the blow molding process, from material handling and extrusion to part ejection and stacking. These significantly increase efficiency and consistency and are best suited for large volume production.

Working with automated systems requires proficiency in programming, troubleshooting automated systems, and understanding robotic integration. One key aspect is ensuring proper integration between the various components of the automated line, including material handling, extrusion, molding, and quality control systems. I am familiar with PLC programming and troubleshooting in these systems, enabling efficient operation and maintenance.

Automation improves repeatability, reducing variations and improving overall part quality, while also freeing up human operators to focus on process monitoring, maintenance, and quality control.

Q 22. Explain your understanding of different blow molding head designs.

Blow molding heads are the heart of the extrusion blow molding process, responsible for delivering the molten plastic parison (a hollow tube) into the mold cavity. Different designs cater to specific needs and product geometries. Common types include:

- Single-stage heads: These are simpler, more cost-effective designs suitable for lower-volume production and simpler part geometries. The parison is formed and then directly inflated within the mold.

- Multi-stage heads: These offer more precise control over parison thickness and distribution, allowing for complex shapes and thinner wall sections. They often incorporate features like mandrel adjustment for better parison control.

- Rotating heads: Used for high-speed production of symmetrical parts. The head rotates to distribute the parison evenly, increasing efficiency.

- Die heads with adjustable mandrel: Allows for precise control of the parison diameter and wall thickness along its length. This is crucial for parts with varying wall thicknesses.

- Screen-change heads: These heads incorporate a screen pack to filter the molten plastic, preventing contamination and ensuring a smooth parison.

The choice of head depends on factors such as production rate, part complexity, and desired quality. For instance, a multi-stage head would be preferred for creating a complex bottle with varying wall thicknesses, while a simpler single-stage head might suffice for a basic container.

Q 23. How do you diagnose and resolve problems related to air leaks?

Air leaks are a common problem in extrusion blow molding, leading to inconsistent wall thickness, weak products, and even process failure. Diagnosis typically involves a systematic approach:

- Visual Inspection: Carefully inspect all air connections, the mold, and the blow head for visible cracks, loose fittings, or worn seals. Often, a small leak is detectable by a hissing sound.

- Pressure Testing: Isolate sections of the air system and pressurize them individually to pinpoint the leak location. A soapy water solution applied to suspected areas will show bubbles where the air is escaping.

- Checking Air Pressure Gauges and Regulators: Ensure that the air pressure is properly regulated and consistent throughout the process. Inconsistent pressure is a common cause of leaks.

- Mold Maintenance: Regular cleaning and lubrication of the mold are crucial. Worn or damaged mold components can lead to air leaks around the mold sealing surfaces.

Resolving the leak depends on its source. A simple loose fitting might only require tightening, while a damaged component may necessitate repair or replacement. Often, preventative maintenance, including regular inspection and lubrication, is the best approach to minimize air leaks.

Q 24. Describe your experience with different types of mold clamping systems.

Mold clamping systems are critical for ensuring a tight seal between the mold halves during the blow molding process. My experience includes several types:

- Hydraulic Clamping: This is a widely used system offering high clamping force and precise control. It’s ideal for large, heavy molds.

- Pneumatic Clamping: A more cost-effective option, pneumatic clamping uses compressed air for clamping. It’s generally suitable for smaller molds.

- Mechanical Clamping: This involves toggle mechanisms or other mechanical systems for clamping. It’s simpler and typically used in smaller or simpler machines.

Each system has its advantages and disadvantages. Hydraulic systems offer the greatest clamping force and control but are more complex and expensive. Pneumatic systems are faster but may not provide as much clamping force. Mechanical systems are the simplest but offer less control over clamping force.

The selection of the appropriate clamping system depends on the size, weight and complexity of the mold, and the production requirements.

Q 25. What is your experience with troubleshooting problems related to the extrusion screw?

Extrusion screw problems can significantly impact the quality and consistency of the blown parts. Common issues include:

- Screw Degradation/Wear: Over time, screws can wear down, leading to reduced output, inconsistent melt flow, and increased material degradation. This can often be diagnosed by uneven parison thickness or reduced melt output. Replacing or repairing the screw may be necessary.

- Insufficient Melt Homogeneity: Inadequate mixing in the screw can result in inconsistent melt viscosity and temperature, leading to defects. Modifications to screw geometry or processing parameters may be required.

- Screw Damage: Foreign material in the feedstock or excessive torque can cause damage to the screw. This could manifest as reduced output, noisy operation, or inconsistent melt flow. Repair or replacement might be necessary.

Troubleshooting usually involves careful observation of the process parameters (temperature, pressure, screw speed), visual inspection of the screw for damage, and analysis of the output material for inconsistencies. Detailed analysis of the melt flow characteristics may be required to determine the root cause and find a suitable solution.

Q 26. How do you ensure consistency in the quality of the final product?

Maintaining consistent product quality in extrusion blow molding requires careful control over multiple parameters. This is achieved through a combination of practices including:

- Process Parameter Monitoring: Continuous monitoring of key parameters such as melt temperature, air pressure, clamping force, and screw speed is critical. Deviations from set points are immediately addressed.

- Regular Material Testing: Consistent resin quality is essential. Regular quality checks on incoming material help prevent problems stemming from variations in resin characteristics.

- Preventive Maintenance: A regular preventative maintenance schedule for the machine and the mold helps prevent unexpected failures and maintain consistent performance.

- Operator Training: Well-trained operators are vital in ensuring consistent operation and identifying early signs of potential problems.

- Statistical Process Control (SPC): Using SPC methods allows for identification and correction of process variations before they lead to quality issues. Data analysis reveals trends and patterns.

By implementing these strategies, we can ensure that the final products meet the required specifications consistently.

Q 27. Explain your understanding of the relationship between process parameters and part quality.

Process parameters and part quality are intricately linked. Adjusting one often affects the other. For instance:

- Melt Temperature: Too low a melt temperature can result in a thick, weak parison, while too high a temperature can lead to a thin, brittle parison and potential degradation of the polymer.

- Air Pressure: Insufficient air pressure results in thin-walled parts, while excessive pressure can cause the parison to burst or result in uneven wall thickness.

- Clamp Force: Inadequate clamping force can lead to leakage between the mold halves, while excessive force can damage the mold.

- Screw Speed: Affects the output rate and melt homogeneity. Incorrect settings can lead to uneven parison formation.

Understanding the relationship between these parameters and their effect on the final product is crucial for optimizing the process and producing high-quality parts. It requires a combination of experience, process knowledge, and careful observation.

Q 28. Describe a time you had to troubleshoot a complex issue on an extrusion blow molding machine.

In one instance, we were experiencing significant variations in wall thickness on a large-volume water bottle production line. The problem was intermittent and difficult to pinpoint. We ruled out simple issues like inconsistent resin supply and air pressure fluctuations.

After a thorough investigation, we discovered microscopic debris embedded in the mold causing inconsistencies in the parison distribution. This was only revealed through a meticulous visual inspection of the mold using a high-powered magnification system. We subsequently implemented a more rigorous cleaning procedure, and the problem was resolved. This experience highlighted the importance of thorough and systematic troubleshooting, utilizing advanced diagnostic techniques where necessary.

Key Topics to Learn for Extrusion Blow Molding Machine Operation Interview

- Machine Setup and Operation: Understanding the entire process from material loading to finished product ejection, including die adjustments, air pressure regulation, and clamp force control.

- Quality Control and Troubleshooting: Identifying and resolving common issues such as parison defects, wall thickness variations, and air trapping, emphasizing preventative measures and root cause analysis.

- Material Properties and Selection: Knowledge of different polymers used in blow molding, their processing characteristics, and the impact of material selection on product quality and performance.

- Safety Procedures and Regulations: Demonstrating understanding of lockout/tagout procedures, emergency shutdowns, and adherence to relevant safety standards and regulations within the manufacturing environment.

- Preventive Maintenance and Troubleshooting: Knowing routine maintenance tasks, identifying potential problems before they occur, and understanding the basics of troubleshooting mechanical and electrical issues.

- Production Efficiency and Optimization: Understanding methods to improve cycle times, minimize waste, and maximize output while maintaining quality standards.

- Process Parameter Optimization: Understanding the relationship between various process parameters (temperature, pressure, air volume, etc.) and the final product quality, and how to adjust these parameters for optimal results.

- Understanding Different Blow Molding Processes: Familiarity with variations in the extrusion blow molding process, such as injection blow molding or stretch blow molding, and their respective applications.

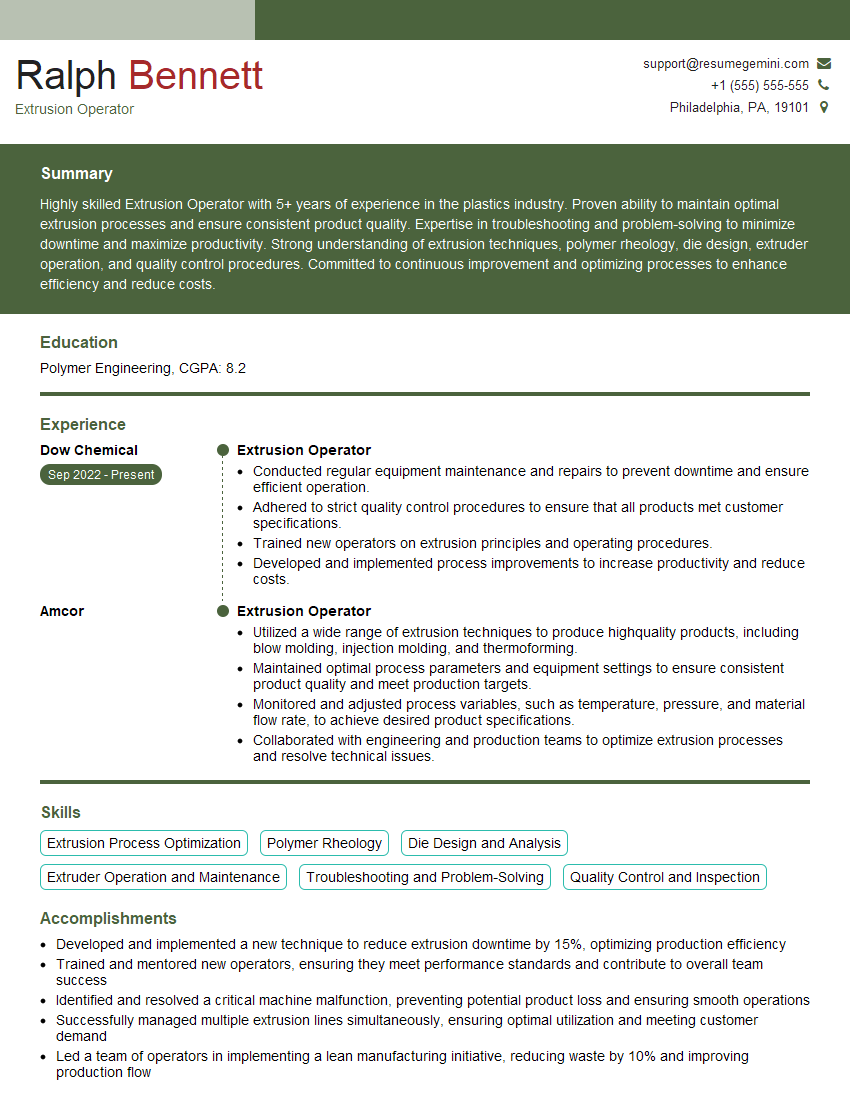

Next Steps

Mastering Extrusion Blow Molding Machine Operation opens doors to a rewarding career with excellent growth potential in manufacturing. As the demand for skilled operators increases, your expertise will be highly valued. To stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that grabs the attention of recruiters. They offer examples of resumes tailored specifically to Extrusion Blow Molding Machine Operation roles to help you showcase your qualifications. Invest in your future – craft a compelling resume that reflects your expertise and makes you the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO