Unlock your full potential by mastering the most common Cost Control and Expense Management interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Cost Control and Expense Management Interview

Q 1. Explain your understanding of variance analysis.

Variance analysis is a crucial technique in cost control that compares planned (budgeted) costs with actual costs. It helps pinpoint areas where spending deviated from expectations, allowing for corrective actions and improved future budgeting. The difference between the planned and actual figures is the variance. A favorable variance means costs were lower than anticipated, while an unfavorable variance indicates costs were higher.

For example, imagine we budgeted $10,000 for marketing in a quarter but spent $12,000. The $2,000 difference is an unfavorable variance. Variance analysis goes beyond simply identifying the difference; it delves into why the variance occurred. Was it due to higher advertising costs, increased marketing campaign participation, or unforeseen expenses? Understanding the root cause is key to effective cost control.

We usually categorize variances into different types, such as:

- Purchase Price Variance: Difference between actual and budgeted purchase prices of materials.

- Labor Rate Variance: Difference between actual and budgeted labor rates.

- Labor Efficiency Variance: Difference between actual and budgeted labor hours.

- Sales Volume Variance: Difference in revenue due to sales volume exceeding or falling short of budget.

Analyzing these variances helps businesses improve their forecasting accuracy, refine their cost structures, and optimize their operations for better profitability.

Q 2. Describe different cost accounting methods (e.g., absorption, variable costing).

Cost accounting methods categorize and track business expenses. Two prominent methods are absorption costing and variable costing.

Absorption costing, also known as full costing, includes all manufacturing costs (direct materials, direct labor, and factory overhead) in the cost of a product. This means that fixed manufacturing overhead is allocated to each unit produced. This method is required for financial reporting under Generally Accepted Accounting Principles (GAAP).

Variable costing, on the other hand, only includes variable manufacturing costs in the cost of a product. Fixed manufacturing overhead is treated as a period cost and is expensed in the period incurred. This provides a clearer picture of the variable cost behavior and contribution margin, which is particularly useful for internal decision-making, such as pricing and break-even analysis.

Example: Let’s say a company manufactures widgets. Absorption costing would include rent for the factory in the cost of each widget, while variable costing would expense this rent separately, regardless of the number of widgets produced.

The choice between absorption and variable costing depends on the purpose of the analysis. Absorption costing is better for external reporting and compliance, while variable costing is more suitable for internal management decision-making and profitability analysis.

Q 3. How do you identify and analyze cost drivers?

Cost drivers are factors that influence the total cost of a product or service. Identifying and analyzing them is crucial for effective cost control and management. Think of them as the levers that, when adjusted, impact costs.

We can identify cost drivers through various methods:

- Activity-Based Costing (ABC): This method assigns overhead costs to products based on their consumption of various activities. It helps pinpoint activities that significantly drive costs.

- Data Analysis: Examining historical data on costs and production volumes can reveal correlations and identify key cost drivers.

- Interviews and Observation: Talking to employees involved in production and operations can shed light on cost-influencing factors.

- Process Mapping: Visualizing the production or service delivery process can highlight areas with high cost drivers.

Example: In a manufacturing company, the number of machine hours might be a cost driver for electricity expenses, while the number of customer orders might be a driver for order processing costs. Analyzing these drivers allows for more informed decision-making, such as investing in more efficient machinery to reduce electricity costs or streamlining order processing to reduce administrative expenses.

Q 4. What strategies do you employ to reduce operational expenses?

Reducing operational expenses requires a multi-pronged approach. Strategies I employ include:

- Process Improvement: Streamlining workflows, automating tasks, and eliminating redundancies to improve efficiency.

- Negotiation with Suppliers: Securing better prices and terms from suppliers through strategic negotiation and leveraging volume discounts.

- Technology Optimization: Implementing cost-effective technologies to automate processes and improve productivity.

- Energy Efficiency: Implementing energy-saving measures to reduce utility costs.

- Waste Reduction: Minimizing waste in materials, time, and resources through better planning and execution.

- Outsourcing: Considering outsourcing non-core functions to specialized providers to reduce overhead costs.

- Employee Training and Development: Investing in employee training to enhance their skills and improve their productivity.

A holistic approach, considering all aspects of the business, is critical for significant and sustainable cost reduction. Focusing on efficiency improvements, smarter sourcing, and eliminating unnecessary expenses is key.

Q 5. How would you develop a budget for a new project?

Developing a project budget requires a detailed and systematic approach. Here’s how I’d do it:

- Define Project Scope: Clearly outline the project’s objectives, deliverables, and timelines.

- Identify Resources: Determine all resources needed, including personnel, materials, equipment, and software.

- Estimate Costs: Assign costs to each resource based on market rates, historical data, and vendor quotes.

- Develop a Work Breakdown Structure (WBS): Break down the project into smaller, manageable tasks.

- Allocate Costs: Assign costs to each task in the WBS.

- Create a Budget: Consolidate the costs from individual tasks to create a comprehensive project budget.

- Add Contingency: Include a contingency reserve to account for unforeseen expenses or risks.

- Review and Approve: Review the budget for accuracy and completeness, and get it approved by relevant stakeholders.

Using software like Excel or project management tools can greatly aid in budget development and tracking. The key is to be thorough, realistic, and include sufficient contingency to account for unforeseen issues.

Q 6. Explain your experience with budget monitoring and control.

Budget monitoring and control involves consistently tracking actual spending against the planned budget and taking corrective actions when variances arise. My experience includes:

- Regular Reporting: Developing and presenting regular budget performance reports to stakeholders.

- Variance Analysis: Analyzing variances to identify their root causes.

- Corrective Actions: Implementing corrective actions to address unfavorable variances.

- Forecasting: Developing and using forecasting techniques to predict future costs and adjust the budget accordingly.

- Performance Metrics: Tracking key performance indicators (KPIs) related to cost efficiency.

- Communication: Keeping all relevant stakeholders informed about budget performance and any necessary adjustments.

Effective budget monitoring requires proactive measures, clear communication, and a willingness to adjust plans based on actual performance. Using dashboards and visualization tools makes the monitoring process more efficient and insightful.

Q 7. Describe a time you successfully identified and resolved a cost overrun.

In a previous role, we faced a significant cost overrun on a software development project due to unforeseen complexities in integrating a third-party API. The original budget didn’t account for the extensive debugging and rework required.

To resolve this, I:

- Investigated the Root Cause: Thoroughly analyzed the reasons behind the overrun, focusing on the complexities of the API integration.

- Identified Mitigation Strategies: Explored options such as reducing the scope of the integration, renegotiating with the third-party vendor, and reallocating resources.

- Presented Solutions: Presented a comprehensive report to the project team and management with the root cause analysis, mitigation strategies, and revised budget.

- Implemented Corrective Actions: We decided to adjust the project scope slightly and implement more rigorous testing protocols in the future. This involved re-prioritizing some features and negotiating an extension with the client.

- Monitored Progress: Closely monitored the project’s progress and costs after implementing the corrective actions.

Through proactive investigation, clear communication, and collaborative decision-making, we managed to bring the project back on track and limit the overall cost overrun to a manageable level. This experience highlighted the importance of thorough planning, risk assessment, and flexible budgeting in managing complex projects.

Q 8. How do you prioritize cost-cutting initiatives?

Prioritizing cost-cutting initiatives requires a strategic approach that balances immediate needs with long-term goals. I use a framework that combines urgency, impact, and feasibility. First, I identify all potential cost-saving opportunities through a thorough analysis of the organization’s spending patterns. Then, I categorize them based on their potential impact – high, medium, or low – and the urgency of addressing them. Finally, I assess the feasibility of implementation, considering factors like time constraints, resource availability, and potential risks. High-impact, urgent, and feasible initiatives are prioritized first. For instance, if an energy-intensive process is both highly impactful (significant cost savings) and urgent (due to rising energy prices), it would be prioritized over a less impactful initiative, even if that initiative is easier to implement.

This prioritization isn’t static. I regularly review the prioritization matrix to accommodate changing market conditions or business priorities. For example, a sudden economic downturn might necessitate a shift towards quicker, smaller wins to stabilize cash flow, while during periods of growth, investment in efficiency-improving initiatives may be given precedence.

Q 9. What are some key performance indicators (KPIs) you use to measure cost control effectiveness?

Key Performance Indicators (KPIs) are crucial for measuring the effectiveness of cost control efforts. I use a balanced scorecard approach, tracking KPIs across financial, operational, and customer perspectives. Some vital KPIs include:

- Cost Reduction Percentage: Measures the percentage decrease in specific cost categories compared to a baseline period. For example, a 10% reduction in operational costs year-over-year.

- Return on Investment (ROI) on Cost Reduction Initiatives: Calculates the financial return relative to the investment made in cost-reduction projects. A high ROI indicates that the initiatives are delivering substantial value.

- Cost per Unit/Service: Tracks the cost of producing a unit of output or providing a service. A decrease in this KPI suggests improved efficiency and cost control.

- Budget Variance: Measures the difference between the budgeted and actual costs. Regular monitoring helps identify areas where costs are exceeding budgets.

- Efficiency Ratios: These KPIs reveal how efficiently resources are used. For example, employee productivity (output per employee) or machine utilization rate.

These KPIs are regularly reviewed and analyzed to identify trends and areas for improvement. The data is presented in dashboards and reports, allowing for real-time monitoring and proactive adjustments.

Q 10. How familiar are you with forecasting techniques?

I am highly familiar with various forecasting techniques, which are critical for proactive cost management. My experience encompasses both qualitative and quantitative methods.

- Quantitative methods include time series analysis (e.g., moving averages, exponential smoothing), regression analysis (predicting costs based on historical data and other variables), and causal modeling (identifying the relationships between different factors affecting costs).

- Qualitative methods involve expert opinions, market research, and scenario planning (considering different potential future scenarios and their impact on costs).

Choosing the appropriate forecasting method depends on factors such as the availability of data, the complexity of the cost drivers, and the desired level of accuracy. For example, when dealing with stable, predictable costs, simpler methods like moving averages might suffice. However, for costs with significant seasonality or external influences, more complex models may be necessary. I often employ a combination of methods to improve forecasting accuracy and reduce uncertainty.

Q 11. Explain your experience with cost-benefit analysis.

Cost-benefit analysis (CBA) is a fundamental tool in my cost management arsenal. It’s a systematic approach to evaluating the economic feasibility of projects or initiatives by comparing their total costs to their total benefits. A successful CBA helps to make informed decisions by quantifying the financial implications of different options.

I have extensive experience conducting CBAs, involving the following steps:

- Identify Costs: This includes direct costs (materials, labor, equipment) and indirect costs (overhead, administration).

- Identify Benefits: These might include increased revenue, reduced operational costs, improved efficiency, or enhanced customer satisfaction. Quantifying benefits often involves making estimations and assumptions.

- Assign Monetary Values: All costs and benefits need to be expressed in monetary terms. This might require using market prices, discounted cash flow techniques, or other valuation methods.

- Calculate Net Present Value (NPV): This is a key metric in CBA, representing the present value of the project’s net benefits over its lifetime. A positive NPV indicates that the project is financially viable.

- Conduct Sensitivity Analysis: This assesses how changes in key assumptions (e.g., cost estimates, discount rates) would affect the outcome of the CBA. It helps to identify critical factors and potential risks.

For instance, in a previous role, we used CBA to evaluate the implementation of a new software system. The analysis weighed the software’s purchase and implementation costs against projected gains from increased efficiency and reduced labor costs. The positive NPV ultimately justified the investment.

Q 12. How do you communicate cost control findings to senior management?

Communicating cost control findings effectively to senior management requires clarity, conciseness, and visual appeal. My approach emphasizes data visualization and storytelling. I typically use a combination of the following:

- Executive Summaries: Concisely present the key findings and recommendations, focusing on the most important aspects.

- Data Visualizations: Charts, graphs, and dashboards effectively communicate complex data, highlighting key trends and insights. For instance, a bar chart comparing actual costs against budgeted costs for different departments or a line graph illustrating the trend of cost reduction over time.

- Storytelling: Frame the findings within a narrative context, highlighting successes and challenges encountered and emphasizing the impact of cost control efforts on the organization’s overall financial health.

- Recommendations: Clearly outline concrete steps and actions that senior management can take to address identified cost issues.

- Interactive Dashboards: Allowing for real-time exploration of the data and providing deeper insights.

For example, I’ve presented cost-saving analyses by starting with a high-level overview of overall cost reduction achieved, then diving into department-specific breakdowns through charts, and finally concluded with actionable recommendations that included specific cost-saving strategies for each department.

Q 13. Describe your experience with different budgeting software or tools.

I have experience with several budgeting and expense management software tools, including:

- SAP BusinessObjects Planning and Consolidation (BPC): A comprehensive enterprise performance management (EPM) system, offering advanced budgeting, forecasting, and reporting capabilities.

- Oracle Hyperion: Another leading EPM suite providing similar functionalities to BPC, often integrated with other Oracle systems.

- Microsoft Excel (with add-ins): While not a dedicated budgeting software, Excel, combined with budgeting and financial modeling add-ins, can be very effective for smaller organizations or specific projects. I’m adept at creating custom financial models and dashboards within Excel.

- Adaptive Insights: A cloud-based solution that allows for collaborative budgeting, forecasting, and reporting, particularly suitable for organizations with decentralized financial processes.

My choice of software depends on the organization’s size, budget, and specific requirements. I am comfortable adapting my skills to utilize different tools effectively.

Q 14. How do you handle unexpected cost increases?

Handling unexpected cost increases requires a proactive and structured approach. My process involves the following steps:

- Identify the Source: Thoroughly investigate the reasons behind the cost increase. This often involves analyzing variance reports, gathering information from different departments, and, if necessary, conducting external market research.

- Quantify the Impact: Determine the magnitude of the cost increase and its potential effect on budgets and timelines.

- Develop Mitigation Strategies: Brainstorm potential solutions to address the cost increase. These might include renegotiating contracts with suppliers, identifying cost-saving opportunities in other areas, adjusting project scopes, or seeking additional funding.

- Prioritize and Implement: Prioritize the most effective mitigation strategies based on their impact and feasibility. Implement the chosen solutions promptly and monitor their effectiveness.

- Communicate and Update: Keep stakeholders informed of the situation, the actions taken, and the potential impact on the overall project or budget. Regularly update the budget and projections to reflect the new circumstances.

For example, if an unexpected surge in raw material prices affects manufacturing costs, I would analyze the market to understand the reasons for this increase, explore alternative suppliers, review production processes to find efficiency gains, and potentially adjust product pricing, while ensuring transparent communication with relevant teams and management throughout the process.

Q 15. What’s your approach to negotiating with vendors to reduce costs?

Negotiating with vendors requires a strategic approach that balances building strong relationships with achieving cost reductions. My approach begins with thorough preparation. I start by analyzing historical spending data to identify areas for potential savings and research market prices for similar goods or services. Then, I enter negotiations armed with this data, presenting a clear and concise case for lower prices. This includes showing the vendor the volume of business we provide and the potential for increased business with improved pricing. I always focus on value, not just price, exploring options like longer-term contracts, bulk discounts, or alternative payment terms to unlock additional savings. For example, in a previous role, I negotiated a 15% discount on our annual software licensing fees by highlighting our consistent on-time payments and commitment to long-term usage, resulting in significant cost savings for the company.

Furthermore, I prioritize building strong, mutually beneficial relationships with vendors. Open communication and transparency are key. Instead of adversarial tactics, I favor collaborative discussions, focusing on finding win-win solutions that meet both our needs. By demonstrating a willingness to compromise and being fair, I aim to foster long-term partnerships that are both cost-effective and reliable.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with process improvement initiatives to reduce costs.

I have extensive experience leading and participating in process improvement initiatives focused on cost reduction. My approach typically involves using Lean methodologies and Six Sigma principles. This starts with identifying and mapping the current processes, pinpointing bottlenecks and inefficiencies. For example, in one project, we mapped our invoice processing workflow, which revealed significant delays caused by manual data entry and a lack of automation. By implementing robotic process automation (RPA) to automate data entry and integrating the system with our ERP, we reduced processing time by 70% and significantly lowered labor costs.

Another key aspect is data analysis. We collect and analyze relevant data to identify areas for improvement and measure the impact of our interventions. For example, we used data to identify redundant tasks, unnecessary steps in workflows, and inefficiencies in resource allocation. This data-driven approach ensures that our improvements are targeted and effective. Continuous improvement is crucial. We regularly review processes to ensure ongoing efficiency and make adjustments as needed.

Q 17. How do you ensure compliance with financial regulations related to cost control?

Ensuring compliance with financial regulations related to cost control is paramount. This involves a multi-faceted approach. First and foremost, a robust internal control system is essential. This includes implementing clear policies and procedures for expense reporting, procurement, and contract management. We also conduct regular audits to ensure that these procedures are followed and that our financial records are accurate and transparent. This includes both internal audits and external audits performed by independent third parties. Regular training for employees is vital to ensure that everyone understands and adheres to these procedures.

Staying updated on the relevant financial regulations is critical. This requires ongoing monitoring of changes in accounting standards (like GAAP or IFRS) and other pertinent legal requirements. We engage with legal and compliance professionals to ensure that we are compliant with all applicable laws and regulations. By maintaining comprehensive documentation, we can demonstrate compliance and minimize any potential risks.

Q 18. What is your experience with activity-based costing?

Activity-based costing (ABC) is a powerful method for allocating overhead costs more accurately than traditional methods. Instead of allocating costs based on volume (like machine hours), ABC traces costs to specific activities that drive those costs. For instance, instead of simply allocating overhead to a product based on direct labor hours, ABC would identify the specific activities involved in producing the product (design, machining, assembly, testing) and allocate the costs of those activities accordingly. This provides a much clearer picture of the true cost of producing a product or service.

My experience with ABC includes its application in a manufacturing environment where we were able to identify significant cost differences between seemingly similar products. By using ABC, we discovered that one product, despite having similar labor hours, consumed significantly more resources in the testing phase. This allowed us to focus improvement efforts on the testing process, ultimately leading to cost reductions for that product line. ABC is most beneficial in industries with diverse product lines or complex manufacturing processes where traditional costing methods can be misleading.

Q 19. How do you utilize data analytics to improve cost control?

Data analytics plays a crucial role in improving cost control. By analyzing historical spending data, we can identify trends, patterns, and outliers. For example, we can use data visualization tools to identify which departments or projects are overspending relative to their budgets. We can also use predictive modeling to forecast future costs based on historical trends, allowing for proactive budget planning and resource allocation. This data-driven approach allows for more informed decision-making.

Furthermore, we utilize data mining techniques to discover hidden cost drivers. For example, by analyzing data on vendor performance, we might identify opportunities to negotiate better pricing or consolidate vendors. We can also use data analytics to identify and address wasteful spending, such as unnecessary subscriptions or unused resources. The key is to turn data into actionable insights that lead to tangible cost reductions. We use various software and tools like Tableau and Power BI to facilitate this analysis.

Q 20. Describe your experience with implementing cost-saving measures in a specific project.

In a recent project involving the implementation of a new CRM system, we focused on minimizing implementation costs. Our initial budget was significantly high, so we implemented several cost-saving measures. First, we opted for a cloud-based solution instead of on-premise installation, significantly reducing upfront infrastructure costs. Second, we prioritized training resources, focusing on providing targeted training sessions based on roles, instead of a one-size-fits-all approach. This reduced the overall training hours needed. Third, we leveraged internal resources whenever possible for tasks such as data migration and system configuration, instead of relying entirely on external consultants. This reduced the reliance on expensive external expertise.

These strategies significantly reduced our overall implementation costs while still ensuring a successful project launch. The project came in under budget by 12%, a considerable achievement resulting from a proactive and carefully planned approach to cost control. It underscores the importance of identifying potential cost-saving opportunities from the planning stage onward.

Q 21. What are the key challenges in cost control, and how do you overcome them?

Key challenges in cost control include inaccurate forecasting, unexpected expenses, lack of employee awareness, and resistance to change. Inaccurate forecasting can lead to budget overruns. To mitigate this, we rely on robust data analysis, incorporating historical data and market trends to develop realistic forecasts. Unexpected expenses are inevitable, so establishing contingency funds is vital. This prepares us for unforeseen circumstances.

Lack of employee awareness about cost-saving initiatives can hinder success. This is addressed through comprehensive training programs and communication strategies to encourage everyone’s involvement in cost control efforts. Resistance to change is a common barrier. Here, effective change management is key, involving stakeholders, clearly communicating the benefits of proposed changes, and providing necessary support to facilitate smooth transitions. Ultimately, building a culture of cost consciousness throughout the organization is crucial for effective cost control.

Q 22. How do you maintain accuracy and efficiency in cost reporting?

Maintaining accuracy and efficiency in cost reporting requires a multi-pronged approach focusing on automation, standardization, and robust internal controls. Think of it like building a finely-tuned engine – each part needs to work seamlessly.

Automation: I leverage accounting software and tools to automate data entry and calculations, minimizing manual errors. For instance, integrating our expense management system directly with our accounting software eliminates double-handling and potential discrepancies.

Standardization: Consistent chart of accounts, coding procedures, and reporting templates are crucial. Imagine a factory assembly line – standardization ensures every product is made the same way, leading to predictable results. This simplifies analysis and comparison across different periods and departments.

Internal Controls: Implementing strong internal controls, such as segregation of duties, regular reconciliations (comparing bank statements to internal records), and approval workflows, is essential to prevent fraud and ensure data integrity. Think of this as the security system for your cost reporting – protecting your data from threats.

Regular Review and Reconciliation: I conduct periodic reviews of cost reports to identify inconsistencies or anomalies. Reconciling actual costs with budgeted costs helps to pinpoint areas needing attention and allows for timely corrective action.

Q 23. How do you work with cross-functional teams to achieve cost control objectives?

Effective cost control requires collaboration. I approach cross-functional teamwork with a proactive and communicative style. Imagine it as orchestrating a symphony – each section (department) needs to play in harmony to achieve the overall goal (cost control objectives).

Shared Goals and KPIs: I start by clearly defining cost control objectives and key performance indicators (KPIs) with each team, ensuring everyone understands their role and how their actions contribute to the overall success.

Open Communication: Regular meetings and transparent reporting keep everyone informed and foster a collaborative environment. Sharing successes and challenges promotes a sense of shared ownership.

Data-Driven Decisions: I present data and analysis in an accessible format, facilitating informed discussions and enabling data-driven decision-making. This ensures everyone is on the same page, understanding the financial implications of various choices.

Conflict Resolution: Inevitably, differing opinions arise. I facilitate constructive dialogue, focusing on finding mutually beneficial solutions that align with the overall cost control strategy.

Q 24. Describe your experience with zero-based budgeting.

Zero-based budgeting (ZBB) is a budgeting approach where every expense must be justified for each new period, rather than simply basing the budget on the previous year’s spending. It’s like starting a new project from scratch each time – no assumptions are made.

In my experience, implementing ZBB involves:

Defining Objectives: Clearly articulating departmental and organizational goals to guide resource allocation.

Activity-Based Costing: Breaking down activities and their associated costs to identify areas for potential savings.

Prioritization: Ranking activities based on their contribution to organizational objectives, ensuring resources are allocated effectively.

Collaboration: Working closely with department heads to gather data, justify expenses, and negotiate budgets.

Monitoring and Adjustment: Regularly monitoring actual versus budgeted costs and making adjustments as needed. This is crucial for ongoing cost control.

Implementing ZBB can be time-consuming, but the resulting efficiency gains and cost savings often outweigh the effort. For example, in a previous role, implementing ZBB resulted in a 15% reduction in operating expenses within the first year.

Q 25. Explain your approach to identifying and mitigating financial risks.

My approach to identifying and mitigating financial risks is proactive and systematic. I view risk management not as a reaction to problems, but as a process integrated into all financial operations.

Risk Assessment: I begin with a thorough assessment of potential financial risks, considering factors such as market volatility, regulatory changes, and operational disruptions. This involves identifying both internal and external factors.

Risk Prioritization: I prioritize risks based on their likelihood and potential impact. This allows me to focus on the most critical areas.

Mitigation Strategies: Once risks are identified and prioritized, I develop and implement mitigation strategies. These strategies can include hedging against market volatility, establishing contingency plans, and enhancing internal controls.

Monitoring and Review: Risks are not static; they evolve. I regularly monitor the effectiveness of mitigation strategies and revise them as needed. This ongoing monitoring is key to maintaining strong financial health.

For example, during a period of economic uncertainty, I successfully implemented a hedging strategy that minimized the company’s exposure to currency fluctuations, protecting profitability.

Q 26. How do you ensure data integrity in your cost control processes?

Data integrity is paramount in cost control. It’s the foundation upon which all decisions are made. Think of it as the cornerstone of a building – if it’s weak, the whole structure is at risk.

Data Validation: I implement checks and balances to ensure data accuracy at the point of entry. This includes data validation rules in our systems, regular data cleansing, and cross-referencing with other data sources.

Access Control: Restricting access to financial data based on roles and responsibilities prevents unauthorized modifications. Think of it as implementing strong security protocols for sensitive information.

Data Backup and Recovery: Regular data backups and disaster recovery plans protect against data loss due to unforeseen events.

Data Governance Policy: Establishing a clear data governance policy that outlines data standards, processes, and responsibilities ensures consistent data management throughout the organization.

In a previous role, I implemented a data quality program which resulted in a significant reduction in data errors and improved the reliability of our cost reports.

Q 27. How do you measure the return on investment (ROI) of cost-saving initiatives?

Measuring the ROI of cost-saving initiatives is crucial to demonstrate their value. It’s about proving the bottom-line impact of our efforts. Think of it as providing a tangible demonstration of success.

I use a variety of methods to measure ROI, including:

Cost Savings Calculation: Quantifying the reduction in expenses resulting from the initiative. This might involve calculating the difference between pre- and post-implementation costs.

Benefit-Cost Analysis: Comparing the total benefits of the initiative (e.g., increased efficiency, improved quality) to its total costs.

Payback Period: Determining the time it takes for the cost savings to equal the initial investment in the initiative.

Return on Investment (ROI) Calculation: Calculating the ROI as (Net Benefit / Total Investment) * 100%. This provides a clear percentage demonstrating the return.

For instance, in a previous project, implementing a new procurement system resulted in a 12% reduction in procurement costs, with a payback period of six months. The ROI calculation clearly demonstrated the significant return on the investment in the new system.

Q 28. Describe your experience with implementing and managing a cost control system.

Implementing and managing a cost control system requires a structured approach. I typically follow these steps:

Needs Assessment: Identifying the organization’s specific cost control needs and challenges. This involves understanding current processes, identifying pain points, and defining objectives.

System Selection and Implementation: Choosing appropriate software and tools based on the organization’s needs and budget, followed by careful implementation to ensure seamless integration with existing systems.

Process Mapping and Optimization: Mapping out current processes and identifying areas for improvement. This can involve streamlining workflows, automating tasks, and eliminating redundancies.

Training and Support: Providing thorough training to users on the new system and ongoing support to address any issues or questions.

Monitoring and Reporting: Continuously monitoring the effectiveness of the system, tracking KPIs, and generating regular reports to identify areas for improvement and potential cost savings. This allows for ongoing optimization and adaptation.

In a previous role, I successfully implemented a new expense management system, resulting in a 10% reduction in processing time and a significant improvement in expense report accuracy. The key was a phased implementation, coupled with comprehensive user training and ongoing support.

Key Topics to Learn for Cost Control and Expense Management Interview

- Budgeting and Forecasting: Understanding different budgeting methods (zero-based, incremental, etc.), developing accurate forecasts, and analyzing variances.

- Cost Accounting: Applying cost accounting principles to track, analyze, and report on costs, including direct and indirect costs, fixed and variable costs.

- Variance Analysis: Identifying and analyzing deviations between budgeted and actual costs, determining root causes, and recommending corrective actions.

- Expense Management Systems: Familiarity with various expense management software and processes, including expense reporting, approvals, and reconciliation.

- Process Improvement: Identifying areas for cost reduction and efficiency improvements within expense management processes. This includes streamlining workflows and implementing automation.

- Financial Statement Analysis: Interpreting key financial statements (income statement, balance sheet, cash flow statement) to assess cost performance and identify potential risks.

- Data Analysis and Reporting: Utilizing data analysis techniques to identify cost trends, create insightful reports, and support decision-making.

- Negotiation and Vendor Management: Developing strong negotiation skills to secure favorable pricing and terms with vendors.

- Internal Controls: Understanding and implementing internal controls to ensure accuracy, prevent fraud, and maintain compliance.

- Strategic Cost Management: Connecting cost control initiatives to broader organizational strategic goals and objectives.

Next Steps

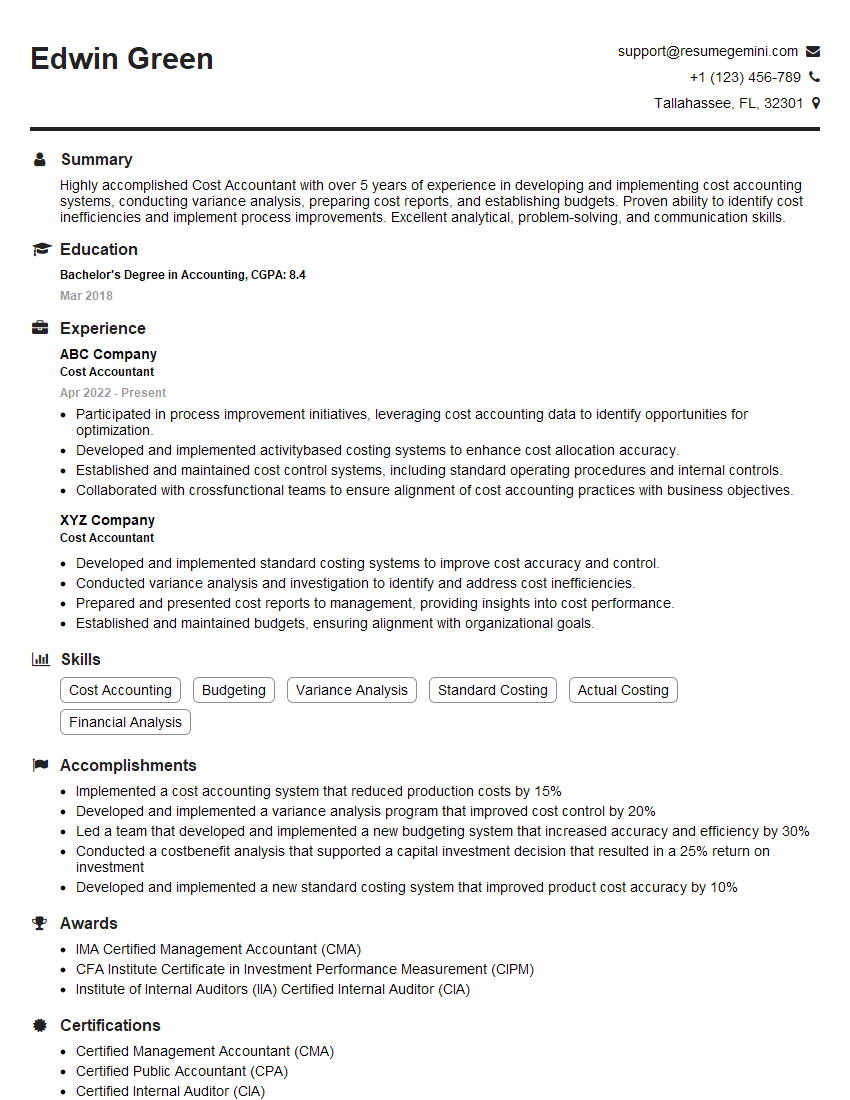

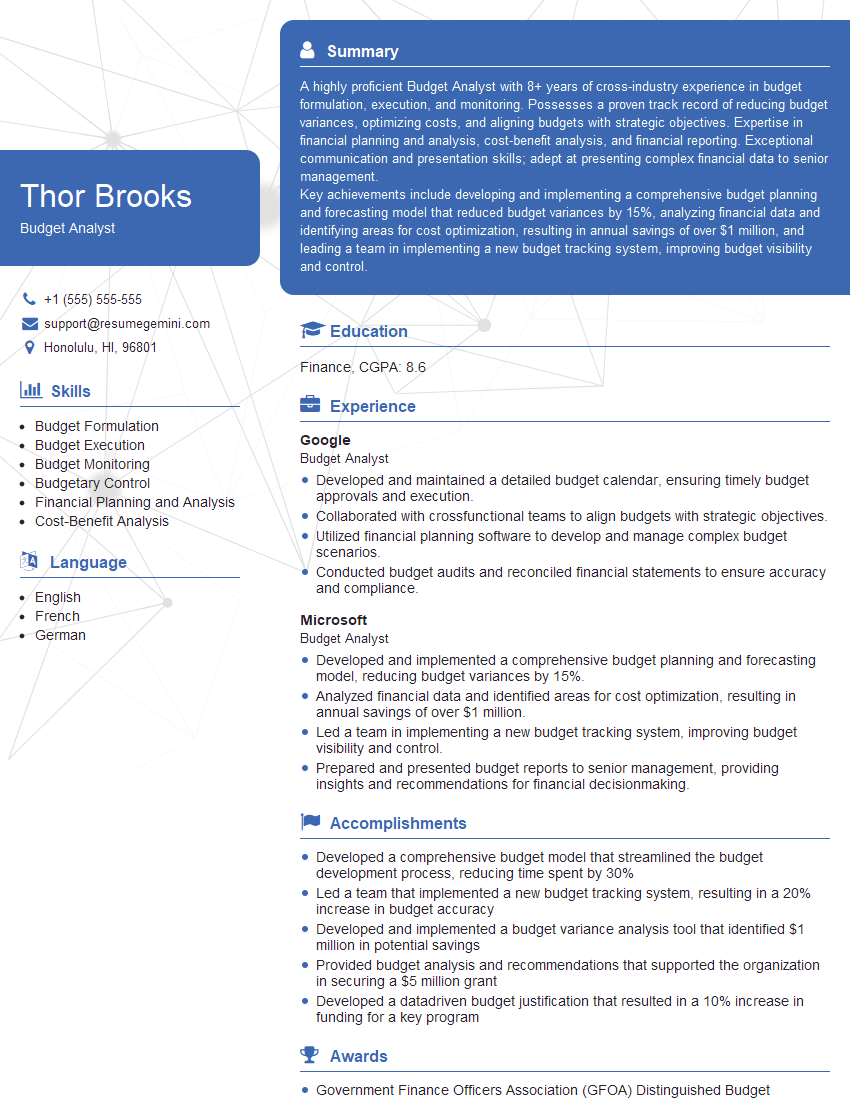

Mastering Cost Control and Expense Management is crucial for career advancement in finance and accounting, opening doors to leadership roles and higher earning potential. A well-crafted resume is your first step towards landing your dream job. To significantly increase your chances of getting noticed by Applicant Tracking Systems (ATS), focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini can be a trusted resource to help you build a professional and impactful resume that showcases your expertise in Cost Control and Expense Management. We offer examples of resumes tailored to this specific field to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO