Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Operation of CNC Machines interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Operation of CNC Machines Interview

Q 1. Explain the difference between G-code and M-code.

G-code and M-code are both essential parts of the programming language used to control CNC machines, but they serve distinct purposes. Think of it like this: G-code tells the machine where to go and what to do (the geometry of the cut), while M-code tells the machine how to do it (auxiliary functions).

- G-code (Preparatory Codes): These codes define the geometric movements of the machine’s tools. Examples include G00 (rapid positioning), G01 (linear interpolation), G02 (circular interpolation clockwise), and G03 (circular interpolation counter-clockwise). For instance,

G01 X10 Y20 F50would command the machine to move linearly to the coordinate (10,20) at a feed rate of 50 units per minute. - M-code (Miscellaneous Codes): These codes control machine functions that aren’t directly related to toolpath movements. Examples include M03 (spindle on clockwise), M05 (spindle stop), M06 (tool change), and M30 (program end).

M03 S3000would turn on the spindle at 3000 RPM.

In essence, G-codes form the backbone of the part’s shape, while M-codes manage the machine’s operational aspects to execute the G-code instructions correctly and safely.

Q 2. Describe your experience with different CNC machine types (e.g., lathes, mills).

My experience spans a wide range of CNC machines, primarily lathes and mills. I’ve worked extensively with both 3-axis and 5-axis milling machines, as well as various lathe configurations, including those with live tooling.

On the milling side, I’m proficient in programming and operating machines from Fanuc and Siemens controls. I’ve handled complex milling operations such as high-speed machining (HSM) of intricate parts and 5-axis simultaneous machining for complex geometries, often utilizing CAD/CAM software such as Mastercam and Fusion 360 to generate the G-code. For example, I once programmed a 5-axis machine to mill a highly detailed mold cavity using a high-speed end mill to achieve a mirror-like finish.

With lathes, I’m experienced in both turning and facing operations, including internal and external threading, and the use of live tooling for secondary machining operations. I’ve worked with both manual and CNC lathes, which provided me with a deep understanding of machine mechanics and control systems. One memorable project involved producing high-precision shafts with tight tolerances on a Swiss-type lathe.

My expertise includes the ability to adapt my skills to different machine types and control systems, ensuring efficiency and accuracy across various manufacturing tasks.

Q 3. How do you troubleshoot common CNC machine errors?

Troubleshooting CNC machine errors requires a systematic approach. My process typically involves:

- Safety First: Always ensure the machine is powered down and locked out before attempting any repairs or investigations.

- Review the Error Message: Most CNC controls display error codes or messages. These provide crucial initial clues. Consult the machine’s manual to decipher the code’s meaning.

- Visual Inspection: Carefully examine the machine for obvious problems like loose connections, damaged tooling, or coolant leaks.

- Check the Program: Review the G-code for errors, such as incorrect coordinates, missing parameters, or toolpath collisions. Simulate the program if possible using CAM software.

- Verify Tooling and Workholding: Ensure the correct tools are installed and securely clamped. Check that the workpiece is properly fixtured to prevent vibrations or movement.

- Check Limits and Sensors: Inspect limit switches and other safety sensors for proper functioning. A faulty sensor can trigger errors.

- Diagnostic Tools: Many CNC controls have built-in diagnostic capabilities that can help pinpoint problems. Use these to monitor machine parameters and identify anomalies.

If the problem persists after these steps, I consult technical manuals or contact the machine manufacturer’s support team. Documenting each step and finding root causes is critical to prevent future occurrences.

Q 4. What are the safety precautions you take when operating CNC machines?

Safety is paramount when operating CNC machines. My safety precautions include:

- Proper Training and Certification: I have undergone comprehensive training on CNC machine operation and safety procedures.

- Lockout/Tagout Procedures: Always following lockout/tagout procedures before performing any maintenance or repair work.

- Personal Protective Equipment (PPE): Consistent use of safety glasses, hearing protection, and appropriate clothing (no loose clothing or jewelry).

- Machine Guarding: Ensuring all safety guards are in place and functioning correctly.

- Tooling Safety: Properly securing and inspecting cutting tools before each operation. Discarding damaged tools immediately.

- Emergency Stop Procedures: Familiarizing myself with the location and operation of the emergency stop button.

- Work Area Cleanliness: Maintaining a clean and organized workspace to prevent accidents.

- Regular Inspections: Regularly inspecting the machine for wear and tear, and reporting any issues promptly.

I always prioritize safety, treating every situation with the utmost caution, remembering that even a small mistake can have significant consequences.

Q 5. Explain the process of setting up a CNC machine for a new job.

Setting up a CNC machine for a new job involves a methodical process:

- Review the Drawings and Specifications: Carefully examine the engineering drawings and specifications to understand the part’s geometry, tolerances, and material.

- Select the Appropriate Tools: Choose the correct cutting tools based on the material and desired finish.

- Program the Machine: Develop or import the CNC program (G-code) that accurately describes the cutting operations.

- Fixture Design and Setup: Design and set up a fixture to hold the workpiece securely during machining. The fixture must ensure accurate positioning and prevent vibration or movement.

- Workpiece Setup: Securely mount the workpiece in the fixture and align it with the machine’s coordinate system.

- Tool Setting: Use a tool setter to accurately measure the length and diameter of each cutting tool to ensure proper cutting depths and positioning.

- Machine Parameter Settings: Configure the machine’s parameters such as spindle speed, feed rate, coolant pressure, and other relevant settings, based on the material and tooling.

- Test Run (Optional): Perform a test run at a reduced speed to check the program, toolpaths, and overall setup before running the full production job.

- Production Run: Execute the CNC program to produce the parts.

- Inspection: Inspect the finished parts to ensure they meet the required specifications.

This systematic approach ensures accuracy, efficiency, and minimizes the risk of errors or damage.

Q 6. How do you interpret engineering drawings and blueprints for CNC machining?

Interpreting engineering drawings and blueprints for CNC machining requires a strong understanding of both machining principles and technical drawing conventions. My process involves:

- Understanding Views and Projections: I carefully examine the various views (orthographic projections) of the part to fully comprehend its three-dimensional shape.

- Dimensioning and Tolerances: I pay close attention to the dimensions and tolerances specified on the drawing to ensure the final part meets the required specifications. This includes understanding GD&T (Geometric Dimensioning and Tolerancing) symbols.

- Material Specifications: I identify the material of the workpiece, as this dictates appropriate cutting parameters and tooling selection.

- Surface Finish Requirements: I note any surface finish requirements (e.g., Ra value) to choose appropriate cutting tools and machining strategies.

- Feature Recognition: I identify key features like holes, pockets, slots, and other geometric elements to determine the appropriate machining operations.

- CAD/CAM Software Integration: I frequently use CAD/CAM software to translate the 2D drawings into a 3D model and then generate the necessary G-code to machine the part.

Through experience and rigorous attention to detail, I can accurately translate the information from the blueprints into a functional CNC program.

Q 7. What are your preferred methods for measuring and inspecting machined parts?

Measuring and inspecting machined parts requires precision and accuracy. My preferred methods include:

- Coordinate Measuring Machine (CMM): For high-precision parts, a CMM provides the most accurate dimensional measurements. It allows for highly accurate verification of dimensions and geometric tolerances.

- Micrometers and Calipers: These are essential for quick checks of linear dimensions and provide reliable measurements for many applications.

- Height Gauges: Useful for precise measurements of height or depth.

- Optical Comparators: Optical comparators allow for quick visual inspection of part geometry against a master template.

- Go/No-Go Gauges: These are specialized gauges for checking if a part is within the acceptable tolerance range. They are particularly useful for mass production inspection.

- Digital Indicators: These provide quick and precise measurements, and can be easily interfaced with other measuring equipment.

The choice of method depends on the part’s complexity, the required accuracy, and the available equipment. I always document the inspection process and record the measurement data to maintain traceability and quality control.

Q 8. Describe your experience with different cutting tools and materials.

My experience with cutting tools and materials is extensive, spanning a wide range of applications. I’m proficient in selecting and utilizing various tools, from high-speed steel (HSS) end mills and drills for general machining to carbide inserts for heavy-duty operations on tougher materials. The choice depends heavily on the material being machined. For instance, aluminum readily machines with HSS tools, while hardened steels require the durability and wear resistance of carbide inserts. I’ve worked with a diverse range of materials, including aluminum alloys (6061, 7075), various steels (mild steel, stainless steel, tool steel), plastics (ABS, acrylic), and even some exotic materials like titanium alloys. Understanding the properties of each material – its hardness, machinability, tendency to work-harden, etc. – is crucial for selecting the right tool and optimizing cutting parameters for optimal surface finish, tool life, and productivity. For example, when machining stainless steel, I’d choose a carbide insert specifically designed for stainless steel to prevent built-up edge (BUE) and ensure a smooth cut. My experience allows me to quickly assess the material and select the best tooling strategy, maximizing efficiency and minimizing waste.

Q 9. How do you ensure the accuracy and precision of your work?

Accuracy and precision are paramount in CNC machining. I achieve this through a multi-faceted approach. First, meticulous attention to detail is essential throughout the entire process, from the initial CAD design and CNC program creation to the final inspection. I rigorously verify the program through simulations, ensuring the toolpaths are correct and collision-free. This often involves checking for potential issues like gouging or undercuts. Secondly, regular maintenance of the machine is vital. This includes ensuring the machine’s mechanical components (spindles, axes, etc.) are properly lubricated and calibrated. I frequently inspect for wear and tear on machine components, reporting any issues promptly. Thirdly, workholding is critical. Securely clamping the workpiece is essential to avoid vibrations and inaccuracies during machining. I employ various workholding methods, from vises and clamps to specialized fixtures, depending on the part’s geometry and machining requirements. Finally, post-machining inspection using calibrated measuring instruments, such as CMMs or dial indicators, verifies the part’s dimensions and tolerances meet the specifications. Regular calibrations of my tools and equipment also play a crucial part.

Q 10. What software programs are you familiar with for CNC programming and operation?

I’m proficient in several CNC programming and operation software packages. My experience includes Mastercam, Fusion 360, and Siemens NX CAM. Mastercam is excellent for complex 3D surfaces and multi-axis machining. I’ve used it extensively for generating toolpaths for intricate parts. Fusion 360 provides a powerful integrated CAD/CAM environment, ideal for rapid prototyping and smaller projects. Siemens NX CAM is a robust solution for high-end manufacturing environments, handling large assemblies and complex tooling strategies. Furthermore, I’m familiar with the various post-processors required to translate the CAM data into machine-specific G-code. My understanding extends to editing and troubleshooting G-code directly on the machine controller, which is essential for on-the-fly adjustments and optimization. For example, I can easily modify feed rates or tool depths within the G-code to achieve a desired finish.

Q 11. How do you handle unexpected issues or malfunctions during operation?

Handling unexpected issues requires a systematic and methodical approach. My first step is always safety – ensuring the machine is safely stopped and the area is secure. Then I systematically troubleshoot the issue. This might involve checking for obvious causes such as tool breakage, improper workholding, or coolant issues. I also utilize the machine’s diagnostic capabilities, checking for error messages and sensor readings. If the issue persists, I’ll consult the machine’s manuals and documentation, seeking solutions to the specific error codes. If I can’t resolve it, I escalate the problem to experienced maintenance personnel or the machine’s manufacturer. The key is to remain calm and methodical, following established safety protocols and troubleshooting procedures. For example, if I encounter a sudden spindle stop, I’d immediately stop the machine and check the spindle motor current, the coolant flow, and look for any physical obstructions before trying to restart.

Q 12. Describe your experience with different types of CNC controllers.

My experience encompasses several types of CNC controllers, including Fanuc, Siemens, and Heidenhain. Each controller has its unique programming language and user interface, but the underlying principles remain consistent. I’m adept at navigating different control systems, understanding their operational parameters, and programming them efficiently. Fanuc controllers are widely used in the industry known for their reliability and extensive library of features. I’ve worked extensively with their conversational and G-code programming options. Siemens controllers, particularly on more sophisticated machines, offer powerful capabilities for complex tasks. Heidenhain controllers are known for their precision and are commonly found on high-precision milling machines. I’m comfortable working with the different HMI (Human Machine Interface) styles, adapting my approach to the specific controller’s capabilities and limitations. Understanding these differences allows for efficient programming and operation regardless of the machine type.

Q 13. Explain the concept of workholding and its importance in CNC machining.

Workholding is the method of securely fixing a workpiece to the machine table during machining. It’s critical for ensuring accuracy and safety. Improper workholding can lead to vibrations, inaccuracies, and even catastrophic tool or workpiece damage. The choice of workholding method depends on the part’s geometry, material, and the machining operation. Common methods include vises, clamps, magnetic chucks, and dedicated fixtures. Vices are versatile but may not provide ideal support for complex parts. Clamps offer flexibility but require careful placement to avoid workpiece distortion. Magnetic chucks are excellent for ferrous materials but not suitable for non-ferrous ones. Dedicated fixtures offer the highest level of accuracy and repeatability, especially for high-volume production runs. A well-designed fixture minimizes vibration and ensures consistent part location and orientation, leading to improved accuracy and efficiency. For example, when machining a delicate part, I’d use a soft jaw chuck or custom fixture to prevent damage during clamping.

Q 14. What are your strategies for optimizing CNC machining processes for efficiency and productivity?

Optimizing CNC machining processes involves a holistic approach. First, I focus on toolpath optimization, using efficient cutting strategies to minimize machining time and tool wear. This involves optimizing feed rates, cutting depths, and spindle speeds based on the material and tool being used. Second, I carefully select cutting tools, ensuring they are sharp and appropriate for the material. Regular tool changes are crucial, preventing premature tool wear and ensuring consistent part quality. Third, proper workholding is essential for reducing vibrations and ensuring stability. Well-designed fixtures and efficient clamping techniques minimize setup time and machining errors. Finally, I leverage the machine’s capabilities. This includes using high-speed machining techniques, if appropriate, and utilizing advanced control features such as adaptive control for better surface finish and consistent material removal rate. Regular machine maintenance, preventative actions and monitoring of tool wear contribute to a robust and efficient process. Analyzing machining times and identifying bottlenecks also play a key role in streamlining production workflows. Using monitoring tools to check on tool wear and machine status is a vital part of ongoing optimization.

Q 15. How do you maintain and perform routine maintenance on CNC machines?

Routine maintenance on CNC machines is crucial for ensuring accuracy, prolonging lifespan, and preventing costly downtime. Think of it like regular servicing for your car – neglecting it leads to major problems later. My approach involves a multi-pronged strategy focusing on preventative and corrective maintenance.

- Daily Checks: This includes visually inspecting the machine for loose parts, coolant leaks, unusual noises, and ensuring proper lubrication. I also check tool condition and clean away chips.

- Weekly Maintenance: This involves more in-depth checks, like inspecting the air filters, checking the coolant levels and quality, and cleaning the machine thoroughly, including the ways and slides. This is when I’d also check the accuracy of the machine using precision tools.

- Monthly Maintenance: More extensive tasks like checking the spindle bearings for wear, lubricating critical components based on the manufacturer’s recommendations, and checking for electrical connections are performed.

- Preventative Maintenance Schedules: I meticulously follow the manufacturer’s recommended preventative maintenance schedule. This often involves replacing worn parts proactively rather than waiting for a failure. I maintain detailed logs of all maintenance activities.

- Corrective Maintenance: If any problems arise, I troubleshoot systematically, consulting manuals and utilizing diagnostic tools to identify and rectify the issue quickly and efficiently.

For example, once I identified a recurring vibration issue on a milling machine, by carefully checking and tightening all the bolts and the machine bed, I was able to pinpoint a loose component causing the vibration. Addressing this early saved us significant time and potential damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of different cutting fluids and their applications.

Cutting fluids are essential in CNC machining to lubricate the cutting process, manage heat, and improve chip removal. Choosing the right fluid significantly impacts surface finish, tool life, and overall machining efficiency. I’m experienced with various types, including:

- Water-Soluble Fluids (Emulsions): These are commonly used due to their cost-effectiveness and good cooling properties. They are a mixture of water and oil, and require regular monitoring to ensure the concentration remains optimal. I find they’re best suited for general purpose machining applications.

- Water-Miscible Fluids (Synthetics): These provide excellent cooling and lubricity, minimizing friction and wear. They tend to be more environmentally friendly and have a longer lifespan than emulsions, but are more expensive. I use these when working with difficult-to-machine materials.

- Straight Oils: These are used for heavy-duty operations and provide superior lubrication, but are not as effective at cooling as water-based solutions. They are less environmentally friendly and require more frequent disposal.

- Synthetic Fluids: Offer optimal performance across a wide range of machining operations, combining excellent cooling, lubrication, and environmental compatibility. They are often a premium solution, justifying their use in high-precision applications.

The selection of cutting fluid depends greatly on the material being machined, the cutting tool, and the specific machining operation. For instance, when machining titanium alloys, I’d opt for a high-performance synthetic fluid to maximize tool life and ensure a good surface finish. For aluminum, a water-soluble emulsion would likely suffice. Regular monitoring of the fluid’s properties and appropriate disposal are critical aspects I always prioritize.

Q 17. How do you calculate machining parameters (e.g., feed rate, spindle speed)?

Calculating machining parameters like feed rate and spindle speed is crucial for efficient and effective machining. Getting these wrong can lead to tool breakage, poor surface finish, or inaccurate parts. I typically use a combination of manufacturer recommendations, experience, and often, CAM software calculations, but here’s the general approach:

- Spindle Speed (RPM): This is determined using the cutting tool’s recommended cutting speed (Vc in meters/minute) and the diameter (D) of the cutter using the formula:

RPM = (Vc * 1000) / (π * D) - Feed Rate (mm/rev or mm/min): This depends on several factors including the material being machined, the cutting tool geometry, and the desired surface finish. It represents the amount of material removed per unit of time or rotation. Manufacturers provide recommendations for different materials and tools. Extensive experience gives me an intuition to adjust these based on the specific cutting conditions.

- Depth of Cut: This influences the rate of material removal and the required power. I carefully select the depth based on the material properties and the available machine power to avoid overloading the machine.

For example, when machining a steel component with a 10mm diameter end mill, I’d use the recommended cutting speed for steel and apply the formula to calculate the optimal RPM. The feed rate would be adjusted based on the material’s hardness and the desired surface finish, often starting with conservative values and making adjustments based on real-time observation.

I always prioritize a conservative approach initially and gradually increase parameters once I verify that the process is stable and the workpiece is not exhibiting any signs of stress.

Q 18. Describe your experience with CNC programming using CAM software.

My experience with CAM software is extensive. I’m proficient in several packages, including Mastercam and Fusion 360. I can generate efficient toolpaths for a wide range of machining operations including milling, turning, and drilling. This isn’t just about generating G-code; it’s about optimizing the process.

- Toolpath Strategies: I select appropriate toolpath strategies to achieve the desired surface finish and tolerances. This involves choosing between roughing and finishing strategies, considering factors like step-over and depth of cut.

- Tool Selection: I select appropriate cutting tools considering the material being machined, the required machining tolerances, and the available machine capabilities. I leverage the software’s capabilities for efficient tool selection and collision avoidance.

- Simulation: I thoroughly simulate the toolpaths to detect and resolve potential collisions before sending the code to the machine. This significantly reduces the risk of machine damage and workpiece spoilage.

- Post-Processing: I’m adept at post-processing to generate machine-specific G-code, adapting the code to accommodate machine limitations and specific requirements. I know how to optimize the generated code for optimal machining performance.

For instance, I recently worked on a complex part requiring intricate features. By using Fusion 360, I designed the part, generated highly optimized toolpaths, and simulated the entire machining process. This resulted in a significant reduction in machining time and scrap compared to traditional methods. The simulation feature identified and prevented potential tool collisions that may not have been immediately apparent.

Q 19. What is your experience with automated tool changing systems?

I have extensive experience with automated tool changing (ATC) systems. These systems are invaluable for improving efficiency in CNC machining, particularly for complex parts requiring multiple tools. My experience covers various types of ATC systems, including those with robotic arms and turret-style systems.

- System Operation: I understand the operational principles of different ATC systems. This involves the mechanics of tool changing, including tool indexing and magazine management.

- Troubleshooting: I’m proficient in troubleshooting issues related to ATC systems, including tool misalignment, magazine malfunctions, and sensor problems. This includes systematically checking for mechanical issues, electrical faults and software glitches.

- Maintenance: I understand and perform routine maintenance of ATC systems to minimize downtime. This includes regular lubrication, cleaning, and component inspection.

- Programming: I can program the machine to utilize the ATC system effectively, ensuring efficient tool changes and minimizing non-productive time.

During one project, we had an issue with an ATC system that resulted in slow tool changes. Through systematic troubleshooting and by referencing the manufacturer’s documentation, I discovered a problem with the pneumatic system responsible for actuating the tool changer. After replacing a faulty valve, the system was restored to its optimal performance, significantly increasing productivity.

Q 20. How do you ensure the quality of your work meets specified tolerances?

Ensuring the quality of my work consistently meets specified tolerances is paramount. My approach is multi-faceted, focusing on preventative measures and rigorous quality checks.

- Process Planning: I meticulously plan the entire machining process, including fixture design, tool selection, and machining parameters. This step is crucial in avoiding errors and ensuring quality from the outset.

- Program Verification: I thoroughly verify the CNC program using simulation software to detect potential errors and ensure that the toolpaths are correct before running them on the machine.

- In-Process Inspection: During the machining operation, I regularly monitor the process to detect any deviations from the planned parameters or unexpected issues. This may involve using dial indicators and other measuring tools to check the dimensions of the workpiece at various stages.

- Post-Process Inspection: After machining, I perform a thorough inspection of the finished part using various measuring instruments, including CMM (Coordinate Measuring Machines), calipers, micrometers, and optical comparators to ensure that all dimensions are within the specified tolerances.

- Statistical Process Control (SPC): I utilize SPC methods to monitor and control the process to minimize variation and maintain consistency over time.

For example, when machining a critical part with tight tolerances, I implemented a multi-stage inspection process. At each stage, measurements were taken and compared against the specifications. Any deviations were investigated and corrective actions taken immediately to prevent further errors. This approach ensures that the final product meets the required quality standards.

Q 21. Describe your experience working with different types of measuring equipment.

I have extensive experience working with a wide array of measuring equipment crucial for verifying the accuracy and quality of CNC machined parts. These tools range from basic hand tools to sophisticated precision instruments.

- Calipers and Micrometers: These are essential for measuring linear dimensions. I’m proficient in using both vernier calipers and digital calipers for precise measurements.

- Dial Indicators: I use dial indicators for measuring run-out, surface flatness, and alignment. This is important for ensuring the accuracy of set-ups.

- Coordinate Measuring Machines (CMMs): I’m experienced in using CMMs for high-precision dimensional inspection of complex parts. This includes programming the CMM for automated inspection routines and interpreting the results.

- Optical Comparators: For detailed inspection of part geometries and surface finish I’ve had extensive use of optical comparators and other optical systems.

- Laser Scanners: I’ve used laser scanners for non-contact inspection of larger parts or those with complex geometries where traditional methods may be challenging.

In one instance, I used a CMM to inspect a complex aerospace component requiring tolerances down to a few micrometers. The CMM allowed for precise measurements of critical dimensions and ensured that the part met the stringent quality requirements. The detailed report generated by the CMM was crucial in validating the accuracy of the machining process.

Q 22. What is your experience with using offset values in CNC programming?

Offset values in CNC programming are crucial for accurately machining parts. They compensate for the difference between the tool’s geometry and the programmed path. Think of it like this: your program tells the machine where to *ideally* cut, but the tool itself has a certain size and shape. The offset value adjusts the programmed path to account for this, ensuring the final part meets the desired dimensions.

There are two main types: cutter compensation (or tool radius compensation – G41/G42) and work offset (G54-G59). Cutter compensation adjusts the toolpath in real-time based on the tool’s radius, ensuring the cut is made at the programmed center point, regardless of the tool’s size. Work offset, on the other hand, is used to compensate for workpiece misalignment or to program parts relative to a different reference point. For instance, if your workpiece is slightly off from where it’s supposed to be in relation to the machine’s reference point, you can adjust for it using a work offset.

I have extensive experience with both. In a recent project, I used G41 cutter compensation to machine a complex curved profile, and G55 work offset when dealing with a slightly warped workpiece, achieving micron-level precision in both instances.

Q 23. How do you manage and organize your work in a CNC machine shop?

Organization is key in a CNC machine shop. My approach involves a combination of digital and physical methods. I utilize a Computer-Aided Manufacturing (CAM) software for program management, meticulously storing all files, including programs, tool paths, and associated documents, in a well-structured folder system. This system makes searching and retrieving necessary files very quick.

Physically, I keep my workspace clean and organized. Tools are stored in designated locations, and materials are sorted for easy access. A system of visual cues (like color-coded labels or clearly labeled bins) further simplifies locating needed components. Furthermore, I maintain a detailed log of each job, including material used, machining parameters, and any quality control checks performed. This log serves as an important reference for future jobs and is essential for troubleshooting any issues that arise.

This systematic approach ensures efficiency and prevents costly errors.

Q 24. Explain your understanding of coordinate systems used in CNC machining.

CNC machines primarily utilize three coordinate systems: the machine coordinate system (MCS), the work coordinate system (WCS), and the part coordinate system (PCS). Understanding these is fundamental for accurate programming.

- MCS: This is the fixed coordinate system inherent to the machine itself. It’s the origin point for all machine movements and is usually located at a physical point on the machine.

- WCS: This is user-defined and provides a reference point for the workpiece. It’s often set at a convenient location on the workpiece’s surface and simplifies programming. Multiple WCSs (G54-G59) can be defined for a single part, making it useful for multiple setups or operations on one workpiece.

- PCS: This is defined by the part’s geometry and is used for creating part programs. It is the reference point relative to the drawing or design of the part. The CAM software typically handles the transformation between PCS and WCS/MCS.

Using these coordinate systems in combination allows for precise and efficient machining, especially on complex parts requiring multiple setups.

Q 25. Describe your problem-solving skills in a CNC machining environment.

Problem-solving in CNC machining often involves a systematic approach. My process usually involves these steps:

- Identify the problem: Is the part dimensionally inaccurate? Is there a tool breakage? Is the machine alarming?

- Gather information: Check the CNC program, machine logs, tool condition, and the workpiece itself. Look for patterns or anomalies.

- Develop hypotheses: Based on the gathered information, formulate potential causes for the problem. Could it be a programming error, a tool wear issue, a machine malfunction, or a material defect?

- Test hypotheses: Systematically test each hypothesis to isolate the root cause. For example, run a test program or check tool parameters.

- Implement solution: Once the cause is identified, implement the appropriate corrective action, whether it’s modifying the program, replacing a tool, adjusting machine settings, or addressing a material issue.

- Verify solution: After implementing a solution, verify that it has resolved the problem and that the subsequent parts are being machined correctly.

For example, I once encountered a recurring dimensional error on a part. By meticulously reviewing the program, I discovered a subtle mistake in the cutter compensation settings. Correcting this setting resolved the issue completely.

Q 26. What are your experience with different types of fixturing?

I’m experienced with a variety of fixturing methods, selecting the appropriate one depends on the part geometry, material, and machining process. Some common types I frequently use include:

- Vices: Simple and effective for holding smaller, relatively simple parts.

- Clamps: Offer versatile holding solutions for a wider range of part shapes and sizes. Careful consideration is needed to avoid workpiece distortion.

- Fixtures with locating pins and clamping mechanisms: Used for complex parts requiring precise positioning and repeatability, minimizing part shifting during machining.

- Magnetic fixtures: Ideal for ferrous materials, providing quick and secure holding.

- Workholding chucks: Essential for rotational machining processes like turning, offering strong clamping capabilities.

The choice of fixturing directly impacts part accuracy and machining efficiency. I always ensure the fixture securely holds the workpiece while preventing deformation or damage.

Q 27. How do you deal with material defects during machining process?

Dealing with material defects during machining requires careful attention and a methodical approach. The first step is to identify the defect – is it a surface imperfection, an internal flaw, or something else? Once identified, I assess the severity of the defect and its impact on the final part.

If the defect is minor and doesn’t affect critical dimensions or functionality, I might adjust the machining parameters to work around it, such as reducing cutting speed or depth of cut in the affected area. For more severe defects, the workpiece may need to be scrapped and replaced. In some cases, pre-machining inspection helps to identify defects early, minimizing wasted material and time. Maintaining detailed records of material lots and defects helps in identifying potential issues with specific batches.

Preventative measures, such as selecting high-quality materials and properly storing them, are equally important. I always carefully inspect the material before machining to minimize potential problems.

Q 28. How familiar are you with the concept of adaptive control in CNC machining?

Adaptive control in CNC machining is a sophisticated technology that adjusts machining parameters in real-time based on feedback from sensors. This feedback can include cutting forces, tool deflection, or surface finish. The system automatically modifies parameters such as feed rate, spindle speed, and depth of cut to maintain optimal cutting conditions. This results in improved surface finish, increased tool life, and reduced machining time.

While I haven’t had direct hands-on experience with implementing adaptive control algorithms myself, I understand its principles and benefits. I’ve witnessed its applications in high-precision machining environments, where it significantly improves the quality and efficiency of the process. I am eager to learn more and further develop my skills in this advanced area.

Key Topics to Learn for Your CNC Machine Operation Interview

Ace your upcoming interview by focusing on these key areas. Understanding both the theory and practical application will set you apart.

- CNC Programming Fundamentals: Understanding G-code, M-code, and common programming techniques. This includes interpreting existing programs and identifying potential errors.

- Machine Setup and Operation: Mastering the process of setting up tooling, workholding, and workpiece placement for efficient and accurate machining. Practice explaining your safety procedures.

- Tooling and Material Selection: Demonstrate your knowledge of selecting appropriate cutting tools and materials based on the job requirements. Discuss considerations for tool wear and breakage.

- Quality Control and Inspection: Explain your methods for ensuring dimensional accuracy, surface finish, and overall part quality. Be ready to discuss quality control processes and documentation.

- Troubleshooting and Maintenance: Be prepared to discuss common machine malfunctions and your approach to troubleshooting and preventative maintenance. Highlight your problem-solving skills.

- Safety Procedures and Regulations: Emphasize your understanding and adherence to all relevant safety regulations and procedures within a CNC machine shop environment. This is crucial for any interview.

- CAD/CAM Software Familiarity (if applicable): If your experience includes using CAD/CAM software, be ready to discuss your proficiency and how you utilize it in the machining process.

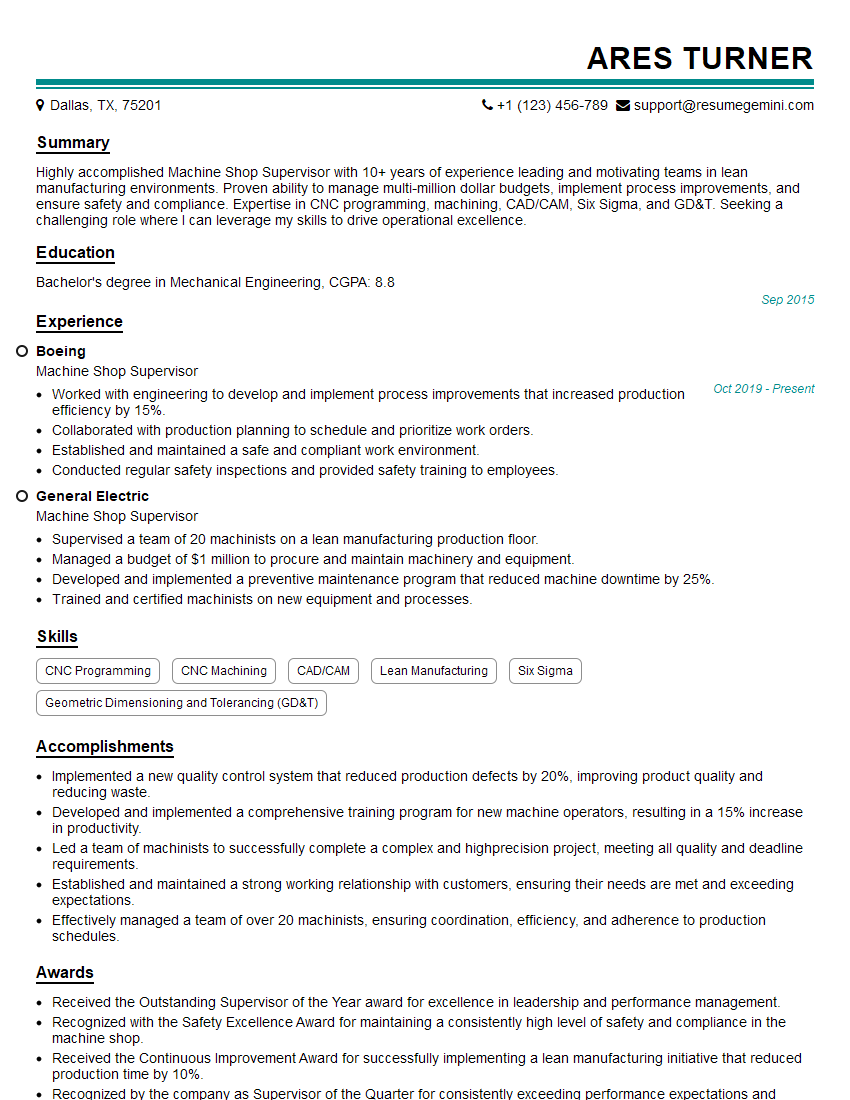

Next Steps: Unlock Your Career Potential

Mastering CNC machine operation opens doors to exciting career opportunities with excellent growth potential. To maximize your job prospects, a strong, ATS-friendly resume is essential. ResumeGemini can help you craft a compelling resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to Operation of CNC Machines to help guide you. Take the next step towards your dream job – build a winning resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO