Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Truck and Equipment Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Truck and Equipment Operation Interview

Q 1. Describe your experience operating a [specific type of equipment, e.g., backhoe].

My experience operating a backhoe spans over eight years, encompassing various projects from utility line installation to residential foundation excavation. I’m proficient in all aspects of backhoe operation, including digging, trenching, loading, and material handling. I’ve worked with diverse soil types, mastered precise maneuvering in confined spaces, and consistently met project deadlines while maintaining high safety standards. For example, on a recent project involving the installation of underground utilities, my precise backhoe operation minimized disruption to surrounding infrastructure, ensuring the timely completion of the project without any damage.

I’m also experienced with different backhoe attachments, such as augers and rippers, allowing me to adapt to various site conditions and project requirements. This versatility has been crucial in several projects requiring diverse tasks within a single operation.

Q 2. Explain the pre-operation checklist you follow for [specific type of equipment].

My pre-operation checklist for a backhoe is meticulous and follows a consistent procedure. It’s designed to ensure both the machine and my own safety before commencing any operation. First, I perform a visual inspection, checking for any visible damage, fluid leaks, or loose parts. Then, I check all fluid levels (hydraulic fluid, engine oil, coolant), ensuring they’re within the recommended ranges. Next, I check tire pressure and confirm the stability of the machine on the ground. I test the functionality of all controls – bucket operation, steering, braking, and horn. Finally, I ensure all safety features are operational, including lights, warning devices, and emergency stops. This rigorous routine prevents equipment failure and minimizes potential hazards during operation.

Think of it like a pilot’s pre-flight check – a thorough examination ensures a smooth and safe operation.

Q 3. How do you ensure the safety of yourself and others while operating heavy machinery?

Safety is my paramount concern. I adhere to a multi-layered approach. Before starting any work, I thoroughly assess the worksite, identifying potential hazards like overhead obstructions, underground utilities, and uneven terrain. I establish clear communication protocols with other personnel on-site, using hand signals and radio communication to coordinate movements and avoid collisions. I always maintain a safe distance from the edge of excavations, using proper shoring and barricades when needed. Furthermore, I wear appropriate personal protective equipment (PPE) at all times, including a hard hat, safety glasses, hearing protection, and high-visibility clothing. Regular maintenance and keeping the equipment in top condition play a vital role in preventing accidents.

Safety isn’t just a checklist; it’s a mindset. It’s a constant awareness of my surroundings and a commitment to minimizing risk at every stage of the operation.

Q 4. What are the common maintenance checks you perform on a [specific type of equipment]?

Regular maintenance on a backhoe is crucial for its longevity and safe operation. My routine checks include inspecting hydraulic lines for leaks, checking the condition of the bucket teeth and ensuring they are securely attached, lubricating moving parts, examining the engine compartment for any loose components, and verifying the proper function of the braking system. I also monitor tire pressure regularly and check for any wear and tear. I pay close attention to the condition of the stabilizers, ensuring they extend and retract smoothly and securely. Any unusual noises or vibrations are immediately investigated and addressed to prevent further damage.

Think of it as regular check-ups for a car – preventative maintenance saves time, money, and prevents potential breakdowns.

Q 5. Describe a time you had to troubleshoot a mechanical issue with your equipment.

During a large excavation project, the backhoe’s hydraulic system suddenly malfunctioned, causing the bucket to become unresponsive. My first step was to shut down the machine completely and assess the situation. I checked the hydraulic fluid level, finding it low. After topping it off, I still had no response. I then systematically checked the hydraulic lines and fittings for leaks, eventually discovering a small but significant leak at a connection point near the boom cylinder. I carefully tightened the fitting using the appropriate wrench. This resolved the issue, and after a quick test, the backhoe operated normally. I then documented the incident in the machine’s maintenance log for future reference.

Troubleshooting involves a methodical approach: assess, investigate, and resolve. Rushing the process can lead to further complications.

Q 6. How do you handle challenging terrain or weather conditions while operating equipment?

Operating equipment in challenging terrain or weather conditions demands extra caution and skill. For hilly or uneven terrain, I adjust my speed and operating techniques to maintain stability and avoid rollovers. I use the stabilizers strategically to enhance stability on slopes. In slippery conditions due to rain or snow, I reduce speed significantly, maintain a wider turning radius, and avoid sudden movements. Extreme weather like heavy rain or strong winds necessitate postponing operations unless the project is absolutely critical and safety measures can be implemented to mitigate the risks.

Adaptability and situational awareness are critical in such scenarios. Safety always comes first.

Q 7. What are the legal regulations and safety standards you adhere to while driving a truck?

When driving a truck, I strictly adhere to all applicable federal, state, and local regulations, including speed limits, weight restrictions, and hours-of-service rules. I am familiar with the Commercial Driver’s License (CDL) requirements and maintain a valid CDL with the appropriate endorsements. I ensure the truck is regularly inspected and maintained to meet all safety standards. I always wear my seatbelt and comply with all traffic laws. I am also trained in defensive driving techniques and prioritize safety awareness, constantly scanning the road and surroundings for potential hazards. Regular logbook maintenance and adherence to all regulations are critical.

Driving a truck responsibly is not just about following the rules; it’s about safeguarding lives and property.

Q 8. How do you manage your time effectively during a long haul or demanding job?

Effective time management during long hauls is crucial for safety and productivity. It’s not just about driving hours; it’s about planning, rest, and proactive problem-solving. My approach involves a multi-pronged strategy. First, I meticulously plan my routes using GPS navigation and factoring in potential delays like traffic or construction. I always account for mandatory rest breaks mandated by the Hours of Service regulations, scheduling them strategically to avoid fatigue. Secondly, I prioritize tasks. For example, I’ll often pre-check my load securement before departure, saving time later. Finally, I maintain a detailed logbook, recording my hours, maintenance checks, and any issues encountered. This helps in analyzing my efficiency and identifying areas for improvement.

Think of it like running a marathon – pacing yourself is key. You can’t sprint the entire distance. Similarly, I prioritize consistent driving with planned breaks, ensuring I arrive safely and on time.

Q 9. What is your experience with different types of load securing techniques?

Load securing is paramount for safety and legal compliance. My experience encompasses various techniques, including the use of straps, chains, winches, and blocks. I’m proficient in using different types of cargo securing devices, ensuring they are appropriate for the type of load and its weight. For instance, I would use chains for heavier, more stable loads like steel, while straps are better suited for lighter and more irregularly shaped cargo like pallets. I always ensure that the load is properly distributed and that the securing devices are correctly tensioned and properly fastened to prevent shifting during transit. I’m also familiar with the use of dunnage (materials used to fill voids in the load) and load bars to further improve stability.

On one occasion, I was transporting a load of fragile pottery. Careful planning, using specialized padding and multiple securing straps, was critical to ensure the delivery arrived undamaged. This involved precise placement and tensioning of straps to prevent any shifting that could cause breakage.

Q 10. Explain the importance of load weight and distribution.

Load weight and distribution are critical for several reasons: safety, fuel efficiency, and legal compliance. Exceeding weight limits is dangerous and illegal. Uneven weight distribution can cause instability, leading to rollovers or sway, especially at high speeds or on curves. Proper weight distribution ensures the truck’s center of gravity is low and centered, improving handling. The gross vehicle weight rating (GVWR) must never be exceeded. Furthermore, incorrect weight distribution impacts fuel efficiency; a poorly balanced load increases drag and reduces mileage.

I always use weight scales to accurately determine the total weight of the load. I then strategically arrange items on the trailer to maintain a balance and to meet all legal weight restrictions for various axles. For example, heavier items are placed lower and towards the center, while lighter items are placed strategically to distribute the weight evenly. This meticulous approach safeguards against accidents and ensures efficient fuel consumption.

Q 11. Describe your experience with GPS navigation systems in trucking.

GPS navigation systems are indispensable in modern trucking. I’m experienced with various systems, from basic route guidance to more advanced features that include real-time traffic updates, weight restrictions alerts, and fuel-efficient routing options. I regularly use these systems to plan routes, optimize fuel consumption, avoid congestion, and comply with regulations. The ability to receive real-time traffic updates is particularly beneficial in avoiding delays. These systems allow for more precise trip planning and efficient use of driver time. The advanced routing options help identify and bypass potential issues or delays.

In one instance, using real-time traffic updates from my GPS, I navigated around a major accident, preventing a significant delay and ensuring on-time delivery.

Q 12. How do you manage fuel efficiency while operating heavy equipment or trucks?

Fuel efficiency is a significant concern in trucking. My approach to maximizing fuel economy involves several strategies. First, I maintain a consistent speed and avoid aggressive acceleration or braking. Smooth driving reduces fuel consumption dramatically. Secondly, I plan routes to avoid unnecessary idling or stops. I also monitor tire pressure regularly; under-inflated tires increase rolling resistance and fuel consumption. Thirdly, I understand and utilize the vehicle’s capabilities, choosing the right gear and maintaining optimal RPMs to minimize fuel waste. Regular vehicle maintenance, including engine tune-ups, also plays a critical role.

Think of it like sailing – a smooth and steady course consumes less energy than erratic maneuvering. The same principle applies to trucking; a gentle driving style directly translates to fuel savings.

Q 13. How do you handle unexpected delays or traffic disruptions?

Unexpected delays are inevitable in trucking. My approach involves proactive planning and effective communication. When faced with delays (e.g., traffic jams, accidents, or mechanical issues), I immediately inform my dispatch and clients, providing regular updates. I assess the situation, identify alternative routes if necessary (using my GPS system), and take steps to mitigate the impact of the delay. In cases of mechanical problems, I ensure the vehicle is safely parked and follow all safety protocols while waiting for roadside assistance. Documentation of the delay and any actions taken is crucial for legal and logistical purposes.

For example, during a recent snowstorm, I encountered road closures. I promptly informed my dispatch, found a safe place to park, and used my GPS to find alternative routes once the roads reopened. This kept my cargo safe, minimized delivery disruption, and kept me within regulatory compliance.

Q 14. What is your experience with different types of trailers and their configurations?

My experience includes operating various trailer types, including flatbeds, van trailers, refrigerated trailers (reefers), and lowboys. Each trailer type has specific configurations and functionalities suited to different cargo needs. Flatbeds are ideal for open-air cargo, while van trailers offer enclosed protection. Reefer trailers maintain temperature-controlled environments for perishable goods, and lowboys are used for oversized or heavy equipment. Understanding each type’s capacity, limitations, and proper securing techniques is essential. I’m familiar with various configurations like double drop trailers for moving extra-high loads, and also with the use of specialized equipment for securing different types of cargo within these trailers.

My experience with these various configurations enables me to efficiently transport a wide range of goods, from construction materials on flatbeds to sensitive pharmaceuticals in reefer trailers.

Q 15. Explain your understanding of DOT regulations.

The Department of Transportation (DOT) regulations are a crucial set of rules governing the trucking and transportation industry in the United States, ensuring safety and efficiency. My understanding encompasses several key areas, including:

- Hours of Service (HOS): These rules strictly limit the number of hours a driver can operate a commercial motor vehicle (CMV) within a given timeframe, preventing driver fatigue and promoting safety. I am meticulously familiar with the different duty cycles and exception rules, ensuring compliance. For example, I know the difference between 70-hour and 60-hour restart rules and adhere to them strictly.

- Vehicle Maintenance: DOT regulations mandate regular vehicle inspections and maintenance to prevent mechanical failures. I am proficient in pre- and post-trip inspections, meticulously checking components like brakes, tires, lights, and fluid levels to ensure the vehicle is roadworthy. I’m also well-versed in documenting these inspections.

- HazMat Transportation: If transporting hazardous materials, additional, stringent regulations apply, including proper placarding, packaging, and documentation. I have experience in the secure handling and transportation of various classes of hazardous materials and understand the required certifications and training. For example, I know the differences in handling flammable liquids compared to explosives.

- Driver Qualification and Licensing: DOT sets forth requirements for drivers, including holding a valid commercial driver’s license (CDL) with appropriate endorsements, passing drug and alcohol screenings, and maintaining a clean driving record. I hold a valid CDL and maintain all necessary documentation.

Understanding and adhering to DOT regulations isn’t just about avoiding fines; it’s about prioritizing safety for myself and other road users. I treat it as a critical part of my daily routine.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with log books or electronic logging devices (ELDs).

I have extensive experience with both paper log books and electronic logging devices (ELDs). I started with paper logs, diligently recording my hours and meticulously maintaining accurate records. This process required careful attention to detail to avoid violations. The transition to ELDs has improved efficiency. ELDs automatically track driving time, ensuring compliance with HOS regulations. I am proficient in using ELD systems, understanding their capabilities, and troubleshooting minor issues.

For example, I know how to effectively manage my available hours, plan my routes strategically to maximize available driving time within regulations, and use the ELD’s reporting features to provide accurate information to dispatchers. While I appreciate the accuracy and convenience of ELDs, I also maintain a strong understanding of manual log book processes should technological issues arise.

Q 17. What is your understanding of different types of cargo and their handling requirements?

Different types of cargo demand unique handling procedures to ensure safety and prevent damage. My experience includes handling:

- General Freight: This encompasses a wide range of items, requiring careful loading and securing to prevent shifting during transit. I utilize proper securing techniques, including straps, chains, and bracing, depending on the type and weight of the cargo. I also prioritize the distribution of weight to maintain balance and stability.

- Oversized and Overweight Loads: These shipments require specific permits, specialized equipment, and careful route planning to ensure legal and safe transportation. I’m experienced in handling these loads safely, ensuring the proper use of pilot cars and escort vehicles when necessary.

- Hazardous Materials (HazMat): I have experience in handling various classes of HazMat, adhering to strict regulations outlined by the DOT. This includes understanding the proper placarding, handling, and documentation procedures to prevent accidents and environmental damage.

- Refrigerated Cargo: This necessitates monitoring temperature levels throughout the transit and ensuring the proper functioning of the refrigeration unit. This involves understanding the settings and being able to identify and troubleshoot problems to maintain the integrity of the refrigerated goods.

Understanding the specific needs of different cargo types allows me to ensure efficient and safe transport, avoiding potential damage or delays.

Q 18. How do you communicate effectively with dispatchers and other team members?

Effective communication is paramount in this profession. I prioritize clear, concise, and timely communication with dispatchers and team members. I use various methods:

- Clear and Concise Messaging: I avoid jargon and provide accurate and timely updates on my location, estimated time of arrival (ETA), and any challenges encountered. For example, if a delay is anticipated, I provide specific reasons and estimated time of resolution.

- Active Listening: I pay close attention to instructions and actively seek clarification when needed. This prevents misunderstandings and ensures I carry out tasks accurately.

- Professionalism: I maintain a professional demeanor in all communication, fostering a positive working relationship with everyone.

- Technology: I utilize various communication tools such as mobile phones, two-way radios, and company-provided messaging systems effectively and efficiently.

Open communication prevents issues before they arise, making for smoother operations and a more harmonious working environment.

Q 19. Describe your experience with different types of braking systems.

My experience encompasses various braking systems used in heavy vehicles:

- Air Brakes: This is the most common braking system in heavy-duty trucks. I understand the principles of air pressure build-up, the function of air compressors, and the importance of regular maintenance to ensure optimal braking performance. I’m familiar with troubleshooting common air brake issues, such as low air pressure or leaks.

- Anti-lock Braking Systems (ABS): ABS prevents wheel lockup during braking, enhancing vehicle control and stability, particularly during emergency stops. I know how to recognize the signs of a malfunctioning ABS system.

- Exhaust Brakes (Jake Brakes): These supplementary braking systems use engine compression to assist in slowing down, especially on steep downhill grades. I understand the proper operation and limitations of exhaust brakes, using them safely and effectively.

Understanding these different systems allows me to operate the vehicle safely and efficiently under various conditions.

Q 20. Explain your understanding of hydraulic systems in heavy equipment.

Hydraulic systems are essential in many heavy equipment operations, providing the power for lifting, digging, and other functions. My understanding covers:

- Hydraulic Pumps: These create the pressure needed to move hydraulic fluid through the system. I understand the different types of hydraulic pumps, their operating principles and the importance of maintaining proper fluid levels and pressure.

- Hydraulic Cylinders: These convert hydraulic pressure into linear motion, allowing for lifting, pushing or pulling. I am familiar with identifying potential issues such as leaks, piston malfunctions, or worn seals.

- Hydraulic Valves: These control the flow and direction of hydraulic fluid, directing the movement of the equipment. I understand the function of various valves and their role in precise equipment operation.

- Fluid Maintenance: Proper fluid levels and condition are critical for the health of the system. I know the importance of regular fluid changes and checks for contamination or leaks.

Understanding these components allows me to identify and often resolve minor hydraulic problems before they escalate into major equipment malfunctions, minimizing downtime and maximizing productivity. For example, I can identify a leak by its location and the type of fluid and can often temporarily address a problem using standard procedures.

Q 21. How do you identify and report equipment malfunctions?

Identifying and reporting equipment malfunctions is crucial for maintaining safety and preventing larger issues. My process includes:

- Regular Inspections: I conduct thorough pre-trip and post-trip inspections, noting any unusual sounds, leaks, or performance issues.

- Operational Awareness: I pay close attention to how the equipment operates, recognizing deviations from normal performance. For example, I am aware of how my equipment usually sounds and would recognize unusual changes immediately.

- Documentation: I maintain accurate records of any observed malfunctions, including the date, time, location, and a description of the problem. I use photos and videos to help clarify my reporting.

- Reporting Procedures: I follow the established reporting procedures, notifying the appropriate personnel (dispatchers, mechanics, supervisors) immediately. I clearly and concisely explain the issue, its severity, and any potential safety concerns.

Proactive identification and reporting of malfunctions prevent more serious problems and ensures the continued safe operation of equipment.

Q 22. What are your strengths and weaknesses as a truck and equipment operator?

My greatest strengths as a truck and equipment operator lie in my meticulous attention to detail, my proactive approach to safety, and my adaptability to various situations. I consistently perform pre-operational checks with thoroughness, ensuring equipment is in optimal condition before commencing any task. This minimizes the risk of accidents and downtime. My safety-first mentality is ingrained in my work ethic, and I am always vigilant about adhering to all safety regulations and procedures. Finally, I’ve worked on a variety of projects, from highway construction to utility work, so I’m comfortable adapting my skills to different equipment and environments.

My area for improvement is delegation. While I can handle a lot independently, sometimes I struggle to effectively delegate tasks when working as part of a larger team. I’m actively working on this by improving my communication skills and practicing trust in my colleagues’ abilities. I’m confident in my ability to become even more effective in leading and collaborating with a team.

Q 23. What are your salary expectations for this role?

My salary expectations for this role are in the range of $65,000 to $75,000 per year, depending on the benefits package and overall compensation structure. This range reflects my experience, skills, and the prevailing market rates for similar positions in this region. I’m open to discussing this further and am confident that my contributions will justify this compensation.

Q 24. Why are you interested in this specific job?

I’m particularly interested in this job because of [Company Name]’s reputation for safety and its commitment to employee development. The description of the role highlighted the opportunity to work with [specific equipment or project type], something I’m highly experienced in and passionate about. Furthermore, the company culture, as described, seems to align perfectly with my values of teamwork and professional growth. I see this as an ideal opportunity to leverage my skills in a challenging and rewarding environment.

Q 25. Where do you see yourself in 5 years?

In five years, I envision myself as a highly skilled and respected member of [Company Name]’s team, potentially in a supervisory role. I plan to expand my expertise in [specific area, e.g., heavy equipment maintenance or project management] through continued training and on-the-job experience. My goal is to contribute significantly to the company’s success and mentor junior operators, sharing my knowledge and experience to build a strong and skilled team.

Q 26. Describe a time you had to make a quick decision under pressure.

During a highway construction project, a sudden rainstorm caused a landslide that threatened to block a major thoroughfare. I had to quickly assess the situation and decide whether to attempt to clear the debris immediately or wait for additional equipment and personnel. Considering the potential for further landslides and the urgent need to keep the road open, I made the decision to mobilize the available equipment and personnel to begin clearing the debris while simultaneously requesting backup. This allowed us to mitigate the disruption quickly and safely. Although stressful, the quick thinking and decisive action prevented a much larger and potentially dangerous situation.

Q 27. Describe your experience with preventative maintenance.

Preventative maintenance is a cornerstone of my operating practice. I’m proficient in performing daily, weekly, and monthly inspections on a wide range of equipment, including identifying and reporting any issues. My experience encompasses checking fluid levels (oil, coolant, hydraulic fluid), inspecting tire pressure and tread depth, examining belts and hoses for wear and tear, and lubricating moving parts. I meticulously document all inspections and maintenance activities using electronic logging systems, ensuring compliance with company and regulatory requirements. This proactive approach minimizes equipment downtime, reduces the risk of breakdowns, and extends the lifespan of machinery. For example, regularly checking the brake system on a heavy-duty truck prevents potential catastrophic failure.

Q 28. What is your experience with operating equipment in confined spaces?

I have significant experience operating equipment in confined spaces, adhering strictly to all safety protocols. This includes working in trenches, tunnels, and other areas with limited maneuverability and potential hazards. I am familiar with confined-space entry procedures, including the use of proper personal protective equipment (PPE), atmospheric monitoring, and communication systems. Safety is paramount in these situations, and I prioritize meticulous planning, teamwork, and adherence to all safety regulations to ensure a safe working environment for myself and my colleagues. For example, when operating an excavator in a narrow trench, extra caution and precision are required to prevent accidental damage to surrounding structures or equipment.

Key Topics to Learn for Truck and Equipment Operation Interview

- Vehicle Operation & Maintenance: Understanding basic vehicle mechanics, preventative maintenance schedules, and troubleshooting common issues. Practical application: Describe your experience performing routine checks and addressing minor repairs.

- Safety Regulations & Procedures: Knowledge of relevant safety regulations, including load securement, pre-trip inspections, and defensive driving techniques. Practical application: Explain how you ensure compliance with safety protocols in your daily work.

- Specialized Equipment Operation: Proficiency in operating specific equipment relevant to the job description (e.g., forklifts, excavators, loaders). Practical application: Detail your experience operating specific machinery, highlighting your proficiency level and any certifications held.

- Load Planning & Management: Efficient and safe loading and unloading procedures, understanding weight limits and distribution. Practical application: Describe a situation where you had to optimize load distribution for safe and efficient transport.

- Navigation & Route Planning: Effective route planning, considering traffic, weather conditions, and delivery schedules. Practical application: Explain how you plan routes to maximize efficiency and minimize delays.

- Communication & Teamwork: Effective communication with dispatchers, colleagues, and clients. Practical application: Describe a situation where clear communication prevented a potential problem.

- Problem-solving & Troubleshooting: Ability to identify and resolve mechanical issues, navigate unexpected situations, and adapt to changing conditions. Practical application: Give an example of a problem you encountered on the job and how you solved it.

Next Steps

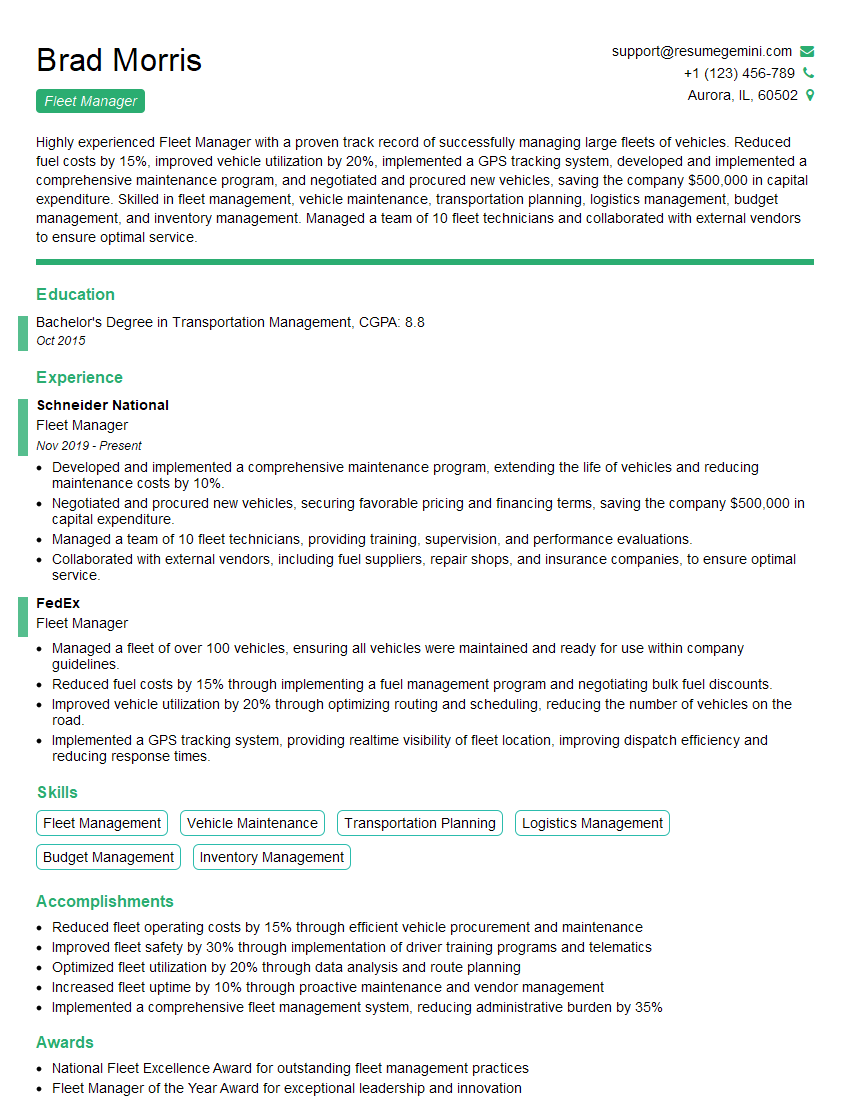

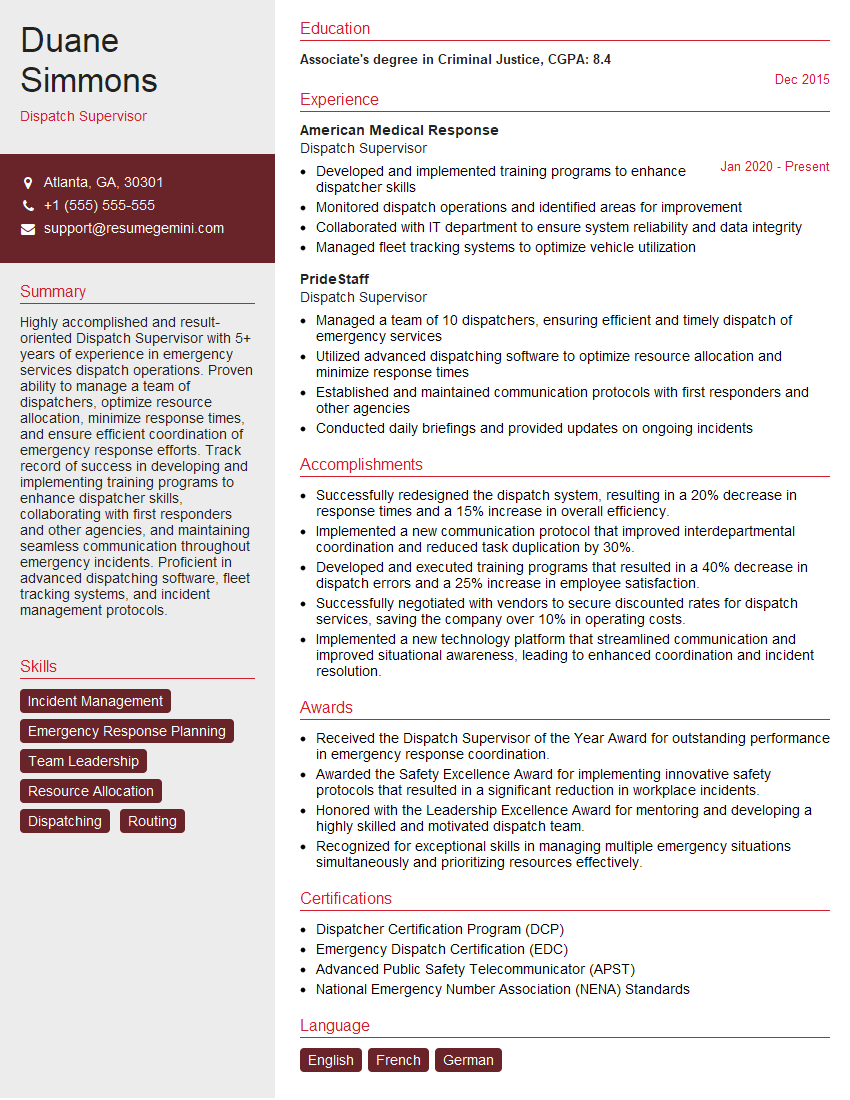

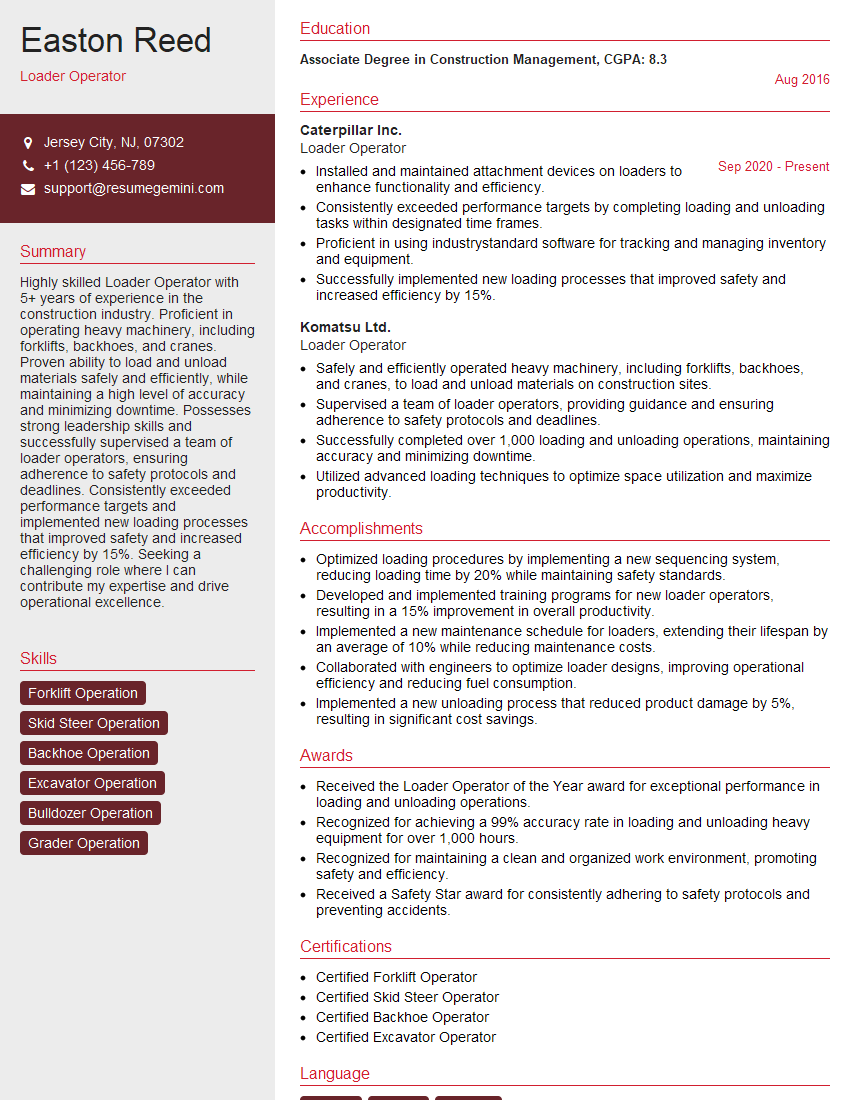

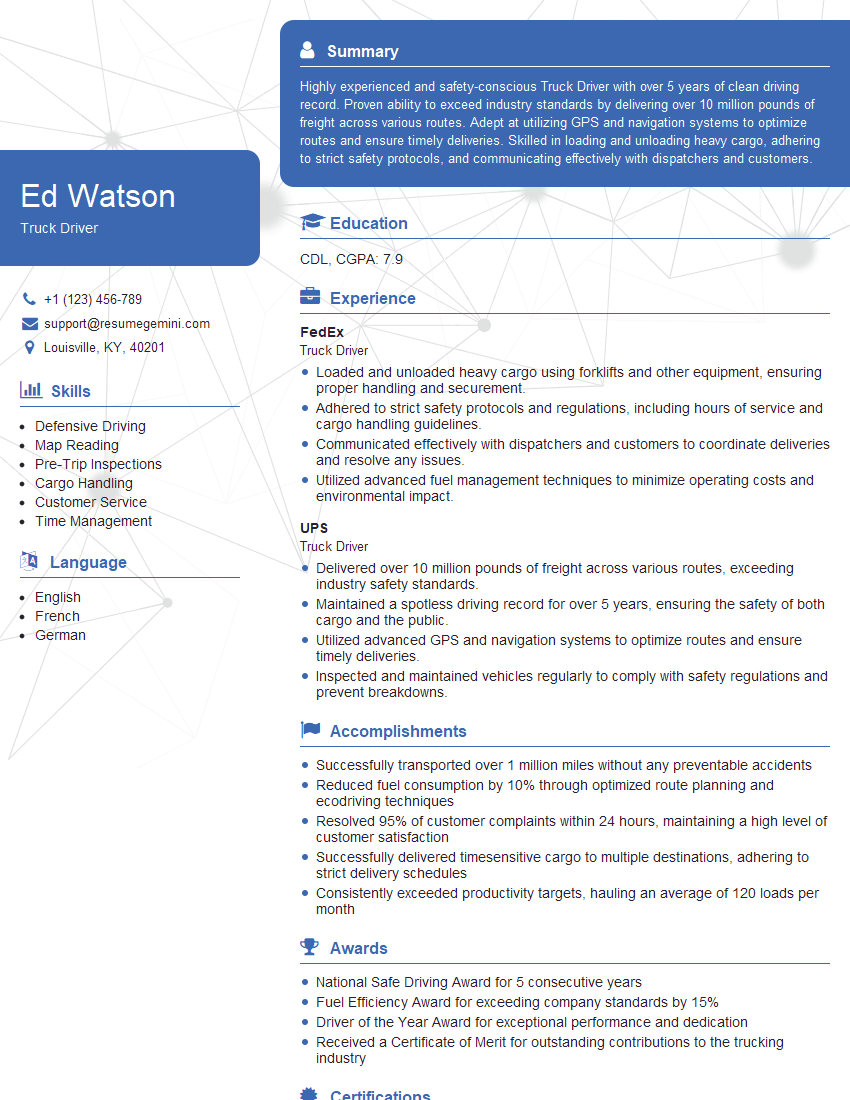

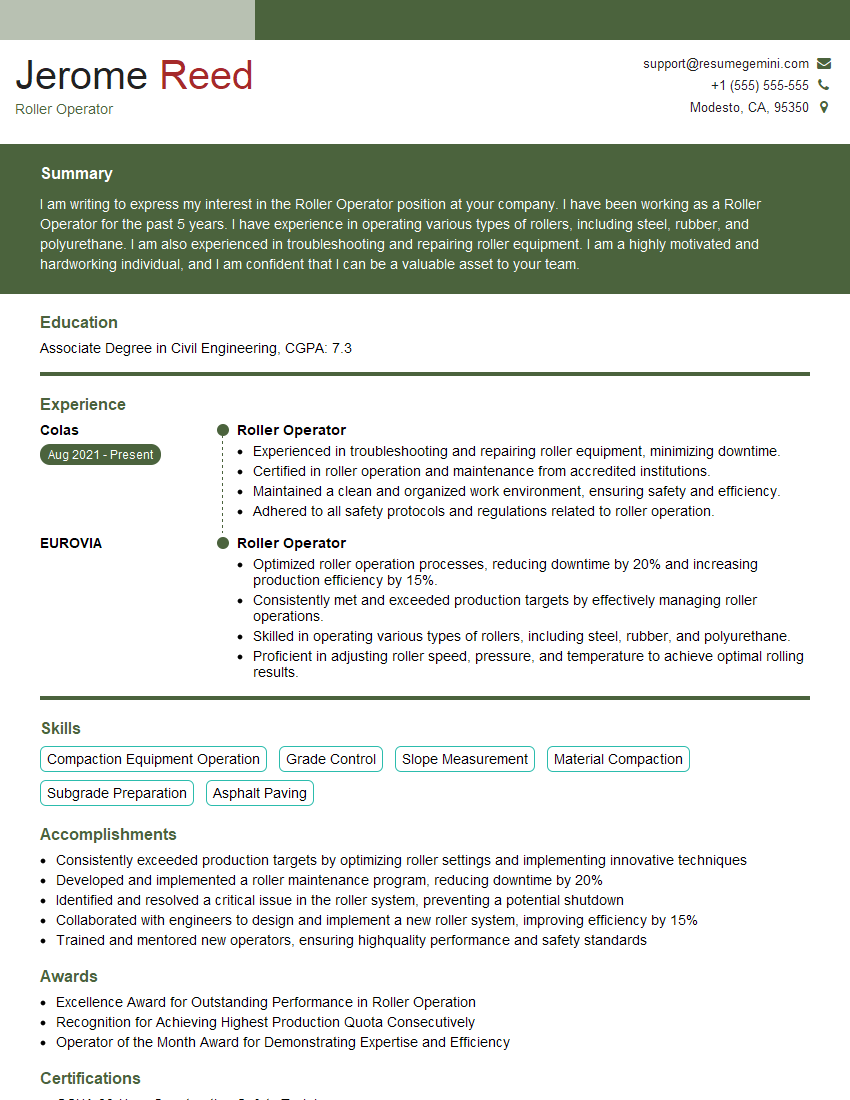

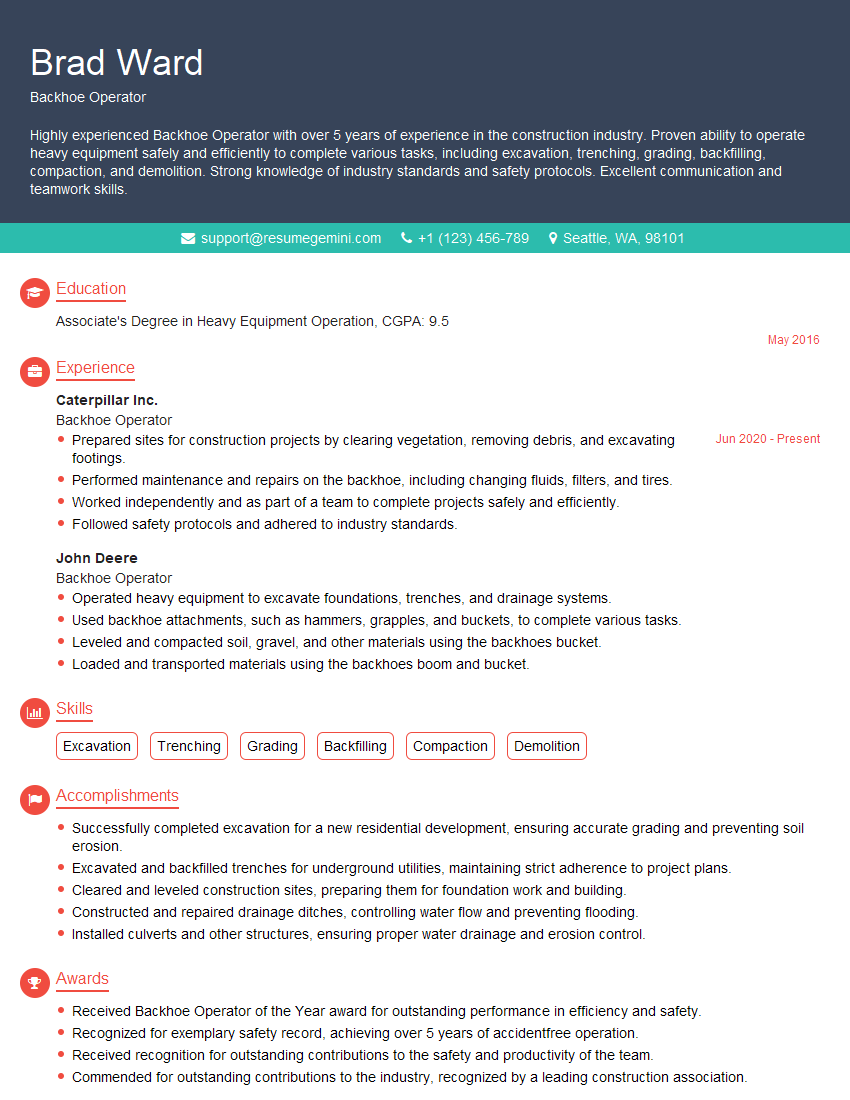

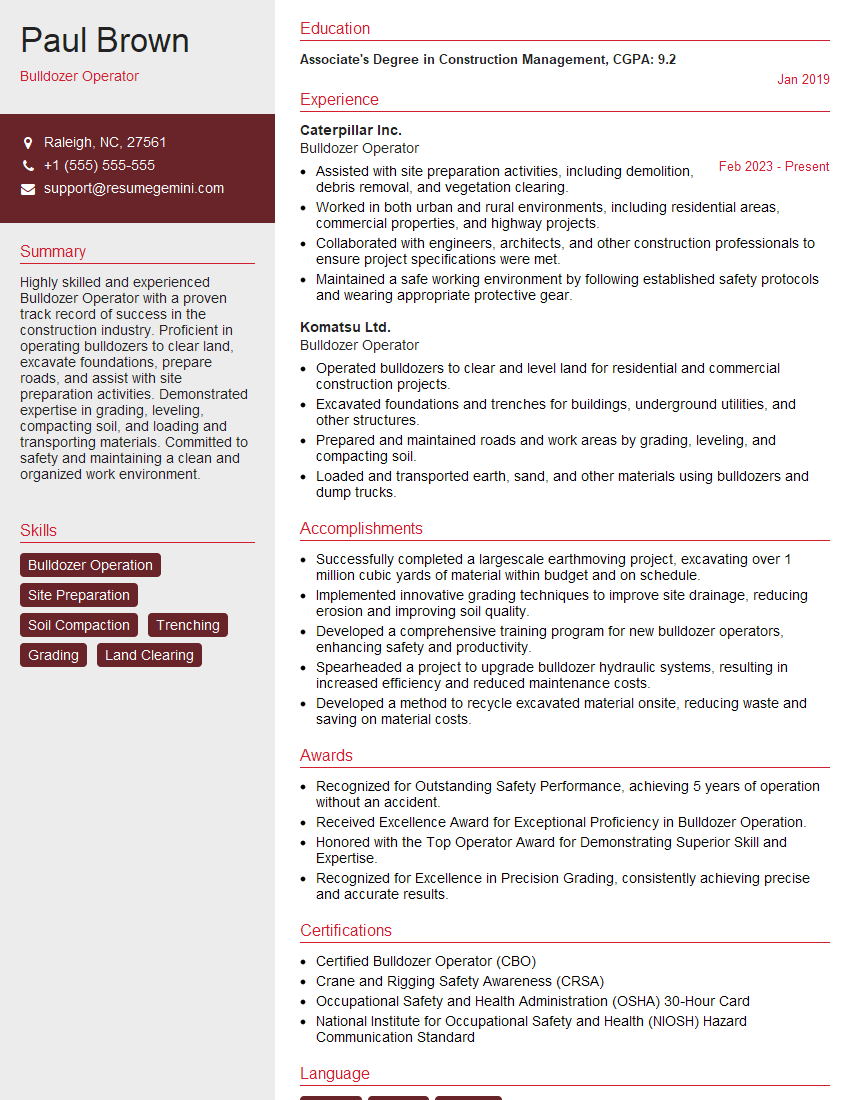

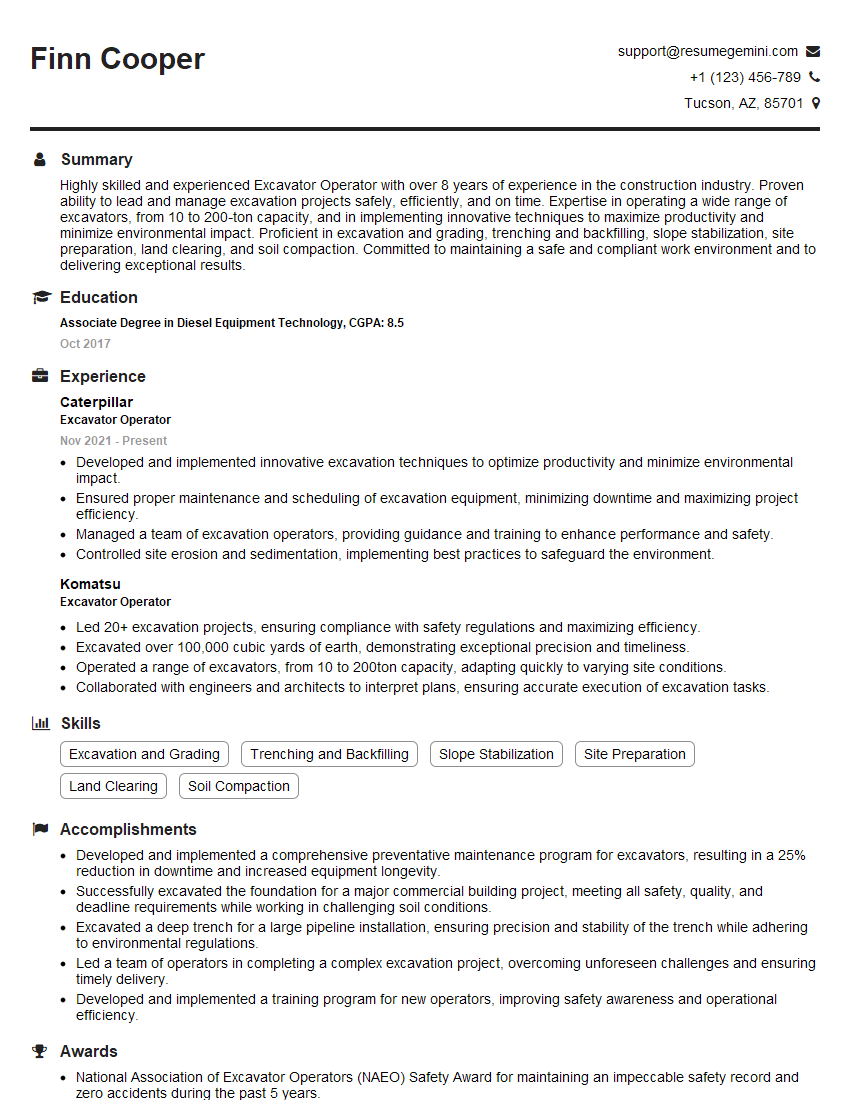

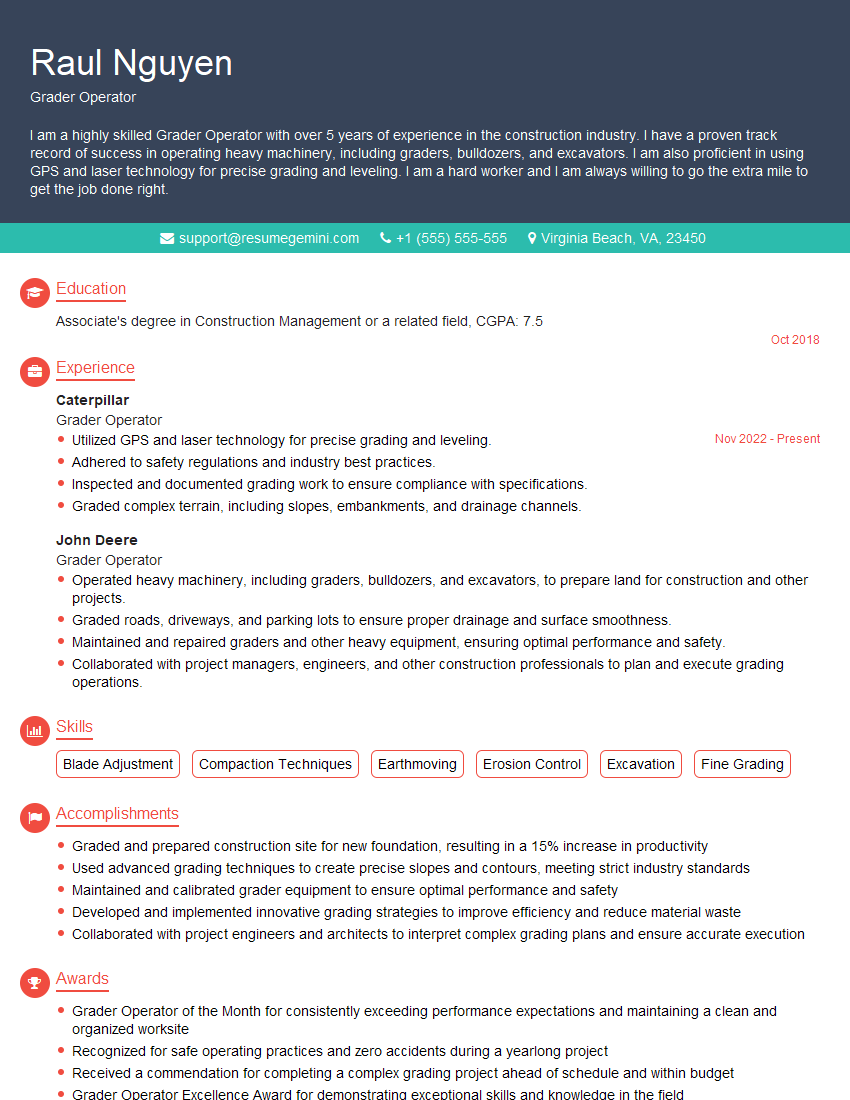

Mastering Truck and Equipment Operation opens doors to a rewarding and diverse career path, offering opportunities for advancement and specialization. A well-crafted resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the demands of the Truck and Equipment Operation industry. Examples of resumes tailored to this field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO