Unlock your full potential by mastering the most common Servo Press Setup interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Servo Press Setup Interview

Q 1. Explain the different types of servo press systems.

Servo press systems are categorized primarily by their control system and drive mechanism. While all utilize a servo motor for precise control, variations exist in their architecture.

- Hydraulic Servo Presses: These combine the power of hydraulics with the precision of servo control. The servo motor regulates the hydraulic pump, offering excellent force control and responsiveness. They are suitable for high-tonnage applications requiring precise force regulation.

- Mechanical Servo Presses: These use a servo motor directly coupled to the press ram through a ball screw or other mechanical linkages. They offer high speed and accuracy but may have limitations in terms of maximum force compared to hydraulic systems. They’re often preferred for high-speed, precision stamping operations.

- Hybrid Servo Presses: These integrate aspects of both hydraulic and mechanical systems. For instance, a servo-controlled hydraulic system might utilize a smaller, more efficient servo motor to regulate a hydraulic system, balancing power and precision.

The choice of system depends heavily on the specific application. For example, a high-speed, low-tonnage operation might favor a mechanical servo press, while a heavy-duty forming application would benefit from a hydraulic servo press.

Q 2. Describe the process of setting up a servo press for a new job.

Setting up a servo press for a new job involves a systematic process. Imagine it like setting up a complex recipe – each step is crucial for the final product.

- Die Selection and Installation: The correct die matching the job’s specifications is paramount. Ensure the die is properly mounted and secured in the press, paying close attention to alignment and parallelism.

- Material Selection and Preparation: The material’s properties (thickness, strength, etc.) directly influence press settings. Ensure the sheet metal is properly sized and free from defects.

- Program Creation and Input: Modern servo presses rely on sophisticated control systems. This step involves creating a program with the specific parameters for the job, including bending angle, tonnage, speed, and stroke length. This is often done through a user-friendly interface on the press control panel. Many presses also use offline programming which allows for offline parameter adjustment and optimization before running on the press itself.

- Test Run and Adjustments: Always start with a test run using scrap material to verify the program’s accuracy and to fine-tune the settings. Monitor the bending process closely and make adjustments to ensure optimal results.

- Production Run: Once satisfied with the test run and the bending quality, initiate the production run. Continuous monitoring is essential to catch any potential issues early on.

Example: When setting up a press for bending 1/8” aluminum, I’d carefully program the correct tonnage based on the bending radius and material properties, ensure die alignment for a clean bend and then test on scrap metal before running the actual job.

Q 3. How do you determine the appropriate tonnage for a specific press brake operation?

Determining appropriate tonnage for a press brake operation requires careful consideration of several factors, it’s not a simple formula. Think of it as finding the right amount of force to gently but firmly bend the metal without causing damage.

- Material Properties: Material tensile strength and yield strength are critical. Stronger materials require higher tonnage.

- Sheet Metal Thickness: Thicker materials naturally require more force to bend.

- Bend Angle and Radius: Sharper bends necessitate more force than gentler ones. A smaller bend radius will require significantly more force.

- Die Geometry: The design of the press brake dies, specifically the die opening and punch nose radius, influences the required tonnage. These geometries impact the distribution of force.

- Safety Factor: Always incorporate a safety factor to account for variations in material properties or unexpected conditions. This ensures you don’t push the press to its absolute limit.

Often, specialized bending force calculation software or formulas are employed, taking these parameters into consideration. Many software packages allow for inputting your metal type and desired bend parameters, and the software automatically computes the required tonnage.

Q 4. What safety precautions are essential when setting up and operating a servo press?

Safety is paramount when working with servo presses. These machines are powerful and can cause serious injury if not handled correctly. Remember, safety is not just a procedure, it’s a mindset.

- Lockout/Tagout Procedures: Always implement proper lockout/tagout procedures before performing any maintenance or adjustments on the press. This prevents accidental activation.

- Personal Protective Equipment (PPE): Wear appropriate PPE including safety glasses, hearing protection, and gloves. Depending on the operation, additional protection might be needed.

- Proper Training: Only trained and authorized personnel should operate or maintain a servo press. Thorough training is crucial.

- Machine Guards: Ensure all safety guards are in place and functioning correctly. Never bypass safety features.

- Emergency Stop Buttons: Know the location and function of all emergency stop buttons. Regular testing of these is important.

- Work Area Safety: Maintain a clean and organized work area to prevent accidents. Ensure adequate lighting and floor space.

A real-world example is a situation where a coworker failed to use the lockout/tagout procedure before performing maintenance. This resulted in an accidental activation, highlighting the importance of strict adherence to safety protocol.

Q 5. How do you calculate bending allowance for sheet metal parts?

Bending allowance is the additional length of material required to compensate for the stretching that occurs during bending. Think of it as the extra material needed to achieve the desired final dimensions after the bend is formed.

There are various formulas for calculating bending allowance, and the most accurate ones often require considering material properties. A simplified formula, suitable for many applications, is:

Bending Allowance = (Bend Radius x Bend Angle in Degrees x π)/180

Where:

- Bend Radius: The radius of the bend in the sheet metal.

- Bend Angle: The angle of the bend in degrees.

However, more precise calculations, which are essential for critical applications, incorporate the material’s K-factor (bend compensation factor). This factor accounts for the material’s elasticity and the way it stretches during the bend. The K-factor varies from material to material and should be sourced from relevant material datasheets.

Example: For a 90-degree bend with a 0.25-inch bend radius, a simplified calculation provides an approximate bending allowance. However, the actual allowance is fine-tuned based on material properties and experience.

Q 6. Explain the role of a die in a servo press.

The die in a servo press plays a crucial role in shaping the workpiece. It’s the defining element in achieving the desired bend or form. Imagine it as the mold in a bakery – it shapes the final product.

- Punch: The top portion of the die which applies the bending force.

- Die: The bottom portion of the die which provides support and guides the forming process.

The die’s design elements directly impact the quality of the bend, and the geometry of both punch and die work in conjunction to create the desired shape and tolerance. Different die designs exist for various bending operations (e.g., V-dies, air bending dies). The die selection and maintenance directly influence the quality and consistency of the produced parts.

Die materials must be selected to resist wear and tear from repeated press cycles. High-quality dies are crucial for minimizing the risk of defects and maintaining production efficiency. Improperly maintained dies can lead to inconsistencies in bending and increased risk of part defects.

Q 7. How do you troubleshoot common servo press malfunctions?

Troubleshooting servo press malfunctions requires a systematic approach. It’s like diagnosing a car problem – you need to methodically check different components.

- Error Codes and Diagnostics: Modern servo presses display error codes that indicate the source of the problem. Consult the machine’s manual to interpret these codes.

- Visual Inspection: Carefully inspect the press for any visible issues like loose connections, damaged components, or material debris.

- Hydraulic System Check (If applicable): For hydraulic servo presses, check oil levels, pressure, and filter condition. Low oil levels or a faulty filter can cause malfunctions.

- Servo Motor and Drive Check: Assess the functionality of the servo motor and its drive system. This may involve checking power supply, feedback signals, and motor encoder functionality. Servo motor diagnostic tools can help isolate the problem.

- Sensor and Limit Switch Check: Verify that all sensors and limit switches are functioning correctly and that their signals are accurately interpreted by the control system. Often, problems in the press originate from problems with these sensors.

- Program Verification: Double-check the press program parameters. Incorrect parameters can lead to unexpected behavior or errors.

For example, if a press suddenly stops mid-cycle, error codes might indicate a fault in the hydraulic system or a problem with a limit switch. Following these steps can allow for prompt identification and effective resolution of the issue.

Q 8. Describe the process of changing a die in a servo press.

Changing a die in a servo press is a crucial process requiring precision and safety. It involves several steps, beginning with ensuring the press is completely powered down and locked out/tagged out for safety. Next, you carefully remove the existing die, typically using a die handling system like a crane or forklift, depending on the die’s weight and size. This is often done using specialized die handling equipment to prevent damage or injury. Once the old die is removed, the new die is meticulously placed in the press, ensuring proper alignment and seating. This involves careful attention to the die’s location, bolts, and alignment pins, often checked multiple times with precision measuring tools. Finally, you thoroughly inspect the new die setup before restarting the press, conducting a trial run with close monitoring to verify correct functionality and safety.

For example, imagine changing a progressive die used for stamping out complex automotive parts. The entire process must be meticulously documented, with before and after photos and alignment checks recorded, to maintain quality control and track any potential issues. The process necessitates careful handling, as improperly aligned dies can cause serious damage to the equipment or produce faulty parts.

Q 9. What are the different types of dies used in servo presses?

Servo presses utilize a variety of dies depending on the application. The choice of die depends largely on the complexity of the part and the material being stamped. Some common types include:

- Progressive Dies: These perform multiple operations in a single pass, significantly increasing efficiency. Imagine a single die creating a complex part like a car door handle in one stroke.

- Compound Dies: They perform two or more operations simultaneously with separate cutting and forming stages, useful for creating intricately shaped parts.

- Combination Dies: These combine blanking and forming operations, offering versatility for different shapes and part geometries.

- Single-Stage Dies: These perform only one operation per stroke, suitable for simpler parts requiring just blanking or forming.

- Transfer Dies: These are used for high-volume production and complex part geometries. Parts are transferred between die stages via mechanical fingers for multiple operations in a single machine cycle.

The selection of the appropriate die is crucial for achieving the desired product quality, efficiency, and cost-effectiveness.

Q 10. How do you perform routine maintenance on a servo press?

Routine maintenance on a servo press is critical for preventing costly breakdowns and ensuring optimal performance. It should be performed regularly according to the manufacturer’s recommendations, often on a daily, weekly, and monthly basis. Daily maintenance can involve visual inspections for leaks, loose bolts, and unusual sounds. Weekly maintenance might include checking lubrication levels and cleaning the press bed and die area. Monthly checks might include more in-depth lubrication and cleaning, inspecting electrical components and hydraulic systems for wear, and testing safety features such as light curtains and emergency stops. Regular preventative maintenance dramatically extends the life of the press and minimizes production downtime. Think of it like regular car maintenance—oil changes, tire rotations, etc.—preventing larger, more costly repairs down the road.

Q 11. Explain the importance of proper lubrication in servo press operation.

Proper lubrication is paramount in servo press operation. It minimizes friction and wear on moving parts, preventing premature failure and ensuring smooth operation. Lubrication reduces heat generation, protects against corrosion, and extends the lifespan of critical components. Insufficient lubrication can lead to increased wear, potential seizures of moving parts, and costly repairs. Imagine trying to run a car engine without oil—catastrophic failure would be likely. Similarly, neglecting lubrication in a servo press can have devastating consequences. Regular lubrication, using the correct type and amount of lubricant specified by the manufacturer, is essential for maintaining the efficiency, reliability, and longevity of the equipment.

Q 12. Describe the process of calibrating a servo press.

Calibrating a servo press involves precisely adjusting the press’s mechanical and electronic systems to ensure accuracy and repeatability. This usually involves checking and adjusting several parameters using specialized tools and software. These include stroke length, tonnage, speed, and positioning accuracy. The process often involves using calibrated gauges and measurement devices and following detailed calibration procedures provided by the manufacturer. For example, verifying the tonnage accuracy might require using a load cell to measure the actual force exerted by the press, compared to the programmed setting. Improper calibration can lead to inconsistent part quality, scrap, and potential machine damage. Precise calibration is essential for maintaining high-quality production and ensuring parts meet the required specifications.

Q 13. How do you interpret a servo press operation manual?

Interpreting a servo press operation manual requires a systematic approach. Start by reviewing the safety precautions carefully, understanding lockout/tagout procedures and emergency shutdown protocols. Next, study the operational sections, focusing on the steps for setting up the die, programming the press parameters (speed, tonnage, stroke), and running the machine. Pay close attention to diagrams, illustrations, and troubleshooting guides. Understanding the meaning of warning symbols and error codes is also critical. Finally, review the maintenance sections, noting recommended lubrication schedules and preventative maintenance steps. The manual should be considered the ultimate guide to your specific servo press’s operation. Regularly referring to it prevents mistakes and ensures safe and efficient operation.

Q 14. What are the key performance indicators (KPIs) for a servo press?

Key Performance Indicators (KPIs) for a servo press are crucial for monitoring efficiency, quality, and overall productivity. Some important KPIs include:

- Overall Equipment Effectiveness (OEE): This measures the percentage of time the press is actively producing good parts.

- Downtime: Tracks the time the press is not operational due to maintenance, repairs, or other issues.

- Production Rate: Measures the number of parts produced per unit of time (e.g., parts per hour).

- Scrap Rate: Indicates the percentage of defective parts produced.

- Energy Consumption: Tracks the amount of energy consumed during operation.

- Die Life: Measures the number of parts produced before the die requires replacement or maintenance.

By tracking these KPIs, manufacturers can identify areas for improvement, optimize production processes, and reduce costs. Regularly analyzing these metrics facilitates data-driven decision-making and process optimization.

Q 15. How do you monitor the performance of a servo press?

Monitoring a servo press’s performance involves a multi-faceted approach, focusing on both mechanical and electrical aspects. Think of it like regularly checking your car’s engine and tires – crucial for optimal performance and longevity.

Production Output: Track parts per minute (PPM) to identify any drop in efficiency. A sudden decrease might indicate a tooling issue or a problem with the press itself.

Part Quality: Regularly inspect the produced parts for dimensional accuracy and surface finish defects. Inconsistencies signal potential problems with the press’s accuracy or the tooling setup.

Energy Consumption: Monitor energy usage over time. Significant spikes can point towards mechanical friction, hydraulic leaks (if applicable), or electrical component failures.

Servo Motor Performance: The servo press control system provides data on motor currents, speeds, and positions. Deviations from the norm can highlight issues with the motor, drive, or feedback system. Look for error codes or warning messages.

Maintenance Logs: Maintain detailed records of all maintenance activities, including lubrication, part replacements, and calibrations. This aids in predictive maintenance and troubleshooting.

By combining these monitoring strategies, you create a comprehensive overview of your servo press’s health and pinpoint potential problems before they cause significant downtime or product defects. For example, a consistent drop in PPM alongside an increase in energy consumption could point towards wear and tear in the press’s mechanical components, requiring timely maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of press brake bending errors?

Bending errors in press brakes, whether servo-electric or hydraulic, stem from several common sources. Imagine baking a cake – if your oven temperature is wrong or your ingredients are measured incorrectly, the result will be flawed. Similarly, inaccuracies in the press brake setup lead to imperfect bends.

Incorrect Bending Angle: This is the most frequent error, often due to inaccurate programming, faulty tooling, or incorrect material thickness input. Using a digital angle gauge for verification is vital.

Material Properties: Variations in material thickness, hardness, or surface quality can affect the bending process. Material inconsistencies can lead to uneven bends, requiring adjustments in bending force and angle.

Tooling Issues: Worn, damaged, or improperly sized tooling is a major contributor. Worn punches and dies result in inconsistent bends and can even damage the material.

Improper Setup: Incorrectly aligned tooling, inadequate clamping force, or insufficient back gauge setting can also lead to bending errors. Proper alignment is crucial and requires meticulous setup procedures.

Machine Calibration: A miscalibrated press brake won’t bend accurately. Regular calibration using precision instruments is non-negotiable.

Troubleshooting these errors requires a systematic approach, involving checking each component individually. For instance, if you are seeing inconsistent bends, check the tooling first, then material consistency, and then machine calibration. A detailed error log helps to track and prevent recurring issues.

Q 17. How do you ensure the safety of personnel during servo press operation?

Safety is paramount when operating a servo press. Think of it like a highly sophisticated, powerful tool – respect is needed. We need to establish a safety culture and follow strict protocols.

Lockout/Tagout Procedures: Strict adherence to lockout/tagout (LOTO) procedures during maintenance or repairs is critical. This prevents accidental activation and ensures the machine is completely safe to work on.

Emergency Stop Buttons: Easily accessible emergency stop buttons should be present throughout the press area. These are lifelines in case of unexpected issues.

Light Curtains and Safety Sensors: These photoelectric sensors create a safety zone around the press. If the zone is broken, the press immediately stops.

Proper Training: Operators must receive comprehensive training on safe operating procedures, including emergency shutdown procedures. Regular refresher courses are recommended.

Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including safety glasses, hearing protection, and sturdy work shoes. Hand protection is particularly important.

Machine Guards and Enclosures: The press should be equipped with appropriate guards and enclosures to prevent accidental contact with moving parts.

Regular safety audits and inspections are necessary to maintain a safe working environment. Think of it as a quality control process for safety. For instance, conducting regular inspections of safety devices and verifying that LOTO protocols are followed correctly prevents accidents before they happen.

Q 18. How do you address unexpected downtime on a servo press?

Unexpected downtime on a servo press is a serious issue, impacting productivity and profitability. It’s like a sudden flat tire on your way to an important meeting; prompt action is key.

Immediate Assessment: First, identify the cause of the downtime. Is it a mechanical failure, an electrical fault, a software glitch, or a tooling issue?

Troubleshooting: Use diagnostic tools and manuals to diagnose the problem. Many modern servo presses provide error codes that can help pinpoint the issue.

Emergency Repairs: If the problem can’t be resolved quickly, contact qualified service technicians. The goal is to minimize downtime.

Preventative Maintenance: A robust preventative maintenance schedule minimizes the likelihood of unexpected failures. This includes regular lubrication, inspections, and part replacements.

Spare Parts Inventory: Maintaining a stock of frequently needed spare parts can significantly reduce repair times.

Remote Diagnostics: Modern presses often offer remote diagnostic capabilities, allowing technicians to assess the problem even when not physically present. This is a significant advantage.

A well-defined emergency response plan speeds up the resolution process and minimizes the impact of downtime. For example, having a dedicated team trained to handle specific problems can get the press back online far quicker. Comprehensive documentation and a well-organized spare parts inventory are crucial for swift recovery.

Q 19. Describe the process of troubleshooting a servo press electrical fault.

Troubleshooting electrical faults in a servo press requires a systematic and cautious approach. It’s like detective work, tracing the problem back to its source.

Safety First: Always follow proper lockout/tagout procedures before attempting any electrical troubleshooting.

Check Error Codes and Messages: The press’s control system likely displays error codes or messages providing clues about the fault’s location.

Visual Inspection: Carefully inspect wiring harnesses, connectors, and components for loose connections, damaged insulation, or burned components. Look for anything out of place.

Voltage and Current Measurements: Use a multimeter to check voltage and current levels at different points in the electrical system. Compare readings to the specifications outlined in the press’s documentation.

Continuity Testing: Check the continuity of wires and components to identify broken circuits. This verifies that the electrical pathways are unbroken.

Component Testing: If necessary, test individual components, such as relays, sensors, and circuit boards, to isolate the faulty component. Sometimes replacing a suspicious component is faster than extensive testing.

Consult Schematics and Manuals: Reference the press’s electrical schematics and manuals to understand the electrical system’s layout and component functions. This allows for targeted troubleshooting.

Documenting each step, along with measurements and observations, is crucial for efficient troubleshooting and future reference. A systematic approach, combined with clear documentation, dramatically improves the speed and accuracy of electrical fault resolution.

Q 20. Explain the difference between hydraulic and servo-electric press brakes.

Hydraulic and servo-electric press brakes differ significantly in their power source, control precision, and energy efficiency. Think of it as comparing a powerful but less precise horse-drawn carriage to a technologically advanced electric car.

Power Source: Hydraulic presses use hydraulic fluid pressurized by pumps to generate force, whereas servo-electric presses use electric motors and precisely controlled servo drives.

Control Precision: Servo-electric presses offer superior control precision and repeatability due to the precise control of the electric motor. This leads to higher accuracy in bending.

Energy Efficiency: Servo-electric presses are generally more energy-efficient than hydraulic presses because they only consume energy during bending. Hydraulic systems lose energy through heat generation.

Maintenance: Servo-electric presses generally require less maintenance compared to hydraulic presses, reducing downtime and costs. Hydraulic systems require frequent oil changes and maintenance of hydraulic components.

Noise Level: Servo-electric presses are significantly quieter than their hydraulic counterparts. Noise is a key factor in workplace environment considerations.

Cost: Initially, servo-electric presses are more expensive than hydraulic presses, but the long-term savings from reduced maintenance and energy consumption can offset this initial investment.

The choice between the two depends on the specific application requirements, budget, and desired level of precision. High-precision applications and those valuing energy efficiency often favor servo-electric presses, while hydraulic presses may still be preferred in some heavy-duty or less precision-demanding applications.

Q 21. How do you handle material handling during servo press setup and operation?

Efficient material handling during servo press setup and operation is crucial for productivity and safety. Think of it as an orchestra – every instrument needs to be in the right place at the right time.

Material Storage: Store materials in an organized and accessible manner, minimizing the time required to retrieve materials for processing. This optimizes the workflow.

Material Feeding Systems: Use automated material handling systems, such as conveyors or robots, to efficiently feed materials to the press. Automation minimizes manual handling and increases efficiency.

Material Staging: Use staging areas to temporarily hold materials before processing. This prevents congestion around the press and ensures a smooth workflow.

Material Handling Equipment: Employ appropriate material handling equipment, such as forklifts, pallet jacks, or cranes, depending on the material’s weight and size. The right tools significantly improve efficiency and safety.

Safety Procedures: Implement safety procedures for material handling, including proper lifting techniques and the use of safety equipment, to prevent accidents and injuries. Safety should always be paramount.

Waste Disposal: Establish a system for collecting and disposing of scrap material, minimizing clutter and environmental impact. Proper waste disposal is part of responsible manufacturing.

A well-planned material handling system minimizes wasted time, improves efficiency, and reduces the risk of workplace accidents. For instance, using automated conveyors to feed material into the press eliminates manual handling, significantly increasing productivity and reducing the potential for worker injury.

Q 22. Describe your experience with different servo press control systems.

My experience encompasses a wide range of servo press control systems, from simpler proportional-integral-derivative (PID) controllers to advanced CNC systems with closed-loop feedback. I’ve worked extensively with systems from major manufacturers like Fanuc, Siemens, and Allen-Bradley. This includes experience with both stand-alone control units and integrated systems that manage the entire press operation, including die protection and part ejection.

For instance, in a recent project involving a high-speed stamping application, we integrated a Fanuc CNC system with a vision system to precisely control the press’s position and speed based on real-time image analysis of the incoming material. This allowed us to maintain extremely tight tolerances and dramatically improve production efficiency. In another case, I worked on troubleshooting a Siemens-controlled press where a faulty sensor was causing inconsistent press strokes. Through systematic testing, I identified the faulty sensor, leading to a rapid resolution and minimal downtime.

Beyond specific brands, I’m adept at understanding the underlying principles of servo press control, including the role of feedback loops in maintaining accuracy and consistency. I can effectively program and troubleshoot various control systems, adapt to new software interfaces, and optimize controller parameters for specific applications.

Q 23. How do you program a servo press for complex bending operations?

Programming a servo press for complex bending operations requires a deep understanding of both the press’s capabilities and the mechanics of bending. It’s not simply a matter of inputting coordinates; it involves careful planning of the bending sequence to minimize springback and ensure the part meets specifications. This often involves breaking down the bending process into smaller, manageable steps.

Typically, I start by using Computer-Aided Design (CAD) software to create a detailed model of the part and define the bend angles and radii. Then, I translate this data into a program that controls the press’s movements, including the press stroke, ram speed, and positioning of the tooling. This often involves the use of specialized software provided by the press manufacturer. For instance, I might use a CAM system to generate the G-code that directly controls the press.

Example G-code snippet (simplified): G90 G01 X100 Y50 F100 ;Rapid move to position

G01 Z-50 F50 ;Press down

G04 P1 ;Pause for 1 second

G01 Z0 F50 ;Press up

G01 X200 Y100 F100 ;Move to next position

Beyond basic movements, more sophisticated programming can incorporate features such as adaptive control, where the press adjusts its actions in real-time based on sensor feedback, compensating for variations in material thickness or springback.

Q 24. What are the advantages of using a servo press compared to a mechanical press?

Servo presses offer several key advantages over mechanical presses, primarily stemming from their precise control over ram motion and force. This results in improved part quality and efficiency.

- Precise Control: Servo presses provide precise control over ram speed, stroke, and force, allowing for accurate bending and forming even for complex parts. Mechanical presses, on the other hand, rely on the momentum of the flywheel and cam mechanism, leading to less precise control and increased wear and tear on the machine.

- Energy Efficiency: Servo presses only consume energy when actively working, whereas mechanical presses continuously run their flywheel, even during idle time. This results in significant energy savings, particularly in high-volume operations.

- Reduced Material Waste: The precise control of a servo press leads to less material waste due to improved accuracy and reduced scrap parts. Inconsistent bending on a mechanical press can cause significant material loss.

- Gentle Bending: Servo presses can execute slow and gentle bending, which is especially important for delicate materials that are prone to cracking or deformation.

- Improved Safety: Many servo presses incorporate advanced safety features such as automatic die protection, reducing the risk of accidents compared to more basic mechanical presses.

Q 25. Describe your experience with preventative maintenance on a servo press.

Preventative maintenance is crucial for maximizing the lifespan and performance of a servo press. My approach follows a structured schedule based on the manufacturer’s recommendations and supplemented by regular visual inspections.

This includes:

- Regular Lubrication: I meticulously lubricate all moving parts, including slides, bearings, and gears, using the correct lubricants recommended by the manufacturer to minimize friction and wear. This often means following a detailed lubrication chart.

- Electrical Inspections: Regular checks of electrical connections, wiring harnesses, and sensors, to ensure that the press’s control systems are in good working order and all the safety circuits are functioning properly.

- Hydraulic System Checks (if applicable): For presses with hydraulic systems, I regularly monitor hydraulic fluid levels, check for leaks, and ensure the hydraulic pump is operating efficiently.

- Mechanical Inspections: I carefully inspect the press’s mechanical components for wear, damage, or misalignment, paying close attention to the ram, slides, and tooling. I often use precision measuring instruments to detect deviations.

- Software Updates: Staying updated with the latest software updates and patches from the manufacturer to improve press performance and address any known bugs.

I maintain detailed records of all maintenance activities, including dates, procedures, and any identified issues. This allows for proactive identification of potential problems before they lead to significant downtime. For example, by tracking the wear rate on specific components through regular measurement, I can predict when replacement is needed.

Q 26. How do you determine the correct bending sequence for complex parts?

Determining the correct bending sequence for complex parts is a critical aspect of successful press brake operation. The goal is to minimize springback and ensure the part’s accuracy. It’s a process that combines experience, engineering principles, and often, trial and error.

My approach starts with analyzing the part’s geometry and material properties in CAD software. Then, I consider the following factors:

- Bend Order: I prioritize bending operations that minimize the impact of subsequent bends on previously formed features. Typically, I start with the bends that are most likely to influence the final shape. Often, this involves simulating the bending process using specialized software.

- Tooling Selection: The right tooling is crucial. I select tooling that minimizes bending radius and springback, while considering the required bend angle and material thickness. Sometimes, custom tooling may be required for very intricate parts.

- Material Properties: The material’s springback characteristics are critical, and accurate prediction necessitates understanding the material’s yield strength and elastic modulus.

- Sequence Simulation: I often use simulation software to predict the final part shape based on the proposed bending sequence and tooling choices. This helps identify potential issues and optimize the process before physical bending commences.

- Iterative Refinement: Often, the initial bending sequence needs refinement. I conduct test bends and use the results to adjust the sequence and tooling until the desired accuracy and tolerances are achieved.

For instance, on a part with multiple bends, starting with the bends that define the overall shape, then adding more detailed bends, is often more efficient and reduces errors.

Q 27. What is your experience with different types of press brake tooling?

My experience with press brake tooling encompasses various types, from standard V-dies and Gooseneck dies to more specialized tooling such as air bending dies and multi-stage dies. I’m familiar with different materials, such as hardened steel, carbide, and polyurethane, each with its own strengths and weaknesses.

I understand the importance of selecting the appropriate tooling for the job. For instance, V-dies are suitable for most standard bending applications, but air bending dies offer advantages when bending thin materials to minimize deformation. For extremely sharp bends, a specialized punch and die combination may be necessary.

Beyond choosing the right type of tooling, I’m adept at maintaining tooling and ensuring it’s properly aligned and maintained. This includes inspecting for wear, damage, and proper alignment. Regular maintenance is crucial to avoid errors and damage to the press. Sharpening or replacing tooling as needed is an integral part of efficient operation.

Furthermore, I have experience working with custom tooling designs, modifying existing dies, and understanding the nuances of tool selection based on material properties and the required tolerances of the final part. Proper tooling selection and maintenance are critical factors in ensuring the accuracy and consistency of the bending process.

Key Topics to Learn for Servo Press Setup Interview

- Understanding Servo Press Mechanics: Grasp the fundamental principles of servo-driven press operation, including the role of servo motors, controllers, and feedback systems.

- Press Setup Procedures: Familiarize yourself with the step-by-step process of setting up a servo press for various jobs, including die setup, material handling, and safety protocols.

- Die Protection and Safety Mechanisms: Understand the importance of safety interlocks, light curtains, and other safety features integrated into modern servo presses. Be prepared to discuss preventative maintenance procedures.

- Troubleshooting and Diagnostics: Develop your skills in identifying and resolving common servo press malfunctions. This includes understanding error codes, using diagnostic tools, and applying problem-solving methodologies.

- Production Optimization: Learn about optimizing press parameters for speed, accuracy, and efficiency. This could involve adjusting press settings based on material properties and job specifications.

- Quality Control and Monitoring: Understand the importance of quality control in servo press operation, including techniques for monitoring and ensuring consistent product quality.

- Programming and Control Systems (if applicable): Depending on the specific press and company, familiarity with PLC programming or other control systems might be beneficial. Explore this aspect if relevant to the job description.

- Material Handling and Feed Systems: Understand how materials are fed into and removed from the servo press and the impact of different feeding methods on productivity and quality.

Next Steps

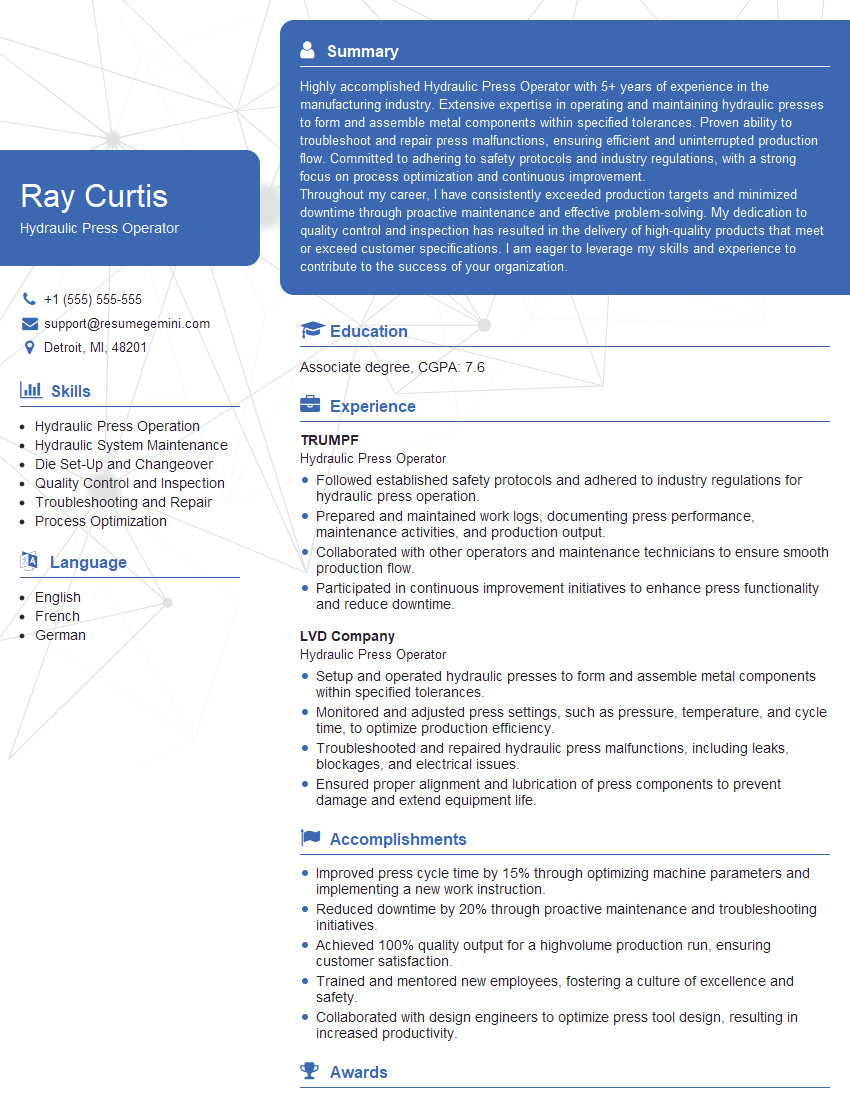

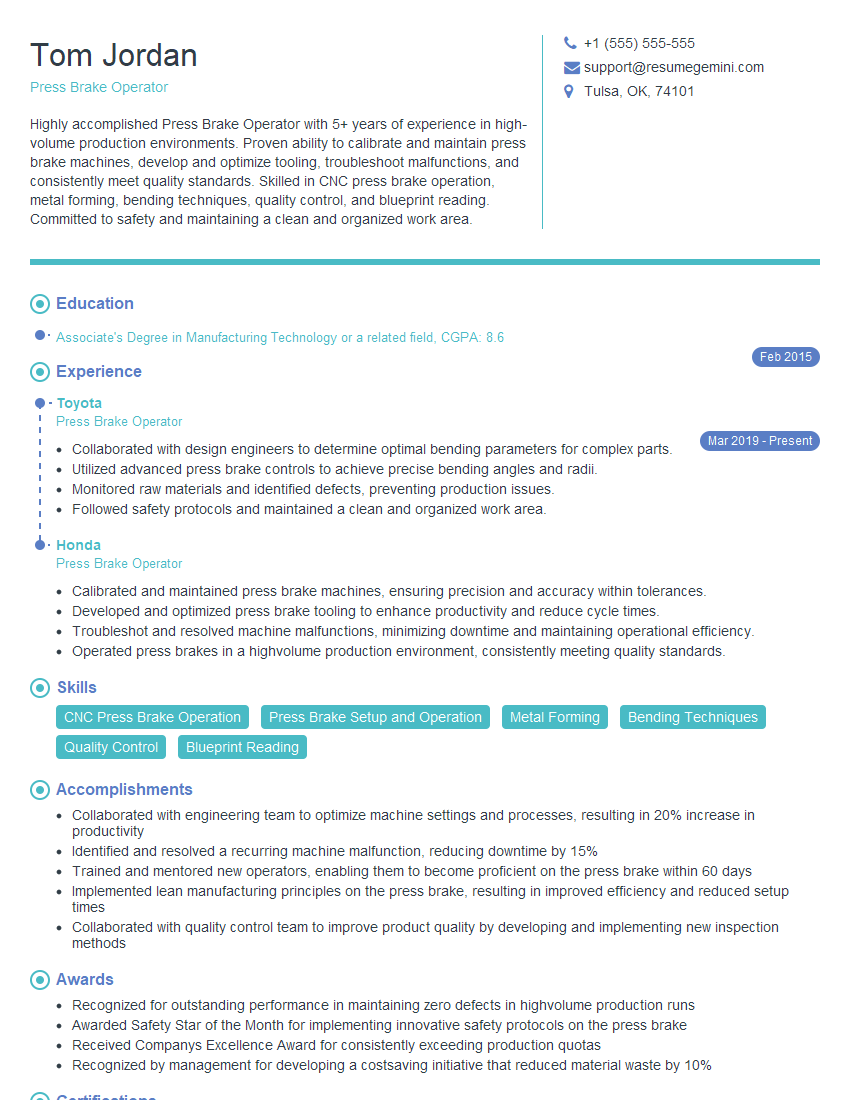

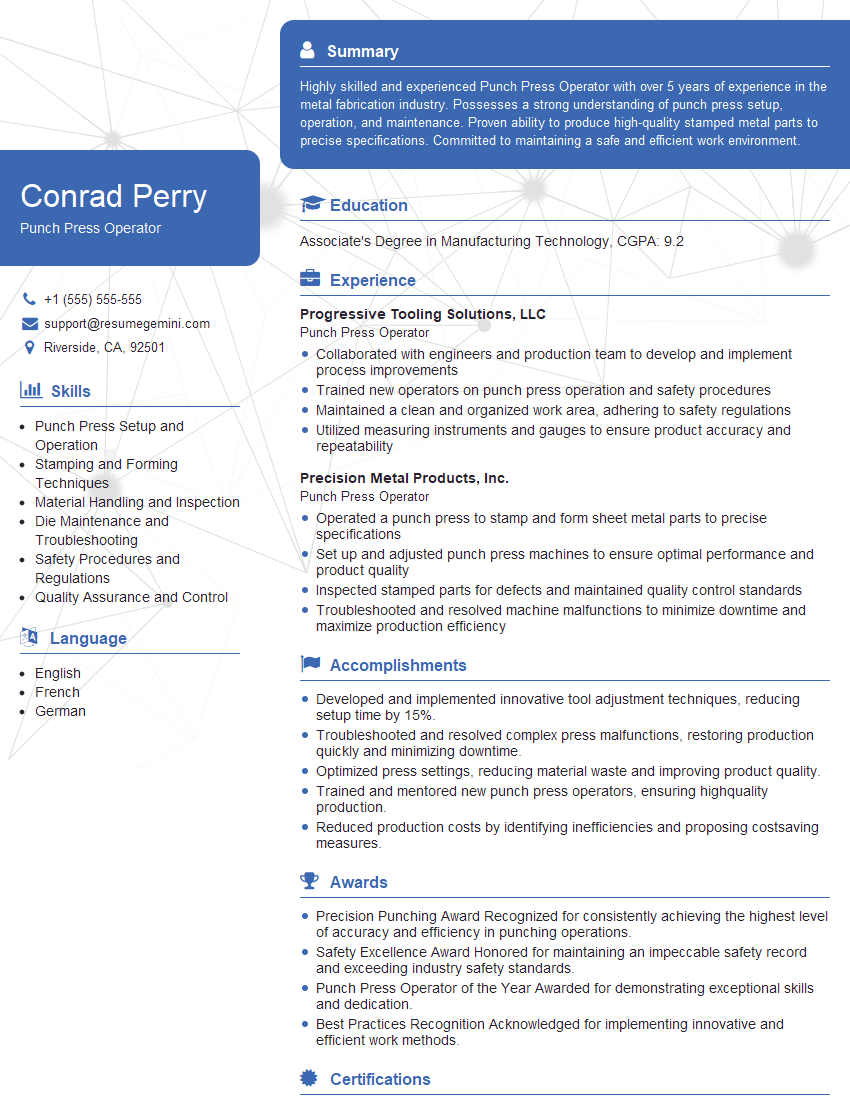

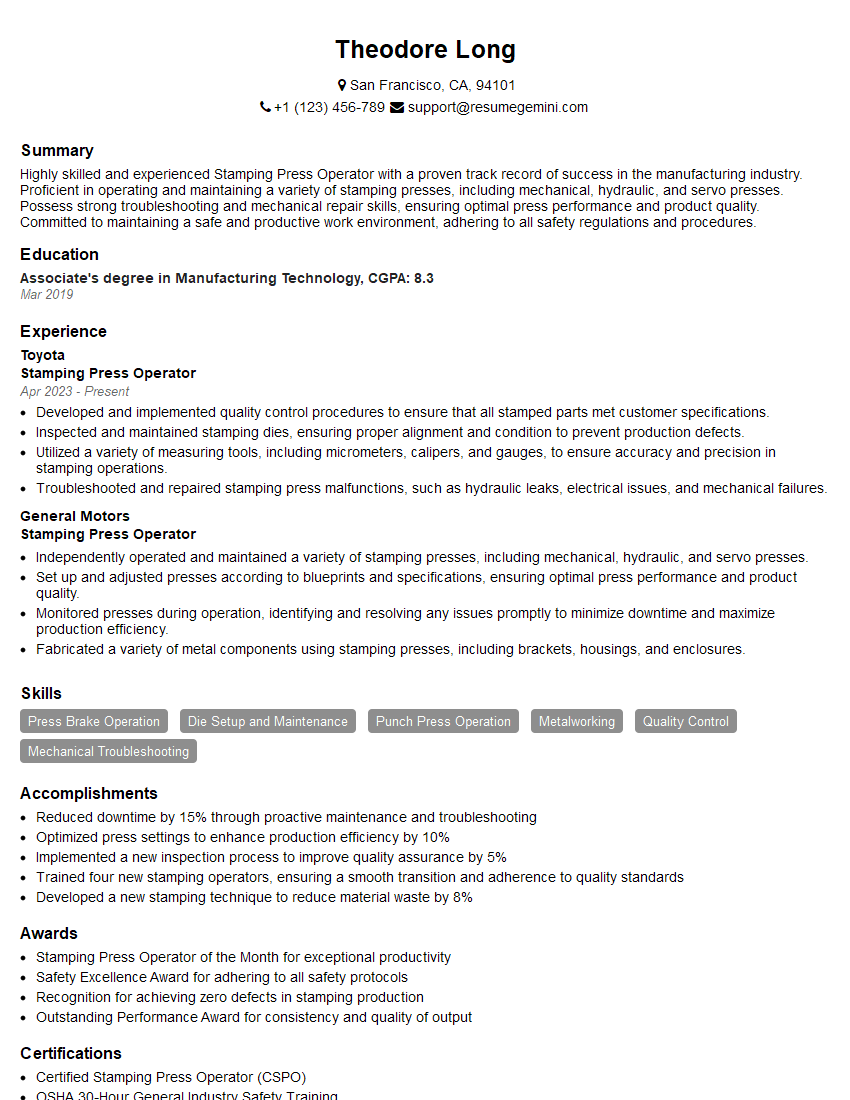

Mastering Servo Press Setup significantly enhances your career prospects within the manufacturing industry, opening doors to higher-skilled roles with increased responsibility and earning potential. A well-crafted resume is crucial for showcasing your abilities to potential employers. Building an ATS-friendly resume is key to ensuring your application gets noticed. We strongly recommend using ResumeGemini to create a professional and impactful resume that highlights your skills and experience in Servo Press Setup. ResumeGemini offers tools and resources to build a standout resume, and examples of resumes tailored to Servo Press Setup are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO