The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Rim sizing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Rim sizing Interview

Q 1. Explain the significance of rim diameter in vehicle performance.

Rim diameter significantly impacts a vehicle’s performance, primarily affecting speed, handling, and speedometer accuracy. A larger diameter rim, combined with the appropriate tire size, increases the overall rolling diameter of the wheel. This means the vehicle travels further with each wheel revolution, potentially resulting in a higher top speed (though this is also dependent on engine power and gearing). However, larger rims can negatively impact acceleration and fuel efficiency, as the engine works harder to turn the larger diameter wheels. The speedometer calibration is directly tied to the rolling diameter; using an incorrect rim size can lead to inaccurate speedometer readings.

Think of it like bicycle wheels: a larger wheel requires less effort to maintain speed on flat ground but might require more effort to accelerate uphill compared to a smaller wheel.

Q 2. What are the common units used to measure rim diameter and width?

Rim diameter and width are typically measured in inches. For example, a rim might be described as 17×7.5, where ’17’ represents the diameter (17 inches) and ‘7.5’ represents the width (7.5 inches). Although millimeters are sometimes used in manufacturing specifications, inches remain the dominant measurement unit in the automotive aftermarket.

Q 3. Describe the relationship between rim width and tire width.

The relationship between rim width and tire width is crucial for optimal performance and safety. The tire should be appropriately matched to the rim’s width. Too narrow a tire on a wide rim can lead to excessive sidewall flexing, reduced handling, and uneven tire wear. Conversely, too wide a tire on a narrow rim can cause the tire to bulge excessively, potentially leading to tire failure at higher speeds and impacting handling. Tire manufacturers provide recommended rim width ranges for their tires; always consult these recommendations to ensure a safe and effective match.

Imagine trying to fit a narrow balloon onto a wide rim—it won’t sit properly. Similarly, a wide balloon on a narrow rim will stretch and potentially burst.

Q 4. How does rim offset affect wheel fitment?

Rim offset refers to the distance between the wheel’s mounting surface and the centerline of the wheel. It determines how far the wheel sits in or out relative to the vehicle’s suspension. A positive offset means the mounting surface is closer to the outside of the wheel, while a negative offset means it’s closer to the inside. Offset significantly influences wheel fitment, affecting clearance with suspension components, brakes, and the fender wells. Incorrect offset can result in rubbing against these parts, leading to damage or requiring modifications such as fender rolling.

Choosing the correct offset is essential for proper wheel fitment and avoids interference with other components. Always check the vehicle’s specifications to ensure the offset is compatible with the wheel and tire assembly.

Q 5. Explain the concept of rim bolt pattern and its importance.

The rim bolt pattern, also known as the lug pattern, specifies the number of lug nuts and the diameter of the circle they form on the wheel. It’s crucial for securing the wheel to the vehicle’s hub. For instance, a 5×114.3 bolt pattern means there are five lug nuts arranged on a circle with a diameter of 114.3 millimeters. Using an incorrect bolt pattern can be extremely dangerous, as it could lead to the wheel detaching from the vehicle while driving.

Think of it like a screw and its corresponding hole. The wrong screw won’t fit and won’t provide a secure hold. Similarly, a mismatched bolt pattern is a safety hazard.

Q 6. What are the consequences of using an incorrectly sized rim?

Using an incorrectly sized rim can lead to several problems. Incorrect diameter can affect speedometer accuracy, handling, and acceleration. A mismatched rim width can cause uneven tire wear, reduced handling, and increased risk of tire failure. An incorrect offset can lead to rubbing against suspension components, brakes, or fender wells, potentially causing damage. Finally, a wrong bolt pattern could lead to wheel detachment – a catastrophic failure with potentially fatal consequences.

Q 7. How do you determine the appropriate rim size for a specific vehicle?

Determining the appropriate rim size for a specific vehicle involves several steps:

- Consult the vehicle’s owner’s manual: This will provide the factory-recommended rim sizes and specifications.

- Check the existing wheels and tires: The current setup provides a starting point.

- Consider aftermarket options: Many aftermarket wheels are available, but always verify their compatibility with your vehicle using fitment guides or consulting a tire specialist.

- Verify offset, bolt pattern, and center bore diameter: These must match your vehicle’s specifications. Incorrect values will prevent proper installation or cause damage.

- Check for clearance: Even if the specifications match, ensure there’s sufficient clearance with suspension components, brakes, and fender wells.

Using online fitment guides can greatly simplify this process, but always double-check the information with a reliable source.

Q 8. What are the different types of rim materials and their properties?

Rim materials significantly impact a wheel’s performance, weight, and durability. The most common types are aluminum (cast and forged), steel, and magnesium.

- Aluminum: Lightweight, strong, and relatively inexpensive, making it popular for most vehicles. Cast aluminum is more cost-effective, while forged aluminum offers superior strength and fatigue resistance.

- Steel: Durable and heavy, often used in heavy-duty vehicles or situations requiring extreme strength. They are generally less expensive than aluminum but significantly heavier.

- Magnesium: The lightest option, offering exceptional strength-to-weight ratio. However, magnesium rims are expensive and require specialized handling due to their susceptibility to corrosion.

The choice of material depends heavily on the vehicle’s application and the desired performance characteristics. A lightweight sports car might benefit from magnesium or forged aluminum, while a heavy-duty truck might use steel for its robustness.

Q 9. Explain the difference between a cast aluminum rim and a forged aluminum rim.

The primary difference between cast and forged aluminum rims lies in their manufacturing process, which directly impacts their properties.

- Cast Aluminum: Molten aluminum is poured into a mold. This process is relatively inexpensive but results in a less structurally sound rim. Cast aluminum rims are more prone to cracking under stress compared to forged ones.

- Forged Aluminum: A solid block of aluminum is shaped under immense pressure. This forging process strengthens the aluminum’s grain structure, resulting in a significantly stronger and more durable rim. They are better able to withstand impacts and fatigue.

Think of it like this: casting is like making a sandcastle – relatively easy but fragile. Forging is like sculpting a statue from a solid block – more labor-intensive but yields a far more robust end product. Forged aluminum rims are generally preferred for performance vehicles due to their increased strength and reduced risk of failure.

Q 10. How do you identify a damaged or worn rim?

Identifying damaged or worn rims requires careful inspection. Look for:

- Bends or cracks: These can weaken the structural integrity of the rim, potentially leading to failure.

- Scratches and gouges: Deep scratches can compromise the rim’s structural strength, while shallow scratches might be primarily cosmetic.

- Corrosion: Rust or pitting weakens the metal and compromises its strength.

- Curb rash: Damage to the rim’s outer edge from hitting a curb.

- Flat spots: Indications of a significant impact.

- Leaks: A slow leak or significant air loss indicates a compromised rim seal.

Any of these issues can significantly compromise the rim’s safety and performance; even seemingly minor damage warrants careful evaluation by a professional.

Q 11. Describe the process of visually inspecting a rim for damage.

Visually inspecting a rim for damage is crucial for safety. Here’s a systematic approach:

- Rotate the rim: Carefully turn the wheel to observe all sides thoroughly.

- Inspect the wheel face: Look closely for bends, cracks, scratches, and gouges.

- Check the inner and outer wheel lips: These areas are particularly susceptible to damage.

- Examine the valve stem area: Ensure there are no cracks or damage to the valve stem’s mounting point.

- Check for corrosion: Look for signs of rust or pitting, particularly around bolt holes.

- Measure the rim diameter and width: Compare these measurements to the manufacturer’s specifications (see questions 6 & 7).

Using a bright light can help to highlight any imperfections. Remember, any doubt necessitates professional inspection.

Q 12. What safety measures should be taken when working with rims?

Safety is paramount when working with rims. Always:

- Wear appropriate safety gear: Safety glasses, gloves, and closed-toe shoes are essential to prevent injury from sharp edges or debris.

- Use proper lifting techniques: Rims can be heavy; always use a jack and jack stands for safe handling.

- Work in a well-ventilated area: When working with cleaning solvents or chemicals, ensure adequate ventilation.

- Dispose of hazardous waste properly: Follow local regulations for disposing of solvents and other hazardous materials.

- Never work on rims with the vehicle parked on an incline: Ensure the vehicle is on a level surface before undertaking any maintenance.

Remember that a damaged rim can pose a significant safety risk; taking precautions prevents accidents.

Q 13. How do you measure rim diameter accurately?

Accurately measuring rim diameter involves measuring the distance across the rim’s bead seat, which is the surface where the tire bead rests. Use a flexible tape measure.

- Locate the bead seat: This is the flat, circular surface on the inside of the rim.

- Measure across the bead seat: Extend the tape measure across the bead seat, ensuring it passes through the center of the rim.

- Record the measurement: Note the measurement in inches or millimeters.

The diameter measurement, typically expressed in inches (e.g., 17″, 18″), is crucial for selecting the correct tires.

Q 14. How do you measure rim width accurately?

Rim width refers to the distance between the bead seats, measured at the widest point of the rim. Again, use a flexible tape measure.

- Locate the bead seats: Find the two bead seats on the inside of the rim.

- Measure between the bead seats: Place the tape measure across the widest part between the bead seats.

- Record the measurement: Note the measurement in inches or millimeters.

Rim width (e.g., 7″, 8″, 9″) is critical for proper tire fitment; selecting an incorrect width can impact handling, tire wear, and even safety.

Q 15. Explain how to interpret rim specifications found on the rim itself.

Rim specifications are crucial for ensuring tire compatibility and vehicle safety. They’re usually stamped directly onto the rim itself, often on the inner or outer surface. You’ll typically find information such as:

- Diameter (e.g., 17″): This is the overall diameter of the rim, measured in inches.

- Width (e.g., 7J): Indicates the rim’s width, measured in inches (J signifies the rim profile, affecting its shape).

- Bolt Pattern (e.g., 5×114.3): Specifies the number of lug holes and the diameter of the circle passing through their centers, measured in millimeters. This is crucial for proper wheel mounting.

- Offset (e.g., ET45): The distance between the mounting surface of the wheel and the centerline of the rim. A positive offset means the mounting surface is closer to the inside of the wheel, while a negative offset moves it towards the outside.

- Load Rating (e.g., 1000 kg): The maximum weight the rim can safely support. This is often represented by a numerical code and needs to be referenced in a load rating chart.

For example, a rim marked “17x7J ET45 5×114.3” has a 17-inch diameter, 7-inch width, 45mm offset, a 5-lug pattern with a bolt circle diameter of 114.3mm.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper tire bead seating on a rim?

Proper tire bead seating is essential for safety and optimal performance. Inadequate seating can lead to tire failure. Here’s how to ensure it:

- Inflation: Use a high-quality tire pressure gauge to inflate the tire to the pressure specified on the tire sidewall. Begin slowly, monitoring for seating. Don’t overinflate.

- Visual Inspection: Carefully check if the tire bead is fully seated on the rim’s bead seat. The bead should sit evenly and firmly in the groove. Look for any bulging or misalignment.

- Bead Seater (Optional): For stubborn tires, a bead seater tool can assist in getting the bead seated correctly. Never attempt to force the bead without the right tool.

- Professional Assistance: If you’re unsure, take your vehicle to a professional tire installer. They have the expertise and tools to seat tires properly.

Think of it like snapping a lid onto a jar – it needs to be seated securely to ensure a proper seal. Incorrect seating can lead to air leaks and potential safety hazards.

Q 17. What are the implications of incorrect tire pressure on rim integrity?

Incorrect tire pressure significantly impacts rim integrity. Underinflation causes the tire sidewall to flex excessively, putting increased stress on the rim. This can lead to rim bending or cracks over time, especially at high speeds or during impacts. Conversely, overinflation can cause the tire to bulge outwards, potentially exceeding the rim’s stress limit. It also increases the risk of tire damage and a sudden blowout.

Imagine a balloon: underinflating it weakens it and makes it prone to bursting, while overinflating it could make it rupture unexpectedly. Similar stress impacts apply to the tire and rim relationship. Always maintain proper tire pressure as specified by the vehicle manufacturer.

Q 18. Explain the role of rim offset in vehicle handling.

Rim offset plays a crucial role in vehicle handling and stability. It influences the position of the wheel relative to the vehicle’s chassis. A positive offset places the wheel closer to the car’s body, while a negative offset pushes it outward. This affects:

- Tracking and Steering Responsiveness: Offset directly impacts the wheel’s position within the wheel well. Altering the offset might improve steering feel, but extreme changes can negatively affect handling and stability.

- Wheel Clearance: Negative offsets can result in tire rubbing against the fenders or suspension components, especially during turns or with larger tires. Positive offsets increase clearance.

- Vehicle Stance: The offset affects the overall look and stance of the vehicle. Different offsets can provide a wider or narrower track width.

Imagine it like adjusting the angle of a caster wheel – a small change can significantly impact the direction and stability.

Q 19. Describe the impact of rim weight on vehicle performance.

Rim weight directly impacts vehicle performance. Heavier rims increase unsprung mass, which is the weight of the components that are not supported by the suspension (wheels, tires, brakes). A higher unsprung mass:

- Reduces Fuel Efficiency: It requires more energy to accelerate and decelerate the heavier wheels.

- Decreases Handling Responsiveness: Heavier unsprung mass makes the vehicle less agile and more prone to body roll, reducing handling precision.

- Increases Tire Wear: The increased inertia can lead to more rapid tire wear.

- Impacts Ride Quality: Heavier wheels can make the ride harsher by transmitting more road imperfections to the chassis.

Choosing lighter rims, where possible, improves performance by reducing unsprung mass, similar to how a lighter bicycle is easier to accelerate and handle.

Q 20. How do you identify a rim’s load rating?

A rim’s load rating indicates the maximum weight it can safely support. This is usually found stamped on the rim itself, though sometimes indirectly through a part number that must be referenced against the manufacturer’s charts. It’s essential to select rims with a load rating that exceeds the weight of the vehicle, including passengers and cargo.

For example, a rim might have a load rating of 1000 kg printed directly on it or be identified by a part number that indicates a load capacity in manufacturer documentation. Selecting a rim with insufficient load rating could lead to dangerous rim failure.

Q 21. What is the importance of rim balance in vehicle safety?

Rim balance is paramount for vehicle safety and comfort. An unbalanced rim causes vibrations at various speeds, impacting:

- Tire Wear: Uneven weight distribution leads to premature and uneven tire wear.

- Steering Stability: Vibrations can make the steering wheel feel shaky, especially at higher speeds, leading to poor handling.

- Vehicle Damage: Prolonged imbalance can cause stress on suspension components, steering linkages, and even the vehicle frame.

- Driver Fatigue & Comfort: Vibrations from imbalanced rims can be annoying and contribute to driver fatigue.

Imagine a spinning top: an unbalanced top wobbles and falls. Similarly, an unbalanced wheel leads to instability and can create hazardous driving conditions. Regular wheel balancing is crucial for safety and extends the life of your tires and vehicle components.

Q 22. Explain the process of balancing a wheel and tire assembly.

Wheel and tire balancing is crucial for a smooth and safe ride. An unbalanced wheel causes vibrations, which can damage your vehicle’s suspension, steering components, and even lead to premature tire wear. The process aims to distribute the weight evenly around the wheel and tire assembly, minimizing vibrations.

The process typically involves two steps: static balancing and dynamic balancing. Static balancing addresses the overall imbalance of the wheel and tire, while dynamic balancing accounts for imbalances in the rotation of the wheel.

Static Balancing: The wheel is mounted on a balancing machine. The machine spins the wheel and identifies the heaviest point. Small weights (stick-on weights) are then added to the opposite side of the wheel to counteract the imbalance. This is a simpler process, often sufficient for smaller wheels.

Dynamic Balancing: This method is more precise and essential for larger diameter wheels and higher speeds. The balancing machine identifies both the static and dynamic imbalances. Weights are added to both the inside and outside of the wheel rim to balance the rotation and reduce vibrations. The machine precisely calculates the weight and placement for optimal balance.

In practice, a technician will mount the tire on the wheel, then use the balancing machine to determine the necessary weights. They carefully attach the weights to the rim and then re-check the balance. This ensures a smooth, safe, and comfortable driving experience.

Q 23. What are the common causes of rim damage?

Rim damage is unfortunately common, stemming from various sources. Think of it like this: your rim is constantly taking a beating from the road.

- Potholes and Curbs: Impacts from potholes or hitting curbs are the most frequent culprits, leading to bending, cracking, or even breaking the rim.

- Sidewalk Impacts: Driving over a sidewalk or curb can easily bend the rim, compromising its structural integrity and potentially leading to leaks.

- Road Debris: Sharp objects like rocks or metal fragments can damage the rim, causing scrapes, gouges, or punctures.

- Corrosion: Over time, especially in areas with harsh winters or salty environments, corrosion can weaken the rim, leading to cracks or pitting.

- Improper Mounting/Dismounting: Incorrect tire mounting or dismounting techniques by inexperienced mechanics can damage the rim’s bead seat, causing leaks or weakening the structure.

- Vehicle Accidents: Significant impacts during accidents often lead to severely bent or broken rims.

It’s essential to regularly inspect your rims for any signs of damage to avoid further problems and ensure safety.

Q 24. Describe the repair process for a bent or damaged rim.

Repairing a bent or damaged rim depends on the severity of the damage. Minor bends can often be repaired, while severe cracks or breaks usually require replacement.

Repairing Minor Bends: A specialized rim repair shop uses a hydraulic press or a similar machine to carefully straighten the bent area. This process requires precision to restore the rim’s original shape and ensure it’s structurally sound. The rim is then inspected for cracks or other damage and is checked for roundness and trueness.

Repairing Cracks: Depending on the location and size of a crack, welding or specialized rim repair epoxy may be used. However, this is typically only attempted on less severe cracks, with the success rate varying significantly based on the nature and extent of damage.

Important Note: After any repair, the rim should be thoroughly inspected, balanced, and road-tested to ensure it’s safe for use. A poorly repaired rim can be dangerous and lead to accidents.

Q 25. How do you determine if a rim is repairable or needs replacement?

Determining repairability depends on several factors, most importantly the extent and location of the damage:

- Minor bends: Usually repairable.

- Severe bends: May be repairable but often requires significant work, potentially making it uneconomical.

- Cracks: Small cracks might be repairable, but larger or structural cracks generally necessitate replacement.

- Breaks: A broken rim is almost always beyond repair and needs replacement.

- Curb Rash: This cosmetic damage is generally repairable with a combination of repair methods, including filling and repainting. However, structural integrity should be checked if the rash is severe.

Cost-Benefit Analysis: A crucial element of the decision is a cost-benefit analysis. The cost of repair should be compared to the cost of a replacement rim. If the repair costs exceed a significant portion (often more than 50%) of the replacement cost, replacement is usually the wiser and safer choice. The safety risk associated with a poorly repaired rim must also always be considered.

Q 26. Explain the different methods of mounting and dismounting tires from rims.

Mounting and dismounting tires from rims require specialized equipment and expertise. Improper techniques can easily damage both the tire and the rim.

Methods:

- Tire Mounting Machine: This is the standard method used by professionals. The machine uses a combination of clamps, levers, and inflation to seat the tire bead onto the rim.

- Hand Methods (for smaller wheels): Although less common, experienced individuals may utilize hand tools such as tire irons to carefully mount and dismount tires. This method requires significant skill and experience to avoid damage.

Safety Precautions: Safety is paramount. Always use the correct tools, ensure the tire is properly lubricated, and work in a safe area. Avoid using excessive force, as this can easily damage the rim or the tire. The process should be performed by trained individuals to prevent accidents or damage.

Q 27. How do you choose the correct size and type of wheel lug nuts or bolts?

Selecting the correct wheel lug nuts or bolts is critical for safety and proper wheel attachment. Incorrect lug nuts can lead to wheel detachment and serious accidents.

Factors to consider:

- Thread Size and Pitch: This is the most important factor. The lug nuts or bolts must match the thread size and pitch of the wheel studs. Incorrect threads can lead to stripped threads or improper fastening.

- Length: The lug nuts or bolts must be long enough to securely engage the wheel studs and provide sufficient clamping force. Too short will not properly secure the wheel; too long might interfere with braking components.

- Material: Steel is the most common material but you may find alloy steel or even lighter materials like titanium, offering varying strengths.

- Head Type: The head of the lug nut determines the socket size required for tightening. Common types include cone seat, ball seat, and tapered seat.

Vehicle’s specifications: Always refer to your vehicle’s owner’s manual for the correct lug nut specifications. Using incorrect hardware can compromise safety.

Key Topics to Learn for Rim Sizing Interview

- Understanding Rim Dimensions: Learn the various methods for measuring rim diameter, width, and offset. Understand the significance of each dimension in wheel fitment and vehicle performance.

- Rim Construction and Materials: Familiarize yourself with different rim materials (aluminum, steel, etc.), their properties, and how they influence strength, weight, and cost. Explore various construction techniques and their impact on durability.

- Rim Standards and Certifications: Study relevant industry standards and certifications related to rim safety and performance. Understand how these standards ensure compatibility and safety.

- Wheel and Tire Combinations: Develop a strong understanding of the relationship between rim size and tire size. Learn how to calculate appropriate tire sizes for different rims and vehicle applications. This includes aspects like aspect ratio and load index.

- Practical Application: Practice calculating rim size requirements based on vehicle specifications and tire size. Understand how to identify compatible rim and tire combinations from manufacturer data.

- Troubleshooting and Problem Solving: Be prepared to discuss common problems encountered in rim sizing, such as incorrect fitment, wheel imbalance, and potential safety hazards. Practice identifying and resolving these issues.

- Advanced Concepts (for senior roles): Explore advanced topics such as custom rim design, finite element analysis of rim structures, or the impact of rim design on vehicle handling and braking performance.

Next Steps

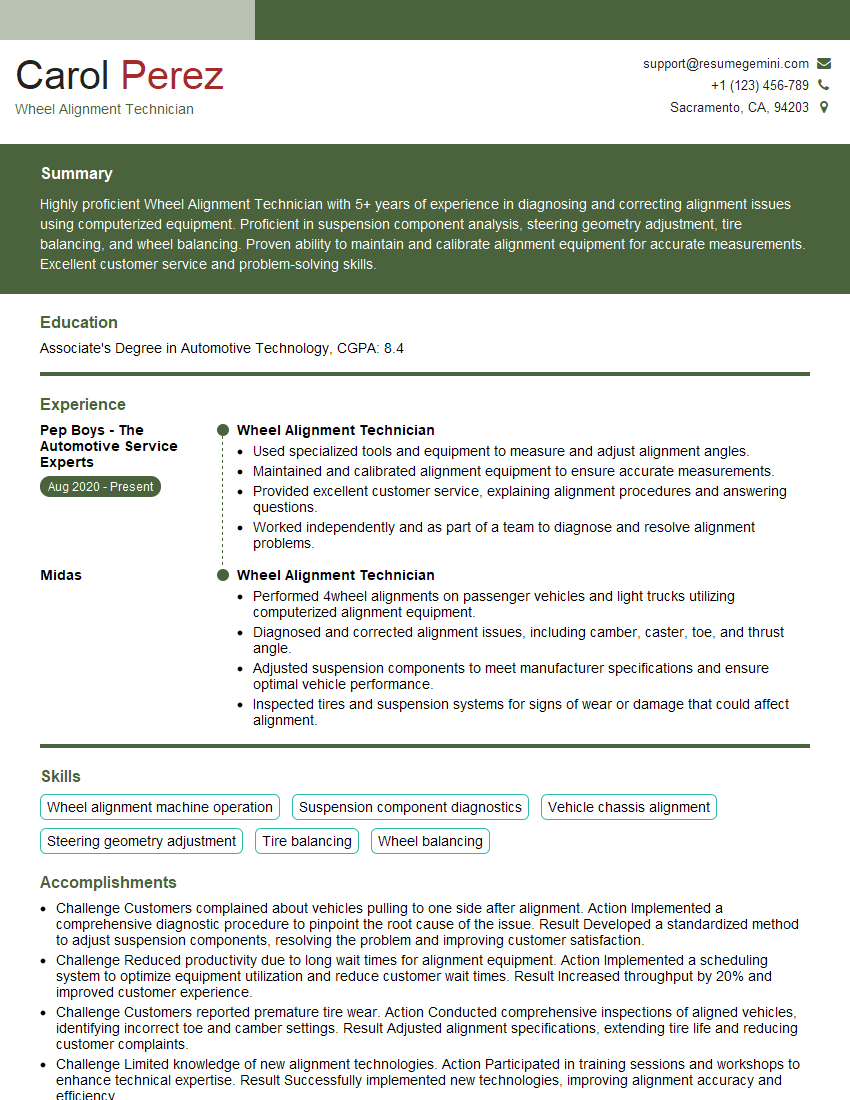

Mastering rim sizing is crucial for career advancement in the automotive and related industries. A strong understanding of these concepts opens doors to specialized roles and increased earning potential. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your qualifications are showcased to potential employers. Examples of resumes tailored to Rim Sizing expertise are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO