Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Timber Harvesting Operations Management interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Timber Harvesting Operations Management Interview

Q 1. Describe your experience with different harvesting methods (clearcutting, selective cutting, etc.).

My experience encompasses a wide range of timber harvesting methods, each tailored to specific forest conditions and management objectives. Clearcutting, while sometimes controversial, is highly efficient for establishing even-aged stands of fast-growing species like pines. It involves removing all trees from a designated area, allowing for rapid regeneration and cost-effective replanting. However, it can have significant impacts on biodiversity and soil erosion if not carefully planned and executed, requiring meticulous site preparation and post-harvest management.

Selective cutting, on the other hand, focuses on removing individual trees or small groups, leaving the majority of the stand intact. This method is ideal for maintaining biodiversity, preserving forest structure, and promoting the growth of high-value species. While more labor-intensive and potentially more expensive, it minimizes environmental disruption and offers a more sustainable approach. I’ve also worked extensively with shelterwood cutting, where a series of harvests are conducted over time, leaving enough mature trees to provide shade and seed for regeneration. This approach is especially useful for shade-tolerant species.

Finally, I have experience with thinning operations, which focus on removing smaller, less desirable trees to improve the growth and quality of the remaining trees. This method helps to maximize timber yield while promoting forest health and resilience. Each method requires a thorough understanding of the forest ecosystem, tree species, and site-specific factors to ensure optimal results and minimize environmental impacts.

Q 2. What safety protocols do you implement to ensure worker safety during timber harvesting operations?

Worker safety is my paramount concern. I implement a comprehensive safety program that includes pre-harvest planning, daily safety briefings, and rigorous adherence to all applicable regulations. This begins with thorough site assessments to identify and mitigate potential hazards like unstable terrain, overhead hazards, and proximity to power lines. We use pre-shift safety meetings to communicate hazards and reinforce safe work practices. All personnel are required to wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, hearing protection, and high-visibility clothing.

We utilize advanced technologies like proximity sensors on harvesting equipment to prevent collisions, and GPS tracking systems to monitor worker locations and ensure they are not in harm’s way. Regular maintenance and inspections of all equipment are crucial, and we maintain comprehensive safety training programs covering topics like fall protection, emergency response, and first aid. We also conduct regular safety audits and incident investigations to continually improve our safety procedures and learn from any incidents.

For example, in one project, we identified a significant risk of falling trees near a road used by the public. To mitigate this, we temporarily closed the road during harvesting operations and implemented a clear warning system to prevent unauthorized access. A proactive approach to safety is not only ethically responsible but also improves productivity and reduces costly downtime.

Q 3. Explain your experience with harvesting equipment maintenance and repair.

My experience in equipment maintenance and repair is extensive. I understand the importance of preventative maintenance to maximize uptime and minimize repair costs. We establish a rigorous preventative maintenance schedule for all harvesting equipment, including feller bunchers, skidders, and loaders. This involves regular inspections, lubrication, and replacement of worn parts. Our mechanics are highly skilled and are trained to diagnose and repair complex mechanical and hydraulic systems.

I utilize computerised maintenance management systems (CMMS) to track maintenance records, schedule inspections, and manage inventory of spare parts. This system ensures that all equipment is properly maintained and reduces the risk of unexpected breakdowns. In addition to preventative maintenance, we also have a rapid response system for dealing with breakdowns in the field. Our mechanics are equipped with the necessary tools and parts to quickly diagnose and repair problems, minimizing downtime and maximizing productivity. We also use telematics data to monitor equipment performance and identify potential problems before they occur. For example, we can monitor fuel consumption, engine hours, and other performance indicators to identify trends and proactively address potential issues.

Q 4. How do you manage and mitigate environmental risks associated with timber harvesting?

Environmental risk management is integrated into every phase of our operations. We meticulously plan each harvest to minimize soil erosion, protect water quality, and preserve biodiversity. This starts with a thorough environmental impact assessment that identifies potential risks and outlines mitigation measures. We utilize best management practices (BMPs) to minimize soil disturbance during harvesting and road construction. This includes the use of directional felling techniques, proper road placement and drainage systems, and riparian buffer zones to protect streams and wetlands.

We also implement measures to protect sensitive habitats and endangered species. This may involve restricting harvesting activities in certain areas or adjusting harvesting methods to avoid impacting these areas. Post-harvest activities, such as reforestation or afforestation, are crucial to restoring the ecosystem’s health and long-term productivity. For instance, we may plant native tree species to promote biodiversity and ensure the long-term sustainability of the forest. We also monitor water quality and soil conditions after harvesting to assess the effectiveness of our mitigation measures and make adjustments as necessary. Detailed record-keeping and reporting are essential for ensuring environmental compliance and demonstrating our commitment to sustainable forestry practices. We routinely engage with environmental consultants to ensure that our operations align with the most up-to-date environmental regulations and best practices.

Q 5. What software and technologies are you proficient in for timber harvesting planning and execution?

I’m proficient in a range of software and technologies used for timber harvesting planning and execution. This includes GIS software (like ArcGIS) for creating detailed maps and analyzing forest inventory data. These tools are crucial for planning harvest units, designing roads, and optimizing logging routes. I also utilize forest growth and yield modeling software to predict the future growth of the forest and optimize harvesting schedules. This allows us to project timber yield and make informed decisions about harvesting intensity and timing.

Furthermore, I have experience with harvesting simulation software that allows us to model different harvesting scenarios and evaluate their impact on various factors, including cost, environmental impact, and forest structure. We use GPS-enabled equipment and fleet management systems to track the location of harvesting equipment and monitor productivity in real-time. This data is essential for improving operational efficiency and reducing downtime. I am also familiar with various data analytics tools to process and interpret the large volumes of data generated by harvesting operations, allowing for data-driven decisions regarding future operations. This might include analysing data on fuel efficiency, equipment maintenance, or worker productivity to optimize operations further.

Q 6. How do you ensure compliance with all relevant regulations and permits for timber harvesting operations?

Ensuring compliance with all relevant regulations and permits is critical. We maintain a detailed understanding of all applicable federal, state, and local regulations pertaining to timber harvesting, including environmental protection laws, worker safety regulations, and forestry practices. Before commencing any harvesting operation, we obtain all necessary permits and licenses. This involves submitting detailed plans to regulatory agencies and demonstrating compliance with all applicable requirements. We maintain comprehensive records of all harvesting activities, including logging plans, harvest maps, and environmental monitoring data.

Regular audits and inspections are conducted to ensure that we remain compliant with all regulations and that our operations meet the highest standards. We also proactively engage with regulatory agencies to address any concerns and ensure that our operations align with evolving regulations. Our commitment to compliance is not just about avoiding penalties; it’s about demonstrating our responsibility as environmental stewards and building trust with the community. Failure to comply can result in significant fines, operational shutdowns, and reputational damage. Therefore, our proactive approach to regulatory compliance is essential to our long-term success and sustainability.

Q 7. Describe your experience in developing and managing harvesting budgets.

Developing and managing harvesting budgets requires a detailed understanding of all cost elements involved in the operation. This includes the cost of labor, equipment, transportation, permits, and environmental monitoring. I use sophisticated cost estimating software to develop accurate and comprehensive budgets. This involves analyzing historical data, current market prices, and projected production levels. These budgets are typically broken down into smaller work packages to track costs and monitor progress throughout the project. Regular budget monitoring and variance analysis are essential to identify any potential cost overruns or inefficiencies.

To ensure efficient budget management, we implement rigorous cost control measures, including tracking of equipment hours, fuel consumption, and labor costs. We strive to optimize resource allocation to minimize costs without compromising safety or environmental standards. For example, careful planning of logging roads can reduce transportation costs, while proper equipment maintenance can minimize downtime and repair expenses. Effective communication and collaboration between the planning team, the field crews, and the finance team are crucial for successful budget management. Throughout the project, we conduct regular budget reviews to track actual costs against the budget and make necessary adjustments. This proactive approach ensures that the project remains within budget and that resources are used effectively.

Q 8. How do you optimize timber harvesting operations for efficiency and profitability?

Optimizing timber harvesting for efficiency and profitability requires a holistic approach encompassing planning, execution, and post-harvest analysis. It’s like orchestrating a complex symphony – every instrument (resource) needs to play its part harmoniously.

- Pre-harvest planning: This involves detailed assessments of the stand (area of trees), including species composition, tree size distribution, terrain analysis, and road network design. We use sophisticated software to model different harvesting scenarios and optimize factors such as skidding distances, road layout, and equipment selection to minimize costs and maximize yield.

- Efficient harvesting techniques: Selecting the right harvesting system (e.g., clear-cutting, selection cutting) based on the stand characteristics is crucial. Implementing techniques like pre-bunching (grouping logs) and using GPS-guided machinery improves productivity and reduces waste. For example, using feller bunchers and grapple skidders can significantly speed up the process compared to traditional methods.

- Real-time monitoring and data analysis: Utilizing telematics (GPS tracking and data logging systems on machinery) allows real-time monitoring of machine performance, fuel consumption, and operational efficiency. This data helps identify bottlenecks and areas for improvement. We can pinpoint inefficiencies, whether it’s a specific operator, a machine malfunction, or even a poorly planned road system.

- Post-harvest analysis: Regular review of operational data allows us to continually improve our methods. Analyzing factors like machine downtime, fuel costs, and harvesting rates identifies areas where improvements can be made in future operations.

For example, in a recent project, by optimizing the road network and using pre-bunching, we managed to reduce skidding distances by 20%, resulting in a 15% increase in productivity and a 10% reduction in fuel costs.

Q 9. Explain your experience with timber volume estimation and yield prediction.

Accurate timber volume estimation and yield prediction are foundational to successful harvesting operations. It’s like knowing how much flour you need before baking a cake – you wouldn’t want to run out or have too much left over!

My experience encompasses various techniques, including:

- Cruising and sampling: This involves systematically measuring a representative sample of trees within the stand to estimate the total volume. We use various sampling techniques, such as fixed-area plots or point sampling, depending on the stand characteristics.

- Remote sensing and LiDAR: LiDAR (Light Detection and Ranging) technology uses laser pulses to create highly accurate 3D models of the forest. This data allows for precise volume estimations and identification of areas with high-value timber.

- Growth and yield models: These models predict future timber yields based on past growth data, site characteristics, and management practices. They are essential for long-term planning and sustainable forest management.

- Software applications: I’m proficient in using various software packages designed for timber volume estimation and yield prediction, such as Forest Management Software and GIS (Geographic Information System) programs.

In a recent project, using LiDAR data combined with a growth and yield model, we were able to predict timber yield with an accuracy of within 5%, significantly improving the accuracy of our harvesting plan and reducing risks associated with under or overestimation.

Q 10. What is your approach to managing and motivating a team of harvesting personnel?

Managing and motivating a team of harvesting personnel requires a blend of strong leadership, clear communication, and fostering a positive work environment. It’s about creating a team where everyone feels valued and contributes to a shared goal.

- Clear communication and expectations: I maintain open communication channels, ensuring everyone understands their roles, responsibilities, and safety procedures. Regular briefings and feedback sessions are vital.

- Safety training and enforcement: Safety is paramount. I emphasize strict adherence to safety protocols, provide ongoing training, and conduct regular safety inspections. Leading by example is key.

- Recognition and rewards: Recognizing and appreciating hard work and achievements boosts morale and productivity. This can include bonuses, promotions, or simply acknowledging a job well done.

- Conflict resolution: Addressing conflicts promptly and fairly is crucial for maintaining a harmonious work environment. I use mediation and open dialogue to resolve disagreements.

- Team building and collaboration: Fostering teamwork through activities and communication encourages cooperation and efficiency.

In my experience, a team that feels valued and respected works more effectively and produces high-quality results. By prioritizing safety and rewarding good performance, I cultivate a positive and productive work environment.

Q 11. How do you handle unexpected challenges and delays during timber harvesting operations?

Unexpected challenges and delays are inevitable in timber harvesting. It’s crucial to have contingency plans in place and to be able to react effectively and adapt to changing circumstances. It’s like having a spare tire for your car – you hope you won’t need it, but it’s essential to have when you do.

- Risk assessment and mitigation: Proactive identification of potential risks (e.g., weather, equipment malfunction, regulatory changes) allows us to develop mitigation strategies beforehand.

- Contingency planning: Developing backup plans for various scenarios (e.g., alternative transportation routes, equipment repair schedules) ensures that operations can continue with minimal disruption.

- Problem-solving and decision-making: When unexpected issues arise, it’s important to gather information, analyze the problem, and make informed decisions quickly and effectively.

- Communication and collaboration: Open communication with all stakeholders (clients, contractors, regulatory agencies) is essential for coordinating responses and resolving issues.

- Adaptability and flexibility: The ability to adapt to unforeseen circumstances and adjust plans accordingly is crucial for success.

For example, during a recent operation, unexpected heavy rainfall caused a road washout. Our contingency plan, which included an alternative route, allowed us to resume operations within a few hours, minimizing delays and cost overruns.

Q 12. Describe your experience with road construction and maintenance in logging operations.

Road construction and maintenance are critical aspects of efficient logging operations. Without well-maintained roads, getting logs out of the forest becomes significantly more challenging and expensive. It’s like the arteries of the operation – they need to be clear and functional.

My experience includes:

- Road design and planning: I’m proficient in designing and planning logging roads, considering factors like terrain, soil type, traffic volume, and environmental protection. This involves using specialized software and adhering to relevant regulations.

- Construction supervision: I oversee the construction of logging roads, ensuring adherence to design specifications and environmental standards. This includes managing contractors and monitoring progress.

- Maintenance and repair: I’m responsible for the maintenance and repair of logging roads, including drainage systems, culverts, and road surfaces. Regular maintenance is crucial for preventing damage and ensuring safety.

- Erosion control: Implementing erosion control measures, such as water bars and ditch checks, is essential to prevent soil erosion and protect water quality.

In one project, we implemented a new road design incorporating more sustainable practices which reduced construction costs by 10% and significantly decreased the environmental impact.

Q 13. What are your strategies for minimizing soil erosion and water pollution during harvesting?

Minimizing soil erosion and water pollution is crucial for environmental stewardship and maintaining the long-term sustainability of timber harvesting. It’s about leaving the forest healthier than we found it.

- Erosion control measures: Implementing effective erosion control measures, such as water bars, ditch checks, and sediment basins, is essential for preventing soil erosion and sediment runoff into waterways.

- Stream buffer zones: Maintaining buffer zones along streams and rivers prevents the direct impact of harvesting activities on water quality. This protects aquatic habitats and water resources.

- Proper skidding techniques: Using appropriate skidding techniques and limiting traffic in sensitive areas minimizes soil compaction and erosion.

- Fuel management: Proper management of fuel spills and other potential pollutants prevents water contamination.

- Reforestation and site preparation: Prompt reforestation after harvesting helps restore soil stability and prevent erosion.

For example, in a recent project, we utilized specialized skidders with low ground pressure tires and implemented a strict skid trail management plan, resulting in a 30% reduction in soil erosion compared to previous projects.

Q 14. Explain your understanding of sustainable forestry practices and their implementation.

Sustainable forestry practices are essential for ensuring the long-term health and productivity of forests while meeting current timber needs. It’s about balancing economic viability with environmental responsibility. It’s like managing a bank account – you need to make sure you’re not overdrawing.

- Selective harvesting: This involves removing only mature or less desirable trees, leaving younger trees to grow and maintain forest structure and biodiversity. This is opposed to clear-cutting where the entire stand is removed.

- Reduced impact logging (RIL): RIL techniques minimize damage to residual trees, soil, and water resources during harvesting.

- Reforestation and afforestation: Planting trees after harvesting ensures the continued productivity of the forest and maintains carbon sequestration.

- Forest certification: Adhering to forest certification schemes (e.g., FSC, SFI) ensures that timber harvesting practices meet stringent environmental and social standards.

- Biodiversity conservation: Incorporating measures to protect biodiversity, such as maintaining wildlife corridors and habitat protection areas, is critical for sustainable forest management.

In my work, I actively incorporate sustainable practices by utilizing selective harvesting techniques, employing reduced-impact logging strategies, and ensuring prompt reforestation. We work closely with local communities and environmental agencies to ensure that our operations are environmentally and socially responsible.

Q 15. How do you utilize GIS technology in timber harvesting planning and execution?

GIS, or Geographic Information Systems, is indispensable in modern timber harvesting. It allows us to create highly detailed and accurate maps of the harvesting area, integrating data from various sources like LiDAR scans, aerial photography, and ground surveys. This helps in several key ways:

- Pre-harvest Planning: We use GIS to identify optimal logging roads, delineate harvesting units based on slope, soil type, and tree species, and plan skid trails to minimize environmental impact. For instance, we can avoid sensitive areas like wetlands or streams by visualizing their locations on the map and planning around them.

- Road Network Design: GIS helps design efficient road networks that minimize the distance logs need to travel, reducing transportation costs and environmental impact. This includes analyzing terrain and considering factors like slope, soil bearing capacity, and proximity to water sources.

- Yield Estimation: By combining GIS data with tree species and volume information, we can accurately estimate the timber volume expected from a specific area. This informs decision-making related to harvesting schedules and resource allocation.

- Post-harvest Monitoring: We use GIS to monitor the impact of harvesting operations. We can compare pre- and post-harvest imagery to assess erosion, changes in forest cover, and compliance with environmental regulations.

In one project, using GIS helped us reduce road construction by 15% by optimizing the layout, significantly lowering project costs and environmental impact. The accuracy of GIS also reduced errors in timber volume estimation by about 5% compared to traditional methods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with log scaling and quality control procedures.

Log scaling and quality control are vital for ensuring fair payment and meeting mill specifications. Log scaling involves precisely measuring the volume of each log, typically using scaling sticks or electronic measuring devices. We meticulously record species, length, diameter, and any defects like knots or rot. Quality control measures are implemented at every stage:

- Pre-harvest Assessment: Assessing tree quality in the stand helps to predict log grades and plan harvesting accordingly. We use tools such as increment borers to assess tree health and growth.

- During Harvesting: Operators are trained to identify and separate logs based on quality grades. Logs with significant defects are marked for alternative uses or removal.

- At the Landing: Logs are inspected at the landing (the temporary collection point) to confirm scaling accuracy and check for damage incurred during harvesting and transportation.

- At the Mill: Final quality checks are performed at the mill to ensure that logs meet the specifications for various products (lumber, pulpwood, etc.).

Imagine a situation where a large knot is missed during scaling. This could lead to significant financial loss for the company and dissatisfaction from the mill receiving logs of lower quality. Our rigorous quality control procedures help prevent such scenarios.

Q 17. How do you manage the logistics of timber transportation from the harvesting site to the mill?

Timber transportation logistics is a complex process requiring careful planning and coordination. We consider several factors:

- Road Conditions: Assessing road quality and capacity to determine the suitable type and size of trucks. Poor road conditions might necessitate using smaller trucks or employing specialized equipment.

- Truck Availability: Securing enough trucks and drivers based on the volume of timber and distance to the mill. We often work with trucking companies that specialize in hauling timber.

- Route Optimization: Planning the most efficient routes to minimize travel time and fuel consumption, taking into consideration weight limits and bridge clearances.

- Scheduling: Coordinating harvesting and transportation schedules to avoid bottlenecks and delays. We frequently use scheduling software to optimize the logistics process.

- Safety Regulations: Ensuring compliance with regulations regarding load security, driver hours of service, and permits.

Effective coordination is key here. In a recent operation, by carefully coordinating with the trucking company and optimizing the route, we reduced transportation costs by 10% and delivery times by a day. This translates to significant savings and improved efficiency.

Q 18. What is your experience with different types of harvesting equipment and their applications?

My experience encompasses a wide range of harvesting equipment, each suited for different situations. Here are some examples:

- Feller Bunchers: These machines fell trees and bunch them together for easier processing, ideal for high-volume harvesting in relatively flat terrain.

- Harvesters: Combine felling, delimbing, and bucking (cutting into log lengths) in one operation, highly efficient for large-scale operations.

- Forwarders: Transport logs from the felling site to a landing, crucial for reducing ground disturbance and improving efficiency. Different types exist depending on terrain (e.g., wheeled or tracked).

- Skidders: Also used for log transportation, but often less efficient over longer distances than forwarders. They’re often employed on steeper slopes or in areas unsuitable for forwarders.

- Chainsaws: Essential for selective harvesting, salvage operations, or working in difficult-to-access areas where larger machinery isn’t feasible.

Choosing the right equipment is crucial for maximizing efficiency and minimizing costs. For example, using a feller buncher in a steep terrain would be impractical, whereas a skidder might be a more appropriate option.

Q 19. How do you assess and manage the risks associated with working in remote and challenging terrains?

Working in remote and challenging terrains presents numerous risks, including those related to safety, equipment damage, and environmental damage. Effective risk management requires a proactive approach:

- Pre-harvest Site Assessment: A thorough assessment identifies potential hazards like unstable slopes, difficult access points, and proximity to water bodies. We use topographical maps, aerial imagery and on-site surveys to assess the terrain.

- Safety Protocols: Implementing strict safety procedures including daily safety briefings, emergency response plans, and appropriate personal protective equipment (PPE).

- Equipment Maintenance: Regular equipment inspections and maintenance to prevent breakdowns and accidents. We often develop a maintenance schedule that factors in the type of terrain and the equipment type.

- Environmental Protection: Implementing measures to minimize erosion, protect water quality, and preserve biodiversity. This may include using erosion control mats, constructing temporary sediment basins, and restricting harvesting near sensitive areas.

- Emergency Preparedness: Having well-defined emergency response plans and communication systems in place to deal with unforeseen events like equipment failures or injuries.

Once, during a harvesting operation in a mountainous area, we had to revise the harvesting plan to avoid a particularly unstable slope identified during a site visit. This proactive measure prevented a potential accident and ensured the safety of our team.

Q 20. Explain your approach to conflict resolution within a timber harvesting team.

Conflict resolution is vital in a team environment. My approach is based on open communication, clear expectations, and fair processes:

- Proactive Communication: Regularly communicating with the team to address concerns and prevent conflicts from escalating. This includes team meetings, one-on-one conversations, and feedback sessions.

- Clear Roles and Responsibilities: Defining roles and responsibilities clearly to avoid misunderstandings and overlapping tasks. A well-defined task list helps ensure that everyone understands their contribution.

- Mediation and Facilitation: If conflicts arise, I act as a mediator, ensuring all parties have a chance to express their concerns and work toward a mutually agreeable solution.

- Fair and Consistent Application of Rules: Enforcing rules and regulations consistently and fairly to avoid bias and perceived favoritism. This builds trust and respect within the team.

- Focus on Solutions: Shifting the focus from blame to finding solutions. The goal is to find a solution that addresses the underlying concerns and prevents future recurrence.

In one instance, a disagreement arose between the feller buncher operator and the forwarder operator regarding the placement of the felled trees. By facilitating open communication and finding a mutually agreeable approach to tree placement, we were able to resolve the conflict and improve efficiency. This required active listening and finding a solution that satisfied both parties.

Q 21. Describe your experience with pre-harvest planning and site assessments.

Pre-harvest planning and site assessments are critical for successful and efficient timber harvesting. This involves a multi-step process:

- Data Acquisition: Gathering data such as aerial photographs, LiDAR data, and ground surveys to create detailed maps of the area. This step is crucial for creating a base map to be used in analysis.

- Stand Delineation and Assessment: Identifying and characterizing different stands of timber based on tree species, size, density, and quality. This informs decisions regarding harvesting methods and equipment selection.

- Road and Skid Trail Planning: Designing efficient road networks and skid trails to minimize environmental impact and transportation costs. Considering slope, soil conditions and proximity to sensitive areas is crucial for planning these elements.

- Environmental Impact Assessment: Identifying and mitigating potential environmental impacts such as erosion, water pollution, and habitat loss. We use appropriate environmental impact assessment methodologies to inform the management plan.

- Harvesting Plan Development: Developing a detailed harvesting plan outlining the sequence of operations, equipment allocation, and timelines. This plan serves as a roadmap for the project.

A thorough pre-harvest assessment can save time and money by identifying potential problems early on. For instance, in one project, a detailed site assessment revealed the presence of an endangered species near a planned logging road. Adjusting the road alignment prevented any potential harm to this species and avoided legal complications.

Q 22. How do you ensure accurate tracking and reporting of harvesting progress and productivity?

Accurate tracking and reporting of harvesting progress and productivity are crucial for efficient operations and profitability. We employ a multi-faceted approach combining technology and meticulous record-keeping.

- GPS Tracking of Equipment: Each harvesting machine is equipped with GPS tracking devices that provide real-time location data, allowing us to monitor progress against the planned harvesting schedule. This helps identify potential bottlenecks and allows for proactive adjustments.

- Production Monitoring Software: We utilize specialized software that integrates data from GPS trackers, along with information on tree volume harvested (obtained through pre-harvest assessments and on-site measurements), and machine operating hours. This software generates reports on daily/weekly productivity per machine, crew, and overall project. We can even track fuel consumption and maintenance needs.

- Manual Data Collection and Verification: While technology is key, manual data collection remains important as a cross-check. Foresters on the ground verify harvested volumes, assess tree species and quality, and identify any unexpected issues. This ensures data accuracy and allows for adjustments to our harvesting plans as needed. For example, if we encounter unexpectedly high numbers of damaged trees, this can be flagged and accounted for in our reports.

- Regular Reporting and Analysis: We generate regular reports on harvesting progress, productivity, costs, and any identified issues. These reports are analyzed to identify areas for improvement and to inform future planning. This might involve adjustments to crew assignments or equipment allocation based on performance data.

Q 23. Explain your knowledge of relevant forestry regulations and compliance requirements.

Adherence to forestry regulations is paramount. My knowledge encompasses federal, state, and local regulations relating to timber harvesting, including environmental protection, worker safety, and sustainable forestry practices.

- Environmental Regulations: This includes understanding and complying with regulations regarding water quality protection, habitat preservation, endangered species protection, and erosion control. We meticulously follow approved harvesting plans that minimize environmental impact, employing techniques such as directional felling and minimizing soil disturbance.

- Worker Safety Regulations: I am proficient in Occupational Safety and Health Administration (OSHA) standards and other relevant safety regulations. This ensures a safe working environment for all crews through regular safety training, equipment inspections, and adherence to established safety protocols. For example, we conduct daily safety briefings to reinforce safe practices, emphasizing fall protection and proper use of machinery.

- Sustainable Forestry Practices: We integrate principles of sustainable forestry into all operations, adhering to guidelines for selective harvesting, reforestation, and forest regeneration. This means that the harvesting process considers the long-term health and productivity of the forest.

- Permitting and Compliance: I am experienced in navigating the permitting process, ensuring all necessary permits and approvals are obtained before commencing operations and maintaining meticulous records to demonstrate ongoing compliance.

Q 24. What are your strategies for improving communication and collaboration among harvesting crews?

Effective communication and collaboration are fundamental to successful timber harvesting operations. My strategies focus on fostering a positive and productive team environment.

- Daily Briefings: Starting each day with a briefing ensures everyone is aware of the day’s plans, safety concerns, and potential challenges. This allows for problem-solving and proactive adjustments before issues escalate.

- Open Communication Channels: We utilize a combination of radio communication, mobile apps, and regular meetings to ensure seamless information flow between crews, supervisors, and support staff. This allows for quick responses to unforeseen circumstances.

- Regular Feedback and Performance Reviews: Providing regular feedback allows crew members to understand their performance, identify areas for improvement, and receive recognition for their contributions. This fosters a culture of continuous improvement.

- Team Building Activities: Investing in team-building activities helps build camaraderie and trust among crew members, leading to improved collaboration and problem-solving skills. These activities can be as simple as informal gatherings or more structured events aimed at improving teamwork.

- Conflict Resolution Mechanisms: We establish clear procedures for addressing conflicts or disagreements, fostering a culture of open communication and mutual respect.

Q 25. How do you manage and mitigate risks associated with inclement weather during timber harvesting?

Inclement weather poses significant risks to timber harvesting operations, impacting safety, productivity, and equipment integrity. Risk mitigation is crucial.

- Weather Monitoring: We use reliable weather forecasts to plan operations, avoiding work during periods of high risk (e.g., severe storms, heavy snowfall). This involves a combination of daily forecasts and longer-term weather patterns to make informed decisions.

- Safety Protocols for Adverse Conditions: We have specific safety protocols for different weather conditions. For instance, during periods of heavy rain, work may be halted to prevent soil erosion and risks to workers. During high winds, felling operations will be adjusted to mitigate the risk of tree falls.

- Emergency Response Plan: A comprehensive emergency response plan outlines procedures for dealing with unexpected weather events, including evacuation procedures, equipment protection, and communication protocols.

- Equipment Maintenance and Protection: Regular equipment maintenance ensures reliability during challenging weather conditions. Protective measures such as covering equipment when not in use can prevent damage from rain or snow.

- Flexible Scheduling: Our schedule is flexible enough to adapt to unexpected weather events, allowing us to reschedule tasks or adjust work hours as needed.

Q 26. Describe your experience with post-harvest site restoration and reforestation.

Post-harvest site restoration and reforestation are integral to sustainable forestry practices. My experience encompasses various techniques to ensure responsible land management after timber harvesting.

- Site Preparation: This involves activities such as clearing debris, reducing erosion risks, and preparing the ground for planting seedlings. This might involve controlled burning (if permitted) or mechanical site preparation.

- Reforestation: We use various methods of reforestation, including direct seeding, planting seedlings, and natural regeneration. The chosen method depends on factors like site conditions, species requirements, and cost-effectiveness.

- Erosion Control: We employ various techniques to prevent erosion, including terracing, contour plowing, and planting cover crops. These techniques help protect soil and water quality.

- Monitoring and Maintenance: Post-harvest monitoring is crucial to assess the success of restoration efforts and to identify any necessary remedial actions. Regular site visits allow us to monitor seedling growth and address any issues like weed encroachment.

- Biodiversity Considerations: Our approach considers maintaining biodiversity by planting a mix of species, creating wildlife habitat features, and minimizing disruption to existing ecosystems.

Q 27. How do you measure the success of your timber harvesting operations?

The success of timber harvesting operations is measured using a combination of quantitative and qualitative metrics.

- Productivity: This involves measuring the volume of timber harvested per unit of time and per machine, comparing actual performance to the planned schedule and identifying areas for improvement. We look at metrics such as cubic meters per machine hour or tons per day.

- Cost-Effectiveness: We track costs associated with harvesting, including labor, equipment, and transportation, to ensure profitability and efficient resource utilization. This involves careful budgeting and cost analysis throughout the process.

- Safety Record: A strong safety record is paramount. We measure this through the number of accidents, near misses, and lost-time injuries, continuously striving to improve our safety performance.

- Environmental Impact: We evaluate the environmental impact of our operations by monitoring soil erosion, water quality, and habitat impacts, ensuring minimal disruption to the environment.

- Customer Satisfaction: Meeting customer requirements, delivering high-quality timber products, and maintaining positive relationships are essential indicators of success.

Q 28. What are your professional development goals in the field of timber harvesting?

My professional development goals focus on enhancing my expertise in sustainable forestry practices and technological advancements in timber harvesting.

- Advanced Certification: I plan to obtain advanced certifications in sustainable forestry management and timber harvesting best practices. This will enable me to stay at the forefront of industry standards and ensure we continue to meet the highest ecological and safety standards.

- Technology Integration: I aim to further develop my skills in using advanced technology, such as remote sensing, drones, and AI-powered analytics, to improve operational efficiency, increase productivity, and minimize environmental impact. The implementation of these technologies is crucial for achieving greater precision and reducing waste.

- Leadership Development: I intend to enhance my leadership capabilities to mentor and guide younger professionals, fostering a culture of innovation and continuous improvement within the team. This will ensure the skills and knowledge needed for efficient and sustainable timber harvesting are preserved and developed.

Key Topics to Learn for Timber Harvesting Operations Management Interview

- Sustainable Harvesting Practices: Understanding and applying principles of sustainable forestry, including selective logging, reforestation, and minimizing environmental impact. Practical application: Analyzing a harvesting plan for its ecological sustainability and proposing improvements.

- Harvest Planning & Logistics: Developing efficient and safe harvesting plans, including road network design, timber transportation, and equipment allocation. Practical application: Optimizing a harvesting schedule to minimize costs and maximize efficiency while adhering to environmental regulations.

- Crew Management & Safety: Supervising and motivating teams, ensuring adherence to safety regulations, and promoting a positive work environment. Practical application: Developing and implementing a safety training program for your harvesting crew, and addressing safety concerns proactively.

- Equipment Maintenance & Operation: Understanding the operation and maintenance of harvesting equipment (e.g., feller bunchers, skidders, loaders). Practical application: Troubleshooting equipment malfunctions and scheduling preventative maintenance to minimize downtime.

- Budgeting & Cost Control: Managing budgets, tracking expenses, and optimizing resource allocation for profitable operations. Practical application: Analyzing cost data to identify areas for improvement and developing strategies to reduce operational costs.

- Regulations & Compliance: Staying informed about and adhering to all relevant environmental, safety, and forestry regulations. Practical application: Ensuring all harvesting activities comply with local, state, and federal regulations.

- Technology in Timber Harvesting: Utilizing technology such as GPS, GIS, and remote sensing for improved planning, efficiency, and data analysis. Practical application: Using GIS software to plan efficient harvesting routes and minimize environmental impact.

Next Steps

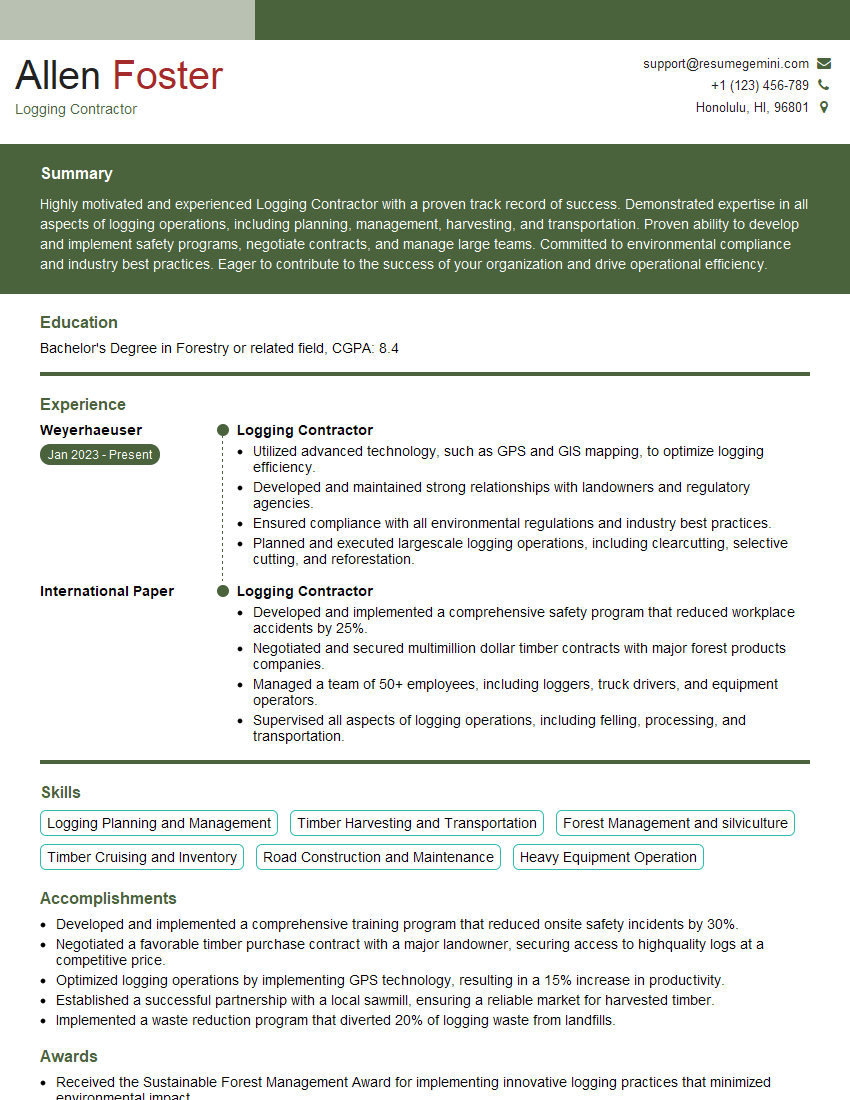

Mastering Timber Harvesting Operations Management is crucial for career advancement within the forestry industry, opening doors to leadership roles and increased earning potential. A strong resume is your first impression; an ATS-friendly resume ensures your qualifications are seen by potential employers. To craft a professional and effective resume that highlights your skills and experience, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to Timber Harvesting Operations Management to guide you in creating a compelling application. Take the next step towards your dream career today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO