Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Band Saw Operations interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Band Saw Operations Interview

Q 1. What types of band saw blades are you familiar with and what are their applications?

Band saw blades come in a variety of types, each designed for specific materials and cutting applications. The key differences lie in the blade’s tooth configuration, material, and width.

- Skip-tooth blades: These blades have large gaps between teeth, ideal for cutting rough lumber or wood with knots. The large gullets effectively remove waste material. Think of them as the ‘heavy-duty’ option for wood.

- Standard-tooth blades: These blades have evenly spaced teeth, offering a fine cut and are suitable for most woodworking tasks. They are versatile and a good all-around choice.

- Hook-tooth blades: Designed for smooth, accurate cuts in hardwoods, these blades have teeth that are slightly bent or ‘hooked.’ This helps prevent tear-out and produces a clean finish. They’re the precision tool for fine woodworking.

- High-speed steel (HSS) blades: Common and relatively inexpensive, these blades are durable and work well on most materials, including wood and some metals. They are a good balance of cost and performance.

- Bi-metal blades: These blades combine a high-speed steel cutting edge with a flexible high-carbon steel backing. This design makes them extremely durable and capable of cutting tough materials like metal. These are your go-to for metal cutting applications.

- Carbide-tipped blades: Offering extreme longevity, these blades feature carbide teeth brazed onto a steel backing. They’re best for cutting abrasive materials and for long production runs due to their resistance to wear. Think cutting through reinforced plastics or very hard woods.

The selection of the correct blade is crucial for achieving the desired cut quality and efficiency. Choosing the wrong blade can lead to poor cuts, blade damage, or even safety hazards.

Q 2. Explain the process of setting up a band saw for a specific cutting task.

Setting up a band saw for a specific cutting task involves several crucial steps, and attention to detail here is paramount for both safety and accurate cuts. First, you must choose the right blade for the material and desired cut quality (as described above). Next:

- Blade Installation: Carefully install the blade, ensuring it’s correctly seated in the wheel’s grooves. Incorrect installation can lead to blade derailment and injury.

- Blade Tension: Adjust the blade tension according to the manufacturer’s instructions for the specific blade and saw model. Too little tension can cause the blade to wander or break, while too much tension can damage the blade or the saw itself.

- Guide Adjustment: Position the guides close to the blade (but without touching!) to minimize blade flex and vibration, leading to improved accuracy and cut quality. These guides need to be adjusted based on the thickness of the material you are cutting. The thicker the material, the further away the guides need to be from the blade.

- Fence Alignment: For straight cuts, accurately align the rip fence to the blade. Double and triple check this before cutting; a misaligned fence will result in inaccurate cuts.

- Test Cut: Always perform a test cut on scrap material of the same type you’ll be cutting to verify the setup before working on your final piece.

Proper setup minimizes errors, maximizes blade life, and promotes a safe working environment.

Q 3. How do you ensure the proper tension of a band saw blade?

Proper band saw blade tension is essential for safe and accurate cutting. Insufficient tension can cause the blade to wander, break, or even derail, while excessive tension can lead to blade stretching, breakage, or damage to the saw itself.

Most band saws use a tensioning system that involves either a hand wheel or a lever to adjust the tension. The exact procedure varies depending on the saw’s make and model. However, there are some common steps:

- Consult the Manual: Always refer to the manufacturer’s instructions for the correct tension setting for your specific blade and saw.

- Visual Inspection: Before and after tensioning, visually inspect the blade for signs of bending or unusual deflection. The blade should appear uniformly taut.

- Tension Gauge (if available): Some saws include tension gauges that provide a numerical reading of blade tension. Use this gauge to achieve the recommended tension.

- Sound Test: As you adjust the tension, listen for the blade’s pitch. A properly tensioned blade will typically produce a resonant ‘ping’ when plucked gently.

- Test Cut: Make a test cut on scrap material after adjusting tension to verify that the blade cuts straight and smoothly.

Think of it like tuning a musical instrument: you need the right amount of tension for optimal performance.

Q 4. Describe the different types of band saw guides and their purpose.

Band saw guides play a critical role in supporting the blade and maintaining its stability during operation. They minimize blade flex and vibration, which greatly improves cut accuracy and reduces the risk of blade breakage. Different types of guides exist, each serving a specific purpose.

- Thrust guides: These guides support the blade from the side, preventing it from wandering. They are essential for maintaining straight cuts.

- Upper guides: Located above the workpiece, these guides maintain the blade’s tracking and help to prevent the blade from being pulled off course.

- Lower guides: Situated below the workpiece, these guides provide additional support to the blade, further minimizing flex and vibration.

The materials and design of guides can also vary. Some are made of hardened steel or ceramic for superior durability and wear resistance, especially important when cutting metal. Proper adjustment of guides is crucial. They should be close enough to the blade to provide adequate support, but not so close as to cause friction or damage.

Q 5. What safety procedures must be followed when operating a band saw?

Safety should always be the top priority when operating a band saw. Never compromise on safety procedures. Here’s a list of crucial precautions:

- Proper Training: Always receive proper training on band saw operation before using one.

- Personal Protective Equipment (PPE): Wear appropriate safety glasses or a face shield, hearing protection, and dust mask (depending on the material being cut).

- Clothing: Wear clothing that fits snugly and avoids loose sleeves or jewelry that could get caught in the blade.

- Clear Work Area: Keep your work area free of clutter to prevent tripping hazards.

- Blade Inspection: Regularly inspect the blade for damage before each use.

- Secure Workpiece: Use appropriate clamping methods to secure the workpiece, preventing it from shifting or kicking back.

- Feed Rate: Feed the workpiece slowly and steadily to avoid overloading the blade.

- Never Reach Over the Blade: Never reach over the moving blade to retrieve a workpiece.

- Emergency Stop: Know the location of the emergency stop switch and how to use it.

- Maintenance: Regularly maintain the band saw according to the manufacturer’s instructions.

A moment of carelessness can lead to serious injury. Following these procedures is essential for a safe working experience.

Q 6. How do you identify and address a broken or damaged band saw blade?

Identifying a broken or damaged band saw blade is relatively straightforward. Look for:

- Visible breaks or cracks: These are obvious signs of blade failure and require immediate replacement.

- Bent or distorted teeth: This indicates stress or impact on the blade and should be addressed by replacement or, in some cases, professional sharpening.

- Excessive wear: Dull teeth or significant wear on the blade’s edge is a sign that the blade needs sharpening or replacement. Continue cutting with a worn blade can create safety concerns.

- Blade tracking issues: If the blade wanders or deviates from its intended path, this may signify a damaged blade or a problem with the saw’s alignment. Addressing tracking issues could potentially involve adjusting the blade’s tension and/or the guides, but often requires replacement.

Addressing a broken blade is simple: replace it. Never attempt to repair a broken blade, as this poses significant safety risks. For worn blades, sharpening may be an option, depending on the blade material and the extent of wear.

Q 7. Explain the process of sharpening a band saw blade.

Sharpening a band saw blade is a specialized task best left to professionals unless you have the necessary tools, experience, and safety equipment. Improper sharpening can easily damage the blade, rendering it unusable or even dangerous. However, a basic understanding is useful.

Professional sharpening typically involves using specialized equipment, such as a blade-grinding machine, to precisely reshape and hone each tooth. This process requires specific angles and pressures to maintain the blade’s integrity and cutting efficiency. The process typically addresses the tooth shape, rake angle, and set (the slight bending of teeth to create kerf).

Attempting to sharpen a blade at home using files or other hand tools risks uneven sharpening, dulling the blade prematurely, or even causing injury.

In short: If you’re not an experienced bladesmith with the proper tools, leave the sharpening to a professional. It’s a cost-effective way to ensure the safety and efficiency of your blades.

Q 8. How do you maintain and lubricate a band saw to ensure optimal performance?

Maintaining a band saw is crucial for its longevity and safe operation. Regular lubrication and cleaning are key. Think of it like a well-oiled machine – if you don’t lubricate it properly, parts will wear down prematurely and performance will suffer.

Lubrication: The most important lubrication point is the blade guides. These guides experience significant friction as the blade moves, and inadequate lubrication leads to rapid wear and even blade breakage. Use the correct type of lubricant recommended by the manufacturer – typically a high-quality, low-viscosity oil designed for band saw guides. Apply a small amount to each guide, ensuring even coverage. Also, lubricate the blade itself with a specialized band saw blade lubricant to reduce friction and heat buildup. Remember to check and clean the guide mechanisms regularly to prevent the buildup of saw dust and lubricant grime that hinders proper lubrication.

Maintenance: Beyond lubrication, regular cleaning of the saw is vital. Sawdust accumulates quickly, potentially causing damage to the guides and blade. Use a brush or compressed air to remove the dust regularly. Periodically inspect the blade for any damage, check the tension, and ensure all moving parts are functioning smoothly. Pay close attention to the tires – worn or damaged tires can lead to tracking problems and blade breakage.

Q 9. What are the common causes of blade breakage and how can they be prevented?

Blade breakage on a band saw can be frustrating and dangerous. It’s usually caused by a combination of factors, often preventable with proper care and operation. Imagine a chain breaking – too much tension, worn links, or hitting a snag will break it. Similarly, a band saw blade needs careful management.

- Dull or damaged blade: A dull blade has to work harder, generating excessive heat and stress, leading to breakage. Chips or cracks in the blade are also weak points. Regular blade inspection and sharpening or replacement is crucial.

- Incorrect blade tension: Too loose a blade will flap and wander, creating uneven cuts and potential breakage. Too tight a blade can overload the saw and cause stress fractures. The correct tension is critical and should be verified regularly.

- Improper tracking: A blade that’s not tracking straight rubs against the guides, causing friction, heat, and ultimately breakage. Proper tracking adjustment is paramount.

- Overfeeding: Pushing the workpiece too forcefully against the blade creates excessive strain and leads to breakage. A steady, controlled feed rate is essential.

- Hard or abrasive materials: Some materials, like hardened steel, put immense strain on the blade. Using the correct blade type and reducing the feed rate for these materials prevents breakage.

- Blade misalignment: A blade not aligned correctly during installation puts excessive stress on certain portions, leading to premature failure. Precise and careful blade installation procedures should be followed.

Preventing blade breakage involves regular inspections, proper setup, and safe operating procedures. This includes using the appropriate blade for the material being cut and ensuring proper blade tension, tracking, and feed rates.

Q 10. How do you measure and adjust the blade tracking on a band saw?

Blade tracking refers to the blade’s straight movement along the wheels. Proper tracking prevents the blade from rubbing against the guides and causing damage. Imagine a train on a track – it needs to stay centered for smooth travel. The same goes for the band saw blade.

Measuring: You can visually check the tracking by observing the blade’s position relative to the guides. A slightly off-center blade is often visible. More precise tracking is done by using a tracking indicator which is often a small gauge, included with many saws, that is placed along the guides. This gauge can provide a quantitative measure of how far off the blade is.

Adjusting: Most band saws have adjustment mechanisms to correct blade tracking. This may involve adjusting guide post positions or using blade tracking wheels. The adjustment methods vary depending on the saw’s design. Small adjustments are usually made, checking after each adjustment to ensure the blade is centered. If you cannot adjust the blade tracking with these mechanisms, the issue likely lies elsewhere, such as worn or misaligned wheels or guides which may need professional attention.

Q 11. Describe the different types of material you have experience cutting with a band saw.

My experience with band saws encompasses a broad range of materials. It’s like having a versatile tool for different tasks. I’ve worked with everything from hardwoods and softwoods to metals, plastics, and composites.

- Wood: Various species of hardwoods (oak, maple, cherry) and softwoods (pine, fir, cedar) with varying grain patterns and densities.

- Metals: Mild steel, aluminum, brass, and even some stainless steels, though specialized blades are often required for harder metals.

- Plastics: Acrylics, PVC, and various other plastics, often requiring specific blades to avoid melting or chipping.

- Composites: Materials like fiberglass-reinforced plastics, requiring careful consideration of blade selection and feed rate to avoid damage.

The selection of the proper blade for the material is critical, as is understanding the properties of each material, to prevent the blade from being overwhelmed and to ensure a clean and safe cut.

Q 12. How do you handle different thicknesses of material when cutting with a band saw?

Cutting different thicknesses requires adjustments to the feed rate and, in some cases, the blade. Think of cutting butter versus cutting a thick steak – you’d use different approaches. Thinner materials require a slower feed rate to prevent breakage or tear-out, while thicker materials may require a faster feed rate depending on the material. For exceptionally thick materials, a different style of blade, such as a thicker blade with a different tooth configuration, may be needed.

- Thin materials: Slow feed rate, possibly a finer-toothed blade to prevent chipping or tear-out.

- Thick materials: Increased feed rate within the limits of the blade and machine, a blade with a coarser tooth pattern may be used to remove more material per pass.

The key is to match the feed rate to the blade, the material and the machine’s capabilities. Overfeeding will overload the blade, while underfeeding will be slow and inefficient.

Q 13. Explain the importance of proper workpiece clamping and fixturing.

Proper workpiece clamping and fixturing is paramount for safety and cut quality. It’s like building a strong foundation – if the foundation is weak, the whole structure is at risk. Without secure clamping, the workpiece can move unexpectedly, potentially leading to a dangerous kickback or an inaccurate cut.

Importance: Secure clamping prevents movement during the cutting process. This ensures a straight, accurate cut, prevents kickback (a sudden, forceful ejection of the workpiece), and minimizes the risk of injury to the operator. Using appropriate jigs and fixtures improves repeatability, particularly when cutting multiple identical pieces.

Methods: Various clamping methods exist, including vise clamping, hold-downs, and specialized jigs depending on the workpiece size, shape and material. Always ensure the workpiece is firmly secured before starting the cut, and remember to be mindful of the clamping pressure and the potential for damage to the material.

Q 14. What are the different cutting speeds and feeds for various materials?

Cutting speeds and feeds are material-dependent. There’s no one-size-fits-all answer. It’s like adjusting the speed of a car based on the road conditions and traffic. Harder materials require slower speeds and feeds to prevent blade breakage and overheating. Softer materials allow for faster speeds and feeds.

Factors: The ideal speed and feed rate depend on the material being cut, the type of blade, and the desired finish. Consult the band saw’s manual and the blade manufacturer’s recommendations for optimal settings. Incorrect cutting parameters can cause poor cut quality, blade breakage, or overheating and damage the equipment.

Examples: Cutting mild steel might require a slower speed and feed than cutting softwood. Cutting aluminum, depending on the hardness, will require a different speed and feed than cutting hardwoods.

Experimentation: Start with conservative settings and gradually increase the feed rate while monitoring the blade and the cut for any signs of stress or overheating. Always prioritize safety and consult the equipment and blade manufacturer’s recommendations.

Q 15. How do you calculate the correct cutting speed for a given material and blade?

Calculating the correct cutting speed for a band saw is crucial for efficiency, blade life, and safety. It’s determined primarily by the material being cut and the type of blade used. The formula is straightforward: Cutting Speed (SFM) = (π x Diameter x RPM) / 12, where SFM is surface feet per minute, Diameter is the blade’s diameter in inches, and RPM is revolutions per minute.

However, you don’t typically start with this formula directly. Instead, you consult charts or tables provided by blade manufacturers. These charts specify recommended cutting speeds (SFM) for various materials (steel, aluminum, wood, etc.) and blade types (high-speed steel, carbide-tipped, etc.). For example, a high-speed steel blade cutting mild steel might have a recommended speed of 90 SFM, while aluminum might require 200 SFM.

Once you have the recommended SFM, you can use the formula to calculate the necessary RPM for your specific blade diameter. Let’s say you have a 1-inch diameter blade and the recommended SFM for your material is 90. Solving for RPM, we get: RPM = (SFM x 12) / (π x Diameter) = (90 x 12) / (π x 1) ≈ 344 RPM. Always remember to adjust this based on the specific blade and material properties.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the signs of a malfunctioning band saw, and what actions should be taken?

A malfunctioning band saw can be dangerous, so recognizing the signs is critical. Common signs include unusual noises (squeaking, squealing, grinding), blade deflection or wandering, excessive vibration, slow cutting speed, or difficulty in starting. The blade might also break or become loose, potentially causing serious injury.

Actions to take depend on the specific issue. If you hear unusual noises, immediately stop the machine and inspect the blade, guides, and tires for wear, damage, or misalignment. Excessive vibration could indicate a loose component, worn bearings, or an unbalanced blade. A slow cutting speed could be due to a dull blade or incorrect cutting speed settings. Always address any issues promptly. Never operate a band saw if you suspect a malfunction. If the problem is beyond your expertise, contact a qualified technician for repair. A broken blade is an immediate shut down and safety inspection.

Q 17. How do you perform routine maintenance checks on a band saw?

Routine maintenance is essential for a band saw’s longevity and safety. This should be done before each use and more thoroughly on a regular schedule (weekly or monthly depending on usage).

- Blade Inspection: Check the blade for wear, cracks, or damage. Replace the blade if necessary. Ensure proper tension.

- Guide Adjustment: Inspect and adjust the blade guides (upper and lower) to maintain proper alignment and clearance with the blade. Improper alignment can lead to blade breakage.

- Tire Inspection: Check the tires (upper and lower wheels) for wear, cracks, or slippage. Replace worn or damaged tires.

- Lubrication: Lubricate all moving parts according to the manufacturer’s recommendations. This includes the bearings, guides, and tires.

- Cleanliness: Keep the machine clean and free of debris. Sawdust buildup can hinder performance and cause safety hazards.

- Tension Adjustment: Regularly check and adjust the blade tension. Incorrect tension can cause breakage or poor cutting performance.

Proper maintenance isn’t just about extending the life of the machine; it’s about ensuring the safety of the operator. A well-maintained saw is a safer saw.

Q 18. Describe your experience with different types of band saw machines (horizontal, vertical, etc.).

My experience encompasses various band saw types, including horizontal band saws (used for cutting larger, heavier materials), vertical band saws (ideal for cutting smaller pieces and intricate shapes), and specialized models like cold saws. Horizontal band saws typically offer greater cutting capacity, while vertical band saws provide greater precision and are better suited for intricate cuts.

I’ve worked extensively with horizontal band saws used for cutting structural steel in a fabrication shop. The emphasis there was on efficient material removal and handling large components. In contrast, my work with vertical band saws has primarily involved smaller scale projects, like custom metalwork and prototype creation, where accuracy is paramount. Cold saws, while not strictly band saws, are often utilized in similar contexts and involve similar safety precautions and maintenance considerations, which I am also versed in.

Each type demands a different skill set and approach. Horizontal band saws require a focus on effective material handling and controlling the cut, while vertical band saws demand precision in guiding the workpiece and selecting appropriate blade speed and feed rate.

Q 19. How do you handle emergency situations involving a band saw malfunction?

Emergency situations involving band saws require immediate and decisive action. The first priority is always safety. If a blade breaks, immediately shut down the machine and clear the area. Do not attempt to approach the broken blade until the machine is completely stopped and the power is disconnected. The area around the saw should also be inspected for any hazards from the blade.

Depending on the nature of the malfunction, additional steps may be needed. For example, if a workpiece gets jammed, carefully power off the machine and use appropriate tools to remove the obstruction. Always follow established safety protocols, including using appropriate personal protective equipment (PPE) such as eye protection, hearing protection, and cut-resistant gloves. If an injury occurs, first aid should be administered, and medical attention should be sought immediately. A detailed report of the incident should be filed as well to prevent recurrence.

Q 20. What are your experience with CNC controlled band saws?

My experience with CNC-controlled band saws is significant. These saws offer automated cutting, significantly improving precision, repeatability, and efficiency compared to manual operation. The programming aspect involves using CAM software (Computer-Aided Manufacturing) to create cutting paths based on the design of the workpiece. I’m familiar with various programming languages and software used to control these machines. This allows for complex cuts and automated operations.

I’ve used CNC band saws for high-volume production runs and for creating complex shapes that would be impractical or impossible to achieve manually. This type of saw demands familiarity with the software, and understanding of machine parameters for the correct cut. The ability to create efficient cutting routines and optimize parameters for various materials is a key skill with these machines. The enhanced safety features and automated processes are also critical considerations for effective operation.

Q 21. Explain the process of troubleshooting common band saw problems.

Troubleshooting band saw problems involves a systematic approach. First, identify the symptom: unusual noise, blade breakage, inaccurate cuts, etc. Then, carefully examine the machine, checking for obvious issues like loose components, worn parts, or misalignment. A logical approach to elimination of possible problems is key.

For example, if the blade is breaking frequently, check the blade tension, guide alignment, and blade quality. If the cuts are inaccurate, inspect the blade guides, workpiece clamping, and blade teeth. Unusual noises often point to worn bearings, loose components, or a damaged blade. If the problem persists, consult the machine’s manual and/or contact a qualified technician. Keeping detailed notes, as well as logging the symptoms and the troubleshooting steps, helps in identifying the root causes and aids in resolving recurring issues. This systematic and logical approach is crucial for efficient problem-solving.

Q 22. How do you ensure the accuracy and precision of cuts made on a band saw?

Ensuring accurate and precise cuts on a band saw hinges on several key factors. It’s not just about the machine itself; it’s about a holistic approach.

- Blade Tension: Proper blade tension is paramount. Too loose, and the blade will wander; too tight, and it can snap. The manufacturer’s recommendations should always be followed, and a tension gauge should be used regularly. Think of it like a guitar string – needs to be just right for optimal performance.

- Blade Tracking: The blade must track perfectly down the center of the wheels. Misalignment leads to inaccurate cuts and blade damage. Adjusting the tracking mechanism is critical; often it’s a simple adjustment, but essential for accuracy. Imagine trying to cut straight with a crooked blade – impossible!

- Guide Post and Fence Alignment: The fence (for straight cuts) and guide posts must be precisely aligned with the blade. Any deviation results in an inaccurate cut. These components prevent the blade from wandering and ensure straight, parallel cuts. Regular checking and calibration are crucial here.

- Material Support: The workpiece must be firmly supported to prevent vibration and deflection during the cut. Using support blocks and a vise helps in this regard. This prevents the material from wobbling, leading to a clean cut.

- Cutting Speed and Feed Rate: Selecting the appropriate cutting speed and feed rate for the material being cut directly impacts accuracy. Too fast, and the blade will overheat and possibly break, impacting the accuracy of your cuts; too slow can result in a rough, inaccurate cut. This requires experience and knowledge of the materials you work with.

By diligently attending to these factors, you can significantly enhance the precision of your band saw cuts.

Q 23. What are the best practices for maximizing the lifespan of a band saw blade?

Maximizing the lifespan of a band saw blade requires a multi-pronged approach focusing on prevention and care.

- Proper Blade Selection: Choosing the right blade for the material and application is fundamental. Using a skip-tooth blade for hardwood is preferable to a fine-tooth blade, and vice versa.

- Correct Tension: Maintaining the correct blade tension as stated by the manufacturer is critical. Over-tensioning leads to premature breakage, while under-tensioning results in poor cuts and wandering.

- Regular Inspection: Before each use, examine the blade for any signs of damage, such as cracks, nicks, or set loss. Early detection of problems prevents larger issues.

- Lubrication: Regular lubrication of the blade and guides is essential to minimize friction and heat buildup, extending the blade’s life and maintaining cutting efficiency. Think of it like oiling a bicycle chain – smooth operation and longer life.

- Appropriate Cutting Techniques: Avoiding aggressive cutting, using proper feed rates, and preventing blade contact with metal or other hard objects minimizes wear and tear. Avoid forcing the blade; let it do its work.

- Proper Storage: When not in use, store the blade in a safe, dry place to prevent rust and corrosion. Keeping it clean is also a great practice.

By consistently following these best practices, you can significantly extend the useful life of your band saw blades and reduce your operating costs.

Q 24. How do you deal with material that is difficult to cut on a band saw?

Cutting difficult materials on a band saw requires adjustments to technique and sometimes equipment. Some materials are simply more challenging than others.

- Blade Selection: Choose a blade specifically designed for the material. For example, a carbide-tipped blade is ideal for hard metals, while a high-speed steel blade with a specific tooth configuration works best for certain plastics or composites.

- Cutting Speed and Feed Rate: Adjust these parameters based on the material’s hardness and toughness. Slower feed rates and potentially a lower cutting speed is typically needed for harder materials to prevent blade breakage or excessive heat buildup.

- Cooling: For materials prone to heat buildup during cutting (like certain plastics or aluminum alloys), consider using a coolant. This helps prevent melting or burning and extends blade life. Always ensure the coolant is compatible with the material.

- Multiple Passes: For very thick or hard materials, multiple passes may be necessary to avoid stressing the blade. This allows for a more controlled and safer cut.

- Workpiece Support: Extra support is especially important when cutting challenging materials to prevent vibration and deflection.

Remember, safety is paramount when working with challenging materials. Take your time and proceed with caution.

Q 25. Describe your experience with different types of band saw blade teeth (e.g., skip tooth, hook tooth).

I have extensive experience with various band saw blade teeth configurations. Each type serves a unique purpose.

- Skip Tooth Blades: These blades feature teeth spaced farther apart, with some teeth removed. This design is excellent for rough cutting, removing significant material quickly in wood and softer materials. They’re great for fast cuts where precision isn’t as critical.

- Hook Tooth Blades: These blades have teeth with a pronounced hook shape. This design provides aggressive cutting action, facilitating smoother cuts in harder materials like hardwoods and certain metals. They are efficient for curves and intricate cuts, however, they’re less suited for rough cutting.

- Standard Tooth Blades: These blades have uniformly spaced teeth, offering a balance between cutting speed and smoothness. They’re versatile and suitable for many materials and applications. These are a good all-around choice for various tasks.

- Fine Tooth Blades: These blades have closely spaced, smaller teeth, designed for precise and smooth cuts in softer materials like thin wood or plastics. They’re best for fine detailed work.

- Specialty Blades: There are many other specialty blades for specific applications, such as carbide-tipped blades for metals or blades designed for cutting specific materials.

Understanding the characteristics of each tooth type allows me to select the optimal blade for each cutting task, maximizing efficiency and minimizing material waste. The selection depends on factors such as material type, desired finish, and cutting speed.

Q 26. How do you ensure the safety of yourself and others around the band saw?

Safety is my top priority when operating a band saw. I adhere to rigorous safety procedures to protect myself and others.

- Proper PPE: I always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and cut-resistant gloves. This is non-negotiable.

- Machine Inspection: Before each use, I thoroughly inspect the band saw for any damage or loose parts. This includes checking the blade tension and tracking.

- Clear Workspace: I maintain a clean and organized workspace, ensuring that there are no obstructions around the machine. This prevents tripping hazards and allows for better visibility.

- Proper Technique: I employ safe cutting techniques, avoiding sudden movements or forceful actions. I feed the material slowly and steadily, never reaching into the cutting area while the blade is moving.

- Emergency Stop: I am always aware of the location of the emergency stop button and how to use it effectively.

- Training and Awareness: I regularly review safety procedures and remain aware of potential hazards. I ensure others are aware of safety guidelines, particularly if they are working near the machine.

Safety is a culture, not just a procedure. By following these practices, we create a safe environment for all involved.

Q 27. What are your methods for optimizing cutting efficiency and minimizing waste?

Optimizing cutting efficiency and minimizing waste involves strategic planning and execution.

- Proper Material Handling: Accurate measuring and cutting reduces waste. Precise planning ensures the efficient use of material, optimizing the yield.

- Blade Selection: Choosing the correct blade for the material and application directly impacts cutting speed and finish, reducing wasted time and material.

- Optimized Cutting Parameters: Fine-tuning cutting speed and feed rate for the specific material yields the best results, minimizing wasted effort and material.

- Waste Recycling: Even small scraps of material can often be repurposed for other projects, thereby minimizing waste.

- Jig and Fixture Use: Using jigs and fixtures for repetitive cuts ensures accuracy and consistency, reducing errors and wasted material.

- Careful Planning of Cuts: Planning the sequence of cuts minimizes the number of setups and movements, thus saving time and reducing waste.

Through careful planning and mindful execution, I strive for maximum efficiency and waste reduction in every operation.

Q 28. Describe a time you had to troubleshoot a complex band saw issue. What was the outcome?

During a large production run, our band saw started producing inconsistent cuts; sometimes the cuts were too wide, sometimes too narrow, with a clear pattern to the inconsistency. Initially, we suspected blade issues.

My troubleshooting process involved:

- Visual Inspection: I carefully examined the blade, guides, and wheels for any signs of damage or misalignment. Nothing obvious was apparent.

- Blade Tension Check: I verified the blade tension using a gauge. It was within the manufacturer’s specifications.

- Tracking Adjustment: I checked the blade tracking and found a slight misalignment. I made the necessary adjustment.

- Guide Alignment: I then checked the alignment of the guide posts and the fence, and found that one guide post was slightly bent which was causing the inconsistent cuts.

- Repair and Testing: The bent guide post was repaired or replaced and then the machine was thoroughly tested to ensure the repair was successful before restarting production.

The outcome was a restoration of consistent, accurate cuts. The root cause, a slightly bent guide post, was easily overlooked, highlighting the importance of a systematic troubleshooting approach. The issue was resolved within a couple of hours, preventing significant production downtime and potential scrap.

Key Topics to Learn for Band Saw Operations Interview

- Band Saw Mechanics: Understanding the operational principles of band saws, including blade tension, tracking, and guide systems. This includes knowing the different types of band saws and their applications.

- Safe Operating Procedures: Demonstrating knowledge of safety regulations, emergency shut-off procedures, and personal protective equipment (PPE) requirements for band saw operation. Practical application includes explaining your experience adhering to safety protocols.

- Blade Selection and Maintenance: Knowing how to select the appropriate blade for various materials and thicknesses. This also involves understanding blade sharpening, tooth geometry, and proper storage techniques.

- Material Handling and Feeding: Describing safe and efficient techniques for handling different materials on the band saw, including proper feeding and support methods to prevent workpiece movement and ensure clean cuts.

- Troubleshooting and Maintenance: Explaining your approach to identifying and resolving common band saw issues, such as blade breakage, tracking problems, or motor malfunctions. This includes preventative maintenance practices.

- Quality Control and Inspection: Understanding methods to ensure the quality of cuts, identifying defects, and implementing corrective actions to maintain consistent accuracy and precision.

- Production Efficiency and Optimization: Discuss strategies to improve the overall efficiency and output of band saw operations, including techniques for optimizing cutting speed, minimizing waste, and maximizing throughput.

Next Steps

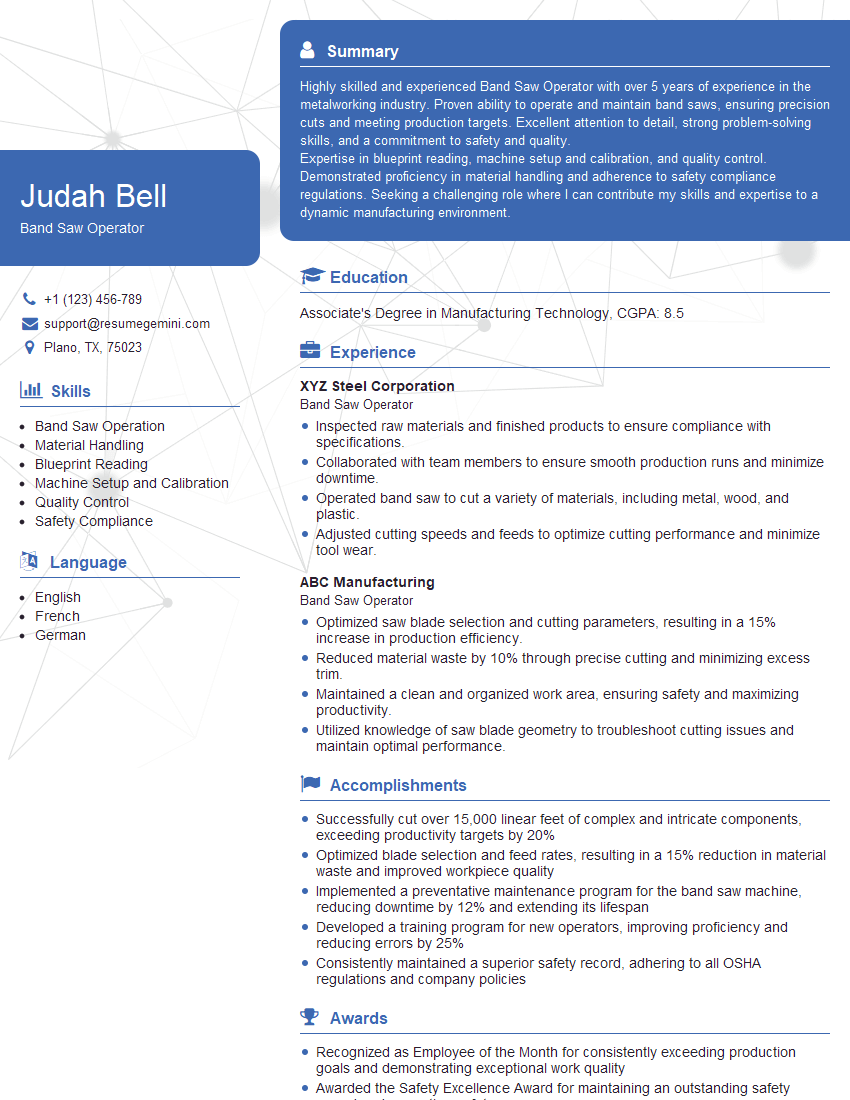

Mastering Band Saw Operations opens doors to exciting career opportunities in manufacturing, woodworking, and metalworking industries. A strong understanding of these principles is highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to Band Saw Operations to guide you. Take advantage of these resources to showcase your expertise and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO