Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Forklift Maintenance Inspection interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Forklift Maintenance Inspection Interview

Q 1. Describe your experience with preventative maintenance schedules for forklifts.

Preventative maintenance schedules for forklifts are crucial for ensuring operational efficiency, safety, and longevity. They’re not just a list of tasks; they’re a proactive strategy to minimize downtime and costly repairs. A well-structured schedule typically follows a tiered approach, encompassing daily, weekly, monthly, and yearly inspections and services.

For example, a daily inspection might include checking fluid levels (engine oil, hydraulic fluid, coolant), tire pressure, and visually inspecting for any damage to the mast, forks, or body. A weekly inspection could involve a more thorough examination of the brakes, steering, and warning lights, possibly including a functional test. Monthly checks often encompass more detailed inspections of the hydraulic system, including leak checks and component inspections. Yearly maintenance usually involves major servicing like complete hydraulic fluid changes, engine tune-ups, and potentially more extensive inspections of the electrical system and safety components. The specific schedule is tailored to the forklift’s make, model, usage intensity, and the specific operational environment. I’ve personally worked with clients who utilize computerized maintenance management systems (CMMS) to track these schedules and generate automated alerts, preventing oversight. Using a CMMS drastically improves efficiency and reduces the likelihood of preventable failures.

Q 2. What are the common causes of forklift hydraulic system failures?

Hydraulic system failures in forklifts are often caused by a combination of factors, and understanding these is key to effective preventative maintenance. Think of the hydraulic system as the forklift’s circulatory system – if it’s compromised, the whole operation falters. Common causes include:

- Contamination: Dirt, debris, or moisture in the hydraulic fluid can cause wear and tear on seals, pumps, and valves. This is often due to inadequate filtration or improper fluid handling during maintenance.

- Leaks: Leaks develop over time due to wear and tear on seals, hoses, and fittings. They lead to fluid loss, reduced pressure, and eventual system failure.

- Overheating: Excessive use or malfunctioning cooling systems can cause the hydraulic fluid to overheat, degrading its properties and potentially damaging components.

- Improper maintenance: Failing to follow the manufacturer’s recommended maintenance schedule – including fluid changes and filter replacements – can dramatically shorten the lifespan of the hydraulic system.

- Component wear: Pumps, valves, and cylinders are subject to wear and tear over time, and eventually they fail. This often manifests as decreased lifting capacity or sluggish operation.

For example, I once diagnosed a hydraulic failure that was initially attributed to a faulty pump. However, a thorough investigation revealed that the root cause was severe contamination due to a damaged filter housing, a relatively simple but critical oversight.

Q 3. How do you diagnose a malfunctioning forklift engine?

Diagnosing a malfunctioning forklift engine requires a systematic approach, similar to diagnosing a medical condition. You need to gather evidence, isolate the problem, and then determine the solution. I usually start by observing the symptoms:

- Does the engine start? If not, this could indicate issues with the battery, starter motor, or ignition system.

- Is the engine running rough? This suggests possible issues with fuel delivery, ignition timing, or compression.

- Is there excessive smoke from the exhaust? Blue smoke often indicates burning oil, while black smoke indicates a rich fuel mixture. White smoke may point towards a coolant leak into the combustion chamber.

- Are there any unusual noises? Knocking, rattling, or squealing could indicate bearing wear, loose components, or belt problems.

Once the symptoms are identified, I perform checks, using diagnostic tools such as code readers for electronically controlled engines, compression testers, and leak detection tools. A combination of visual inspection, diagnostic tools and experience is critical to pinpoint the problem accurately. For instance, a lack of power might be caused by faulty fuel injectors, a clogged air filter, a malfunctioning fuel pump, or even low compression in one or more cylinders. The diagnostic process systematically rules out each possibility to accurately identify the root cause.

Q 4. Explain the importance of regular battery maintenance for forklifts.

Regular battery maintenance is paramount for the operational reliability and safety of electric forklifts. A neglected battery can lead to premature failure, reduced performance, and potentially dangerous situations like unexpected power loss during operation. Proper maintenance extends battery life, minimizes downtime, and keeps operational costs lower.

Key aspects of battery maintenance include:

- Regular cleaning: Keep the battery terminals clean and free of corrosion to ensure good electrical contact and prevent arcing.

- Proper charging: Using the correct charger and charging procedure is crucial to avoid overcharging or undercharging, both of which can damage the battery.

- Water level checks (for flooded batteries): Maintain the correct electrolyte levels by adding distilled water as needed. Never use tap water.

- Equalization charging (periodic): This helps to balance the charge across all cells in the battery, extending its lifespan.

- Temperature monitoring: High temperatures significantly degrade battery performance and lifespan.

Imagine a situation where the forklift suddenly loses power while lifting a heavy load – a poorly maintained battery could directly contribute to such a dangerous incident. That’s why regular, diligent battery care is not just a matter of convenience, but a critical safety procedure.

Q 5. What safety procedures do you follow when inspecting a forklift?

Safety is my utmost priority when inspecting a forklift. Before I even approach the machine, I ensure the area is clear of obstructions and that the forklift is switched off and de-energized, if possible. I wear appropriate safety equipment, including safety glasses, gloves, and steel-toe boots. I also consult the forklift’s operational manual for any specific safety warnings before commencing inspection.

During the inspection, I follow these critical steps:

- Visual Inspection: I carefully examine all components for obvious damage, leaks, or wear and tear. This includes checking the tires, forks, mast, hydraulic lines, and any warning lights or indicators.

- Fluid Levels: I check the levels of engine oil, hydraulic fluid, coolant, and battery electrolyte (if applicable) making sure each is within acceptable ranges.

- Functional Tests: If deemed safe, I conduct basic functional tests such as raising and lowering the forks, checking the brakes, and verifying the operation of the horn and lights.

- Documentation: I meticulously document all findings, including any issues or potential problems that need to be addressed. This documentation serves as a record for future maintenance and helps identify potential patterns or recurring issues.

My safety-first approach isn’t just a protocol – it’s a deeply ingrained habit developed from years of experience, ensuring both my safety and that of those working around me. A careless inspection can easily lead to injury or equipment damage.

Q 6. How do you identify and address potential safety hazards related to forklift operation?

Identifying and addressing potential safety hazards related to forklift operation is crucial for preventing accidents. This involves a combination of proactive inspections, operator training, and workplace safety procedures. My approach involves:

- Workplace Assessment: Regularly evaluating the operating environment for potential hazards such as uneven surfaces, obstructed pathways, poor lighting, and the presence of pedestrians or other equipment.

- Forklift Inspection: Conducting thorough inspections as described previously, ensuring that the forklift is in safe operating condition.

- Operator Training: Ensuring that operators are properly trained and understand safe operating procedures, including the use of seatbelts, speed limits, load handling techniques, and pre-operation checks.

- Maintenance Protocols: Implementing a comprehensive maintenance program to identify and address potential mechanical failures before they lead to accidents.

- Traffic Management: Implementing traffic control measures in areas with high forklift traffic, such as designated walkways, speed limits, and the use of warning signals.

- Emergency Procedures: Establish and regularly practice emergency procedures in case of accidents or malfunctions.

For instance, I once identified a potential hazard where forklift traffic crossed a pedestrian walkway without any warning signals or safety barriers. By implementing clear signage and pedestrian crossing procedures, we significantly reduced the risk of accidents in that area. Proactive hazard identification and mitigation is cheaper and more effective than dealing with the consequences of an accident.

Q 7. What are the key components of a forklift’s braking system?

A forklift’s braking system is critical for safe operation, preventing accidents and ensuring controlled movements. Depending on the make and model, the braking system may consist of several key components working together. The most important are:

- Service Brakes: These are the primary brakes used to slow down or stop the forklift. They’re typically hydraulically actuated, engaging brake shoes or discs to slow the wheels. Regular checks for wear and tear on brake pads or linings are crucial.

- Parking Brake: This brake is used to hold the forklift stationary when parked, preventing accidental movement. It is often a mechanically actuated system, acting directly on the wheels or transmission.

- Brake Pedal: This is the operator’s interface for controlling the service brakes. Its responsiveness and feel are important indicators of brake system health.

- Brake Master Cylinder (Hydraulic systems): In hydraulic systems, this component is responsible for converting the force from the brake pedal into hydraulic pressure which then activates the brake mechanisms at the wheels.

- Brake Lines and Hoses: These carry the hydraulic fluid to the brake actuators at each wheel. Leaks in these lines are a major safety hazard.

- Brake Shoes/Discs and Drums/Calipers: These are the components that actually create friction to slow the wheels. Regular inspection and replacement when worn is essential.

Regular maintenance, including fluid checks and inspections of brake components, ensures the braking system remains effective and responsive. This is not just about preventing costly repairs; it’s about ensuring the safety of the operator and those working around the forklift.

Q 8. Describe the process for conducting a pre-operational inspection of a forklift.

A pre-operational inspection is crucial for ensuring the safety and efficiency of a forklift before each use. Think of it like a driver’s pre-flight check for an airplane – you wouldn’t take off without it! It’s a systematic check of key components to identify potential problems before they cause accidents or breakdowns.

- Visual Inspection: Start with a walk-around, checking for obvious damage like leaks, dents, or cracks in the mast, forks, body, and tires. Look for loose parts or any signs of previous damage.

- Fluid Levels: Check engine oil, transmission fluid, hydraulic fluid, and coolant levels. Low levels indicate potential leaks that need immediate attention. Use the dipstick to check oil levels properly. Low levels should be reported immediately and addressed before operation.

- Tires: Inspect tire pressure and tread depth. Insufficient pressure can lead to punctures or uneven wear, impacting stability. Worn tires compromise grip and should be replaced according to company policy and manufacturer’s guidelines.

- Lights and Signals: Verify that headlights, brake lights, turn signals, backup alarms, and horn are all functioning correctly. These are critical for safe operation, particularly in busy environments.

- Steering and Brakes: Test the steering for smooth operation and free movement. Check the braking system for responsiveness and effectiveness. A jerky response or weak braking ability is a serious safety hazard.

- Mast and Forks: Check for any signs of damage, bending, or wear to the mast and forks. Ensure the forks are securely attached and that chains are properly secured. Bent forks can be extremely hazardous.

- Safety Features: Examine the seatbelt, operator restraint systems, and other safety features to ensure they are in good working order. Confirm that emergency stops are easily accessible and operational.

- Leaks: Check for any fluid leaks, paying close attention to hydraulic lines, engine components, and transmission areas. Leaks can indicate significant mechanical problems and potentially lead to equipment failure or fire.

Remember to document your findings, typically using a pre-shift inspection checklist provided by your employer. This creates a record that can be used to track maintenance needs and ensure accountability.

Q 9. How do you interpret and utilize forklift maintenance manuals?

Forklift maintenance manuals are your bible – they contain essential information about your specific forklift model. They’re not just a collection of diagrams; they provide step-by-step procedures, torque specifications, component diagrams, troubleshooting guides, and safety precautions. Consider them the ultimate reference guide for all maintenance tasks.

- Locate the Right Manual: First, ensure you have the correct manual for your specific forklift model and year. The serial number usually located on a plate on the forklift will help identify the correct manual.

- Understand the Diagrams: Maintenance manuals usually include detailed diagrams showing the location of components and how they are connected. These diagrams are invaluable for locating parts and understanding the overall system.

- Follow Procedures Precisely: Adhere strictly to the instructions in the manual when performing any maintenance task. This ensures that the work is done correctly and reduces the risk of damage or injury. Improper techniques can easily void warranties.

- Interpreting Specifications: Pay close attention to torque specifications, fluid types, and other technical data. Using incorrect specifications could result in component damage or premature failure. Always use the manufacturer’s recommended parts and fluids.

- Troubleshooting: Use the troubleshooting sections to diagnose and fix common problems. This is where the manual provides systematic steps to identify the root cause of a malfunction.

- Regular Review: Regularly review the manual to stay updated on the proper maintenance procedures and to familiarize yourself with any changes or updates.

Think of the manual as your partner in maintenance; it’s there to guide you through every step, from the simplest oil change to the most complex repair. Always refer to it before attempting any maintenance task.

Q 10. What are the common types of forklift fuel systems and their maintenance requirements?

Forklifts typically use either gasoline, diesel, propane (LPG), or electric fuel systems. Each system has unique maintenance needs.

- Gasoline: Gasoline-powered forklifts require regular fuel filter changes, air filter cleaning or replacement, and carburetor cleaning or adjustment (if applicable). Ensure proper ventilation while refueling and avoid prolonged idling.

- Diesel: Diesel forklifts need similar attention to fuel filters and air filters, but also require more frequent checks of the fuel injection system and regular lubrication of moving parts. Proper handling of diesel fuel is critical due to its flammability and potential environmental impact.

- Propane (LPG): Propane systems require regular inspection of the fuel tank, lines, and regulator for leaks. Proper tank handling and storage are crucial to minimize risks.

- Electric: Electric forklifts use batteries, which require periodic charging, watering (depending on the battery type), and cleaning. Battery maintenance also includes regular inspection for signs of damage or corrosion. They have no combustion engine, so the main focus is electrical system maintenance, like proper wire connections.

Regardless of fuel type, regular maintenance is essential. Ignoring maintenance can lead to reduced performance, increased fuel consumption, and increased risk of breakdowns or accidents. Always refer to your specific forklift’s maintenance manual for the exact requirements.

Q 11. Explain the proper procedures for changing forklift tires.

Changing forklift tires requires safety precautions and proper tools. Think of it like changing a car tire but with added weight and potential hazards.

- Safety First: Block the wheels securely, engage the parking brake firmly, and use wheel chocks to prevent movement. Never work under a raised forklift without proper supports.

- Equipment: Gather necessary tools: tire iron, jack (with adequate capacity for the forklift), and safety glasses or a face shield.

- Jacking: Position the jack securely at the designated jack point on the forklift’s frame, following the manufacturer’s instructions precisely. Avoid damaging the frame by using an incorrectly placed jack.

- Tire Removal: Carefully loosen the lug nuts before jacking up the wheel. Then, lift the wheel until it clears the ground, remove the lug nuts entirely, and take off the tire.

- Tire Installation: Install the new tire, ensuring the valve stem is positioned correctly. Tighten the lug nuts snugly but not fully at this point, then slowly lower the wheel to the ground.

- Final Tightening: Once the wheel is on the ground, use the tire iron to tighten the lug nuts in a star pattern. Follow manufacturer’s specifications regarding tightening torque.

- Inspection: After changing the tire, lower the forklift, check that the wheel is securely mounted, and visually inspect the surrounding areas for any signs of damage.

Always follow the manufacturer’s recommendations for proper tire pressure. Incorrect pressure can cause premature tire wear, instability, and potential accidents.

Q 12. How do you troubleshoot electrical issues in forklifts?

Troubleshooting electrical issues in forklifts requires systematic approach. It’s like detective work, where you follow the clues to find the culprit. Safety is paramount; always disconnect the battery before working on any electrical components.

- Visual Inspection: Begin with a careful visual inspection of all wiring, connectors, and components. Look for loose wires, damaged insulation, corrosion, or burnt components.

- Check Connections: Securely reconnect any loose wires or connectors. Clean any corroded terminals with a wire brush and apply a corrosion inhibitor.

- Multimeter: Use a multimeter to test voltage, continuity, and resistance. This allows for precise identification of faulty components. Check for voltage at suspected points in the circuit.

- Component Testing: Systematically test components like switches, relays, solenoids, and motors. A faulty component might be indicated by an unexpected reading on the multimeter.

- Wiring Diagrams: Refer to the forklift’s electrical wiring diagrams to trace circuits and identify the location of components. Diagrams will help navigate the complexities of the forklift’s electrical system.

- Professional Help: If you are not experienced in electrical diagnostics or if the problem persists, seek assistance from a qualified forklift technician. Attempting complex repairs without proper expertise can lead to further damage or injury.

Remember, working with electricity can be dangerous. If unsure, always consult a professional. Safety should always be the top priority.

Q 13. What are the signs of a worn-out forklift mast?

A worn-out forklift mast is a serious safety hazard. Imagine the mast as the backbone of the forklift; if it’s compromised, the entire operation is at risk. Signs of wear include:

- Bending or Damage: Any visible bending, cracks, or damage to the mast structure indicates significant wear and compromises structural integrity. This should be addressed immediately; operating a forklift with a damaged mast is extremely dangerous.

- Excessive Play or Movement: Excessive play or movement in the mast, particularly when lifting or lowering loads, indicates worn-out rollers, sheaves, or other components. This compromises the stability of the lift and poses a severe risk of load drop or mast collapse.

- Hydraulic Leaks: Leaks in the mast hydraulic system suggest seal failure or damage to hydraulic cylinders, potentially impacting lifting capacity and creating a safety hazard.

- Unusual Noises: Grinding, squeaking, or other unusual noises during operation are warning signs of wear or damage. This often means parts are rubbing together where they shouldn’t. These noises usually indicate that an inspection should be conducted.

- Difficult Operation: Difficulty in raising or lowering loads, or uneven lifting, can point toward problems within the mast assembly. This compromises the efficiency of operation and impacts the stability of the lift.

Regular inspection and maintenance are crucial to prevent mast failure. Prompt attention to any of these signs is essential for safe forklift operation.

Q 14. How do you perform a thorough inspection of forklift forks?

Forklift forks are essential for handling loads safely and efficiently. Regular inspection is critical to prevent accidents. Inspect them thoroughly, much like a doctor does a complete physical examination.

- Visual Inspection: Look for any signs of bending, cracks, damage, or excessive wear to the fork surface. Even small cracks can propagate and compromise structural integrity.

- Measurement: Measure the thickness of the forks at multiple points using a caliper to detect wear. Excessively worn forks will not meet safety standards and should be replaced immediately.

- Check for Alignment: Ensure the forks are properly aligned and straight. Bent forks can affect the stability of the load and present a safety risk.

- Check for Cracks: Carefully check for any cracks in the welds or fork body. Focus on the areas that experience the greatest stress during lifting and handling operations. Look for signs of impact damage.

- Surface Condition: Examine the surface condition of the forks for excessive wear, pitting, or scoring. These imperfections reduce the fork’s strength and load-bearing capability.

- Fork Tips: Check the condition of the fork tips for wear or damage. Worn or damaged fork tips are particularly dangerous as they affect the stability of the load during handling.

If any damage is detected, the forks should be removed from service. Replacing damaged or worn forks is non-negotiable; continued operation with compromised forks poses significant risks.

Q 15. Describe your experience with repairing forklift transmissions.

Forklift transmission repair requires a deep understanding of hydraulics, gear systems, and torque converters. My experience spans over ten years, encompassing troubleshooting, repair, and preventative maintenance on a wide range of transmissions, from simple manual units to complex automatic systems. I’ve worked on both wet and dry clutch systems, diagnosing issues such as gear slippage, bearing failure, and hydraulic leaks. For example, I once diagnosed a complete transmission failure on a sit-down propane forklift by systematically checking hydraulic fluid levels and pressure, identifying a faulty hydraulic pump that was causing insufficient pressure to the clutches. Replacing the pump resolved the issue. In another instance, I pinpointed a worn synchronizer ring in a manual transmission using a combination of listening for unusual noises during operation and physically inspecting the components after disassembly. My approach always involves a thorough diagnostic process before undertaking repairs, ensuring the most efficient and cost-effective solution.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of forklift tire wear and tear?

Uneven tire wear on forklifts is often a symptom of underlying mechanical or operational problems. Common causes include:

- Improper inflation: Under-inflation leads to excessive sidewall flexing and premature wear, while over-inflation can cause center wear.

- Misaligned wheels or axles: This puts uneven stress on the tires, resulting in uneven wear patterns. A simple visual check can often reveal this.

- Excessive loading or overloading: Continuously exceeding the forklift’s weight capacity puts immense pressure on the tires, accelerating wear and tear.

- Harsh operating conditions: Operating on rough terrain, sharp turns, and sudden braking can quickly wear down forklift tires.

- Poor driving techniques: Aggressive acceleration and braking contribute significantly to tire wear.

Regular tire pressure checks and visual inspections, combined with prompt attention to any misalignment issues are crucial in extending tire life and ensuring safe operation.

Q 17. How do you ensure compliance with OSHA regulations regarding forklift maintenance?

OSHA compliance is paramount in forklift maintenance. We maintain meticulous records of all inspections and repairs, ensuring all work is performed according to OSHA standards. This includes:

- Regular inspections: Daily pre-operational checks, weekly inspections, and periodic thorough inspections, all documented in a comprehensive log.

- Proper maintenance schedules: Following manufacturer-recommended maintenance schedules to ensure all components are serviced at the appropriate intervals.

- Qualified personnel: Employing trained and certified technicians to perform maintenance and repairs.

- Repair documentation: Detailed records of all repairs, including parts replaced, dates, and technician signatures.

- Safety training for operators: Ensuring that all forklift operators receive comprehensive safety training, including pre-shift inspections.

Our commitment to OSHA compliance extends beyond mere documentation. It’s ingrained in our daily work practices, reflecting a culture of safety and responsibility.

Q 18. What is your experience with different types of forklift models and their unique maintenance needs?

My experience encompasses a wide variety of forklift models, including electric, propane, and diesel-powered units from various manufacturers like Toyota, Hyster, and Crown. Each model has its own nuances in maintenance, requiring specific knowledge of its components and systems. For instance, electric forklifts require specialized knowledge of battery maintenance and charging procedures, while propane forklifts necessitate understanding of fuel systems and emissions controls. Diesel forklifts demand expertise in diesel engine maintenance, including fuel injection systems and emission control systems. I’m proficient in working with both sit-down rider and stand-up reach trucks, understanding their unique operational requirements and corresponding maintenance needs. This broad experience allows me to adapt quickly to any forklift model and effectively address its specific maintenance requirements.

Q 19. Explain your proficiency in using diagnostic tools for forklift maintenance.

Proficiency in using diagnostic tools is essential for efficient and accurate forklift maintenance. I’m adept at using a range of tools, including:

- Digital Multimeters: For testing electrical circuits and components, identifying shorts, open circuits, and voltage drops.

- Hydraulic Pressure Gauges: Measuring hydraulic system pressures to diagnose leaks, pump failures, and other hydraulic issues.

- Engine Diagnostic Scanners: Used on diesel and propane forklifts to retrieve diagnostic trouble codes (DTCs) and analyze engine performance data.

- Specialized Software: Accessing manufacturer-specific software to retrieve diagnostic information and perform programming tasks.

I can interpret data from these tools to pinpoint problems quickly, minimizing downtime and repair costs. For example, using an engine diagnostic scanner, I once identified a faulty oxygen sensor in a propane forklift, resulting in a quick and accurate repair, preventing more serious engine damage.

Q 20. Describe your experience with maintaining forklift attachments.

Maintaining forklift attachments is crucial for safety and efficiency. My experience covers a wide range of attachments, including forks, side-shifters, clamps, and rotating heads. Maintenance involves regular inspections for damage, wear, and proper function. This includes checking for cracks, bends, and loose fasteners. Hydraulic attachments necessitate inspection of hoses, cylinders, and fittings for leaks and damage. Regular lubrication is key to prolonging the life of moving parts. For example, I’ve resolved several instances of clamp malfunction due to leaking hydraulic cylinders, requiring replacement or repair of seals and thorough cleaning of the system. Proper attachment maintenance is integral to safe operation and prevents costly repairs down the line.

Q 21. How do you document your forklift maintenance activities?

Comprehensive documentation is essential for effective forklift maintenance management. We use a combination of methods, including:

- Digital maintenance management systems: These systems allow for electronic logging of all inspections, repairs, and preventative maintenance tasks. This ensures clear traceability of all work done and aids in scheduling future maintenance.

- Physical logs: Pre-operational inspection checklists are completed by operators daily and maintained in a central location. These logs document basic operational checks.

- Repair orders: Detailed repair orders are created for each repair, outlining the problems encountered, parts replaced, labor hours, and technician signatures.

This multi-faceted approach ensures accuracy, facilitates auditing, and provides a comprehensive history of maintenance activities for each forklift, enhancing safety and operational efficiency.

Q 22. How do you prioritize maintenance tasks based on urgency and criticality?

Prioritizing forklift maintenance tasks involves a blend of urgency (how quickly something needs fixing) and criticality (how important the task is to safety and operational efficiency). I use a system combining a criticality matrix and a risk assessment.

Criticality Matrix: I categorize tasks based on their potential impact. For instance, a faulty brake system is extremely critical and requires immediate attention (high urgency, high criticality). A minor oil leak, while needing attention, is less critical and can be scheduled (low urgency, medium criticality).

Risk Assessment: This evaluates the likelihood of failure and the potential consequences. A high-risk component (e.g., a mast bearing showing significant wear) necessitates preemptive maintenance regardless of immediate impact, while a low-risk component (e.g., a minor dent on the body) can be deferred.

Practical Application: I use a computerized maintenance management system (CMMS) that allows me to input these factors, automatically prioritizing tasks based on a pre-defined algorithm. This ensures that critical issues are addressed promptly while managing less urgent tasks effectively.

Q 23. Describe your experience with working on different forklift brands.

My experience encompasses a wide range of forklift brands, including Toyota, Hyster, Crown, and Yale. I’m proficient in working on various models, from smaller counterbalanced forklifts to large capacity reach trucks and order pickers. This experience extends to both gasoline/LPG and electric powered forklifts. I’m familiar with their unique electrical systems, hydraulic components, and engine configurations. For example, I’ve successfully diagnosed and repaired a complex hydraulic leak in a Hyster reach truck, involving pinpointing the leak source in a multi-stage hydraulic system using pressure tests and component inspection.

Understanding the nuances of each brand is crucial. Each manufacturer has its own design philosophies and component specifications, making familiarity with their service manuals essential. This ensures effective and safe repairs and minimizes downtime.

Q 24. What are your strategies for reducing forklift downtime?

Minimizing forklift downtime is crucial for productivity. My strategy is multifaceted and relies on a combination of preventative maintenance, proactive repairs and efficient troubleshooting.

- Preventative Maintenance (PM): A rigorous PM schedule based on manufacturer recommendations is key. This includes regular inspections, lubrication, fluid changes, and component replacements before they fail. I advocate for condition-based maintenance as well, utilizing tools like vibration analysis and oil analysis to detect developing problems before they become major breakdowns.

- Proactive Repairs: Identifying and fixing minor issues before they escalate is vital. During routine inspections, even seemingly insignificant problems are documented and addressed.

- Efficient Troubleshooting: This involves using diagnostic tools, understanding the forklift’s system architecture, and having access to relevant technical documentation to quickly diagnose and fix problems. I emphasize systematic troubleshooting, eliminating possibilities until the root cause is identified. A well-stocked parts inventory also drastically reduces downtime waiting for replacements.

Real-world Example: By implementing a predictive maintenance program using vibration analysis, we were able to identify a failing motor bearing on a forklift several weeks before complete failure. This allowed for a scheduled replacement, avoiding unexpected downtime and costly emergency repairs.

Q 25. How do you handle emergency forklift repairs?

Emergency forklift repairs demand immediate and decisive action. My approach follows a structured process:

- Assess the situation: Prioritize safety – secure the area, assess the damage and potential hazards, and ensure no one is injured.

- Diagnose the problem: Quickly identify the root cause. This might involve using diagnostic tools or relying on experience and knowledge of common failure points.

- Implement temporary fix (if necessary): In some cases, a temporary fix can get the forklift running until a permanent repair is possible. This requires careful consideration to prevent further damage.

- Complete permanent repair: Once the immediate danger is mitigated, I focus on a proper and lasting repair to prevent recurrence.

- Document everything: Detailed records of the emergency, diagnostic process, repair actions, and parts used are essential for future reference and analysis.

Example: I once responded to a forklift with a complete hydraulic failure. After securing the area, I quickly diagnosed a burst hydraulic line. I temporarily repaired the line using a clamp, enabling the safe removal of the forklift from the operational area. This allowed me to perform a permanent repair – replacing the damaged line – at a later time without hindering critical operations.

Q 26. Explain your experience with managing a team of forklift maintenance personnel.

Managing a team of forklift maintenance personnel involves effective leadership, training and delegation. My approach is focused on fostering a culture of safety, efficiency, and continuous improvement.

- Clear Communication: Regular team meetings and individual check-ins ensure everyone is informed, understands expectations, and feels heard.

- Skill Development: Continuous training, both on-the-job and through external courses, keeps the team updated on the latest technologies and best practices. This also involves cross-training to ensure flexibility and backup when needed.

- Delegation and Empowerment: I delegate tasks appropriately, providing the team with the autonomy to make decisions within their area of expertise. This boosts morale and builds confidence.

- Performance Monitoring and Feedback: Regular performance reviews, focusing both on individual contributions and team performance, ensure accountability and identify areas for improvement.

Example: To improve efficiency, I implemented a new workflow system that standardized repair procedures. Through regular team feedback and adjustments, this increased our repair completion rates and minimized downtime.

Q 27. Describe a time you had to troubleshoot a complex forklift problem.

A particularly challenging situation involved a forklift exhibiting erratic braking behavior. Initially, I suspected a problem with the braking system itself, checking the master cylinder, brake lines, and calipers. However, after thorough inspection, these components were found to be in good working order. This prompted a broader investigation.

I eventually traced the problem to a faulty sensor in the anti-lock braking system (ABS). The sensor was malfunctioning, sending inconsistent signals to the braking control unit. Replacing the sensor completely resolved the issue. The complexity lay in identifying the root cause beyond the obvious braking components. I systematically eliminated possibilities, utilizing diagnostic software and checking electrical connections. This incident highlighted the importance of not prematurely concluding a diagnosis and thoroughly investigating all potential causes, even those seemingly unrelated to the primary symptom.

Q 28. What are your continuous learning strategies for staying current on forklift technology and maintenance best practices?

Staying current in forklift technology and maintenance best practices requires a proactive approach.

- Manufacturer Training: Participating in manufacturer-sponsored training programs and workshops provides in-depth knowledge of specific forklift models and their maintenance requirements.

- Industry Publications and Conferences: I regularly read industry publications, attending conferences and webinars to stay informed about the latest technologies, safety standards, and maintenance techniques.

- Online Resources: Utilizing online resources, such as technical forums and manufacturer websites, provides access to a wealth of information and best practices.

- Professional Certifications: Pursuing relevant professional certifications (e.g., those from the Industrial Truck Association) demonstrates ongoing commitment to professional development and adherence to industry standards.

Continuous learning isn’t just about keeping up with technology; it’s about refining my skills and staying at the forefront of the field. The rapidly evolving nature of forklift technology demands constant professional development to ensure optimal safety and efficiency.

Key Topics to Learn for Forklift Maintenance Inspection Interview

- Preventive Maintenance Schedules: Understanding the importance of regular inspections and adherence to manufacturer’s guidelines. Practical application: Explain how different schedules cater to varying forklift types and usage.

- Component Inspection: Thorough knowledge of inspecting key components like tires, brakes, hydraulic systems, masts, and electrical systems. Practical application: Describe the visual and functional checks you’d perform on each component and how to identify potential issues.

- Safety Procedures & Regulations: Familiarity with OSHA and other relevant safety standards for forklift operation and maintenance. Practical application: Explain lockout/tagout procedures and safe handling of potentially hazardous materials.

- Fluid Levels & Leaks: Identifying and addressing issues related to engine oil, hydraulic fluid, coolant, and battery fluid. Practical application: Describe the process of checking fluid levels and interpreting signs of leaks.

- Troubleshooting Common Issues: Diagnosing and resolving basic forklift malfunctions. Practical application: Provide examples of common problems (e.g., hydraulic leaks, battery issues) and explain your approach to troubleshooting.

- Documentation & Reporting: Properly documenting inspection findings and reporting any necessary repairs. Practical application: Describe your experience with maintenance logs and reporting systems.

- Forklift Types & Specific Maintenance Needs: Understanding the differences in maintenance requirements for various forklift types (e.g., electric, propane, diesel). Practical application: Explain how maintenance procedures vary depending on the fuel type and operating environment.

Next Steps

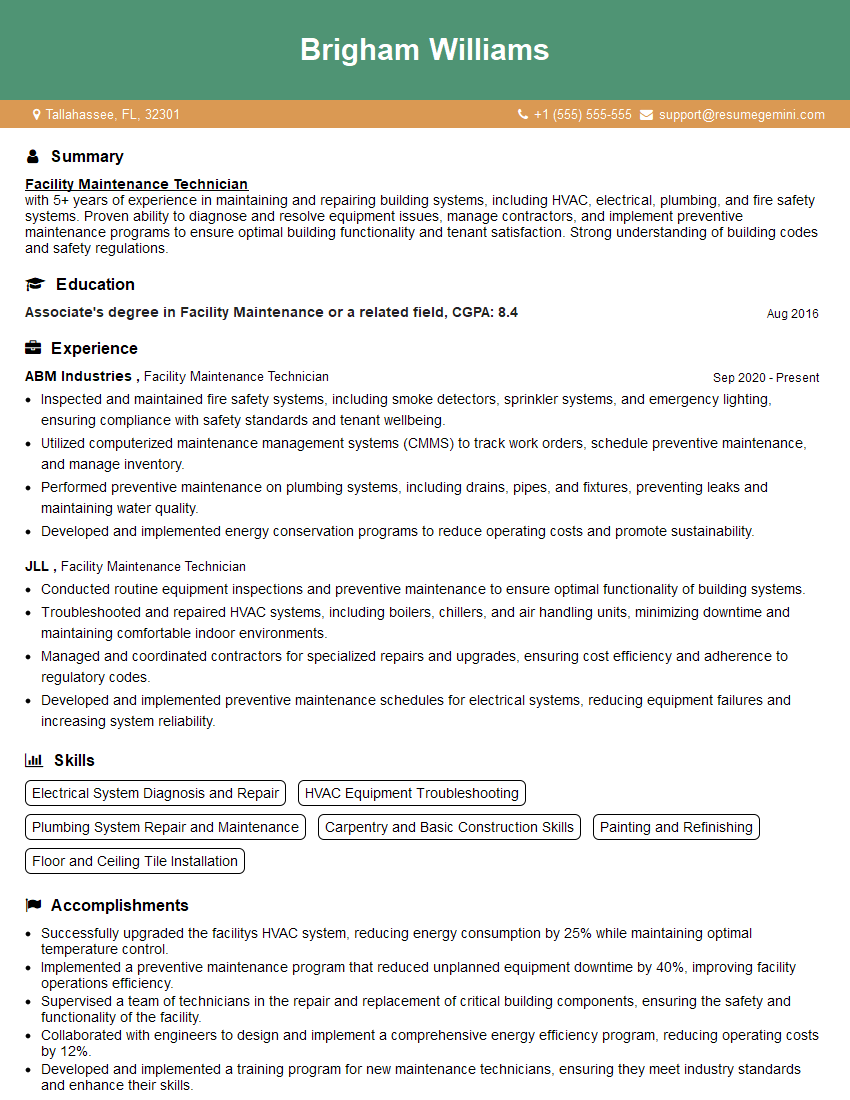

Mastering Forklift Maintenance Inspection is crucial for career advancement in the logistics and warehousing industries. A strong understanding of preventative maintenance, safety regulations, and troubleshooting skills significantly increases your value to potential employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored specifically for Forklift Maintenance Inspection professionals are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO