The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Wood Cutting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Wood Cutting Interview

Q 1. Describe your experience with different types of saws (chainsaw, hand saw, etc.)

My experience with saws spans decades, encompassing various types for diverse applications. Chainsaws are my primary tool for large-scale timber harvesting, offering speed and efficiency. I’m proficient with various chainsaw models, from smaller, lightweight saws for pruning to powerful, professional-grade saws for felling large trees. I’m also highly skilled in using hand saws – both crosscut saws for precise cuts across the grain and ripsaws for cutting along the grain. I find hand saws invaluable for detailed work, where precision and control are paramount, such as shaping timbers or creating intricate joinery. Furthermore, I’m experienced with bow saws for reaching into tight spaces and coping saws for intricate curves, showcasing versatility in my approach to woodworking. Each saw type demands a different technique and level of care, and I’ve mastered the nuances of each.

Q 2. Explain the safety procedures you follow while operating a chainsaw.

Chainsaw safety is paramount. My routine begins with a pre-operational check – ensuring the chain is sharp, properly lubricated, and the brakes function correctly. I always wear personal protective equipment (PPE), including chaps (protective trousers), safety glasses, hearing protection, a helmet with a face shield, and gloves. Before starting the saw, I assess the immediate area, clearing away any obstructions or debris. When felling a tree, I identify escape routes and ensure a safe zone is established to prevent injury from falling branches or the tree itself. I never overreach; maintaining a firm grip and balanced stance is crucial. The saw should always be running at full speed when making a cut, and I use a controlled, steady motion to avoid kickback. After finishing the cut, I ensure the saw is switched off and secured safely before moving on. I frequently participate in safety refresher courses to stay abreast of best practices and adapt to new techniques.

Q 3. How do you assess the risk of falling trees before felling them?

Assessing the risk of a falling tree involves a multifaceted approach. I start by examining the tree’s overall health, checking for signs of disease, decay, or insect infestation. The lean of the tree, the presence of dead branches, and the condition of the root system are all vital factors. I consider wind conditions – a strong gust can dramatically alter a tree’s fall trajectory. The surrounding environment also plays a crucial role; I assess the proximity of other trees, power lines, buildings, and personnel. I meticulously survey the terrain for potential obstacles that could impede the tree’s fall or cause it to ricochet unpredictably. For large or particularly risky trees, I might use specialized equipment like a climbing harness and ropes for closer inspection or to prepare the tree for felling. Experienced judgment is crucial in balancing the risks against available mitigation strategies.

Q 4. What are the different techniques for felling trees in various terrains?

Felling techniques adapt to the terrain. On level ground, I use a standard felling technique, making the notch and back cut with precision. However, on slopes, I modify the approach to account for the tree’s potential to roll or slide. On steep slopes, I aim to make the back cut higher on the tree to direct the fall down the slope. I use wedges to control the direction of the fall and avoid unexpected movement. In rocky terrain, I carefully examine the ground to prevent the tree from striking rocks and splitting unpredictably. Each situation requires thoughtful consideration and adaptation of standard techniques to minimize risks and ensure a safe, controlled fall. Experience and a good understanding of the physics involved are critical.

Q 5. How do you maintain your chainsaw to ensure optimal performance and safety?

Maintaining my chainsaw is crucial for performance and safety. After each use, I clean the bar and chain thoroughly, removing sawdust and debris. Regular sharpening of the chain is essential; a dull chain requires more force, increases the risk of kickback, and produces less efficient cuts. I use a high-quality chain sharpening file and follow the correct filing angles to maintain the chain’s sharpness and cutting efficiency. Lubrication is vital – I keep the automatic oiler properly adjusted to ensure the chain is adequately lubricated during operation. I inspect the air filter regularly and clean or replace it as needed to maintain proper engine performance. I also check for wear and tear on the bar and chain, replacing them when necessary. A well-maintained saw reduces the risk of accidents and ensures optimal performance and longevity.

Q 6. Explain your experience with different wood types and their properties.

My experience encompasses a broad range of wood types, each with unique properties impacting cutting techniques and the final product. Oak, for instance, is incredibly strong and durable, demanding sharp tools and careful cuts due to its hardness. Pine, while softer, can be knotty and unpredictable, necessitating attention to prevent splintering. Maple, prized for its smooth grain, requires precise cuts for clean surfaces. Understanding the grain pattern, density, and moisture content of each wood type is essential for selecting appropriate tools, optimizing cutting techniques, and anticipating potential challenges. I’ve worked with hardwoods like mahogany and cherry, known for their beauty and workability, as well as softwoods like cedar and redwood, valued for their aromatic qualities and resistance to decay. This extensive experience allows me to efficiently and effectively handle any wood type.

Q 7. Describe your experience with wood cutting safety regulations.

I am well-versed in all relevant wood-cutting safety regulations. These regulations cover aspects like PPE requirements, safe operating procedures for various tools, hazard communication, emergency response procedures, and proper disposal of waste materials. I understand and adhere to all local, state, and federal guidelines concerning felling trees near power lines, in populated areas, and other high-risk environments. I’m also familiar with the regulations pertaining to the transport of timber and the safe handling of felled trees. I maintain up-to-date knowledge of these regulations through continuous professional development and training to ensure I’m always working within legal and safe boundaries. Staying informed about evolving best practices and regulations is a crucial part of responsible and safe work.

Q 8. How do you identify and handle potential hazards in a wood cutting environment?

Safety is paramount in wood cutting. My approach to hazard identification begins with a thorough site assessment before any work commences. This involves checking for obstacles like uneven terrain, hidden underground utilities, and potential falling hazards from dead branches or unstable trees. I also inspect the condition of my tools, ensuring they’re sharp and well-maintained to prevent slips or breakage.

For personal protective equipment (PPE), I always wear safety glasses, hearing protection (especially when using power tools), gloves appropriate for the task (e.g., cut-resistant gloves when using chainsaws), and sturdy, closed-toe footwear. Furthermore, I establish a safe working zone, keeping clear of distractions and onlookers. If working with others, clear communication is key, using hand signals when necessary to coordinate movements around moving equipment. Finally, I’m always aware of weather conditions; strong winds, rain, or lightning necessitates a halt to operations.

- Example: Before felling a large tree, I’d carefully assess its lean, identify escape routes, and clear the area around it of any obstructions.

- Example: When using a chainsaw, I always ensure the chain brake is engaged when not actively cutting and check the chain’s tension regularly to prevent kickback.

Q 9. What are your methods for measuring and marking lumber accurately?

Accurate measurement and marking are crucial for clean cuts and minimal waste. I typically use a combination of measuring tapes, rulers, and marking pencils or chalk. For precise measurements, I use a reliable tape measure, double-checking my readings. When marking lumber, I ensure the marking is clear and visible, using a sharp pencil or chalk line for straight lines. For more complex cuts, I often use a combination square or bevel gauge to ensure accurate angles.

For example, when creating a precise dado joint, I’d use a marking gauge to create parallel lines, ensuring the correct width for the dado. Similarly, when cutting angles for a roof truss, I use a speed square and protractor to meticulously mark the correct angles before cutting.

Q 10. Describe your experience with using hand tools for wood cutting (axes, hatchets, etc.)

I’ve extensive experience with various hand tools, including axes, hatchets, and drawknives. Proper technique is critical for safety and efficiency. With an axe, for example, I focus on a controlled swing, using my body weight and momentum for power while maintaining balance and precision. Sharpening is paramount; a dull axe requires more force and increases the risk of injury. I regularly hone the edge of my axes and hatchets, using a file or sharpening stone to maintain a sharp cutting edge.

I understand the different applications of each tool; an axe is ideal for felling trees or splitting larger pieces of wood, while a hatchet is more suited for smaller tasks like limbing or shaping. Drawknives require a specific technique to avoid gouges and ensure a smooth finish. Experience has taught me the importance of proper grip, posture, and control to avoid injuries and achieve precise results.

Q 11. How do you ensure the precision and accuracy of your cuts?

Precision and accuracy are achieved through a combination of sharp tools, proper technique, and careful planning. Before making any cut, I double-check my measurements and markings. I always use a guide or jig whenever possible, such as a miter box for crosscuts or a fence for rip cuts. For intricate cuts, I may use a coping saw or a jigsaw for added control and accuracy.

Example: When creating a dovetail joint, I use a marking gauge and chisel to ensure precise mortises and tenons. I take my time, ensuring the cuts are clean and accurate to avoid any gaps or misalignments. Regularly checking my work for accuracy throughout the process helps to avoid costly mistakes later on.

Q 12. What techniques do you use to minimize wood waste?

Minimizing wood waste is both environmentally responsible and economically beneficial. Careful planning is key – I always measure twice and cut once. I prioritize using the full length of the lumber whenever possible, optimizing cuts to maximize material usage. For smaller pieces, I often save scraps for smaller projects or kindling.

Example: When cutting multiple pieces of the same size, I arrange the lumber strategically to minimize offcuts. I also strive to create efficient cutting patterns to reduce waste during larger projects, like framing a building. I often sketch out designs and calculate cuts beforehand to optimize materials.

Q 13. Describe your experience with different wood cutting techniques (e.g., crosscutting, ripping)

Crosscutting and ripping are fundamental woodcutting techniques. Crosscutting involves cutting across the grain of the wood, whereas ripping involves cutting along the grain. Crosscutting is often used for shorter, more precise cuts and requires a sharp blade to ensure a clean cut, avoiding splintering. I frequently use a miter saw for precise crosscuts and a hand saw for more delicate work. Ripping, on the other hand, requires a stronger, more robust saw blade to prevent the blade from binding or getting caught.

Example: When building a table, I’d use crosscutting to cut the legs to the correct length and ripping to cut the tabletop to its desired width. The choice of technique and tool depends entirely on the nature of the cut and the type of wood being used.

Q 14. How do you handle unexpected situations during a wood cutting operation?

Unexpected situations can arise, such as a tool malfunction or a hidden obstacle. My response is always guided by safety. If a tool malfunctions, I immediately stop the operation and assess the situation, ensuring the tool is safe before attempting any repairs or replacements. If an unexpected obstacle is encountered, I’ll carefully assess the situation and plan a safe workaround, possibly adjusting my approach or halting the operation until the issue is resolved.

Example: If a chainsaw kicks back unexpectedly, I would immediately release the throttle and let the chain come to a complete stop before assessing the situation and making adjustments. Maintaining composure and carefully assessing each situation is critical.

Q 15. What is your experience with sharpening and maintaining hand tools?

Sharpening and maintaining hand tools is fundamental to safe and efficient woodworking. It’s not just about a sharp edge; it’s about the longevity and performance of the tool. My experience spans decades, encompassing various techniques for axes, hatchets, saws, and chisels.

For instance, with axes and hatchets, I use a combination of rough grinding, honing, and stropping. Rough grinding removes significant damage, honing refines the edge to a keen sharpness, and stropping polishes it for an exceptionally smooth cut. The specific process depends on the tool’s condition and the type of steel. I regularly inspect my tools for signs of wear, chipping, or damage, addressing these issues promptly to prevent larger problems.

Saws require a different approach. I use various files – depending on the tooth configuration of the saw – to sharpen individual teeth and maintain the correct set (the slight outward bend of the teeth). Regular cleaning and lubrication also extend a saw’s life. Chisels are similarly treated, with honing and stropping being key. Proper maintenance minimizes the risk of injury and ensures precise, clean cuts every time.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your knowledge of tree anatomy and its impact on felling techniques.

Understanding tree anatomy is crucial for safe and efficient felling. A tree’s structure, including the grain, knots, and lean, significantly impacts how it will fall. The grain, essentially the direction of wood fibers, determines the ease of cutting. Following the grain requires less effort and creates cleaner cuts.

For example, a tree with a pronounced lean will fall in the direction of the lean unless properly controlled with felling cuts. Knots can significantly affect the strength of the wood and may create unpredictable splitting during felling. I also take into consideration the presence of tension wood which is stronger on one side and more prone to splitting on the other.

My felling techniques always begin with a thorough assessment of the tree, taking into account its size, lean, surrounding trees, and potential hazards. I always plan escape routes in case the tree falls unexpectedly. I utilize different cutting techniques, like the ‘Humboldt’ or ‘face’ cut, depending on the circumstances, to ensure a controlled and safe fall. This knowledge, gained through years of experience and formal training, ensures safety and minimizes risk.

Q 17. What are the different types of wood and their applications?

Wood varies significantly in its properties, impacting its applications. Hardwoods, like oak, maple, and cherry, are known for their density, durability, and strength, making them ideal for furniture, flooring, and structural elements. Softwoods, such as pine, fir, and cedar, are generally lighter and less dense, often used for construction, framing, and less demanding applications.

- Hardwoods: Oak – durable, strong, used for furniture; Maple – hard, smooth, used for flooring and furniture; Cherry – beautiful grain, used for fine furniture.

- Softwoods: Pine – affordable, versatile, used for construction and crafts; Fir – strong, straight grain, used for framing; Cedar – aromatic, resistant to decay, used for outdoor applications.

Beyond these broad categories, many other species exist with unique characteristics. For example, mahogany’s rich color and workability make it popular for high-end furniture, while teak’s weather resistance is ideal for outdoor furniture and decking. Choosing the right wood depends on the project’s demands, including strength, durability, aesthetics, and budget.

Q 18. Describe your experience with using personal protective equipment (PPE).

Safety is paramount in woodworking. My experience with PPE is extensive and encompasses various items crucial for different tasks. This includes safety glasses or goggles to protect against flying debris, hearing protection to reduce noise exposure, sturdy work gloves to prevent cuts and abrasions, and appropriate footwear with steel toes to protect against falling objects.

When felling trees, additional safety measures are essential, such as a hard hat to protect against falling branches and potentially a chainsaw chaps to protect the legs from chain saw kickback. I always assess the risks before beginning any work, selecting the appropriate PPE accordingly. Regular maintenance and inspection of PPE are also essential to ensure their effectiveness.

I firmly believe that complacency is the greatest risk, and consistently using and maintaining PPE is a critical part of a safe work environment. I lead by example and expect the same adherence to safety protocols from others.

Q 19. How do you handle emergency situations (e.g., injury, equipment malfunction)?

Handling emergencies requires a calm, decisive approach. My training includes first aid and CPR, enabling me to provide immediate assistance in case of injury. In the event of a cut, I would immediately stop the bleeding with direct pressure and seek advanced medical attention. For more serious injuries, I’d follow established emergency protocols, including calling for help and providing necessary first aid until professional help arrives.

Equipment malfunctions are addressed through preventative maintenance and careful inspection before use. If a tool malfunctions, I immediately cease operation, assess the situation, and repair or replace the tool as necessary. Safety always comes first, and I never compromise on that principle. I have protocols in place for reporting accidents and near misses, and I participate in regular safety training to stay current on best practices.

Q 20. What is your understanding of sustainable forestry practices?

Sustainable forestry practices are not merely a trend; they are crucial for preserving our forests for future generations. My understanding encompasses several key principles, including selective logging, which involves removing only mature trees while leaving younger trees to grow. This approach maintains forest health and biodiversity.

Reforestation is another critical element, where trees are replanted after logging to ensure continued forest cover. Responsible harvesting methods minimize soil erosion and damage to the ecosystem. I’m also committed to reducing waste by using all usable parts of the harvested tree, which may include sawdust for other applications.

Furthermore, my commitment to sustainability goes beyond simply avoiding unnecessary logging. It includes awareness of endangered species and understanding how forestry impacts their habitats. By practicing these sustainable methods, we can ensure the long-term health of our forests and the valuable resources they provide.

Q 21. Describe your experience with various wood finishing techniques.

Wood finishing techniques enhance the beauty and durability of wood. My experience covers a range of methods, from simple oil finishes to more complex lacquers and stains. Oil finishes, like linseed oil or tung oil, penetrate the wood, enhancing its natural beauty and providing some protection. They’re relatively easy to apply and maintain, making them suitable for many projects.

Stains are used to alter the color of the wood, either darkening or lightening it, or to create more specific color tones. They don’t typically offer significant protection, so a topcoat like varnish or lacquer is usually applied. Varnishes provide a durable, clear protective layer, while lacquers dry quickly and provide a hard, smooth finish.

Choosing the right finishing technique depends on several factors, including the type of wood, the intended use of the finished product, and the desired aesthetic. Each technique requires careful preparation and application to achieve optimal results; factors like temperature and humidity influence the drying and curing processes significantly.

Q 22. Explain your knowledge of wood preservation methods.

Wood preservation is crucial for extending the lifespan of wood and protecting it from decay, insect infestation, and weathering. It involves treating the wood with various substances to enhance its durability and resistance. Methods range from simple surface treatments to more complex pressure treatments.

- Surface Treatments: These include applying paints, stains, varnishes, and sealants. Paints offer a protective barrier against moisture and UV rays, while stains enhance the wood’s natural beauty while providing some protection. Varnishes create a clear, protective film. Sealants are often used to prevent water penetration into the wood’s pores. This is best for smaller projects or areas needing cosmetic protection.

- Pressure Treatments: For larger projects or wood exposed to harsh conditions, pressure treatment is significantly more effective. This involves forcing preservatives deep into the wood under high pressure. Common preservatives include chromated copper arsenate (CCA), though it’s being phased out due to environmental concerns, and newer, more eco-friendly alternatives like copper azole and micronized copper quat.

- Water-Borne Preservatives: These are environmentally friendly options offering good protection against decay fungi and insects. They are easier to apply and require less drying time compared to oil-borne preservatives.

The choice of method depends on the type of wood, its intended use, and the environment it will be exposed to. For example, outdoor furniture might require pressure treatment with a durable preservative, while interior trim might only need a few coats of varnish.

Q 23. How do you select the appropriate tools and techniques for a specific wood cutting task?

Selecting the right tools and techniques for a wood cutting task is paramount for safety and achieving the desired result. The choice depends on factors like the wood’s type and hardness, the project’s complexity, and the desired cut’s precision.

- Hardwoods vs. Softwoods: Harder woods like oak or maple require more robust tools and techniques than softer woods like pine or fir. A dull blade on a hand saw might struggle with hardwoods, potentially leading to binding or uneven cuts.

- Cut Type: A precise crosscut (cutting across the grain) demands a sharp, fine-toothed saw, while a rip cut (cutting with the grain) benefits from a coarser tooth pattern. A tenon saw is ideal for precise, intricate work. For curves, a coping saw or jigsaw is necessary.

- Project Complexity: Simple cuts can often be made with hand tools, while more intricate projects might require power tools like table saws, miter saws, or routers. A bandsaw allows for smooth curves and intricate shapes.

For example, creating a finely detailed dovetail joint would require hand tools like chisels and a fine-toothed saw, ensuring precise cuts and accurate fitting. On the other hand, cutting large planks of wood for framing would utilize a circular saw or table saw for speed and efficiency.

Q 24. Describe your experience with working as part of a team in a wood cutting environment.

Teamwork in a wood cutting environment is essential for safety, efficiency, and high-quality output. I’ve consistently worked effectively within teams, contributing my expertise and coordinating tasks effectively.

In one project, constructing a large timber frame building, our team comprised carpenters, joiners, and machinery operators. My role involved precise cutting and shaping of intricate joints, while others handled larger cuts and assembly. Effective communication, clear task assignments, and mutual respect were crucial for successful collaboration. We established safety protocols, ensuring everyone understood the safe operation of machinery and procedures for handling materials.

Collaboration also involved problem-solving. When a design issue arose, open discussion helped us find a creative and efficient solution, improving both the final product and the team’s overall problem-solving capabilities.

Q 25. How do you adapt your techniques based on the type of wood and the desired outcome?

Adapting techniques based on wood type and the desired outcome is fundamental to successful wood cutting. Wood grain direction, hardness, and species all influence how it is best cut and worked.

- Wood Type: Hardwoods are denser and more challenging to cut than softwoods. Hardwoods might require sharper tools and slower cutting speeds to avoid tear-out. Softwoods are easier to work with but can still splinter if not handled correctly.

- Grain Direction: Cutting with the grain (rip cut) is generally easier than cutting against the grain (crosscut). Ignoring grain direction can lead to splintering and uneven cuts.

- Desired Outcome: A smooth finish might require techniques like planing or sanding, while a rustic look may be achieved with less precise cuts or leaving a natural edge.

For instance, when creating fine furniture from cherry wood, I’d utilize a sharp hand plane to achieve a smooth, polished surface, paying close attention to the wood grain. Conversely, for a rough-hewn fence post made from cedar, a less refined cut and potentially using a chainsaw would be suitable.

Q 26. What are the different types of cuts and their applications?

Various cuts serve different purposes in woodworking. Understanding their applications is vital for achieving desired outcomes and structural integrity.

- Crosscut: Cutting across the wood grain. Used for chopping wood, creating shorter pieces, and making joints that run perpendicular to the grain.

- Rip Cut: Cutting with the wood grain. Used for producing longer pieces of wood, cutting planks to size, and creating joints that run parallel to the grain.

- Miter Cut: An angled cut, typically used to join two pieces of wood at an angle, frequently seen in picture frames or crown molding.

- Bevel Cut: An angled cut that is not a 45-degree angle and allows for angled pieces to fit together. Often used in making joints.

- Dado Cut: A rectangular groove cut into the edge or face of a piece of wood, typically used for creating shelves or drawers.

- Rabbet Cut: A rectangular groove cut along the edge of a board, often used for edge joining or creating frames.

For example, creating a simple box would involve crosscuts for the sides and bottom and rip cuts to create the appropriate lengths. Constructing a miter joint would require precise miter cuts on the ends of each board before assembly.

Q 27. How do you ensure the quality and consistency of your work?

Maintaining quality and consistency requires meticulous attention to detail throughout the process. This involves careful planning, precise execution, and continuous quality checks.

- Planning & Measurement: Accurate measurements and well-defined plans prevent costly mistakes and ensure consistent results. Detailed sketches or blueprints are valuable in visualizing the project and the cuts required.

- Tool Maintenance: Sharp tools are essential for clean cuts and prevent tear-out or splintering. Regularly sharpening blades and maintaining power tools ensures they operate efficiently and safely.

- Quality Checks: Consistent checks at each stage—from measuring wood to joint assembly—identify and correct errors early on, avoiding significant rework and ensuring uniformity.

- Material Selection: Choosing high-quality wood free of knots and defects contributes to the final product’s strength and appearance.

For instance, when building a set of chairs, I ensure consistent measurements and use jigs to create identical cuts. Regularly sharpening my chisels guarantees smooth and precise mortise and tenon joints. Careful attention to detail ensures every chair is visually identical and structurally sound.

Q 28. Explain your experience with different types of wood cutting machinery (e.g., band saws, table saws)

My experience encompasses a range of wood cutting machinery, each offering unique capabilities and applications. Safety procedures are always paramount when using such equipment.

- Band Saws: Excellent for curved cuts and intricate shaping. I’ve used band saws extensively for creating curved components in furniture and other projects, adjusting the blade tension and speed based on the wood type and cut complexity. Safety involves ensuring the blade guard is properly in place and using push sticks to avoid hand contact with the blade.

- Table Saws: Ideal for precise rip cuts and crosscuts, especially when working with large pieces. Accuracy is crucial and dependent on correctly setting the blade’s height and angle. Safety precautions involve using push blocks and never reaching across the blade.

- Miter Saws: Used for precise angled cuts, commonly employed for creating miter joints in frames and molding. The accuracy of the miter angle is key and adjustments must be made with care.

- Circular Saws: Versatile tools suitable for both rip and crosscuts, frequently used for rough cuts and on-site construction. Safety involves maintaining good control of the saw to avoid kickback.

In one project, we used a combination of a table saw for accurate rip cuts on long boards, a band saw for shaping curved components, and a router for creating decorative edges. Safe operation and regular maintenance of this machinery were vital to the project’s success.

Key Topics to Learn for Wood Cutting Interview

- Safety Procedures and Regulations: Understanding and applying safety protocols for various cutting techniques and equipment, including personal protective equipment (PPE) use and emergency procedures.

- Wood Selection and Properties: Knowledge of different wood types, their grain patterns, hardness, and suitability for specific applications. This includes understanding how wood properties influence cutting techniques and results.

- Cutting Techniques: Mastery of various cutting methods (e.g., hand sawing, chainsaw operation, power tool usage), understanding the advantages and limitations of each, and selecting the appropriate technique for different tasks.

- Tool Maintenance and Sharpening: Proper care and maintenance of cutting tools, including sharpening techniques to maximize efficiency and safety. Recognizing signs of tool wear and knowing when replacement is necessary.

- Measuring and Marking: Accurate measurement and marking techniques to ensure precise cuts and minimize waste. Understanding the use of various measuring tools and their precision.

- Waste Management and Environmental Considerations: Responsible disposal of wood waste, adherence to environmental regulations, and understanding sustainable forestry practices.

- Problem-solving and Troubleshooting: Identifying and resolving common issues encountered during wood cutting, such as wood splitting, tool malfunctions, and inaccurate cuts. Demonstrating problem-solving skills in practical scenarios.

Next Steps

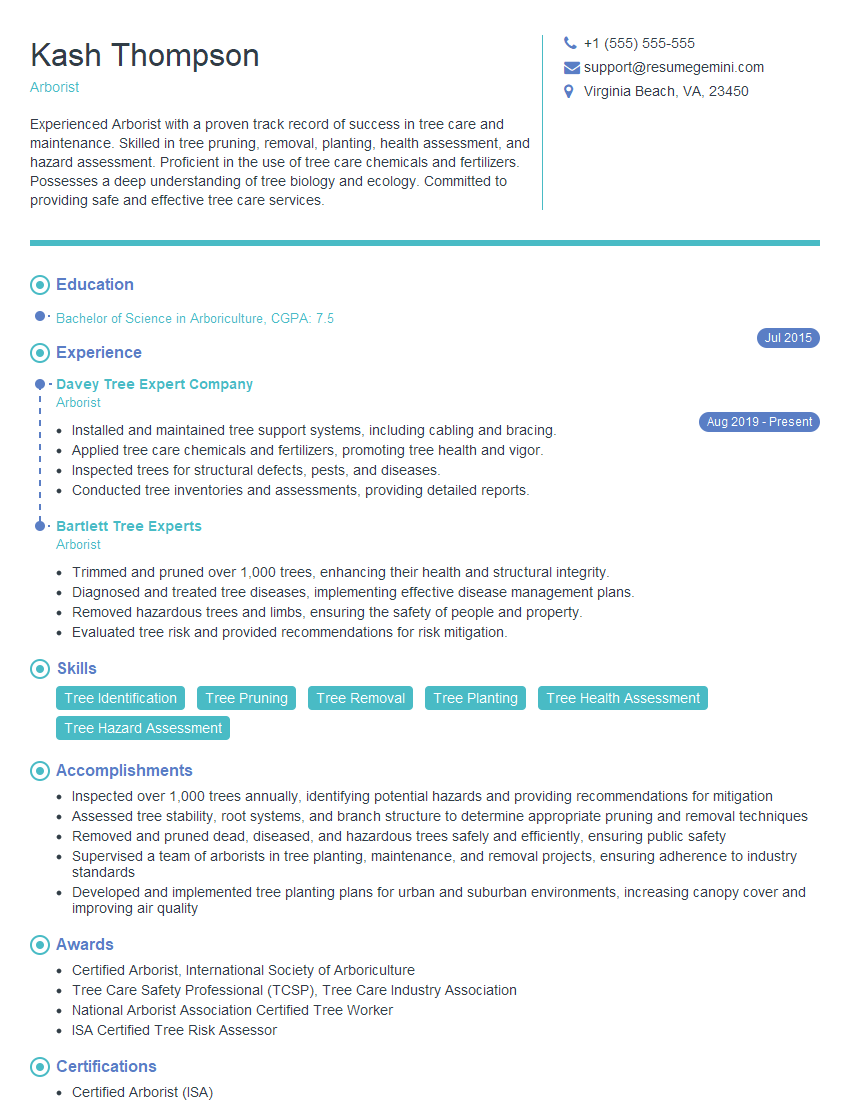

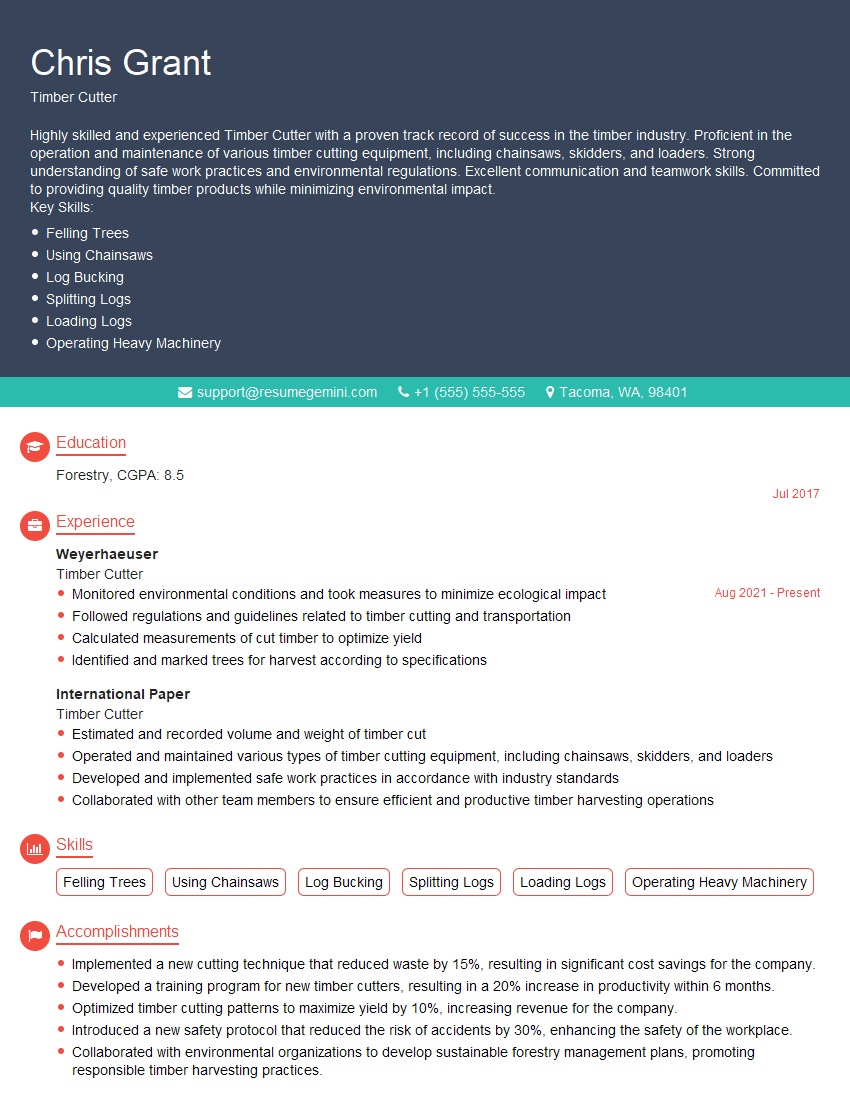

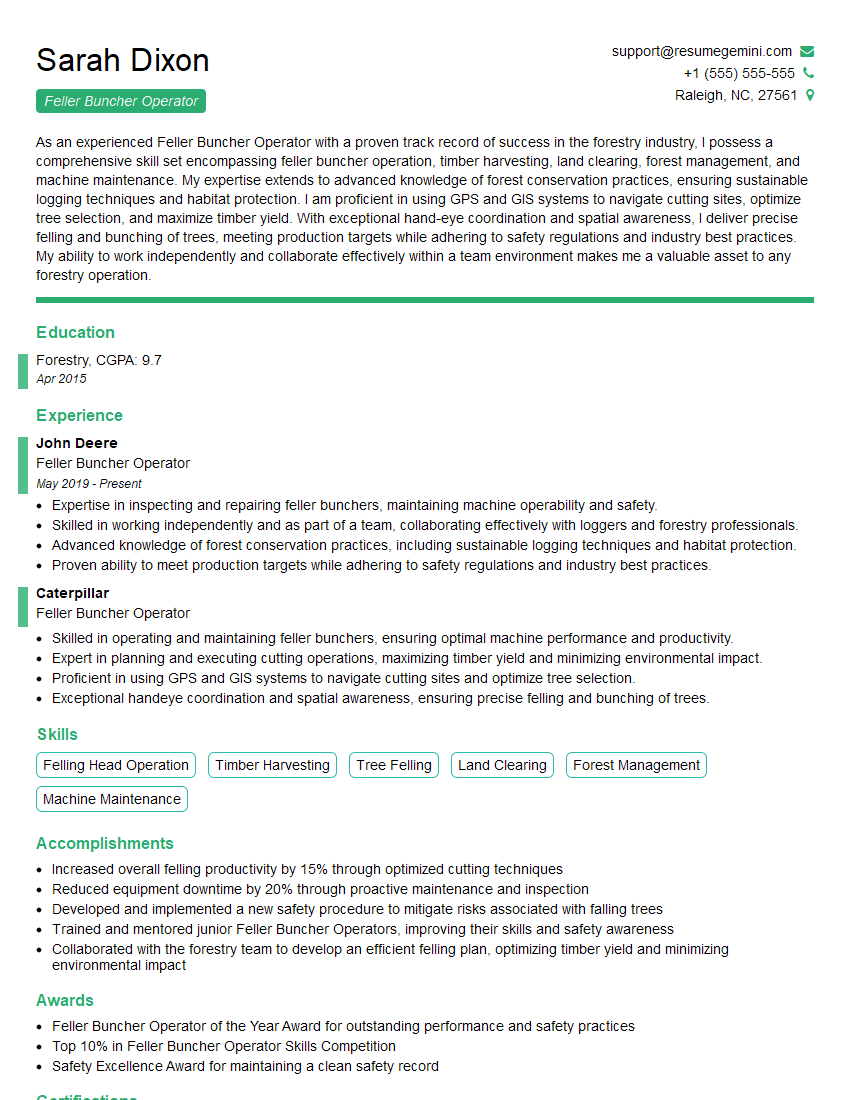

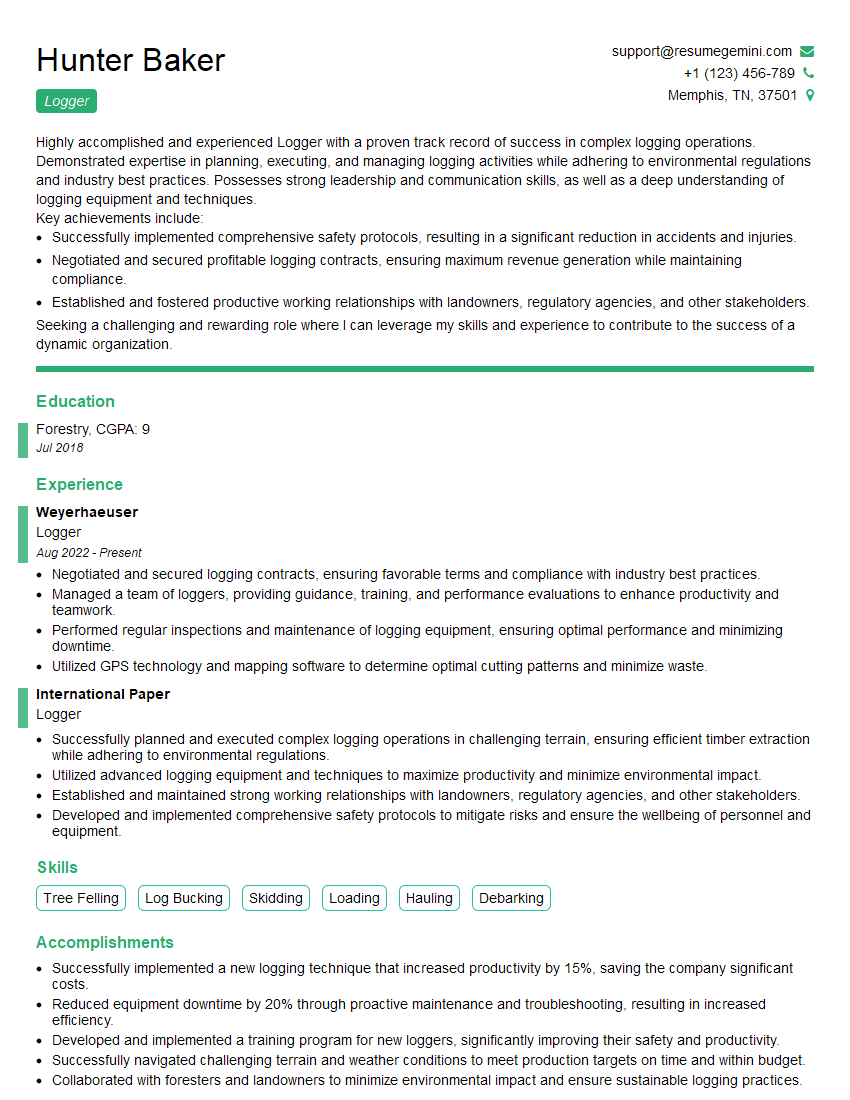

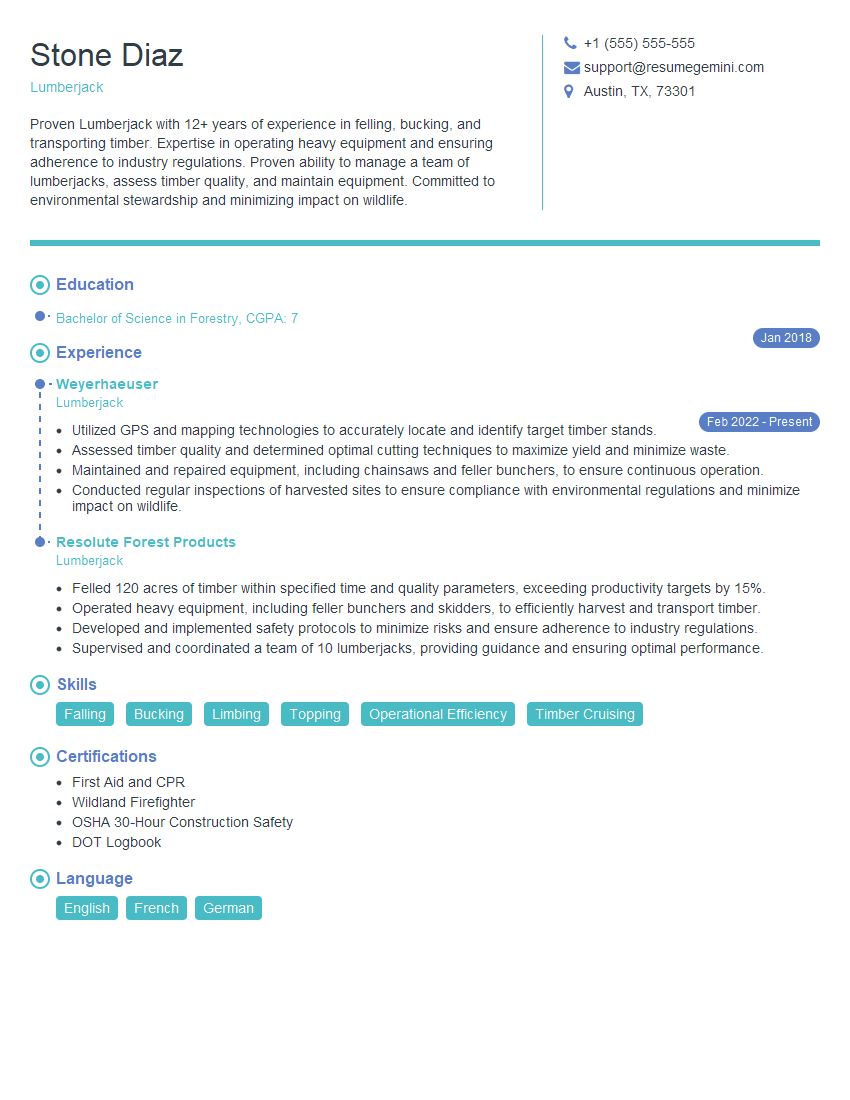

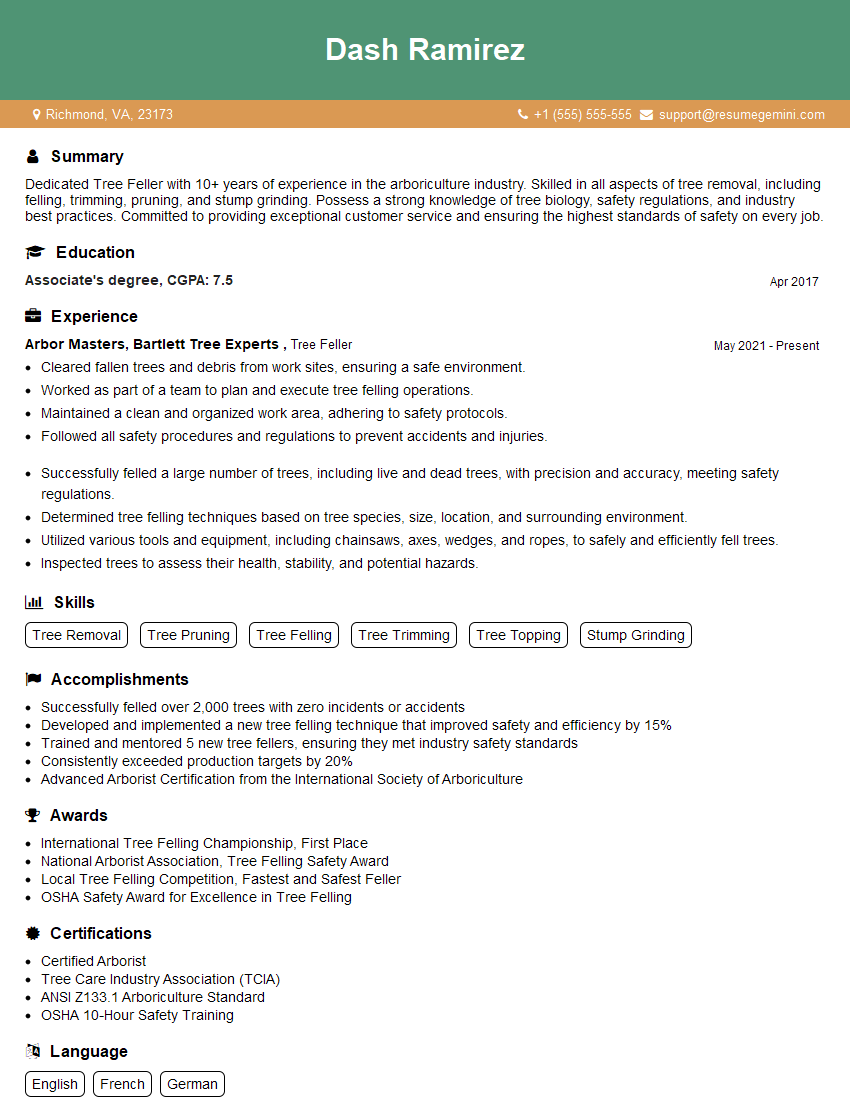

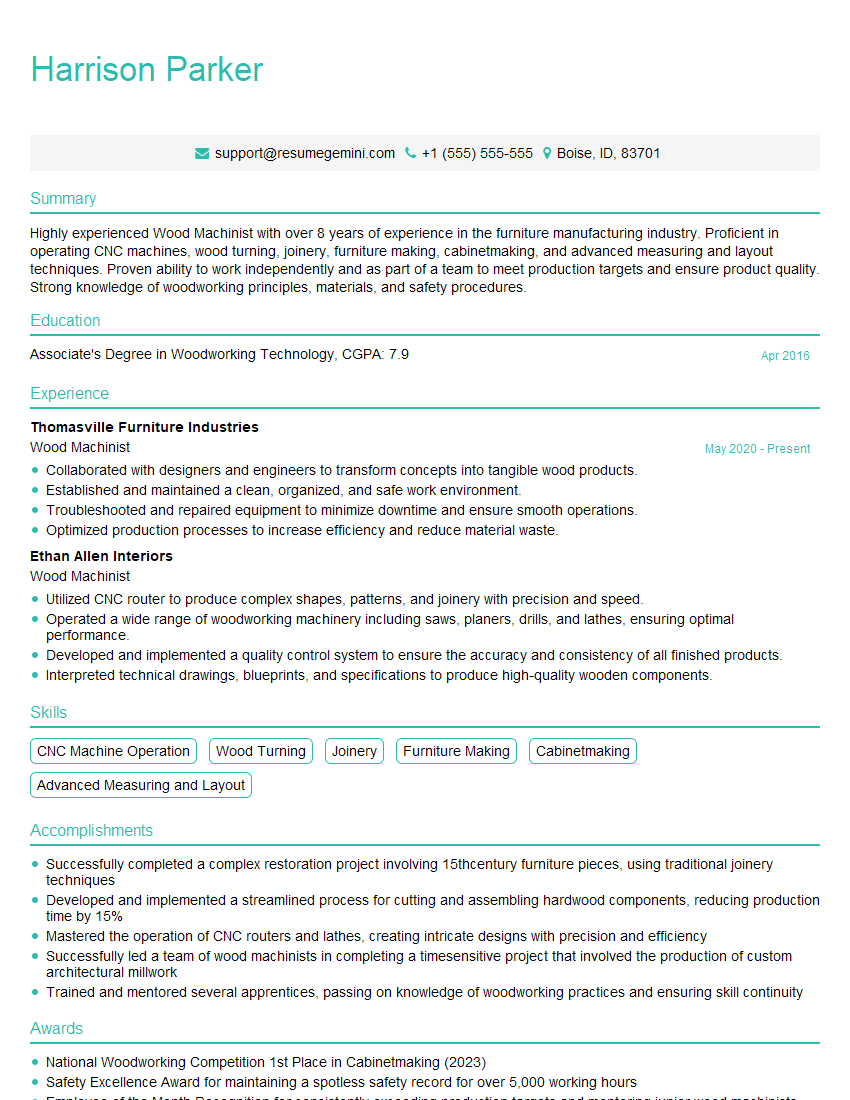

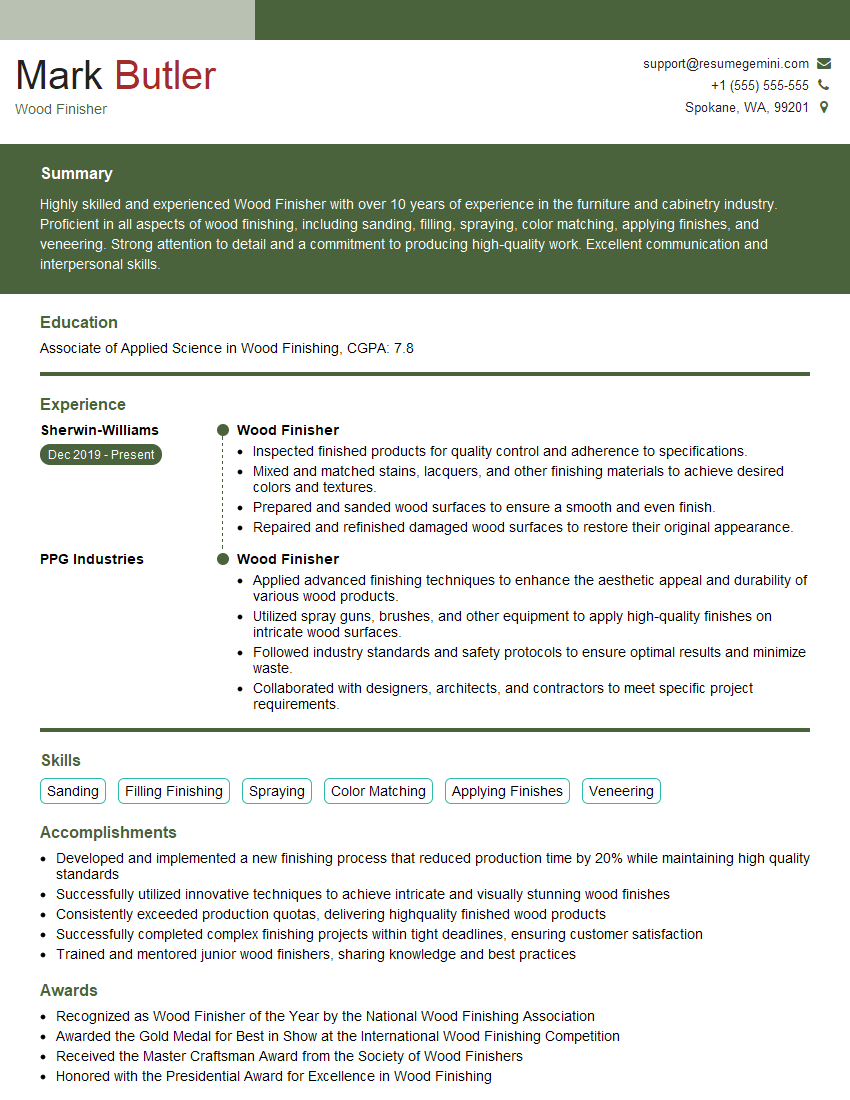

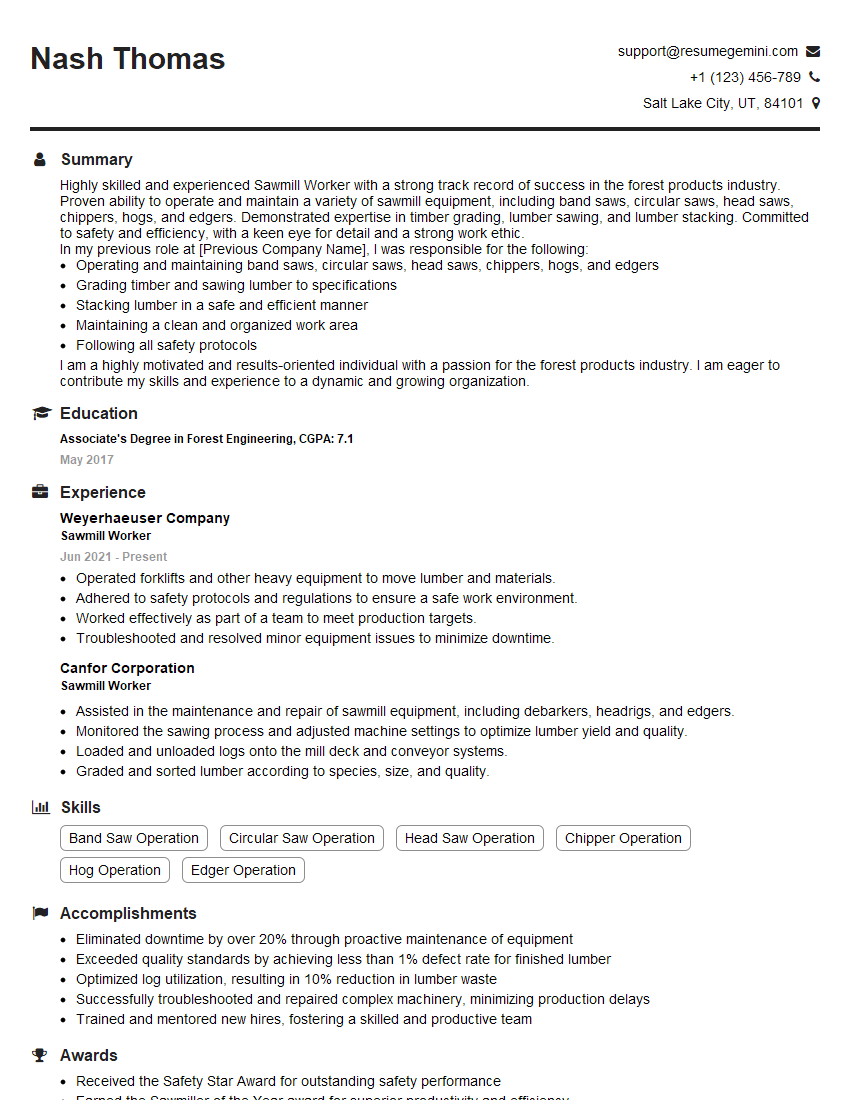

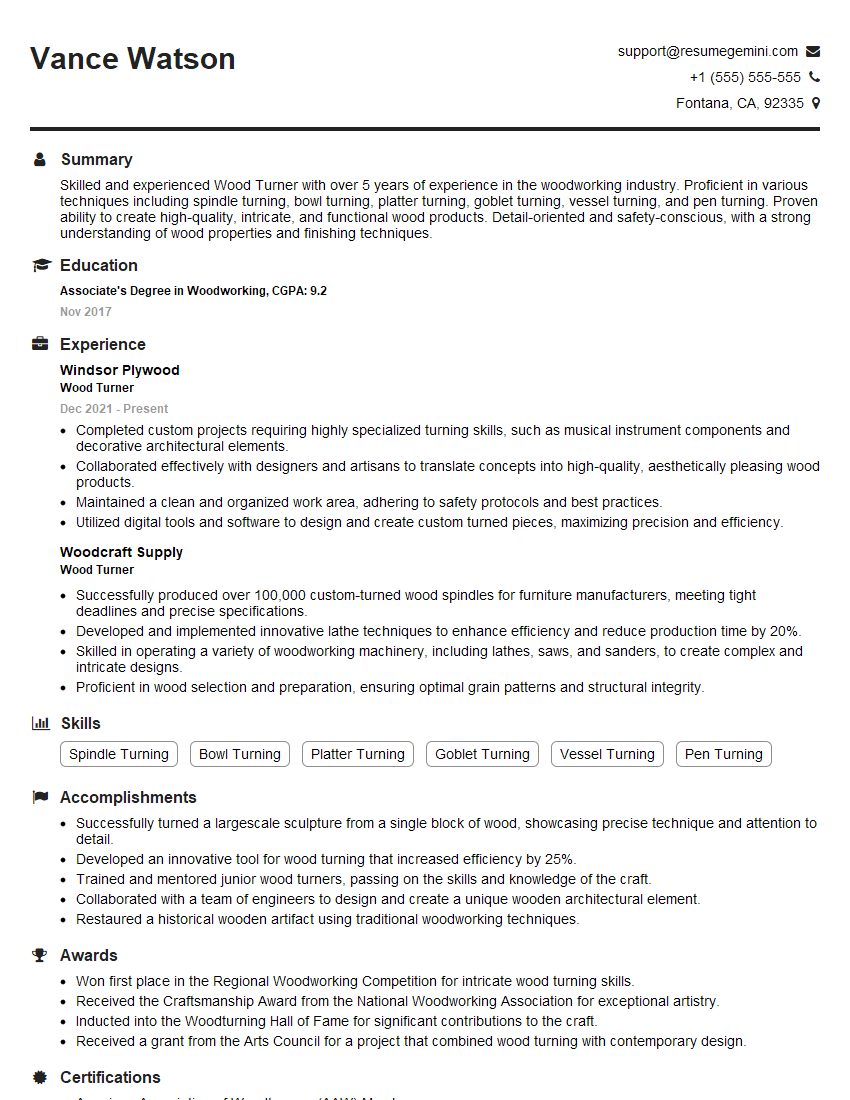

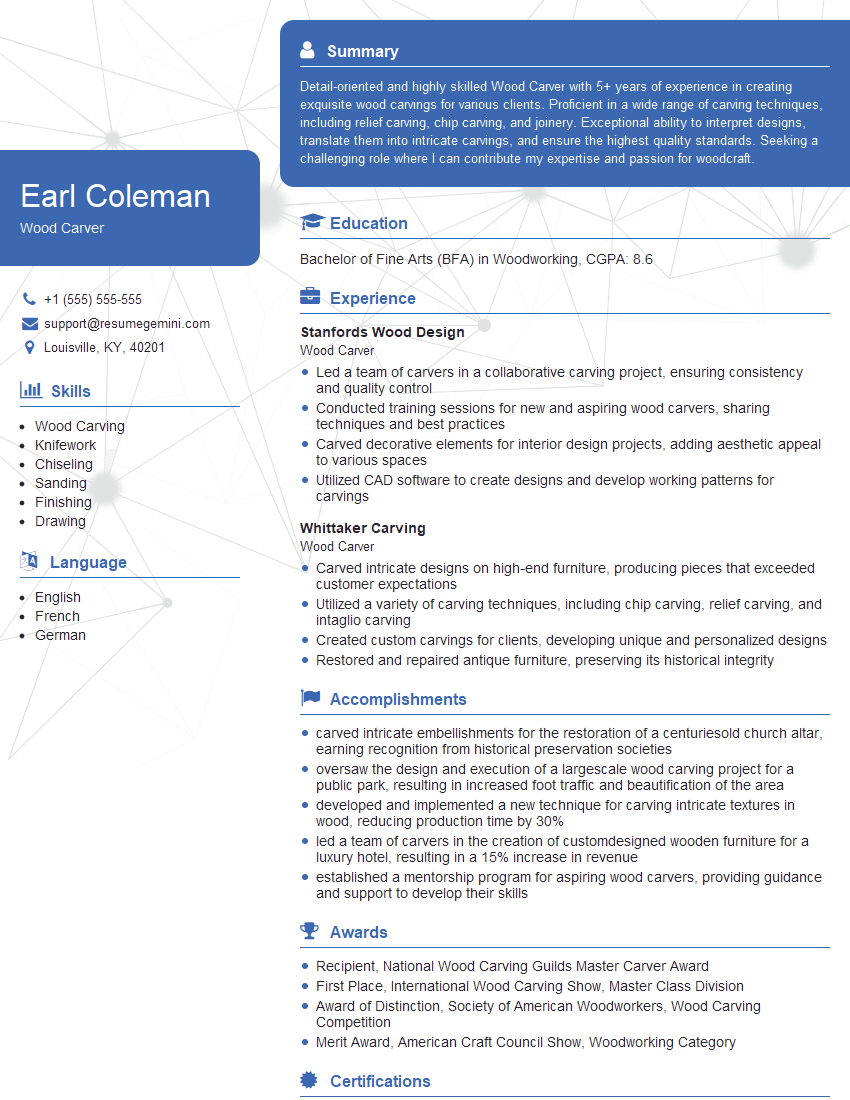

Mastering wood cutting skills opens doors to a rewarding career with opportunities for advancement and specialization. To stand out to potential employers, a well-crafted, ATS-friendly resume is crucial. This is where ResumeGemini can help. ResumeGemini provides the tools and resources to build a professional, impactful resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to the wood cutting industry to help you create a winning application. Take the next step in your career journey – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO