Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Dock Leveling interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Dock Leveling Interview

Q 1. Describe the different types of dock levelers.

Dock levelers come in various types, each designed to meet specific needs and bridge the gap between loading docks and truck beds. The primary distinction lies in their operating mechanisms:

- Hydraulic Dock Levelers: These are the most common type, using hydraulic cylinders to raise and lower the platform. They’re known for their robust construction and smooth operation. Think of them as the workhorses of the dock leveling world, capable of handling heavy loads.

- Mechanical Dock Levelers: These use a system of gears and levers, offering a simpler, more cost-effective option. While reliable, they may lack the smooth operation and lifting capacity of hydraulic models. They are a good choice when budget is a primary concern, but may need more frequent maintenance.

- Electric Dock Levelers: These utilize electric motors to power the lifting mechanism. They often incorporate advanced features such as automatic leveling and safety systems. They are popular in settings requiring precise control and higher levels of automation. Think of this as an advanced version of hydraulic, offering refined control.

- Scissor Lift Dock Levelers: Similar to the mechanics of a scissor lift, these provide a compact solution for loading docks with limited space. They have a lower profile when retracted, making them space-efficient and often preferred for indoor installations.

The choice of leveler depends heavily on factors like budget, load capacity requirements, available space, and the frequency of use.

Q 2. Explain the safety procedures for operating a dock leveler.

Safety is paramount when operating dock levelers. Here’s a breakdown of essential procedures:

- Pre-Operation Inspection: Always inspect the leveler before use. Check for any damage, leaks, or loose components. Ensure the lip is free of obstructions.

- Proper Positioning: Make sure the truck is correctly positioned against the dock leveler before attempting to operate it.

- Controlled Operation: Operate the leveler slowly and carefully, avoiding sudden movements. Never rush the process.

- Wheel Chocks: Always engage wheel chocks on the trailer wheels to prevent accidental movement during loading and unloading.

- Bridge Plate Securement: Ensure the bridge plate is securely locked in place before allowing personnel or equipment to cross.

- Warning Systems: Be aware of and utilize any warning lights or alarms provided on the leveler.

- Training: Only trained and authorized personnel should operate dock levelers.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety shoes and gloves.

Imagine a scenario where a worker rushes the operation. A poorly secured bridge plate could result in a serious accident, leading to injury or even death. Careful operation and preventative measures significantly mitigate these risks.

Q 3. How do you perform preventative maintenance on a dock leveler?

Preventative maintenance is crucial for ensuring the longevity and safe operation of a dock leveler. A regular maintenance schedule should include:

- Visual Inspection: Regularly inspect all components for wear, damage, or leaks. Look closely at welds, hydraulic lines, and mechanical parts.

- Hydraulic System Check: Check the hydraulic fluid level, condition, and look for leaks. Periodically replace the fluid.

- Mechanical Component Lubrication: Lubricate all moving parts and pivoting points as per the manufacturer’s recommendations.

- Lip Seal Inspection: Check the lip seal for damage or wear, replace if necessary.

- Safety System Testing: Test all safety features such as emergency stops, limit switches and interlocks.

- Load Testing: Periodically perform a load test to confirm the leveler’s capacity and stability.

- Documentation: Maintain thorough records of all maintenance activities.

Think of it like regular car maintenance; a small investment in preventative care can save you from expensive repairs or even dangerous failures down the line.

Q 4. What are the common causes of dock leveler malfunctions?

Dock leveler malfunctions can stem from various sources:

- Hydraulic Leaks: Leaks in hoses, cylinders, or seals are common causes of failure, resulting in decreased lifting capacity or complete failure.

- Electrical Faults: Problems with motors, switches, or wiring can cause the leveler to malfunction or become inoperable.

- Mechanical Wear and Tear: Wear and tear on gears, chains, or other mechanical components can affect the leveler’s performance.

- Improper Maintenance: Lack of regular maintenance can lead to premature wear and tear and eventual failure.

- Overloading: Exceeding the leveler’s rated capacity can damage components.

- Environmental Factors: Exposure to harsh weather conditions can affect the leveler’s performance and longevity.

- Structural Damage: Damage to the dock or leveler’s support structure can compromise safety and operation.

For instance, a consistently overloaded leveler will experience premature wear on its hydraulic components, leading to costly repairs. Regular inspections and adherence to weight limits are crucial.

Q 5. How do you troubleshoot hydraulic leaks in a dock leveler?

Troubleshooting hydraulic leaks requires a systematic approach:

- Identify the Leak Source: Carefully inspect all hydraulic lines, cylinders, and fittings for leaks. Look for dampness or dripping fluid.

- Isolate the Problem Area: Once the source is identified, isolate the affected component to prevent further fluid loss.

- Determine the Leak Type: Is it a slow leak, or is it a high-pressure leak? This helps to pinpoint the likely cause.

- Repair or Replace: For minor leaks, tightening fittings or replacing damaged seals might suffice. Severe leaks may require replacing hoses, cylinders, or other components.

- Refill and Test: After repairs, refill the hydraulic system with the correct fluid and test the leveler’s functionality.

Consider this: a persistent slow leak might go unnoticed, causing the leveler to eventually fail at a critical moment. Early detection and timely repair are vital to preventing such failures.

Q 6. Describe the process for replacing a dock leveler’s lip seal.

Replacing a dock leveler’s lip seal requires careful attention to detail. This process varies depending on the leveler’s design, but generally involves these steps:

- Safety First: Secure the area, disconnect the power, and ensure the leveler is fully lowered.

- Remove the Old Seal: Carefully remove the old lip seal using appropriate tools. Avoid damaging the surrounding components.

- Clean the Surface: Thoroughly clean the sealing surface to ensure proper adhesion for the new seal.

- Install the New Seal: Carefully install the new lip seal, ensuring it’s correctly positioned and seated.

- Test the Seal: Thoroughly test the seal for leaks after installation.

If a lip seal is compromised, it risks damaging the deck surface or could even result in hydraulic fluid leaking, posing a safety hazard. This seemingly small component is crucial for proper functioning and safety.

Q 7. How do you inspect a dock leveler for structural damage?

Inspecting for structural damage involves a thorough visual examination and may involve additional tests in some cases:

- Visual Inspection: Check for cracks, bends, or deformations in the leveler’s frame, support structures, and the dock itself. Look carefully at welds and connections.

- Leveling Check: Verify that the dock leveler is level when fully extended and retracted; this indicates a problem with the structural support or the dock itself.

- Component Alignment: Ensure that all components are aligned properly and operate smoothly. Misalignment suggests potential structural problems.

- Load Testing: A load test can reveal subtle structural weaknesses or damage that might not be visible through inspection.

- Professional Assessment: If significant damage is suspected, consult a structural engineer for a thorough evaluation.

Failure to detect structural damage can lead to catastrophic failure of the dock leveler and risk serious injury or even death to workers on the loading dock. Thorough inspection is key.

Q 8. What are the safety regulations surrounding dock levelers?

Safety regulations surrounding dock levelers are paramount to prevent workplace accidents. They vary slightly by region and are often dictated by OSHA (Occupational Safety and Health Administration) in the US and similar bodies internationally. These regulations focus on ensuring the safe operation and maintenance of the equipment to protect workers from falls, crushing injuries, and other hazards.

- Regular Inspections: Frequent inspections are mandatory to identify potential problems before they lead to accidents. This includes checking for damage to the lip, structural components, and safety features.

- Proper Training: Workers operating and maintaining dock levelers must receive adequate training on safe operating procedures and emergency protocols.

- Warning Systems: Dock levelers must be equipped with appropriate warning systems, such as audible alarms and visual indicators, to alert workers of potential hazards.

- Load Capacity: Operators must never exceed the rated weight capacity of the leveler. Overloading can lead to catastrophic failure.

- Personal Protective Equipment (PPE): Appropriate PPE, such as safety shoes and high-visibility vests, should be worn when working around dock levelers.

- Lockout/Tagout Procedures: Strict lockout/tagout procedures must be followed during maintenance or repair to prevent accidental activation.

For instance, a company failing to conduct regular inspections, leading to a collapse and injury, could face significant fines and legal repercussions.

Q 9. Explain the importance of regular inspections and maintenance.

Regular inspections and maintenance are absolutely critical for the safe and efficient operation of dock levelers. Think of it like regular car maintenance – neglecting it leads to breakdowns and potentially serious consequences. These checks prevent costly repairs and downtime, extending the lifespan of the equipment significantly.

- Preventative Maintenance: Regular lubrication of moving parts, checking hydraulic fluid levels, and inspecting for wear and tear on seals and components prevent unexpected failures.

- Early Problem Detection: Regular inspections allow for the early detection of minor issues before they escalate into major problems. A small hydraulic leak, for example, is much easier (and cheaper) to fix than a complete hydraulic system failure.

- Safety Assurance: Thorough maintenance ensures all safety features are functioning correctly, minimizing the risk of accidents. This includes checking emergency stops, lip restraints, and load-bearing capabilities.

- Compliance: Regular maintenance is often a legal requirement and helps demonstrate compliance with safety standards.

Imagine a scenario where a dock leveler’s lip suddenly malfunctions due to lack of maintenance; this could lead to a dangerous gap between the truck and the dock, resulting in serious injury to workers.

Q 10. How do you handle emergency situations involving a malfunctioning dock leveler?

In case of a malfunctioning dock leveler, the priority is always safety. Immediate action is needed to prevent accidents and potential injuries.

- Emergency Stop: Immediately activate the emergency stop button on the dock leveler.

- Isolate the Area: Secure the area around the malfunctioning equipment by placing warning cones or barriers to prevent unauthorized access.

- Evacuate Personnel: Clear the area of any personnel to prevent potential harm.

- Report the Incident: Inform relevant personnel, such as supervisors and maintenance staff, about the incident and the nature of the malfunction.

- Assess the Situation: Once the area is secured, assess the situation to determine the extent of the damage and the potential safety hazards.

- Contact Qualified Technicians: Only qualified and trained technicians should attempt to repair or troubleshoot the malfunctioning dock leveler. Never attempt DIY repairs.

- Document the Incident: Document the incident, including the date, time, nature of the malfunction, and any actions taken.

For example, if a hydraulic failure causes the leveler to suddenly drop, immediate evacuation and securing the area will prevent serious injury.

Q 11. What are the different types of lip seals used in dock levelers?

Lip seals are crucial for maintaining a safe and efficient loading/unloading process. They prevent damage to goods, protect against weather, and stop the ingress of debris. Several types exist, each with its advantages and disadvantages.

- Rubber Lip Seals: These are the most common, offering good durability, flexibility, and a relatively low cost. They’re effective against dust and light debris but can wear down over time.

- Polyurethane Lip Seals: More durable and resistant to abrasion, chemicals, and extreme temperatures than rubber seals. They last longer but come with a higher price tag.

- Combination Seals: These combine different materials, often using a tougher outer layer for protection and a softer inner layer for a good seal. This offers a balance between durability and cost.

The choice of lip seal often depends on the specific application and environmental conditions. For example, a facility in a cold climate might opt for polyurethane seals for their better resistance to low temperatures.

Q 12. What are the advantages and disadvantages of different dock leveler types?

Several dock leveler types exist, each suited for different needs and environments.

- Mechanical Dock Levelers: These are typically less expensive but require more manual effort. They may lack some of the safety features of more advanced models.

- Hydraulic Dock Levelers: These offer smooth, reliable operation with greater safety features (such as automatic lip extension and retraction) and generally higher load capacities. However, they are usually more expensive and require regular hydraulic fluid maintenance.

- Edge-of-Dock Levelers: These are space-saving options and suitable for situations where space is limited but come with more limited load capacity.

- Vehicle-Mounted Levelers: These are installed on the truck, eliminating the need for dock-side equipment but are more expensive and require coordination between shipper and receiver.

The choice depends on budget, space constraints, required load capacity, and the frequency of use. A high-volume warehouse might choose hydraulic levelers for their efficiency and safety features, while a smaller business might opt for a more cost-effective mechanical model.

Q 13. Describe the process of aligning a dock leveler with a trailer.

Aligning a dock leveler with a trailer requires precision and careful operation to ensure a safe and efficient loading/unloading process. Think of it as a precision docking maneuver, just on a larger scale.

- Engage the Leveler: Ensure the truck is properly positioned and the dock leveler is fully retracted. Always check the brakes on the trailer.

- Activate the Leveler: Slowly extend the dock leveler towards the trailer, ensuring it aligns with the trailer bed. Proper alignment prevents damage to both the trailer and the dock leveler.

- Adjust for Alignment: Fine-tune the alignment to ensure the leveler rests evenly and securely on the trailer bed. Minor adjustments may be needed to bridge any height differences.

- Secure the Leveler: Secure the dock leveler once it’s firmly in place. This usually involves engaging locking mechanisms to prevent accidental movement or detachment.

- Check for Stability: Before commencing loading or unloading, conduct a final stability check to ensure the leveler is safely connected and stable.

Improper alignment can lead to the leveler tilting or shifting during operation, posing a serious risk of damage and injury. Always prioritize safety when aligning a dock leveler.

Q 14. How do you ensure the proper weight capacity is not exceeded?

Exceeding the weight capacity of a dock leveler can lead to serious accidents, including structural failure and potential injuries. Knowing and respecting the weight limits is non-negotiable.

- Check the Rated Capacity: Always consult the manufacturer’s specifications for the maximum weight capacity of the dock leveler. This information is usually found on a data plate attached to the equipment.

- Weigh the Load: Before placing any load on the dock leveler, determine the weight of the load using a calibrated scale. Never guess the weight.

- Implement Weight Monitoring: Consider using load-monitoring systems or other technologies to track and monitor the weight of goods being moved. Some modern dock levelers include built-in weight sensors.

- Load Distribution: Evenly distribute the load across the dock leveler to prevent uneven stress and maximize capacity. Avoid concentrating weight in one area.

- Operator Training: Operators must be properly trained to understand and adhere to weight limits. They should be instructed on safe loading practices and what to do if the weight limit is exceeded.

For example, attempting to load a pallet exceeding the dock leveler’s capacity can result in the leveler collapsing, causing damage and potentially injuring workers. Safe loading practices are crucial to prevent such incidents.

Q 15. What are the signs of a worn-out dock leveler?

Recognizing a worn-out dock leveler requires a keen eye and understanding of its components. Think of it like a car – if you ignore warning signs, bigger problems arise. Here are key indicators:

Lip plate damage: Scratches, dents, or significant wear on the lip plate, which is the critical part that bridges the gap between truck and dock, indicates heavy use and potential structural compromise. This might manifest as uneven lip plate positioning or difficulty in achieving a smooth, level transition.

Hydraulic system leaks: Oil leaks are a major warning sign, pointing towards possible seal failure or damage within the hydraulic cylinders. Look for stains on the floor around the leveler. This significantly reduces operational efficiency and could lead to complete system failure.

Slow or erratic movement: If the dock leveler moves sluggishly, hesitates, or makes unusual noises during operation, it’s a sign of potential problems within the hydraulics, motor, or control system. Imagine your car struggling to accelerate—it needs attention.

Worn-out seals and gaskets: Regular inspection of seals and gaskets is crucial, especially around the hydraulic cylinders and the lip plate. These prevent leaks and ensure smooth operation. If cracked or damaged, they should be replaced promptly.

Damaged or bent components: Check for any physical damage to structural elements like the frame, supports, or the lip plate itself. Bending or misalignment suggests significant impact and potential safety hazards.

Control system malfunctions: Erratic behavior from the control panel, such as buttons failing to respond or inaccurate readings, may indicate wiring issues or problems with the control components.

Addressing these issues promptly prevents larger, more costly repairs and ensures safety for workers and equipment.

Career Expert Tips:

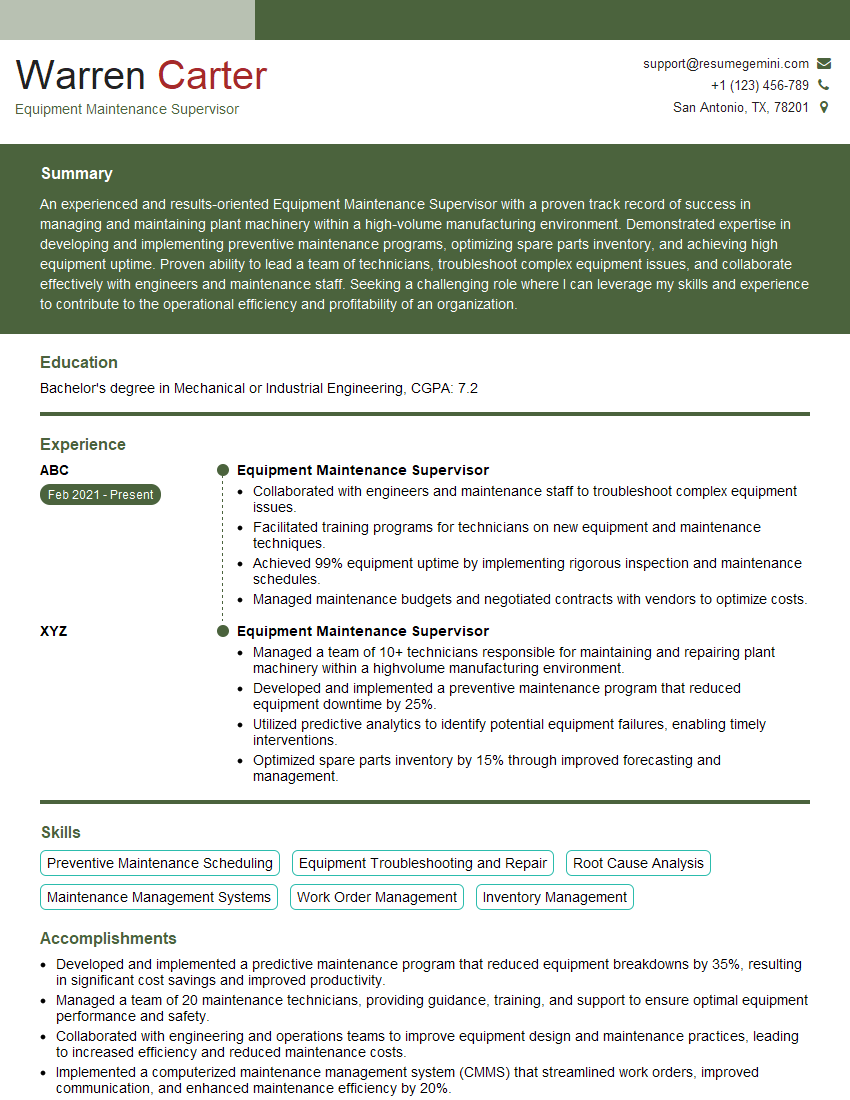

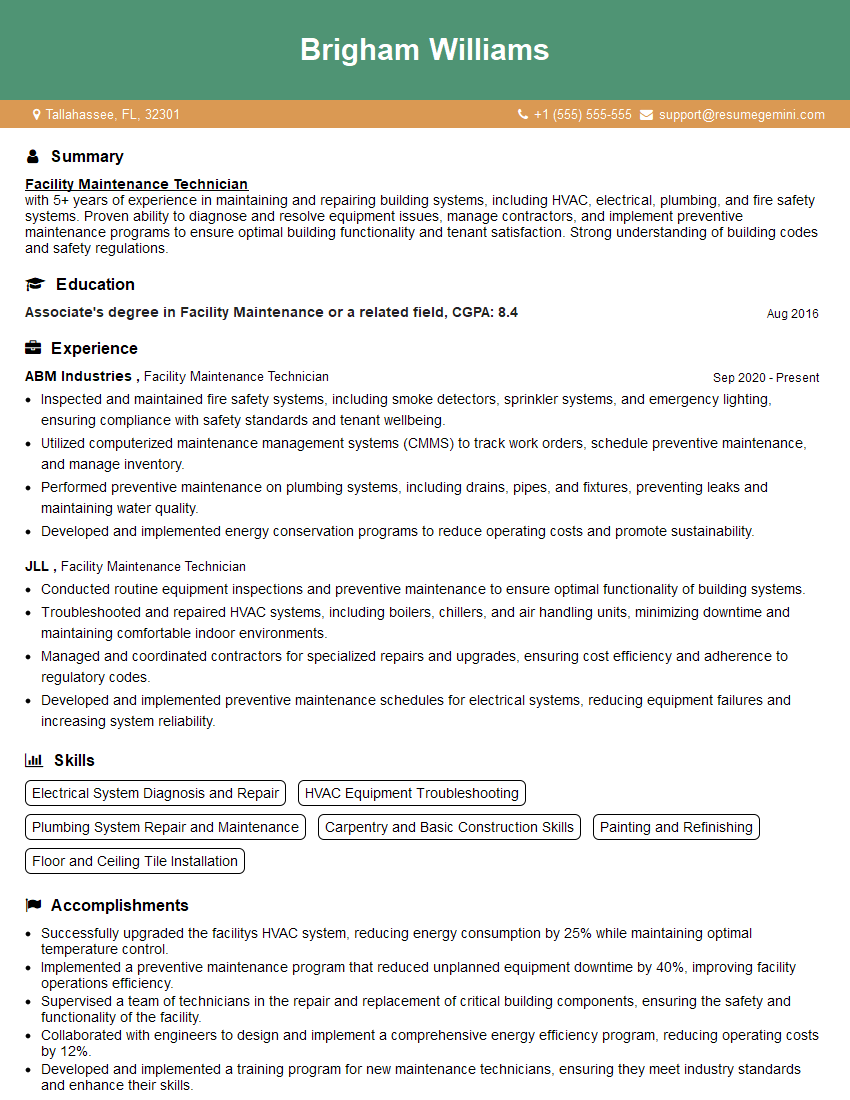

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you address issues with the dock leveler’s control system?

Troubleshooting a dock leveler’s control system requires a systematic approach. I always start with visual inspection: checking for loose connections, damaged wiring, or burnt components. Think of it as detective work.

Visual Inspection: Begin by carefully examining all wiring and connections for any signs of damage, loose connections, or corrosion. A simple visual inspection often reveals the root cause.

Testing Components: Once visually inspected, I would systematically test individual components, such as limit switches, pressure sensors, and the control panel itself, using a multimeter to check for voltage and continuity. This helps pinpoint the faulty component.

Software Diagnostics (if applicable): Some modern dock levelers have sophisticated software diagnostics. I would access these to identify any error codes or stored diagnostic data that could assist in identifying the problem.

Calibration: If the issue is related to the leveler’s accuracy or positioning, a calibration procedure may be required to re-establish correct operation.

Replacement of faulty components: Based on my testing, I would replace any faulty components and restore the correct configuration. Documentation and schematics are essential here. It’s always advisable to replace worn or suspect components in tandem to avoid recurring issues.

In cases of complex problems, a specialized technician or the manufacturer’s service team might be necessary. However, many issues can be resolved with basic troubleshooting techniques and readily available tools. Safety is paramount, so always ensure the power is disconnected before working on the system.

Q 17. Explain the role of a dock leveler in efficient warehouse operations.

Dock levelers are the unsung heroes of efficient warehouse operations. They seamlessly bridge the gap between loading docks and delivery trucks, facilitating safe and efficient loading and unloading processes. Imagine trying to load pallets onto a truck with a significant height difference—it’s dangerous and slow.

Safety: The most crucial role is ensuring worker safety by eliminating the need for dangerous manual bridging techniques. Workers no longer have to navigate uneven gaps between the truck and dock, greatly reducing the risk of falls and injuries.

Productivity: By providing a level surface for smooth loading and unloading, dock levelers significantly increase productivity. Trucks can be loaded and unloaded much more quickly, minimizing downtime and maximizing operational efficiency. This directly impacts delivery schedules and warehouse throughput.

Damage Prevention: They protect goods and equipment from damage caused by uneven loading. By ensuring a smooth transition, the risk of pallet damage, equipment damage and worker injury is reduced.

Cost Savings: Increased efficiency and reduced risk of damage lead to significant cost savings in the long run. The investment in a reliable dock leveler pays for itself over time through increased productivity and reduced maintenance costs.

In short, a well-functioning dock leveler is essential for creating a safe, efficient, and cost-effective warehouse environment.

Q 18. Describe your experience with different brands of dock levelers.

Throughout my career, I’ve worked extensively with several leading brands of dock levelers, including Blue Giant, Equipto, and Stertil-Koni, among others. Each brand has its own strengths and specific characteristics.

Blue Giantis known for its robust construction and wide range of options. They are dependable in rugged conditions.Equiptooften offers innovative designs with features focusing on efficiency and ease of maintenance. Their focus on user-friendly designs is a key advantage.Stertil-Konispecializes in heavy-duty solutions and are a solid choice where high weight capacities are essential.

My experience with these brands has given me a comprehensive understanding of the various designs, technologies, and maintenance requirements of different dock levelers, allowing me to tailor recommendations based on the client’s specific needs.

Q 19. How do you handle a situation where a dock leveler is damaged?

Handling a damaged dock leveler involves a multi-step process prioritizing safety and prompt action. It’s a serious issue that can halt operations.

Immediate Safety Measures: The first step is to immediately isolate the damaged leveler and make sure the area is safe. This might involve turning off the power, erecting barriers and warning signage to prevent accidental use or injury.

Assessment of Damage: Conduct a thorough assessment of the extent of the damage, carefully documenting all visible damage, including photographs. Identify the specific components affected.

Contacting Professionals: Depending on the severity of the damage, contact either a qualified repair technician or the manufacturer directly. For significant damage, calling the manufacturer is generally the best first step.

Temporary Solutions: If the damage is not critical and the warehouse can handle a short interruption, implement a temporary solution, like using ramps, but ensure this temporary setup does not compromise safety.

Repair or Replacement: Once the assessment is complete, work with the service provider to repair or replace the damaged components. This is where my experience with different brands becomes invaluable.

Post-Repair Inspection: After the repairs are complete, conduct a thorough inspection to ensure all aspects of the leveler’s functionality are restored to their original condition. Thorough testing before resuming operations is crucial.

Thorough documentation throughout the process is vital for insurance claims or warranty purposes.

Q 20. How do you maintain accurate records for dock leveler maintenance?

Maintaining accurate records for dock leveler maintenance is crucial for ensuring the equipment’s longevity and safety. I use a combination of methods:

Digital Maintenance Management Software: A dedicated software program is highly effective for tracking maintenance schedules, recording inspections, and documenting repairs. This offers a centralized database that is easily accessible and provides a complete history of maintenance activities.

Physical Logbooks: Even with digital systems, maintaining a physical logbook at the dock leveler can be helpful for quick access during inspections. This could include a checklist for routine checks.

Detailed Inspection Checklists: Using detailed checklists ensures consistency in inspections and helps identify potential problems early. These checklists include visual inspections of mechanical components and hydraulic systems.

Digital Photographs: Documenting damage with photos during inspections adds visual confirmation to maintenance records.

Service Reports: Keep records of all service calls, repairs, and replacement parts. This ensures that all maintenance activities are accurately tracked and that warranties are maintained.

The key is to use a system that is easily accessible, understandable, and comprehensive, ensuring complete transparency.

Q 21. What are some common causes of damage to a dock leveler?

Damage to a dock leveler can stem from several common causes. Prevention is key—think of it as preventative car maintenance.

Impact from Trucks: The most frequent cause is impacts from delivery trucks during docking. Misjudged backing or forceful impact can severely damage the lip plate, the hydraulic system, and other structural components.

Overloading: Exceeding the leveler’s weight capacity will stress the hydraulic system and other mechanical components and cause premature wear. Always adhere to the weight limits specified by the manufacturer.

Neglecting Maintenance: Inadequate or delayed maintenance leads to accumulated wear and tear. Regular lubrication, inspections and timely repairs extend the lifespan of your leveler and prevent sudden failures.

Environmental Factors: Exposure to harsh weather conditions like extreme temperatures, rain, and snow can accelerate corrosion and damage critical components.

Improper Operation: Incorrect operation, such as attempting to level while the truck is still moving, can cause sudden stress that compromises its structural integrity.

Improper Installation: Faulty installation can lead to premature failure and potential safety concerns.

By understanding these common causes, warehouse managers can implement preventative measures to minimize damage and extend the lifespan of their dock levelers.

Q 22. What safety equipment is essential when working with a dock leveler?

Safety is paramount when working with dock levelers. Essential equipment includes:

- High-visibility safety vests: Ensuring all personnel are easily seen, especially in busy loading docks.

- Gloves: Protecting hands from potential cuts, scrapes, or chemical exposure.

- Steel-toed boots: Protecting feet from dropped objects or accidental crushing.

- Hearing protection: Reducing noise exposure from the operation of the hydraulic systems.

- Eye protection: Protecting eyes from debris or hydraulic fluid spray.

- Proper lockout/tagout devices: Essential before performing any maintenance or repair work to prevent accidental activation.

- Wheel chocks: To secure trailers and prevent movement during loading and unloading.

Regular safety inspections of the equipment and the surrounding area are also crucial. For example, ensuring the lip of the dock leveler is free from obstructions and the surrounding area is properly lit.

Q 23. How do you train others on the safe operation of a dock leveler?

Training on dock leveler operation needs to be comprehensive and hands-on. I start with classroom instruction covering the mechanics, safety procedures, and emergency protocols. This includes:

- Detailed explanation of the dock leveler’s components and functions. We cover the hydraulic system, the control panel, and the safety features.

- Step-by-step demonstration of the proper operation procedure. This includes how to engage and disengage the leveler, safely position it, and respond to malfunctions.

- Emphasis on safety regulations and best practices. This involves covering the use of personal protective equipment (PPE) and highlighting potential hazards.

- Hands-on practical training. Trainees operate the dock leveler under supervision, ensuring they are comfortable and confident with the equipment.

- Regular competency assessments. To ensure knowledge retention and identify areas for improvement.

I use visual aids like diagrams, videos, and real-world examples to make the training engaging and effective. A key part of my training is emphasizing the consequences of improper operation, both for the individual and the company.

Q 24. What is the typical lifespan of a dock leveler?

The lifespan of a dock leveler varies greatly depending on factors like usage frequency, maintenance schedules, and environmental conditions. A well-maintained dock leveler can last for 15-20 years, but neglecting regular service can significantly reduce its lifespan.

For example, consistent exposure to harsh weather conditions or excessive use can accelerate wear and tear on the hydraulic system and mechanical components. Regular lubrication, leak checks, and inspections are critical to extend the useful life.

Q 25. How do you determine if a dock leveler needs to be replaced?

Several indicators suggest a dock leveler needs replacement. These include:

- Frequent breakdowns and costly repairs: When the repair costs start exceeding a certain percentage of the replacement cost, it’s often more economical to replace.

- Hydraulic leaks: Persistent hydraulic leaks indicate significant damage to seals or components, often difficult and expensive to repair.

- Safety concerns: Malfunctions that compromise the safety of workers or damage goods require immediate attention and may necessitate replacement.

- Excessive wear and tear: Visible signs of significant damage to structural components or inability to meet the load requirements.

- Outdated technology: Older dock levelers may lack advanced features that improve efficiency and safety.

A thorough inspection by a qualified technician is crucial to accurately assess the condition of the dock leveler and determine whether repair or replacement is the most cost-effective solution. This often involves checking the hydraulic system for leaks, inspecting the mechanical components for wear, and assessing the overall structural integrity.

Q 26. What are your experiences with different types of hydraulic systems?

My experience encompasses various hydraulic systems used in dock levelers, including:

- Conventional Hydraulic Systems: These are the most common, utilizing a pump, reservoir, valves, and cylinders to lift and lower the leveler. I’m adept at troubleshooting issues like leaks, low pressure, and valve malfunctions in these systems.

- Electro-hydraulic Systems: These systems integrate electrical controls for precise positioning and improved safety features. My expertise extends to diagnosing and repairing electrical components and their integration with the hydraulic system.

I’ve worked on both single-acting and double-acting hydraulic cylinders, understanding the nuances of their operation and maintenance. One challenging experience involved diagnosing a seemingly intermittent leak in a double-acting cylinder. It turned out to be a tiny crack in a seemingly inconspicuous weld, requiring a complete cylinder replacement.

Q 27. How familiar are you with different types of electrical components in dock levelers?

My familiarity with electrical components in dock levelers is extensive. I’m proficient in working with:

- Control Panels: Understanding the circuitry, troubleshooting malfunctions, and repairing or replacing damaged components.

- Proximity Sensors: Diagnosing and replacing these sensors critical for safety features like preventing operation when a vehicle is not properly positioned.

- Hydraulic Pumps and Motors: Understanding the electrical controls and drive systems for these vital components.

- Wiring Harnesses: Tracing and repairing wiring issues, ensuring proper grounding and electrical safety.

- Safety Interlocks: Ensuring these mechanisms function correctly to prevent accidental operation.

I’m experienced in using various diagnostic tools, including multimeters and specialized testing equipment, to identify and resolve electrical issues in dock levelers.

Q 28. What is your experience with troubleshooting and repairing mechanical components?

Troubleshooting and repairing mechanical components forms a significant part of my expertise. I’ve handled:

- Repairing and replacing worn or damaged mechanical components: This includes chains, gears, bearings, and other moving parts within the leveler’s mechanism. For example, I once diagnosed a noisy gear system by carefully inspecting gear teeth for wear and replacing the damaged components.

- Welding and fabrication: Repairing damaged structural components such as the lip and frame.

- Hydraulic cylinder repair and replacement: Diagnosing leaks, replacing seals, and performing complete cylinder overhauls.

- Troubleshooting mechanical linkages: Identifying and correcting issues in the mechanical system causing misalignment or binding.

My approach involves a systematic process of inspection, diagnosis, and repair. I often utilize schematics, manuals, and specialized tools to ensure accurate and efficient repairs. I prioritize safety throughout the process, ensuring proper lockout/tagout procedures are followed.

Key Topics to Learn for Dock Leveling Interview

- Types of Dock Levelers: Understand the differences between various dock leveler designs (e.g., hydraulic, mechanical, scissor lift) and their respective applications.

- Safety Procedures and Regulations: Familiarize yourself with OSHA and industry-specific safety guidelines for operating and maintaining dock levelers, including lockout/tagout procedures and safe loading/unloading practices.

- Hydraulic Systems: Grasp the fundamental principles of hydraulic systems as they relate to dock levelers, including pressure, flow, and maintenance. Be prepared to troubleshoot basic hydraulic problems.

- Mechanical Systems: Understand the mechanical components of dock levelers, such as gears, chains, and linkages. Be able to explain how they work together and identify potential points of failure.

- Electrical Components and Controls: If applicable to your target roles, be familiar with the electrical systems controlling dock levelers, including safety switches, sensors, and control panels.

- Preventive Maintenance: Discuss the importance of regular inspections and maintenance to extend the lifespan of dock levelers and prevent accidents. Describe common maintenance tasks.

- Troubleshooting and Repair: Prepare to discuss your approach to diagnosing and resolving common issues with dock levelers. This could involve identifying the source of a problem, ordering parts, and performing repairs.

- Capacity and Weight Limits: Understand the importance of adhering to weight and capacity limits to prevent damage to equipment and ensure safety.

- Integration with Dock Systems: Explain how dock levelers integrate with other dock equipment, such as seals, shelters, and restraints.

- Industry Best Practices: Stay up-to-date on current industry best practices for dock leveler operation and maintenance.

Next Steps

Mastering dock leveling knowledge significantly enhances your career prospects in logistics, warehousing, and transportation. A strong understanding of these systems showcases your technical skills and commitment to safety. To boost your job search, create an ATS-friendly resume that highlights your relevant experience and qualifications. ResumeGemini is a trusted resource to help you build a professional resume that stands out. Examples of resumes tailored to Dock Leveling positions are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO