Cracking a skill-specific interview, like one for Chainsaw Operation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Chainsaw Operation Interview

Q 1. What are the different types of chainsaws and their applications?

Chainsaws are categorized primarily by their power source and intended use. The most common types are:

- Gasoline-powered chainsaws: These are the workhorses of the industry, offering high power and extended run times, ideal for larger-scale projects like felling trees or heavy timber cutting. They come in various sizes, from smaller, lightweight models for homeowners to powerful, professional-grade saws for arborists and loggers.

- Electric chainsaws (corded and cordless): Corded electric saws offer a good balance of power and convenience for smaller jobs, but their cord can be limiting. Cordless options are increasingly powerful and provide more maneuverability, perfect for smaller properties and pruning jobs. They are cleaner and quieter than gas saws, however, battery life is a consideration.

- Battery-powered chainsaws: These are the most environmentally friendly option. Technology has made these chainsaws more powerful and suitable for even larger tasks.

The choice depends on the job’s scope. For instance, felling a large oak tree would require a powerful gas-powered chainsaw, while trimming branches in a small garden might be best handled with a lightweight electric or battery-powered saw.

Q 2. Explain the proper procedure for starting a chainsaw.

Starting a chainsaw safely requires a methodical approach. First, ensure the chain brake is engaged. Then:

- Prepare the area: Clear debris and ensure you have a firm footing.

- Fuel and oil check (for gas saws): Verify adequate fuel and bar oil levels. Never run a chainsaw dry.

- Engage the chain brake: This is critical for safety.

- Set the choke (gas saws only): If needed, adjust the choke as indicated in your user manual.

- Start the saw: Follow the manufacturer’s instructions (typically involves pulling the starter rope firmly while holding the saw securely).

- Release the choke (gas saws only): Once the engine starts, gradually release the choke.

- Check for chain movement: Engage the throttle briefly to ensure the chain rotates freely.

- Engage the safety device: (If your chainsaw has a secondary safety switch).

Remember to always start the saw on the ground, away from your body, and never attempt to start it while it’s in a tree or high above the ground.

Q 3. Describe the different types of chainsaw bars and chains.

Chainsaw bars and chains are crucial components, and their selection significantly impacts performance and safety.

- Bars: These come in various lengths (e.g., 12”, 16”, 20”), measured from tip to mounting holes. Longer bars are suitable for larger cuts, while shorter bars are more maneuverable for smaller tasks. Different types include:

- Standard/Full-Compensated Bars: These are the most common type for general use.

- Semi-Skip-Tooth Bars: Designed for cutting hardwoods, these bars have less friction.

- Rollomatic Bars: Designed to reduce friction and increase cutting speed.

- Chains: Chains vary in pitch (distance between drive links), gauge (thickness), and type of cutter (e.g., chisel, semi-skip, full-skip).

- Pitch: This dictates the chain’s speed and power; improper pitch will damage the saw.

- Gauge: Thicker gauge chains are more durable but require more power.

- Cutter Type: Chisel chains are aggressive for fast cuts in softwood, while skip-tooth chains are better for hardwoods, reducing vibration.

Matching the bar and chain correctly to the saw is essential for optimal performance and safety.

Q 4. How do you select the correct chain for a specific job?

Chain selection is crucial for efficiency and safety. The job dictates the chain type:

- Softwoods (pine, fir): A chisel-tooth chain is ideal for fast cutting.

- Hardwoods (oak, maple): A semi-skip or full-skip tooth chain is recommended to reduce vibration and increase durability.

- Frozen Wood: A chain designed for frozen wood is recommended as this type of wood is tougher than regular wood.

- Branching/Pruning: Chains designed for this purpose often have smaller cutting teeth and less aggressive cutting angles.

Consider the wood type, its hardness, and the size of the cuts you need to make. Always consult your chainsaw’s manual for recommended chain specifications.

Q 5. What safety equipment is essential when operating a chainsaw?

Safety is paramount when operating a chainsaw. Essential equipment includes:

- Safety Helmet with Face Shield or Visor: Protects your head and face from flying debris.

- Eye Protection: Safety glasses or goggles are essential to protect your eyes.

- Hearing Protection: Earplugs or earmuffs are vital to protect your hearing from the loud noise.

- Chainsaw Chaps: These are vital protective gear to protect the legs from the chain saw. They are designed to stop a chain saw.

- Gloves: Provide grip and protection for your hands.

- Steel-Toed Boots: Protect your feet from falling debris.

Never compromise on safety. All this equipment must be worn correctly every time a chainsaw is operated.

Q 6. Explain the proper techniques for felling a tree.

Felling a tree is a complex task requiring careful planning and execution.

- Assess the tree and the surroundings: Identify the direction of the fall, considering wind direction, obstacles, and slope.

- Plan the escape route: Establish a clear escape path at a 45-degree angle to the anticipated fall direction.

- Make the felling cut: The felling cut (also called the hinge cut) is a series of two cuts. The first (the notch cut) is a V-shaped notch cut into the side of the tree facing the direction of the fall. The second cut is the back cut, and is made horizontally slightly above the notch cut. It’s important to leave a hinge to control the tree’s fall.

- Monitor the fall: Keep a safe distance and observe the tree as it falls. Do not stand in a position where you could be hit by the tree. If the tree is not falling as planned, do not attempt to redirect it.

- Clear the area: Once the tree has fallen, remove any debris that may pose a danger.

Practicing felling techniques under the supervision of an experienced professional is strongly recommended.

Q 7. How do you assess tree risk before felling?

Assessing tree risk before felling is critical for safety. Several factors must be considered:

- Tree health: Look for signs of disease, decay, insect infestation, or structural weakness.

- Lean: Note the direction and degree of the tree’s lean. This significantly impacts the fall direction.

- Obstacles: Identify any nearby structures, power lines, or other obstacles that could be endangered by the falling tree.

- Wind conditions: Strong winds can significantly influence the tree’s fall trajectory.

- Soil conditions: Loose or unstable soil can affect the tree’s stability and fall pattern.

- Surrounding trees: The presence of other trees that could be affected by the falling tree should be considered.

If there’s any doubt about the safety of felling a tree, consult a professional arborist. It’s better to err on the side of caution.

Q 8. Describe the process of limbing and bucking a tree.

Limbing and bucking are crucial steps in processing a felled tree. Limbing involves removing the branches, while bucking means cutting the trunk into manageable lengths. Think of it like preparing a log for a fireplace – you need to remove the branches (limbing) before you can cut the log into smaller pieces (bucking).

Limbing: Always start at the base of the tree and work your way up. Use a combination of cuts to remove branches efficiently and safely. A common technique involves making an undercut on the branch, followed by a top cut slightly further out to prevent bark tearing and reduce stress on the saw. Keep a firm grip on the saw and maintain proper body positioning to avoid strain and injury. Avoid reaching across the branch; this dramatically increases risk of kickback.

Bucking: Once limbed, the tree is ready for bucking. This involves making precise cuts to divide the trunk into sections. It’s crucial to plan your cuts carefully to avoid pinching the bar or causing kickback. A common approach involves making a bore cut (a small notch to guide the saw), followed by a felling cut to separate the log. Always be aware of the direction the log will fall and ensure a clear escape route.

- Safety First: Always assess the surroundings before starting limbing and bucking, ensuring a stable working area, and checking for hazards like rocks or other obstacles.

Q 9. What are the signs of a malfunctioning chainsaw?

A malfunctioning chainsaw can be dangerous, so recognizing the signs is critical. Think of your chainsaw like a finely tuned machine – any deviation from its normal performance is a potential warning sign.

- Reduced Power/Slow Cutting: Dull chains, clogged air filters, or carburetor issues can cause a significant drop in cutting power. This is one of the earliest indicators that something needs attention.

- Excessive Vibration: Unusual vibration can indicate loose components, chain problems, or bearing wear. Ignoring this can lead to more severe damage or injury.

- Unusual Noises: Grinding, squealing, or knocking sounds are never good. These sounds often point to chain problems, bearing wear, or loose parts.

- Chain Malfunction: Check for slack, improper tension, or damaged chain links. A properly tensioned chain is essential for safe and efficient operation.

- Smoke or Burning Smell: This could indicate friction in the drive system or a serious problem that needs immediate attention. Never operate a chainsaw that’s smoking.

- Difficult Starting: If the chainsaw is difficult to start, check fuel and oil levels, air filter, spark plug, and start cord.

Addressing these issues promptly will prevent further damage and ensure the chainsaw operates safely and effectively. Regular maintenance is key to avoiding many of these issues.

Q 10. How do you maintain and sharpen a chainsaw chain?

Maintaining and sharpening your chainsaw chain is essential for safety and performance. A sharp chain cuts cleanly, requires less effort, and is less likely to cause kickback. Regular maintenance is like giving your chainsaw a tune-up.

Sharpening: Use a chainsaw file or electric sharpener, following the manufacturer’s instructions. File each tooth individually to achieve a consistent and sharp edge. It’s better to make several passes with light pressure than a few with heavy pressure. Maintain the proper depth gauge for optimum performance.

Maintenance:

- Clean the chain: Remove sawdust and debris after each use.

- Lubricate the chain: Use chainsaw bar oil regularly to reduce friction and extend chain life.

- Check chain tension: Ensure the chain is properly tensioned; too tight or too loose can damage the bar or cause the chain to jump off.

- Inspect the bar: Regularly check for damage to the bar. Look for wear, damage, or gouges.

Consider using a chain gauge to ensure uniform chain filing. Regular maintenance will drastically improve the lifespan of your chain and bar.

Q 11. What are the emergency procedures in case of a chainsaw accident?

Chainsaw accidents can be serious. Knowing emergency procedures is crucial. Think of it as a safety net for potential problems.

- Stop the chainsaw immediately: Turn off the chainsaw and ensure it is secure.

- Assess the injury: Determine the severity of the injury.

- Call for emergency medical help: This is paramount, especially for serious injuries.

- Control bleeding: Apply direct pressure to any wounds to control blood loss.

- Immobilize the injured area: This helps prevent further damage.

- Treat for shock: Keep the injured person warm and calm.

- Do not move the injured person unless absolutely necessary: Avoid causing further injury.

Post-accident, report the incident to your supervisor or employer according to company procedures. Proper training and adherence to safety guidelines are crucial in minimizing the risk of accidents.

Q 12. Explain the proper techniques for using a chainsaw in various terrain conditions.

Terrain significantly impacts chainsaw operation. Adapting your techniques is crucial for safety and efficiency. Think of the terrain as a variable you need to account for in every cut.

- Level Ground: This is the ideal scenario. Maintain a balanced stance, keeping your feet apart for stability.

- Slopes: On slopes, always work uphill to avoid losing control. Keep a firm stance and use your legs to absorb the force of the saw. Cut smaller pieces in tough areas to enhance safety.

- Uneven Terrain: Choose a stable position. Use wedges to help control falling trees and limbs. Be extra cautious to avoid slips and falls.

- Muddy or Wet Conditions: Exercise extreme caution as the risk of slips is significantly increased. Ensure firm footing and keep the chainsaw area clear. Consider using extra safety gear.

- Rough Terrain: Use extra precaution and take shorter cuts for better control.

Proper footwear and clothing are crucial in all terrain conditions. Always assess the terrain before you start cutting and adjust your technique accordingly.

Q 13. How do you handle kickback situations?

Kickback is a dangerous situation where the saw suddenly moves upward and backward, potentially causing serious injury. Think of kickback as a rapid, forceful reaction of the saw.

Prevention:

- Maintain a firm grip on the saw: Never let go.

- Use proper cutting techniques: Avoid pinching the bar. Make sure the chain is always in contact with the wood.

- Keep the saw chain sharp: A sharp chain is less likely to kickback.

- Avoid cutting small branches: Small branches are more likely to cause kickback.

- Check for obstructions: Remove nails and other debris from wood before cutting.

If kickback occurs:

- Maintain your grip: Do not let go of the saw.

- Try to direct the saw away from your body: Control the movement as much as possible.

- Release the throttle immediately: As soon as you can, release the throttle.

Proper training, correct technique, and regular maintenance are your best defense against kickback.

Q 14. Describe the different types of chainsaw cuts (e.g., undercut, back cut).

Different cuts are used for various situations in felling and bucking. Think of these cuts as a toolbox of techniques.

- Undercut: A notch cut on the side of the tree facing the direction of the fall. It guides the direction of the fall and reduces the risk of pinching the saw.

- Back Cut: Made on the opposite side of the undercut, this cut completes the felling process. It should be slightly higher than the undercut to leave a hinge.

- Bore Cut: A small notch cut into the wood. Used for guiding the saw on larger cuts, particularly when bucking.

- Felling Cut: The cut that separates the tree from its stump. Typically used after the undercut and completed by making a back cut.

- Hinge: The remaining wood between the undercut and back cut, which controls the direction of the fall.

Understanding these techniques is crucial for safe and efficient tree felling. It’s important to master each type of cut.

Q 15. What are the legal requirements and regulations for chainsaw operation in your area?

Chainsaw operation is heavily regulated for safety reasons. Specific regulations vary by location, but generally include licensing or certification requirements, especially for professional use. For example, in many jurisdictions, operating a chainsaw commercially requires a license demonstrating competency in safe operation and maintenance. These regulations often include requirements for personal protective equipment (PPE), such as helmets with face shields, chaps, gloves, and safety boots. Further, there might be noise and emission regulations, especially in environmentally sensitive areas. It’s crucial to contact your local forestry department or occupational safety agency to obtain the specific legal requirements and regulations applicable to your area. Failure to comply can lead to hefty fines and potential legal repercussions.

For instance, I once worked on a project where a subcontractor failed to obtain the necessary permits for operating chainsaws in a protected woodland. This resulted in significant delays and costly fines for the entire project.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the safe transportation and storage of a chainsaw?

Safe transportation and storage of a chainsaw are paramount to prevent accidents. During transport, the chainsaw should always be in a protective case or sheath to prevent accidental starts and injury. The fuel tank should be at least partially empty to minimize the risk of fuel leaks. When transporting it in a vehicle, it should be secured to prevent movement. For storage, the chainsaw should be kept in a dry, secure location out of the reach of children and unauthorized individuals. The blade should be covered, and the fuel tank should be emptied or nearly emptied to prevent fuel degradation and potential fire hazards. Regular checks for rust or damage are also necessary.

I always remember a situation where a colleague left a chainsaw unsecured in the back of a truck. During a sudden stop, the chainsaw shifted, causing minor damage to the vehicle and a near-miss accident. This reinforced the importance of secure transportation.

Q 17. What are the best practices for working with a chainsaw crew?

Working with a chainsaw crew requires meticulous communication, coordination, and adherence to safety protocols. Before commencing any operation, a thorough job briefing is crucial, outlining the felling plan, safety zones, and individual responsibilities. Clear hand signals are essential to avoid miscommunication, especially in noisy environments. Each crew member should be aware of their position and the actions of their colleagues to minimize the risk of collisions or accidents. Regular communication checks are essential throughout the operation. Everyone should wear the appropriate PPE, and the worksite should be kept clean and organized to minimize tripping hazards. A designated spotter should be assigned to monitor the felling operation and alert others to potential hazards.

In one project, our effective communication strategy during a complex tree removal in a densely populated area prevented any accidents despite the challenges of the setting. It was a great example of teamwork and a well-executed plan.

Q 18. How do you identify different tree species and their properties relevant to felling?

Identifying tree species is fundamental to safe and efficient felling. Different species have varying wood density, grain patterns, and branch structures, impacting felling strategies. For example, hardwoods like oak are denser and stronger than softwoods like pine, necessitating different cutting techniques. I use a combination of visual identification (bark texture, leaf shape, branch structure) and field guides to identify tree species. Understanding the grain structure is crucial; a straight grain is easier to fell than a twisted one. Knowledge of a tree’s lean, its height, and potential for hidden decay informs decisions about the felling direction and necessary safety precautions. Misidentifying a tree can lead to unexpected reactions during felling and put the crew at risk.

I once misidentified a seemingly healthy tree as a less dense species. Fortunately, I was aware enough during the felling process to adjust, and I avoided serious injury, but the incident emphasized the critical need for accurate tree identification.

Q 19. Explain the importance of pre-felling tree assessment.

Pre-felling tree assessment is critical to prevent accidents and ensure efficient felling. It involves a thorough examination of the tree’s overall condition, including its height, lean, size, and presence of any defects like rot or decay. Assessing the surrounding environment is equally vital, identifying potential hazards such as power lines, buildings, or other obstructions. The assessment informs the felling plan, including the direction of the fall, the use of wedges, and the necessary safety precautions. A well-executed pre-felling assessment saves time, resources, and most importantly, it prevents accidents. Overlooking even a small detail can have drastic consequences.

I recall an incident where a pre-felling assessment revealed a significant lean in a tree. By planning the felling direction accordingly, we avoided a potentially dangerous situation.

Q 20. Describe your experience with different chainsaw models.

My experience encompasses a wide range of chainsaw models, from lightweight homeowner models to professional-grade, high-powered units. I’ve worked extensively with Stihl, Husqvarna, and Echo chainsaws, appreciating the strengths and weaknesses of each brand. For example, Stihl models are known for their durability and precision, while Husqvarna offers a wider range of features and power options. Echo chainsaws are often praised for their lower weight and ease of use. The choice of chainsaw depends heavily on the application; smaller, lighter saws are suitable for pruning and smaller jobs, while larger, more powerful saws are necessary for felling large trees.

The most powerful chainsaw I used was the Stihl MS880. It was perfect for large-scale felling but required greater skill and attention to detail.

Q 21. What are your preferred maintenance schedules for chainsaws?

Maintaining a chainsaw is crucial for its longevity and safe operation. My preferred maintenance schedule involves a daily check of the chain tension, bar lubrication, and fuel/oil mix levels. After each use, I clean the bar and chain thoroughly and lubricate them. A more comprehensive service is done monthly or after every 20 hours of operation. This includes sharpening the chain, inspecting the air filter, spark plug, and fuel system. An annual service includes a thorough inspection of all components, including the carburetor and engine. Proper maintenance prevents breakdowns, maximizes performance, and ensures safety. Neglecting maintenance can lead to malfunctions, damage, and potential injury.

I once experienced a serious malfunction due to neglected maintenance, highlighting the importance of regular care and thorough servicing. Fortunately, the incident wasn’t catastrophic, but the experience provided an unforgettable lesson.

Q 22. Describe a situation where you had to solve a problem related to chainsaw operation.

One time, I was felling a large oak tree on a hillside. The tree was leaning significantly, and I misjudged the direction of the fall. As the tree began to fall, it caught on a smaller tree, causing it to hang precariously. This created a dangerous situation, as the tension could cause a sudden, unpredictable shift in the tree’s direction.

To solve this, I first ensured my own safety, maintaining a safe distance and clear escape route. Then, I carefully assessed the situation, using my knowledge of rigging and tree mechanics. I determined that the best course of action was to use a come-along (a type of hand-operated winch) and a sturdy rope to carefully ease the large tree down and relieve the pressure on the smaller tree. This required careful maneuvering and precise application of force, but it successfully resolved the situation without incident or damage to surrounding property.

Q 23. How do you deal with unexpected obstacles during tree felling?

Unexpected obstacles during tree felling are common and require quick thinking and adaptability. These could range from hidden underground obstructions (like rocks or pipes) to unexpected wind gusts, changes in tree lean, or interference from nearby trees or power lines.

My approach involves a multi-step process: 1. Assessment: I immediately stop the felling process and carefully assess the nature and severity of the obstacle. 2. Re-evaluation of felling strategy: Depending on the obstacle, I might need to adjust the felling cut, use wedges to direct the fall, or even abandon the current felling plan and choose a safer approach. 3. Safety Measures: I always prioritize safety, ensuring I have a clear escape route and maintaining a safe distance. If necessary, I would call for assistance or use specialized equipment. For example, if an underground pipe is discovered, I will call the relevant utility company before proceeding. 4. Communication: Clear communication is crucial, especially when working with a team. I would ensure everyone on site is aware of the obstacle and the adjusted plan.

Q 24. Explain your experience working with different types of wood.

My experience encompasses a wide variety of wood types, from softwoods like pine and fir to hardwoods such as oak, maple, and hickory. Each type presents unique challenges and requires a different approach.

- Softwoods are generally easier to cut but can be more prone to binding in the saw chain, requiring more careful technique. Pine, for example, often contains resin which can gum up the chain.

- Hardwoods are denser and more resistant to cutting, demanding more power and a sharper chain. Oak, known for its hardness and density, needs a well-maintained saw and careful cutting technique to avoid dulling the chain or causing kickback.

- Rotting wood presents a completely different challenge. It requires extra caution as the wood is often structurally weak and unpredictable. The chainsaw can easily get caught or the wood can break unexpectedly, leading to dangerous situations.

Understanding the grain pattern and properties of different wood types is critical for efficient and safe cutting. My experience allows me to adapt my technique and chainsaw settings to the specific wood I’m working with.

Q 25. What are the environmental considerations when operating a chainsaw?

Environmental considerations are paramount in chainsaw operation. My work always prioritizes minimizing environmental impact. This involves several key aspects:

- Minimizing soil disturbance: Careful planning of the felling operation reduces soil erosion and protects sensitive vegetation.

- Proper disposal of waste: Following local regulations for disposing of wood waste, avoiding illegal dumping or burning of debris is crucial.

- Protecting water sources: Avoiding operations near water bodies prevents soil erosion and reduces the risk of contaminating water sources with fuel, oil or wood debris.

- Noise pollution: Consideration is given to times of operation, and noise reduction techniques are employed wherever possible.

- Air quality: Chainsaws release exhaust fumes, so ensuring sufficient ventilation and adhering to emission standards are important.

Responsible chainsaw operation is key to preserving the environment and maintaining sustainable forestry practices.

Q 26. Describe your understanding of chainsaw noise and vibration reduction techniques.

Chainsaw noise and vibration are significant occupational hazards. Reducing these impacts is crucial for operator health and safety. Several techniques are implemented to minimize these:

- Using well-maintained equipment: Regularly sharpening the saw chain significantly reduces vibration and improves cutting efficiency. A dull chain requires more force, leading to increased vibration.

- Proper chainsaw selection: Choosing a chainsaw with low-vibration features and an effective anti-vibration system can drastically reduce the impact on the operator.

- Using personal protective equipment (PPE): Wearing anti-vibration gloves and clothing helps to reduce the transmission of vibrations to the body.

- Taking regular breaks: Frequent breaks during prolonged chainsaw operation reduce fatigue and minimize the long-term effects of vibration.

- Using hearing protection: Wearing hearing protection such as earmuffs or earplugs during operation is essential to minimize the risk of noise-induced hearing loss.

Understanding and implementing these techniques is vital for protecting the operator’s health and well-being.

Q 27. How do you ensure the safety of bystanders during chainsaw operation?

Ensuring the safety of bystanders is a top priority. This involves a multifaceted approach:

- Establishing a safety zone: Creating a clearly defined safety zone around the felling area, keeping bystanders a safe distance away (at least twice the height of the tree).

- Warning signs and communication: Using warning signs and verbal communication to inform bystanders of the ongoing operation and potential hazards.

- Designated spotters: Employing spotters to monitor the area and warn against any approaching people or obstructions.

- Controlling the work area: Restricting access to the work area using barriers or other means is essential to prevent unauthorized entry.

- Following safety protocols: Adhering to all relevant safety regulations and company policies, which often include emergency response plans.

By implementing these measures, the risk of injury to bystanders is significantly reduced.

Key Topics to Learn for Chainsaw Operation Interview

- Chainsaw Safety and Regulations: Understanding OSHA regulations, personal protective equipment (PPE) requirements, and safe operating procedures is paramount. This includes pre-operation checks and emergency protocols.

- Chainsaw Maintenance and Repair: Demonstrate knowledge of routine maintenance tasks like chain sharpening, bar lubrication, and identifying signs of wear and tear. Be prepared to discuss troubleshooting common mechanical issues.

- Felling Techniques: Explain different felling techniques, including considerations for tree size, terrain, and environmental factors. Understanding how to assess risk and plan cuts is crucial.

- Limbing and Bucking: Describe safe and efficient methods for limbing and bucking felled trees, emphasizing proper body mechanics and avoiding kickback hazards.

- Tree Identification and Assessment: Show your understanding of identifying different tree species and assessing their condition to determine appropriate felling techniques and potential hazards.

- Emergency Procedures: Discuss your knowledge of emergency response procedures, including first aid for chainsaw injuries and reporting accidents.

- Environmental Considerations: Demonstrate awareness of environmental impact and best practices for minimizing damage during chainsaw operations.

Next Steps

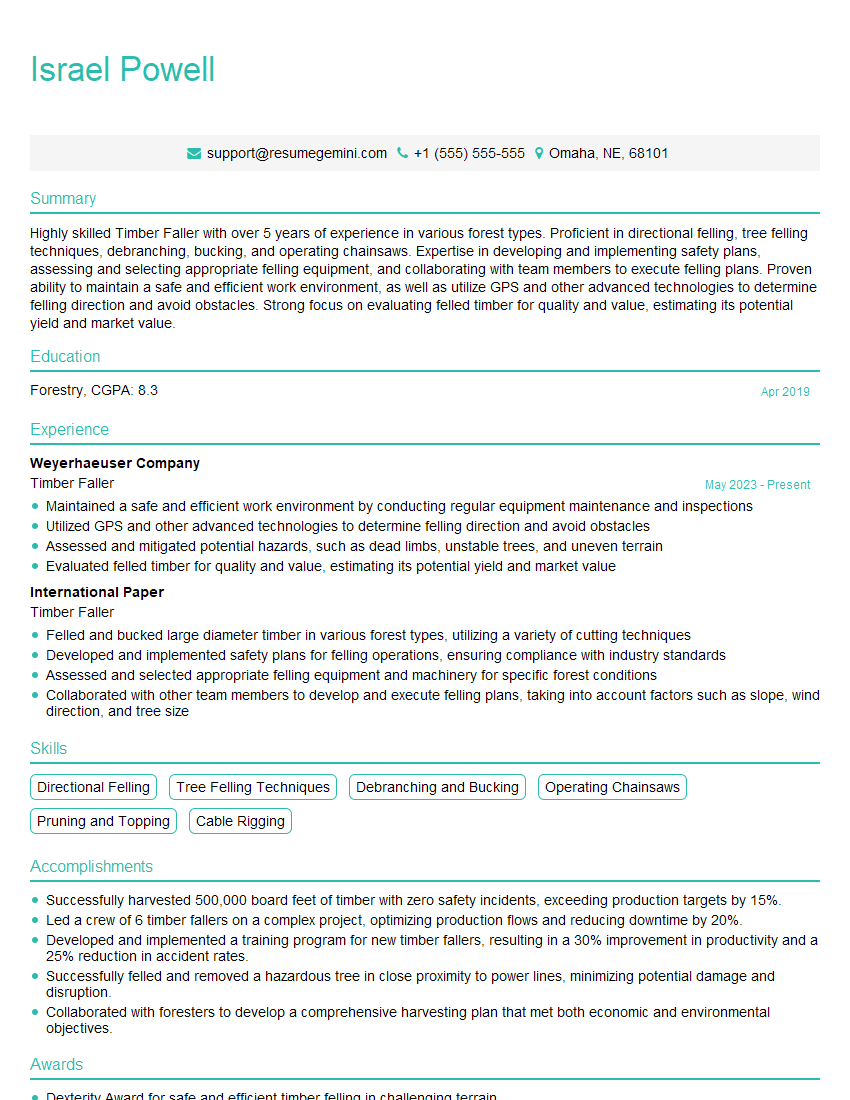

Mastering chainsaw operation opens doors to exciting and rewarding careers in forestry, arboriculture, and land management. A strong understanding of safety, efficiency, and environmental responsibility is highly valued by employers. To significantly enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini can help you build a professional and effective resume that highlights your skills and experience. We provide examples of resumes tailored specifically to the Chainsaw Operation field to guide you in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO