Cracking a skill-specific interview, like one for Spring Tolerance Analysis, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Spring Tolerance Analysis Interview

Q 1. Explain the concept of spring tolerance analysis.

Spring tolerance analysis is a critical engineering process that determines the acceptable range of variations in spring dimensions and material properties to ensure the spring functions correctly within its specified operating parameters. It’s essentially predicting how much the spring’s performance (like force, deflection, or fatigue life) will change given the unavoidable variations introduced during manufacturing. Imagine making hundreds of identical springs – they’ll never be perfectly the same. Tolerance analysis helps us understand if those tiny differences will significantly impact the final product’s functionality.

This analysis is crucial because it prevents costly over-engineering (making springs far more precise than needed) and avoids under-engineering (creating springs that may fail due to excessive variation).

Q 2. What are the different types of spring tolerances?

Spring tolerances encompass various aspects of the spring’s geometry and material characteristics. Key types include:

- Dimensional Tolerances: These define allowable variations in the spring’s free length, wire diameter, coil diameter, number of coils, and other physical dimensions. For example, a spring might have a specified free length of 10mm ± 0.1mm, meaning acceptable lengths range from 9.9mm to 10.1mm.

- Material Tolerances: These specify allowable variations in the material properties of the spring wire, such as tensile strength, yield strength, and modulus of elasticity. Variations in these properties directly affect the spring’s stiffness and fatigue life.

- Set Tolerances: These define the allowable variation in the spring’s final length after it has been compressed and then released. This is especially important for springs that need to return to a specific position.

- Load Tolerances: These specify the allowable variation in the force required to compress the spring to a certain length. Variations in load affect the spring’s ability to perform its intended function.

Each tolerance is crucial and needs to be considered to ensure the spring meets its performance criteria.

Q 3. How does GD&T apply to spring design and tolerance analysis?

Geometric Dimensioning and Tolerancing (GD&T) provides a standardized and unambiguous way to specify tolerances on engineering drawings. It’s essential for spring design because it moves beyond simple plus/minus tolerances to define allowable variations in form, orientation, and location. For springs, GD&T helps ensure:

- Correct coil alignment: Using features like circularity and straightness controls ensures consistent coil geometry, preventing issues like binding or uneven force distribution.

- Precise end conditions: GD&T specifies the acceptable variations in the spring’s end shapes (e.g., ground ends, squared ends), crucial for proper mating with other components.

- Consistent spring length and pitch: Using position tolerances ensures the coils are spaced correctly, avoiding issues related to inconsistent spring rate.

Using GD&T improves communication between designers and manufacturers, reducing ambiguity and improving the overall quality of the springs.

Q 4. Describe the process of performing a tolerance stack-up analysis for a spring assembly.

Performing a tolerance stack-up analysis for a spring assembly involves systematically identifying all sources of variation that affect the final assembly’s performance. This often involves creating a model that combines the tolerances of individual components, accounting for how these variations add up to influence the final result. Here’s a step-by-step process:

- Identify critical dimensions: Determine the key dimensions that affect the spring assembly’s function (e.g., overall compressed length, force at a specific deflection).

- Determine tolerance values for each component: Gather tolerance data for each spring, as well as other components in the assembly.

- Create a tolerance stack-up model: This can be done using various methods, including algebraic addition (worst-case), statistical methods (root-sum-square), or Monte Carlo simulation. The choice depends on the desired level of accuracy and complexity.

- Calculate tolerance limits: Use the chosen method to compute the overall tolerance limits for the critical dimensions. For example, in a worst-case analysis you add the maximum possible deviation of each dimension, while a statistical approach considers the statistical distribution of variations.

- Evaluate results: Assess whether the calculated tolerance range is acceptable, given the design requirements. If the tolerance is too large, redesign or tighter manufacturing tolerances might be necessary.

Example: Consider a spring seated within a housing. The tolerance stack-up will incorporate the tolerances of the spring’s free length, the housing’s internal depth, and potentially the thickness of any shims used to adjust the initial compression. The final compressed length becomes the critical dimension.

Q 5. What software tools are commonly used for spring tolerance analysis?

Several software tools are widely used for spring tolerance analysis. They automate the tolerance stack-up calculations, often incorporating statistical methods for a more accurate assessment. Examples include:

- Specialized Spring Design Software: Many commercial software packages dedicated to spring design include tolerance analysis capabilities.

- Tolerance Analysis Software: Software packages like CETOL and others specifically designed for tolerance analysis can be applied to spring assemblies. They allow for complex modeling and simulation of variation propagation.

- General-Purpose Engineering Simulation Software: Packages like ANSYS or Abaqus can be used for more complex simulations, including finite element analysis that accounts for geometric variation, material property variation and the effects on spring performance.

- Spreadsheet Software: Even spreadsheets like Microsoft Excel or Google Sheets can be employed for simpler tolerance stack-up analyses, particularly using worst-case approaches.

The choice of software depends on the complexity of the spring assembly and the desired level of analysis detail.

Q 6. How do you account for manufacturing variations in spring tolerance analysis?

Accounting for manufacturing variations is the core of spring tolerance analysis. This is done by incorporating the tolerances of all relevant dimensions and material properties into the analysis. The process includes:

- Gathering tolerance data: This involves working with manufacturers to obtain information on the expected variation in spring dimensions and material properties. This might come from process capability studies or historical data.

- Modeling variations: This data is incorporated into the tolerance stack-up model. Different approaches exist, including: Worst-case – assumes maximum variations add up; Statistical – uses standard deviations to account for the statistical distribution of variations; Monte Carlo simulation – runs many simulations with random variations to get a distribution of possible outcomes.

- Sensitivity Analysis: Identifying which manufacturing variations most strongly influence spring performance guides efforts towards process improvement.

For instance, if the wire diameter variation significantly affects the spring rate, addressing the manufacturing process to improve the wire diameter control is prioritized.

Q 7. Explain the difference between worst-case and statistical tolerance analysis.

Worst-case and statistical tolerance analyses differ significantly in their approach and conservatism:

- Worst-case analysis: This method assumes all dimensional and material variations will occur in the worst possible combination, resulting in the most extreme deviation from the nominal performance. This approach guarantees that the spring will perform at a minimum acceptable level but can be overly conservative, potentially leading to unnecessary tight tolerances and higher costs.

- Statistical tolerance analysis: This method uses statistical distributions to model variations in individual dimensions and material properties. This assumes that variations are randomly distributed. It uses statistical measures (like standard deviations) to calculate the probability of exceeding acceptable limits. This approach is often more realistic and less conservative than worst-case analysis, leading to potentially more cost-effective designs.

Choosing between these methods depends on the application’s criticality. For safety-critical applications, worst-case analysis is often preferred. For less critical applications where cost is a major factor, a statistical approach is generally suitable.

Q 8. What are the common sources of error in spring tolerance analysis?

Common sources of error in spring tolerance analysis stem from uncertainties in various aspects of the spring’s design and manufacturing process. These can be broadly categorized as:

- Dimensional Variations: Inaccuracies in wire diameter, free length, coil diameter, and number of coils during manufacturing introduce significant error. Even small deviations can impact spring performance.

- Material Property Variations: The material’s properties, particularly Young’s modulus (E) and shear modulus (G), are not perfectly constant. Variations in these values, due to material inconsistencies or temperature fluctuations, directly affect the spring rate and stiffness.

- Manufacturing Tolerances: Processes like coiling, heat treatment, and finishing operations introduce variations in the final spring dimensions and properties. These tolerances, often specified by the manufacturer, contribute to overall uncertainty.

- Model Simplifications: The analytical models used often make simplifying assumptions (e.g., neglecting end effects or assuming perfectly elastic material behavior). These simplifications can introduce discrepancies between predicted and actual performance.

- Measurement Errors: Inaccuracies in measuring the spring’s dimensions and properties add to the overall uncertainty. This is especially crucial for smaller springs.

Consider a compression spring: a slight variation in wire diameter will significantly affect its stiffness, and a slight variation in free length impacts its initial preload. Addressing these error sources requires careful design, rigorous manufacturing controls, and thorough testing.

Q 9. How do you validate the results of a spring tolerance analysis?

Validating the results of a spring tolerance analysis typically involves a multi-pronged approach:

- Comparison with Experimental Data: The most reliable validation involves comparing the predicted spring characteristics (e.g., spring rate, force-deflection curve) with experimental measurements from a sample of manufactured springs. Statistical analysis helps assess the agreement between predictions and measurements.

- Sensitivity Analysis: A sensitivity analysis identifies which parameters most significantly impact the spring performance. This helps focus efforts on controlling the most critical dimensions and material properties.

- Monte Carlo Simulation Verification: If Monte Carlo simulation is used, the results can be validated by checking for convergence and ensuring the statistical assumptions are appropriate. The distribution of the output parameters should be reasonable given the input distributions.

- Tolerance Stack-up Analysis: Verify that the tolerances assigned to each dimension contribute to an acceptable overall tolerance on the final spring characteristic. This ensures that individual variations don’t accumulate to unacceptable levels.

- Design of Experiments (DOE): A well-planned DOE can systematically explore the design space and evaluate the effects of different tolerance combinations on spring performance. This is particularly useful for complex spring designs.

For instance, if the predicted spring rate varies significantly from the experimental average, it indicates a potential problem with the analysis model or the manufacturing process. Addressing such discrepancies ensures the reliability of the analysis.

Q 10. Explain the significance of spring rate variation in tolerance analysis.

Spring rate variation is a critical factor in tolerance analysis, as it directly affects the spring’s load-deflection characteristics. The spring rate (k) is the change in force divided by the change in deflection. Variations in k result from tolerances in the spring’s dimensions and material properties. A large variation in k can lead to unpredictable performance, such as:

- Inconsistent Load Support: A spring with a highly variable k might not consistently support the designed load, potentially causing system malfunction or failure.

- Increased Wear and Fatigue: The inconsistent load distribution caused by k variations can accelerate wear and fatigue in the spring and associated components.

- Reduced Operational Life: A spring with a large k variation is more likely to exceed its design limits, shortening its operational life.

- System Instability: In dynamic systems, large k variations might lead to instability or undesirable oscillations.

Imagine a car suspension system: a highly variable spring rate will make the ride bumpy and unpredictable. Therefore, minimizing spring rate variation is crucial for reliable and safe system operation.

Q 11. How do you handle uncertainties in material properties during spring tolerance analysis?

Uncertainties in material properties are handled in spring tolerance analysis using statistical methods. These methods allow for the incorporation of variations in material properties (like Young’s modulus and shear modulus) during the analysis. Common approaches include:

- Statistical Distributions: Instead of using single values for material properties, statistical distributions (e.g., normal, uniform) are used to represent the variability in these properties. The distribution parameters (mean and standard deviation) are obtained from material testing or supplier specifications.

- Monte Carlo Simulation: This technique repeatedly samples material properties from their respective distributions and performs spring calculations for each sample. This generates a distribution of spring performance characteristics (e.g., spring rate, stress), reflecting the uncertainty in material properties.

- Worst-Case Scenario Analysis: A conservative approach involves using the worst-case values for material properties within the specified tolerances to determine the potential range of spring performance. This guarantees acceptable performance even under the most unfavorable material conditions.

For example, if the Young’s modulus of the spring material has a normal distribution with a mean of 200 GPa and a standard deviation of 5 GPa, Monte Carlo simulation will repeatedly sample values from this distribution to determine the effect on spring rate.

Q 12. What is the role of Monte Carlo simulation in spring tolerance analysis?

Monte Carlo simulation plays a crucial role in spring tolerance analysis by providing a probabilistic assessment of spring performance. Unlike deterministic methods that use single values for design parameters, Monte Carlo simulation accounts for the inherent variability in these parameters. It works by:

- Generating Random Samples: The simulation randomly samples values for each design parameter (e.g., wire diameter, material properties) from its probability distribution.

- Performing Spring Calculations: For each set of randomly sampled parameters, the spring’s characteristics are calculated using appropriate analytical models or finite element analysis.

- Creating Output Distributions: The simulation generates distributions of spring performance characteristics, such as spring rate, stress, and deflection. These distributions show the range of possible outcomes and their probabilities.

- Quantifying Uncertainty: By analyzing the output distributions, the simulation quantifies the uncertainty in the spring’s performance, providing valuable insights for design optimization and risk assessment.

This probabilistic approach is especially valuable when dealing with multiple sources of uncertainty and complex spring designs, enabling a more realistic and thorough assessment of potential performance variations.

Q 13. How do you determine the acceptable tolerance limits for a spring?

Determining acceptable tolerance limits for a spring involves a balance between manufacturing feasibility and performance requirements. The process generally involves:

- Defining Performance Specifications: First, establish clear specifications for the spring’s performance characteristics, such as the allowable range of spring rate, maximum stress, and deflection. These specifications are determined by the application’s functional requirements.

- Tolerance Allocation: Based on the performance specifications and sensitivity analysis, allocate appropriate tolerances to each design parameter. Parameters that significantly influence performance should have tighter tolerances.

- Manufacturing Capabilities: The chosen tolerances must be realistic and achievable with the available manufacturing processes. Unrealistic tolerances can increase manufacturing costs and lead to rejection rates.

- Statistical Analysis: Statistical methods, such as Monte Carlo simulation or worst-case analysis, can be employed to evaluate the impact of the chosen tolerances on spring performance, ensuring that the probability of exceeding the performance specifications is acceptably low.

- Cost-Benefit Analysis: Tightening tolerances generally increases manufacturing costs. A cost-benefit analysis should be conducted to find the optimal balance between acceptable performance and manufacturing costs.

For example, a high-precision application might demand tight tolerances, even at a higher cost, while a less critical application might tolerate looser tolerances.

Q 14. Describe your experience with different types of springs (e.g., compression, extension, torsion).

My experience encompasses various spring types, including compression, extension, and torsion springs. Each type presents unique design and analysis challenges:

- Compression Springs: I’ve extensively worked with compression springs, analyzing their spring rate, buckling resistance, and fatigue life. The primary focus is on ensuring sufficient stiffness and preventing premature failure under compressive loads. I’ve dealt with various end configurations (e.g., squared and ground ends) and their impact on spring characteristics.

- Extension Springs: Extension spring analysis focuses on the spring rate, hook strength, and fatigue life under tensile loads. The design considerations often include hook geometry and the prevention of hook failure. I’ve worked on various applications, including spring-loaded mechanisms and retaining devices.

- Torsion Springs: Torsion spring analysis focuses on the spring rate, stress concentration at the coil ends, and fatigue life under torsional loads. The design considerations often include the wire diameter, coil diameter, and number of coils. I’ve addressed applications in various industries, including automotive and consumer electronics.

In each case, I’ve applied appropriate analytical models, finite element analysis, and tolerance analysis techniques to ensure optimal design and reliable performance. Understanding material behavior and manufacturing limitations is crucial for successful spring design across all these types.

Q 15. Explain how you would approach a spring design problem with tight tolerance requirements.

Designing a spring with tight tolerance requirements necessitates a meticulous approach combining robust design principles, advanced analysis techniques, and close collaboration with manufacturing. My strategy would begin with a thorough understanding of the application’s needs, specifically the critical performance parameters (e.g., spring rate, deflection, fatigue life) and their allowable variations.

Next, I’d utilize statistical tolerance analysis methods, such as Monte Carlo simulation, to evaluate the impact of individual component tolerances on the overall spring performance. This involves defining tolerance ranges for material properties (Young’s modulus, yield strength), dimensions (wire diameter, coil diameter, number of coils), and manufacturing processes. The Monte Carlo simulation would then run numerous iterations, each with slightly different parameter values drawn randomly from their respective tolerance distributions. This allows for a probabilistic assessment of the likelihood of the spring meeting its performance specifications.

Furthermore, I’d explore design modifications to minimize sensitivity to variations. For example, selecting a material with a lower variation in Young’s modulus, utilizing a manufacturing process with tighter controls, or optimizing the spring geometry to reduce its sensitivity to dimensional tolerances. Finally, I’d work closely with the manufacturing team to ensure process capability is aligned with the required tolerances, potentially incorporating statistical process control (SPC) to monitor and control the manufacturing process.

Career Expert Tips:

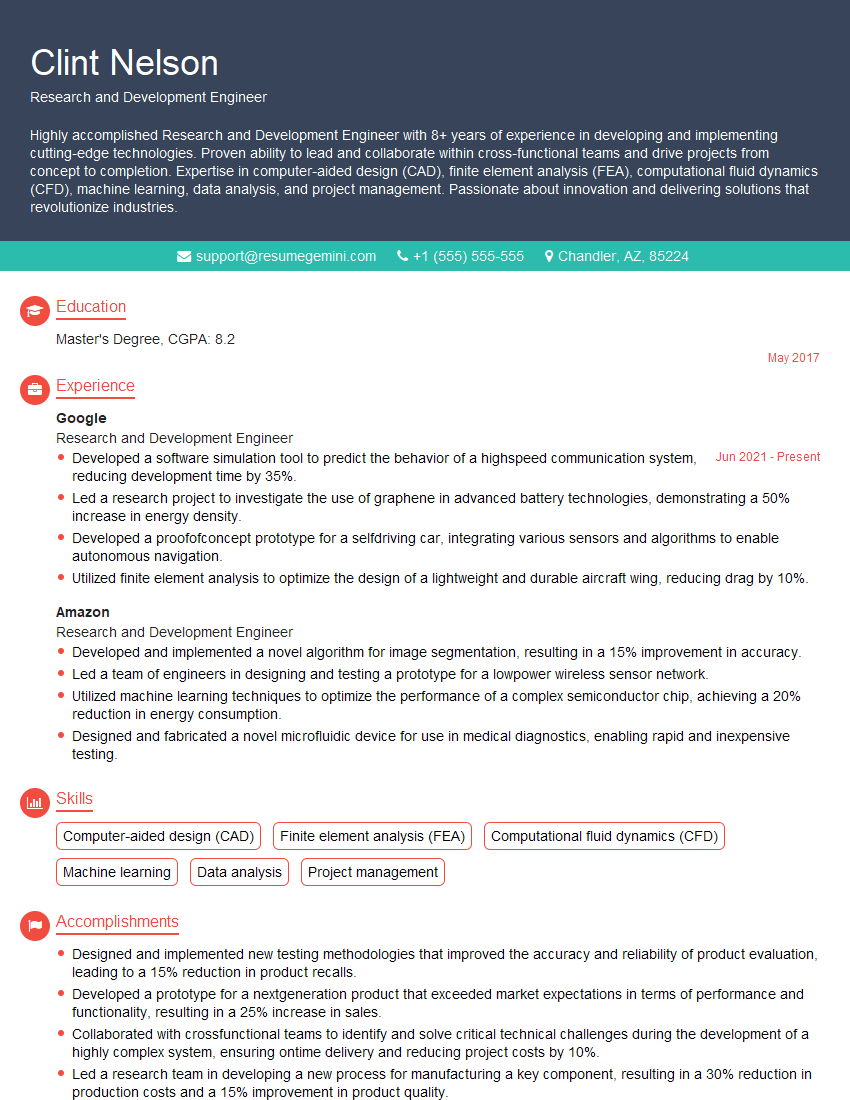

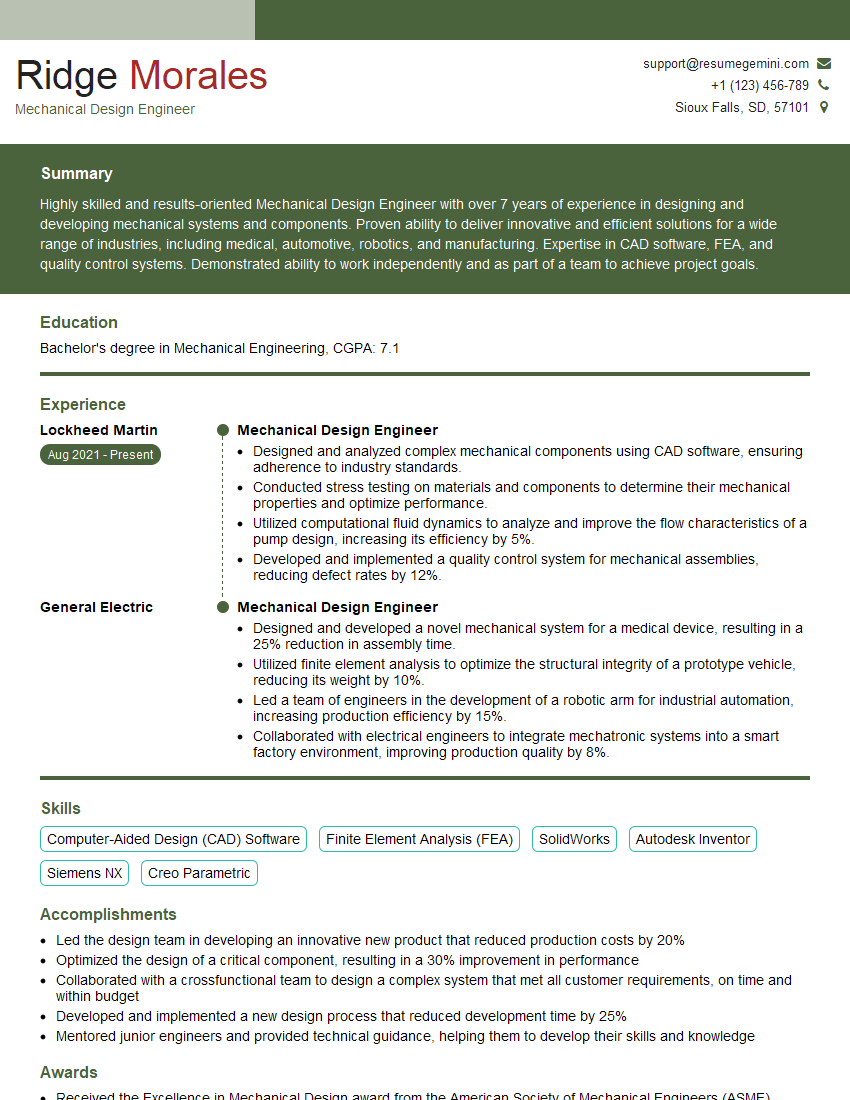

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you balance cost and performance considerations in spring tolerance analysis?

Balancing cost and performance in spring tolerance analysis is a critical aspect of design optimization. The ideal solution lies in finding the sweet spot where performance requirements are met while minimizing unnecessary precision and associated costs. This involves a multi-faceted approach.

Firstly, a thorough cost analysis is required to understand the cost implications of different tolerance levels for each spring parameter. This includes evaluating the cost of raw materials, manufacturing processes (e.g., winding, heat treatment), inspection and testing, and potential scrap due to out-of-tolerance parts. Next, sensitivity analysis helps determine which parameters most significantly impact spring performance. Resources can then be focused on tightening tolerances for critical parameters while allowing wider tolerances for less sensitive ones.

For example, if a slight variation in coil diameter has minimal impact on the spring rate but a variation in wire diameter significantly affects fatigue life, prioritizing tighter tolerances on wire diameter is crucial. Finally, value engineering techniques should be employed to explore alternative materials, manufacturing processes, or designs that achieve the desired performance at a lower cost without compromising reliability. This iterative process of cost-benefit analysis and design optimization ensures a cost-effective solution that meets performance requirements.

Q 17. What are the limitations of different tolerance analysis methods?

Various methods exist for tolerance analysis, each with its own limitations. These limitations often stem from simplifying assumptions or computational constraints.

- Worst-case analysis: This method assumes all tolerances stack up in the worst possible combination. While simple to implement, it is overly conservative and can lead to unnecessarily tight tolerances and increased costs. It doesn’t account for the statistical distribution of tolerances.

- Root-sum-square (RSS) method: This method assumes tolerances are statistically independent and normally distributed. This is a more realistic approach than worst-case analysis, but it can be inaccurate if the assumptions about independence and distribution are not met.

- Monte Carlo simulation: This is a powerful method that can handle complex relationships and non-normal distributions. However, it requires significant computational resources, and the results depend on the number of simulations run. The accuracy is also affected by the quality of the input probability distributions.

Choosing the appropriate method depends on the complexity of the spring design, the available computational resources, and the acceptable level of conservatism. A hybrid approach, combining different methods, might be necessary in certain scenarios.

Q 18. Describe your experience with tolerance analysis software (e.g., ANSYS, Abaqus).

I have extensive experience using ANSYS and Abaqus for spring tolerance analysis. In ANSYS, I leverage its robust finite element analysis (FEA) capabilities to model the spring’s geometry and material properties. Then, I use DesignXplorer or similar tools within ANSYS to perform Design of Experiments (DOE) and Monte Carlo simulations to evaluate the effects of tolerance variations on spring performance metrics, such as stress, deflection, and natural frequency. I typically define design variables (toleranced parameters) and response variables (performance parameters), and then ANSYS runs the simulations and generates statistical outputs.

Similarly, in Abaqus, I utilize its FEA capabilities and scripting features to conduct detailed spring models, incorporating stochastic material properties and geometric tolerances. I frequently employ Python scripting for automating the process of generating multiple model variations for the Monte Carlo analysis and post-processing the large datasets. Both ANSYS and Abaqus provide powerful tools for visualizing the results and assessing the robustness of the spring design against manufacturing variations. My expertise encompasses not only running simulations but also validating the models using experimental data and interpreting the results to guide design decisions.

Q 19. How do you communicate the results of a spring tolerance analysis to a non-technical audience?

Communicating complex tolerance analysis results to a non-technical audience requires clear and concise language, avoiding technical jargon. I would typically start by presenting the overall findings in a simple, visual manner. For instance, using a bar chart to show the probability of the spring meeting its key performance requirements under various tolerance scenarios or a histogram illustrating the distribution of a critical performance parameter such as spring rate.

I might explain the concept of tolerance using an analogy, such as comparing the spring’s performance to a dartboard: tight tolerances would mean the darts consistently hit the bullseye, while loose tolerances increase the risk of missing the target. Focusing on the implications rather than the methods is crucial. Instead of detailing the Monte Carlo simulation, I’d emphasize the conclusions drawn, for example, stating that there’s a 95% probability the spring will meet its required stiffness within the specified manufacturing tolerances. Finally, I’d answer any questions in straightforward terms, ensuring everyone understands the risks and the potential impact on product performance and cost.

Q 20. How do you ensure the robustness of a spring design against manufacturing variations?

Ensuring robustness against manufacturing variations involves a multi-pronged strategy. It begins with designing the spring for inherent robustness, minimizing sensitivity to tolerances. This can involve using design optimization techniques to identify a design that is less sensitive to variations in key dimensions or material properties. For instance, a properly designed spring might be less sensitive to changes in wire diameter if the coil diameter is optimized.

Secondly, selecting materials with consistent properties and lower variability is critical. Choosing materials with tight tolerance specifications on key parameters, such as Young’s modulus and yield strength, reduces the impact of manufacturing variability on the spring’s performance. Furthermore, robust manufacturing processes are paramount. This involves implementing rigorous quality control measures during manufacturing to minimize variations in dimensions and material properties. Statistical Process Control (SPC) helps monitor and control the process and identify potential sources of variability early on.

Finally, incorporating design margins into the specifications allows for some degree of variation without compromising performance. This approach adds a safety factor, accounting for unavoidable uncertainties in the manufacturing process and material properties. By combining these approaches, you can design a spring with a much higher probability of meeting its requirements, even in the face of unavoidable manufacturing variations.

Q 21. What are the key performance indicators (KPIs) for evaluating spring design with respect to tolerance?

Key Performance Indicators (KPIs) for evaluating spring design with respect to tolerance should reflect both the likelihood of meeting specifications and the potential consequences of deviations. These KPIs should be chosen based on the application’s critical requirements.

- Probability of meeting specifications: This quantifies the likelihood that the spring’s performance will fall within acceptable limits given the defined tolerances. This is often obtained from statistical tolerance analysis, such as Monte Carlo simulations.

- Yield strength margin: This indicates how far the maximum stress experienced by the spring is from the material’s yield strength. A larger margin indicates a more robust design that is less sensitive to tolerance variations. A low margin means the spring is more prone to failure.

- Spring rate variation: This measures the range of spring rates observed across different simulated variations, reflecting the impact of tolerances on the stiffness. A small range is desirable for consistent performance.

- Fatigue life variability: This shows how much the fatigue life of the spring varies depending on the tolerances. A small variation implies the spring is robust to variations.

- Cost of quality: This encompasses the cost of scrap, rework, and potential warranty claims due to tolerances resulting in substandard springs.

The specific KPIs employed should reflect the critical performance aspects and cost implications relevant to the given application.

Q 22. Explain your experience using Design of Experiments (DOE) in tolerance analysis.

Design of Experiments (DOE) is crucial for efficient spring tolerance analysis. Instead of individually testing every possible combination of tolerances, DOE uses a statistically designed set of experiments to identify the most influential parameters and their interactions. This significantly reduces the number of tests needed while providing a comprehensive understanding of the system’s response to variations.

In my experience, I’ve extensively used both fractional factorial designs and Taguchi methods. For instance, when analyzing the tolerance stackup in a complex spring assembly, a fractional factorial design helped me pinpoint that the wire diameter and the number of coils were the most sensitive factors affecting the spring rate. This allowed me to focus optimization efforts on these critical parameters, saving both time and resources.

Taguchi methods, with their focus on orthogonal arrays, are particularly effective in situations with many factors and limited resources. I’ve successfully applied this technique to identify robust spring designs that are less sensitive to manufacturing variations.

Q 23. How do you handle situations where tolerances are conflicting or unachievable?

Conflicting or unachievable tolerances are a common challenge in engineering. When faced with such a situation, my approach involves a multi-faceted strategy.

- Tolerance Negotiation: The first step involves revisiting the design specifications with the stakeholders. Sometimes, slightly relaxing less critical tolerances can significantly improve feasibility without dramatically affecting the overall performance. This requires clear communication and a shared understanding of the design requirements and their priorities.

- Design Modification: If tolerance negotiation isn’t enough, I explore design modifications. This might involve simplifying the assembly, using alternative materials with tighter tolerances, or changing the manufacturing process to improve precision.

- Statistical Tolerance Analysis: Employing Monte Carlo simulations allows me to evaluate the probability of exceeding critical limits even with tighter tolerances. This helps to assess the risk and make data-driven decisions about the trade-off between cost and performance.

- Process Capability Analysis: Analyzing the capability of the manufacturing processes is critical. If the process isn’t capable of meeting the required tolerances, improvements in the manufacturing process are necessary before even considering tighter tolerances in the design.

For example, in one project, we initially had conflicting tolerances on the spring length and free length. By using Monte Carlo simulation, we showed that even with slightly relaxed tolerances, the probability of failure was still acceptable, leading to a more realistic and achievable design.

Q 24. What are some common mistakes to avoid during spring tolerance analysis?

Several common mistakes can lead to inaccurate or misleading results in spring tolerance analysis. Avoiding these pitfalls is crucial for successful design.

- Ignoring Interactions: Assuming that tolerances add linearly ignores the potential interaction effects between different parameters. DOE methods are essential to uncover and quantify these interactions.

- Oversimplification: Using only worst-case scenarios can lead to overly conservative designs and potentially increased costs. Statistical methods provide a more realistic assessment of risk.

- Neglecting Process Capability: Ignoring the variability of the manufacturing process can result in designs that are impossible to manufacture consistently.

- Inappropriate Tolerance Allocation: Assigning tolerances arbitrarily without considering sensitivity analysis can lead to inefficient or ineffective designs.

- Lack of Verification: Failing to validate the tolerance analysis with physical prototypes or simulations can lead to unexpected issues during manufacturing or operation.

For instance, neglecting interaction effects could lead to a design that seems feasible based on individual tolerances, but fails in practice due to the cumulative effects of variations.

Q 25. Explain your understanding of statistical process control (SPC) in relation to spring manufacturing tolerances.

Statistical Process Control (SPC) is indispensable for ensuring that the spring manufacturing process remains stable and capable of meeting the required tolerances. SPC involves monitoring key process parameters (e.g., wire diameter, coil pitch, free length) using control charts. This allows for early detection of any deviations from the target values. By implementing SPC, we can prevent the production of non-conforming springs and improve overall quality.

For example, using control charts for wire diameter helps to identify any shifts or trends in the manufacturing process before they lead to a significant number of rejected springs. This proactive approach saves resources and ensures consistent product quality. Furthermore, process capability indices (Cp and Cpk) derived from SPC data quantify the ability of the process to meet the specified tolerances. A low Cpk indicates that process improvements are needed before we can confidently meet the desired tolerances.

Q 26. Describe a time when you had to troubleshoot a problem related to spring tolerance issues.

In a previous project involving a miniature compression spring for a medical device, we experienced unexpectedly high failure rates during assembly. The initial tolerance analysis hadn’t accounted for the variability in the surface finish of the spring and the mating component.

My troubleshooting process involved:

- Detailed Failure Analysis: We examined the failed assemblies to pinpoint the root cause, discovering scratches and burrs on the spring interfering with smooth assembly.

- Process Evaluation: We audited the spring manufacturing and component finishing processes to identify areas for improvement.

- Tolerance Refinement: We revised the tolerance analysis to include the impact of surface roughness on the assembly process. This involved using a more sophisticated model that considered the geometrical variations resulting from the surface finish.

- Implementation of Improvements: We implemented improvements in the finishing process to reduce surface roughness, ultimately resolving the assembly issues and improving the overall yield.

This experience highlighted the importance of considering all potential sources of variation, even seemingly minor ones, during tolerance analysis.

Q 27. How do you incorporate spring tolerance analysis into the overall design process?

Spring tolerance analysis is not an isolated activity; it’s an integral part of the overall design process. I typically incorporate it at multiple stages:

- Conceptual Design: Preliminary tolerance analysis helps in selecting appropriate materials and manufacturing processes. A quick worst-case analysis or a simple Monte Carlo simulation at this stage informs early design decisions.

- Detailed Design: A comprehensive tolerance analysis, potentially using DOE, is performed to optimize the design for manufacturability and to assess the impact of tolerances on the spring’s performance parameters.

- Design Verification: The results of the tolerance analysis are validated through prototyping and testing to ensure the design meets the requirements under real-world conditions.

- Manufacturing Planning: The tolerances are communicated to the manufacturing team, and process capability studies are conducted to ensure the process can meet the specifications.

By integrating tolerance analysis throughout the design lifecycle, we can ensure the design is both functional and manufacturable, minimizing costs and maximizing product quality.

Key Topics to Learn for Spring Tolerance Analysis Interview

- Fundamental Concepts: Understanding the principles of spring design, stress-strain relationships, and material properties relevant to tolerance analysis.

- Static and Dynamic Analysis: Differentiate between static and dynamic load conditions and their impact on spring performance and tolerance calculations.

- Tolerance Stack-up Analysis: Mastering methods for analyzing the cumulative effect of individual component tolerances on the overall spring assembly.

- Statistical Methods: Applying statistical distributions (e.g., normal, uniform) to model tolerance variations and predict spring performance within specified limits.

- Software Tools: Familiarity with common engineering software packages used for spring design and tolerance analysis (mentioning specific software is optional, keep it general).

- Practical Applications: Understanding how spring tolerance analysis is applied in various engineering domains (e.g., automotive, aerospace, medical devices).

- Failure Modes and Effects Analysis (FMEA): Applying FMEA to identify potential failure modes related to spring tolerances and mitigate risks.

- Design Optimization: Exploring techniques for optimizing spring designs to minimize tolerance-related issues and improve performance.

- Problem-Solving Strategies: Develop your ability to approach and solve real-world problems involving spring tolerance analysis systematically and efficiently.

- Communication of Results: Clearly and concisely communicate technical findings related to spring tolerance analysis to both technical and non-technical audiences.

Next Steps

Mastering Spring Tolerance Analysis significantly enhances your value to any engineering team, opening doors to challenging and rewarding career opportunities. A strong understanding of this critical area will set you apart from other candidates. To maximize your job prospects, focus on creating an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Spring Tolerance Analysis to guide you through the process, ensuring your qualifications shine through.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO