Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Wood Products Manufacturing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Wood Products Manufacturing Interview

Q 1. Describe your experience with different wood types and their properties.

My experience encompasses a wide range of wood types, each with unique properties influencing their suitability for specific applications. For instance, hardwoods like oak and maple are known for their strength, durability, and beautiful grain patterns, making them ideal for furniture and flooring. They’re also relatively dense, requiring more power for machining. Softwoods such as pine and fir are lighter, easier to work with, and more affordable, frequently used in construction and less demanding projects. However, they’re less durable than hardwoods. Then you have exotic woods like mahogany and cherry, valued for their rich color and luxurious feel, often used in high-end furniture and veneers. Understanding these differences – density, hardness, grain pattern, workability, and durability – is crucial for selecting the right wood for a given project and optimizing the manufacturing process.

I’ve worked extensively with these and other species, including walnut, birch, and various types of cedar, constantly refining my understanding of their unique characteristics and how best to utilize them. For example, I once had to choose between oak and maple for a high-traffic restaurant table. Considering the durability needed and the aesthetic preference of the client, we opted for the denser, harder oak.

Q 2. Explain your understanding of wood drying processes and their impact on product quality.

Wood drying is a critical step in wood product manufacturing, directly impacting the quality, stability, and longevity of the final product. Improper drying can lead to warping, cracking, and checking, rendering the wood unusable or significantly reducing its value. There are two primary methods: air drying and kiln drying. Air drying is a slower, more natural process where wood is stacked and allowed to dry gradually over months or even years, minimizing internal stress. Kiln drying is a faster, more controlled method using specialized equipment to regulate temperature and humidity, speeding up the drying process significantly.

The choice of method depends on factors like wood species, desired final moisture content, and production timeline. Kiln drying allows for quicker turnaround times but requires careful monitoring to prevent defects. Air drying offers superior quality in some cases but can be far slower. For example, high-value furniture often benefits from the more gradual air drying method, while mass-produced items might utilize kiln drying for efficiency. Understanding the moisture content of wood at each stage is paramount; this is usually measured using a moisture meter. I regularly monitor and adjust drying parameters to minimize defects and ensure the optimal final moisture content for different applications.

Q 3. What are the common defects found in wood and how do you address them?

Wood is a natural material, and defects are unavoidable. Common defects include knots (branches embedded in the wood), checks (cracks that run across the grain), shakes (separation of the wood along the grain), and splits (longitudinal cracks). These defects can impact the structural integrity and aesthetic appeal of the final product.

How we address them depends on the severity and location of the defect and the intended use of the wood. Minor defects might be acceptable and simply incorporated into the design. For example, a small knot in a rustic-style furniture piece can add character. More significant defects may require cutting the wood around the damaged area, reducing material wastage. In some cases, advanced techniques like wood filling or patching can be employed to restore structural integrity and improve appearance. Quality inspection at every stage is essential to identify and manage these defects effectively. We use a combination of visual inspection and advanced tools like moisture meters and stress sensors to check for hidden damage.

Q 4. How familiar are you with different woodworking machinery (e.g., planers, jointers, lathes)?

My experience with woodworking machinery is extensive. I’m proficient in operating and maintaining a wide range of equipment, including planers for creating smooth, flat surfaces; jointers for creating perfectly straight edges; and lathes for shaping round pieces like table legs or chair spindles. I understand the safety protocols associated with each machine and regularly perform preventative maintenance to ensure optimal performance and minimize the risk of accidents. Beyond these, I’m also skilled in using various saws (circular, band, and table saws), routers, shapers, and sanding equipment.

I’m not just mechanically proficient; I understand the principles of operation for each piece of machinery. This allows me to not just use them efficiently, but also trouble-shoot issues and make appropriate adjustments to improve quality and minimize material waste. For instance, adjusting the feed rate on a planer affects the smoothness of the surface finish, and a well-adjusted jointer minimizes tearout.

Q 5. Describe your experience with CNC machining in wood.

I have significant experience with CNC machining in wood. This technology allows for precise, automated cutting and shaping of wood components, enhancing efficiency and precision beyond what’s achievable manually. I’m familiar with various CAM software packages and proficient in programming CNC routers and other CNC machines for various operations, including cutting, carving, and engraving. I can design, program, and operate CNC machines to produce complex shapes and designs with high accuracy and repeatability.

My expertise extends to selecting appropriate tooling, optimizing cutting parameters to avoid material damage, and troubleshooting machine issues. For example, I’ve used CNC routers to create intricate inlays for furniture and to produce high-volume runs of identical components with minimal variation. This reduces labor costs and ensures consistency in product quality compared to manual methods.

Q 6. Explain your understanding of wood finishing techniques (e.g., staining, painting, varnishing).

Wood finishing is the final stage in wood product manufacturing, significantly impacting the aesthetics and durability of the product. My experience encompasses various techniques, including staining to enhance the natural wood color or create custom tones; painting to add a layer of protection and color; and varnishing or lacquering to provide a protective finish and enhance shine and durability.

I understand the importance of proper surface preparation before applying any finish, such as sanding to achieve the desired smoothness. I also understand the different properties of various finishes and how to select the appropriate one for each application. For instance, a durable polyurethane varnish is suitable for high-traffic areas, while a more delicate oil-based finish might be preferred for fine furniture where the natural wood grain is to be highlighted. I am familiar with both traditional hand-application techniques and spray systems for efficient and uniform finishes.

Q 7. What quality control measures do you employ in wood product manufacturing?

Quality control is integrated throughout the entire wood product manufacturing process, starting from raw material selection and continuing through each stage of production. We begin with thorough inspection of incoming lumber for defects, ensuring that only high-quality wood is used. Throughout the manufacturing process, regular checks are performed at various key stages to identify and address any potential issues. This includes visual inspections, dimensional checks, and moisture content measurements.

We utilize statistical process control (SPC) methods to monitor key parameters and identify trends. This allows us to proactively address potential problems and maintain consistent product quality. Our finished products undergo a final inspection to ensure they meet our stringent quality standards before they are shipped to customers. We also regularly calibrate our equipment and maintain detailed records to ensure traceability and accountability. This rigorous approach has helped us consistently deliver high-quality products and minimize defects, building strong customer relationships based on trust and reliability.

Q 8. How do you ensure the safety of workers and equipment in a woodworking environment?

Ensuring worker and equipment safety in woodworking is paramount. It’s a multi-layered approach focusing on prevention, protection, and response. Think of it like building a strong safety net – multiple layers working together to catch any potential falls.

Personal Protective Equipment (PPE): This is the first line of defense. Every worker needs appropriate PPE based on their task, including safety glasses, hearing protection, dust masks (especially respirators for fine dust), cut-resistant gloves, and appropriate footwear. Regular inspections and training on proper use are crucial.

Machine Guarding: All machinery, from table saws to planers, must have properly functioning guards in place. These guards prevent accidental contact with moving parts. Regular maintenance and inspections are vital to ensure their effectiveness. I’ve personally overseen the implementation of light curtains on several band saws, dramatically reducing the risk of hand injuries.

Safe Work Practices: Training is key. Workers need comprehensive training on safe operating procedures for each machine, proper material handling techniques, emergency procedures, and the importance of reporting near misses. We use a combination of classroom training and hands-on demonstrations, followed by regular refresher courses.

Shop Organization and Housekeeping: A clean, organized shop reduces trip hazards and the risk of accidents. Proper storage of materials, tools, and waste is essential. We implement a 5S system (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a safe and efficient workspace.

Emergency Response Plan: Having a clear and well-rehearsed emergency plan is vital. This includes designated emergency exits, clearly marked first-aid stations, and procedures for handling various emergencies like fires, injuries, or equipment malfunctions. Regular drills help ensure everyone knows their role.

Q 9. What are your strategies for managing inventory and minimizing waste in wood product manufacturing?

Inventory and waste management are critical for profitability and sustainability in woodworking. It’s all about optimizing material flow and minimizing unnecessary consumption.

Demand Forecasting: Accurate forecasting based on sales data and market trends allows us to order the right amount of materials, minimizing storage costs and preventing stockouts. We utilize sophisticated software to analyze historical data and project future demand.

Just-in-Time (JIT) Inventory: This system minimizes storage space and reduces the risk of material spoilage by ordering materials only when needed. Careful coordination with suppliers is crucial for JIT to work effectively. In one project, implementing JIT saved us 15% on storage costs.

Lean Manufacturing Principles: By identifying and eliminating waste (muda) in all aspects of production – excess inventory, overproduction, waiting, transportation, over-processing, unnecessary motion, and defects – we optimize efficiency. Value stream mapping is a valuable tool for visualizing and improving the flow of materials.

Waste Reduction Strategies: This includes optimizing cutting patterns to minimize offcuts, using scrap wood for smaller projects, and implementing efficient recycling programs for sawdust and other waste materials. We’ve partnered with a local biomass plant to utilize our sawdust as fuel.

Inventory Management Software: Using specialized software provides real-time tracking of inventory levels, automating reordering processes, and providing accurate data for forecasting and analysis.

Q 10. Describe your experience with production scheduling and planning.

Production scheduling and planning involve creating a detailed roadmap for manufacturing processes to ensure timely completion of projects while optimizing resource utilization. It’s like orchestrating a symphony – each instrument (machine, worker) plays its part at the right time to create a beautiful finished product.

Master Production Schedule (MPS): This high-level plan outlines the overall production schedule, considering customer orders, available capacity, and material availability. We use software to generate and update the MPS regularly.

Capacity Planning: This involves evaluating the available resources – machines, personnel, and materials – to ensure sufficient capacity to meet the production schedule. Bottlenecks are identified and addressed proactively.

Material Requirements Planning (MRP): This system ensures that the necessary materials are available at the right time. It calculates the quantity and timing of material orders, considering lead times and inventory levels.

Shop Floor Control: Real-time monitoring of the production process allows for timely identification and resolution of any issues that may arise. This may involve adjusting the schedule or allocating resources to address bottlenecks.

Gantt Charts and other Visual Tools: These provide clear visual representations of the production schedule, facilitating better communication and coordination among team members.

Q 11. How familiar are you with relevant safety regulations and compliance standards in the wood industry?

I am very familiar with the relevant safety regulations and compliance standards in the wood industry. This includes OSHA (Occupational Safety and Health Administration) regulations in the US, and any equivalent regulations in other regions where we operate. Staying compliant is not just about avoiding penalties; it’s about creating a safe and healthy work environment for everyone.

OSHA Standards: I’m well-versed in OSHA standards related to woodworking machinery, dust control, personal protective equipment, emergency response, and hazardous materials handling. I ensure our facility meets or exceeds these standards.

Regular Audits and Inspections: We conduct regular internal audits to ensure compliance with all applicable regulations and identify any potential hazards. We also cooperate fully with any external audits.

Training Programs: Our comprehensive training programs cover all relevant safety regulations and procedures. Workers are trained on identifying hazards, using PPE, and following safe work practices.

Record Keeping: Meticulous record keeping is essential to demonstrate compliance. We maintain detailed records of training, inspections, accidents, and any corrective actions taken.

Q 12. Explain your problem-solving approach to addressing production line issues.

My problem-solving approach to production line issues is systematic and data-driven. I don’t believe in quick fixes; rather, I favor a thorough investigation to understand the root cause of the problem before implementing a solution. Think of it as detective work – finding the clues to solve the mystery.

Identify the Problem: Clearly define the issue and its impact on production. Gather data to quantify the problem, including the frequency, severity, and cost implications.

Investigate the Root Cause: Use various problem-solving tools such as the 5 Whys, fishbone diagrams (Ishikawa diagrams), and Pareto charts to identify the underlying cause. Involving the team in this process fosters ownership and creativity in finding solutions.

Develop and Implement Solutions: Based on the root cause analysis, develop and implement solutions that address the problem effectively. This might involve process improvements, equipment upgrades, or retraining of personnel.

Monitor and Evaluate: After implementing the solution, carefully monitor its effectiveness and evaluate the results. If necessary, adjustments or further improvements may be needed.

Q 13. How do you handle unexpected equipment malfunctions or breakdowns?

Unexpected equipment malfunctions or breakdowns are dealt with swiftly and efficiently, minimizing downtime and production disruptions. We have a proactive maintenance program, but unplanned issues will always arise. Our response follows a well-defined protocol.

Immediate Response: The first step is to ensure the safety of personnel. The affected machine is immediately shut down and the area secured. If necessary, emergency services are contacted.

Troubleshooting and Diagnosis: Trained technicians use diagnostic tools and their expertise to determine the cause of the malfunction. Sometimes, this involves contacting the equipment manufacturer for support.

Repair or Replacement: Once the problem is diagnosed, the necessary repairs are made or parts are replaced. We maintain a stock of common spare parts to minimize downtime.

Preventive Maintenance: After the repair, a thorough inspection of the equipment is conducted to prevent future issues. This is a key component of our proactive maintenance program.

Production Rescheduling: If necessary, the production schedule is adjusted to account for the downtime. This might involve prioritizing other tasks or temporarily shifting resources.

Q 14. Describe your experience with different wood joinery techniques.

My experience encompasses a wide range of wood joinery techniques, from traditional methods to more advanced techniques. Proper joinery is crucial for the strength, durability, and aesthetics of any wood product. It’s the backbone of quality woodworking.

Traditional Joiners: I’m proficient in various traditional joinery techniques like mortise and tenon, dovetail, lap joints, and finger joints. These techniques are often used in furniture making and other high-quality woodworking projects.

Modern Techniques: I’m also familiar with modern joinery techniques, including dowel joints, biscuit joints, and the use of various adhesives and fasteners. These techniques can be faster and more efficient in certain applications.

Machine Joinery: I have significant experience with using specialized machinery for joinery, such as mortising machines, tenoning machines, and CNC routers. These machines can increase efficiency and precision.

Joint Selection: The selection of the appropriate joint depends on several factors, including the type of wood, the intended use of the product, and the aesthetic requirements. For example, a mortise and tenon joint is strong and suitable for furniture, while a biscuit joint may be sufficient for less demanding applications.

Adhesives and Fasteners: I have extensive knowledge of various adhesives and fasteners, their properties, and their appropriate use in different types of joints. Choosing the right adhesive and fastener is as critical as choosing the right joint itself.

Q 15. What are your strategies for maintaining equipment and preventing costly repairs?

Maintaining wood processing equipment is crucial for preventing costly downtime and ensuring consistent product quality. My strategy is multifaceted, focusing on preventative maintenance, predictive maintenance, and reactive maintenance.

Preventative Maintenance: This involves a scheduled program of inspections, lubrication, cleaning, and minor repairs to prevent major breakdowns. Think of it like regularly servicing your car – changing the oil, checking tire pressure – to avoid major engine problems. For example, we’d schedule regular blade sharpening on planers and resaw machines, and check for wear and tear on bearings in our kilns.

Predictive Maintenance: This involves using sensors and data analysis to predict when equipment is likely to fail. For instance, we might monitor the vibration levels of a lathe motor; increased vibration could signal impending bearing failure, allowing us to replace it before a catastrophic breakdown. This saves us money and minimizes production disruptions.

Reactive Maintenance: This addresses breakdowns as they occur. While this is the most costly approach, it is sometimes unavoidable. To mitigate its impact, we have a well-stocked parts inventory and a team of skilled technicians who can quickly diagnose and repair issues. We also document all repairs thoroughly to identify recurring problems and improve preventative maintenance procedures.

This combined approach allows for maximizing equipment lifespan, minimizing downtime and associated costs, and ensuring the safety of our personnel.

Career Expert Tips:

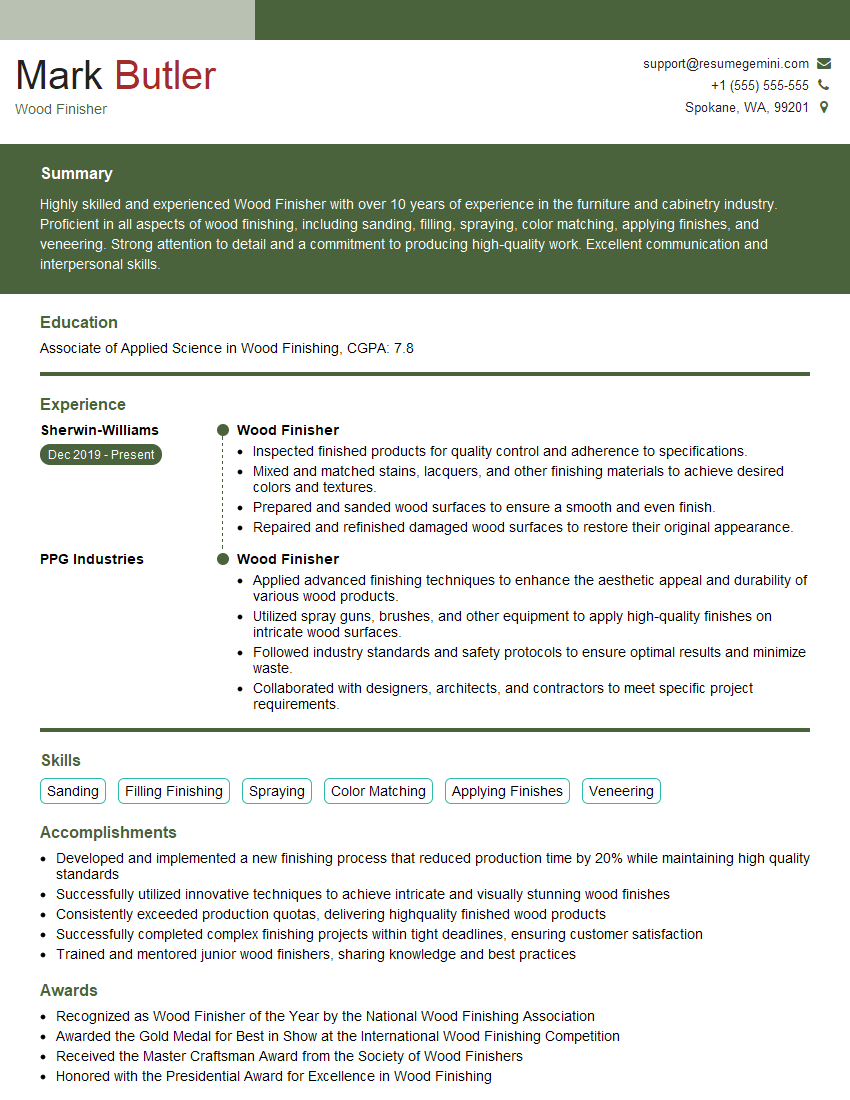

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistent product quality throughout the manufacturing process?

Consistent product quality is paramount in wood products manufacturing. We achieve this through a rigorous quality control system implemented at each stage of production, from raw material selection to final inspection.

Raw Material Selection: We meticulously inspect incoming lumber for defects like knots, splits, and discoloration, ensuring only suitable material enters the manufacturing process. This involves using moisture meters to ensure proper kiln drying and visual inspections by experienced personnel.

In-Process Quality Checks: At each manufacturing stage, we conduct quality checks. For example, after cutting, dimension lumber is checked for size accuracy, and during finishing, the paint or stain application is inspected for evenness. We utilize calibrated measuring instruments and establish clear quality thresholds.

Final Inspection: Before products are shipped, a final inspection ensures that they meet our quality standards. This includes checking for defects, confirming measurements and verifying that the finished product matches the customer’s specifications.

Data Tracking and Analysis: We maintain detailed records of all quality checks, allowing us to identify trends and areas for improvement. This data informs decisions about equipment adjustments, process modifications, and even employee training.

This multi-layered approach ensures that our products consistently meet or exceed customer expectations.

Q 17. Describe your experience with Lean Manufacturing principles in a wood products setting.

Lean Manufacturing principles have significantly improved efficiency and reduced waste in our wood products operation. We’ve implemented several key elements:

Value Stream Mapping: We mapped our entire production process, identifying bottlenecks and areas of waste. This revealed opportunities to streamline workflows and reduce unnecessary steps.

5S Methodology (Sort, Set in Order, Shine, Standardize, Sustain): We implemented 5S in our workshop, creating a cleaner, more organized, and safer work environment. This reduces time spent searching for tools or materials, improves efficiency, and enhances safety.

Kanban System: We use Kanban to manage inventory and production flow. This just-in-time system ensures that we only produce what is needed, minimizing waste and storage costs.

Kaizen Events: We regularly hold Kaizen events, bringing teams together to identify and implement small, incremental improvements. These events foster a culture of continuous improvement.

For example, by implementing Kanban, we reduced our lead times significantly, and by optimizing our value stream, we were able to reduce material waste by approximately 15%.

Q 18. How familiar are you with different wood preservation methods?

I’m familiar with various wood preservation methods, each offering different levels of protection depending on the application and type of wood. These methods broadly fall into categories of:

Pressure Treatment: This involves forcing preservatives into wood under pressure. Common preservatives include chromated copper arsenate (CCA), but due to environmental concerns, copper azole (CA-B) and alkaline copper quaternary (ACQ) are increasingly used for residential applications. This method is effective for outdoor applications where wood is exposed to the elements.

Surface Treatment: This involves applying preservatives to the wood’s surface. Examples include paints, stains, and water-repellent sealants. While not as effective as pressure treatment, surface treatments offer protection against weathering, insects, and fungal decay.

Thermal Modification: This involves heating wood to modify its properties, making it more resistant to decay and insects. This process alters the wood’s cellular structure, improving its dimensional stability and durability without the use of chemical preservatives.

Oil Treatments: Natural oils like linseed oil or tung oil can penetrate wood, providing some protection against moisture and decay. However, this method provides limited protection compared to pressure treatment or thermal modification.

The choice of method depends on factors such as the type of wood, intended application, budget, and environmental concerns.

Q 19. What are your strategies for improving efficiency and productivity in wood product manufacturing?

Improving efficiency and productivity in wood product manufacturing requires a holistic approach. Key strategies include:

Process Optimization: Analyzing and streamlining workflows to eliminate bottlenecks and waste. This can involve improving material flow, optimizing machine setups, and reducing handling times.

Technology Integration: Implementing advanced technologies such as Computer Numerical Control (CNC) machines and automated systems to increase precision, speed, and throughput. CNC machines allow for precise cuts and complex designs, leading to less waste and faster production.

Employee Training and Development: Investing in employee training to improve skills and efficiency. Well-trained employees are more productive and less prone to errors, reducing waste and improving quality.

Inventory Management: Implementing efficient inventory management systems to minimize storage costs and ensure materials are available when needed. This might involve using inventory tracking software or implementing a just-in-time inventory system.

Preventive Maintenance: Regular maintenance of equipment ensures minimal downtime and maximizes machine lifespan.

By implementing these strategies, we can significantly boost productivity, reduce costs, and improve product quality.

Q 20. Describe your experience with reading and interpreting blueprints and technical drawings.

Reading and interpreting blueprints and technical drawings is a fundamental skill in wood products manufacturing. I have extensive experience in this area, utilizing both traditional paper blueprints and digital CAD drawings. I’m proficient in understanding:

Orthographic Projections: Interpreting multiple views (front, side, top) to understand the three-dimensional form of a product.

Dimensioning and Tolerances: Accurately measuring and adhering to specified dimensions and tolerances to ensure product consistency and fit.

Material Specifications: Identifying the types and grades of wood required for each component.

Assembly Drawings: Understanding how different components fit together to create the final product.

Bill of Materials (BOM): Using the BOM to accurately determine the required quantity of each material.

My experience extends to using various CAD software packages, enabling me to work efficiently with both digital and physical blueprints. I can translate technical drawings into practical, buildable components, ensuring accuracy and efficiency in the manufacturing process.

Q 21. Explain your understanding of different wood adhesives and their applications.

Wood adhesives play a critical role in the strength and durability of many wood products. I’m familiar with various types and their applications:

Polyvinyl Acetate (PVA) Adhesives: These water-based adhesives are commonly used for interior applications due to their non-toxicity and ease of use. They are suitable for most wood types and are cost-effective. They’re ideal for furniture assembly or smaller projects.

Urea-Formaldehyde (UF) Adhesives: These are also water-based, and while strong, they aren’t suitable for exterior use due to their susceptibility to moisture degradation. Often used in plywood manufacturing.

Polyurethane (PU) Adhesives: These are moisture-resistant and very strong, making them suitable for exterior applications and high-stress joints. Their stronger bond is beneficial for structural applications.

Resorcinol Adhesives: These are high-strength, water-resistant adhesives used for demanding structural applications, such as boat building and exterior construction. However, they are more expensive and may require more careful application techniques.

Choosing the right adhesive depends on the specific application, the type of wood being used, the environmental conditions, and the desired strength and durability of the final product. I have practical experience selecting and applying these adhesives to ensure optimal performance and longevity.

Q 22. How do you manage and supervise a team in a wood products manufacturing environment?

Managing a team in wood products manufacturing requires a blend of technical expertise and strong leadership. It’s about fostering a collaborative environment where everyone feels valued and empowered to contribute their best work. My approach centers around clear communication, delegation based on individual strengths, and consistent feedback.

- Clear Communication: I utilize daily huddles to discuss immediate priorities, weekly meetings to review progress and address challenges, and regular one-on-one sessions to provide individualized feedback and address concerns. This ensures everyone is on the same page and any issues are identified promptly.

- Strength-Based Delegation: I carefully assign tasks based on each team member’s skills and experience. For example, a seasoned craftsman might lead a complex project involving intricate joinery, while a newer employee might focus on simpler tasks like sanding and finishing. This maximizes efficiency and allows individuals to develop their expertise.

- Consistent Feedback: Regular feedback, both positive and constructive, is crucial for growth. I provide both immediate feedback on day-to-day tasks and formal performance reviews. This ensures that everyone understands their performance, areas for improvement, and opportunities for advancement.

- Safety First: A safe working environment is paramount. Regular safety training, clear safety protocols, and proactive hazard identification are crucial aspects of my management approach.

For instance, during a recent project involving the production of custom cabinetry, I noticed one team member struggling with a new CNC machine. By providing hands-on training and support, I was able to address their concerns, boost their confidence, and improve the overall efficiency of the project.

Q 23. What are your strategies for addressing customer complaints or product defects?

Addressing customer complaints or product defects is crucial for maintaining customer satisfaction and our reputation. My strategy is rooted in prompt response, thorough investigation, and proactive solutions.

- Prompt Response: I prioritize acknowledging customer complaints immediately, showing them that we value their feedback and take their concerns seriously. This often involves a quick phone call or email to express empathy and outline the next steps.

- Thorough Investigation: Once a complaint is received, we conduct a thorough investigation to determine the root cause of the problem. This might involve examining the defective product, reviewing production records, and interviewing team members involved in the manufacturing process. For instance, a warped table top might point to issues with kiln drying or improper clamping during gluing.

- Proactive Solutions: Based on the investigation, we determine the best course of action. This could involve repairing the defect, replacing the product, or offering a partial refund. We strive to resolve the issue swiftly and effectively, minimizing the customer’s inconvenience. Open communication throughout the process is key to maintaining customer trust.

- Preventative Measures: Finally, we analyze the root cause of the defect to implement corrective actions to prevent similar issues from occurring in the future. This might involve modifying manufacturing processes, improving quality control checks, or investing in new equipment.

For example, we once received a complaint about a chair with a loose leg. Our investigation revealed a problem with the adhesive used. We immediately switched to a stronger adhesive and implemented a stricter quality control check to ensure all chairs met our quality standards. We also offered the customer a replacement chair and a sincere apology.

Q 24. Describe your experience with project management in the context of woodworking projects.

My experience in project management within woodworking involves meticulous planning, efficient resource allocation, and close monitoring of progress. I’ve managed projects ranging from small, bespoke furniture pieces to larger-scale commercial projects involving intricate paneling installations.

- Detailed Planning: Each project starts with a detailed plan, including detailed drawings, material lists, timelines, and budgets. This ensures everyone understands the scope of work and their individual responsibilities.

- Resource Allocation: Effective resource allocation is crucial for on-time and within-budget project completion. This includes careful selection of materials, allocation of personnel, and scheduling of equipment usage. I utilize project management software to streamline this process.

- Progress Monitoring: Regular monitoring is essential for keeping the project on track. This includes checking materials inventory, reviewing production progress, and addressing any arising challenges promptly. Regular meetings with the team keep everyone informed and engaged.

- Risk Management: Anticipating and mitigating potential risks is crucial for project success. This includes identifying potential supply chain issues, equipment malfunctions, and unforeseen design changes. Having contingency plans is essential.

For example, a recent commercial project involved the production of custom wooden wall panels for a high-end hotel. Through meticulous planning and close monitoring of the process, we delivered the project on time and within budget, exceeding the client’s expectations.

Q 25. How do you stay up-to-date with the latest technologies and trends in wood manufacturing?

Staying current with the latest technologies and trends in wood manufacturing is critical for maintaining competitiveness and efficiency. My approach involves a multi-pronged strategy:

- Industry Publications and Journals: I regularly read industry publications like Woodworking Network and Woodworking Industry, keeping abreast of new technologies, materials, and manufacturing techniques.

- Trade Shows and Conferences: Attending industry trade shows and conferences provides opportunities to network with peers, see new technologies in action, and learn from experts in the field. Examples include IWF (International Woodworking Fair).

- Online Courses and Webinars: Online learning platforms offer numerous courses on advanced woodworking techniques, CNC programming, and sustainable manufacturing practices. I regularly take advantage of these resources to enhance my skillset.

- Networking with Professionals: Engaging with colleagues and professionals in the industry through online forums, professional organizations (like the Forest Products Society), and industry events fosters knowledge sharing and access to valuable insights.

Recently, I completed an online course on advanced CNC programming, allowing me to improve our efficiency in producing complex designs for custom furniture. This directly translated into improved speed and precision in our production processes.

Q 26. What is your understanding of sustainable practices in wood product manufacturing?

Sustainable practices in wood product manufacturing are essential for environmental responsibility and long-term viability. My understanding encompasses several key areas:

- Sustainable Sourcing: Prioritizing wood from responsibly managed forests certified by organizations like the Forest Stewardship Council (FSC) ensures that our products don’t contribute to deforestation or harm biodiversity.

- Waste Reduction: Minimizing waste through efficient material utilization, optimizing cutting patterns, and implementing recycling programs reduces our environmental footprint. We often use offcuts for smaller projects or donate them to local schools for craft projects.

- Energy Efficiency: Adopting energy-efficient technologies in our manufacturing processes reduces our reliance on fossil fuels. This includes upgrading to energy-efficient kilns and optimizing our machinery’s energy consumption.

- Water Conservation: Implementing water-saving measures in our finishing processes reduces water usage and minimizes potential water pollution.

- Emissions Reduction: Minimizing emissions from our processes, through the use of low-VOC (Volatile Organic Compound) finishes and efficient dust collection systems, is crucial for air quality.

For example, we recently invested in a new CNC router with a significantly reduced energy consumption compared to our older model, leading to substantial savings in energy costs and reduced emissions.

Q 27. Describe your experience with cost estimation and budgeting for woodworking projects.

Accurate cost estimation and budgeting are crucial for profitable project completion. My approach involves a detailed breakdown of all project costs:

- Material Costs: This involves detailed costing of all lumber, hardware, finishes, and other materials, considering potential price fluctuations and waste factors. We utilize a material requirement planning (MRP) system to manage inventory and anticipate future needs.

- Labor Costs: This includes calculating the labor hours required for each phase of the project, considering the hourly wage rates of our skilled labor. Historical data helps estimate labor time accurately.

- Overhead Costs: This includes facility costs, equipment maintenance, utilities, and administrative expenses. These are allocated to individual projects based on a predetermined formula.

- Profit Margin: A reasonable profit margin is built into the cost estimate to ensure profitability. This is determined based on market analysis, project complexity, and competition.

- Contingency: A contingency buffer is added to the budget to accommodate unforeseen expenses, such as material defects or equipment malfunctions.

We use specialized software to create detailed cost estimates and track expenses throughout the project. For instance, a recent custom cabinet project involved a detailed breakdown of lumber costs, hardware costs, labor hours for design, fabrication, finishing and installation, and overhead. This allowed us to provide an accurate quote to the client and successfully manage the project’s budget.

Q 28. How do you ensure compliance with environmental regulations related to wood processing?

Ensuring compliance with environmental regulations related to wood processing is crucial for responsible business operations. This involves understanding and adhering to all relevant local, state, and federal regulations.

- Wastewater Management: We meticulously manage wastewater generated from finishing processes to ensure compliance with water quality standards. This involves the use of appropriate filtration systems and proper disposal methods.

- Air Emissions Control: We utilize effective dust collection and air filtration systems to control air emissions, complying with air quality regulations. Regular maintenance of these systems is crucial.

- Hazardous Waste Management: Proper handling, storage, and disposal of hazardous waste, such as solvents and adhesives, is essential. We partner with licensed hazardous waste disposal companies to ensure compliance.

- Record Keeping: Meticulous record keeping of all our environmental activities is crucial for demonstrating compliance during inspections. We maintain detailed logs of waste generation, disposal methods, and emission monitoring data.

- Permitting and Licensing: We obtain all necessary permits and licenses to operate our facility legally and environmentally responsibly.

- Employee Training: Regular employee training on environmental regulations, safety protocols, and proper waste handling practices is essential for maintaining compliance.

We regularly conduct internal audits and engage environmental consultants to ensure ongoing compliance and identify potential areas for improvement. For example, we recently updated our finishing process to use a low-VOC finish, reducing our volatile organic compound emissions and improving air quality.

Key Topics to Learn for Wood Products Manufacturing Interview

- Wood Species and Properties: Understanding the characteristics of different wood types (hardwoods vs. softwoods), their strengths, weaknesses, and suitability for various applications. Practical application: Choosing the right wood for a specific project based on its durability, workability, and aesthetic qualities.

- Manufacturing Processes: Familiarize yourself with key processes like logging, milling, drying, treating, and finishing. Practical application: Analyzing the efficiency of a manufacturing process and identifying potential bottlenecks or areas for improvement.

- Machinery and Equipment: Gain a foundational understanding of common woodworking machinery (planers, saws, lathes, etc.) and their operation. Practical application: Troubleshooting equipment malfunctions and performing basic maintenance.

- Safety Regulations and Procedures: Mastering relevant safety protocols and regulations within the wood products industry. Practical application: Implementing safety measures to prevent accidents and ensure a safe working environment.

- Quality Control and Assurance: Understanding the importance of quality control throughout the manufacturing process. Practical application: Implementing quality checks to ensure products meet specified standards.

- Sustainability and Environmental Impact: Familiarize yourself with sustainable forestry practices and the environmental impact of wood product manufacturing. Practical application: Identifying opportunities to reduce waste and improve environmental performance.

- Wood Treatment and Preservation: Understanding different methods for treating wood to enhance durability and resistance to pests and decay. Practical application: Selecting appropriate treatments for specific applications and environmental conditions.

- Inventory Management and Supply Chain: Understanding how efficient inventory management contributes to a successful operation. Practical application: optimizing stock levels to minimize waste and ensure timely production.

Next Steps

Mastering the fundamentals of Wood Products Manufacturing opens doors to exciting career opportunities with significant growth potential. To significantly increase your chances of landing your dream role, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to the Wood Products Manufacturing industry to help guide you. Take the next step towards your successful career in this exciting field!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO