Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Navigate Warehouse Safely interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Navigate Warehouse Safely Interview

Q 1. Describe your experience navigating large warehouse facilities.

My experience navigating large warehouse facilities spans over eight years, encompassing various environments from small distribution centers to expansive fulfillment warehouses exceeding 500,000 square feet. I’ve worked with facilities utilizing diverse layouts and technologies, ranging from traditional rack systems to automated guided vehicles (AGVs). I’m adept at using both physical maps and digital systems for navigation, always prioritizing efficient and safe route planning.

For instance, in my previous role at Acme Distribution, I routinely navigated a high-bay warehouse using a combination of physical aisle markers, a WMS system providing real-time location information for inventory, and a handheld scanner to confirm accurate product retrieval. This required constant situational awareness to avoid collisions with forklifts and other personnel, especially during peak operational hours.

In another experience at Beta Logistics, I dealt with a more complex U-shaped layout incorporating multiple loading docks and cross-docking operations. Mastering this required a deeper understanding of workflow patterns to effectively navigate the facility and avoid congestion.

Q 2. Explain your understanding of warehouse safety regulations.

My understanding of warehouse safety regulations is comprehensive, encompassing OSHA standards (in the US) and equivalent local regulations. I’m intimately familiar with regulations concerning forklift operation, pedestrian safety, hazardous material handling, fire prevention, and emergency procedures. I also have experience with implementing and adhering to safety protocols for PPE (Personal Protective Equipment), such as the mandatory use of safety vests, steel-toed boots, and hearing protection in high-noise areas.

I understand the importance of regular safety training and inspections. I’ve participated in and led numerous safety audits, focusing on identifying potential hazards and implementing corrective actions. My approach always prioritizes proactive risk management to prevent accidents before they occur. For instance, I played a critical role in implementing a new forklift training program that reduced near-miss incidents by 25%.

Q 3. How do you identify and avoid potential hazards in a warehouse setting?

Identifying and avoiding potential hazards in a warehouse is a proactive process that begins with regular observation and risk assessment. I use a methodical approach, scanning my surroundings for potential dangers. This includes looking for:

- Obstructions: Pallet jacks, boxes, debris, or improperly stacked materials in aisles.

- Forklift traffic: Maintaining a safe distance and paying close attention to blind spots.

- Spills: Liquids, powders, or other materials that could cause slips, trips, or falls.

- Electrical hazards: Damaged wiring, exposed outlets, or malfunctioning equipment.

- Poor lighting: Areas with insufficient lighting create increased risk of accidents.

If I identify a hazard, I immediately report it to the appropriate personnel, following established protocols for hazard reporting and remediation. My goal is to make the environment safe for myself and others. For example, I once discovered a significant oil spill near a loading dock which I immediately reported, preventing a potential serious accident. The spill was cleaned up promptly and the appropriate safety measures were implemented to prevent a recurrence.

Q 4. What are your strategies for maintaining situational awareness in a busy warehouse?

Maintaining situational awareness in a busy warehouse is crucial for safety. My strategies include:

- 360-degree awareness: Continuously scanning my surroundings to identify potential hazards and moving equipment.

- Predictive awareness: Anticipating the movement of forklifts and other equipment, giving them a wide berth.

- Communication: Using verbal and/or visual cues to communicate with others, especially when approaching blind corners or intersections.

- Active listening: Paying attention to the sounds of equipment, like the beeping of forklifts, which signals their presence.

- Use of technology: Leveraging WMS systems for real-time location of personnel and inventory to help anticipate potential conflicts.

Think of it like driving in heavy traffic – you need to be constantly alert, anticipate the actions of other drivers, and communicate your intentions effectively to prevent collisions. This translates directly to warehouse navigation, where proactive awareness is a key component of safety.

Q 5. Describe your experience using warehouse management systems (WMS) for navigation.

I have extensive experience using Warehouse Management Systems (WMS) for navigation. I’m proficient with several leading WMS platforms, including [mention specific systems if applicable, e.g., Manhattan Associates, Blue Yonder]. These systems provide real-time inventory location, directional guidance, picking lists, and order tracking information, significantly improving efficiency and accuracy. I can use these systems to efficiently plan my routes, ensuring I’m retrieving the correct items in the fastest, safest manner.

For example, in my previous role, we used a WMS system with integrated mapping functionality. The system would automatically generate the optimal route for picking an order based on item location, minimizing travel time and reducing the chance of conflicts with other workers or equipment. This streamlined the entire process, leading to a substantial increase in productivity and a reduction in errors.

Q 6. How familiar are you with different types of warehouse layouts (e.g., U-shaped, I-shaped)?

I am familiar with various warehouse layouts, including U-shaped, I-shaped, L-shaped, and multi-level configurations. Understanding the layout is fundamental to efficient and safe navigation. Each layout presents unique challenges and opportunities. For example, a U-shaped layout might optimize workflow for specific processes but could potentially create more congestion in certain areas.

My experience allows me to quickly assess a warehouse’s layout, identify potential bottlenecks, and adapt my navigation strategies accordingly. This includes understanding how different layouts impact the flow of goods, personnel, and equipment. This knowledge is critical for optimizing routes, ensuring safety, and improving overall warehouse operations. I can easily adapt to different designs, making me a flexible and effective member of any warehouse team.

Q 7. Explain your process for locating specific items within a warehouse.

Locating specific items within a warehouse is a systematic process. My approach typically involves:

- Consulting the WMS: The system provides accurate location information for each item using its unique SKU (Stock Keeping Unit) number.

- Using physical location guides: Many warehouses utilize aisle and location markers to assist with item retrieval.

- Verifying item location: Once I’ve arrived at the designated location, I visually verify the item’s identification and condition before retrieving it.

- Documenting retrieval: After retrieving an item, I appropriately document the retrieval in the WMS system, updating its status and location information.

In cases of discrepancies or difficulties in locating an item, I follow established procedures for investigating the issue, which may include contacting supervisors or utilizing additional warehouse inventory systems to locate the item. I prioritize accuracy and efficiency, always confirming item location and condition prior to retrieval to avoid errors and maintain the integrity of the inventory.

Q 8. How do you prioritize safety when working with material handling equipment?

Prioritizing safety when operating material handling equipment is paramount. It’s not just about following rules; it’s about cultivating a safety-first mindset. This involves a multi-pronged approach:

- Pre-Operational Checks: Before even starting, I meticulously inspect the equipment. This includes checking fluid levels, tire pressure (for forklifts), lights, brakes, and any visible damage. I’d refuse to operate faulty equipment and report it immediately. Think of it like a pre-flight check for an airplane – essential for a safe journey.

- Safe Operating Procedures: I strictly adhere to all company policies and regulations regarding speed limits, load capacity, and designated routes. I always maintain a safe distance from other personnel and equipment. Ignoring these rules is like driving a car without paying attention to traffic signals – reckless and dangerous.

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, including safety glasses, high-visibility clothing, and steel-toed boots. PPE is not optional; it’s my shield against potential hazards. A minor bump that might bruise an unprotected foot could cause a serious injury if a heavy object were to fall.

- Awareness and Communication: I am constantly aware of my surroundings, paying close attention to pedestrian traffic, blind spots, and potential obstacles. Clear communication with others is vital; I use hand signals, verbal warnings, and backup alarms effectively to avoid collisions.

- Training and Certification: I’m properly trained and certified to operate the equipment I use. This ensures I have the skills and knowledge to handle the equipment safely and efficiently. Untrained operation is akin to surgery without medical training – disastrous consequences are highly likely.

Q 9. What are the common causes of accidents in warehouses, and how can they be prevented?

Common warehouse accidents often stem from a few key causes:

- Poor Housekeeping: Cluttered aisles, misplaced objects, and inadequate lighting create tripping hazards and obstruct visibility, leading to falls and collisions. Imagine navigating a dark, cluttered room – accidents are practically inevitable.

- Improper Lifting Techniques: Incorrect lifting procedures strain muscles and cause back injuries. Using proper techniques, such as bending at the knees and keeping the load close to the body, is crucial. Lifting incorrectly is like trying to carry a heavy suitcase with a weak grip – you’ll likely drop it and hurt yourself.

- Unsafe Equipment Operation: Operating equipment without proper training or disregarding safety regulations increases the risk of accidents. This includes exceeding weight limits, speeding, or failing to conduct pre-operational checks.

- Lack of Communication: Poor communication between workers, particularly when using machinery, can result in collisions and injuries. This underscores the importance of clear signaling and awareness.

- Inadequate Training: A lack of proper training on safety procedures, equipment operation, and emergency response leaves workers vulnerable. Comprehensive safety training is like a life jacket – it protects you when things go wrong.

Prevention involves proactive measures like regular safety training, implementing strict safety protocols, conducting thorough equipment inspections, promoting good housekeeping, and fostering a strong safety culture within the warehouse.

Q 10. Describe your experience with using RF scanners or other navigation technologies.

I have extensive experience using RF scanners for inventory management and order fulfillment. These devices are indispensable for efficient and accurate warehouse operations. They significantly reduce human error compared to manual processes. My proficiency extends to using the scanners for receiving shipments, picking orders, and verifying inventory levels. I’m also familiar with other navigation technologies, such as warehouse management systems (WMS) integrated with pick-to-light systems or voice-directed picking, that improve accuracy and efficiency while guiding operators through the warehouse.

For instance, in a previous role, we implemented a new WMS with a voice-directed system. Initially, there was a learning curve, but after a week of training, the system significantly improved picking speed and accuracy by reducing the need to consult paper pick lists, minimizing distractions, and keeping my hands free.

Q 11. How do you handle unexpected obstacles or delays while navigating the warehouse?

Encountering unexpected obstacles or delays requires immediate, decisive action. My response is guided by a priority system:

- Safety First: If the obstacle poses a safety risk, I immediately stop operations and assess the situation. If necessary, I alert my supervisor and other workers.

- Assess and Plan: I analyze the situation to determine the cause of the delay and explore potential solutions. This could involve rerouting, seeking assistance, or clearing the obstacle safely.

- Communicate: I inform relevant personnel about the delay and proposed solutions. Clear communication prevents further complications or accidents.

- Document: After resolving the issue, I document the event, including the cause, the solution, and any lessons learned. This helps identify recurring issues and improve future workflow.

For example, I once encountered a pallet obstructing an aisle. I immediately stopped my forklift, assessed the risk of collision, and alerted colleagues using the radio. We then safely moved the pallet to a designated area, documenting the incident for future review.

Q 12. What is your understanding of emergency procedures in a warehouse environment?

My understanding of warehouse emergency procedures is comprehensive. It encompasses:

- Emergency Exits and Assembly Points: I know the location of all emergency exits and designated assembly points. Familiarity with these locations is crucial for swift and orderly evacuation.

- Fire Safety: I am trained to use fire extinguishers (knowing the PASS method – Pull, Aim, Squeeze, Sweep) and understand the warehouse’s fire alarm system. I know the location of fire suppression systems and the procedures to follow in case of a fire.

- First Aid: I’m aware of the location of first-aid kits and have basic first-aid knowledge to provide initial assistance to injured personnel.

- Reporting Procedures: I know how to report accidents and incidents to the appropriate personnel. Accurate and timely reporting is vital for investigation and preventive measures.

- Hazardous Materials Response: If hazardous materials are present, I’m trained on appropriate handling procedures and emergency protocols. This may involve containment, evacuation, or calling emergency services.

Regular safety drills and training maintain proficiency in emergency response. This is just like the safety briefings on an airplane – they are crucial in ensuring we’re prepared for unexpected events.

Q 13. How do you maintain awareness of your surroundings while operating equipment?

Maintaining awareness of my surroundings while operating equipment is a constant priority. This involves:

- Visual Scanning: I regularly scan my surroundings using both mirrors and direct observation to identify potential hazards or obstacles, particularly in blind spots. This is akin to a pilot constantly checking their instruments and scanning the horizon.

- Auditory Awareness: I listen for warning signals, other equipment, and pedestrian movements. Hearing is a vital sense for anticipating potential problems.

- Defensive Driving Techniques: I use defensive driving techniques, anticipating the movements of others and adjusting my actions accordingly. This includes maintaining a safe following distance and keeping a clear path.

- Regular Breaks: Taking regular breaks prevents fatigue, which impairs concentration and reaction time. Fatigue is like driving while drowsy – extremely hazardous.

- Clear Communication: I utilize horns, lights, and verbal warnings to communicate my intentions and warn others of my movements.

Q 14. Describe your experience with different types of warehouse racking systems.

My experience encompasses various warehouse racking systems, including:

- Selective Pallet Racking: This is the most common type, allowing for individual pallet access. I’m proficient in loading, unloading, and ensuring proper stacking techniques to avoid collapses.

- Drive-In/Drive-Through Racking: These systems maximize storage density but limit accessibility. I understand the safety considerations of navigating these systems, particularly regarding collision avoidance.

- Push-Back Racking: This system uses rollers to allow for efficient pallet storage and retrieval, increasing density. I’m trained on the specific loading and unloading procedures to avoid damage.

- Cantilever Racking: Ideal for long or bulky items, I know the specific safety requirements for securing loads to prevent accidents.

- Double-Deep Racking: This maximizes storage capacity, but access is limited. I’m skilled in carefully maneuvering equipment in these denser storage areas.

My understanding extends beyond just recognizing the types of racking; it includes understanding the weight capacities, proper loading techniques, and safety procedures specific to each system. Improper usage can lead to catastrophic collapses, resulting in significant injury or damage. Therefore, understanding the specifics of each racking system is essential for safe operations.

Q 15. How would you respond to a spill or other hazardous situation in the warehouse?

Responding to a spill or hazardous situation requires immediate action and adherence to established safety protocols. My first priority is ensuring the safety of myself and others. I would immediately:

- Assess the situation: Determine the nature of the spill (e.g., chemical, oil, water), its extent, and any immediate dangers.

- Secure the area: Immediately cordon off the affected area using cones, caution tape, or other readily available barriers to prevent access by unauthorized personnel. This is crucial to prevent accidents and further contamination.

- Alert relevant personnel: Notify my supervisor, safety officer, and/or emergency response team, depending on the severity of the spill. Clear and concise communication is paramount.

- Implement appropriate containment and cleanup: Follow the company’s established spill response plan, which will specify the appropriate personal protective equipment (PPE) to use and the methods for containing and cleaning up the specific type of spill. This could involve using absorbent materials, neutralizing agents, or specialized equipment.

- Document the incident: Complete an incident report, detailing the time, location, nature of the spill, actions taken, and any injuries or damages. Accurate record-keeping is vital for analysis and future prevention.

For example, if I encountered a chemical spill, I’d immediately don appropriate PPE like gloves, eye protection, and a respirator before attempting any cleanup, following the instructions on the chemical’s safety data sheet (SDS).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your process for reporting near misses or accidents in a warehouse?

Reporting near misses and accidents is critical for preventing future incidents. My process involves these steps:

- Immediate reporting: Report any near miss or accident to my supervisor as soon as possible. Timely reporting allows for quick responses and minimizes potential further risks.

- Detailed description: Provide a comprehensive description of the incident, including the time, location, individuals involved, circumstances leading to the event, and any injuries or damages. The more details provided, the better the understanding of root causes.

- Incident report completion: Complete the company’s official incident report form, ensuring accuracy and completeness. This standardized form allows for efficient data collection and analysis.

- Follow-up: Attend any necessary investigations or meetings to contribute information and discuss preventative measures.

- Observation and learning: Following the incident report, I actively observe improvements that are implemented to prevent similar incidents.

In a recent situation, I noticed a pallet stacked precariously high. Reporting this near miss led to a review of our stacking procedures, preventing a potential collapse and potential injury.

Q 17. How do you ensure the safe operation of powered industrial trucks?

Safe operation of powered industrial trucks (PITs), such as forklifts, is paramount. My approach involves:

- Proper training and certification: I possess the necessary training and certification to operate the specific types of PITs I’m authorized to use. This ensures I’m proficient in safe operating procedures.

- Pre-operation checks: Before operating any PIT, I conduct thorough pre-operation checks to ensure it’s in safe working condition. This includes checking fluid levels, tire pressure, brakes, lights, and horn.

- Adherence to speed limits and traffic rules: I strictly adhere to established speed limits and traffic rules within the warehouse, prioritizing safety over speed.

- Safe load handling: I ensure loads are appropriately secured and balanced to prevent tipping or accidents. I understand the weight limits of the PIT and the load’s center of gravity.

- Awareness of surroundings: I maintain constant awareness of my surroundings, paying attention to pedestrians, other PITs, and obstacles. I use appropriate warning signals before making turns or maneuvers.

- Regular maintenance: I report any mechanical issues or required maintenance immediately to ensure the PIT remains safe and operational.

For example, before operating a forklift, I always check the hydraulic fluid level, ensuring it’s within the acceptable range to prevent malfunctions.

Q 18. Explain your understanding of load capacity and weight distribution.

Understanding load capacity and weight distribution is crucial for preventing accidents and damage. Load capacity refers to the maximum weight a piece of equipment, such as a forklift or pallet, can safely handle. Weight distribution is how that weight is spread across the area. Uneven distribution can lead to instability and tipping.

I always check the load capacity of any equipment I’m using before lifting or moving a load. I also ensure the weight is distributed evenly to maintain stability. For example, when using a forklift, I’ll ensure heavy items are placed low and centered on the forks to prevent tipping. Incorrect weight distribution can cause serious accidents.

Furthermore, I understand the concept of center of gravity. Knowing where the center of gravity is in a load is essential to safe transport. Keeping it low and central minimizes the risk of tipping.

Q 19. How do you maintain proper communication with co-workers to ensure safe navigation?

Effective communication is key to safe navigation in a busy warehouse environment. My strategies include:

- Verbal communication: I use clear and concise verbal communication, announcing my intentions (e.g., ‘Backing up’, ‘Moving to aisle 3′) to alert others of my movements. I also acknowledge others’ communications.

- Visual signals: I use appropriate hand signals or lights to indicate my movements, especially in areas with limited visibility or noise. This provides additional layers of communication.

- Two-way radios: When available, I use two-way radios to communicate with colleagues, particularly during complex maneuvers or emergency situations. This facilitates clear communication even from a distance.

- Awareness of others: I maintain constant visual contact with colleagues, anticipating their movements and adjusting my own maneuvers to prevent collisions.

For instance, before backing up a forklift, I always verbally announce my intention and use my horn to alert others in the vicinity, even if I have visual confirmation they’re aware.

Q 20. Describe your experience with using safety equipment (e.g., high-visibility vests, safety shoes).

I always utilize the required safety equipment according to the task and warehouse regulations. This includes:

- High-visibility vests: I wear high-visibility vests in areas with low lighting or heavy traffic to ensure I’m easily seen by others operating machinery.

- Safety shoes: I wear safety shoes with steel toes to protect my feet from falling objects or crushing hazards. These shoes provide significant protection in the warehouse environment.

- Hearing protection: In noisy areas, I use appropriate hearing protection, like earplugs or earmuffs, to protect my hearing from long-term damage. This is particularly crucial around heavy machinery.

- Gloves: When handling materials that may cause cuts or irritations, I wear appropriate gloves to protect my hands. This is important when handling sharp objects or chemicals.

- Other PPE: Depending on the task, I use additional PPE such as safety glasses, respirators, or hard hats as needed. Safety is always my top priority.

For instance, while operating a forklift, I always wear my high-visibility vest and safety shoes, and ensure my hard hat is securely fastened.

Q 21. How do you adapt your navigation strategies to different warehouse environments?

Adapting my navigation strategies to different warehouse environments is essential for maintaining safety and efficiency. My approach involves:

- Understanding the layout: Before navigating a new warehouse, I familiarize myself with its layout, including the location of aisles, storage areas, loading docks, and potential hazards. This knowledge prevents confusion and potential accidents.

- Assessing traffic patterns: I identify and understand the typical traffic patterns and flow of pedestrian and vehicle traffic within the warehouse, allowing me to anticipate and react to potential conflicts.

- Adjusting speed: I adjust my speed to match the conditions, reducing it in areas with limited visibility or heavy traffic. Safety always outweighs speed.

- Using appropriate equipment: I select the most suitable equipment for the task and environment, considering factors like aisle width, load size, and floor conditions.

- Being aware of obstacles: I remain aware of potential obstacles such as uneven flooring, spills, or obstructions, adjusting my route accordingly to avoid risks.

For example, in a narrow-aisle warehouse, I might use a narrower forklift and adopt a slower, more cautious driving style compared to a wider, more open warehouse.

Q 22. What are the key factors to consider when designing a safe warehouse layout?

Designing a safe warehouse layout is crucial for preventing accidents and maximizing efficiency. It’s like designing a well-organized city – you need clear pathways, designated zones, and easy access to everything. Key factors include:

Traffic flow: Separate pedestrian and vehicle traffic with clearly marked walkways, designated loading docks, and ample space for maneuvering. Think of it like designing one-way streets to prevent head-on collisions.

Storage organization: Implement a system for storing materials based on frequency of use and weight. Frequently accessed items should be easily reachable, while heavier items should be stored at lower levels to prevent strain and potential collapses. This is like organizing your kitchen – frequently used items are front and center.

Aisles and clearances: Ensure sufficient space between racks, shelves, and equipment to allow for safe passage. OSHA has specific guidelines for minimum aisle widths. Think of it as creating fire lanes in a city, ensuring emergency vehicles can pass easily.

Lighting and visibility: Adequate lighting eliminates blind spots and reduces the risk of trips and falls. This is akin to properly illuminated streets at night, enhancing visibility and safety.

Emergency exits and signage: Clearly marked and easily accessible emergency exits are paramount. Signage should be prominent and easy to understand, guiding people to safety in case of emergency. This is similar to clear exit signs and emergency routes in buildings.

Ergonomics: Design workstations to minimize strain and injury. Consider factors such as chair height, reach distances, and proper lifting techniques. Think of it as designing a comfortable and efficient workspace to prevent musculoskeletal problems.

Q 23. Explain your experience with maintaining a clean and organized workspace.

Maintaining a clean and organized workspace is non-negotiable for warehouse safety. In my previous role at Acme Distribution, I implemented a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). We started by decluttering unnecessary items, then organized the remaining items logically. Regular cleaning schedules were established, and we used visual aids like color-coded zones and labeling to maintain order. This system significantly reduced tripping hazards, improved efficiency, and fostered a sense of pride in the workspace. We saw a 20% reduction in workplace accidents after implementing this system. One example involved clearly labeling heavy items and ensuring they were stored at appropriate heights to prevent back injuries during handling. This systematic approach ensured that the warehouse wasn’t just clean but also highly organized and safe.

Q 24. How do you ensure compliance with OSHA regulations for warehouse safety?

OSHA compliance is a top priority. My approach involves a three-pronged strategy: understanding, implementation, and monitoring. I familiarize myself thoroughly with all relevant OSHA standards for warehousing, paying special attention to regulations concerning forklift operation, hazard communication, personal protective equipment (PPE), and emergency action plans. We then implement these standards by providing comprehensive training to all employees, ensuring proper use of PPE, and regularly inspecting equipment and work areas for compliance. Finally, we maintain detailed records of all safety training, inspections, and incident reports to demonstrate ongoing compliance. For example, we regularly conduct forklift safety training, including both classroom instruction and hands-on practice, and we maintain a detailed log of inspections for each forklift, ensuring it’s regularly serviced and meets safety standards. This proactive approach ensures we maintain a safe and compliant work environment.

Q 25. How do you contribute to a positive safety culture within the warehouse?

A positive safety culture isn’t just about rules; it’s about shared responsibility. I actively contribute by leading by example, always adhering to safety procedures, and encouraging others to do the same. I participate in safety meetings, actively listen to employee concerns, and contribute to developing and implementing safety initiatives. I also utilize positive reinforcement, recognizing and rewarding safe behaviors. At my previous company, we implemented a peer-to-peer safety observation program where employees could point out unsafe practices to each other respectfully. This fosters a sense of shared responsibility and improved safety awareness throughout the warehouse. This created a more collaborative and proactive approach to safety, rather than a top-down, punitive approach.

Q 26. Describe your experience with fire safety protocols in a warehouse.

Fire safety is critical in a warehouse environment due to the presence of flammable materials. My experience involves familiarity with and enforcement of fire safety protocols. This includes knowing the location and operation of fire extinguishers, fire alarms, and emergency exits. I’ve participated in fire drills and facilitated training sessions for employees on fire prevention measures, including proper storage of flammable materials, handling of electrical equipment, and procedures in case of a fire. We maintained detailed records of fire extinguisher inspections and ensured regular maintenance of the sprinkler system, following all relevant fire codes. For example, we implemented a strict ‘no smoking’ policy throughout the warehouse, and clearly marked designated smoking areas far from flammable materials. A proactive approach to fire safety minimizes risks and ensures the preparedness of the workforce.

Q 27. How do you handle challenging weather conditions in outdoor warehouse areas?

Handling challenging weather conditions in outdoor warehouse areas requires a proactive approach. This includes having contingency plans for extreme temperatures, heavy rainfall, snow, or strong winds. For example, we might use weather-resistant coverings for stored materials, implement drainage systems to prevent water accumulation, and secure loose items to prevent damage or injury from high winds. For extreme temperatures, we may adjust work schedules to minimize employee exposure to harsh conditions. We also regularly inspected outdoor equipment and structures to ensure they could withstand weather stress, and we implemented a system to promptly address any weather-related damage. This proactive planning ensures that operations can continue safely and efficiently despite unexpected weather events.

Key Topics to Learn for Navigate Warehouse Safely Interview

- Warehouse Layout and Navigation: Understanding warehouse organization, including aisle identification, zone mapping, and efficient route planning. Practical application: Describe how you would locate a specific item given its location code and warehouse map.

- Safety Regulations and Procedures: Knowledge of OSHA standards, company-specific safety protocols, and emergency procedures. Practical application: Explain your approach to identifying and mitigating potential hazards in a warehouse environment.

- Equipment Operation and Safety: Safe operation of forklifts, pallet jacks, and other warehouse equipment. Practical application: Describe your experience operating warehouse equipment and how you ensure safe operation, including pre-shift checks and adherence to safety guidelines.

- Material Handling Techniques: Proper lifting techniques, load securing, and preventing workplace injuries. Practical application: Explain how you would safely load and unload a pallet of heavy boxes.

- Inventory Management and Accuracy: Understanding inventory control systems, cycle counting, and maintaining accurate stock levels. Practical application: Describe a situation where you had to resolve an inventory discrepancy.

- Communication and Teamwork: Effective communication with supervisors, colleagues, and other stakeholders. Practical application: Explain how you would handle a situation involving a damaged product or a delivery delay.

- Problem-solving and Decision-making: Ability to identify and resolve problems related to warehouse operations, including delays, equipment malfunctions, or safety concerns. Practical application: Describe your approach to problem-solving in a fast-paced warehouse environment.

Next Steps

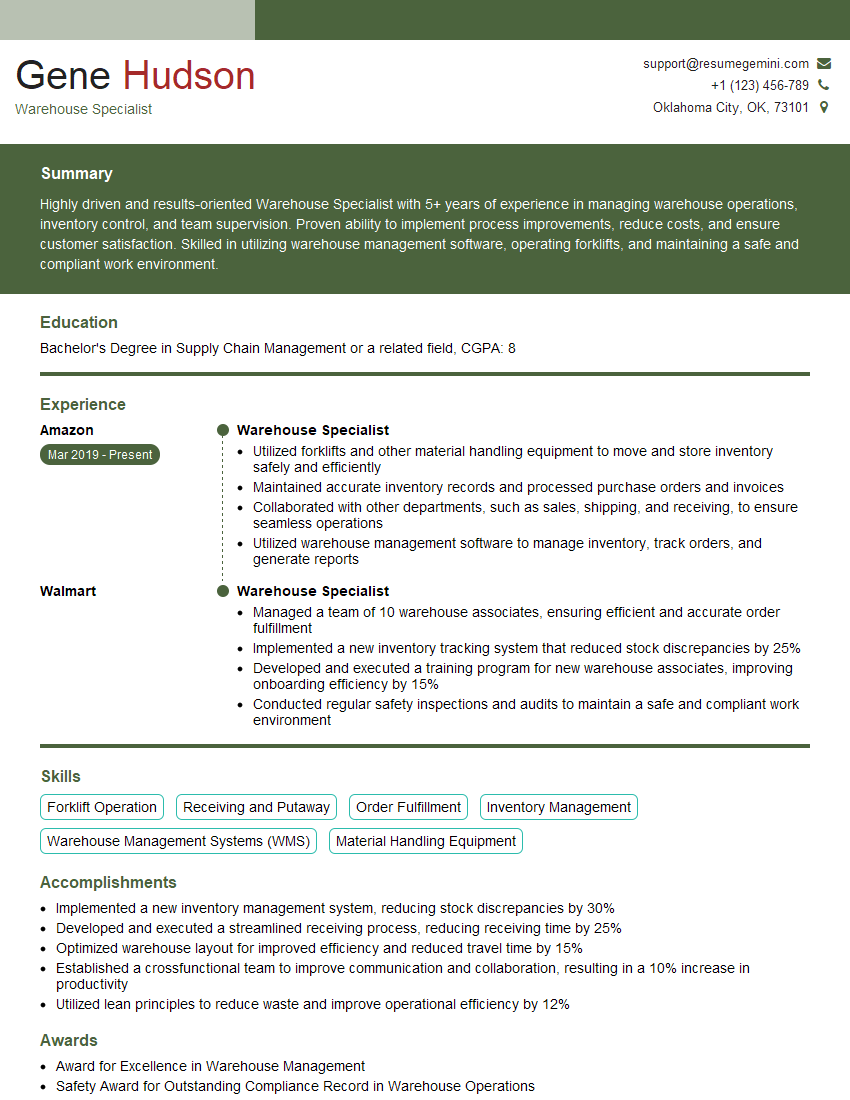

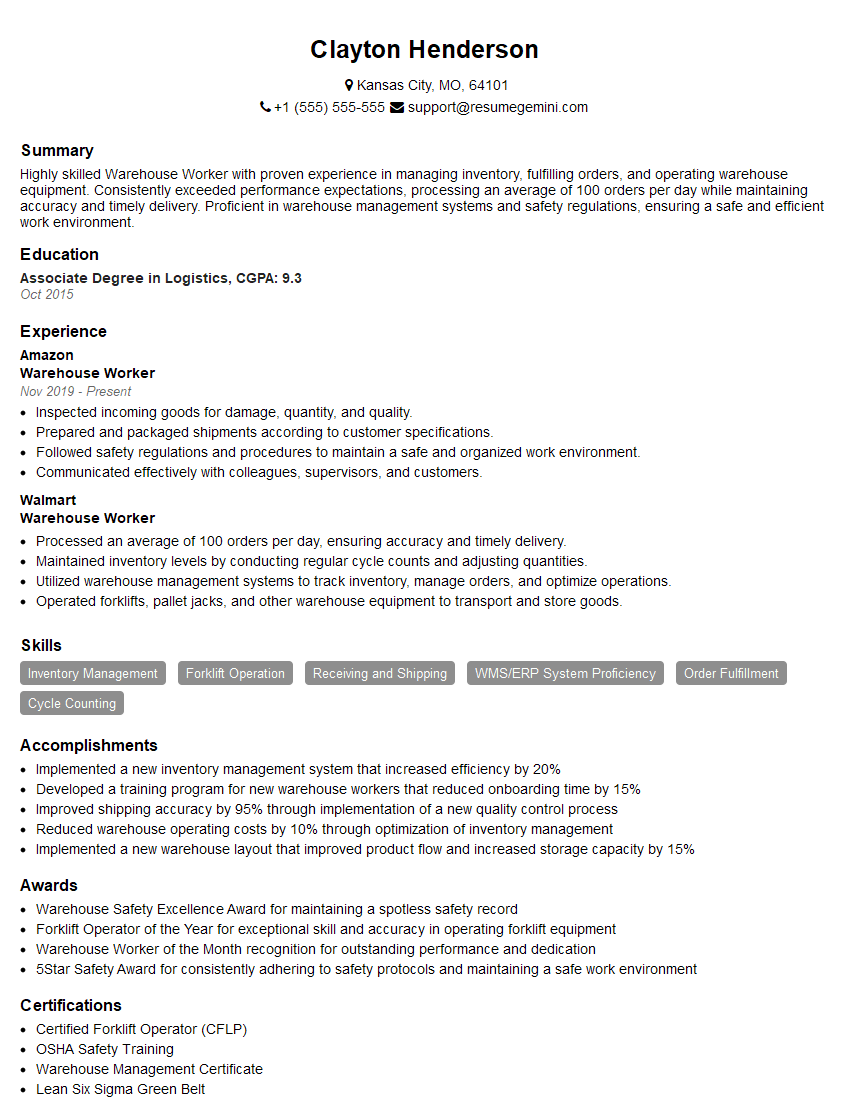

Mastering the principles of Navigate Warehouse Safely is crucial for a successful career in logistics and warehouse management. It demonstrates your commitment to safety, efficiency, and effective operations. To significantly enhance your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. We strongly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to Navigate Warehouse Safely, helping you present your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO