Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Unload and Stack Heavy Objects interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Unload and Stack Heavy Objects Interview

Q 1. Describe your experience unloading heavy objects.

My experience in unloading heavy objects spans over ten years, encompassing various industries like logistics, warehousing, and construction. I’ve handled a wide range of materials, from palletized goods weighing several tons to individual, irregularly shaped items requiring specialized techniques. I’m proficient in using various material handling equipment and have a strong understanding of safe lifting and unloading procedures. For example, during my time at Acme Logistics, I was responsible for the efficient and safe unloading of over 100 truckloads of construction materials per month, consistently meeting deadlines and maintaining a zero-incident record.

This experience has instilled in me a keen awareness of potential hazards and a commitment to meticulous planning and execution. I’m accustomed to working under pressure, adapting to different environments and demands, and always prioritizing safety above all else.

Q 2. What safety procedures do you follow when handling heavy objects?

Safety is paramount when handling heavy objects. My safety procedures always begin with a thorough risk assessment of the job. This includes identifying potential hazards like uneven surfaces, obstructions, and unstable loads. I always wear appropriate personal protective equipment (PPE), including safety shoes, gloves, and in some cases, a safety harness. Before starting any lift, I inspect the load to identify any potential points of failure.

- Proper Lifting Techniques: I always utilize proper lifting techniques, bending at the knees and lifting with my legs, keeping the load close to my body.

- Teamwork and Communication: When handling extremely heavy loads, I work in a team, ensuring clear communication and coordination between team members.

- Equipment Inspection: I inspect all equipment such as forklifts, pallet jacks, and cranes before use, ensuring they are in good working order.

- Clear Pathways: I ensure clear pathways to prevent trips and falls.

- Emergency Procedures: I’m familiar with emergency procedures and know where to find first aid equipment.

Imagine trying to lift a heavy refrigerator alone; it’s much safer and more efficient to have someone help, clearly communicating each step of the process.

Q 3. How do you ensure the stability of a stacked load?

Ensuring the stability of a stacked load is critical to prevent collapses and accidents. I follow a layered approach, beginning with a firm, level base.

- Base Stability: The base should be strong and level, preferably a pallet.

- Uniform Distribution: I distribute the weight evenly across the base, preventing any concentration of weight in one area.

- Interlocking Pattern: I use an interlocking pattern when stacking, ensuring that the layers interlock and support each other. For example, bricks are usually laid with a running bond pattern for stability.

- Weight Capacity: I always consider the weight capacity of the base and never exceed it.

- Load Size: I avoid stacking loads that are too tall or too wide, potentially causing instability.

- Proper Securing: Depending on the material, I may use straps, shrink wrap, or other securing devices to ensure the load remains stable during transport or storage.

Think of building a tower of blocks; a stable base and an interlocking pattern are crucial to prevent it from toppling over. The same principle applies to stacked loads.

Q 4. What techniques do you use to lift heavy objects safely?

Safe lifting techniques are fundamental to my work. I always prioritize proper body mechanics to minimize strain and risk of injury.

- Assess the Load: Before lifting, I carefully assess the weight and size of the object.

- Get a Good Grip: I ensure a firm and secure grip on the object.

- Bend Your Knees: I bend at the knees and keep my back straight, lifting with my leg muscles, not my back.

- Keep it Close: I keep the object close to my body.

- Lift Smoothly: I lift smoothly and steadily, avoiding jerky movements.

- Use Assistance: For heavier objects, I always get assistance or use appropriate material handling equipment.

- Proper Footwear: Always wear appropriate, sturdy footwear with good grip.

Think of lifting a heavy suitcase; bending at the knees and keeping the suitcase close to your body makes the lift much easier and safer on your back.

Q 5. Explain your experience with different types of material handling equipment.

I have extensive experience with various types of material handling equipment, including:

- Forklifts: I’m certified to operate forklifts and am proficient in safe operation procedures, including pre-operation checks and load securing.

- Pallet Jacks: I regularly use pallet jacks for moving palletized goods.

- Hand Trucks: I’m skilled in using hand trucks for moving smaller, heavier items.

- Overhead Cranes: I have experience operating and directing overhead cranes for the safe movement of exceptionally heavy and large items.

- Conveyor Belts: I understand how to load and unload items onto conveyor belts safely and efficiently.

My familiarity with these different machines allows me to adapt quickly to various situations and choose the most appropriate equipment for the job.

Q 6. How do you prioritize tasks when unloading and stacking multiple items?

When unloading and stacking multiple items, I prioritize tasks based on several factors:

- Urgency: Items with urgent delivery requirements or those that are perishable are handled first.

- Weight and Size: Heavier and larger items are often prioritized to ensure they are not left until the end, potentially creating an unstable situation.

- Storage Location: Items intended for immediate use might be placed closer to the work area.

- Fragility: Fragile items are handled carefully and placed in designated areas to protect them from damage.

- Customer Requirements: Specific customer requirements for order fulfillment are always prioritized.

It’s like running a kitchen – you’d focus on dishes that need to be served immediately before prepping dishes for later.

Q 7. What is your experience with pallet wrapping and securing?

My experience with pallet wrapping and securing is extensive. Proper wrapping and securing are critical to preventing damage and ensuring load stability during transport.

- Wrap Selection: I select the appropriate type and strength of wrapping film based on the load’s weight, size, and fragility.

- Wrapping Technique: I utilize proper wrapping techniques to ensure that the load is evenly and securely wrapped. This often involves overlapping layers of film and applying even tension.

- Securing Devices: Where necessary, I use additional securing devices, like straps or corner boards, to further stabilize the load.

- Inspection: Before moving the load, I always inspect the wrapping to ensure its integrity and effectiveness.

Think of wrapping a gift – a poorly wrapped gift is prone to damage during transit. The same logic applies to palletized loads.

Q 8. How do you handle damaged or incorrectly labeled goods?

Handling damaged or incorrectly labeled goods requires a methodical approach prioritizing safety and accuracy. First, I would visually inspect the item for damage, noting the extent and type of damage (e.g., cracks, dents, punctures, water damage). I would then carefully document the damage using a company-provided form, including photos if necessary. This ensures accountability and allows for claims to be processed if appropriate. For mislabeled goods, I would immediately check the manifest or shipping documents to verify the contents. If the label is incorrect, I’d isolate the item, clearly mark it as ‘mislabeled,’ and report it to my supervisor immediately. This prevents the item from being inadvertently placed in the wrong location or shipped to the incorrect destination. We can’t afford to ship the wrong products to our clients.

For example, imagine finding a box of glassware with a large crack. I’d photograph the damage, note it on the damage report, and set it aside for the appropriate handling procedure – possibly return to sender or disposal depending on company policy.

Q 9. Describe a time you had to adapt to unexpected challenges while unloading and stacking.

During a particularly busy holiday season, our usual loading dock was undergoing maintenance. We had to unload a shipment of oversized furniture from a narrow alleyway with limited access. This presented several immediate challenges: maneuvering large pieces in a confined space, preventing damage to the furniture, and maintaining worker safety.

To overcome this, we utilized a teamwork approach. We assigned specific roles: one person guided the furniture, another positioned it for safe handling, and another directed traffic. We communicated constantly and adjusted our plans as needed, carefully measuring each move. We also used specialized equipment, including a smaller forklift better suited for the space, and took extra safety precautions, such as extra spotters. By adapting our strategy and working collaboratively, we successfully unloaded the shipment without incident and met our tight deadlines.

Q 10. How do you maintain a safe work environment when handling heavy objects?

Maintaining a safe work environment when handling heavy objects is paramount and requires adherence to several key principles. It starts with proper training on lifting techniques (always lift with your legs, keeping your back straight), the use of appropriate personal protective equipment (PPE) like safety shoes and gloves, and understanding the weight limits of equipment like forklifts and pallet jacks.

We also need to be mindful of the work area itself. We must ensure the floor is clear of obstacles, well-lit, and that there’s enough space for maneuverability. Additionally, we should always use lifting aids whenever possible, such as dollies or hand trucks, especially for items exceeding a certain weight. Regular safety meetings reinforcing these principles are vital.

- Proper lifting techniques

- Use of PPE

- Understanding weight limits

- Clear and safe work areas

- Utilization of lifting aids

- Regular safety meetings

Q 11. What is your understanding of weight limits and load capacity?

Understanding weight limits and load capacity is crucial for preventing accidents and damage. Weight limits refer to the maximum weight an individual can safely lift, which varies depending on factors such as the individual’s strength and the object’s size and shape. Load capacity refers to the maximum weight a piece of equipment (like a forklift or pallet jack) or a structure (like a shelf or rack) can safely support. Exceeding these limits can lead to serious injuries or equipment failure.

For instance, a forklift will have a clearly stated weight capacity plate. It’s essential to check this plate before loading any items and never exceed the listed limit. Similarly, if an item exceeds my personal weight limit, I’ll request assistance from a colleague or utilize the appropriate equipment.

Q 12. How do you identify potential hazards when unloading and stacking?

Identifying potential hazards when unloading and stacking requires a proactive and systematic approach. Before beginning any task, I perform a thorough visual inspection of the area. This includes checking for uneven surfaces, slippery floors, poorly stacked items that could topple, damaged pallets, and obstructions that could impede movement. I also assess the condition of the items themselves, looking for anything that might be unstable or pose a risk.

Beyond the physical environment, I consider potential human factors: are there enough people to safely handle the load? Are there adequate safety measures in place, such as proper lighting and warning signs? Reporting any identified hazards to my supervisor immediately is a non-negotiable part of the process.

Q 13. Explain your experience working in a fast-paced environment.

I thrive in fast-paced environments. My previous role at a large distribution center required me to unload and stack numerous items daily during peak seasons. To manage the pressure, I rely on efficient organization and prioritization skills. I focus on maintaining a steady, consistent pace, and avoid rushing, which can lead to mistakes and accidents. Clear communication with my team, anticipating bottlenecks, and quick problem-solving skills are crucial in a high-volume environment.

For example, during Black Friday, we experienced a significant increase in inbound shipments. I helped establish a system for sorting and prioritizing deliveries according to urgency and size, ensuring quicker processing and minimizing storage congestion. This system helped us maintain our output while upholding safety standards.

Q 14. How do you handle physically demanding tasks throughout the day?

Handling physically demanding tasks throughout the day requires a combination of physical preparedness and smart work strategies. Maintaining good physical condition through regular exercise, proper sleep, and a healthy diet is essential. On the job, I emphasize proper lifting techniques, regular hydration, and taking short breaks to avoid fatigue. I also actively seek help when needed, understanding that asking for assistance is not a sign of weakness but a smart safety precaution. Pacing myself and utilizing available equipment efficiently are key elements in managing physical demands over an entire workday.

I liken it to running a marathon rather than a sprint; maintaining a steady, sustainable pace is more efficient and minimizes the risk of injury compared to periods of intense exertion followed by complete rest.

Q 15. What are your strategies for preventing injuries while performing heavy lifting?

Preventing injuries during heavy lifting is paramount. My strategy centers around three key principles: proper lifting techniques, utilizing assistive devices, and maintaining a safe working environment.

Proper Lifting Technique: This involves assessing the weight, maintaining a stable base, bending at the knees, keeping the load close to the body, and lifting smoothly, avoiding sudden jerks. Imagine lifting a heavy box: I’d never try to lift it with my back straight; instead, I’d squat down, get a firm grip, and engage my leg muscles to lift, keeping my back straight.

Assistive Devices: I always prioritize using appropriate equipment like pallet jacks, hand trucks, or forklifts whenever possible, especially for heavier or bulkier items. This significantly reduces strain on my body. For instance, moving a stack of 50lb bags of cement would be done with a hand truck, not by manually carrying each bag.

Safe Work Environment: This includes ensuring the area is clear of obstacles, the floor is level and stable, and adequate lighting is available. A cluttered workspace or uneven ground significantly increases the risk of slips, trips, and falls, leading to injuries. I always make sure the path is clear before beginning any heavy lifting task.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with OSHA regulations regarding material handling?

I’m very familiar with OSHA regulations (Occupational Safety and Health Administration) concerning material handling. My understanding encompasses regulations on personal protective equipment (PPE), safe lifting practices, equipment maintenance, and hazard communication. I am particularly knowledgeable about regulations concerning forklift operation, including certification requirements and safe operating procedures. For example, I know that OSHA mandates regular inspections of forklifts and the use of safety devices such as seatbelts and backup alarms. I always ensure my actions comply with these standards to maintain a safe workplace.

Q 17. Describe your experience with different types of pallets and crates.

My experience includes working with a wide variety of pallets and crates, including standard wooden pallets, plastic pallets, and specialized crates designed for specific goods. I’m familiar with different pallet sizes and configurations, and I understand the importance of inspecting pallets for damage before use to prevent accidents during stacking or transport. I’ve also handled crates of varying materials, from wood and metal to plastic, and know how to identify and handle the specific challenges each material presents—for instance, the need for extra care with fragile crates or the appropriate techniques for securing heavy metal crates.

Q 18. How do you handle inventory discrepancies?

Handling inventory discrepancies requires a methodical approach. First, I verify the discrepancy by conducting a physical count and comparing it with the inventory records. If there’s a difference, I investigate potential causes: errors in data entry, damaged goods, theft, or shipping mistakes. I document my findings meticulously and then initiate corrective actions. This might involve adjusting inventory records, discarding damaged goods, or reporting a theft or loss. Accurate record-keeping and regular inventory audits are essential to minimizing these discrepancies.

Q 19. Explain your understanding of inventory management systems.

I understand inventory management systems as the processes used to track and manage the flow of goods. These systems, often software-based, allow for precise tracking of stock levels, optimizing storage, and minimizing waste. I’m familiar with several systems, ranging from simple spreadsheet-based methods to sophisticated enterprise resource planning (ERP) software. My experience includes using systems that track goods from receiving to shipping, including lot tracking for quality control. A good inventory management system, much like a well-organized pantry, helps you easily find what you need, know what’s running low, and reduce waste. It’s crucial for efficient operations.

Q 20. What is your experience with using hand trucks and dollies?

I’m proficient in using hand trucks and dollies to move heavy objects safely and efficiently. My experience includes selecting the appropriate equipment based on the load’s weight and size, securing the load properly to prevent slippage, and maneuvering the equipment safely through tight spaces. For example, I know to use a two-wheeled hand truck for lighter, more maneuverable loads and a four-wheeled dolly for heavier, bulkier items. Understanding the limitations of each tool and utilizing appropriate safety measures is crucial.

Q 21. Describe your experience using a forklift or other powered equipment.

I possess a valid forklift certification and have extensive experience operating forklifts and other powered material handling equipment, including reach trucks and order pickers. My experience covers pre-operation checks, safe operation procedures, load stability, and load securing techniques. I am acutely aware of the safety regulations associated with operating such equipment and strictly adhere to them. For example, I always perform a pre-shift inspection of the forklift, ensuring brakes, lights, and other safety features are functioning correctly before operating it. Safety is my top priority.

Q 22. How do you effectively communicate with coworkers in a warehouse setting?

Effective communication in a warehouse is crucial for safety and efficiency. I prioritize clear, concise, and direct communication. In a noisy environment, I ensure visual cues like hand signals are used alongside verbal communication, especially when directing machinery or coordinating lifting tasks. For instance, if I’m signaling a coworker to move a pallet, I’ll make eye contact, point to the pallet, and use hand signals to show the direction and speed of movement. I also use radio communication when needed for larger tasks or emergency situations. Regular team briefings help clarify daily tasks and address potential safety concerns proactively.

Furthermore, I actively listen to my colleagues and ensure I understand their instructions before proceeding. This collaborative approach minimizes misunderstandings and prevents accidents. Open communication also allows me to promptly report any potential hazards or equipment malfunctions.

Q 23. How do you maintain accurate records of inventory movements?

Maintaining accurate inventory records is essential for efficient warehouse operations. I typically use a combination of methods. Firstly, a barcode or RFID scanning system ensures quick and precise recording of each item’s movement. I meticulously scan items as they are received, stored, and shipped, ensuring the system reflects the actual physical inventory. Secondly, I use a warehouse management system (WMS) software to generate and track inventory reports, providing a digital audit trail of all inventory movements. This allows for easy identification of discrepancies and assists with stock reconciliation. Regular cross-referencing with physical inventory counts helps validate the accuracy of the system. Any discrepancies are immediately investigated and corrected to maintain data integrity.

Finally, documentation is crucial. I carefully maintain paper trails of manual adjustments or exceptions to the system. This includes documenting any damaged or lost items, along with reasons for discrepancies, creating a clear, transparent record-keeping process. This multi-faceted approach ensures accuracy and transparency in inventory tracking.

Q 24. Describe your experience working with diverse materials and their weight variations.

My experience encompasses handling a wide variety of materials, from lightweight cardboard boxes to heavy machinery parts weighing several hundred pounds. I’m adept at assessing the weight and characteristics of different materials. For example, I know that palletized goods are more stable than loose items and require different handling techniques. Similarly, I understand the fragility of certain goods and adapt my handling procedures to avoid damage. Understanding the different weights is critical in selecting the right equipment, for instance, choosing a forklift for heavier items and hand trucks for lighter materials. The correct technique for lifting is also vital and is adapted to the material’s weight and size.

I’ve worked with materials like timber, steel, electronics, and food products, each requiring specific safety precautions. For instance, sharp edges on steel require extra caution and protective gear, while fragile electronics require gentler handling and padded surfaces. This experience has honed my ability to quickly assess the characteristics of any material and choose the safest and most efficient handling methods.

Q 25. What is your experience with different stacking patterns and their stability?

Different stacking patterns are crucial for stability and maximizing warehouse space. I am familiar with various techniques, including interlock stacking, which creates a stable structure by interlocking units, and tiered stacking, which allows for optimal height utilization. The stability of the stack depends on factors such as the weight distribution, the size and shape of the objects, and the surface on which they are stacked. For instance, fragile items require careful placement and support to prevent damage or collapse. Heavier items should be placed at the bottom for better weight distribution, with lighter items stacked above.

I have experience with various stacking aids, including pallets, racking systems, and specialized containers, optimizing the stability and accessibility of stored items. I understand the importance of ensuring even weight distribution across pallets and avoiding overhangs to prevent instability. Regular inspections of the stacks are essential to identify any potential hazards and address them promptly.

Q 26. How do you prioritize safety over speed while performing heavy object handling?

Safety always comes first. While speed is important, compromising safety for speed is unacceptable. My approach prioritizes risk assessment before any heavy object handling task. This includes checking the weight, dimensions, and condition of the object, as well as the surrounding environment. I ensure I have the right equipment – forklifts, hand trucks, or other lifting aids – and am using appropriate safety gear, including safety shoes, gloves, and back supports. I always lift with my legs, keeping my back straight to minimize strain, and I never attempt to lift anything that exceeds my physical capabilities or safe lifting limits.

I collaborate with my coworkers to safely lift heavy items, using teamwork and proper lifting techniques. Before beginning any lifting activity, I communicate with my colleagues to coordinate our efforts and avoid collisions. Furthermore, regular safety training refreshes my knowledge of best practices and ensures adherence to company safety protocols.

Q 27. Describe a time you had to improvise a solution to a problem related to heavy object handling.

During a particularly busy shipment, a crucial piece of machinery, unusually shaped and exceptionally heavy, arrived without the proper lifting equipment specified on the manifest. The original plan involved a specialized crane, which was unavailable. Instead of delaying the shipment, I assessed the situation. We used a combination of sturdy wooden planks, heavy-duty straps, and a forklift to create a makeshift ramp and sling system to carefully maneuver the object into position. We carefully measured and secured the item to ensure stability during transport. This collaborative problem-solving ensured that the shipment remained on schedule without compromising safety.

This experience highlighted the importance of adaptability and resourcefulness in handling unexpected challenges. It also reinforced the value of teamwork and open communication in overcoming obstacles.

Q 28. How do you keep yourself physically fit for the demands of this job?

Maintaining physical fitness is paramount for this physically demanding job. I incorporate regular exercise into my routine to strengthen my back, legs, and core muscles, crucial for safe lifting. This includes activities such as weight training focusing on compound exercises, regular cardio workouts to improve stamina, and stretching to maintain flexibility and prevent injuries. I pay attention to proper posture both during work and outside of work. Adequate sleep, proper nutrition, and regular hydration are also critical components of my wellness plan. This holistic approach ensures I am physically prepared to handle the job’s demands and minimizes the risk of work-related injuries.

Furthermore, I actively participate in workplace safety programs and training sessions that emphasize proper lifting techniques and injury prevention. This continuous learning ensures I consistently use safe and effective practices.

Key Topics to Learn for Unload and Stack Heavy Objects Interview

- Safe Lifting Techniques: Understanding proper body mechanics, including posture, lifting methods (e.g., using legs, keeping back straight), and avoiding strain. Practical application: Demonstrating knowledge of how to safely lift and move various sizes and weights of objects.

- Load Distribution and Balancing: Understanding how to distribute weight evenly to prevent instability and maximize efficiency. Practical application: Explaining strategies for stacking objects to ensure stability and prevent collapses or damage.

- Equipment Operation and Safety: Familiarity with relevant equipment like forklifts, pallet jacks, and other material handling devices. Understanding safety protocols and regulations related to their operation and maintenance. Practical application: Describing safe operating procedures and identifying potential hazards.

- Inventory Management and Organization: Understanding efficient methods for unloading, sorting, and stacking objects according to organizational systems. Practical application: Describing strategies for optimizing warehouse space and workflow.

- Workplace Safety Regulations and Procedures: Knowledge of OSHA guidelines (or relevant regional regulations) regarding heavy object handling, including personal protective equipment (PPE) and accident prevention. Practical application: Explaining how to follow safety regulations to minimize risks and ensure a safe work environment.

- Problem-Solving and Adaptability: Ability to quickly assess situations and adapt strategies when faced with unexpected challenges (e.g., damaged packaging, unusual object shapes, space constraints). Practical application: Describing how to handle unforeseen difficulties efficiently and safely.

Next Steps

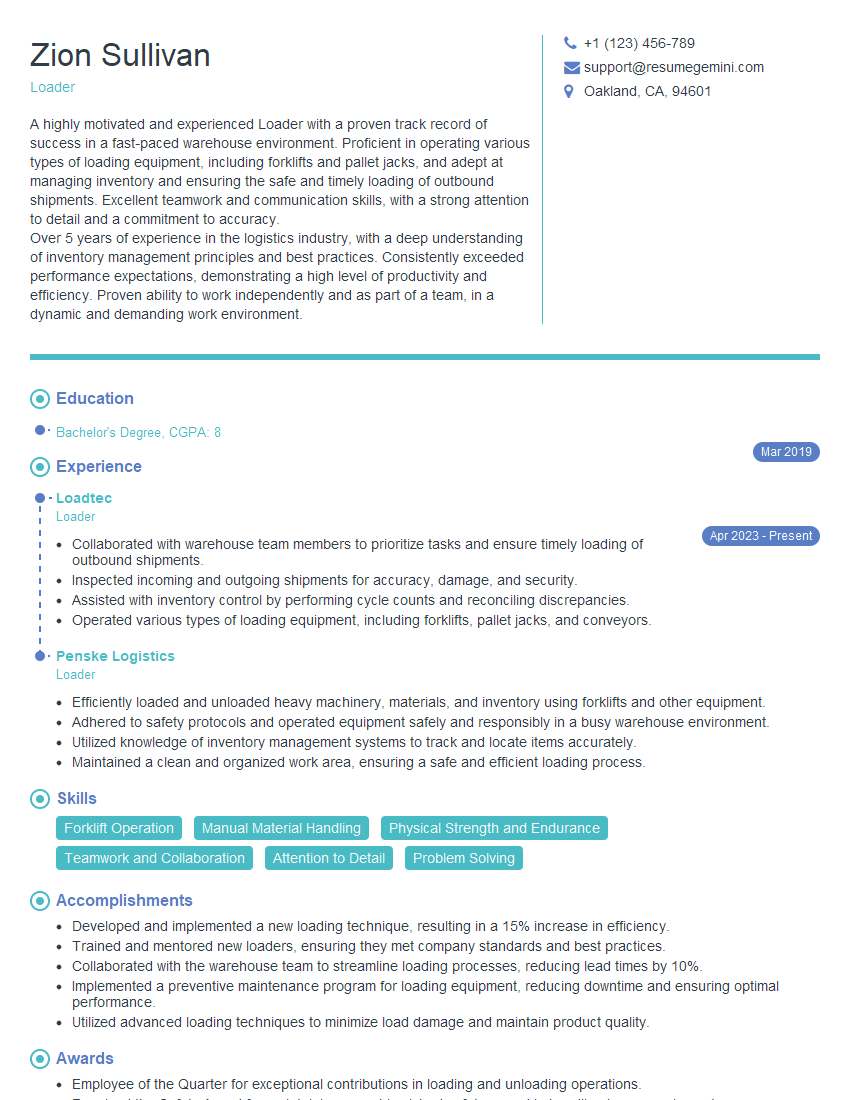

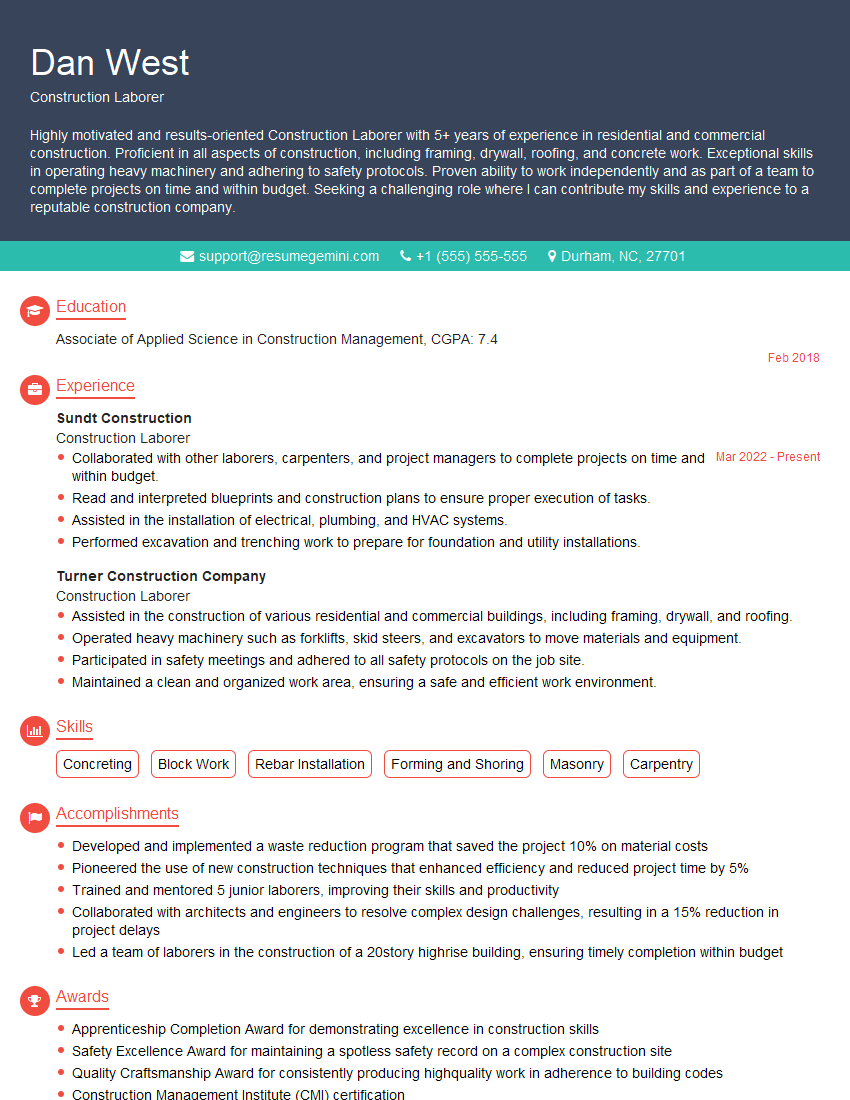

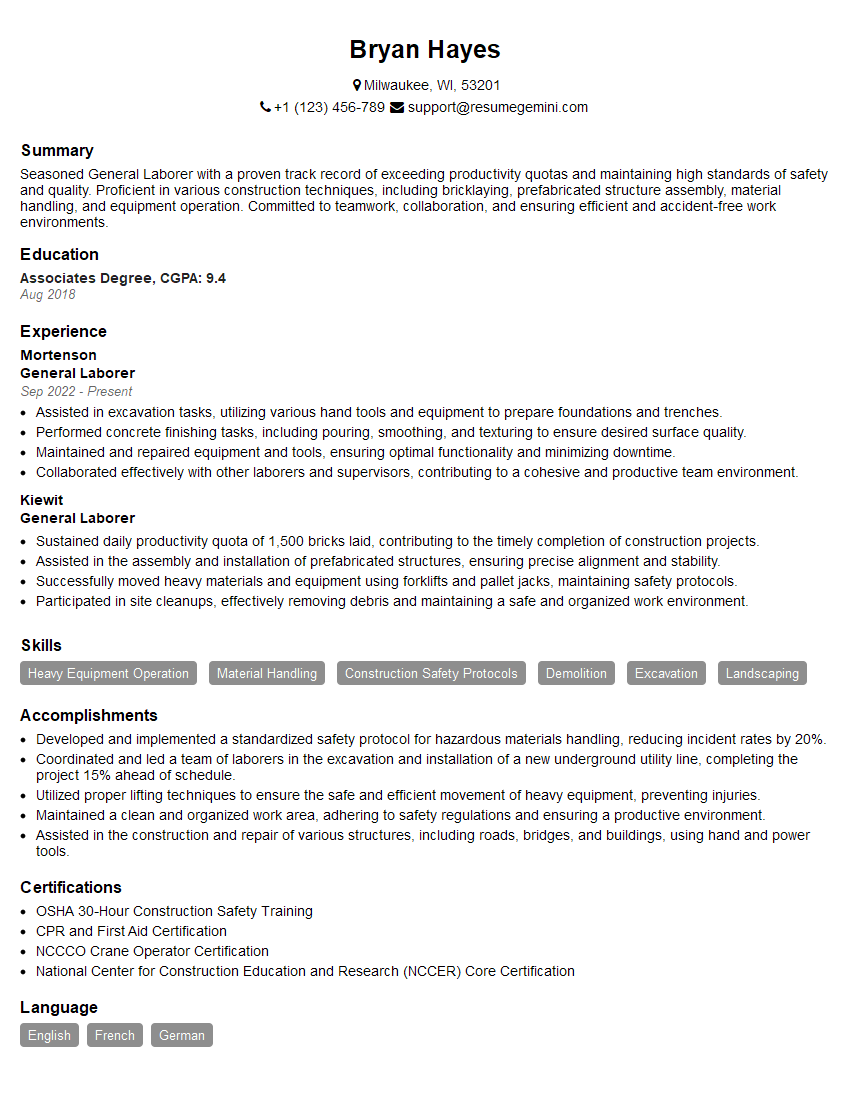

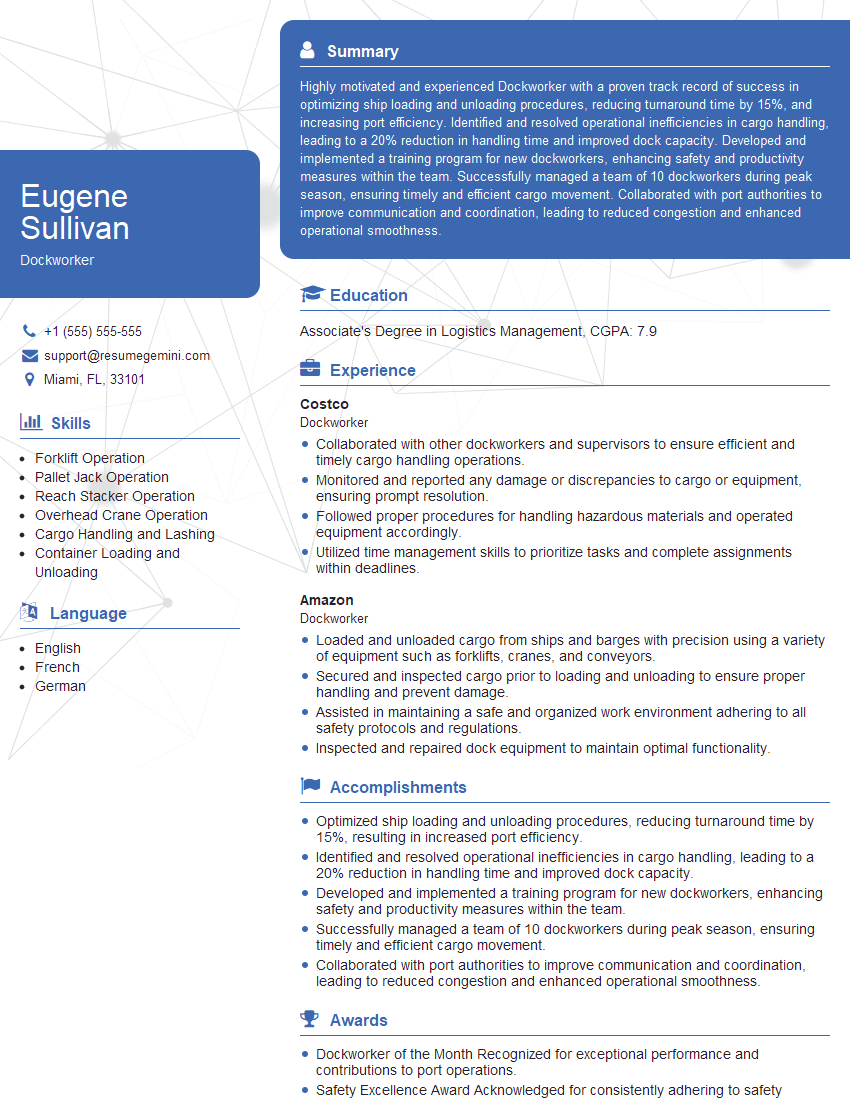

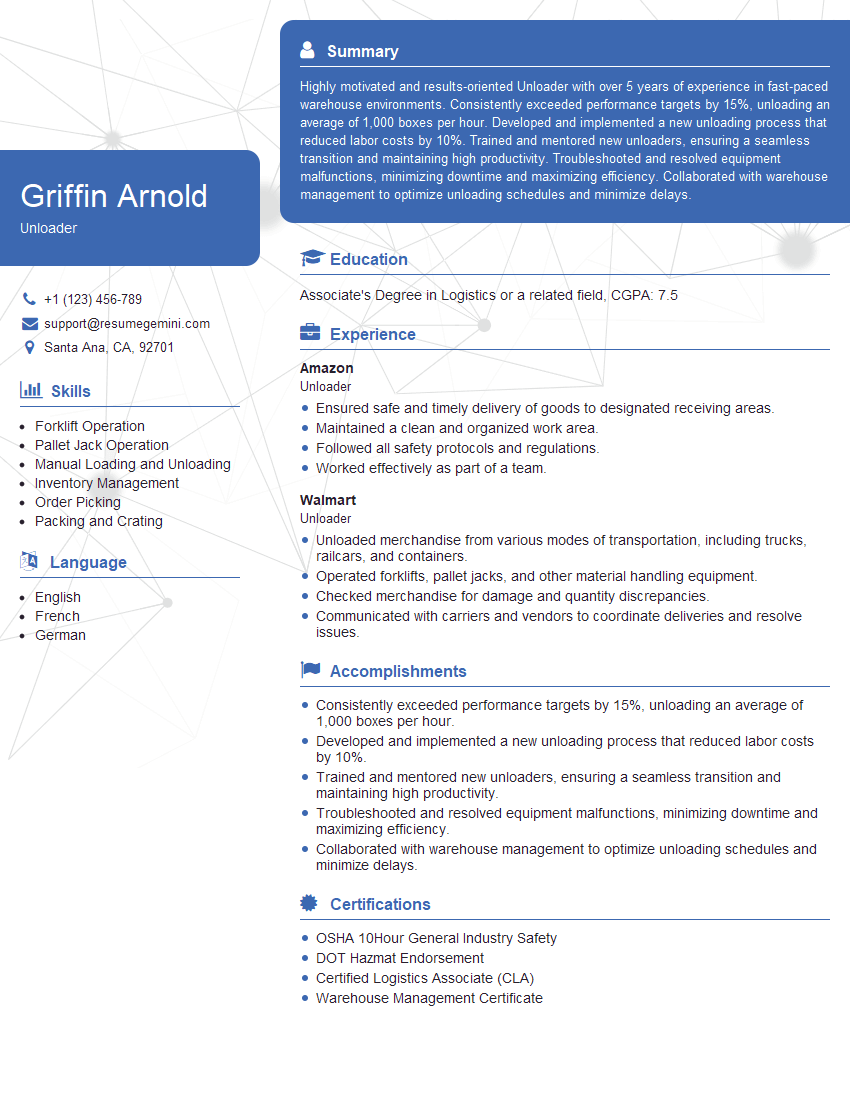

Mastering the skills related to unloading and stacking heavy objects is crucial for career advancement in logistics, warehousing, and numerous other physically demanding industries. These skills demonstrate your commitment to safety, efficiency, and a strong work ethic – all highly valued by employers. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and effective resume, maximizing your chances of landing your dream job. Examples of resumes tailored to highlight experience in unloading and stacking heavy objects are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO