Unlock your full potential by mastering the most common Troubleshooting and Equipment Repair interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Troubleshooting and Equipment Repair Interview

Q 1. Describe your experience diagnosing and repairing faulty equipment.

Diagnosing and repairing faulty equipment involves a systematic approach combining technical expertise with problem-solving skills. It starts with understanding the equipment’s function and identifying the symptoms of the malfunction. This often involves observing the equipment in operation, listening for unusual noises, checking for visual damage, and reviewing any error messages displayed. Then, using specialized tools and diagnostic software (which I’ll detail later), I isolate the faulty component, assess the extent of the damage, and determine the most effective repair strategy. This may involve replacing a faulty part, repairing a circuit board, or recalibrating sensors. Throughout the process, meticulous documentation is crucial, ensuring accurate record-keeping and facilitating future troubleshooting.

For example, I once diagnosed a malfunctioning industrial printer that wasn’t feeding paper correctly. By systematically checking each component – sensors, rollers, and the paper path itself – I identified a worn roller causing friction and jamming. Replacing the roller restored the printer’s functionality.

Q 2. Explain your troubleshooting methodology.

My troubleshooting methodology follows a structured approach, often described as a ‘five-why’ analysis combined with a process of elimination. First, I clearly define the problem: what exactly is malfunctioning and what are the observable symptoms? Next, I gather information, including any error codes, operational logs, or user reports. Then, I formulate hypotheses about the potential causes, prioritizing those most likely based on my experience and the available data. I test each hypothesis systematically, ruling out possibilities until the root cause is identified. This process often involves using specialized tools to check voltage, current, signal integrity, and component functionality. Finally, I implement the solution, thoroughly test the repair, and document the entire process.

Imagine a computer that won’t boot. My methodology would involve first checking power supply, then RAM, then the hard drive, and finally the motherboard – eliminating potential causes one by one until the source of the problem is identified. This approach ensures efficient and effective repair, minimizing downtime.

Q 3. How do you prioritize multiple equipment repair requests?

Prioritizing multiple repair requests requires a balanced approach considering urgency, impact, and available resources. I use a system that combines urgency levels (critical, high, medium, low) with an assessment of the potential impact of the equipment failure on operations. Critical failures (e.g., a production line shutdown) take immediate precedence. High-impact failures affecting multiple users or key processes are next. I also consider the complexity of the repair, the availability of parts, and the skill set required to complete the task. This allows for efficient allocation of my time and resources, ensuring timely resolution of the most pressing issues.

A simple analogy is a triage system in a hospital; life-threatening emergencies are handled first, followed by urgent cases, and then less urgent ones. This ensures the most critical issues are addressed promptly.

Q 4. What safety precautions do you follow while repairing equipment?

Safety is paramount in equipment repair. I always adhere to strict safety protocols, beginning with a thorough risk assessment before commencing any repair. This involves identifying potential hazards, such as electrical shock, burns, or exposure to hazardous materials. I use appropriate personal protective equipment (PPE), including safety glasses, gloves, and insulated tools. I ensure the equipment is properly grounded and disconnected from power sources before commencing work. I also follow lockout/tagout procedures to prevent accidental energization. I am always aware of my surroundings and maintain a clean and organized workspace to minimize the risk of accidents.

For instance, when working with high-voltage equipment, I wear insulated gloves and use specialized tools designed for high-voltage work. Always, safety is my top priority.

Q 5. How do you document your repair procedures?

Thorough documentation is essential for effective equipment repair and maintenance. I maintain detailed records of all repairs, including the date, time, equipment ID, problem description, troubleshooting steps, parts used, and the final solution. I use a combination of digital and physical documentation. Digital records often include photos and videos to capture visual details, while physical records, such as work orders, provide a tangible audit trail. This documentation serves multiple purposes; it aids in future troubleshooting, facilitates warranty claims, and provides valuable data for preventative maintenance programs. Standardized reporting formats ensure consistency and ease of access.

For example, I’d create a detailed report for each repair detailing the fault, the steps undertaken, the components used and their part numbers and the final operational status.

Q 6. Describe a time you had to troubleshoot a complex equipment failure.

One particularly challenging case involved a complex robotic arm used in a precision manufacturing process. The arm experienced intermittent malfunctions, exhibiting erratic movements and occasionally shutting down completely. Initial diagnostics yielded no obvious faults. I systematically checked the power supply, motor controllers, sensors, and the communication network, employing specialized diagnostic software and multimeters. The problem turned out to be a subtle issue in the feedback loop of one of the motors – a tiny component causing fluctuating signals, resulting in the erratic behavior. Replacing that specific component resolved the issue. This highlighted the importance of meticulous investigation even when obvious faults are absent and the use of the right diagnostic tools.

This case demonstrated the importance of a systematic approach and not jumping to conclusions. Each component needed thorough inspection.

Q 7. What software or tools do you use for diagnostics?

The software and tools I use for diagnostics vary depending on the type of equipment. For electrical systems, I utilize multimeters to measure voltage, current, and resistance. Oscilloscopes are invaluable for analyzing signal waveforms and identifying subtle timing issues. For programmable logic controllers (PLCs), I use dedicated programming software to monitor operational parameters and diagnose errors in the control logic. Specialized diagnostic software provided by the equipment manufacturers also plays a significant role, providing access to error logs and enabling more in-depth analysis. In some cases, thermal imaging cameras are useful for detecting overheating components. The selection of tools is always tailored to the specific equipment and the nature of the problem.

Example: Using a multimeter to check for continuity in a circuit.

Q 8. How do you handle situations where you can’t immediately identify the problem?

When faced with an unfamiliar problem, my systematic approach ensures efficient troubleshooting. I begin by gathering all available information: observing the equipment’s behavior, reviewing error messages, and consulting any relevant documentation. This initial assessment helps me narrow down potential causes.

Next, I employ a process of elimination. I start with the most likely causes based on my experience and the information gathered. For example, if a computer is not booting, I’d first check the power supply, then the RAM, then the hard drive, etc. Each step is meticulously documented. If the issue remains unresolved, I escalate to more advanced diagnostics, possibly using specialized testing equipment. This could involve checking signal levels, component voltages, or using diagnostic software. I might also consult online resources, technical manuals, or seek advice from colleagues with expertise in a specific area if my initial troubleshooting fails to pinpoint the root cause.

For instance, I once encountered a malfunctioning industrial robotic arm. Initial checks revealed no obvious problems. By meticulously analyzing the robot’s control system logs, I discovered a minor software glitch causing intermittent signal disruptions, which led to the erratic arm movement. This highlights the importance of detailed documentation and a methodical approach, even when the issue isn’t immediately apparent.

Q 9. How do you stay up-to-date with the latest technologies and repair techniques?

Staying current in this rapidly evolving field requires a multifaceted approach. I actively participate in professional development opportunities like workshops, conferences, and online courses offered by manufacturers and industry associations. This allows me to learn about the newest tools, techniques and best practices.

I also subscribe to relevant industry publications and journals, keeping me abreast of advancements and emerging technologies. Additionally, I regularly engage with online communities and forums where technicians share experiences, troubleshooting tips, and new repair methods. Participating in these discussions broadens my knowledge base and exposes me to diverse perspectives on problem-solving.

Furthermore, I maintain a network of colleagues in the field. Regular interaction with peers through informal discussions or formal meetings helps me learn from their successes and challenges, accelerating my professional growth and knowledge of new technologies.

Q 10. What is your experience with preventative maintenance?

Preventative maintenance is crucial for maximizing equipment lifespan and minimizing downtime. My experience encompasses a wide range of preventative maintenance activities, from routine inspections and cleaning to more complex tasks like lubrication, calibration, and component replacements.

I’m proficient in developing and implementing preventative maintenance schedules based on manufacturer recommendations and equipment usage patterns. These schedules usually include regular inspections for wear and tear, checking for loose connections or corrosion, and testing critical components to ensure they are operating within their specified tolerances. For example, in a manufacturing environment, this might involve regular lubrication of moving parts on machinery, cleaning cooling systems, and checking the calibration of precision instruments to prevent costly errors.

The implementation of preventative maintenance programs directly translates to reduced repair costs, increased equipment reliability, and enhanced operational efficiency. I’ve consistently demonstrated the ability to create and oversee these programs, resulting in significant improvements in the uptime and performance of equipment in my previous roles.

Q 11. How do you communicate technical information to non-technical personnel?

Effective communication is paramount, especially when explaining technical issues to non-technical audiences. My approach focuses on clarity, simplicity, and the use of visual aids.

I avoid technical jargon and instead use analogies and plain language to convey complex concepts. For instance, explaining the function of a circuit breaker using the analogy of a fuse in a household setting is much more effective than using technical terms like ‘overcurrent protection device’. I also use diagrams, flowcharts, and photographs to illustrate technical points and make them more easily understandable.

Active listening is also key. I ensure I understand the client’s concerns before offering solutions. By asking clarifying questions and tailoring my responses to their level of understanding, I make sure the information is received and acted upon effectively. For instance, if a client is concerned about a power outage, I might explain the cause using a simple diagram showing the power flow and the point of failure, avoiding technical details about voltage regulators or transformers.

Q 12. Describe your experience with calibration and testing equipment.

Calibration and testing equipment are integral parts of my troubleshooting process. I’m experienced in using a variety of instruments, including multimeters, oscilloscopes, signal generators, and specialized diagnostic tools.

My experience extends beyond simply using the equipment; I also understand the importance of proper calibration procedures and maintaining accurate calibration records. Incorrect calibration can lead to misdiagnosis and ultimately, more costly repairs. I adhere strictly to calibration schedules and procedures to ensure the accuracy and reliability of my measurements.

For example, when working with precision electronic devices, I would use a calibrated oscilloscope to examine waveforms and identify anomalies. Similarly, when troubleshooting a temperature control system, I’d use a calibrated thermometer to ensure the system is operating within its acceptable range. Accurate calibration is critical for reliable troubleshooting and repair.

Q 13. What is your experience with electrical safety and procedures?

Electrical safety is my top priority. I am thoroughly familiar with all relevant safety standards and procedures, including lockout/tagout procedures, and the proper use of personal protective equipment (PPE) such as insulated tools and safety glasses.

Before commencing any work on electrical equipment, I always conduct a thorough risk assessment to identify potential hazards. I never work on live circuits without taking appropriate safety precautions. Lockout/tagout procedures are strictly followed to prevent accidental energization during repairs. I am also trained in CPR and first aid, prepared to handle any unforeseen emergencies.

My experience includes working with high-voltage systems and intricate electrical control panels, always prioritizing safety. For instance, before working on a large industrial motor, I would meticulously follow lockout/tagout procedures, ensuring the power is completely isolated and the equipment is safe to work on.

Q 14. How do you handle difficult or demanding clients?

Handling demanding clients requires patience, empathy, and clear communication. I begin by actively listening to their concerns, acknowledging their frustration, and assuring them that I will do my best to resolve the issue.

Maintaining a calm and professional demeanor is essential, even in stressful situations. I explain the troubleshooting process in a transparent manner, keeping them informed of my progress and any potential delays. Providing realistic expectations helps manage their anxieties. If I encounter challenges, I will explain the complexities of the situation without using technical jargon and offer alternative solutions or strategies.

For example, if a client is upset about prolonged downtime, I explain the necessary steps and the time it will take to resolve the issue. I offer regular updates and clearly communicate any unforeseen obstacles. By demonstrating a commitment to finding a solution and maintaining open communication, I can diffuse even the most challenging situations and build trust with the client.

Q 15. Explain your understanding of schematic diagrams and technical manuals.

Schematic diagrams and technical manuals are indispensable tools for troubleshooting and repair. Think of a schematic diagram as a blueprint of a system, showing the interconnection of all its components using standardized symbols. It’s like a map that guides you through the system’s inner workings, highlighting the flow of electricity, signals, or fluids. Technical manuals, on the other hand, provide detailed instructions, specifications, and troubleshooting guides specific to a particular piece of equipment. They’re like the instruction booklet that explains how everything works and what to do if something goes wrong.

For example, when repairing a faulty circuit board, the schematic diagram helps identify the specific component causing the problem by showing its connection to other parts. The technical manual might then provide details on the component’s specifications, replacement procedures, and safety precautions. Without these, troubleshooting would be akin to navigating a maze blindfolded.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of electronic components?

My experience encompasses a wide range of electronic components, from the simplest resistors and capacitors to complex integrated circuits (ICs) and microprocessors. I’m proficient in identifying, testing, and replacing components like transistors, diodes, relays, op-amps, and various types of memory chips. I’m also familiar with surface-mount technology (SMT) components and the specialized equipment required for their handling and soldering. For instance, I’ve worked extensively with repairing motherboards, where identifying a faulty capacitor amongst hundreds on a densely packed board requires meticulous attention to detail and experience.

Beyond passive and active components, I possess a strong understanding of various power supply architectures, including linear and switching regulators, and have experience troubleshooting issues related to power delivery and voltage regulation. Understanding these components is key to effective repair across multiple devices and systems.

Q 17. How do you troubleshoot network connectivity issues?

Troubleshooting network connectivity issues involves a systematic approach. I start by identifying the affected devices and the symptoms – is it a complete loss of connection, slow speeds, or intermittent connectivity? Then, I follow a structured process of elimination.

- Check the physical connections: Ensure cables are securely connected to both the device and the network infrastructure (router, modem, switch).

- Verify network settings: Confirm that IP addresses, subnet masks, and default gateways are correctly configured on the affected device.

- Test network hardware: Use tools like ping, tracert (traceroute), and ipconfig to identify any bottlenecks or connectivity problems within the network.

- Examine the router and modem: Check for error messages, reboot the devices if necessary, and verify that they are functioning correctly.

- Consult network documentation: Refer to the network configuration diagrams and manuals for any specific troubleshooting steps or known issues.

For example, if a computer can’t access the internet but can ping the router, the problem likely lies with the router’s internet connection or the ISP’s service. If it can’t ping the router, the problem is either the computer’s network configuration or the network cabling.

Q 18. What is your experience with hydraulic or pneumatic systems?

I have extensive experience working with both hydraulic and pneumatic systems. My experience includes troubleshooting leaks, diagnosing malfunctions in pumps, valves, and actuators, and performing preventative maintenance. Understanding fluid power systems requires a strong grasp of pressure, flow, and the properties of different fluids. I’m familiar with various components including hydraulic pumps (gear, piston, vane), directional control valves, pressure relief valves, and hydraulic cylinders.

For example, I once diagnosed a problem in a manufacturing plant where a hydraulic press was failing to reach its full operating pressure. Through a systematic approach, I identified a faulty pressure relief valve which, when replaced, restored the press to full functionality. Similarly, in pneumatic systems, I’ve worked on diagnosing leaks using specialized leak detection equipment and repairing damaged pneumatic cylinders and valves.

Q 19. Describe your experience working with various hand tools and power tools.

My experience with hand and power tools is comprehensive. I’m proficient in using a wide variety of hand tools, including screwdrivers (various types and sizes), wrenches, pliers, sockets, hammers, and measuring instruments (calipers, micrometers, etc.). I’m also experienced in using power tools, such as drills, saws (circular, jigsaw, reciprocating), grinders, and impact wrenches. Safety is paramount, and I always adhere to all safety regulations when using any tool.

I’m familiar with various techniques like proper drilling practices to avoid damaging surfaces, using appropriate cutting tools for different materials, and understanding the limitations of each tool. For example, selecting the correct drill bit for the material being drilled ensures a clean and accurate hole, preventing damage to the workpiece and ensuring the longevity of the bit itself. This attention to detail contributes greatly to the quality and efficiency of repairs.

Q 20. What is your understanding of different types of sensors and actuators?

Sensors and actuators are fundamental components in many systems. Sensors convert physical quantities (like temperature, pressure, or position) into electrical signals, while actuators convert electrical signals into mechanical movement or other forms of energy. I understand various types of sensors, including temperature sensors (thermocouples, RTDs, thermistors), pressure sensors, proximity sensors, optical sensors, and accelerometers.

Similarly, I’m familiar with different actuators such as pneumatic cylinders, hydraulic cylinders, electric motors, solenoids, and servo motors. Understanding the operating principles, limitations, and interfaces of these components is crucial for effective troubleshooting and repair. For instance, a malfunctioning temperature sensor in a heating system could lead to incorrect temperature readings and inefficient heating, necessitating sensor replacement or calibration.

Q 21. How do you manage your time effectively when working on multiple repairs?

Managing time effectively when working on multiple repairs requires a structured approach. I typically use a combination of techniques:

- Prioritization: I prioritize repairs based on urgency and impact, focusing on the most critical issues first.

- Task Breakdown: I break down complex repairs into smaller, manageable tasks to avoid feeling overwhelmed.

- Time Estimation: I estimate the time required for each task and allocate time slots accordingly.

- Scheduling: I create a schedule or to-do list to ensure that I stay on track and meet deadlines.

- Multitasking (Strategic): I strategically switch between tasks to maintain momentum, but avoid spreading myself too thin, focusing on completion of a singular task before moving onto another. This minimizes context switching overhead.

For example, if I have multiple repairs requiring similar parts, I might order the parts in bulk to save time. By prioritizing and planning my work, I can efficiently handle multiple tasks without sacrificing quality or exceeding deadlines. This organized approach is vital to ensuring client satisfaction and maintaining a reputation for reliability.

Q 22. What is your experience with soldering and desoldering techniques?

Soldering and desoldering are fundamental skills in equipment repair. Soldering involves melting solder to create a permanent electrical connection between two or more components, while desoldering is the reverse process, removing existing solder connections. My experience spans over [Number] years, encompassing various soldering techniques like through-hole soldering, surface mount technology (SMT) soldering, and rework using specialized tools like hot air stations and vacuum desoldering tools. I’m proficient in using different types of solder, including lead-free solder, and I understand the importance of proper flux application to ensure clean and reliable joints. For example, I’ve successfully repaired complex circuit boards with densely packed components, requiring precision and patience to avoid damage to surrounding parts. I also regularly use specialized tools like magnification equipment and anti-static mats to maintain high quality of the work.

I am also experienced in identifying and fixing bad solder joints which include cold solder joints, bridging and cracked solder pads, using appropriate methods to repair them.

My approach always prioritizes safety, using proper ventilation and personal protective equipment (PPE) like safety glasses and gloves to prevent injuries.

Q 23. How do you maintain a clean and organized workspace?

Maintaining a clean and organized workspace is paramount for efficient and safe repair work. Think of it like a surgeon’s operating room – everything needs to be in its place and meticulously clean. My workspace is organized using a 5S methodology: Seiri (Sort), Seiton (Set in Order), Seisō (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). This means regularly sorting through tools and parts, storing them logically, cleaning the work area frequently, establishing standardized procedures, and maintaining these habits consistently. I use designated containers for screws, components, and waste materials, preventing cross-contamination and accidental damage. Tools are carefully stored after each use to avoid loss and maintain their longevity. This approach minimizes errors, improves efficiency, and promotes a safe work environment. For instance, during the repair of a large industrial machine, I needed to quickly locate a specific size of bolt. Because of my organized system, I found it immediately, minimizing the downtime of the equipment.

Q 24. Explain your knowledge of different types of motors and drives.

My knowledge of motors and drives encompasses various types, including AC induction motors, DC motors (brushless and brushed), stepper motors, and servo motors. I understand the differences in their operating principles, control methods, and applications. For example, AC induction motors are widely used in industrial settings due to their robustness and simplicity, while servo motors provide precise control in applications like robotics. I also have experience working with different types of motor drives, including Variable Frequency Drives (VFDs), which allow for speed and torque control. I can troubleshoot issues related to motor winding failures, bearing wear, and control circuitry problems. I am able to accurately diagnose problems in a variety of motor-driven systems, quickly identifying the root cause of problems like improper voltage or faulty sensors.

Understanding the characteristics of each type is crucial for effective troubleshooting. For instance, a noisy AC motor might indicate bearing wear, while inconsistent speed in a servo motor might point to a faulty encoder.

Q 25. Describe your experience with PLC programming and troubleshooting.

I possess extensive experience with PLC (Programmable Logic Controller) programming and troubleshooting, primarily using [Mention Specific PLC Brands, e.g., Allen-Bradley, Siemens]. My skills include ladder logic programming, designing control systems, and utilizing HMI (Human Machine Interface) software for monitoring and control. I’m proficient in troubleshooting PLC programs, identifying and resolving issues using diagnostic tools and techniques. I’ve worked on numerous projects involving PLC implementation in automation systems across various industries, from manufacturing to process control. For example, I recently debugged a PLC program causing a production line bottleneck by systematically analyzing the ladder logic, identifying a timing error, and implementing a correction.

I am also proficient at reading and interpreting PLC program documentation, and using a variety of diagnostic tools such as hand-held programmers, software simulators, and online monitoring tools.

Q 26. What is your experience with using diagnostic software and tools?

I regularly use various diagnostic software and tools, including oscilloscopes, multimeters, logic analyzers, and specialized software for specific equipment. For example, I use oscilloscopes to analyze waveforms to identify signal integrity issues, multimeters to measure voltage, current, and resistance, and logic analyzers to capture digital signals for debugging. My experience includes using manufacturer-specific diagnostic software for various industrial control systems and equipment. I also utilize software tools for network troubleshooting, such as ping and traceroute, to identify network connectivity problems. I find that combining hardware and software diagnostics is often the most effective approach. For instance, when troubleshooting a faulty industrial motor controller, I would use an oscilloscope to verify the correct voltage and frequency, then use the controller’s diagnostic software to check internal parameters and error logs.

Q 27. How do you ensure the quality of your repairs?

Ensuring the quality of my repairs is a top priority. My approach is based on a combination of meticulous work, thorough testing, and preventative measures. Before beginning a repair, I perform a comprehensive assessment of the problem to understand its root cause. During the repair process, I use clean, organized techniques, employing best practices for soldering, component handling, and cable management. After completing the repair, I conduct rigorous testing to verify its functionality and ensure that the repaired equipment operates within its specifications. This involves running various tests, comparing results to expected values, and often performing load testing to ensure the equipment operates as expected under realistic conditions. If any issues arise during testing, I immediately troubleshoot and make necessary adjustments. Documentation is also crucial; I maintain clear records of the repair process, including parts used, tests performed, and observations.

Q 28. Describe a time you had to work under pressure to meet a deadline.

During my time at [Previous Company Name], we experienced a critical failure in a major production line just before a large shipment deadline. The equipment, a highly automated packaging machine, stopped working completely. The pressure was immense, as the delay could have significant financial consequences. I immediately assembled a team and systematically worked through the troubleshooting process. Using my expertise in PLC programming and electrical systems, I quickly isolated the problem to a faulty sensor. However, a replacement was not readily available. Working under pressure and with limited resources, I devised a temporary workaround by reconfiguring the PLC program and utilizing a redundant sensor. This enabled us to resume production within a few hours. We managed to meet the deadline, avoiding significant losses and demonstrating the value of quick thinking and collaborative problem-solving under pressure. The experience underscored the importance of having contingency plans and a thorough understanding of the systems I work on.

Key Topics to Learn for Troubleshooting and Equipment Repair Interview

- Safety Procedures and Regulations: Understanding and adhering to safety protocols in various work environments, including lockout/tagout procedures and proper use of personal protective equipment (PPE).

- Diagnostic Techniques: Mastering systematic troubleshooting methodologies, including visual inspection, using diagnostic tools (multimeters, oscilloscopes), and interpreting error codes and logs.

- Electrical and Electronic Systems: Solid understanding of basic electrical principles (Ohm’s Law, circuits, etc.) and their application in diagnosing and repairing electronic components and systems.

- Mechanical Systems: Knowledge of mechanical principles (gears, levers, hydraulics, pneumatics) and their application in identifying and resolving mechanical issues in equipment.

- Preventive Maintenance: Understanding the importance of regular maintenance schedules, including lubrication, cleaning, and inspections, to prevent equipment failures and extend lifespan.

- Repair and Replacement Techniques: Proficiency in soldering, wiring, component replacement, and using specialized tools for specific equipment repairs.

- Documentation and Reporting: Accurate record-keeping of repairs, maintenance performed, and any relevant observations, ensuring clear and concise reporting.

- Problem-Solving and Analytical Skills: Demonstrating a structured approach to troubleshooting, identifying root causes, and implementing effective solutions. This includes understanding and applying different problem-solving methodologies.

- Specific Equipment Knowledge: Depending on the job, thorough understanding of the specific types of equipment you’ll be working with (e.g., HVAC systems, industrial machinery, medical devices).

Next Steps

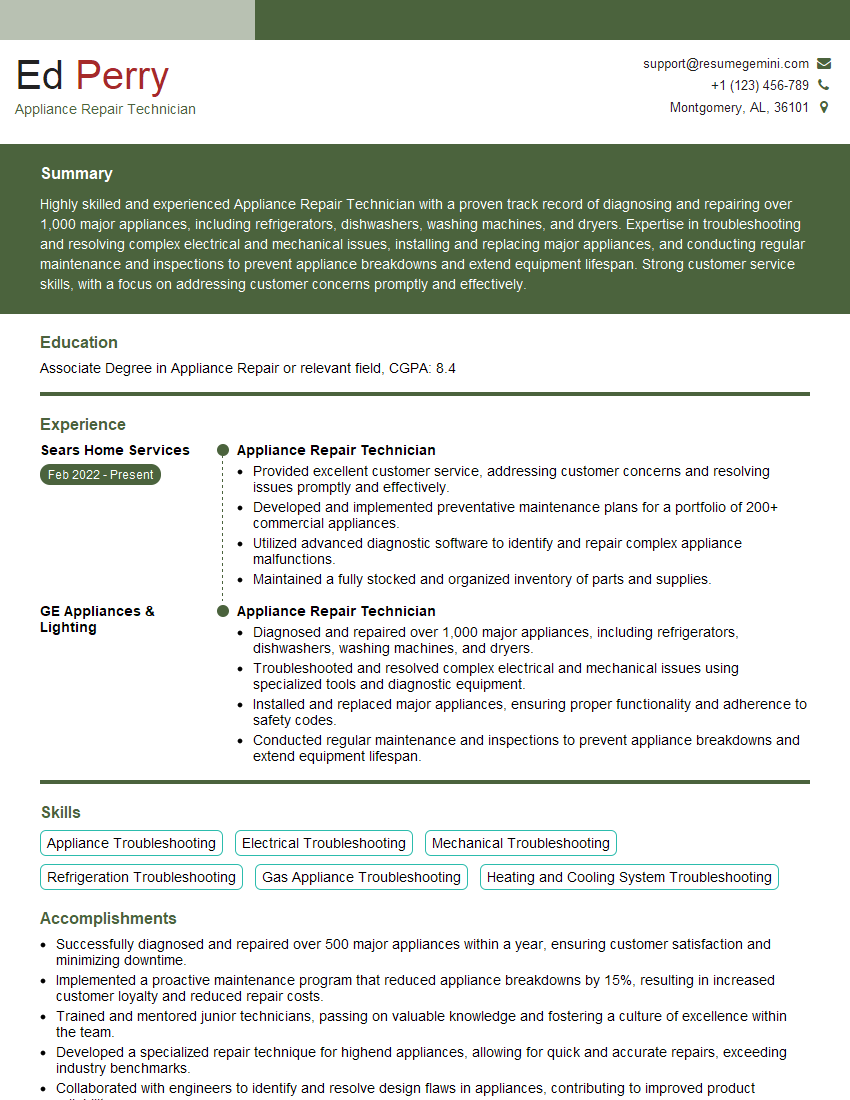

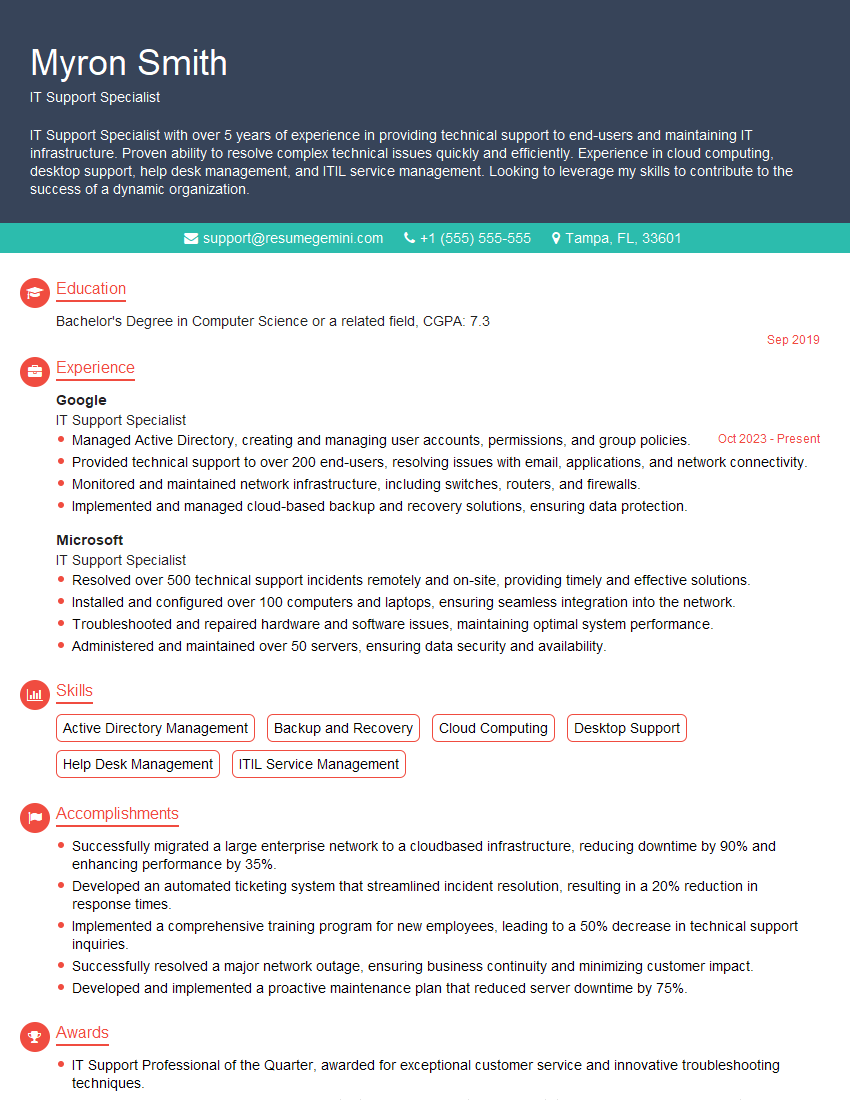

Mastering Troubleshooting and Equipment Repair is crucial for a successful and rewarding career, opening doors to diverse opportunities and increasing your earning potential. A strong resume is your first step to showcasing these valuable skills to potential employers. Creating an ATS-friendly resume is essential to ensure your application gets noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise. Examples of resumes tailored to Troubleshooting and Equipment Repair are available to help guide you. Invest time in crafting a compelling resume – it’s your key to unlocking exciting career prospects.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO