Unlock your full potential by mastering the most common Steel Structural Design interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Steel Structural Design Interview

Q 1. Explain the different types of steel used in structural design.

Steel used in structural design is categorized based on its mechanical properties and chemical composition. The most common types include:

- Mild Steel (A36): This is a versatile, cost-effective steel with moderate strength, widely used in various structural applications. Think of it as the ‘workhorse’ of steel construction.

- High-Strength Low-Alloy (HSLA) Steels: These steels offer improved strength and weldability compared to mild steel, allowing for lighter and more efficient structures. They often require more specialized welding procedures.

- Weathering Steel (Corten Steel): This steel forms a protective layer of rust that inhibits further corrosion, reducing maintenance needs. You often see it in bridges and outdoor sculptures, where its characteristic rusty appearance is embraced.

- Stainless Steel: Known for its corrosion resistance, stainless steel is used in demanding environments, such as coastal structures or chemical plants, where corrosion is a major concern. Its cost is significantly higher than other steel types.

The choice of steel depends on factors such as the structural requirements, environmental conditions, cost constraints, and fabrication methods. For example, in a high-rise building, HSLA steels might be preferred for their strength-to-weight ratio, while weathering steel could be used for exposed elements to minimize maintenance.

Q 2. Describe the process of designing a steel beam for bending.

Designing a steel beam for bending involves several steps:

- Determine Loads: First, calculate all loads acting on the beam, including dead loads (weight of the beam and other permanent elements), live loads (occupancy, equipment, snow), and any other relevant loads.

- Select Steel Grade: Choose an appropriate steel grade based on strength, weldability, and cost considerations.

- Calculate Bending Moments: Determine the maximum bending moment using appropriate structural analysis techniques (e.g., statics, moment distribution, or finite element analysis).

- Section Modulus Determination: Use the bending moment and allowable bending stress (from the steel grade) to calculate the required section modulus (S). The section modulus is a geometric property of the beam’s cross-section.

- Select a Section: Select a standard steel section (e.g., I-beam, W-shape) from a steel manual that meets or exceeds the required section modulus.

- Check Deflection: Ensure the deflection under load remains within acceptable limits based on building codes and serviceability requirements. Excessive deflection can lead to cracking in finishes or damage to non-structural elements.

- Design Connections: Design connections between the beam and other structural members to transfer shear and moment forces adequately.

For example, imagine designing a beam for a warehouse floor. We’d calculate the live load from forklifts, the dead load from the flooring system and the beam itself, determine the maximum bending moment, and then select a W-shape based on the required section modulus. We must also consider deflection to ensure the floor remains level under load.

Q 3. How do you account for wind loads in steel structure design?

Wind loads are significant, particularly for tall structures. They are accounted for during design using several approaches:

- Wind Load Calculation: Wind loads are calculated using established standards and codes (like ASCE 7 in the US). These codes consider factors such as building height, location, terrain roughness, and wind speed data to generate wind pressures on the structure’s surfaces.

- Structural Analysis: Once the wind pressures are determined, structural analysis techniques are used to analyze the structure’s response to the wind loads. This often involves complex computer modeling using finite element analysis (FEA) software to accurately predict stresses and deflections.

- Load Combinations: Wind loads are combined with other loads (dead loads, live loads, snow loads) using specified load combination factors from the relevant codes. This accounts for the possibility of multiple loads acting on the structure simultaneously.

- Design for Wind Forces: The design considers the forces and moments generated from the wind loads to ensure the structural members can withstand the anticipated stresses without excessive deflection or failure.

For instance, designing a high-rise building in a hurricane-prone area requires sophisticated wind load analysis. FEA models are utilized to determine wind pressures on each building face and subsequently the structural members’ sizes required to safely resist these forces. Proper bracing is crucial to ensure stability and prevent wind-induced oscillations.

Q 4. What are the common methods for connecting steel members?

Steel members are connected using a variety of methods, each suitable for different applications and load requirements:

- Bolted Connections: These are widely used due to their ease of assembly and disassembly. Bolts can be high-strength, ensuring excellent load transfer. Different bolt types and arrangements are available (e.g., slip-critical connections that minimize slippage under load).

- Welded Connections: These provide a strong, permanent connection. Different welding processes are available, selected based on the steel grade, thickness, and required strength. Welds must adhere to stringent quality control standards.

- Riveted Connections: Although less common today, riveted connections are still found in older structures. They are durable but more time-consuming to install than bolted or welded connections.

The choice of connection method depends on factors such as load capacity, design aesthetics, construction speed, cost, and accessibility. For example, in a large industrial structure where rapid construction is crucial, bolted connections might be preferred for their ease of installation. However, a high-rise building might utilize a combination of welded and bolted connections for structural efficiency and aesthetics.

Q 5. Explain the concept of shear center and its significance.

The shear center is the point on a cross-section through which a shear force must act to produce bending without torsion. Imagine trying to push a thin, rectangular piece of cardboard; if you push off-center, it will twist. The shear center is the point where you can push and only cause bending.

Its significance lies in preventing twisting during bending. If a shear force is applied away from the shear center, the cross-section experiences both bending and torsion, leading to increased stresses and potential failure. This is particularly critical for thin-walled open sections like channels and angles. For symmetrical sections, the shear center coincides with the centroid.

In design, the shear center’s location is considered to ensure that connections are placed appropriately to avoid unwanted torsion. Misalignment can lead to significant problems, especially in sections like channel sections used as beams where the shear center is significantly different from the centroid. For instance, when connecting a channel section to a column, the connection should be designed to apply the shear load through the shear center to avoid twisting the channel and potentially causing failure.

Q 6. How do you design steel columns for buckling?

Steel columns are designed to resist buckling, a form of instability where the column bends under compressive load. The design process typically involves:

- Determine Loads: Calculate axial loads, moments, and any other forces acting on the column.

- Select Steel Grade: Choose an appropriate steel grade considering strength and cost.

- Buckling Analysis: Analyze the column’s buckling behavior using appropriate methods, such as the Euler formula for long columns or more advanced methods for short columns that also consider material yielding before buckling.

- Effective Length: Determine the effective length of the column, which accounts for boundary conditions (how the column is restrained at its ends). The effective length is crucial because it defines the column’s behavior under buckling.

- Slenderness Ratio: Calculate the slenderness ratio (KL/r), where K is the effective length factor, L is the column length, and r is the radius of gyration (a geometric property of the column’s cross-section).

- Check for Buckling: Compare the calculated stresses to the allowable stresses considering both yielding and buckling, using appropriate design specifications and safety factors. The design criteria should ensure sufficient capacity to resist both buckling and yielding.

- Section Selection: Select a steel section (e.g., wide-flange shape, HSS) that satisfies the strength and stability requirements. The section’s cross-sectional properties are key in influencing buckling behavior.

Consider designing a column in a multi-story building. We’d need to calculate the axial load from the floors above, determine the effective length based on the column’s restraints, and check for buckling using established codes. A suitable section would be selected to ensure the column can handle the loads without buckling or yielding.

Q 7. What are the different types of steel connections and their applications?

Steel connections are diverse, with the choice dictated by the application and load transfer requirements:

- Simple Connections (e.g., bolted angles, welded plates): Used for transferring shear forces or simple moment connections.

- Moment Connections: Designed to transfer both shear and moment forces effectively, often used in rigid frames. These are typically more complex, with a variety of sub-types based on the level of rotational restraint.

- Pinned Connections: Allow rotation but transfer shear only. These are used when a hinge-like connection is desired.

- Bracket Connections: Support beams or other members by providing a cantilever support.

- Base Plates: Transfer column loads to foundations.

For example, in a moment-resisting frame, fully rigid moment connections are typically required, often designed using multiple plates, angles, and high-strength bolts to provide substantial rotational restraint. In contrast, a simple connection, like a bolted angle connecting a beam to a column, is suitable for applications with lower moment demands.

The selection of connections is critical for the overall structural integrity of a steel frame. Proper design ensures that loads are adequately transferred and that the structure remains safe under various conditions, including wind and earthquake loads.

Q 8. Explain the design process for a steel frame building.

Designing a steel frame building is a multi-stage process requiring meticulous planning and execution. It begins with understanding the client’s needs, translating them into architectural and structural concepts, and culminating in a safe and efficient structure.

- Conceptual Design: This initial phase involves defining the building’s purpose, size, and overall layout. We consider factors like occupancy load, anticipated wind and seismic forces, and aesthetic requirements. This stage often includes preliminary sketches and conceptual 3D models.

- Structural Analysis: Once the architectural design is finalized, we perform a detailed structural analysis using software like ETABS or RISA to determine the forces acting on the steel frame under various load combinations (dead load, live load, wind load, snow load, seismic load). The analysis helps determine the required member sizes and connections.

- Member Design: Based on the analysis results, we select appropriate steel sections (beams, columns, braces) that meet the required strength and stability criteria. This involves checking for bending, shear, axial, and combined stresses according to relevant building codes, primarily AISC 360. We also consider factors like deflection and stability.

- Connection Design: This critical stage involves designing the joints that connect the various steel members. Connections can be simple (bolts, welds) or complex (moment connections). The design ensures adequate strength, stiffness, and ductility for the entire structure. Proper connection design is crucial for transferring loads efficiently and preventing premature failure.

- Detailing and Drawings: Detailed shop drawings are prepared to guide the fabrication and erection of the steel structure. These drawings provide precise dimensions, specifications, and connection details for each member and joint. They are reviewed by engineers and fabricators to ensure accuracy.

- Construction Oversight: We often provide construction oversight to monitor the fabrication and erection process, ensuring the structure is built according to the design specifications and safety standards. This may involve site visits, inspections, and close coordination with the construction team.

For instance, in designing a multi-story office building, the conceptual design stage might involve determining the optimal column spacing to maximize usable floor area while maintaining structural integrity. The structural analysis would then incorporate live loads from furniture, occupants, and equipment, along with wind and seismic loads specific to the building’s location. This feeds into the member design and subsequently the connection design, ensuring each component can withstand the calculated forces.

Q 9. Describe your experience with structural analysis software (e.g., RISA, ETABS, SAP2000).

I have extensive experience using various structural analysis software packages, including ETABS, RISA-3D, and SAP2000. My proficiency extends beyond simple model building; I’m adept at performing advanced analyses such as nonlinear analysis, pushover analysis, and time-history analysis. I understand the strengths and limitations of each software and select the most appropriate tool for each project. For example, for a complex high-rise building, I might utilize SAP2000’s advanced finite element capabilities. For a simpler steel frame building, RISA-3D’s user-friendly interface and efficient analysis capabilities might be preferable. My experience also encompasses model verification, checking for errors and ensuring the model accurately reflects the design intent. I’m comfortable interpreting analysis results, recognizing potential issues, and recommending design modifications to optimize the structure’s performance.

Q 10. How do you handle detailing requirements for steel structures?

Steel detailing is a crucial aspect of steel construction, involving the precise preparation of shop drawings. This ensures the fabricator understands exactly how to manufacture and assemble the steel members. I’m familiar with detailing software, such as Tekla Structures and SDS/2, and adhere to AISC detailing guidelines to create accurate and constructible drawings. The process includes:

- Member Modeling: Creating accurate 3D models of each steel member, reflecting its dimensions, shape, and connection details.

- Connection Design: Specifying the type and details of each connection, including bolt size, weld type, and any necessary plates or stiffeners. For example, detailing a moment connection requires careful consideration of the beam-column interaction and potential for weld cracking.

- Material Specifications: Clearly stating the type and grade of steel used for each member.

- Fabrication Drawings: Producing detailed fabrication drawings that guide the manufacturer in cutting, drilling, welding, and assembling the members.

- Erection Drawings: Creating drawings showing how to assemble the fabricated members into the complete steel structure during the erection phase. This includes detailing the sequence and methods of erection, along with appropriate lifting points.

For example, in a recent project involving a large industrial building, I used Tekla Structures to create detailed shop drawings, including bill of materials and fabrication instructions, that were directly used by the fabricator without further clarification. The software’s powerful modeling capabilities allowed us to efficiently manage the complex geometry and optimize the design for fabrication efficiency. Thorough detailing prevents costly errors during fabrication and erection and is key to a smoothly running project.

Q 11. What are the relevant building codes and standards for steel design?

Steel design adheres to various building codes and standards, depending on the project’s location and specific requirements. Key standards include:

- AISC 360: The American Institute of Steel Construction’s specification for structural steel buildings is the primary design standard in the US. It provides the fundamental design criteria for strength, stability, and serviceability.

- IBC (International Building Code): This code establishes minimum requirements for building safety, including structural design, fire protection, and accessibility. It incorporates provisions related to steel design.

- ASCE 7: The American Society of Civil Engineers’ minimum design loads for buildings and other structures provides guidelines for determining wind and seismic loads. These loads are crucial inputs into the structural analysis and design process.

- Local and Regional Codes: Many jurisdictions have their own supplementary codes and regulations that need to be considered in addition to the national standards. These may address specific local conditions or have unique requirements for steel construction.

Understanding and applying these codes correctly is essential to ensure the safety and compliance of the designed structure. A common example is adhering to ASCE 7 for seismic design in earthquake-prone regions, ensuring the steel structure can withstand the ground motion forces.

Q 12. Explain your understanding of AISC specifications.

The AISC (American Institute of Steel Construction) specifications, primarily AISC 360, are the cornerstone of steel structural design in North America. They provide detailed provisions for the design and detailing of steel structures, covering aspects such as:

- Strength Design: AISC 360 outlines methods for calculating the strength of steel members under various loading conditions (bending, shear, axial, torsion), considering factors like material properties, section geometry, and stability.

- Load and Resistance Factor Design (LRFD): The specification uses LRFD, a limit-states design method, which provides a safety factor on both loads and resistances to account for uncertainties in loading and material properties. This probabilistic approach offers a more realistic assessment of structural safety.

- Connection Design: AISC 360 provides guidance on designing various types of steel connections, including bolted and welded connections. It specifies requirements for strength, stiffness, and ductility.

- Stability Design: The specification addresses the stability of steel members, including lateral-torsional buckling, flexural buckling, and other forms of instability. It provides methods for calculating critical buckling loads and designing members to prevent instability.

- Serviceability Limit States: AISC 360 also covers serviceability limit states, such as deflection and vibration, ensuring the structure performs adequately under service loads.

My understanding of AISC specifications allows me to design safe, efficient, and cost-effective steel structures. For example, I use the equations and tables in AISC 360 to determine the design strength of steel sections and select the appropriate members based on the analysis results. I also employ AISC’s recommendations for designing connections to ensure they provide the necessary strength and stiffness.

Q 13. How do you ensure compliance with safety regulations during steel construction?

Ensuring compliance with safety regulations during steel construction is paramount. This involves a multi-faceted approach encompassing several key aspects:

- Adherence to Codes and Standards: Meticulous adherence to relevant building codes (e.g., IBC) and steel design standards (e.g., AISC 360) forms the foundation of safety. This includes careful consideration of all applicable load combinations and performing rigorous structural analysis to ensure the design meets or exceeds all code requirements.

- Quality Control of Materials: Verifying the quality of all materials, including steel sections, welds, and fasteners, is crucial. This often involves mill certifications and on-site inspections to ensure materials meet the specified grades and tolerances.

- Proper Fabrication Techniques: Ensuring the steel members are fabricated according to the detailed shop drawings and specifications is vital. This might involve reviewing welding procedures, checking dimensions, and inspecting the finished product before it leaves the fabrication shop.

- Safe Erection Procedures: The erection process itself poses significant safety risks. To mitigate these risks, we carefully plan the erection sequence, utilize appropriate lifting equipment, and ensure compliance with OSHA (Occupational Safety and Health Administration) regulations. This includes proper fall protection measures, ensuring stability during lifting operations, and proper site layout to prevent accidents.

- Regular Inspections: Regular inspections during the construction phase are essential to monitor progress, identify potential safety issues, and ensure the structure is being built according to the design and safety regulations.

For example, on a high-rise project, I implemented a detailed safety management plan which included daily toolbox talks, regular inspections, and adherence to stringent fall protection protocols, ensuring the safety of workers at every stage of the construction process. The plan, in conjunction with strict adherence to code, ensured the project was completed without any safety incidents.

Q 14. How do you address corrosion protection in steel structures?

Corrosion protection is vital for ensuring the longevity and structural integrity of steel structures. The choice of protection method depends on factors such as the environment (coastal, industrial), budget, and aesthetic requirements. Common methods include:

- Galvanization: A cost-effective and widely used method involving dipping the steel members in molten zinc to create a protective layer. Galvanization provides excellent corrosion resistance, especially in mild environments.

- Painting: Applying multiple coats of high-quality paint provides protection against corrosion. The paint system must be carefully selected based on the exposure conditions to ensure it offers sufficient protection. Proper surface preparation before painting is crucial for adhesion and longevity.

- Protective Coatings: Various coatings, such as epoxy, polyurethane, or zinc-rich primers, can be used to enhance corrosion protection. These coatings provide a barrier between the steel and the environment.

- Cathodic Protection: This electrochemical method involves using an external electrical current to protect the steel from corrosion. It’s commonly used in marine environments or underground structures.

The selection of an appropriate corrosion protection system requires a detailed assessment of the project’s environment. For example, for a bridge in a coastal area exposed to salt spray, I would specify a high-quality, multi-layer paint system with excellent resistance to salt corrosion and UV degradation, potentially supplemented with cathodic protection. For a steel structure in a less harsh environment, galvanization might be a more economical and effective solution. Proper detailing of corrosion protection details on shop drawings is also critical to ensure the correct application and long-term effectiveness of the chosen method.

Q 15. Describe your experience in using BIM for steel structures.

My experience with BIM (Building Information Modeling) in steel structural design is extensive. I’ve utilized software like Revit, Tekla Structures, and Autodesk Advance Steel on numerous projects, ranging from small-scale industrial buildings to large-scale commercial complexes. BIM isn’t just about 3D modeling; it’s about integrated design. I use it for:

- Conceptual Design & Visualization: Creating preliminary 3D models to explore design options and communicate effectively with clients.

- Detailed Design & Modeling: Developing precise models including member sizes, connections, and detailing crucial for fabrication.

- Clash Detection: Identifying and resolving conflicts between different disciplines (MEP, Architecture) early in the process, preventing costly rework.

- Quantity Takeoff & Cost Estimation: Generating accurate material quantities and facilitating budget control.

- Fabrication & Erection Planning: Producing detailed shop drawings and assembly sequences to guide fabrication and construction.

For example, on a recent high-rise project, BIM facilitated seamless collaboration between the structural, architectural, and MEP teams. Early clash detection saved us significant time and cost by identifying and resolving conflicts between steel columns and ductwork before fabrication commenced.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your preferred methods for analyzing and designing steel connections?

My preferred methods for analyzing and designing steel connections depend on the complexity and loading conditions. I utilize a combination of analytical and empirical approaches, leveraging software tools such as RISA-3D, SAP2000, and specialized connection design software. For simpler connections, I rely on established design guides like the AISC (American Institute of Steel Construction) manuals. For complex connections, I perform detailed Finite Element Analysis (FEA) to ensure accuracy and optimize designs.

- AISC Design Guides: For standard connections like simple bolted or welded connections, I use the AISC’s simplified design methods. This provides a quick and efficient design process for common scenarios.

- Finite Element Analysis (FEA): For complex connections, like those involving moment transfer or high cyclic loading, FEA is invaluable. Software like Abaqus or ANSYS allows accurate stress analysis and ensures design safety.

- Software-Based Design: I use software specifically tailored to steel connection design. These programs automate many calculations and checks, reducing design time and enhancing accuracy.

For instance, in designing a base plate connection for a large column, I’d use FEA to accurately model the stress distribution under various loading scenarios, ensuring adequate bearing capacity and preventing local buckling.

Q 17. How do you manage projects with tight deadlines and limited resources?

Managing projects with tight deadlines and limited resources requires a strategic and organized approach. My strategy revolves around efficient planning, effective communication, and leveraging technology.

- Prioritization: I meticulously prioritize tasks based on critical path analysis, focusing on the most time-sensitive and impactful elements first.

- Resource Allocation: I optimize resource allocation, assigning tasks based on individual expertise and availability.

- Value Engineering: I actively seek opportunities for value engineering, exploring alternative design solutions to reduce costs and maintain functionality.

- Collaboration: I foster strong communication with the project team, ensuring everyone is informed and aligned on project goals and progress.

- Technology: I utilize project management software and BIM tools to enhance efficiency, track progress, and manage resources effectively.

For instance, on a project with a compressed timeline, I successfully implemented value engineering by suggesting a more efficient steel connection detail, leading to significant cost and time savings without compromising structural integrity.

Q 18. Explain your experience in working with various steel fabrication techniques.

My experience encompasses a broad range of steel fabrication techniques, including:

- Welding: I’m familiar with various welding processes such as SMAW (Shielded Metal Arc Welding), GMAW (Gas Metal Arc Welding), and FCAW (Flux-Cored Arc Welding). I understand the importance of weld quality control and compliance with relevant codes and standards.

- Bolting: I’m proficient in specifying and detailing high-strength bolted connections, understanding the importance of bolt tensioning techniques and appropriate fastener selection for various loading conditions.

- Plate Fabrication: I’m familiar with different plate fabrication processes including cutting, drilling, and shaping, and am adept at specifying appropriate tolerances and surface finishes.

- Hot-Rolled Shapes: I understand the properties and limitations of various hot-rolled shapes and how to select appropriate sizes for different structural applications.

This knowledge allows me to design steel structures that are not only structurally sound but also practical and cost-effective to fabricate. For example, understanding the limitations of welding certain steel grades allows me to specify alternative connection methods that prevent potential issues during fabrication.

Q 19. What are your strengths and weaknesses in steel structural design?

Strengths: My strengths lie in my detailed understanding of structural mechanics, my proficiency in using various software tools, and my ability to optimize designs for both structural performance and constructability. I’m also a strong communicator and collaborator, able to effectively work with diverse teams.

Weaknesses: While my knowledge base is broad, there are always new advancements in steel design and fabrication. I actively strive to stay updated on the latest technologies and research, attending industry conferences and professional development courses to mitigate this. My time management can sometimes be challenged by taking on complex projects, but I am actively developing strategies for better prioritization and task delegation to overcome this.

Q 20. How do you ensure the accuracy and efficiency of your designs?

Ensuring accuracy and efficiency in my designs is paramount. My approach involves a multi-layered process:

- Detailed Calculations & Checks: I meticulously perform all necessary structural calculations and design checks, using established standards and codes.

- Software Verification: I utilize multiple software tools to verify my calculations and designs, cross-checking results to minimize errors.

- Peer Reviews: I actively seek feedback from colleagues through peer reviews, catching potential oversights and improving the overall quality of my work.

- Code Compliance: Strict adherence to relevant building codes and standards is essential. I carefully review my designs against these requirements to ensure compliance.

- Documentation: I maintain thorough documentation of my designs, calculations, and analyses. This facilitates easy review, understanding, and future modifications.

For instance, before finalizing any design, I always conduct a thorough peer review to ensure that all aspects of the design are correctly addressed and compliant with relevant standards. This multi-layered approach ensures that the designs are robust, safe, and meet all project requirements.

Q 21. Describe your experience with steel erection and installation processes.

My experience with steel erection and installation processes is significant. I’ve been involved in several projects, from small industrial buildings to complex high-rise structures. Understanding the erection process is crucial for efficient and safe construction.

- Sequence Planning: I’ve worked on developing erection sequences for various projects, considering factors like crane capacity, access limitations, and safety regulations.

- Shop Drawings Review: My experience includes meticulously reviewing shop drawings to ensure that the fabricated members meet the design intent and are suitable for erection.

- Field Observations: I’ve participated in site visits to monitor the erection process, observe the installation procedures, and address any unforeseen issues.

- Coordination with Contractors: I collaborate with contractors to ensure a smooth and efficient erection process, resolving any conflicts or challenges that may arise.

For instance, on a recent project, I worked closely with the erection team to develop an optimized lifting plan, minimizing the number of crane lifts and reducing overall erection time. This understanding of construction practices allows me to create designs that are practical and feasible to construct.

Q 22. How do you handle unexpected issues or challenges during a project?

Unexpected issues are inevitable in any project. My approach involves a multi-step process. First, I meticulously document all project details, including initial assumptions and design parameters. This allows for a clear understanding of the baseline. When an issue arises, I prioritize a calm and methodical response. This means first identifying the problem’s root cause – is it a design oversight, a material deficiency, or an unforeseen site condition? Then, I consult relevant codes and standards (like AISC and Eurocodes) to assess the impact. Depending on the severity, I explore several solution paths. This often includes simulations using software like ABAQUS or ANSYS to validate my proposed solution. Communication is paramount; I keep all stakeholders informed, present various options, and collaboratively decide on the optimal course of action. Finally, I document all changes and lessons learned for future projects. For example, on a recent high-rise project, unexpected soil conditions required a redesign of the foundation. Through rigorous analysis and collaboration with geotechnical engineers, we successfully implemented a new solution that met all safety requirements and stayed within budget.

Q 23. Explain your understanding of fatigue analysis in steel structures.

Fatigue analysis is crucial for steel structures subjected to cyclic loading, like bridges or offshore platforms. It assesses a structure’s ability to withstand repeated stress cycles without failure. Unlike static analysis which considers a single load application, fatigue analysis accounts for the cumulative damage caused by countless load cycles. The process begins with identifying critical stress locations using finite element analysis (FEA). Then, stress-life (S-N) curves, which represent the relationship between stress amplitude and the number of cycles to failure for the material, are employed. These curves are often obtained from material testing or design codes. The Palmgren-Miner rule is frequently used to accumulate fatigue damage from various stress ranges. The analysis determines whether the structure will endure its intended service life without fatigue failure. For instance, a railway bridge experiences millions of train passages over its lifespan; fatigue analysis is indispensable in ensuring the bridge’s long-term integrity. Software like ANSYS and Abaqus are commonly used for complex fatigue analyses. Ignoring fatigue can lead to catastrophic failures, emphasizing the importance of robust analysis.

Q 24. What are your experiences in seismic design of steel structures?

Seismic design of steel structures is a specialized field requiring a thorough understanding of earthquake engineering principles. My experience encompasses designing steel structures to withstand seismic forces in accordance with codes like ASCE 7 and IBC. This involves selecting appropriate materials, designing ductile structural elements, and employing seismic detailing techniques to ensure the structure’s stability during an earthquake. I’ve utilized various analysis techniques, including pushover analysis and nonlinear time history analysis, to assess a structure’s seismic performance. For example, on a recent hospital project, we implemented a base isolation system to mitigate the effects of ground shaking. This involved detailed modelling to confirm the effectiveness of the isolators in reducing the forces transmitted to the superstructure. Furthermore, special moment frames and concentric bracing systems are common elements incorporated in seismic design, enhancing a structure’s ductility and preventing brittle failures. Thorough consideration of connections and their capacity to absorb energy during seismic events is paramount, preventing collapse.

Q 25. Describe a project where you had to overcome a significant engineering challenge.

During the design of a large-span industrial warehouse, we encountered a significant challenge involving the placement of a massive crane girder. The initial design, based on conventional methods, proved to be impractical due to the girder’s weight and the site’s limited access. To overcome this, we implemented a phased erection strategy, using specialized lifting equipment and precise calculations to ensure the girder’s safe placement. We used 3D modelling software to visualize the entire erection process, identify potential conflicts, and optimize the lifting sequence. Finite element analysis was also crucial for verifying the stresses during the lifting operation. This innovative solution allowed us to successfully complete the project on time and within budget, highlighting the importance of adapting to constraints and exploring unconventional approaches. This experience significantly enhanced my problem-solving abilities and reinforced the need for comprehensive planning in complex projects.

Q 26. How do you stay up-to-date with the latest advancements in steel structural design?

Staying current in this rapidly evolving field requires a multi-pronged approach. I actively participate in professional organizations like the American Institute of Steel Construction (AISC) and attend industry conferences and workshops. This exposes me to new materials, design techniques, and research findings. I regularly review industry journals, such as the Engineering Journal and the Journal of Structural Engineering, and subscribe to relevant online publications and newsletters. Furthermore, I actively engage with online communities and forums where professionals share insights and best practices. Finally, I participate in continuing education courses to maintain my professional certifications and stay abreast of the latest code revisions. By combining these strategies, I ensure my knowledge base remains current and relevant, allowing me to leverage the most up-to-date advancements in steel structural design.

Q 27. Describe your experience in preparing detailed construction drawings for steel structures.

I have extensive experience in preparing detailed construction drawings for steel structures, ensuring accuracy, clarity, and completeness. This involves utilizing CAD software, such as AutoCAD and Tekla Structures, to create comprehensive plans, sections, elevations, and details. My drawings encompass all aspects, including member sizes, connection details, bolt specifications, and material designations. I follow industry standards and best practices to ensure the drawings are readily understood by fabricators and erectors. My approach involves a systematic process, beginning with conceptual design sketches and progressing to detailed shop drawings. I meticulously review and check each drawing for potential errors or inconsistencies. Collaboration with other disciplines, such as architects and MEP engineers, is paramount to ensure coordination and avoid clashes. Moreover, I incorporate appropriate annotations and callouts to facilitate seamless construction. This systematic approach ensures clear communication throughout the project lifecycle, minimizing errors and delays during fabrication and erection. For example, I have been instrumental in producing detailed drawings for numerous high-rise buildings and industrial complexes, ensuring efficient and safe construction.

Key Topics to Learn for Steel Structural Design Interview

- Loads and Load Paths: Understanding dead loads, live loads, wind loads, seismic loads, and how they transfer through the structure. Practical application: Analyzing load combinations and their impact on member design.

- Material Properties: Familiarize yourself with the mechanical properties of steel, including yield strength, tensile strength, and modulus of elasticity. Practical application: Selecting appropriate steel grades for specific design requirements.

- Stress and Strain Analysis: Mastering concepts of axial stress, bending stress, shear stress, and their relationships to strain. Practical application: Analyzing stresses in beams, columns, and connections under various loading conditions.

- Structural Connections: In-depth knowledge of bolted, welded, and riveted connections. Practical application: Designing efficient and safe connections considering strength, stiffness, and fatigue.

- Beam Design: Understanding flexural behavior, shear design, and deflection calculations. Practical application: Designing beams to meet strength and serviceability requirements.

- Column Design: Understanding buckling behavior, column interaction curves, and design considerations for different end conditions. Practical application: Selecting appropriate column sections and verifying their stability.

- Stability and Lateral-Torsional Buckling: Grasping the concepts of overall and local stability, and understanding the factors influencing buckling behavior. Practical application: Designing structures to prevent instability failures.

- Limit States Design: Understanding the philosophy of limit states design and its application in structural design. Practical application: Checking for ultimate and serviceability limit states.

- Code Compliance: Familiarity with relevant building codes and design standards (e.g., AISC). Practical application: Ensuring designs meet all regulatory requirements.

- Software Proficiency: Demonstrate familiarity with relevant structural analysis and design software (mention specific software if applicable to your target roles). Practical application: Efficiently modeling and analyzing structures using software tools.

Next Steps

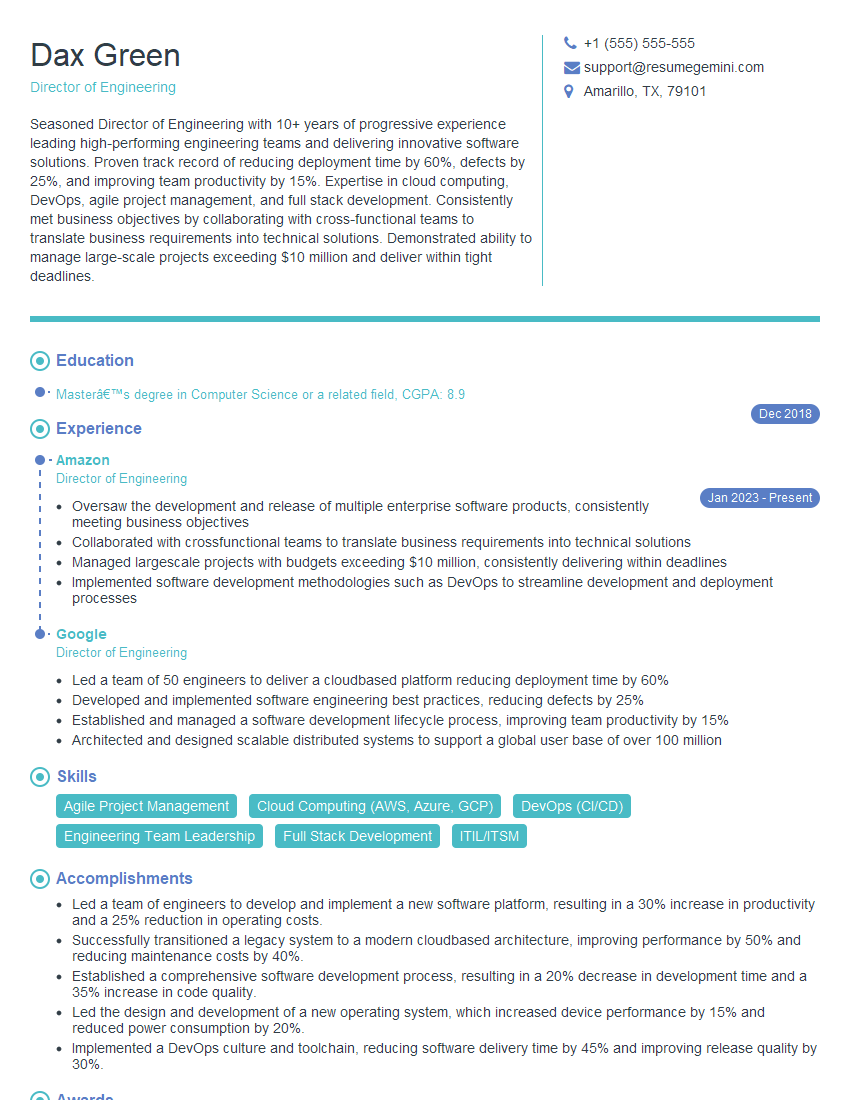

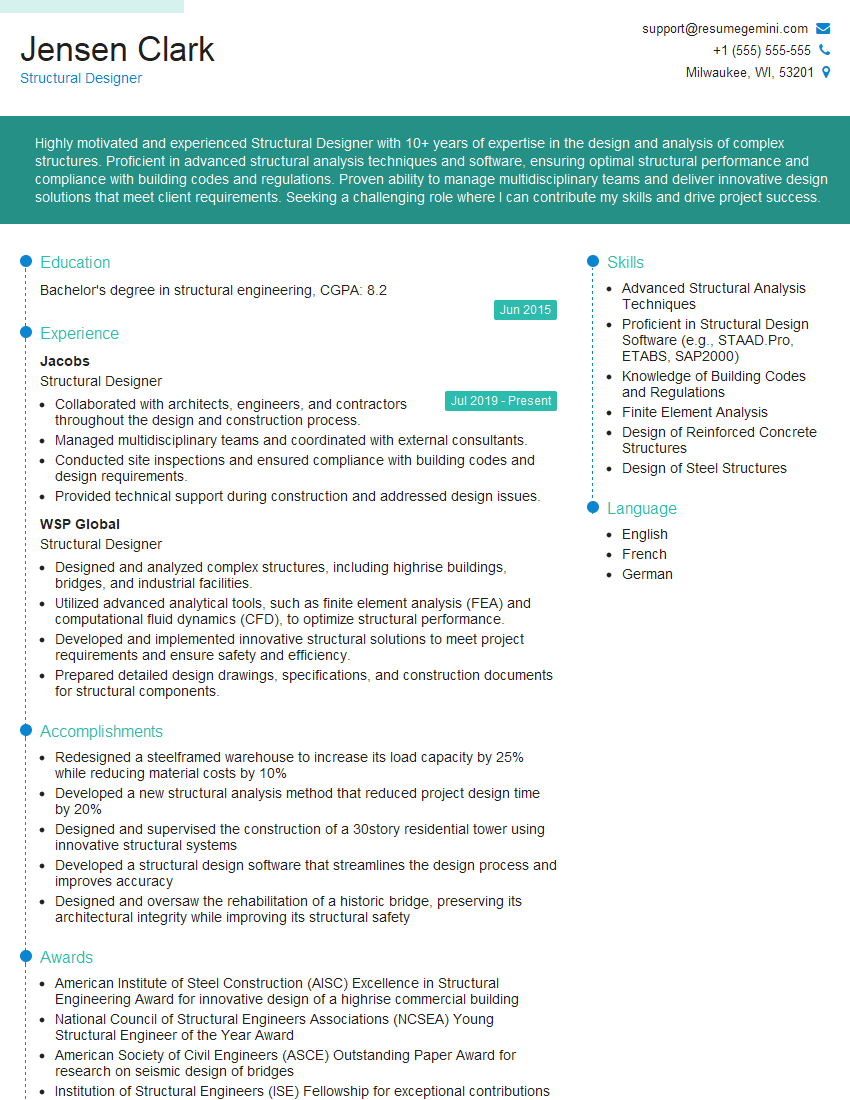

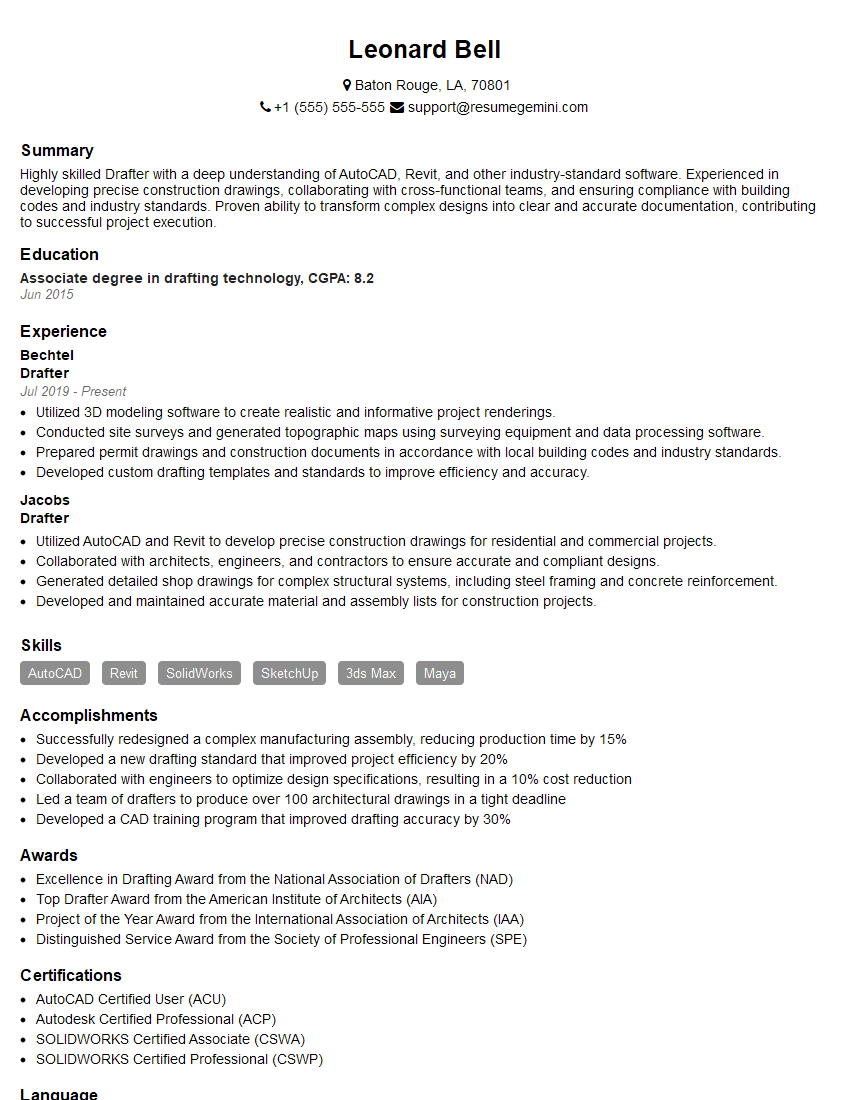

Mastering Steel Structural Design opens doors to exciting and challenging careers in the construction and engineering industries, offering opportunities for continuous learning and professional growth. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. They provide examples of resumes tailored to Steel Structural Design to guide you through the process. Invest the time in crafting a strong resume; it’s your first impression and a critical step in securing your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO