Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Proficient in using measuring tools interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Proficient in using measuring tools Interview

Q 1. What are the different types of measuring tools you are proficient with?

My proficiency extends across a wide range of measuring tools, encompassing both analog and digital instruments. I’m highly experienced with Vernier calipers, micrometers, dial indicators, rulers, steel tapes, and digital multimeters for electrical measurements. Beyond these, I’m also comfortable using more specialized tools like optical comparators for precise dimensional checks and laser measuring systems for larger distances or difficult-to-reach areas. Each tool offers specific advantages depending on the measurement task, and I understand their limitations and applications thoroughly.

Q 2. Describe your experience with Vernier calipers. What are their limitations?

Vernier calipers are a precision instrument I use frequently for measuring external and internal dimensions, as well as depths. They combine a main scale with a vernier scale, allowing for readings to 0.01 mm or 0.0005 inches, significantly more accurate than a typical ruler. I’ve used them extensively in quality control inspections, ensuring parts adhere to design specifications. For example, I once used a Vernier caliper to measure the critical dimensions of a newly manufactured engine component, flagging a slight deviation which, if left unaddressed, could have led to premature wear.

However, Vernier calipers do have limitations. Their accuracy is dependent on the user’s skill and careful handling. Parallax error (reading the scale from an angle) can introduce inaccuracies. Additionally, their range is limited, and they might not be suitable for measuring very small or very large objects. Finally, their jaws can wear over time, gradually reducing their accuracy.

Q 3. How do you ensure accuracy when using a micrometer?

Accuracy with a micrometer relies on several key practices. Firstly, it’s crucial to ensure the micrometer is properly zeroed before each measurement. This involves checking that the anvil and spindle are in perfect contact with zero reading displayed. Secondly, one must apply a consistent, moderate force when closing the micrometer onto the object – excessive force can damage the instrument or deform the object being measured. Thirdly, always read the measurement carefully, paying attention to both the main scale and the thimble scale to avoid parallax errors by keeping your eye directly above the measurement line.

Regular cleaning and maintenance are also vital. Micrometers should be kept clean and lubricated to prevent wear and tear. Finally, it’s good practice to take multiple readings at different locations on the object and average them to minimize the impact of any surface irregularities.

Q 4. Explain the concept of measurement uncertainty.

Measurement uncertainty is an inherent aspect of any measurement process. It represents the range of values within which the true value of the measured quantity is likely to lie. It’s not about the instrument’s precision but encompasses the combined effect of all uncertainties, including those related to the measuring instrument, the environment (temperature, humidity), the measurement method, and the observer’s skill. For instance, a micrometer might have a precision of 0.01mm, but due to human error or temperature variations, the overall measurement uncertainty could be ±0.02mm. Reporting measurement uncertainty is crucial for transparent and reliable data.

Q 5. What are some common sources of error in measurement, and how do you mitigate them?

Common sources of error include parallax error (incorrect angle of observation), instrument wear (misaligned jaws or worn scales), environmental factors (temperature affecting material dimensions), and human error (misreading scales or applying inconsistent force). To mitigate these: always read scales perpendicularly, regularly calibrate and maintain instruments, control environmental conditions as much as possible, and repeat measurements, calculating the average to reduce the effect of random errors. Proper calibration procedures, documented and followed meticulously, are key to high quality measurements.

Q 6. How would you measure the diameter of a small cylindrical object?

For a small cylindrical object, I would use a micrometer. Micrometers are ideal for precise measurements of small diameters. I’d ensure the object is clean and place it between the anvil and spindle of the micrometer. Carefully closing the spindle onto the object, I’d take multiple measurements at different orientations, rotating the object slightly between each measurement. I would then average these readings to reduce the impact of any minor imperfections on the object’s surface. Finally, I would document the average reading, along with the measurement uncertainty, to provide a complete and reliable result.

Q 7. How would you measure the inside diameter of a pipe?

Measuring the inside diameter of a pipe depends on the pipe’s size and accessibility. For smaller pipes, I’d use inside calipers, which have specially designed jaws for accurate internal diameter measurements. For larger pipes, a dial bore gauge or an electronic bore gauge can be used. These gauges provide highly accurate readings and are particularly suitable for larger diameters. In cases where access is limited, I might use a flexible measuring tape or a specially designed tool, such as a telescoping gauge. The choice of instrument always depends on the specific dimensions and accessibility of the pipe.

Q 8. How would you measure the depth of a hole?

Measuring the depth of a hole depends on its size and accessibility. For shallow holes, a simple ruler or depth gauge might suffice. For deeper or inaccessible holes, however, more specialized tools are necessary.

- Ruler or Depth Gauge: For holes where you can easily see the bottom, a simple ruler or a dedicated depth gauge, which often has a probe that extends into the hole, provides a straightforward measurement. I’ve used this method countless times when working with simple woodworking projects.

- Caliper: Inside calipers are excellent for measuring the depth of smaller, relatively shallow holes with precision. The jaws of the caliper are adjusted to fit the diameter of the hole, and then the probe is inserted to measure the depth.

- Depth Micrometer: For very precise depth measurements in manufacturing or engineering, a depth micrometer offers superior accuracy.

- Bore Gauge: For larger holes, a bore gauge allows accurate measurement from the inside. This is especially useful in quality control for manufactured parts.

- Laser Distance Measurer: Laser distance measurers offer a non-contact way to measure the depth, especially in difficult-to-reach places. I’ve found this incredibly helpful when assessing the depth of a hole in a wall during a renovation project.

The choice of tool depends heavily on the hole’s characteristics and the required level of accuracy.

Q 9. How would you measure the thickness of a sheet of material?

Measuring the thickness of a sheet of material involves selecting the right tool based on the material’s thickness and the desired accuracy. For thin sheets, a micrometer is ideal; for thicker sheets, a caliper may be more appropriate.

- Micrometer: A micrometer provides incredibly precise measurements, typically accurate to a thousandth of an inch or a hundredth of a millimeter. This is crucial for thin materials where even small variations matter, like in electronics or precision machining. I regularly use micrometers for measuring the thickness of thin metal sheets and plastic films.

- Caliper (Vernier or Digital): Calipers are versatile tools that can measure both internal and external dimensions, including thickness. They offer a good balance between precision and ease of use. For example, when working with slightly thicker materials like sheet metal or plywood, I often reach for my digital caliper for its speed and clear digital readout.

- Thickness Gauge: Some materials, like paper or thin textiles, are best measured with a specialized thickness gauge. These gauges often use a dial indicator to measure the compression of the material between two surfaces.

Always ensure the measuring tool is properly calibrated to ensure accurate readings. Furthermore, it’s crucial to take multiple measurements at different points on the sheet to account for potential variations in thickness.

Q 10. How do you calibrate measuring instruments?

Calibrating measuring instruments is vital for ensuring accurate and reliable measurements. The method varies depending on the instrument, but generally involves comparing the instrument’s readings to a known standard.

- Standard Weights and Measures: For tools like scales and balances, calibration involves using known weights to check the accuracy of the instrument. Many scales have built-in calibration functions.

- Master Gauges: For tools like calipers and micrometers, calibration typically involves comparing their readings against certified master gauges. These master gauges are highly accurate and traceable to national standards.

- Calibration Certificates: Regular calibration is essential, and calibration certificates provide verification of the instrument’s accuracy. These certificates are often required in quality-controlled environments.

- Manufacturer’s Instructions: Always follow the manufacturer’s instructions for calibrating the specific instrument. Each tool may have unique calibration procedures.

Regular calibration minimizes measurement errors and ensures the integrity of data collected. Failure to calibrate tools can lead to significant inaccuracies and costly mistakes.

Q 11. What is the difference between precision and accuracy in measurement?

Precision and accuracy are often confused, but they represent different aspects of measurement quality. Accuracy refers to how close a measurement is to the true value, while precision refers to how close repeated measurements are to each other.

- Accuracy: A measurement is accurate if it’s close to the actual value. For instance, if the true length of an object is 10cm and you measure it as 10.1cm, that’s more accurate than a measurement of 9.5cm.

- Precision: A measurement is precise if repeated measurements yield similar results. If you measure the same object multiple times and get readings of 10.2cm, 10.3cm, and 10.2cm, that’s more precise than readings of 9.8cm, 10.5cm, and 10.0cm. High precision doesn’t necessarily imply high accuracy.

Imagine shooting arrows at a target. High accuracy means your arrows are all clustered around the bullseye. High precision means your arrows are clustered tightly together, but not necessarily near the bullseye. Ideally, you want both high accuracy and high precision in your measurements.

Q 12. What is the significance of proper tool maintenance in accurate measurement?

Proper tool maintenance is paramount for accurate measurements. Damaged or poorly maintained tools can introduce significant errors, leading to inaccurate data and potentially costly mistakes.

- Cleanliness: Dirt, debris, and corrosion can affect the accuracy of measuring tools. Regular cleaning and proper storage are essential.

- Calibration: As mentioned earlier, regular calibration is key to maintaining accuracy. A tool that’s out of calibration can produce consistently inaccurate readings.

- Damage Prevention: Careful handling and proper storage prevent damage to measuring instruments. Dropping or mishandling tools can lead to misalignment or damage to delicate parts.

- Lubrication: Some tools, such as calipers and micrometers, require regular lubrication to ensure smooth movement and prevent wear.

In my experience, neglecting tool maintenance has resulted in wasted time, materials, and even project failures. A well-maintained tool kit is an invaluable asset for any professional.

Q 13. Explain the difference between analog and digital measuring tools.

Analog and digital measuring tools both serve the purpose of measuring, but they differ in how they display the measurement and their precision.

- Analog Tools: Analog tools, such as vernier calipers and dial indicators, rely on mechanical mechanisms to display the measurement using a scale or pointer. Reading an analog tool requires interpretation, and the precision is limited by the resolution of the scale.

- Digital Tools: Digital tools, such as digital calipers and laser distance measurers, use electronic sensors to measure and display the value digitally. They usually offer higher precision and faster reading compared to analog tools. Digital tools also offer features like data logging and easy transfer of data.

While digital tools generally offer greater convenience and precision, analog tools can still be useful in certain situations, particularly when power is unavailable or when a quick visual estimate is sufficient.

Q 14. Describe your experience using laser measurement tools.

I have extensive experience using laser measurement tools, primarily laser distance measurers and laser levels. These tools have significantly improved my efficiency and accuracy in various projects.

- Laser Distance Measurers: These tools use lasers to measure distances quickly and accurately over long ranges. I’ve used them to measure building dimensions, land surveys, and interior design layouts. Their non-contact measurement capability is incredibly useful when dealing with challenging environments or delicate materials. The instant digital readout eliminates the need for tedious manual calculations.

- Laser Levels: Laser levels project a precise horizontal or vertical plane, enabling accurate alignment and leveling of objects and structures. I’ve employed laser levels extensively in construction projects, ensuring precise alignment of walls, floors, and ceilings. Their use significantly reduces errors and improves efficiency compared to traditional leveling techniques.

The accuracy and speed offered by laser measurement tools have been invaluable, especially in projects requiring precise measurements and alignment. The data logging capabilities of some models are also extremely beneficial for documenting measurements and sharing data with colleagues.

Q 15. How do you select the appropriate measuring tool for a specific task?

Selecting the right measuring tool depends heavily on the task’s requirements, specifically the accuracy needed, the material being measured, and the size and shape of the object. Think of it like choosing the right tool from a toolbox – you wouldn’t use a hammer to screw in a screw!

- High Accuracy: For precise measurements, like in machining or electronics, I’d use a micrometer, digital caliper, or even a laser measurement tool. These offer very fine graduations and minimal error.

- General Purpose: A standard ruler or tape measure suffices for most everyday measurements, like home improvement projects or carpentry. Their accuracy is sufficient for many applications.

- Large Distances: Measuring long distances might involve a laser rangefinder or a total station – tools designed to compensate for terrain and provide accurate measurements over vast areas.

- Irregular Shapes: Measuring the volume of irregularly shaped objects often requires displacement methods using a graduated cylinder and water. For surface area, we might use a planimeter.

The decision always involves considering the acceptable margin of error and the available resources. The most accurate tool isn’t always the best choice if it’s impractical or excessively expensive for the given task.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you encountered a measurement discrepancy. How did you resolve it?

During a construction project, I was measuring the length of a wall for installing drywall. My initial measurement with a tape measure showed 12 feet, but the second time, I got 12 feet and 2 inches. This discrepancy raised a concern about potential errors in the installation.

To resolve this, I first checked the tape measure for any damage or defects. Then, I re-measured the wall three more times, using different starting points and ensuring the tape was taut each time. I also had a colleague perform the measurement as a double check. The results consistently showed around 12 feet and 1.5 inches. This confirmed the initial discrepancy was not a random error but due to less than precise initial measurements. This highlighted the importance of multiple measurements and independent verification for critical projects.

Q 17. What safety precautions do you take when using measuring tools?

Safety is paramount when using measuring tools. Here are some precautions I always take:

- Inspect Tools Before Use: Checking for damage, loose parts, or worn markings is vital to prevent inaccurate readings and potential injury.

- Proper Handling: Using tools as intended, avoiding excessive force, and maintaining a firm grip prevents accidental drops or slips, protecting both myself and the tools.

- Environmental Awareness: Being mindful of surroundings, ensuring proper lighting and clear pathways, prevents tripping hazards or accidental damage to the tools.

- Personal Protective Equipment (PPE): Wearing safety glasses or gloves, when necessary, protects against potential hazards like sharp edges or flying debris during measurement.

- Power Tool Safety: For electronic measuring devices, I ensure the power source is stable and the device is properly grounded to avoid electrical shocks.

Safety isn’t just about avoiding accidents; it’s about ensuring accurate and reliable measurements by maintaining the integrity of the tools and minimizing chances for error introduction.

Q 18. What are the limitations of different types of measuring tools?

Every measuring tool has limitations. Understanding these is crucial for selecting the right tool and interpreting the results accurately.

- Rulers and Tape Measures: Limited accuracy due to their graduations. They are susceptible to bending and stretching, causing measurement inaccuracies, especially over long distances.

- Calipers: While precise, their accuracy is limited by the user’s skill and the instrument’s resolution. They might not be suitable for measuring very small or very large objects effectively.

- Micrometers: Highly accurate but limited by their range. They are best suited for smaller, precisely machined parts.

- Laser Measurement Tools: Affected by atmospheric conditions like temperature and humidity, which can slightly alter the accuracy of their readings. Reflecting surfaces can also interfere with accurate measurements.

Knowing these limitations allows for informed decision-making and interpreting measurements within their acceptable error range.

Q 19. How do you document your measurements?

Documenting measurements meticulously is crucial for reproducibility and accountability. I typically use a combination of methods:

- Written Records: A clearly labeled notebook or data sheet records all measurements, including the date, time, tool used, units of measurement, and any relevant observations (e.g., temperature, surface condition).

- Digital Records: Using spreadsheets or databases to store measurement data allows for easier analysis and sharing of information.

- Photographs and Sketches: Visual documentation complements written records, especially for complex shapes or installations. It can be helpful to illustrate the measurement process.

- Calibration Records: I document the calibration dates of all measuring tools to ensure their accuracy remains within acceptable limits.

Well-documented measurements contribute significantly to error reduction, ensuring consistent results and aiding in subsequent analysis or troubleshooting.

Q 20. How do you handle inconsistent measurements?

Inconsistent measurements signal a problem and require systematic investigation. I follow a structured approach:

- Re-measurement: Repeat the measurements multiple times, using the same tool and technique, to eliminate random errors.

- Tool Verification: Check the measuring tool for calibration, damage, or defects. If necessary, recalibrate or replace the tool.

- Technique Review: Ensure the measuring technique is correct and consistent. A slight change in approach can result in inconsistencies.

- Environmental Factors: Consider the influence of environmental conditions, like temperature or humidity, on the accuracy of measurements.

- Multiple Tools: If discrepancies persist, use a different type of measuring tool to verify the results. For example, check a tape measure result using a laser distance meter.

- Consult with Colleagues: Seeking a second opinion and having another person independently perform the measurements can identify blind spots in the initial procedure.

Addressing inconsistencies requires diligence and systematic investigation, ensuring the final measurements are accurate and reliable.

Q 21. Explain your understanding of tolerance and its importance in measurement.

Tolerance refers to the permissible variation from a specified measurement. It defines the acceptable range of error within which a measurement is still considered accurate. Think of it as a margin of error.

For instance, if a part needs to be 10cm long with a tolerance of ±0.1cm, it means the acceptable length range is between 9.9cm and 10.1cm. Anything outside this range is considered unacceptable.

Tolerance is crucial because:

- Manufacturing: It dictates the precision needed in manufacturing processes to ensure components fit together properly and perform as intended.

- Quality Control: It sets standards for acceptable variations, facilitating quality control inspections and identifying defects.

- Design: Engineers incorporate tolerances in designs to account for inevitable variations in manufacturing processes and material properties.

Understanding and managing tolerances ensures that measurements are not only precise but also fit within the functional requirements of the task or project. Ignoring tolerances can lead to costly errors and malfunctions.

Q 22. Describe your experience working with blueprints and technical drawings using measurements.

Working with blueprints and technical drawings involves meticulous interpretation of dimensions and tolerances to ensure accurate fabrication or inspection. My experience includes translating 2D drawings into 3D spatial understanding, identifying critical dimensions, and understanding the implications of tolerances (e.g., ±0.005 inches). I’m proficient in reading various drawing symbols and notations, including those specifying surface finishes and material specifications. For instance, I’ve worked on projects involving complex mechanical assemblies, where accurately interpreting the drawings was crucial for ensuring proper component fit and function. One particular project involved the construction of a custom jig, and understanding the precise location of each hole, as detailed in the blueprints, was critical to the jig’s functionality. Any error in interpretation could have led to costly rework.

I routinely utilize tools like calipers, micrometers, and height gauges to verify dimensions against blueprint specifications. I always double-check my measurements to minimize human error.

Q 23. How do you ensure the traceability of your measurements?

Traceability in measurement is paramount. I ensure this through a multi-step process. First, I meticulously document all measurements, including the date, time, measuring instrument used, and the measured value. I use clearly labeled data sheets or digital recording systems, ensuring each measurement is uniquely identified and linked to its corresponding blueprint reference. Second, I utilize calibrated instruments with traceable certificates of calibration. This ensures the accuracy and reliability of the instruments themselves. Third, I regularly cross-check measurements using multiple methods or instruments where possible. For instance, I might measure a dimension with calipers and then verify it with a micrometer. Any discrepancies are investigated and documented. This rigorous approach ensures that if any issues arise later, I have a complete audit trail to trace back to the original measurement.

Q 24. Explain your understanding of different units of measurement (e.g., metric, imperial).

I’m fluent in both metric (SI) and imperial systems of measurement. The metric system, based on powers of 10 (meters, centimeters, millimeters), is preferred globally for its simplicity and ease of conversion. The imperial system (inches, feet, yards) is still prevalent in some industries. I understand the conversion factors between the two systems (e.g., 1 inch = 25.4 millimeters) and seamlessly switch between them based on the project requirements. I’ve worked on projects using both systems and understand the importance of avoiding errors during conversions. A common error is neglecting to convert units correctly when working with formulas or calculations. I meticulously ensure all units are consistent before any calculations.

Q 25. Describe your proficiency with statistical process control (SPC) related to measurement.

Statistical Process Control (SPC) is crucial for maintaining consistent measurement accuracy and identifying potential sources of variation. I understand the use of control charts, such as X-bar and R charts, to monitor the stability of a measurement process. These charts help visualize the mean and range of measurements over time, allowing me to quickly identify trends, shifts, or outliers indicative of problems. For example, if I’m consistently measuring a part dimension, and the measurements start drifting outside the control limits, it signals a potential issue with the measuring instrument, the part itself, or the measurement process. This allows for timely intervention to prevent defects. I can also interpret capability indices (Cp, Cpk) to assess the process’s ability to meet specified tolerances.

Q 26. How would you use a dial indicator?

A dial indicator, or dial gauge, is a precision measuring instrument used to measure small displacements or deviations. To use one, I would first ensure it’s properly zeroed and mounted securely to a suitable base. The probe is then carefully positioned against the surface to be measured. I’d gently apply consistent pressure, avoiding any sideways movement to prevent inaccurate readings. The dial indicator’s hand will then rotate, indicating the amount of displacement. The dial’s graduations are read in units such as thousandths or ten-thousandths of an inch (or millimeters). Precise readings require good technique and practice. For example, when measuring run-out on a shaft, it is crucial to maintain consistent contact pressure to get accurate results.

Q 27. Explain your experience with CMM (Coordinate Measuring Machine) or other automated measurement systems.

I have extensive experience using Coordinate Measuring Machines (CMMs). CMMs use probes to measure three-dimensional coordinates of points on an object. I’m proficient in programming CMMs using various software packages (DMIS is one example) to create measurement routines based on CAD models. This includes defining the required measurements, probe paths, and data analysis methods. I understand the importance of proper probe selection and calibration to ensure measurement accuracy. Furthermore, I’m familiar with the principles of CMM operation, including environmental control and proper handling to maintain accuracy. I’ve used CMMs in quality control inspections to verify the dimensions and geometry of complex parts, providing detailed reports on dimensional variations and deviations.

Q 28. Describe your experience with interpreting measurement data and drawing conclusions.

Interpreting measurement data involves more than just reading numbers; it involves analyzing trends, identifying outliers, and drawing meaningful conclusions. I’m proficient in statistical analysis techniques to evaluate measurement data, determine the accuracy and precision of measurements, and identify potential sources of error. For example, if I find a consistent deviation in measurements, I would investigate whether it’s due to tool wear, incorrect calibration, or a flaw in the manufacturing process. I can then utilize this information to improve future measurements and identify areas for process improvement. I also create clear, concise reports that present findings effectively to stakeholders, incorporating charts and graphs to visualize the data and enhance understanding. This might include recommendations for corrective actions or process adjustments based on the conclusions drawn.

Key Topics to Learn for Proficient in using measuring tools Interview

- Understanding Different Measuring Tools: Familiarize yourself with various tools like rulers, calipers, micrometers, tape measures, levels, and laser measuring devices. Understand their accuracy, precision, and appropriate applications.

- Precision and Accuracy: Grasp the difference between precision and accuracy in measurements. Practice calculating measurement errors and understanding tolerances.

- Practical Applications: Be prepared to discuss real-world scenarios where you’ve used measuring tools. Examples include construction, manufacturing, engineering, or quality control. Highlight your problem-solving skills in situations where accurate measurements were critical.

- Reading and Interpreting Measurements: Demonstrate proficiency in reading different scales (e.g., metric, imperial) and understanding fractions and decimals in measurement contexts.

- Calibration and Maintenance: Understand the importance of calibrating measuring tools for accuracy and how to perform basic maintenance to ensure their longevity.

- Safety Procedures: Discuss safe handling procedures for various measuring tools, particularly those involving sharp edges or moving parts.

- Selecting the Right Tool: Explain how to choose the appropriate measuring tool for a specific task, considering factors like the material being measured, required precision, and the overall project context.

- Troubleshooting Measurement Issues: Describe your approach to resolving issues like inconsistent measurements or malfunctioning equipment.

Next Steps

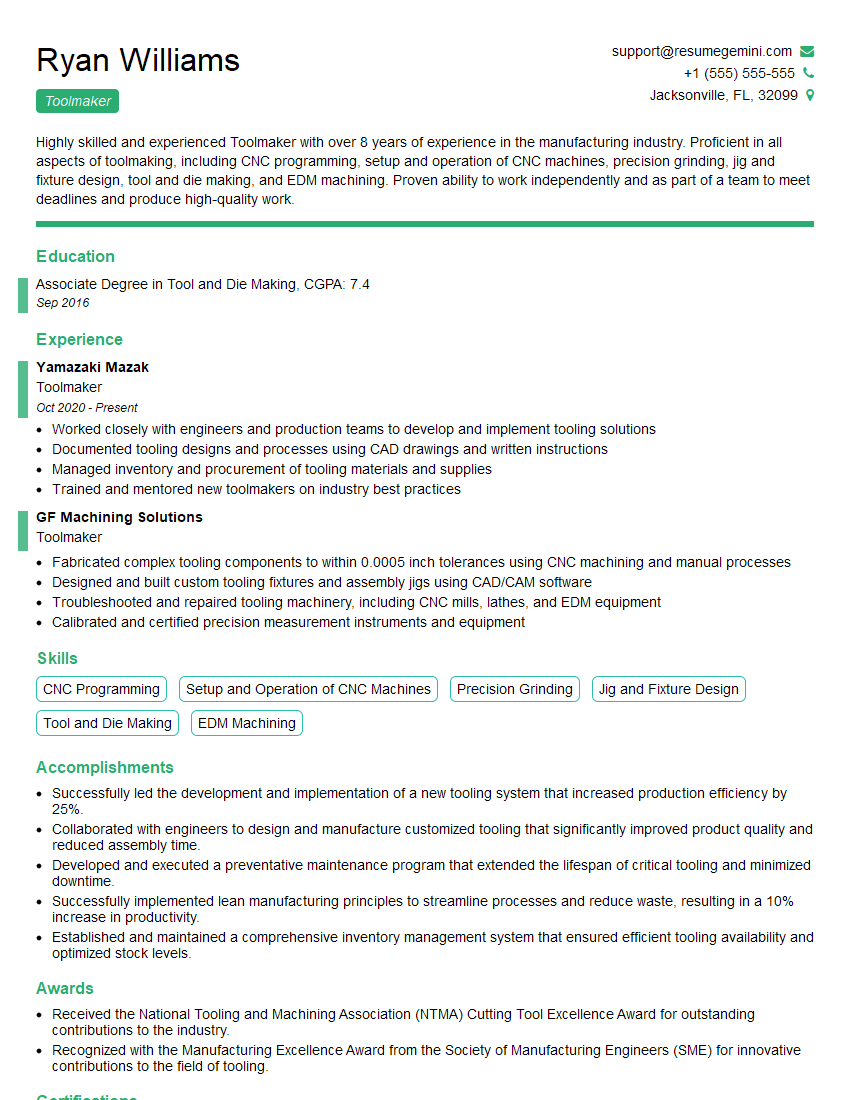

Mastering the use of measuring tools is crucial for career advancement in many technical fields. Accurate and reliable measurements are fundamental to success in roles demanding precision and attention to detail. To maximize your job prospects, create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to highlight proficiency in using measuring tools, helping you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO