Cracking a skill-specific interview, like one for Construction Documents Production, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Construction Documents Production Interview

Q 1. Explain the difference between a construction drawing and a shop drawing.

Construction drawings and shop drawings are both crucial parts of a construction project, but they serve different purposes and have distinct characteristics. Think of construction drawings as the architect’s overall blueprint, outlining the project’s scope and design. Shop drawings, on the other hand, are detailed, manufacturer-specific drawings created by subcontractors to illustrate how they intend to construct specific components within the architect’s plan. They show the precise dimensions, materials, and assembly details of these elements.

For example, the construction drawings might show the location and dimensions of a steel staircase, while the shop drawing would detail the specific steel sections, connection details, and fabrication methods used by the steel fabricator. The construction drawings are the ‘what’ and the shop drawings are the ‘how’ for particular components.

- Construction Drawings: General arrangement, design intent, overall dimensions, and coordination between different systems.

- Shop Drawings: Detailed fabrication and installation information for specific components, often including manufacturer-specific details and specifications.

Q 2. Describe your experience with various CAD software (AutoCAD, Revit, etc.).

I have extensive experience with several CAD software packages, primarily AutoCAD and Revit. My proficiency in AutoCAD spans over 10 years, encompassing 2D drafting and detailing. I’ve used it extensively for creating detailed construction drawings, site plans, and sections for various projects ranging from residential renovations to small commercial buildings. I’m adept at creating complex drawings with accurate dimensions and annotations.

More recently, I’ve embraced BIM methodologies and have become proficient in Revit. I’ve used Revit on several projects, leveraging its 3D modeling capabilities for improved coordination and clash detection. This has significantly improved the efficiency and accuracy of our documentation. I’m also comfortable with other BIM software such as Navisworks for model review and coordination.

For example, in one project, using Revit’s 3D modeling capabilities allowed us to identify clashes between MEP (Mechanical, Electrical, and Plumbing) systems and structural elements before construction even began, saving significant time and money by preventing rework.

Q 3. What are the key components of a complete set of construction documents?

A complete set of construction documents is much more than just drawings. It’s a comprehensive package of information that guides the entire construction process. This usually includes:

- Drawings: Site plans, floor plans, elevations, sections, details, and schedules.

- Specifications: Written descriptions of materials, methods, and quality standards for all aspects of the project.

- Project Manual: This often includes the project’s general conditions, contract documents, and other administrative information.

- Schedules: Door schedules, window schedules, finish schedules etc. These ensure that the project is built consistently.

- Addenda and Revisions: Any updates or changes made to the original documents throughout the design and construction phase.

Think of it like a recipe for a building. The drawings show what the final product will look like, while the specifications define exactly what ingredients and methods to use.

Q 4. How do you manage revisions and updates to construction documents?

Managing revisions and updates is crucial to maintain accuracy and avoid costly errors. We utilize a robust version control system, typically integrated within our CAD software and supplemented by a dedicated document control software. Every revision is assigned a unique number, logged, and clearly identified in the drawings themselves (using revision clouds and revision logs). This allows everyone involved to quickly identify the latest version of the document and track changes.

We establish clear processes for submitting and approving revisions. All changes must be reviewed and approved by the appropriate stakeholders before being released. Using digital document management systems makes distribution and tracking simple. A central repository prevents conflicting versions and ensures everyone is working off the most up-to-date drawings.

For instance, if a change is requested to the location of a door, we create a revised drawing with the necessary changes highlighted, document the reason for the change, obtain approval, and update the central repository.

Q 5. Explain your understanding of BIM (Building Information Modeling) and its role in construction documents.

BIM, or Building Information Modeling, is a process of creating and managing digital representations of physical and functional characteristics of places. It’s more than just 3D modeling; it’s about creating a centralized database that contains all the information related to a project, from design to construction and beyond. In terms of construction documents, BIM plays a vital role in improving accuracy, coordination, and collaboration.

BIM software allows us to create a coordinated model that includes architectural, structural, and MEP information. This helps prevent clashes between different systems, identify potential problems early in the design phase, and significantly improve the overall efficiency of the project. The model itself provides richer and more detailed construction documents. For example, accurate quantities for materials can be extracted directly from the model, improving cost estimation.

Q 6. How do you ensure accuracy and consistency in construction documents?

Ensuring accuracy and consistency is paramount. We implement a multi-layered approach involving rigorous quality checks at each stage. This starts with clear design guidelines and standardized drafting practices. We also utilize automated quality control tools within our CAD software to identify potential errors such as dimension conflicts or missing information.

Regular peer reviews and internal check processes are implemented, where different team members review the drawings for accuracy and consistency. This ‘four-eyes’ principle significantly reduces the risk of errors. Additionally, detailed checking against specifications and other related documents is a crucial step. We also leverage technology such as clash detection software when using BIM models. Finally, clear communication with other stakeholders and a collaborative approach ensure consistency across the board.

Q 7. Describe your experience with document control software and processes.

I have extensive experience using document control software, primarily using systems integrated with our CAD platforms and cloud-based solutions. These systems provide centralized storage, version control, and access permissions, ensuring secure and efficient management of all project documentation. They allow us to track revisions, manage approvals, and easily share documents with other stakeholders.

We implement strict document control procedures, clearly defining roles and responsibilities for document creation, review, approval, and distribution. These procedures ensure that all documents are properly managed and that only the latest approved versions are used on site. This prevents confusion and avoids costly mistakes. The system typically includes features like automated notifications and workflows, which streamline the approval process and enhance collaboration.

Q 8. How do you handle conflicts or discrepancies in construction documents?

Resolving conflicts in construction documents requires a systematic approach. Think of it like a detective solving a case – you need to gather evidence and follow a clear process. First, I meticulously identify the discrepancy, noting the conflicting information from different drawings or specifications. Then, I trace the origin of the conflict; was it a drafting error, an oversight in coordination, or a difference in design intent? I consult relevant documents, such as the project manual, design briefs, and any previous revisions. If the issue isn’t readily resolved, I initiate communication with the relevant design team members (architects, structural engineers, MEP engineers) to clarify the intent and reach a consensus. This often involves meetings, email exchanges, and potentially even the use of conflict resolution matrices to document the decisions made. Finally, I ensure that the resolution is documented clearly, with appropriate revisions reflected in the drawings and specifications. A recent example involved a conflict between the architectural plans and the structural drawings regarding the location of a supporting column. After several discussions, we found a minor error in the architectural plan, resolved the issue by repositioning the column, and updated both documents accordingly.

Q 9. What is your experience with different document formats (PDF, DWF, etc.)?

My experience spans a variety of document formats commonly used in construction. I’m proficient with PDFs for their wide compatibility and ease of sharing, using tools like Adobe Acrobat Pro to mark up and manage revisions. I’m also experienced with DWF (Design Web Format) files, which are particularly useful for larger projects and collaborative reviews, facilitating efficient markups and version control. I’ve worked with other formats like Autodesk Revit files, which offer a powerful BIM (Building Information Modeling) workflow enabling direct manipulation of models and seamless integration with other disciplines. Finally, I am also familiar with image formats like TIFF and JPG used for photo documentation and submittal reviews. Choosing the right format depends on the project’s size, complexity, and the collaborative tools employed.

Q 10. Explain your process for reviewing construction documents for errors.

My document review process is thorough and multi-layered. I start with a high-level overview, checking for consistency in numbering, sheet organization, and overall completeness. Then, I delve into the details, verifying dimensions, specifications, and notations for accuracy and clarity. I utilize checklists tailored to the project type, ensuring all aspects, such as structural details, fire protection, and accessibility requirements, are adequately addressed. I employ a redlining process, using digital tools to highlight and annotate errors or inconsistencies, ensuring clear communication of corrections. The review also includes a thorough check for compliance with relevant codes and standards, as well as a review for potential constructability issues. This method combines careful scrutiny of individual components with a comprehensive understanding of the project’s overall design. Think of it as assembling a complex puzzle – you check each piece individually, but your aim is to see how it fits into the bigger picture.

Q 11. How do you collaborate with other disciplines (architectural, structural, MEP) on construction documents?

Collaboration is key in construction document production. I utilize collaborative platforms like BIM 360 or similar tools for seamless sharing and coordination. Regular meetings with architects, structural, and MEP engineers are crucial. These meetings serve as opportunities to discuss design challenges, address conflicts, and ensure consistency across disciplines. I utilize clear and concise communication, documenting decisions and agreements. I’m adept at translating technical information from one discipline to another, bridging potential communication gaps. For instance, I’ve successfully coordinated the positioning of MEP elements within the structural framework, preventing conflicts and ensuring a streamlined construction process. Open communication and a proactive approach are fundamental to successful interdisciplinary collaboration.

Q 12. Describe your experience with creating specifications for construction materials.

Creating specifications for construction materials requires a deep understanding of construction practices and materials science. I start by identifying the performance requirements for each material, considering factors such as durability, aesthetics, and sustainability. I then research appropriate materials, referencing industry standards and manufacturers’ data. The specification documents I create are clear, concise, and unambiguous, leaving no room for interpretation. This involves utilizing standardized formats, such as MasterFormat, ensuring consistency and readability. I always ensure that the chosen materials comply with relevant building codes and standards. For example, recently I specified sustainable timber flooring, carefully selecting a product that met strength, fire safety, and environmental requirements, including specifying certification details and testing requirements.

Q 13. How do you manage large sets of construction documents effectively?

Managing large sets of construction documents effectively requires a well-organized system. I utilize document management software, such as Autodesk Vault or similar platforms. These systems enable version control, ensuring that only the latest revisions are used. I establish clear naming conventions and file structures, facilitating easy retrieval of specific documents. A robust system of tagging and keywording allows for quick searching. I utilize cloud-based storage for easy access from different locations and devices. Regular backups are essential to prevent data loss. In addition, I utilize organized digital folders reflecting the project’s hierarchy and phase of construction. Think of it as a well-organized library – with a clear cataloging system, you can always find the book you need.

Q 14. How do you ensure construction documents comply with relevant building codes and standards?

Ensuring compliance with building codes and standards is paramount. I begin by identifying the applicable codes and standards relevant to the project’s location and type. This may involve referencing local, state, and national codes such as the International Building Code (IBC) or the Americans with Disabilities Act (ADA) guidelines. Throughout the document production process, I actively check the drawings and specifications for compliance. I utilize code check software where appropriate, further assisting in identifying potential violations. I also leverage the expertise of the project team; any ambiguities or uncertainties are discussed and resolved with relevant experts. Finally, I conduct a thorough review prior to document submission to confirm full compliance. By maintaining this rigorous process, we proactively mitigate risks and ensure a safe and legal project.

Q 15. What is your experience with RFI (Request for Information) processes?

RFIs, or Requests for Information, are crucial in construction. They’re essentially formal requests for clarification or additional information from the architect or engineer to the contractor, clarifying ambiguities or gaps in the construction documents. My experience encompasses the entire RFI lifecycle, from initiating the request to receiving and distributing the response. I’ve managed hundreds of RFIs on projects ranging from small renovations to large-scale developments.

For example, on a recent high-rise project, we encountered inconsistencies between structural drawings and MEP (Mechanical, Electrical, and Plumbing) plans regarding pipe routing. I initiated an RFI detailing the conflict, including specific drawing numbers and locations. This led to a timely clarification from the architect, avoiding potential delays and rework.

My approach to managing RFIs includes:

- Clear and concise documentation: Each RFI is meticulously documented, including the date, subject, sender, recipient, and response. This ensures clear auditability and traceability.

- Prioritization: RFIs are prioritized based on their potential impact on the project schedule and cost. Critical RFIs that might halt construction are addressed first.

- Distribution: All relevant project stakeholders receive copies of the RFI and the response to maintain transparency and alignment.

- Tracking: I use dedicated software to track the status of each RFI, ensuring timely resolution and follow-up.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with creating and maintaining a project document register.

A project document register is a centralized repository of all project documents, acting like a comprehensive table of contents for the entire project. Maintaining one is vital for efficient project management and collaboration. My experience involves creating and managing these registers for projects of varying complexity and sizes. I typically use a spreadsheet or dedicated project management software for this purpose.

A well-maintained register includes information such as the document name, number, version, date created, author, and status. It also often includes hyperlinks to the document’s location, whether it’s a local server or a cloud-based platform. This allows for easy access and tracking of every document relevant to the project.

For instance, on a recent hospital renovation, I established a document register using a shared spreadsheet. This ensured that all project team members had access to the most up-to-date versions of drawings, specifications, and other crucial documents. The register also helped us to easily track approvals and review cycles.

Q 17. How do you prioritize tasks when managing multiple construction document projects?

Prioritizing tasks across multiple projects requires a structured approach. I typically utilize a combination of methods, considering factors like deadlines, project criticality, resource availability, and potential impact of delays.

My strategy involves:

- Project Prioritization Matrix: I assess each project based on its urgency and importance, using a matrix to visualize and prioritize. Projects with tight deadlines and significant consequences of delay are given higher priority.

- Task Breakdown and Sequencing: Within each project, I break down tasks into smaller, manageable units and sequence them logically to maximize efficiency and resource allocation.

- Resource Allocation: I carefully allocate my time and resources to tasks based on their priority. Critical tasks receive more attention and dedicated resources.

- Regular Monitoring and Adjustment: I regularly monitor progress and adjust task priorities as needed, responding to unexpected issues or changing circumstances.

For example, if one project faces a critical deadline while another has more flexibility, I’ll allocate more resources and focus to the high-priority project, ensuring timely completion of crucial milestones.

Q 18. What strategies do you use to improve the efficiency of construction document production?

Improving efficiency in construction document production involves streamlining processes, leveraging technology, and fostering collaboration. I employ several strategies, including:

- Building Information Modeling (BIM): BIM allows for better coordination, clash detection, and improved visualization, significantly reducing errors and rework.

- Template Standardization: Using consistent templates for drawings, specifications, and other documents ensures uniformity, reduces errors and speeds up the production process.

- Automation: Utilizing automation tools for tasks like numbering, sheet generation, and report creation saves time and effort.

- Workflow Optimization: Streamlining the review and approval processes, utilizing digital workflows, eliminates bottlenecks and ensures timely progress.

- Regular Training and Knowledge Sharing: Keeping the team updated with the latest technology and best practices ensures proficiency and fosters innovation.

In one project, implementing a standardized drawing template reduced the time spent on drawing preparation by 20%, freeing up valuable time for design and coordination.

Q 19. Describe your experience with using cloud-based collaboration platforms for document management.

Cloud-based collaboration platforms are essential for modern construction document management. My experience includes extensive use of platforms like BIM 360, Autodesk Docs, and similar solutions. These platforms facilitate real-time collaboration, version control, and efficient document sharing among all project stakeholders.

These platforms offer numerous benefits, including:

- Centralized Document Storage: All project documents are stored in a single, secure location, accessible to authorized personnel.

- Version Control: Changes are tracked, and different versions of documents can be easily accessed and compared.

- Real-time Collaboration: Multiple users can work on the same documents simultaneously, improving efficiency and reducing conflicts.

- Improved Communication: Integrated communication tools facilitate easy and efficient communication among team members.

For instance, on a recent large-scale infrastructure project, using a cloud-based platform allowed for seamless collaboration between our team and the client, even across geographical locations. This significantly improved communication and expedited the review and approval process.

Q 20. How do you handle change orders and their impact on construction documents?

Change orders are inevitable in construction projects. Handling them efficiently requires a systematic approach to minimize their impact on construction documents. My experience includes managing numerous change orders, from minor modifications to substantial alterations to the original design.

My process typically includes:

- Formal Documentation: Each change order is documented formally, clearly stating the change, its rationale, and its impact on the schedule and budget.

- Document Revision: The construction documents are revised to reflect the changes. Revisions are clearly marked and tracked using a version control system.

- Impact Assessment: A thorough impact assessment is conducted to determine the potential effect of the change on other aspects of the project.

- Communication: All relevant stakeholders are informed about the change order and its implications.

- Approval Process: A formal approval process is followed to ensure that all stakeholders agree on the changes before implementation.

For example, a change order requesting an additional elevator in a multi-story building would require updating architectural, structural, MEP, and fire protection drawings. Each drawing must be revised, and the revisions clearly indicated and tracked.

Q 21. What is your experience with construction document automation tools?

Construction document automation tools are vital for efficient and accurate document production. My experience encompasses using various tools, from simple macros in spreadsheet software to sophisticated BIM software with automation capabilities. These tools significantly reduce manual effort and increase accuracy.

Examples of tools I’ve utilized include:

- Autodesk Revit: For automated generation of schedules, drawings, and quantities.

- Bluebeam Revu: For automated markups and batch processing of documents.

- Custom Macros and Scripts: For automating repetitive tasks such as numbering sheets or generating reports.

Utilizing these tools has resulted in substantial time savings and a reduction in errors. For example, automating the numbering of drawings in Revit eliminated manual numbering, reducing the time spent on this task by over 50% on a recent project.

Q 22. Explain your understanding of layering and organization within construction drawings.

Layering and organization in construction drawings are crucial for clarity and efficient collaboration. Think of it like building with LEGOs – each layer represents a different aspect of the design, and proper organization ensures you can easily assemble the final product. We use layers to separate different disciplines (architectural, structural, MEP – Mechanical, Electrical, Plumbing), different phases of construction (demolition, foundation, framing), or different types of information (site plan, floor plans, details).

- Discipline Layers: Architectural layers might contain walls, doors, and windows. Structural layers might include columns, beams, and foundations. MEP layers would contain ductwork, piping, and electrical conduit. This allows each discipline to work independently without interfering with others.

- Phase Layers: Separating demolition from new construction allows for clear visualization of the process. You can turn layers on and off to focus on a particular phase.

- Information Layers: Layers can separate information such as dimensions, notes, and symbols, allowing for easy management and editing. For example, one layer may contain only dimensions, allowing you to easily turn them on or off without affecting other information.

A well-organized drawing set utilizes a consistent naming convention for layers and uses layer properties (color, line weight, linetype) to enhance visual clarity and understanding. This significantly streamlines the review process and reduces errors during construction.

Q 23. How do you ensure the proper level of detail in construction documents for various stakeholders?

Ensuring the proper level of detail is vital. Too much detail overwhelms, too little leads to ambiguity. My approach involves understanding the needs of each stakeholder:

- Client: They need a clear, high-level understanding of the design, focusing on aesthetics and functionality. Detailed technical drawings aren’t necessary at this stage. Instead, we use perspective renderings and simplified floor plans.

- Contractor: They need highly detailed drawings with precise dimensions, specifications, and material information to build the project accurately. We provide comprehensive plans, sections, elevations, and details.

- Subcontractors: They require drawings specific to their trade, with sufficient detail for accurate bidding and execution. We utilize discipline-specific layers and detailed shop drawings.

- Engineers: They need detailed drawings that meet specific engineering standards and regulations. We provide detailed structural, mechanical, electrical, and plumbing drawings.

I use a tiered approach to detail, starting with schematic designs for initial review, progressing to design development with increasing detail, and finally, construction documents with the highest level of precision. This incremental approach facilitates better communication and reduces potential conflicts.

Q 24. Describe your experience with creating and interpreting schedules for construction document deliverables.

I’m proficient in creating and interpreting construction document schedules using various methods like Gantt charts and Microsoft Project. These schedules are essential for project management and ensuring timely delivery of documents. My approach includes:

- Identifying Milestones: We start by defining key milestones, such as design completion, permit submittal, and construction document issue dates.

- Task Breakdown: Each phase is broken down into smaller, manageable tasks, assigning responsible parties and estimated durations.

- Resource Allocation: We consider the availability of personnel and resources when scheduling tasks to prevent bottlenecks.

- Dependency Identification: We define dependencies between tasks to ensure proper sequencing. For example, structural drawings cannot be completed until architectural plans are finalized.

- Regular Monitoring: The schedule is regularly reviewed and updated to reflect progress and address any unforeseen delays.

For example, in a recent project, I used Microsoft Project to create a detailed schedule that tracked the progress of over 100 individual tasks. The schedule facilitated efficient communication among the team, enabling us to complete the construction documents on time and within budget.

Q 25. What is your experience with using version control for construction documents?

Version control is paramount in construction document production. We use centralized systems like BIM 360 Docs or Autodesk Vault to manage revisions and prevent conflicts. These systems allow multiple users to work on the same project simultaneously, track changes made by individuals, and easily revert to previous versions if needed. This ensures that everyone is working with the most up-to-date information and minimizes the risk of errors due to outdated drawings.

Each revision is clearly identified with a version number and description of the changes. This provides a clear audit trail for every modification made to the construction documents, facilitating easy tracking and accountability.

Q 26. How familiar are you with various types of construction drawings (plans, sections, elevations, details)?

I have extensive experience with various types of construction drawings. They are all vital components of a complete set of construction documents:

- Plans: Top-down views showing the layout of spaces, including dimensions, furniture placement, and other features.

- Sections: Vertical cuts through a building, revealing the internal structure and construction details.

- Elevations: Exterior views showing the building’s appearance from different perspectives.

- Details: Large-scale drawings illustrating specific construction elements, like connections or building components, in detail.

Understanding how these different drawing types complement each other is key to interpreting a complete set of construction documents. Each view provides different information, and the combined set helps visualize the building in 3-dimensions.

Q 27. How do you handle incomplete or ambiguous information in construction documents?

Incomplete or ambiguous information is a common challenge. My approach involves a systematic process:

- Identification: Thoroughly review all documents, flagging any inconsistencies or missing data.

- Research: Investigate potential sources of information to clarify ambiguities. This may involve contacting the architect, engineer, or client.

- Documentation: Clearly document all identified issues, including their location and potential impact on the project.

- Resolution: Work collaboratively with stakeholders to find solutions. This may involve issuing RFIs (Requests for Information) to the design team or making educated assumptions based on best practices, clearly documenting these assumptions.

- Version Control: Update the documents to reflect the resolution and track the changes made.

For example, if a detail is missing, I would research relevant standards, consult similar projects, or contact the engineer to clarify the requirements. The goal is to ensure clarity and completeness before construction commences.

Q 28. Describe a time you had to solve a complex problem related to construction document production.

On a recent large-scale commercial project, we encountered a significant clash between the structural and MEP systems near the building’s core. The structural columns were conflicting with the proposed location of major ductwork for the HVAC system. This was discovered late in the design process, and a simple relocation wasn’t feasible due to space constraints.

My approach involved a multi-pronged strategy:

- 3D Modeling Review: I used BIM software to visualize the clash in 3D, clearly demonstrating the conflict to all stakeholders.

- Collaboration: I convened a meeting with the structural and MEP engineers to discuss potential solutions. We brainstormed several options, considering the structural integrity of the building and the functionality of the HVAC system.

- Feasibility Analysis: Each proposed solution was evaluated for its impact on the schedule and budget, considering structural, mechanical, and cost implications.

- Revised Drawings: The chosen solution – a slight modification of the ductwork routing – was implemented in the construction documents. All relevant drawings were updated and re-issued.

This collaborative approach ensured a timely resolution without compromising the quality or safety of the project. The experience emphasized the critical role of communication, collaboration, and 3D modeling in solving complex problems during construction document production.

Key Topics to Learn for Construction Documents Production Interview

- Blueprint Reading and Interpretation: Understanding architectural, structural, mechanical, and electrical drawings; identifying key notations, symbols, and specifications.

- Specification Writing and Management: Creating clear, concise, and accurate specifications; utilizing MasterFormat and using specification software.

- Building Information Modeling (BIM): Familiarity with BIM software (Revit, ArchiCAD, etc.) and its application in document production, coordination, and clash detection.

- Quantity Takeoff (QTO): Accurately estimating quantities of materials and labor from construction documents; utilizing QTO software.

- Document Control and Management: Implementing version control systems, managing revisions, and ensuring document accuracy and consistency.

- Collaboration and Communication: Effective communication with architects, engineers, contractors, and other stakeholders; understanding the role of document production in the overall project lifecycle.

- Construction Technology and Software Proficiency: Demonstrating knowledge of relevant software and technologies used in the industry; showcasing adaptability to new tools and techniques.

- Problem-Solving and Critical Thinking: Identifying and resolving discrepancies in construction documents; demonstrating proactive problem-solving skills in a collaborative environment.

- Plan Production and Workflow Optimization: Understanding the entire production process from initial design to final deliverables; optimizing workflows for efficiency.

Next Steps

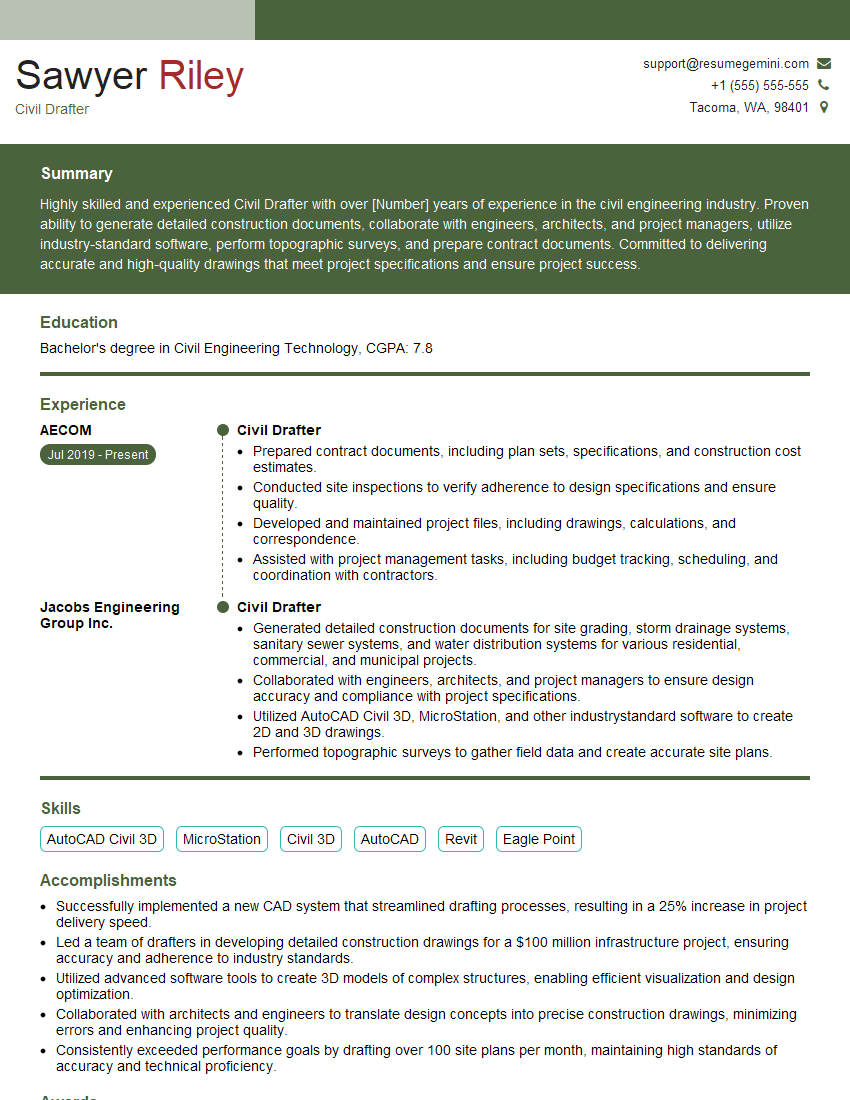

Mastering Construction Documents Production opens doors to exciting career advancements, offering opportunities for specialization and leadership roles within the construction industry. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. To build a professional and impactful resume, we recommend using ResumeGemini, a trusted resource for crafting compelling resumes. Examples of resumes tailored to Construction Documents Production are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO