The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Chick Processing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Chick Processing Interview

Q 1. Describe the different stages of chick processing.

Chick processing involves several stages, from the moment the chicks hatch until they are ready for transportation or placement in grow-out facilities. Think of it as a carefully orchestrated process aiming for the healthiest start for these young birds.

- Hatching: Chicks emerge from eggs in incubators. This stage requires careful monitoring of temperature and humidity.

- Debeaking (Optional): In some operations, the tips of the chicks’ beaks are trimmed to prevent cannibalism. This is done using specialized equipment and requires precise technique to avoid injury.

- Vaccination: Chicks are often vaccinated against common poultry diseases, typically using in-ovo or in-ovo/spray vaccinations. This is critical for ensuring flock health.

- Sexing: Determining the sex of the chicks is crucial for managing flocks efficiently. This is often performed visually or by experienced technicians.

- Grading/Sorting: Chicks are sorted by size and weight, ensuring uniformity within groups. This optimizes growth and resource allocation.

- Packing and Transportation: The graded chicks are carefully packed in boxes or containers designed to minimize stress and maintain ideal temperatures during transportation to farms.

Q 2. What are the critical control points (CCPs) in chick processing?

Critical Control Points (CCPs) in chick processing are steps where control can prevent or eliminate a food safety hazard. Imagine them as the most crucial checkpoints where things can go wrong if not properly managed.

- Incubation Temperature and Humidity: Maintaining optimal conditions is vital for chick viability and health.

- Sanitation of Hatchery Equipment: Thorough cleaning and disinfection of incubators, hatchers, and processing equipment prevent the spread of pathogens.

- Vaccination Procedure: Correct vaccine handling, administration, and storage prevent vaccine failure and disease outbreaks.

- Water Quality: Clean and sanitized water is critical to preventing bacterial contamination throughout the process.

- Temperature Control During Transportation: Maintaining proper temperatures in transport vehicles prevents chick stress and mortality.

Q 3. Explain the importance of hygiene and sanitation in chick processing.

Hygiene and sanitation are paramount in chick processing to minimize the risk of disease transmission and ensure chick health. It’s all about creating a clean and safe environment from egg to transport.

Poor hygiene can lead to outbreaks of highly contagious diseases like Salmonella or E. coli, resulting in significant economic losses and impacting animal welfare. We employ strict protocols, including regular cleaning and disinfection of all equipment and facilities, proper waste disposal, and rigorous handwashing protocols for all personnel. Imagine a hospital – the same principles of cleanliness and sterilization apply.

Q 4. How do you ensure the quality and safety of processed chicks?

Ensuring quality and safety involves a multi-pronged approach, starting from the parent flock and continuing through each stage of processing. Think of it as a quality chain.

- Parent Flock Health: Healthy parent birds produce healthy eggs and chicks. This includes disease monitoring and vaccination.

- Egg Quality Control: Careful selection and handling of eggs prevent contamination and improve hatchability.

- Strict Sanitation Procedures: Maintaining a clean and disinfected environment throughout the processing facility is crucial.

- Proper Vaccination Protocols: Correct vaccination technique and storage ensure vaccine efficacy.

- Regular Monitoring: Continuous monitoring of chick health, temperature, and humidity ensures optimal conditions.

We also employ regular quality checks, including random sampling for disease testing and monitoring mortality rates to fine-tune our processes and ensure that the end product meets the highest standards.

Q 5. What are the common challenges faced in chick processing?

Chick processing faces several challenges, many stemming from biological factors and the delicate nature of newly hatched birds.

- Disease outbreaks: Highly contagious diseases can quickly devastate a flock if biosecurity measures are not strictly adhered to.

- Mortality rates: Maintaining low mortality rates requires careful management of environmental conditions and disease prevention.

- Equipment malfunction: Failures in incubation or processing equipment can significantly impact chick health and survival.

- Maintaining Temperature Control: Fluctuations in temperature during transportation can cause stress and mortality.

- Labor shortages and skilled personnel: Finding and retaining trained staff is a continuous challenge in the industry.

Q 6. What are the different methods of chick grading and sorting?

Chick grading and sorting are essential for efficient flock management and optimal growth. It’s like sorting Lego bricks by size and color – it helps to build things efficiently.

- Visual Grading: Chicks are visually inspected for physical abnormalities, signs of disease, or weakness.

- Weight-Based Sorting: Chicks are weighed and sorted into groups based on their weight, ensuring uniformity within each group for more efficient growth.

- Automated Systems: Modern hatcheries utilize automated systems that can weigh and sort chicks efficiently and accurately. These systems can also identify chicks based on pre-defined parameters, separating those requiring more care.

Q 7. Describe your experience with chick processing equipment.

My experience encompasses a wide range of chick processing equipment, from traditional manual methods to the latest automated systems. I’m familiar with various incubators, hatchers, debeaking machines, chick sexing devices, and automated grading and sorting systems. I’ve worked extensively with both small-scale and large-scale processing facilities, giving me a broad understanding of the equipment’s capabilities and limitations. My expertise extends to troubleshooting and maintenance of this equipment, ensuring optimal performance and minimizing downtime. I’ve even participated in the installation and commissioning of new equipment, optimizing its integration within existing processes.

Q 8. How do you handle equipment malfunctions during processing?

Equipment malfunctions are inevitable in chick processing, but having a robust plan minimizes downtime and ensures product safety. Our approach is multi-faceted, starting with preventative maintenance. We meticulously schedule regular inspections and servicing of all equipment, from the incubators to the evisceration line. This includes lubrication, cleaning, and replacing worn parts before they cause major failures.

However, unexpected breakdowns still occur. We have a dedicated team of skilled technicians trained to diagnose and fix issues quickly. For complex problems, we have service contracts with reputable equipment suppliers, ensuring rapid access to expert assistance. For minor issues, we have standardized operating procedures (SOPs) available for troubleshooting common problems. A well-stocked parts inventory also minimizes wait times. Finally, redundancy is built into the system where possible – backup generators, for instance – to prevent complete shutdowns.

Imagine a scenario where our chilling system malfunctions. Our team will immediately isolate the affected section, preventing further spoilage. They will simultaneously initiate the troubleshooting process, referencing our SOPs and contacting the supplier if needed. The backup chiller will be activated to ensure continued processing while repairs are underway. This layered approach allows for quick response and minimal disruption.

Q 9. Explain the importance of traceability in chick processing.

Traceability is paramount in chick processing for several critical reasons. Primarily, it ensures food safety and enables rapid response to potential contamination. If a batch of chicks is found to be contaminated, traceability allows us to immediately pinpoint the origin, isolating the affected birds and preventing further distribution. This protects consumers and our reputation.

Furthermore, traceability aids in improving operational efficiency. By tracking each flock from hatchery to processing, we can identify bottlenecks and areas for improvement in our processes. For example, if we consistently experience high mortality rates in a particular phase, traceability helps us investigate the cause, whether it’s related to environmental factors, feed quality, or disease.

Finally, traceability provides critical data for meeting regulatory requirements and customer demands. Many retailers and food safety agencies require detailed records of the chick’s journey. We use a robust tracking system which incorporates flock identification numbers, processing dates, and batch numbers throughout the entire chain. This information is digitally recorded and readily accessible, allowing for seamless audits and compliance.

Q 10. What are the common safety hazards associated with chick processing?

Chick processing presents several inherent safety hazards. The most prominent are biological hazards, such as exposure to avian influenza or Salmonella. These require strict adherence to biosecurity protocols and personal protective equipment (PPE), including masks, gloves, and protective clothing.

Physical hazards also abound. Sharp equipment like knives and saws necessitates careful handling and appropriate safety training. Moving machinery parts on processing lines pose a risk of injury, thus we implement lockout/tagout procedures during maintenance and repairs. Slips, trips, and falls are common in wet environments, requiring careful attention to floor hygiene and proper footwear. Finally, repetitive motions during tasks like evisceration can lead to musculoskeletal injuries, necessitating ergonomic considerations and employee rotation.

For example, to mitigate the risk of Salmonella contamination, we implement rigorous sanitation procedures and regularly monitor the plant for bacterial presence. For physical hazards, we provide mandatory safety training to all employees and enforce the consistent use of safety equipment, including cut-resistant gloves and safety glasses.

Q 11. How do you maintain a safe working environment in a chick processing plant?

Maintaining a safe working environment is a top priority, achieved through a combination of engineering controls, administrative controls, and personal protective measures. Engineering controls involve designing the plant layout to minimize hazards. This includes proper lighting, clear pathways, and easily accessible safety equipment. We incorporate guarding on machinery, eliminating pinch points and exposed moving parts. Administrative controls focus on procedures and training. This means establishing clear safety protocols, providing regular safety training, and conducting frequent safety inspections. We also utilize a system for reporting and investigating accidents to identify trends and prevent future occurrences.

Personal protective equipment (PPE) is crucial. Employees are provided with and required to wear appropriate PPE depending on their task, including cut-resistant gloves, safety glasses, hearing protection, and protective clothing. We promote a safety-first culture through employee engagement programs, ensuring everyone feels empowered to report hazards and participate in safety improvement initiatives. Regular safety meetings and drills ensure preparedness for emergencies.

For instance, we conduct mock emergency drills to prepare for situations like equipment malfunctions or sudden illness. This proactive approach to safety fosters a more secure and efficient work environment.

Q 12. What are your knowledge of poultry disease and biosecurity?

My knowledge of poultry diseases and biosecurity is extensive. I understand the various diseases affecting chickens, including Newcastle disease, avian influenza, and Salmonella. I’m familiar with their transmission routes, clinical signs, and preventative measures. This understanding informs our biosecurity strategies.

Biosecurity is a critical component of our operations. We employ a multi-layered approach involving strict hygiene protocols, disinfection procedures, rodent control, and visitor management. Personnel entering the plant are required to follow strict hygiene procedures, such as showering and changing into clean clothing. We rigorously monitor bird health and promptly report any unusual mortality or clinical signs. We maintain accurate records of all disease surveillance and control measures.

For instance, we implement strict quarantine procedures for newly arrived birds before introducing them to the existing flock. Regular disinfection of the processing plant using approved disinfectants is integral to our biosecurity protocol. This comprehensive approach ensures a healthy flock and minimizes the risk of disease outbreaks.

Q 13. Describe your experience with HACCP (Hazard Analysis and Critical Control Points).

I have extensive experience with HACCP (Hazard Analysis and Critical Control Points). I understand its principles and application in food processing. We have a fully implemented HACCP plan, which systematically identifies potential hazards at every stage of the chick processing, from receiving to distribution. This plan outlines critical control points (CCPs) where control measures are essential to prevent or eliminate identified hazards. For each CCP, we establish critical limits, monitoring procedures, and corrective actions.

Our HACCP plan covers biological hazards (like Salmonella), chemical hazards (such as cleaning agents), and physical hazards (like bone fragments). We have established procedures to monitor temperature throughout the processing, ensuring proper chilling and preventing bacterial growth. We regularly conduct audits and review our HACCP plan to ensure its effectiveness. All personnel are thoroughly trained on HACCP principles and their roles in maintaining food safety.

For example, a CCP might be the chilling temperature of the processed chicks. We have established a critical limit of 4°C. Continuous monitoring and recording of temperatures ensure we’re consistently within this limit. Deviations from this limit trigger specific corrective actions, which might involve adjusting the chiller settings or removing affected product.

Q 14. How do you manage inventory control in a chick processing plant?

Inventory control in a chick processing plant is crucial for maintaining efficiency, minimizing waste, and ensuring timely production. We use a combination of manual and computerized systems. Manual tracking involves keeping detailed records of chick arrivals, processing quantities, and storage locations. This helps maintain a physical inventory. Our computerized system provides real-time tracking of inventory levels, allowing for better forecasting of supply and demand.

We utilize a First-In, First-Out (FIFO) system to ensure that the oldest chicks are processed first, minimizing spoilage. Regular inventory checks are conducted to verify accuracy and identify discrepancies. We also incorporate an automated ordering system which triggers replenishment orders based on pre-determined stock levels. This system accounts for anticipated demand and lead times, preventing stockouts. Data analysis helps us predict future demand and optimize our inventory levels, minimizing waste and storage costs.

For example, if we notice an unusually low inventory level of day-old chicks, our system will automatically trigger an order to the hatchery, allowing us to maintain sufficient supply for processing. This streamlined approach avoids production delays and minimizes the impact on the supply chain.

Q 15. Explain your experience with poultry processing regulations.

My experience with poultry processing regulations spans over 10 years, encompassing both USDA and state-level guidelines. I’m intimately familiar with the complexities of the Poultry Products Inspection Act, the Hazard Analysis and Critical Control Points (HACCP) system, and the various Good Manufacturing Practices (GMPs) that are essential for safe and efficient chick processing. This includes detailed knowledge of sanitation procedures, temperature controls throughout the process (from chilling to storage), and the proper handling and disposal of byproducts. I’ve personally overseen audits and successfully implemented corrective actions based on findings. For instance, at my previous role, we implemented a new cleaning schedule guided by the USDA’s recommendations, resulting in a 15% reduction in bacterial contamination rates.

I understand the need for meticulous record-keeping, traceability systems, and employee training to ensure consistent compliance. This includes maintaining detailed documentation of all processing steps, ingredient sourcing, and product distribution. I’ve worked with various regulatory agencies to resolve compliance issues proactively, demonstrating my commitment to safety and legal standards.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with food safety regulations?

Ensuring compliance with food safety regulations is paramount in chick processing. It’s not just about adhering to rules; it’s about building a culture of safety. Our approach is multifaceted:

- HACCP Implementation: We utilize a robust HACCP plan, identifying critical control points (CCPs) such as chilling temperatures and cooking times. Regular monitoring and documentation of CCPs are crucial.

- GMP Adherence: Strict GMPs guide our sanitation practices, employee hygiene, and facility maintenance. This includes regular sanitation of equipment, employee handwashing protocols, and pest control measures. Imagine it like a hospital operating room – cleanliness is non-negotiable.

- Supplier Verification: We meticulously vet our suppliers to ensure they meet our rigorous quality and safety standards. This includes verifying their own safety protocols and ingredient traceability.

- Employee Training: Comprehensive training programs emphasize food safety principles. Employees understand their roles in maintaining a safe environment and know to report potential hazards immediately.

- Regular Audits: Internal and external audits are conducted to verify our processes and identify areas for improvement. We consider these audits opportunities for continuous enhancement.

Ultimately, food safety isn’t just a checklist; it’s an ongoing commitment that integrates itself into every aspect of our operation.

Q 17. What is your understanding of yield and efficiency in chick processing?

Yield and efficiency in chick processing are interconnected metrics vital for profitability. Yield refers to the amount of usable product obtained from the initial raw material (chicks). Efficiency, on the other hand, focuses on minimizing waste and maximizing throughput within a given timeframe. A high yield means minimizing losses during processing (trimmings, etc.), while high efficiency means processing more birds per hour with minimal downtime.

For example, a high yield might be achieved through optimized cutting techniques minimizing waste, while high efficiency could result from streamlined processing lines with minimal bottlenecks. Tracking both metrics allows for identifying areas of improvement. Let’s say a certain cutting technique consistently leads to higher trimming waste. By switching to an alternative, we can improve yield directly. Similarly, reducing downtime through preventative equipment maintenance directly boosts efficiency.

Q 18. How do you improve the efficiency of the chick processing line?

Improving the efficiency of a chick processing line requires a holistic approach. I focus on:

- Line Optimization: Analyzing bottlenecks in the processing line – where are delays occurring? Are there inefficiencies in equipment placement or worker assignments? We might rearrange workstations to improve workflow or invest in automation to reduce manual labor.

- Preventative Maintenance: Regular maintenance of equipment prevents unexpected downtime. This involves scheduled inspections, cleaning, and repairs to ensure machinery operates at peak performance.

- Process Improvement: Continuous improvement methodologies like Lean Manufacturing principles help to streamline processes and eliminate waste. This might involve value-stream mapping to identify non-value-added steps.

- Employee Training and Empowerment: Well-trained employees are more efficient. Empowering them to suggest improvements and participate in problem-solving fosters a culture of continuous improvement.

- Technology Integration: Implementing advanced technology like automated weighing systems, vision-guided cutting, and data-driven analytics enables real-time performance monitoring and optimization.

In one instance, by implementing a new automated weighing system, we increased processing speed by 12% and reduced labor costs by 8%.

Q 19. Describe your experience with different packaging and labeling techniques.

My experience includes various packaging and labeling techniques, encompassing different types of packaging materials (plastic trays, modified atmosphere packaging (MAP), vacuum sealing), and labeling technologies (thermal transfer printing, inkjet printing). We select the most appropriate methods based on factors like product type, shelf life requirements, and cost-effectiveness. For example, MAP is ideal for extending the shelf life of fresh chicken, while vacuum sealing is better for preserving products intended for freezing. The choice of packaging material should be aligned with sustainability goals, too. We’ve recently shifted to using more recyclable materials.

Labeling is crucial for providing consumers with accurate and legally compliant information, including weight, ingredients, nutritional facts, and storage instructions. All labels must adhere to relevant regulations. Proper labeling is essential for traceability and recall management. Any mislabeling can lead to serious repercussions. I have experience setting up and managing labeling systems to ensure accuracy and compliance.

Q 20. What are your experience with waste management in a poultry plant?

Waste management is a critical aspect of responsible chick processing. It goes beyond simple disposal; it involves minimizing waste generation, recycling where possible, and proper disposal of byproducts. Our strategy involves:

- Waste Reduction: Optimizing cutting techniques, improving processing yields, and implementing advanced technologies reduces overall waste. For example, precise cutting machinery can minimize trimmings.

- Recycling Programs: We have established programs for recycling cardboard, plastics, and other materials. This minimizes environmental impact and reduces waste disposal costs.

- Byproduct Management: Byproducts such as feathers, offal, and bones are often processed into valuable byproducts (e.g., pet food ingredients, fertilizer) or handled through environmentally sound disposal methods according to regulations.

- Wastewater Treatment: Proper wastewater treatment is essential to comply with environmental regulations. This might involve biological treatment systems and regular monitoring to ensure treated water meets discharge standards.

- Composting: We explore the possibility of composting organic waste to reduce landfill burden and generate useful compost for agricultural purposes.

We constantly look for ways to improve our waste management practices. A recent initiative involved partnering with a local company to convert feathers into a high-protein animal feed.

Q 21. Explain your experience with staff training and development in a chick processing plant.

Staff training and development are cornerstones of a successful and safe chick processing plant. Our comprehensive training program covers all aspects of the operation, including:

- Food Safety Training: Employees receive thorough training on HACCP principles, GMPs, and sanitation procedures. Regular refresher courses are also conducted.

- Equipment Operation and Maintenance: Employees are trained to safely and efficiently operate the processing equipment. Preventative maintenance training is essential for minimizing downtime.

- Safety Training: Safety training is paramount, covering topics like personal protective equipment (PPE) use, lockout/tagout procedures, and hazard identification.

- Cross-Training: Cross-training enables flexibility and efficiency. Employees are trained in multiple areas, allowing for coverage during absences or peak periods.

- Supervisory Training: Supervisors receive specialized training in leadership, safety management, and employee development.

We use a combination of classroom training, on-the-job training, and mentorship programs. Regular performance reviews and feedback sessions provide opportunities for continuous improvement. Employee development enhances safety, efficiency, and overall productivity. The investment in training is an investment in our success.

Q 22. How do you handle customer complaints related to chick processing?

Handling customer complaints effectively is paramount in maintaining a positive reputation in the chick processing industry. My approach involves a multi-step process beginning with active listening to understand the nature of the complaint. This ensures that I fully grasp their concerns before offering solutions. I then categorize the complaint; Is it related to chick quality (e.g., mortality, deformities), delivery issues (e.g., late delivery, damaged packaging), or billing discrepancies? This helps me determine the appropriate department (e.g., quality control, logistics, accounting) to involve. Next, I document the complaint thoroughly, including the customer’s contact information, details of the issue, and the date and time of the complaint. For example, if a customer reports high chick mortality, I would note the batch number, the number of chicks received, and the number that died. Then, I work with the relevant team to investigate the issue and find a resolution, which might involve providing a replacement order, issuing a refund, or implementing corrective actions to prevent future occurrences. Finally, I follow up with the customer to ensure they are satisfied with the resolution, often offering a small gesture of goodwill as appropriate. Regular feedback sessions with the customer service team helps identify trends in complaints which allows for proactive improvements across our processes.

Q 23. What are your experience with record-keeping and documentation in chick processing?

Record-keeping and documentation are crucial for maintaining compliance, tracing issues, and improving efficiency in chick processing. Throughout my career, I’ve employed a comprehensive system leveraging both physical and digital records. We maintain detailed batch records from the moment chicks arrive at the hatchery until they are shipped to customers. This includes information about the parent flock, incubation parameters, hatching rates, chick grading (weight, health), vaccination records, and shipping details. Each batch receives a unique identification number allowing for complete traceability. We also document daily operational data such as equipment maintenance logs, cleaning and sanitation records, employee training records, and environmental monitoring data (temperature and humidity). All this data is entered into our database management system, allowing for easy retrieval and analysis. For example, tracking chick mortality rates over time can help us pinpoint potential issues with incubation or brooding conditions. Furthermore, accurate records are essential for meeting regulatory requirements and providing audits as necessary. We regularly review our records management system to ensure we are meeting both our internal standards and compliance requirements.

Q 24. Describe your experience with different poultry breeds and their processing requirements.

My experience spans various poultry breeds, each with unique processing requirements. Broiler breeds, known for their rapid growth and meat production, require efficient processing lines optimized for high throughput. Conversely, layer breeds, raised for egg production, have different needs in terms of handling and grading. The processing of heritage breeds, often smaller and more delicate, demands a more careful approach with modified equipment or manual processes. For example, Cornish Cross broilers are much larger and require adjustments to the stunning and evisceration equipment compared to smaller breeds like Rhode Island Reds. Each breed also has different sensitivities to stress and temperature changes, influencing the speed of processing and the care required during handling to ensure chick health and minimize mortality. Understanding these breed-specific characteristics is crucial in optimizing the processing line for each type of bird and maintaining quality standards.

Q 25. How do you manage production targets and deadlines in chick processing?

Managing production targets and deadlines effectively in chick processing requires careful planning and efficient execution. We utilize production scheduling software that takes into account factors such as order volume, breed specifications, available processing capacity, and labor resources. This software generates detailed production schedules that allow us to allocate tasks and resources appropriately. Regular monitoring of the production process is vital, using key performance indicators (KPIs) such as processing speed, yield, and mortality rates. Any deviations from the schedule are promptly addressed through adjusting workforce allocation, optimizing equipment settings, or identifying and resolving bottlenecks. For example, if a specific step in the processing line is causing a delay, we may re-allocate personnel or adjust equipment settings to increase efficiency. Furthermore, effective communication across different teams involved in chick processing is critical. Daily progress meetings allow us to stay informed, address potential delays proactively, and ensure that production targets are met on time and within budget.

Q 26. What is your experience with different poultry processing technologies?

My experience encompasses a range of poultry processing technologies. I’m familiar with both manual and automated systems, from traditional scalding and plucking methods to highly automated processing lines incorporating advanced technologies such as computer-vision systems for grading and robotic evisceration. I have worked with different types of stunning equipment, including electrical and controlled-atmosphere systems, always prioritizing humane treatment. Experience also extends to various packaging technologies, from simple tray packing to automated systems using modified atmosphere packaging (MAP) to extend shelf life. Each technology presents its own advantages and disadvantages, and the optimal choice depends on factors such as production volume, budget, desired level of automation, and product quality requirements. For instance, while automated systems increase throughput, they often require higher initial investment and maintenance costs. Selecting the right technology requires a comprehensive evaluation of these factors and alignment with the business’s overall goals.

Q 27. Explain your understanding of the impact of temperature control on chick quality.

Temperature control is paramount in maintaining chick quality throughout the processing operation. Fluctuations in temperature can lead to stress, reduced quality, and increased mortality. For example, excessively high temperatures during holding or transportation can cause heat stress, leading to increased mortality and reduced meat quality. Conversely, excessively low temperatures can lead to chilling injury, impacting the quality and shelf life of the processed chicks. Therefore, maintaining a consistent temperature throughout the process, from holding areas to the processing line and transportation, is critical. This requires accurate monitoring using appropriate temperature sensors and control systems. Furthermore, understanding the specific temperature requirements for different stages of processing and for different breeds is vital. The proper temperature control protocols are essential to ensure the welfare of the chicks, meet quality standards, and comply with industry regulations. We utilize a sophisticated temperature monitoring and control system with alarm functionalities and regular checks to prevent temperature excursions and maintain optimal conditions.

Q 28. How do you troubleshoot problems in chick processing operations?

Troubleshooting problems in chick processing requires a systematic approach. The first step is identifying the problem accurately. Is it related to equipment malfunction, processing inefficiencies, quality issues, or worker errors? Once identified, we gather data relevant to the problem, including production records, maintenance logs, and quality control reports. This data helps in pinpointing the root cause of the problem. Next, we brainstorm potential solutions based on our experience and industry best practices. These might include adjusting equipment settings, implementing process improvements, providing additional training to workers, or addressing issues with raw materials. After implementing a solution, we monitor its effectiveness and make further adjustments if necessary. For example, if we experience consistently high mortality rates during transportation, we might investigate the transport vehicle’s temperature control system, adjust the packing density of the chicks, or optimize the transportation route. Documenting each troubleshooting step is crucial for learning from past mistakes and preventing similar issues in the future. We also conduct regular equipment maintenance and staff training to proactively prevent problems from occurring. A proactive, rather than reactive, approach is essential.

Key Topics to Learn for Chick Processing Interview

- Hatchery Operations: Understanding the process from egg incubation to chick hatching, including environmental control, egg handling, and chick sexing.

- Chick Quality Assessment: Learning to evaluate chick health, vigor, and uniformity, and identifying potential issues like deformities or disease.

- Vaccination and Medication: Familiarizing yourself with common chick vaccinations and medication protocols, including administration methods and safety procedures.

- Grading and Sorting: Understanding the processes involved in grading chicks by size, weight, and quality, and preparing them for transport.

- Biosecurity and Hygiene: Mastering the crucial aspects of maintaining a clean and sanitary environment to prevent disease outbreaks and ensure chick health.

- Transportation and Logistics: Understanding the safe and efficient transportation of chicks, including climate control and handling procedures.

- Troubleshooting and Problem-Solving: Developing the ability to identify and address common challenges in chick processing, such as high mortality rates or poor chick quality. This includes understanding root cause analysis and preventative measures.

- Record Keeping and Data Analysis: Understanding the importance of accurate record keeping and data analysis to track performance, identify trends, and improve efficiency.

- Health and Safety Regulations: Familiarity with relevant health and safety regulations and best practices within the chick processing industry.

- Equipment Operation and Maintenance: Understanding the operation and basic maintenance of common equipment used in chick processing facilities.

Next Steps

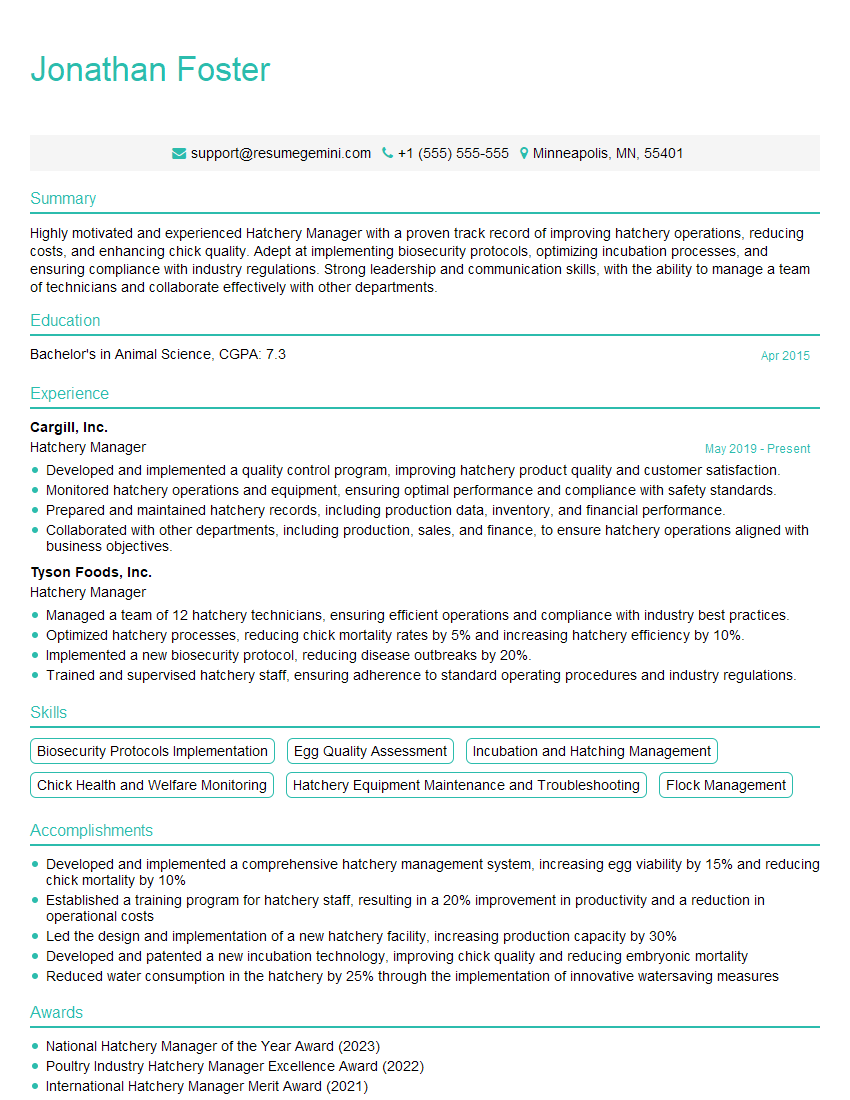

Mastering chick processing techniques is crucial for a successful and rewarding career in the poultry industry, opening doors to diverse roles and opportunities for advancement. To significantly increase your chances of landing your dream job, focus on crafting an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the recruiter’s eye. We provide examples of resumes tailored to the Chick Processing industry to guide you in creating the perfect application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO