Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Shipping and receiving certification interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Shipping and receiving certification Interview

Q 1. Explain the process of receiving a shipment.

Receiving a shipment is a multi-step process crucial for maintaining inventory accuracy and operational efficiency. It begins with anticipating the arrival, checking for proper documentation, and then physically receiving and inspecting the goods. Think of it like expecting a house guest – you need to confirm their arrival time, check their identification (shipping documentation), and then ensure everything is in order upon their arrival.

- Notification and Preparation: The process starts with an advance shipping notice (ASN) from the supplier, which provides details such as the expected arrival date, time, contents, and tracking number. This allows for the preparation of necessary resources like personnel, equipment (forklifts, pallet jacks), and storage space.

- Verification of Documentation: Upon arrival, the shipping documents (bill of lading, packing slip, proof of delivery) are meticulously checked against the ASN. This verification step is crucial to ensure the correct goods have arrived in the expected quantity and condition.

- Physical Inspection and Quantity Check: The goods are physically inspected for any damage (external or internal). A quantity check is performed to ensure the number of units received matches the documentation. This may involve manually counting items or using scanning technology.

- Data Entry and System Update: Once the verification is complete, the data is entered into the inventory management system (IMS), updating the inventory records. This might involve scanning barcodes or manually inputting data, depending on the system and volume.

- Storage and Next Steps: Finally, the goods are moved to their designated storage location within the warehouse. Depending on the urgency, further processing may occur immediately (e.g., quality control, order fulfillment).

Q 2. How do you verify the accuracy of incoming shipments?

Verifying the accuracy of incoming shipments is paramount to avoid discrepancies and maintain inventory control. This involves a multi-pronged approach, combining careful documentation review with physical inspection and technological assistance.

- Cross-referencing Documentation: The primary method involves meticulously comparing the information on the ASN, packing slip, bill of lading, and any other relevant documentation. Each document should corroborate the others regarding the quantity, type, and condition of the goods.

- Physical Inspection: A thorough visual inspection of the packaging and goods themselves is critical. This helps identify any damage, missing items, or discrepancies in quantity. For example, checking for broken seals, damaged boxes, or signs of tampering.

- Quantity Verification: Precisely counting the received goods is essential, particularly for high-value or sensitive items. This might involve using barcode scanners, RFID technology, or manual counting, depending on the shipment size and complexity.

- Quality Control Checks: Depending on the nature of the goods, quality control checks may be performed to ensure they meet specifications. This might involve testing, sampling, or visual inspection.

- System Reconciliation: Finally, the data collected from the inspection and verification processes is entered into the inventory management system. This ensures the system records accurately reflect the actual received goods, allowing for immediate adjustments if needed.

For example, if the packing slip indicates 100 units but only 98 are physically present, immediate action should be taken to investigate the discrepancy, contact the shipper, and initiate a claim if necessary.

Q 3. Describe your experience with different shipping methods (e.g., LTL, FTL, parcel).

My experience encompasses a wide range of shipping methods, each with its own logistical nuances and cost implications. Understanding these differences is crucial for optimizing supply chain efficiency.

- Less-than-Truckload (LTL): LTL shipping is cost-effective for smaller shipments that don’t require a full truck. I’ve handled numerous LTL shipments, coordinating with carriers for pickup and delivery, meticulously tracking shipments, and ensuring proper handling to minimize damage. The key here is careful packaging and labeling to prevent loss or damage during consolidation and transport.

- Full Truckload (FTL): FTL shipping is ideal for larger shipments that require an entire truck. This provides greater control and faster transit times compared to LTL. My experience includes arranging FTL shipments, negotiating rates with carriers, and ensuring timely delivery. Efficient loading and unloading are crucial to maximize space utilization.

- Parcel Shipping: Parcel shipping is suitable for smaller packages, often handled by companies like FedEx, UPS, or USPS. I’ve extensively utilized this method for smaller, time-sensitive shipments, utilizing online tracking tools and managing shipping labels effectively. Accuracy in addressing and packaging is vital to prevent delays or misdeliveries.

Successfully managing these diverse shipping methods requires adaptability, strong carrier relationships, and a keen understanding of the tradeoffs between cost, speed, and security.

Q 4. How do you handle damaged or incorrect shipments?

Handling damaged or incorrect shipments requires a systematic approach to minimize losses and ensure proper recourse. The process prioritizes documentation, communication, and resolution.

- Immediate Documentation: Thoroughly document the damage or discrepancy, including taking photos or videos as evidence. Note the specific nature of the damage (e.g., crushed box, missing items) and the quantity affected. Include the carrier’s proof of delivery and the original shipping documentation.

- Contacting the Carrier and Supplier: Immediately notify both the carrier and the supplier about the problem. Provide them with the documented evidence and request instructions on how to proceed with the claim or return. Follow up promptly on any communications.

- Inspecting Damaged Goods: If the damage is superficial and doesn’t affect the usability of the goods, you may decide to accept the shipment with a damage claim. If the damage renders the goods unusable, or if the discrepancy is significant, a return or replacement will be necessary.

- Initiating a Claim: Follow the carrier’s procedures for filing a claim for damaged or lost goods. Provide all the required documentation and follow up diligently.

- Internal Processes: Update the inventory management system to reflect the damaged or incorrect shipment and adjust inventory accordingly. This might involve creating a return authorization (RMA) number.

Example: If a shipment arrives with a damaged box and missing items, I would document the damage with photos, contact the carrier and the supplier immediately, and file a claim with the carrier while arranging for the return of the damaged goods. I would update our inventory accordingly and communicate the situation to our relevant teams.

Q 5. What inventory management systems are you familiar with?

I’m proficient in several inventory management systems (IMS), including:

- SAP: Experienced in using SAP MM (Materials Management) module for inventory tracking, purchasing, and stock control.

- Oracle Inventory Management: Familiar with Oracle’s robust IMS features, including demand planning, order management, and warehouse management integration.

- Microsoft Dynamics 365 Supply Chain Management: Skilled in using Dynamics 365 for inventory tracking, forecasting, and warehouse operations management.

- Fishbowl Inventory: Proficient in this simpler, more user-friendly IMS, ideal for small to medium-sized businesses.

My experience extends beyond just data entry; I understand the importance of accurate data entry, regular system maintenance, and reporting to ensure inventory accuracy and operational efficiency.

Q 6. Explain your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive. WMS software streamlines warehouse operations by automating tasks like receiving, put-away, picking, packing, and shipping. I’ve worked with various WMS platforms, each with its own strengths and capabilities.

- WMS Implementation and Configuration: I’ve been involved in the implementation and configuration of various WMS solutions, tailoring them to specific warehouse layouts and operational needs. This includes setting up user roles, configuring warehouse zones, and defining picking strategies.

- Data Analysis and Reporting: I can generate reports and analyze data from the WMS to identify areas for improvement in warehouse efficiency and productivity. This involves tracking key performance indicators (KPIs) such as order fulfillment time, storage utilization, and picking accuracy.

- Integration with other systems: I have experience integrating WMS with other enterprise systems, such as ERP (Enterprise Resource Planning) and Transportation Management Systems (TMS). This seamless data flow is essential for maintaining accurate inventory records, managing orders effectively, and tracking shipments.

- Troubleshooting and Support: I’m proficient in troubleshooting WMS-related issues and providing technical support to warehouse staff. This includes resolving software glitches, data entry errors, and addressing operational problems.

For example, I once helped optimize a warehouse’s picking process by implementing a WMS-driven ‘wave picking’ strategy, which significantly reduced order fulfillment time and improved efficiency. A well-configured WMS is invaluable for streamlining operations and improving overall warehouse productivity.

Q 7. How do you prioritize tasks in a fast-paced shipping and receiving environment?

Prioritizing tasks in a fast-paced shipping and receiving environment is crucial for maintaining efficiency and meeting deadlines. I utilize several strategies to manage competing demands:

- Urgency and Importance Matrix: I use an urgency/importance matrix to categorize tasks. Urgent and important tasks, like handling time-sensitive shipments, take precedence. Important but not urgent tasks, such as inventory cycle counts, are scheduled proactively.

- FIFO (First-In, First-Out): For processing incoming shipments, I follow a FIFO method to ensure that older shipments are not overlooked. This prevents stock expiry and minimizes storage issues.

- Communication and Collaboration: Open communication with colleagues and management is crucial. This includes clearly stating task priorities and seeking assistance when needed. Collaborative teamwork is essential for smooth workflow.

- Technology Utilization: Leveraging WMS and other technological tools helps automate tasks and streamline workflows, freeing up time for higher-priority tasks. Real-time tracking of shipments and inventory allows for proactive management.

- Flexibility and Adaptability: In a fast-paced environment, unexpected issues may arise. Maintaining flexibility and adaptability is key to effectively adjusting priorities and responding to changing demands.

Think of it like conducting an orchestra; each instrument (task) has its own rhythm and importance. A skilled conductor (shipping and receiving manager) prioritizes to create a harmonious and efficient performance (smooth workflow).

Q 8. Describe your experience with cycle counting and inventory control.

Cycle counting is a crucial inventory control method where a portion of the inventory is physically counted and verified against the system records on a regular basis, rather than a full inventory count. This prevents large discrepancies from building up. In my experience, I’ve implemented and managed cycle counting programs in several warehouses, significantly improving inventory accuracy.

For example, in my previous role, we implemented a system where we divided our warehouse into zones. Each zone was assigned a specific day for cycle counting, ensuring consistent coverage without disrupting daily operations. We used barcode scanners to update the inventory system in real-time, minimizing manual data entry errors. We analyzed the cycle count data to identify areas with high discrepancy rates, allowing us to investigate and correct root causes such as damaged goods, inaccurate data entry, or theft. This led to a 20% reduction in inventory discrepancies within six months.

Effective inventory control also involves robust stock management procedures, regular stock audits, and strong communication between receiving, warehousing and shipping departments. A well-defined system ensures that we know exactly what we have, where it is, and when it was received.

Q 9. How do you maintain accurate shipping and receiving records?

Maintaining accurate shipping and receiving records is paramount for efficient warehouse operation and customer satisfaction. This involves using a reliable Warehouse Management System (WMS) or ERP system, along with meticulous manual processes as backup.

My approach involves using a system that tracks every item from the moment it arrives until it leaves. This includes recording the shipment ID, purchase order number, quantity, weight, condition, and any relevant tracking numbers. Every received item is carefully checked against the purchase order to ensure accuracy. We use barcodes or RFID tags for accurate and quick identification and tracking. Additionally, we regularly audit our records to identify and resolve any discrepancies. This minimizes losses, streamlines order processing, and prevents potential disputes with suppliers or customers.

For instance, we utilize a WMS that automatically updates inventory levels after every successful receiving scan. This eliminates manual intervention and reduces the chance of human error.

Q 10. What are your strategies for preventing shipping errors?

Preventing shipping errors requires a multi-faceted approach focusing on process standardization, training, and technology.

- Standardization: Clear, documented procedures for order picking, packing, and shipping are essential. This ensures everyone follows the same steps, reducing inconsistencies.

- Training: Thoroughly training employees on these procedures, using visual aids and hands-on practice, is critical. Regular refresher courses reinforce best practices.

- Technology: Implementing a WMS with order management and shipping label generation features reduces the possibility of manual errors. Barcodes and scanners minimize the risk of incorrect item selection or quantity.

- Double-checking: Implementing multiple checks at different stages of the process (picking, packing, and shipping) is a simple yet highly effective strategy.

For example, we use a ‘pick-pack-check’ system where one employee picks the items, another packs them, and a third verifies the contents against the packing list before shipment. This triple-check system significantly reduces errors.

Q 11. How do you ensure the safety and security of shipments?

Ensuring shipment safety and security involves multiple layers of protection, starting from the moment goods arrive at the warehouse until they reach their destination. This includes physical security measures, procedural controls, and insurance.

- Physical Security: Secured warehouse facilities with access control systems, CCTV surveillance, and regular security patrols deter theft and damage. Proper storage practices, such as climate-controlled environments for sensitive goods, also play a role.

- Procedural Controls: Detailed procedures for handling high-value items, including secure storage, tracking, and delivery processes. Regular inventory checks and reconciliation help identify any discrepancies or loss.

- Insurance: Adequate insurance coverage protects against loss or damage during transit. We choose carriers with a good safety and claims record.

- Packaging: Proper packaging is crucial for protecting goods from damage. This involves using appropriate packaging materials and techniques, especially for fragile items.

In one instance, we implemented a new security system that reduced theft by 75% in the first year. This included improved access control and better surveillance.

Q 12. Explain your experience with loading and unloading procedures.

Loading and unloading procedures must be efficient, safe, and damage-free. My experience involves overseeing and implementing procedures that prioritize safety and minimize risk of damage.

We use a structured approach to loading and unloading, assigning specific personnel to manage each process. Forklifts and other material handling equipment are maintained regularly and operated only by trained and certified personnel. Proper equipment usage is crucial; we conduct safety checks before each use and follow all safety protocols. We utilize designated loading and unloading areas to minimize congestion and maximize efficiency. We ensure proper weight distribution to prevent overloading and damage to equipment or goods.

For example, we implemented a color-coded system for designating loading zones, making it easier for drivers to understand where to position their vehicles, reducing delays and improving safety.

Q 13. How familiar are you with shipping regulations and documentation?

I possess a strong understanding of various shipping regulations and documentation, including but not limited to International Commercial Terms (Incoterms), hazardous materials regulations (e.g., IATA, IMDG), customs regulations, and relevant documentation requirements for international and domestic shipments.

My familiarity extends to various shipping documents such as Bills of Lading, commercial invoices, packing lists, certificates of origin, and customs declarations. I understand the importance of accurate documentation for customs clearance, insurance claims, and compliance with legal requirements. I regularly update my knowledge to stay informed of any changes in regulations or best practices.

For example, I’ve successfully navigated complex customs procedures for shipments to various countries, ensuring timely and compliant delivery of goods by understanding and correctly utilizing relevant documentation for each jurisdiction.

Q 14. How do you handle discrepancies between purchase orders and received goods?

Discrepancies between purchase orders and received goods require immediate attention and a systematic approach to investigation and resolution.

My approach involves the following steps:

- Verification: We carefully check the received goods against the purchase order, noting any discrepancies in quantity, description, or condition.

- Documentation: We create a detailed discrepancy report documenting all identified inconsistencies.

- Investigation: We investigate the root cause of the discrepancy. Was it due to a packing error, a data entry mistake, or damage during transit?

- Communication: We promptly contact the supplier to inform them of the discrepancy and initiate the resolution process. This could involve returning damaged goods, requesting a credit note, or negotiating a replacement order.

- Resolution: We implement corrective measures to prevent similar errors in the future. This could involve improving data entry procedures or working with the supplier to improve their packaging or shipping practices.

For example, a recent discrepancy involved a shipment with a missing carton. After investigation, we discovered a labeling error at the supplier’s facility. We worked with them to correct the error, and they sent us the missing carton promptly. We also implemented a new process for verifying labels to prevent future occurrences.

Q 15. What is your experience with using scanners and other shipping technology?

My experience with shipping technology is extensive. I’m proficient in using various barcode scanners, handheld RF scanners, and warehouse management system (WMS) interfaces. These tools are crucial for efficient receiving and shipping. For example, I’ve used Zebra scanners to quickly scan incoming packages, verifying against purchase orders and updating inventory levels in real-time. This ensures accuracy and minimizes errors. I’m also experienced with integrating scanner data into WMS platforms to track shipments from receiving to dispatch. This includes familiarity with different scanner technologies, such as laser, CCD, and imagers, and understanding their optimal application in various settings (e.g., laser scanners for high-volume applications, imagers for damaged packaging). Beyond scanners, I’m comfortable using shipping software to generate labels, track packages, and manage carrier accounts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage returns and exchanges?

Managing returns and exchanges requires a systematic approach. First, I ensure the returned item is inspected thoroughly to assess its condition and determine eligibility for a refund or exchange. Documentation is crucial – this includes checking the return authorization (RMA) number, verifying the customer’s order details, and comparing the returned item to the original order. Once verified, the process involves updating inventory levels, processing refunds or exchanges, and potentially issuing a replacement shipment. We use a specific RMA system that tracks each return through every step; this ensures transparency for both the customer and the business, and aids in identifying potential issues in product quality or handling. For instance, if we see a high volume of returns for a particular item, we investigate to identify any potential defects or reasons for customer dissatisfaction. This data allows proactive improvements in product quality and customer service.

Q 17. Describe your experience working with different carriers.

I have worked extensively with a variety of carriers, including UPS, FedEx, USPS, and DHL. My experience covers negotiating rates, selecting the most cost-effective and efficient shipping methods, and resolving any shipment-related issues. Understanding each carrier’s strengths and weaknesses is key. For example, USPS might be cost-effective for smaller, lighter packages, while FedEx offers greater speed and tracking options for expedited deliveries. I’ve learned to adapt my shipping strategies based on the destination, delivery timeframe, and package characteristics. This includes knowledge of their respective online portals for tracking, scheduling pickups, and managing shipping labels. Effectively managing multiple carrier accounts involves careful record-keeping and a strong understanding of each carrier’s service level agreements (SLAs) to ensure timely and efficient shipping.

Q 18. How do you track shipments and maintain visibility?

Shipment tracking and maintaining visibility are vital for efficient shipping and receiving. We leverage the tracking numbers provided by carriers to monitor shipments in real-time through their respective websites or integrated WMS platforms. This allows us to proactively identify and address potential delays or issues. For example, if a shipment is delayed, we can immediately contact the carrier to investigate and inform the customer. We use various reporting tools to gain insights into shipping times, costs, and carrier performance. This data is crucial for optimizing our shipping strategies and improving overall efficiency. We also utilize a centralized tracking system that consolidates data from different carriers, giving us a comprehensive overview of all shipments.

Q 19. What are some common challenges in shipping and receiving, and how have you addressed them?

Common challenges include inaccurate orders, damaged goods, shipping delays, and mislabeling. To address inaccurate orders, we implement robust verification processes at every stage, starting from order entry to receiving and shipping. For damaged goods, we meticulously document the damage using photos and descriptions, and work with the carrier to file claims. Shipping delays are mitigated through careful carrier selection, proactive communication, and contingency planning. Mislabeling is addressed through rigorous training and implementation of double-checking systems. For example, we implemented a barcode scanning system that cross-references the label with the item details before shipping. This has significantly reduced errors and improved accuracy. By systematically addressing these issues, we enhance our efficiency and customer satisfaction.

Q 20. How do you handle high-volume shipments during peak seasons?

Managing high-volume shipments during peak seasons requires strategic planning and resource allocation. This typically involves forecasting demand, securing additional resources (temporary staff, increased warehouse space), optimizing workflows, and establishing clear communication channels. We utilize WMS technology to automate tasks and streamline processes. For example, we might implement a more efficient picking and packing strategy during peak periods. Prioritizing shipments based on urgency and implementing overtime schedules can also help manage the increased volume. Effective communication with carriers to ensure sufficient capacity and timely pickups is also paramount. Proactive planning and flexible staffing strategies are key to successfully handling the increased workload and maintaining service levels during peak times.

Q 21. Describe your experience with using a Bill of Lading.

A Bill of Lading (BOL) is a crucial document in shipping, acting as a contract between the shipper and carrier. It details the shipment’s origin, destination, contents, and other important information. My experience encompasses creating, reviewing, and managing BOLs. I ensure accuracy in all fields, including the shipper and consignee information, the number of packages, and the description of goods. The BOL serves as proof of the shipment and is used for tracking and insurance claims. In case of discrepancies or damage, a correctly filled BOL helps in efficient claim processing. For instance, using a standardized format and system for generating BOLs ensures consistency and helps in better record-keeping and easy access to shipment details. I am proficient in various BOL formats used by different carriers and understand the legal implications associated with it.

Q 22. How do you ensure compliance with safety regulations in the warehouse?

Ensuring warehouse safety compliance is paramount. It’s not just about following rules; it’s about creating a culture of safety. My approach is multi-faceted and starts with a thorough understanding of all applicable OSHA (or equivalent international) regulations, including those pertaining to material handling, hazardous materials, and personal protective equipment (PPE).

- Regular Safety Audits: I conduct and participate in regular safety audits, identifying potential hazards like obstructed walkways, damaged equipment, or improper stacking procedures. These audits aren’t just checklists; they involve actively looking for areas for improvement.

- Training and Education: I believe in proactive training. This includes regular refresher courses on safe forklift operation, proper lifting techniques, hazard communication, and emergency procedures. I use a combination of classroom training and hands-on demonstrations to ensure understanding.

- Incident Reporting and Investigation: A robust incident reporting system is critical. Any near-misses or accidents are thoroughly investigated to determine root causes and prevent recurrence. This involves interviewing witnesses, analyzing data, and implementing corrective actions.

- PPE Enforcement: Consistent and visible enforcement of PPE policies is vital. This includes ensuring that employees use appropriate safety gear, such as safety shoes, gloves, and high-visibility vests, depending on the task.

- Maintaining Cleanliness and Order: A cluttered warehouse is an unsafe warehouse. Regular cleaning and organization of the work area minimizes tripping hazards and improves efficiency.

For example, in a previous role, we implemented a new system for reporting near-misses, resulting in a 20% reduction in workplace incidents within six months.

Q 23. What is your experience with different types of packaging and materials?

My experience encompasses a wide range of packaging materials and types, selected based on the product’s fragility, size, weight, and destination. I’m proficient in using various packaging materials, understanding their strengths and limitations.

- Corrugated Cardboard: The workhorse of shipping, offering good protection at a relatively low cost. I understand the different grades and flute types, selecting the appropriate one for the item’s weight and fragility. For example, double-walled cardboard is used for heavier items.

- Bubble Wrap and Foam Packaging: Excellent for cushioning fragile items. I’m adept at using these materials effectively to prevent breakage during transit.

- Pallet Wrapping: Essential for securing and protecting palletized goods, especially during long-distance or international shipping. Different types of film and wrapping techniques are applied depending on the load’s weight and stability.

- Specialized Packaging: I have experience with specialized packaging for hazardous materials, temperature-sensitive goods (requiring insulated packaging and coolants), and oversized items requiring custom crates or other protective structures.

- Sustainable Packaging: I’m familiar with and actively promote the use of sustainable packaging materials such as recycled cardboard, biodegradable fillers, and eco-friendly tapes to minimize environmental impact.

One project involved designing custom packaging for a client shipping delicate glassware internationally. By utilizing a combination of foam inserts, custom-fit cardboard boxes, and robust exterior packaging, we achieved a zero-damage rate.

Q 24. Explain your experience with different types of shipping labels and barcodes.

I’m experienced with a variety of shipping labels and barcodes, crucial for efficient tracking and delivery. My knowledge extends to both manual and automated label generation and application processes.

- Standard Shipping Labels: I’m proficient in creating and applying labels using various label printers and software, ensuring all necessary information (sender’s and receiver’s addresses, tracking numbers, and weight) is accurate and clearly legible.

- Barcodes (e.g., UPC, EAN, ISBN): I understand different barcode symbologies and their applications in inventory management, tracking, and automated sorting. I can troubleshoot barcode scanning issues and ensure data accuracy.

- International Shipping Labels: For international shipments, I’m familiar with creating labels compliant with international regulations and customs requirements, including the proper documentation for customs declarations.

- Hazardous Materials Labels: I’m experienced with the proper labeling and handling of hazardous materials, including understanding and adhering to strict regulations on the type, placement, and size of required labels.

- RFID Tags: In more advanced settings, I have some familiarity with Radio-Frequency Identification (RFID) tags for enhanced tracking and inventory management.

In one instance, I successfully implemented a new barcode scanning system that improved order processing speed by 30%, reducing errors and improving overall efficiency.

Q 25. How do you handle customer inquiries related to shipping and receiving?

Handling customer inquiries efficiently and professionally is crucial. My approach emphasizes clear communication, timely responses, and problem-solving.

- Active Listening: I begin by actively listening to the customer’s concern, ensuring I fully understand the issue before responding. This often involves asking clarifying questions to get the full picture.

- Tracking Information: I use tracking information to locate shipments and provide updates to the customer. If there’s a delay or problem, I investigate the cause and communicate proactively with the customer.

- Problem Solving: If there’s an issue (e.g., damaged goods, late delivery), I work to resolve the problem, which might involve contacting the carrier, initiating a claim, or offering a suitable solution to the customer (e.g., replacement, refund).

- Documentation: I maintain detailed records of all customer interactions and resolutions for future reference. This ensures consistency and accountability.

- Professionalism: Regardless of the nature of the inquiry, I maintain a professional and courteous demeanor, ensuring the customer feels valued and heard.

A memorable example involved a customer whose shipment was significantly delayed due to unforeseen circumstances. By proactively communicating updates and offering a partial refund, I was able to turn a potentially negative experience into a positive one, fostering customer loyalty.

Q 26. What is your experience with international shipping?

International shipping presents unique challenges, requiring a deep understanding of customs regulations, documentation, and international shipping carriers. My experience includes preparing necessary documentation, selecting appropriate carriers, and handling customs clearance procedures.

- Customs Regulations: I’m well-versed in the varying customs regulations and import/export requirements of different countries, ensuring accurate completion of all necessary customs forms and declarations. This includes understanding HS codes (Harmonized System codes) for proper classification of goods.

- Carrier Selection: I select carriers based on factors such as cost, transit times, reliability, and the specific requirements of the shipment (e.g., temperature-controlled shipping).

- Incoterms: I have a good understanding of Incoterms (International Commercial Terms) to clarify the responsibilities of the buyer and seller in the shipping process.

- Documentation: I meticulously prepare all necessary documentation, including commercial invoices, packing lists, certificates of origin, and other required documents to ensure smooth customs clearance.

- Customs Brokerage: I understand when to utilize the services of a customs broker to navigate complex customs procedures, particularly for high-value or sensitive goods.

I successfully managed the international shipment of a high-value piece of equipment to Japan, navigating complex customs regulations and ensuring its safe arrival on time and within budget.

Q 27. How do you maintain a clean and organized work area?

Maintaining a clean and organized workspace is not just about aesthetics; it’s crucial for safety, efficiency, and productivity. My approach focuses on consistent effort and preventative measures.

- 5S Methodology: I’m familiar with the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) for workplace organization, applying it to maintain a clean, efficient, and safe environment.

- Regular Cleaning: I participate in or lead regular cleaning activities, ensuring that all areas are kept clean and free of debris. This includes sweeping, mopping, and removing any unnecessary materials.

- Designated Storage Areas: I ensure that all materials and equipment are stored in designated areas, preventing clutter and improving efficiency in locating items.

- Inventory Management: Proper inventory management helps to keep the warehouse organized and prevents overstocking or the accumulation of unnecessary items.

- Waste Reduction: I actively look for ways to reduce waste through efficient material usage and recycling initiatives.

In my previous role, we implemented a visual management system that significantly improved organization and reduced time spent searching for materials, leading to increased productivity.

Q 28. Describe your experience with forklift operation (if applicable).

Yes, I am a certified forklift operator with extensive experience operating various types of forklifts, including sit-down, stand-up, and reach trucks. My experience includes safe operation, preventative maintenance, and adherence to safety regulations.

- Certification and Training: I hold a valid forklift operator’s certification and regularly undergo refresher training to maintain my skills and knowledge of safe operating procedures.

- Safe Operating Procedures: I am proficient in all aspects of safe forklift operation, including pre-operation checks, load stability, maneuvering in tight spaces, and proper load handling techniques.

- Preventative Maintenance: I’m familiar with performing basic preventative maintenance checks on forklifts, reporting any mechanical issues to the appropriate personnel promptly.

- Load Capacity Awareness: I consistently adhere to load capacity limits, ensuring the safety of myself and others. I understand the importance of weight distribution and stability.

- Safety Awareness: I’m always aware of my surroundings and maintain a safe operating distance from other personnel and equipment.

In one instance, my quick thinking and knowledge of safe operating procedures helped to prevent a potential accident involving another worker and a forklift.

Key Topics to Learn for Shipping and Receiving Certification Interview

- Inventory Management: Understanding inventory control systems, cycle counting, and stock rotation techniques. Practical application: Explain how you would handle a discrepancy between physical inventory and system records.

- Warehouse Operations: Knowledge of warehouse layout, safety procedures, and efficient material handling practices. Practical application: Describe your experience with different types of material handling equipment and their safe operation.

- Shipping Documentation: Proficiency in creating and interpreting shipping documents like bills of lading, packing slips, and commercial invoices. Practical application: Explain the importance of accurate and complete documentation for efficient shipping and receiving.

- Receiving Processes: Understanding the steps involved in receiving shipments, verifying quantities and conditions, and processing returns. Practical application: Describe your approach to handling damaged or incorrect shipments.

- Logistics and Supply Chain: Basic knowledge of the supply chain process and how shipping and receiving fits within it. Practical application: Explain how delays in shipping and receiving can impact the overall supply chain.

- Quality Control: Implementing quality control measures to ensure the accuracy and integrity of shipments. Practical application: Describe your experience with inspecting incoming and outgoing goods.

- Technology and Software: Familiarity with warehouse management systems (WMS) and other relevant software applications. Practical application: Discuss your experience using WMS software to track inventory and manage orders.

- Safety and Compliance: Adherence to safety regulations and compliance standards within a warehouse environment. Practical application: Explain how you would ensure a safe working environment for yourself and colleagues.

Next Steps

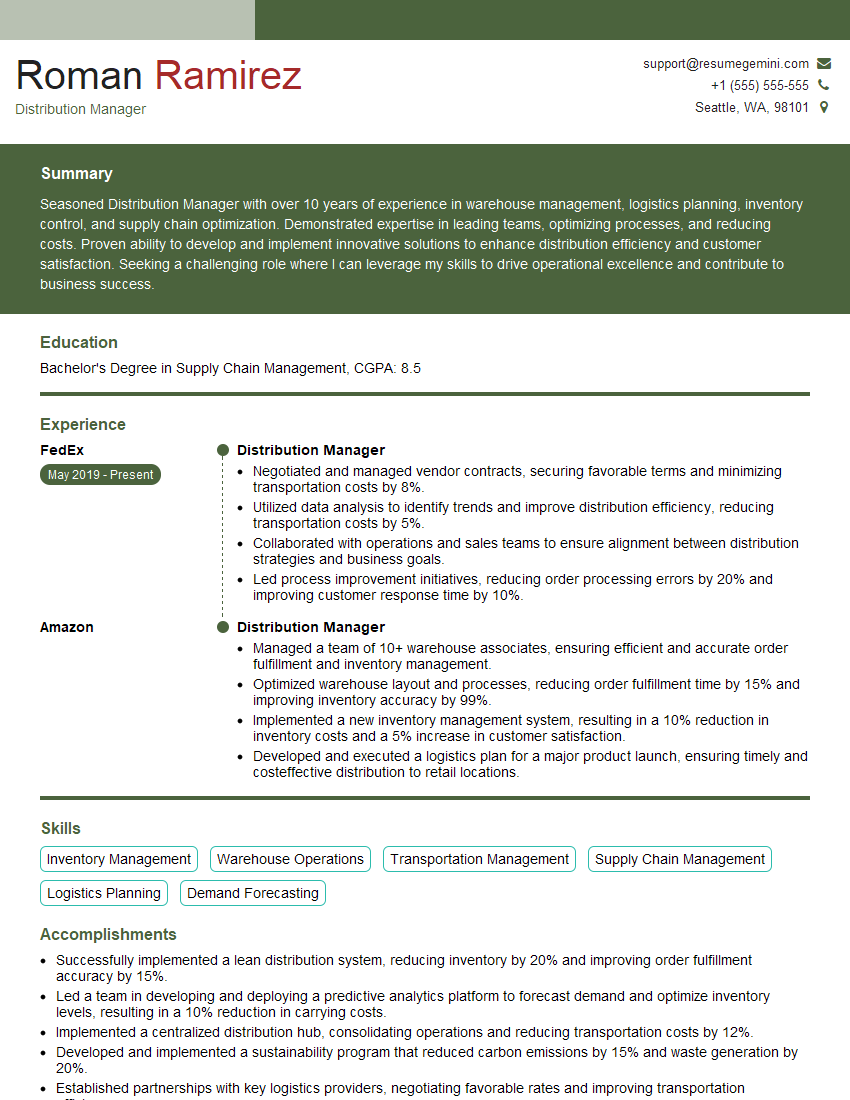

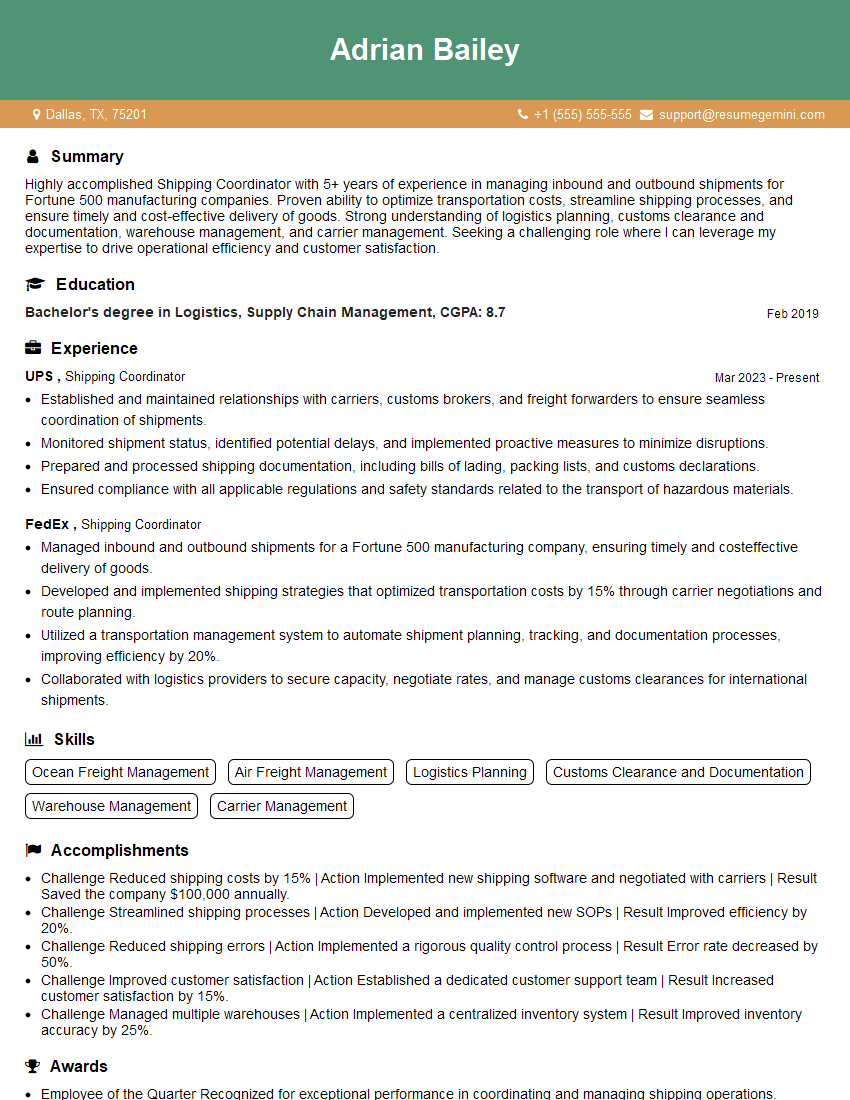

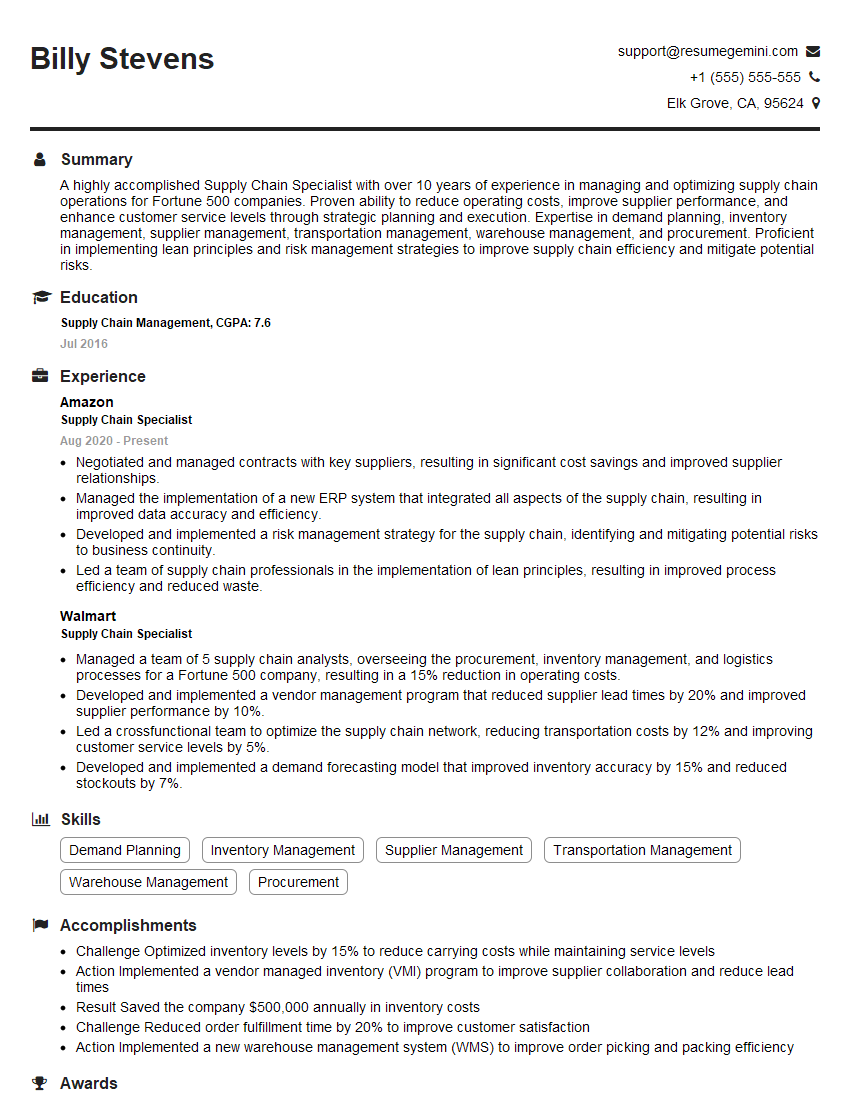

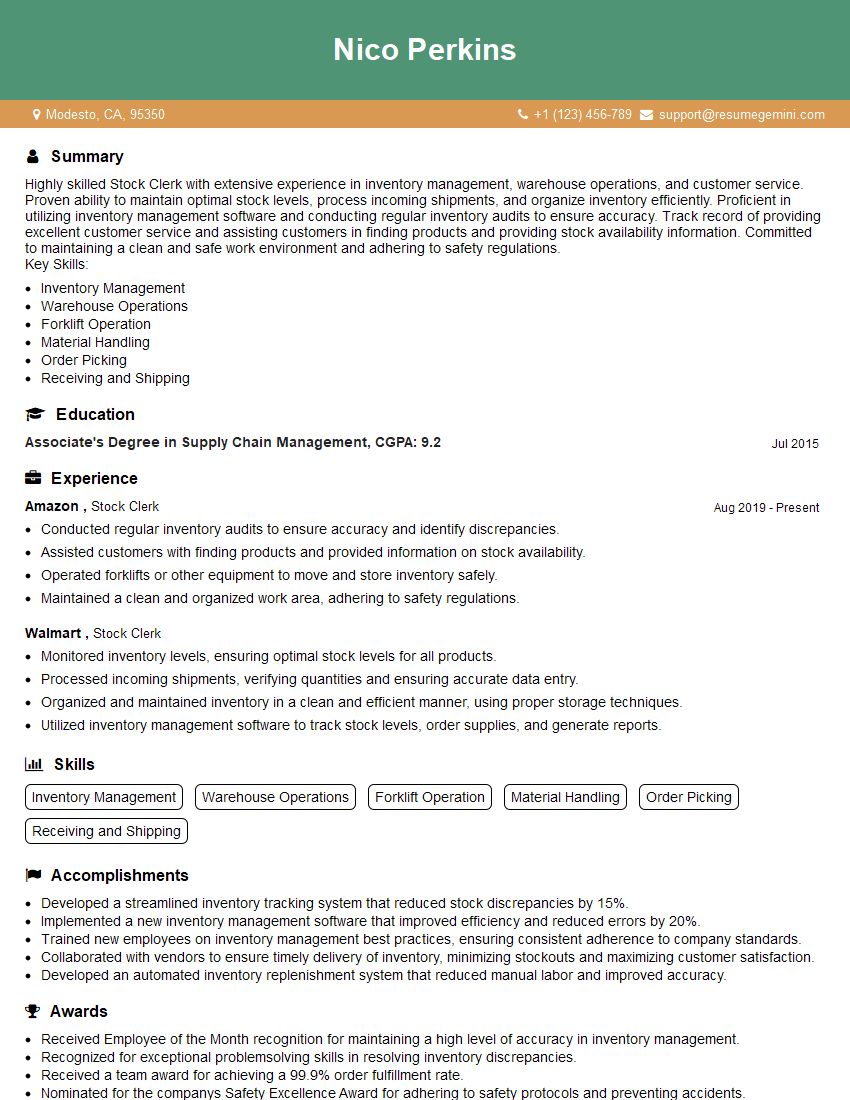

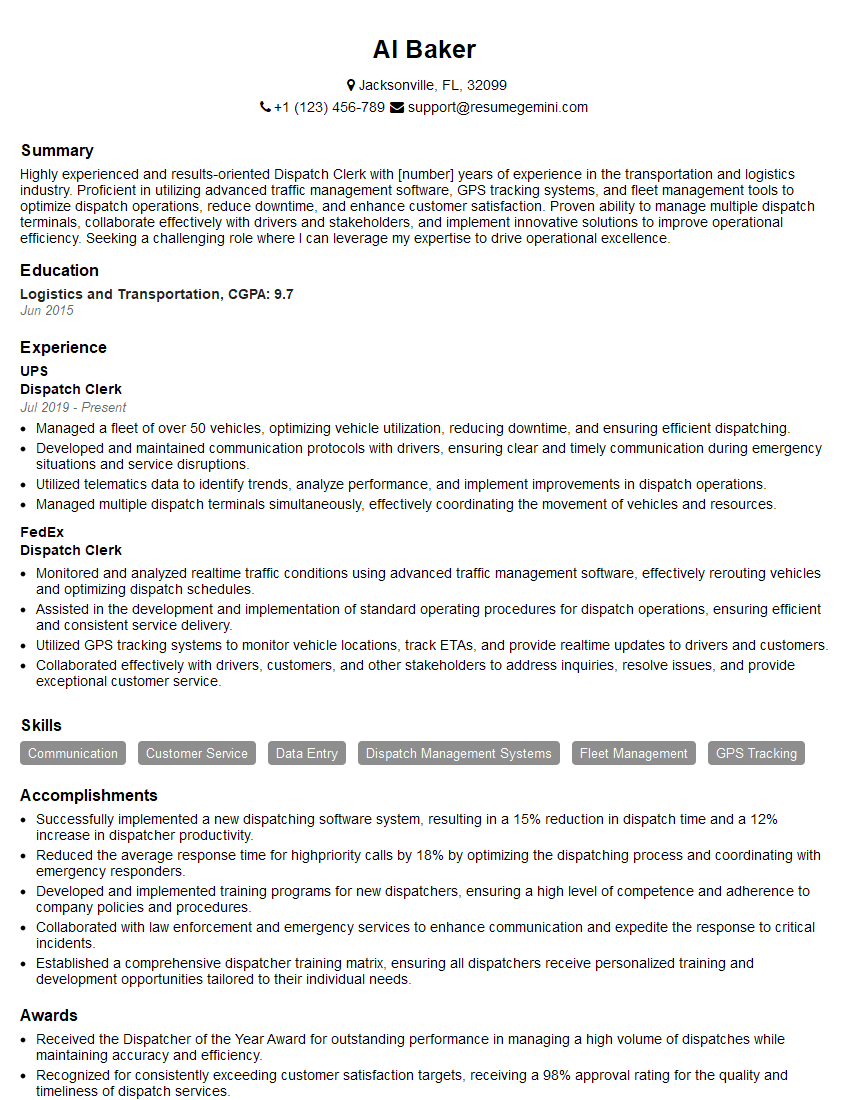

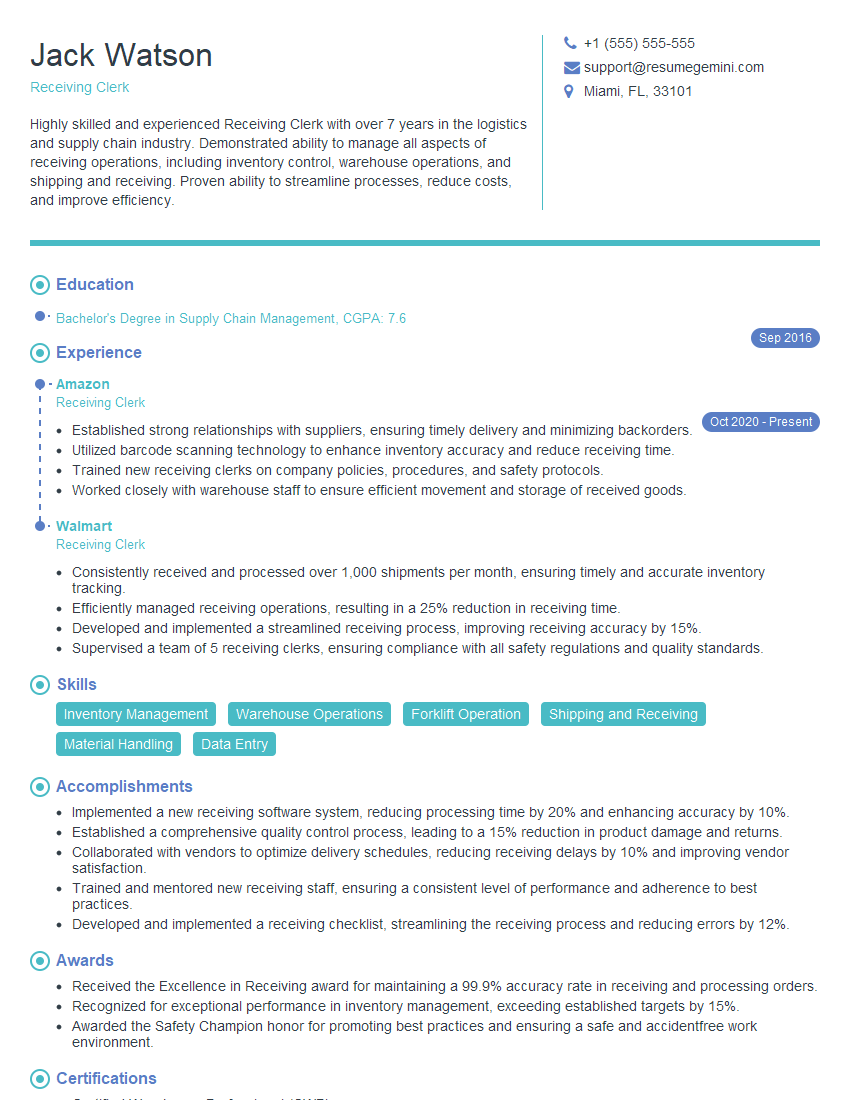

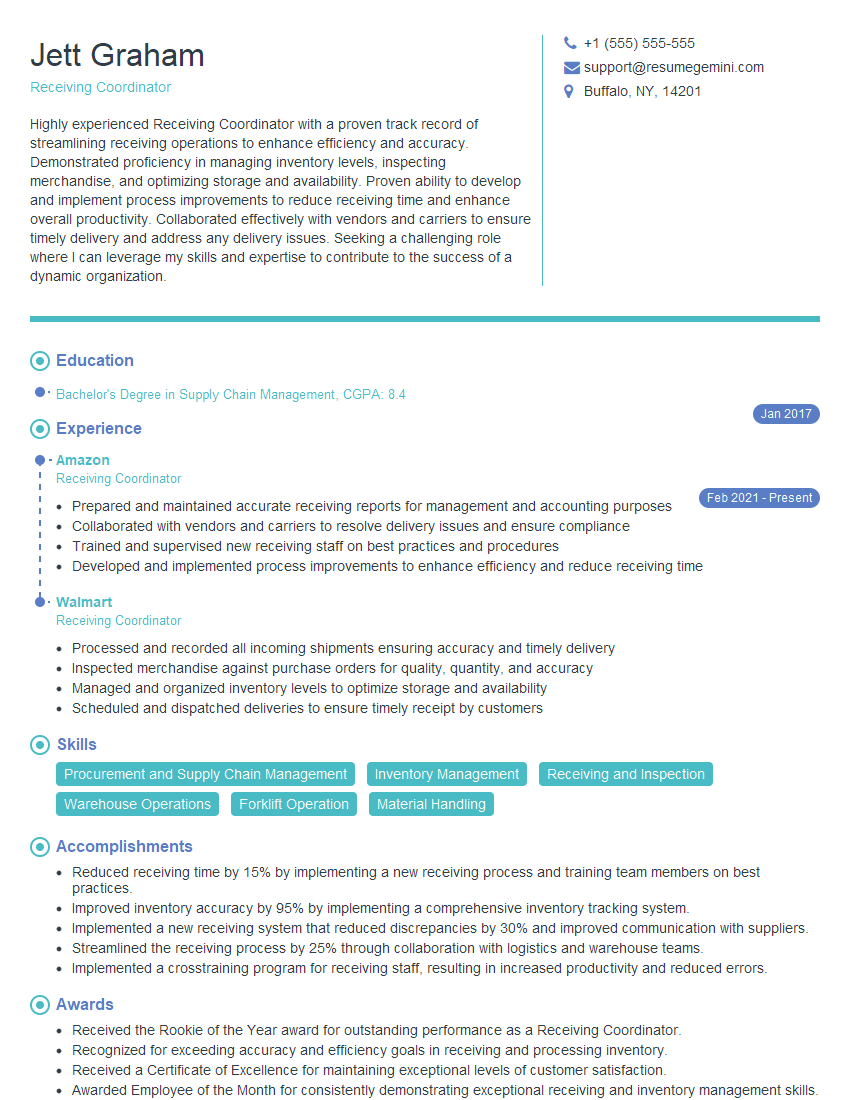

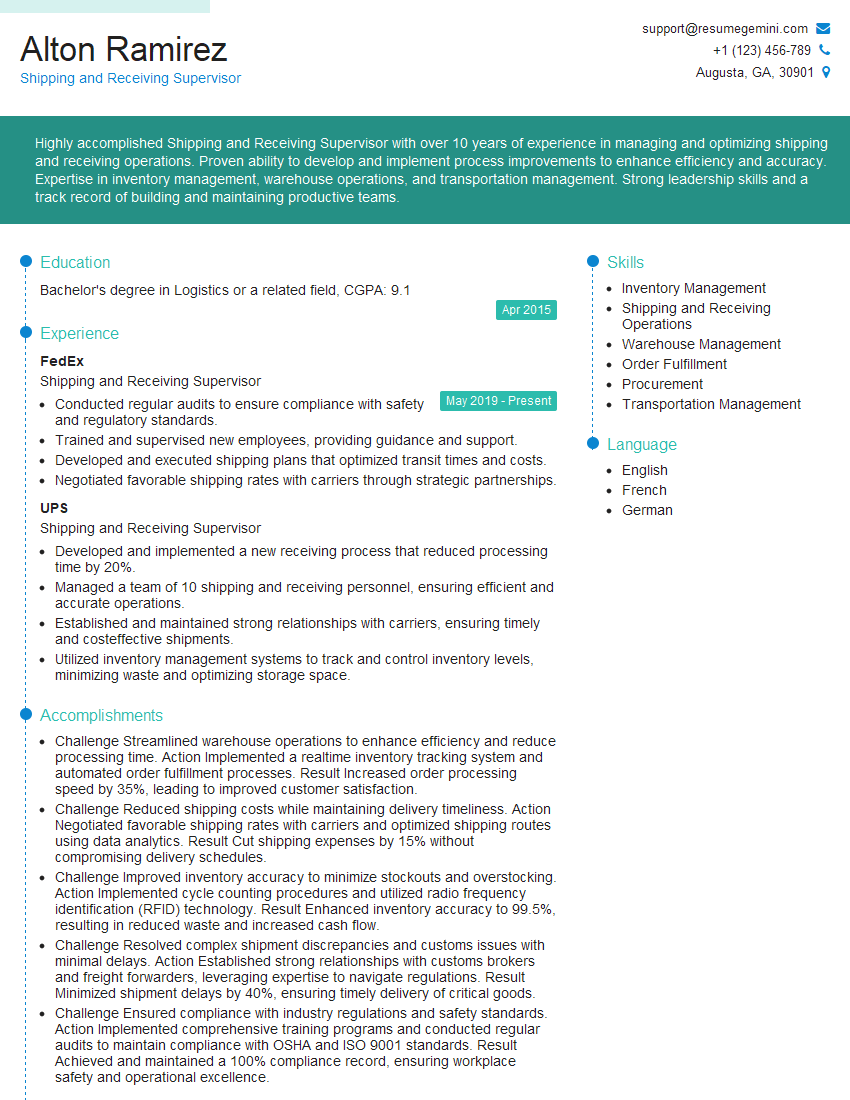

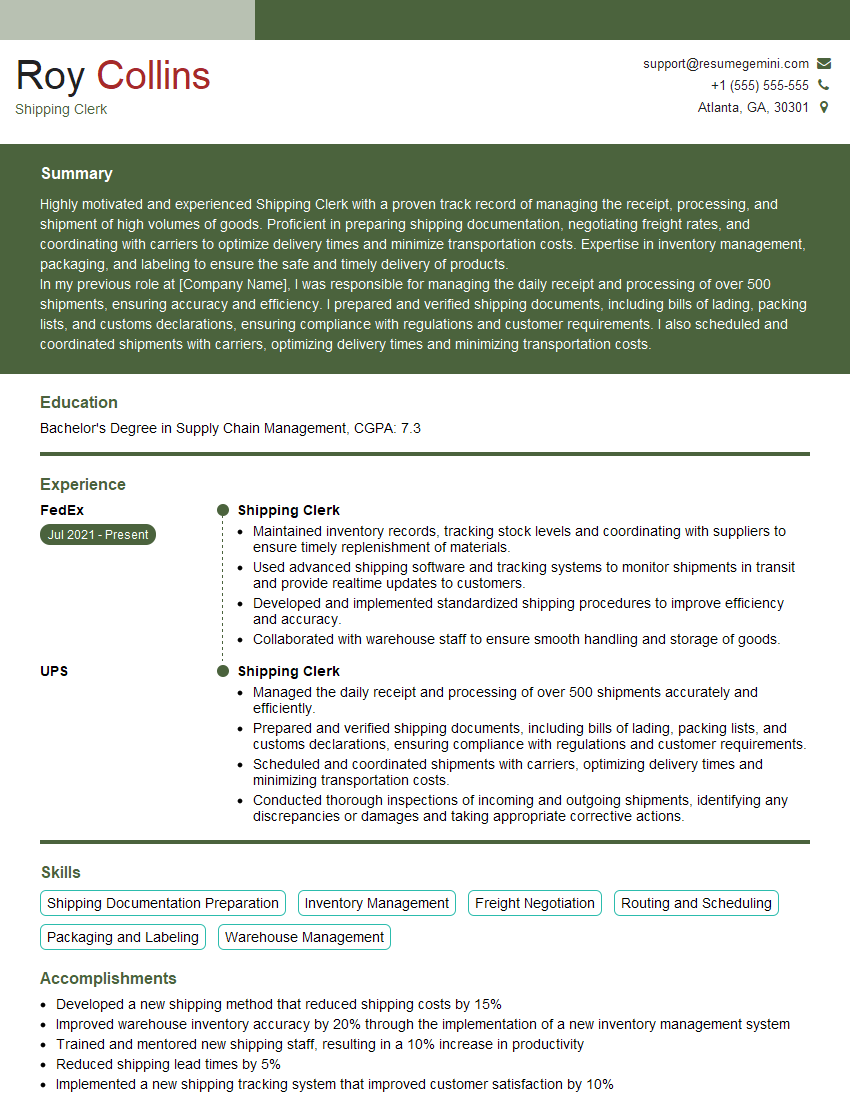

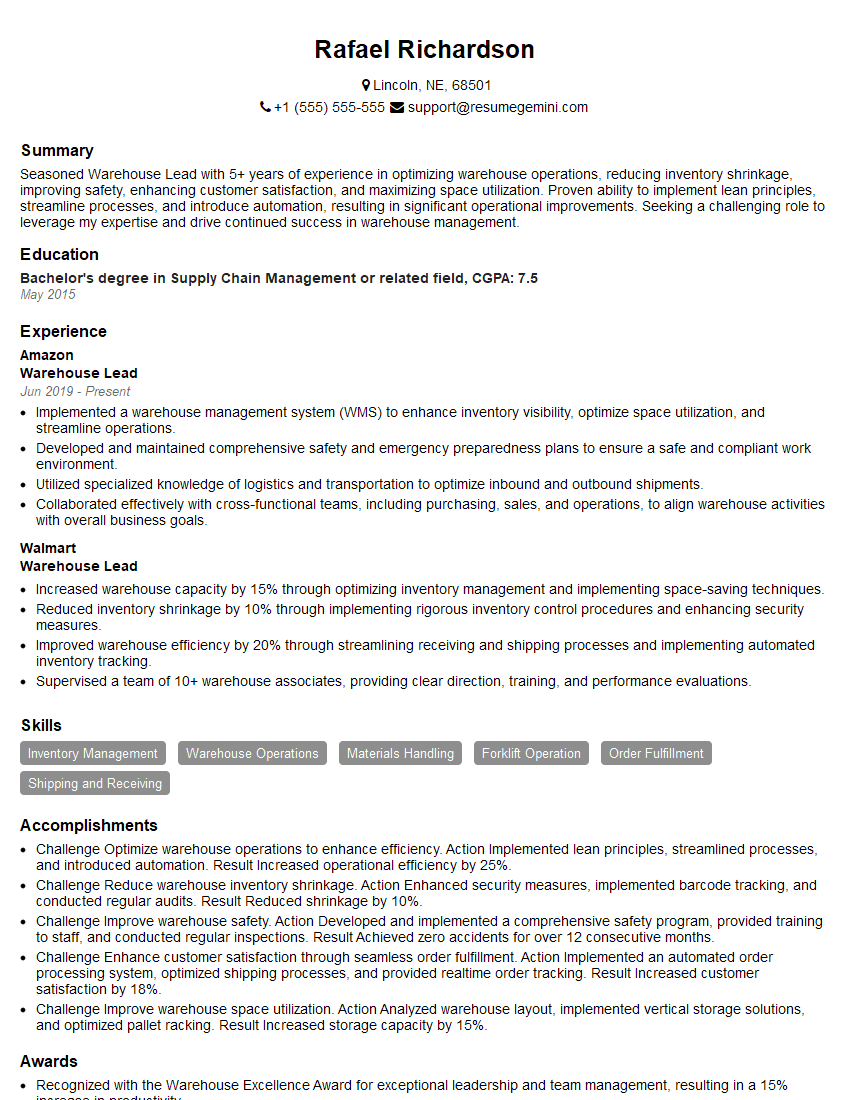

Mastering Shipping and Receiving certification significantly boosts your career prospects, opening doors to higher-paying roles and greater responsibility within logistics and supply chain management. An ATS-friendly resume is crucial for getting your application noticed by potential employers. ResumeGemini can help you craft a compelling and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Shipping and Receiving certification to help guide your resume creation process, ensuring your qualifications shine through.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO