Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Transportation logistics certification interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Transportation logistics certification Interview

Q 1. Explain the difference between LTL and FTL shipping.

LTL (Less than Truckload) and FTL (Full Truckload) shipping are two distinct methods for transporting goods by road, differing primarily in the amount of space occupied. FTL involves reserving an entire truck for a single shipment, ideal for large volumes. LTL, on the other hand, consolidates smaller shipments from multiple shippers onto a single truck, sharing space and cost. Think of it like this: FTL is like renting a whole apartment, while LTL is like sharing a dorm room – you only pay for your share of the space.

Key Differences:

- Cost: FTL is generally more expensive per unit but cheaper overall for large quantities. LTL is more cost-effective for smaller shipments but may be more expensive per unit.

- Transit Time: FTL typically offers faster transit times as it’s a direct shipment. LTL transit times can be longer due to consolidation and multiple stops.

- Flexibility: FTL provides greater control and flexibility over the shipment. LTL offers less control, as your goods are handled with others.

- Cargo Handling: FTL involves less handling and minimizes the risk of damage compared to LTL.

Example: A furniture manufacturer shipping a large order of sofas would opt for FTL. A small online retailer sending individual orders across the country would use LTL.

Q 2. Describe your experience with different modes of transportation (e.g., air, sea, rail, road).

My experience spans all major modes of transportation. I’ve managed logistics for air freight, primarily for time-sensitive, high-value goods like electronics and pharmaceuticals, leveraging speed and reliability. Sea freight has been crucial for handling large, bulky, and less time-sensitive shipments such as raw materials and manufactured goods – a cost-effective solution for global trade, but with longer transit times. I’ve also overseen rail freight for transporting goods across long distances, where cost-effectiveness and large volumes are prioritized, such as bulk commodities like grain or minerals. Finally, road freight (both LTL and FTL) forms the backbone of my experience, handling the last-mile delivery and shorter-distance transport of diverse goods. The choice of mode depends heavily on the specific needs of the shipment – cost, time sensitivity, volume, and fragility of the goods are key factors.

For example, one project involved coordinating the international shipment of medical equipment using a multimodal approach: air freight for urgent components, sea freight for bulk supplies, and road freight for final delivery to hospitals. This required careful planning and coordination across different carriers and handling processes.

Q 3. How do you calculate transportation costs?

Calculating transportation costs is a multi-faceted process. It’s not a simple formula, but rather a careful assessment of various factors.

- Line Haul Costs: This is the primary cost, representing the cost to move goods from origin to destination. It varies based on distance, mode of transport, and fuel prices.

- Accessorial Charges: These are additional fees for services like fuel surcharges, handling charges (loading/unloading), special equipment (refrigerated trucks), hazardous material handling, and insurance.

- Freight Class: For LTL, the freight class (based on density, stowability, and liability) determines the rate.

- Weight and Volume: The weight and dimensional weight (volume converted to weight) of the shipment determine the billable weight, which affects pricing.

- Surcharges: Various surcharges can apply based on factors like congestion, peak season, and location.

Formula (Simplified): Total Transportation Cost = Line Haul Cost + Accessorial Charges + Surcharges

Example: A shipment weighing 1000 lbs with a freight class of 70 will have a higher cost than a shipment of the same weight with a freight class of 50. Adding a fuel surcharge or hazardous materials handling increases the overall cost.

Q 4. What are Incoterms and how do they impact transportation logistics?

Incoterms (International Commercial Terms) are a standardized set of three-letter trade terms published by the International Chamber of Commerce (ICC). They define the responsibilities of the buyer and seller for the transportation of goods in international trade. They clarify who is responsible for costs and risks associated with shipping, insurance, and customs clearance at various points in the journey.

Impact on Transportation Logistics: Incoterms are crucial because they eliminate ambiguity in contracts, preventing disputes. They determine:

- Point of delivery: Who is responsible for delivering the goods to where?

- Insurance: Who is responsible for insuring the goods during transit?

- Export/Import customs clearance: Who handles the necessary paperwork and fees?

- Transportation costs: Who is responsible for paying what shipping costs?

Example: If a contract specifies Incoterms as ‘CIF’ (Cost, Insurance, and Freight), the seller is responsible for all costs and risks until the goods reach the named port of destination. The buyer then takes over responsibility. Choosing the right Incoterms is vital for efficient and smooth international trade operations.

Q 5. Explain the concept of Just-in-Time (JIT) inventory management.

Just-in-Time (JIT) inventory management is a strategy that aims to receive materials only when they’re needed for production, minimizing storage costs and waste. The goal is to have the right amount of materials at the right place at the right time. It relies heavily on accurate forecasting, efficient transportation, and strong supplier relationships.

Key Aspects of JIT:

- Reduced Inventory: Minimizing warehouse space and storage costs.

- Improved Efficiency: Streamlined production process with less waste.

- Reduced Waste: Less obsolete or damaged inventory.

- Strong Supplier Relationships: Reliable suppliers are crucial for timely deliveries.

- Reliable Transportation: Efficient and on-time delivery systems are essential.

Example: A car manufacturer using JIT might receive engine parts from a supplier only when they are needed for assembly on a particular day, rather than stocking a large inventory of parts in a warehouse.

Q 6. How do you handle unexpected delays in the supply chain?

Handling unexpected delays requires a proactive and adaptable approach. My strategy involves a multi-step process:

- Immediate Assessment: Identify the nature and severity of the delay (weather, port congestion, carrier issues).

- Communication: Immediately notify all relevant stakeholders (customers, suppliers, carriers) and provide transparent updates.

- Contingency Planning: Explore alternative solutions such as rerouting shipments, using alternative modes of transport, or expediting delivery to minimize further disruptions.

- Risk Mitigation: Implement measures to prevent similar delays in the future (diversifying suppliers, building buffer stock for critical items).

- Documentation: Thoroughly document all actions taken to address the delay, including communications and decisions made.

- Root Cause Analysis: After the issue is resolved, conduct a thorough analysis to understand the root cause of the delay and put preventative measures in place.

For instance, during a recent port congestion issue, we rerouted a shipment through a different port, incurring higher costs but ensuring timely delivery. We then worked with the carrier to identify the root cause of the congestion and negotiate better service level agreements for future shipments.

Q 7. Describe your experience with Transportation Management Systems (TMS).

I have extensive experience with Transportation Management Systems (TMS). These software platforms are crucial for optimizing and automating transportation processes. My experience involves using TMS to:

- Plan shipments: Optimize routes, select carriers, and manage freight.

- Track shipments: Monitor the location and status of shipments in real-time.

- Manage documents: Electronically manage shipping documents such as bills of lading and customs forms.

- Analyze data: Track key performance indicators (KPIs) such as on-time delivery rates, cost per shipment, and carrier performance.

- Automate processes: Automate tasks such as rate calculation, invoice processing, and carrier communication.

Examples of TMS features I’ve used: Route optimization algorithms, carrier management modules, automated freight payment systems, and real-time tracking dashboards. Using a TMS significantly improves efficiency, reduces costs, and enhances visibility across the entire transportation network.

Q 8. What are your strategies for optimizing transportation routes and schedules?

Optimizing transportation routes and schedules is crucial for efficiency and cost reduction. My strategy involves a multi-pronged approach leveraging technology and best practices. First, I utilize route optimization software that considers factors like distance, traffic patterns, delivery windows, and fuel costs to generate the most efficient routes. Think of it like using a GPS, but on a much larger scale, considering numerous stops and variables. For example, if delivering to multiple locations in a city, the software will dynamically adjust the route based on real-time traffic data, ensuring timely delivery. Second, I meticulously analyze historical data to identify recurring patterns and potential bottlenecks. This might reveal peak delivery times, specific road closures that frequently occur, or even underutilized delivery personnel. Third, I collaborate closely with carriers to negotiate favorable rates and service level agreements (SLAs). This includes establishing clear communication channels to ensure timely problem resolution and proactive route adjustments. Finally, regular performance reviews and analysis of key performance indicators (KPIs) – such as on-time delivery rates and fuel consumption – inform continuous improvements to the route optimization process. It’s an iterative process, continuously refining and improving efficiency.

Q 9. How do you manage warehouse space efficiently?

Efficient warehouse space management is all about maximizing storage capacity while minimizing operational costs and improving order fulfillment speed. My approach focuses on several key areas. First, I implement a robust warehouse management system (WMS) to track inventory levels in real-time, optimize storage locations, and streamline picking and packing processes. Think of it as a highly organized digital filing cabinet for your warehouse. Second, I employ effective inventory control techniques, such as implementing a FIFO (First-In, First-Out) system to minimize waste and spoilage, especially crucial for perishable goods. Third, I optimize the layout of the warehouse itself. This could involve optimizing shelving arrangements to accommodate different product sizes and weights, creating dedicated zones for specific operations, and ensuring clear pathways for efficient movement of goods and personnel. Regular audits and space optimization analysis help identify areas where improvement is possible. Imagine a well-organized kitchen – everything has its place, making it easy to find and access what you need. Lastly, I ensure appropriate staffing levels are in place to handle the volume of goods moving through the warehouse, and I continuously train staff on best practices for efficiency. This includes implementing lean principles to eliminate waste in processes.

Q 10. How familiar are you with different types of freight documentation?

I am very familiar with various freight documentation. My expertise encompasses the entire range, from Bills of Lading (BOLs) – which act as contracts between the shipper and carrier – to Commercial Invoices detailing the goods being shipped, packing lists itemizing the contents of each package, certificates of origin verifying the origin of the goods, and various customs forms required for international shipments. I also understand the significance of other documents like Certificates of Insurance, Dangerous Goods Declarations (for hazardous materials), and Letters of Credit, depending on the shipment’s nature. For example, a BOL is crucial for tracking a shipment and establishing liability. Without a properly completed BOL, it becomes difficult to trace a missing shipment or determine who is responsible for damages. Familiarity with all these documents ensures smooth and compliant transportation of goods. I understand the critical role each document plays in the supply chain and am adept at ensuring their accuracy and timely completion.

Q 11. Explain your understanding of customs regulations and procedures.

My understanding of customs regulations and procedures is extensive, encompassing both import and export processes. I am familiar with the intricacies of tariff classifications, duty calculations, and various trade agreements. Compliance is paramount, and I understand the potential consequences of non-compliance, including delays, fines, and even legal repercussions. Understanding the specific requirements of different countries is crucial; regulations vary widely, and navigating these complexities demands detailed knowledge. For example, the process for importing goods into the European Union differs significantly from importing into the United States, requiring detailed understanding of respective regulations, documentation, and procedures. I regularly keep abreast of updates and changes in international trade laws and regulations to ensure seamless and compliant international shipping operations. My experience includes working directly with customs brokers to ensure that all necessary documentation is prepared and submitted correctly, and managing the complexities of customs clearance efficiently and effectively.

Q 12. How do you track and trace shipments?

Shipment tracking and tracing is critical for maintaining visibility and ensuring timely delivery. I utilize various methods, including GPS tracking devices installed on vehicles, barcode and RFID scanning at various stages of the transportation process, and electronic data interchange (EDI) systems that provide real-time updates on shipment location and status. Many carriers offer online portals with detailed tracking information. My experience also includes working with third-party logistics providers (3PLs) that specialize in real-time tracking and provide comprehensive shipment visibility dashboards. Think of it like using a package tracking service, but on a much broader and more sophisticated scale. The information gathered through these methods is then integrated into a centralized system for easy access and reporting. This enables proactive issue resolution and efficient management of the entire shipping process. For instance, if a delay is detected, I can immediately take steps to mitigate its impact on the overall delivery schedule and customer satisfaction.

Q 13. What metrics do you use to measure transportation efficiency?

Measuring transportation efficiency involves a suite of key performance indicators (KPIs). These metrics provide insights into the effectiveness and cost-effectiveness of the transportation process. Some critical KPIs include on-time delivery rate (percentage of shipments delivered on time), perfect order rate (percentage of orders delivered correctly, completely, and on time), cost per mile, fuel efficiency (measured in miles per gallon), and inventory turnover rate (measuring how quickly inventory is sold and replenished). Other relevant metrics include driver utilization rate and claims rate, which shows the frequency of damage or loss claims. Analyzing these KPIs allows for identification of areas for improvement, enabling data-driven decisions to optimize operations and enhance overall efficiency. For instance, a low on-time delivery rate might indicate issues with route planning or carrier performance, while a high cost per mile suggests the need to explore more cost-effective transportation options. Regular monitoring and analysis of these KPIs are crucial for maintaining a competitive edge.

Q 14. How do you manage risk in transportation logistics?

Risk management in transportation logistics is multifaceted. My approach involves proactive identification, assessment, and mitigation of potential risks throughout the supply chain. This includes identifying potential risks such as weather-related disruptions, geopolitical instability, carrier failures, and cargo theft. Then, I develop contingency plans to address these scenarios. Examples of mitigation strategies include using multiple carriers to reduce reliance on any single provider, employing cargo insurance to cover potential losses, implementing robust security measures to protect against theft, and establishing clear communication protocols to manage potential disruptions proactively. Continuous monitoring of potential risks through various sources such as news reports, weather forecasts, and intelligence networks allows for a proactive approach. Regular risk assessments and reviews help maintain updated and effective risk management strategies. Building strong relationships with carriers and other stakeholders also enhances communication and collaboration in addressing potential challenges and reducing risks collectively. It’s a proactive and dynamic process, adapting to changing circumstances and emerging challenges.

Q 15. Describe your experience with warehouse safety procedures.

Warehouse safety is paramount in logistics, and my experience encompasses a multifaceted approach. It starts with a thorough understanding and strict adherence to OSHA (Occupational Safety and Health Administration) regulations and company-specific safety protocols. This includes regular safety training covering topics like forklift operation, proper lifting techniques, hazard communication (SDS sheets), and emergency procedures.

In my previous role, I implemented a new warehouse layout to improve workflow and reduce the risk of accidents. This involved analyzing traffic flow patterns, identifying potential bottlenecks and hazards (like blind spots for forklift drivers), and reorganizing storage areas to optimize space and minimize movement. We also installed additional lighting and signage to improve visibility and clarity. We actively encouraged a safety-first culture by implementing a robust reporting system for near misses and accidents, allowing us to proactively address potential hazards before they caused injuries.

For example, we saw a significant reduction in forklift-related incidents after implementing a new training program focusing on blind spot awareness and pre-trip inspections. Furthermore, regular audits ensured that safety protocols were consistently followed, and equipment was properly maintained.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of supply chain security.

Supply chain security is about protecting the integrity of goods, information, and assets throughout the entire supply chain. This involves mitigating risks such as theft, damage, counterfeiting, and disruptions. A robust security strategy uses a layered approach encompassing physical security, cybersecurity, and process controls.

Physical security involves measures like access control systems (e.g., keypads, security cameras, and personnel checks), secure storage facilities, and GPS tracking of shipments. Cybersecurity involves protecting sensitive data from breaches, ensuring data encryption and secure communication channels, and implementing robust IT security protocols. Process controls include verifying supplier credentials, employing proper documentation and auditing procedures, and implementing contingency plans for disruptions.

Think of it like a castle with multiple layers of defense: a strong outer wall (physical security), secure gates and guards (access control), and well-guarded inner chambers (data security). Each layer works together to create a comprehensive security system. In a real-world scenario, this could involve using blockchain technology for tracking high-value goods, preventing counterfeiting, and providing transparent visibility of product provenance.

Q 17. How do you handle customer complaints related to transportation?

Handling customer complaints regarding transportation is crucial for maintaining positive relationships and brand reputation. My approach focuses on empathy, efficient problem-solving, and transparent communication.

First, I actively listen to the customer’s concerns and acknowledge their frustration. I gather all relevant information – tracking data, delivery notes, and any communication history. Then, I investigate the issue thoroughly, identifying the root cause of the problem, whether it’s a delay, damage, or misdelivery. Once I have a clear understanding, I communicate the findings to the customer, offering a sincere apology if warranted.

Depending on the nature of the complaint, the solution could involve a refund, replacement, expedited delivery, or a combination of measures. I always aim to exceed customer expectations and turn a negative experience into a positive one. For instance, if a shipment was damaged, I would not only process a replacement but also offer a discount on their next order. Clear and consistent communication throughout the resolution process is essential, providing regular updates to the customer.

Q 18. Describe a time you had to solve a complex logistics problem.

During a peak season, a major supplier experienced an unexpected facility shutdown due to a fire. This resulted in a critical shortage of a key component needed for our client’s flagship product. The client faced a production standstill with significant financial implications.

My first step was damage control: contacting other potential suppliers to assess their capacity to fulfill the order. Simultaneously, I worked with the original supplier to understand the timeline for recovery. We explored alternative transportation options, including air freight, to expedite delivery of the component from alternative sources. We carefully managed inventory levels, prioritizing the most urgent orders while negotiating flexible delivery schedules with the client.

Through collaboration, we managed to secure sufficient supply within a compressed timeframe, mitigating the production delay to a minimum. This involved meticulous coordination with multiple parties, negotiating favorable rates with carriers, and transparent communication with the client to manage their expectations.

Q 19. What software or tools are you proficient in for managing logistics?

My proficiency in logistics software and tools is extensive. I’m highly skilled in Transportation Management Systems (TMS) such as Oracle Transportation Management (OTM) and SAP Transportation Management (TM). These systems are invaluable for planning, executing, and optimizing transportation operations. They allow for functions such as route optimization, carrier selection, shipment tracking, and document management.

I also have significant experience with Warehouse Management Systems (WMS) like Manhattan Associates and Blue Yonder. These tools facilitate warehouse operations including inventory control, order fulfillment, and labor management. Furthermore, I’m proficient in using Geographic Information Systems (GIS) for route planning and visualization. Finally, I’m adept at using data analysis tools such as Excel and SQL to extract insights from operational data for performance monitoring and improvement.

Q 20. How do you stay updated on industry best practices and regulations?

Staying current with industry best practices and regulations is a continuous process. I subscribe to industry journals and publications like the Journal of Business Logistics and Supply Chain Management Review. I actively participate in industry conferences and webinars, networking with other professionals and learning about emerging trends.

I also leverage online resources such as government websites (e.g., the FMCSA in the US) for regulatory updates. Furthermore, I’m involved in professional organizations like the Council of Supply Chain Management Professionals (CSCMP) to receive updates on industry standards and best practices. Continuous learning through online courses and certifications helps me maintain a high level of expertise.

Q 21. Explain your understanding of Lean logistics principles.

Lean logistics principles focus on eliminating waste and maximizing efficiency throughout the supply chain. It’s an approach that uses various tools and techniques to streamline processes and reduce costs while improving customer service.

The core principles revolve around identifying and eliminating seven types of waste: defects, overproduction, waiting, non-utilized talent, transportation, inventory, and motion. This can be achieved through tools like value stream mapping, 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain), and Kaizen (continuous improvement).

For example, implementing a Kanban system helps to optimize inventory levels, reducing storage costs and preventing overstocking. Optimizing routes using route optimization software minimizes transportation costs and delivery times. By applying Lean principles, companies can significantly reduce operational costs, improve responsiveness to customer demands and achieve a more competitive advantage. It’s a philosophy of continuous improvement and operational excellence.

Q 22. How do you collaborate with different stakeholders in the supply chain?

Effective collaboration in the supply chain hinges on clear communication, trust, and a shared understanding of goals. I approach this by employing a multi-faceted strategy. Firstly, I prioritize establishing strong, open relationships with all stakeholders – from suppliers and manufacturers to carriers, customers, and internal teams. Regular meetings, both formal and informal, are crucial. These sessions allow for the free exchange of information, the identification of potential bottlenecks, and proactive problem-solving.

Secondly, I leverage technology to streamline communication. This includes using collaborative platforms for document sharing, project management tools for task tracking, and communication channels like instant messaging or email for quick updates. For instance, in a past project involving a cross-border shipment, we used a shared project management platform to track the shipment’s progress in real-time, which enabled us to swiftly address any unexpected delays or customs issues collaboratively. Finally, I advocate for a collaborative culture where everyone feels comfortable raising concerns and offering solutions, fostering a shared sense of responsibility for the entire supply chain’s success.

Q 23. Describe your experience with procurement processes.

My procurement experience spans various aspects, from sourcing and negotiation to contract management and supplier relationship management. I’m proficient in using different procurement strategies, including competitive bidding, reverse auctions, and negotiating long-term contracts to secure favorable pricing and service levels. A key part of my approach involves a thorough supplier assessment process, considering factors such as financial stability, operational capability, and quality control measures. This ensures that we partner with reliable suppliers capable of meeting our demands consistently.

For example, when procuring transportation services, I’ve successfully leveraged technology to automate certain steps like RFIs (Request for Information) and RFPs (Request for Proposal) processes, resulting in faster vendor selection and cost savings. I also emphasize building strong, long-term relationships with key suppliers. These relationships foster trust and collaboration, leading to better communication, improved service, and potential for future price reductions and service enhancements.

Q 24. What are your strategies for improving supply chain visibility?

Improving supply chain visibility requires a multi-pronged approach leveraging technology and strong operational processes. My strategy focuses on implementing robust tracking systems, integrating data from various sources, and utilizing real-time data analytics. This begins with deploying GPS tracking devices on shipments, integrating these tracking systems with our Transportation Management System (TMS), and ensuring accurate data input at every stage of the process.

Secondly, I advocate for the use of electronic data interchange (EDI) to facilitate seamless data exchange between different stakeholders. This eliminates manual data entry, minimizes errors, and enables real-time updates on shipment locations, transit times, and inventory levels. Furthermore, I use data analytics tools to identify trends, patterns, and potential risks. For example, analyzing historical data can pinpoint areas of frequent delays or inconsistencies which allows us to proactively address these issues before they impact the overall supply chain efficiency. The goal is to have a clear, comprehensive, and readily accessible view of the entire supply chain, from origin to destination, empowering proactive decision-making and risk mitigation.

Q 25. How do you handle capacity planning in transportation?

Capacity planning in transportation requires a careful balancing act between meeting demand and optimizing resource utilization. My approach involves forecasting future demand, considering factors such as seasonal fluctuations, promotional events, and economic trends. We use a combination of historical data, market intelligence, and sales forecasts to create accurate demand projections. This forecasting then informs our capacity planning decisions regarding the number of vehicles required, warehouse space needed, and staffing levels.

To enhance efficiency, I utilize advanced transportation planning software which allows for optimization of routes, consolidation of shipments, and the allocation of resources based on real-time data and anticipated demand. Moreover, we employ strategies like load balancing to ensure that transportation resources are utilized efficiently. If we anticipate a surge in demand, we proactively engage with additional carriers to prevent potential bottlenecks. This proactive approach mitigates the risk of disruptions and ensures that we can consistently meet customer demands and maintain service levels.

Q 26. What is your experience with international shipping regulations?

My experience with international shipping regulations is extensive, covering various aspects including customs procedures, import/export documentation, and compliance with international trade laws. I’m familiar with regulations from various countries and international organizations like the World Customs Organization (WCO). I understand the importance of correctly classifying goods using the Harmonized System (HS) code, preparing accurate shipping documentation like commercial invoices, packing lists, and certificates of origin, and ensuring compliance with import/export restrictions.

I’ve successfully navigated complex regulatory hurdles, including issues relating to sanctions, embargoes, and specific product requirements. For instance, during a recent project involving the shipment of sensitive electronics to a foreign market, I successfully managed the necessary export licensing and ensured that all documentation met the strict requirements of the destination country. A deep understanding of these regulations is vital for ensuring smooth and legal international shipping operations, minimizing delays, and avoiding costly penalties.

Q 27. How do you ensure compliance with relevant regulations?

Ensuring compliance with transportation regulations is paramount. My strategy involves a multi-layered approach, starting with a thorough understanding of all applicable laws and regulations – this includes national and international regulations pertaining to safety, security, environmental protection, and labor laws. We maintain a comprehensive compliance manual that is regularly updated to reflect changes in legislation and best practices. This manual serves as a guide for all personnel.

Secondly, we implement robust internal controls and audit processes to monitor compliance. This includes regular inspections of vehicles, verification of documentation, and tracking of key performance indicators (KPIs). Finally, we invest in training programs to educate our employees on compliance matters, ensuring that everyone understands their roles and responsibilities in maintaining compliance. We also engage with external compliance experts and legal counsel to stay up-to-date on relevant regulations and proactively address potential compliance gaps. This layered approach ensures we not only adhere to the letter of the law but also embrace a culture of compliance throughout the organization.

Q 28. How do you use data analytics to improve transportation logistics?

Data analytics plays a critical role in optimizing transportation logistics. I leverage data analytics tools and techniques to analyze large datasets from various sources – including TMS, GPS tracking, and ERP systems – to identify trends, patterns, and insights that enhance operational efficiency and decision-making. For instance, using predictive analytics, I can forecast demand fluctuations and optimize resource allocation accordingly.

Specifically, I use data analytics to: (1) Optimize routes and reduce fuel consumption; (2) Identify areas of inefficiency and implement process improvements; (3) Enhance shipment tracking and improve delivery times; (4) Predict potential delays and proactively mitigate risks; (5) Improve load planning to maximize capacity utilization; (6) Analyze carrier performance and negotiate better rates. This data-driven approach allows us to make informed decisions, improving efficiency, reducing costs, and enhancing overall supply chain performance. A concrete example would be using route optimization software to identify the most efficient routes, reducing fuel consumption by 15% in one instance, thus cutting costs significantly.

Key Topics to Learn for Transportation Logistics Certification Interview

- Supply Chain Management Fundamentals: Understanding the entire flow of goods, from origin to consumer, including procurement, manufacturing, warehousing, and distribution. Practical application: Analyzing a case study to identify bottlenecks and inefficiencies in a supply chain.

- Transportation Modes & Selection: Knowing the strengths and weaknesses of different transportation modes (road, rail, sea, air) and how to select the optimal mode based on factors like cost, speed, and reliability. Practical application: Choosing the most efficient transportation method for a time-sensitive shipment of perishable goods.

- Logistics Operations & Optimization: Mastering concepts like inventory management, warehouse optimization, and route planning. Practical application: Developing a plan to reduce delivery times and improve on-time performance.

- Freight Forwarding & Customs Brokerage: Understanding the role of freight forwarders and customs brokers in international trade and the associated documentation and regulations. Practical application: Preparing documentation for international shipments, ensuring compliance with all relevant regulations.

- Transportation Technology & Data Analytics: Familiarity with Transportation Management Systems (TMS), Global Positioning Systems (GPS) tracking, and the use of data analytics for performance monitoring and improvement. Practical application: Utilizing TMS data to identify areas for cost reduction and efficiency gains.

- Risk Management & Security: Identifying and mitigating potential risks throughout the transportation process, such as theft, damage, and delays. Practical application: Developing contingency plans to address potential disruptions in the supply chain.

- Legal and Regulatory Compliance: Understanding relevant laws and regulations related to transportation, such as safety standards and environmental regulations. Practical application: Ensuring compliance with all relevant regulations and minimizing the risk of penalties.

Next Steps

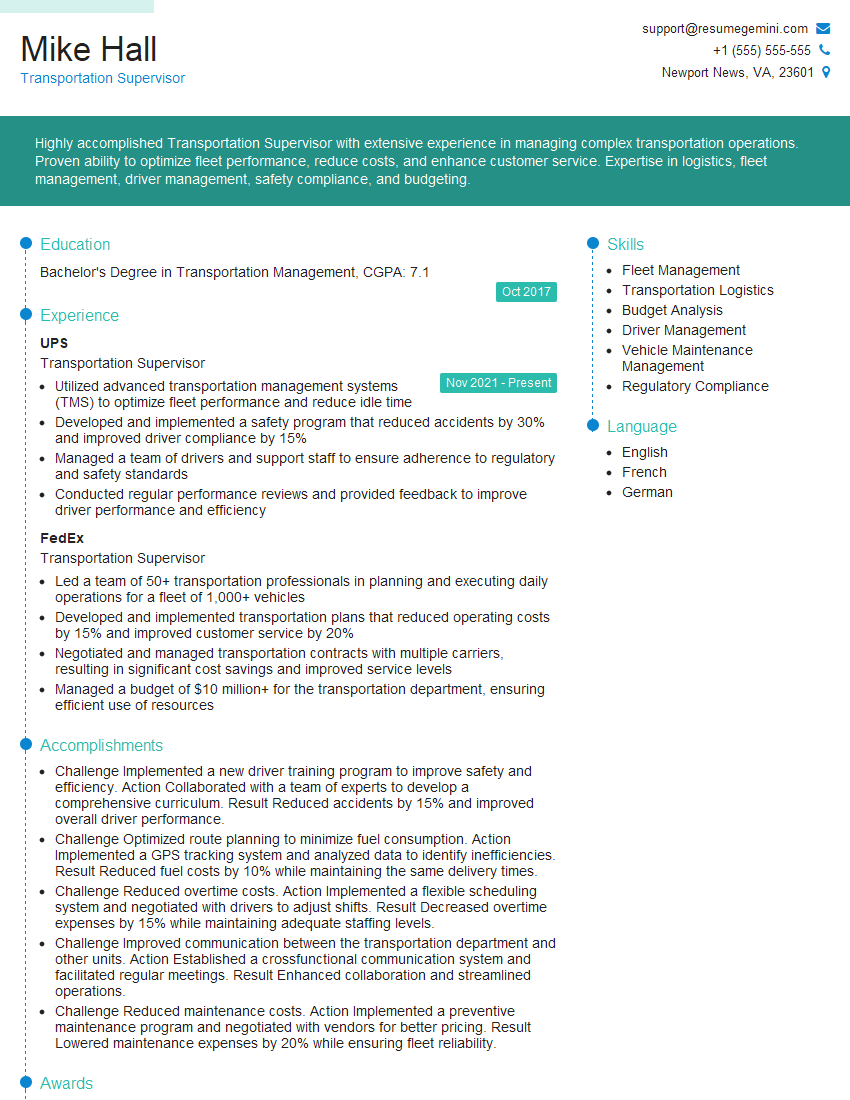

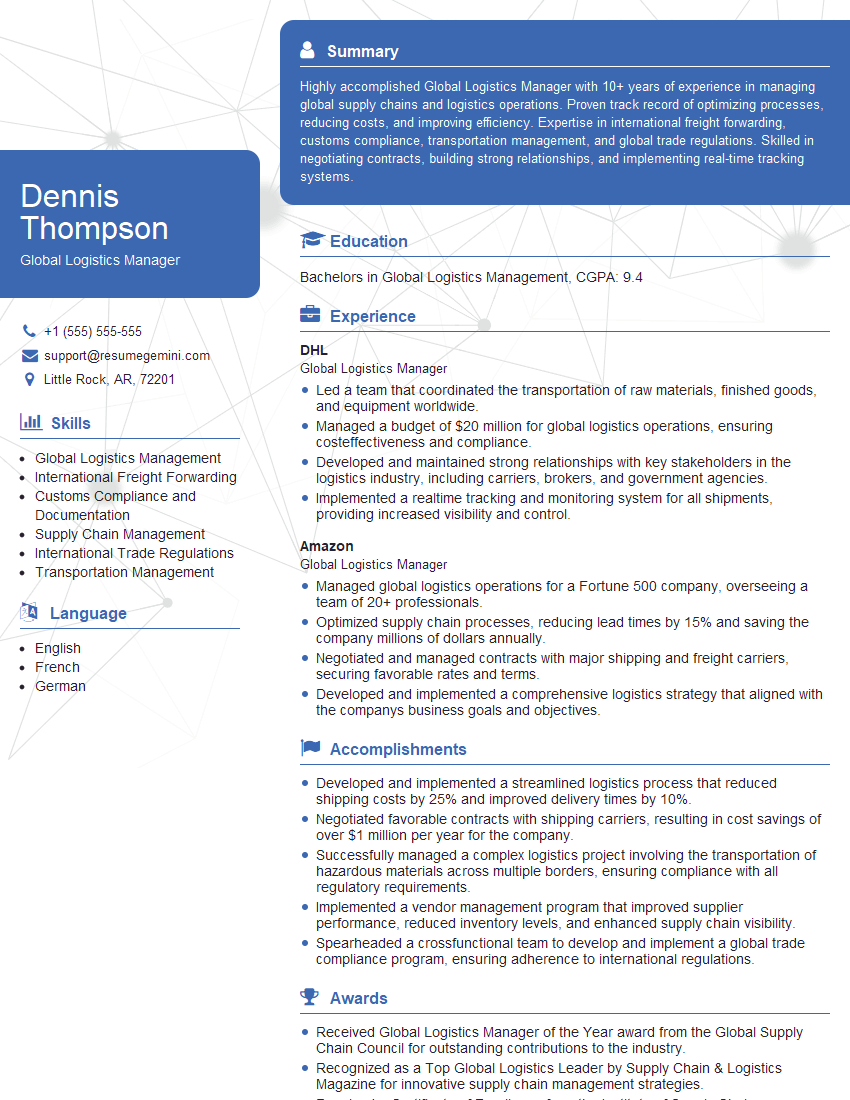

Mastering Transportation Logistics certification significantly enhances your career prospects, opening doors to higher-paying roles and greater responsibility within the industry. To maximize your job search success, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes specifically tailored to Transportation Logistics certification are available to help guide you. Invest time in creating a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO