Unlock your full potential by mastering the most common Extrusion and Coextrusion interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Extrusion and Coextrusion Interview

Q 1. Explain the difference between single-screw and twin-screw extrusion.

Single-screw and twin-screw extruders are both used to melt and homogenize polymers, but they differ significantly in their mechanism and applications. Think of a single-screw extruder like a giant auger, pushing material forward. It uses a rotating screw within a barrel to melt and pump the polymer. Twin-screw extruders, on the other hand, employ two intermeshing screws, allowing for much more efficient mixing and better control over the process.

- Single-screw extruders: Simpler in design, more cost-effective for simpler applications, but less efficient for mixing sensitive materials or high-viscosity polymers. They’re excellent for producing basic films, pipes, and profiles.

- Twin-screw extruders: Offer superior mixing, better control over melt temperature and pressure, and higher output for complex materials. They are ideal for high-performance materials, reactive processing, and coextrusion applications. Think of producing intricate multi-layered films for food packaging, where precise layering and barrier properties are crucial.

The choice between them depends on the material being processed, the desired output quality, and cost considerations. For instance, producing a simple polyethylene pipe might only require a single-screw extruder, while creating a high-barrier, multi-layer film would need the precision and versatility of a twin-screw extruder.

Q 2. Describe the role of a melt pump in the extrusion process.

A melt pump in extrusion acts as a precise metering device, ensuring a consistent flow rate of molten polymer to the die. It’s crucial for maintaining the quality and dimensional accuracy of the extruded product. Imagine trying to squeeze toothpaste from a tube – without consistent pressure, you get inconsistent output. The melt pump plays that role in extrusion. It follows the screw and homogenises the polymer even further.

There are several types, including gear pumps, piston pumps, and lobe pumps, each with its own strengths and weaknesses. Gear pumps are popular due to their reliability and simplicity, while piston pumps offer higher pressures. The choice depends on the polymer’s viscosity and the required extrusion pressure. For instance, high-viscosity polymers may require a more powerful pump to ensure a continuous flow.

Q 3. What are the common types of extrusion dies, and when would you choose one over another?

Extrusion dies are the heart of the extrusion process; they shape the molten polymer into its final form. There are many types, each tailored to a specific product. Some common types include:

- Circular dies: For producing pipes, tubes, and rods.

- Flat dies: Used to create sheets, films, and profiles.

- Coextrusion dies: Designed to combine multiple polymer streams into a single product (more on this later).

- Profile dies: Create intricate shapes such as window frames or other complex geometries.

The choice of die depends on the desired product geometry and its complexity. A simple pipe requires a circular die, while a complex profile might require a custom-designed profile die. Consider a window frame extrusion; this would need a highly engineered profile die to accurately create the various channels and chambers within the frame.

Q 4. How do you control melt temperature and pressure during extrusion?

Controlling melt temperature and pressure is critical for optimal extrusion. Think of it like baking a cake – incorrect temperature and pressure lead to a disaster. Temperature is controlled using heaters positioned along the extruder barrel, and often using separate barrel temperature zones to allow for precise and gradual heating. Pressure is managed by adjusting the screw speed and the die’s resistance to flow. Sensors monitor these parameters, providing feedback for closed-loop control systems, making fine adjustments for maintaining consistency. For instance, changes in ambient temperature might affect melt temperature; the control system compensates for this to keep the process stable.

Precise control prevents degradation of the polymer, ensures proper flow, and yields consistent product quality. For example, controlling melt temperature prevents polymer degradation and improves mechanical properties of the final product. Maintaining sufficient pressure prevents the melt from fracturing or forming voids.

Q 5. Explain the concept of die swell and its implications on product quality.

Die swell refers to the increase in the cross-sectional area of the extrudate as it leaves the die. This happens because the polymer molecules relax as they exit the high-pressure die, expanding to occupy a larger volume. This is much like when a stretched rubber band suddenly releases. The extent of die swell depends on the polymer’s properties and the processing conditions.

Die swell has significant implications for product quality, as it affects the final dimensions and tolerances. Accurate prediction and control of die swell are necessary to produce products to the correct specifications. For example, if you’re making a precision plastic component, uncontrolled die swell can render it unusable. Therefore, engineers often employ sophisticated modeling techniques and careful die design to mitigate the effects of die swell. Careful calibration of process parameters is also necessary.

Q 6. What are the advantages and disadvantages of coextrusion?

Coextrusion, combining multiple polymer melts into a single product, offers several advantages but also comes with challenges. Think of it as creating a layered cake with different ingredients for different functions.

- Advantages: Combining the desirable properties of different polymers, e.g., creating a package with high barrier properties (inner layer) and high strength/flexibility (outer layer). Cost savings are possible by using less of a higher-cost material (placing it strategically). Improved performance and functionality.

- Disadvantages: Increased equipment complexity and cost, more challenging process control, potential for interfacial adhesion problems between layers.

The decision to use coextrusion depends on whether the advantages outweigh the added complexities and costs. For example, creating a food packaging film with excellent oxygen barrier properties, grease resistance, and structural strength would justify the investment in coextrusion.

Q 7. Describe the different types of coextrusion configurations (e.g., multilayer, side-by-side).

Coextrusion configurations vary widely, each offering unique capabilities:

- Multilayer coextrusion: Produces a layered structure, where each layer contributes different properties. Think of a medical IV bag with layers that are biocompatible, flexible, and have a high barrier against oxygen and moisture.

- Side-by-side coextrusion: Combines different materials side-by-side, resulting in a composite structure. An example would be multi-colored or textured materials.

- Concentric coextrusion: Similar to multilayer, but typically involves a core material surrounded by other materials. This is useful for creating products that need enhanced structural support and strength. Think of a wire coated with different polymeric insulations.

The selection of a specific configuration depends on the product’s desired properties and functionality.

Q 8. How do you ensure proper adhesion between layers in a coextruded product?

Ensuring proper adhesion between layers in coextrusion is crucial for product integrity and performance. It relies on several key factors, primarily interfacial tension and melt rheology. Think of it like gluing two materials together – you need the right glue (polymer compatibility) and enough pressure (melt pressure) to create a strong bond.

Polymer Compatibility: Selecting polymers with compatible surface energies is paramount. Incompatible polymers will have poor adhesion, resulting in delamination. For example, using a tie layer – a thin layer of a compatible polymer placed between incompatible layers – is a common technique. This tie layer acts as an adhesive, bridging the gap between the main layers.

Melt Temperature and Pressure: Maintaining optimal melt temperatures ensures sufficient molecular mobility at the interface for interdiffusion, creating a strong bond. Sufficient melt pressure ensures intimate contact between the layers. Too low and you’ll have gaps, too high and you risk defects.

Die Design: The die design itself plays a critical role. A properly designed die ensures uniform flow and consistent pressure distribution across all layers, maximizing contact and minimizing defects. This includes ensuring sufficient dwell time within the die to allow for adequate intermixing at the interfaces.

Surface Treatment (Optional): In some cases, surface treatments can improve adhesion. For example, corona treatment can increase the surface energy of a polymer, enhancing its ability to bond with another layer.

In practice, careful selection of materials, meticulous control of processing parameters, and precise die design are all necessary for achieving robust interlayer adhesion in coextruded products.

Q 9. What are the common causes of defects in extruded products (e.g., fish eyes, gels, streaks)?

Extrusion defects are often caused by irregularities in the material, processing parameters, or the equipment itself. Let’s explore some common ones:

Fish Eyes: These are small, transparent, usually round bubbles trapped within the extruded material. They’re often caused by undissolved volatiles in the polymer melt or insufficient venting in the extruder. Imagine trying to squeeze toothpaste with tiny air pockets inside – those are your fish eyes!

Gels: These are small, solid particles dispersed throughout the extrudate, often appearing as dark specks or streaks. They result from degraded polymer, contamination, or insufficient melt filtration. Think of it like accidentally adding small bits of dirt to your cookie dough.

Streaks: These are long, thin lines of different color or texture running through the extrudate. They can be caused by inconsistent mixing of additives, fluctuations in melt temperature, or die clogging. Imagine unevenly distributed dye in a hand-mixed batch of paint.

Melt Fracture: This is a more complex defect that manifests as a rough or irregular surface on the extrudate. It’s often caused by shear stresses exceeding the elastic limit of the melt, and is frequently associated with high melt flow rates or improper die design.

Troubleshooting requires systematic investigation of the entire process: material properties, screw design, temperature profiles, die design, and filtration efficiency. Each defect points toward a specific area requiring attention.

Q 10. How would you troubleshoot an extrusion process experiencing excessive die swell?

Excessive die swell, an increase in the extrudate diameter beyond the die’s dimensions, can be caused by several factors. Think of it like a balloon expanding after being released.

High Melt Temperature: Elevated melt temperatures reduce viscosity, leading to increased elasticity and consequently greater die swell. Lowering the melt temperature is often the first step.

Low Shear Rate: A lower shear rate within the die means less orientation of the polymer chains, resulting in increased die swell. Adjusting screw speed or die geometry can increase shear rate.

Polymer Properties: The polymer’s inherent elasticity plays a significant role. Some polymers naturally exhibit more die swell than others. This is an inherent material property and is difficult to change.

Die Geometry: The die’s land length (the distance from the capillary entrance to the exit) and its entrance angle significantly affect die swell. A longer land length generally reduces die swell.

Troubleshooting should involve a systematic approach: check melt temperature, assess screw design for shear rate optimization, and consider die land length adjustment. In some cases, modifying the polymer formulation or using different polymer might be necessary.

Q 11. How would you troubleshoot an extrusion process experiencing poor output?

Low output in extrusion means the extruder isn’t producing enough material. Several factors can contribute to this.

Screw Design Issues: An improperly designed screw may not effectively convey and melt the polymer. A worn screw or one with insufficient conveying capacity will reduce output.

Low Screw Speed: Reducing the speed directly reduces the material throughput. Increasing the speed (within safe operating parameters) can boost output.

Insufficient Melt Temperature: If the polymer isn’t melting properly, it won’t flow efficiently, leading to low output. A careful check of the temperature profile is necessary. This would also include checking heating elements for proper function.

Clogged Die or Screen Pack: Blockages restrict flow and severely impact output. Cleaning or replacing the screen pack and/or thoroughly inspecting the die is crucial.

Back Pressure Issues: Excessive backpressure from downstream equipment can hinder extrusion. Checking for proper operation of downstream components is key.

Addressing low output requires a systematic check of all parameters, starting with the simplest (speed) and moving to more complex issues (screw design, die clogging).

Q 12. How would you troubleshoot an extrusion process experiencing inconsistent product dimensions?

Inconsistent product dimensions indicate variations in the extrusion process. These variations can impact product quality and functionality.

Die Wear: A worn die will produce extrudates with inconsistent dimensions. Regular die maintenance and timely replacement is critical.

Temperature Fluctuations: Variations in melt temperature affect the polymer’s viscosity and flow characteristics, leading to dimensional inconsistencies. Proper temperature control is vital.

Pressure Fluctuations: Inconsistencies in melt pressure will directly affect extrudate dimensions. Ensure proper pressure control systems are functioning correctly.

Screw Wear: A worn screw can lead to uneven melt distribution and, consequently, inconsistencies in product dimensions.

Material Variations: Differences in the polymer’s melt flow index (MFI) or other material properties within a batch can also cause dimensional variation.

Troubleshooting should involve careful inspection of the die for wear, thorough temperature and pressure monitoring, and regular screw maintenance. It also requires ensuring consistent material properties throughout the process.

Q 13. Explain the importance of melt flow index (MFI) in extrusion.

The Melt Flow Index (MFI) is a crucial parameter in extrusion, representing the ease with which a polymer melts and flows under specific conditions. It’s essentially a measure of the polymer’s viscosity.

Think of it like measuring the thickness of honey – a low MFI means high viscosity, like thick honey, requiring more energy to process. A high MFI indicates low viscosity, like thin honey, which is easier to process.

Process Optimization: MFI directly impacts extrusion parameters like screw speed, melt temperature, and die pressure. Knowing the MFI allows for accurate adjustments of the process for optimal output and product quality.

Material Selection: Different polymers have different MFI values, and selecting the right polymer for a particular application hinges on its MFI. This helps determine the material’s suitability for extrusion.

Quality Control: Monitoring MFI during processing ensures consistency in the material properties, avoiding production of defective products resulting from material variations.

In short, MFI acts as a critical indicator of the polymer’s processability and is essential for optimizing the extrusion process and maintaining consistent product quality.

Q 14. How does the screw design affect the extrusion process?

The screw design is the heart of the extrusion process. It’s responsible for conveying, melting, and mixing the polymer. Different screw designs lead to different outcomes.

Conveying Section: This section transports the polymer towards the melting zone. Its geometry determines the polymer’s residence time and the effectiveness of conveying.

Melting Section: This section melts the polymer through shear and frictional heating. The design affects the melt quality and homogeneity.

Mixing Section: This section mixes the melt components, ensuring uniformity. Various mixing elements such as pins or flights are employed to achieve thorough mixing.

Compression Section: This section compresses the melt, increasing its pressure and homogenizing the temperature profile. It’s essential for achieving a consistent melt.

The screw design directly affects the melt quality, output, and energy consumption of the extrusion process. Careful screw design is vital for optimizing the overall extrusion process and achieving desired product quality. A poorly designed screw can lead to issues such as incomplete melting, insufficient mixing, or low output.

Q 15. Describe the role of a screen pack in the extrusion process.

A screen pack in extrusion acts like a fine mesh filter, strategically placed before the die. Think of it as a security checkpoint for your plastic melt. Its primary role is to remove contaminants like gels, foreign particles, or degraded polymer that could clog the die or compromise the final product’s quality. These contaminants can originate from various sources, including the raw material itself, degradation during processing, or even accidental ingress during handling. A clogged die leads to production downtime, costly repairs, and inconsistent product dimensions. The screen pack is typically composed of multiple layers of fine metal mesh with varying pore sizes, arranged in a pack to provide progressive filtration. The number of layers and the mesh size depend on the specific application and the material being extruded. A well-maintained screen pack is crucial for ensuring smooth extrusion and maintaining consistent product quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the purpose of a die land?

The die land is the critical section of the extrusion die immediately preceding the die lip. Imagine it as the final shaping area for the molten polymer before it exits the die. Its primary purpose is to provide a consistent and controlled flow of the melt, ensuring uniform thickness and dimensions of the extruded product. The length and geometry of the die land are carefully designed to create a fully developed flow profile. This controlled flow minimizes melt distortion and ensures that the extrudate exits the die smoothly, preventing defects such as sharkskin (rough surface texture) or melt fracture (instabilities in the melt flow). A well-designed die land is crucial for achieving dimensional accuracy and consistent product quality, and its optimization is a key area of focus in extrusion die design.

Q 17. What are some common materials used in extrusion and coextrusion?

Extrusion and coextrusion utilize a wide range of polymeric materials, each suited to different applications. Common examples include:

- Polyethylene (PE): Used extensively in films, bags, pipes, and bottles, PE offers excellent flexibility and chemical resistance. Different types, like HDPE (high-density polyethylene) and LDPE (low-density polyethylene), offer varying properties.

- Polypropylene (PP): Known for its stiffness, good chemical resistance, and heat resistance, PP finds use in containers, fibers, and automotive parts.

- Polyvinyl Chloride (PVC): A versatile material offering good strength and durability, PVC is widely used in pipes, window frames, and flooring.

- Polystyrene (PS): Often used for disposable food containers and insulation, PS is characterized by its low cost and ease of processing.

- Polyesters (PET, PBT): Providing excellent strength, clarity, and chemical resistance, these are found in bottles, fibers, and engineering applications.

- Polyamides (Nylon): Strong, durable, and resistant to wear, nylon is used in automotive components, fibers, and various engineering parts.

In coextrusion, where multiple polymers are combined in a single profile, material selection becomes even more crucial, focusing on achieving the desired properties in the final product. For instance, a multilayer film might combine a high-barrier polymer for oxygen protection with a tough outer layer for mechanical strength.

Q 18. Describe the process of calibrating an extrusion die.

Calibrating an extrusion die is a meticulous process crucial for achieving consistent product dimensions and quality. It involves adjusting the die’s dimensions and flow channels to meet precise specifications. This often involves a combination of techniques:

- Initial Die Design and Manufacturing: The die is initially designed using CAD software, based on the required product dimensions and material properties. Precise manufacturing techniques, like electro-erosion machining, are employed to achieve the required accuracy.

- Experimental Adjustments: After initial production, the extrudate is carefully measured using various tools like micrometers, calipers, and optical measurement systems. Based on the measurements, adjustments are made to the die. This might involve polishing, lapping, or even minor machining of the die land and other critical areas.

- Temperature Control: Die temperature significantly affects the melt flow and final dimensions of the extrudate. Precise control and monitoring of the die temperature are essential to achieving consistent dimensions. Adjustments to the die heating system might be necessary.

- Pressure Adjustments: The melt pressure also impacts product dimensions. Adjustments to the extruder screw speed or back pressure can help fine-tune the product’s geometry.

Calibration is an iterative process, often requiring several cycles of adjustment and measurement until the desired accuracy is achieved. Accurate calibration minimizes waste and ensures consistent, high-quality product throughout the production run.

Q 19. Explain the importance of material selection in relation to the extrusion process.

Material selection is paramount in extrusion. The choice of polymer directly impacts the processability, cost, and final properties of the extrudate. Several factors must be considered:

- Melt Flow Index (MFI): This indicates the polymer’s melt viscosity and flow characteristics. A polymer with a suitable MFI ensures smooth extrusion without excessive pressure or degradation.

- Thermal Stability: The polymer’s ability to withstand the high temperatures of the extrusion process without degradation is crucial. Thermal degradation can lead to discoloration, loss of mechanical properties, and die fouling.

- Rheological Properties: Understanding the polymer’s flow behavior under shear is crucial for die design and process optimization. This ensures consistent melt flow and prevents defects like melt fracture or sharkskin.

- Chemical Compatibility: The polymer must be compatible with the extrusion equipment and any additives used. Incompatible materials can cause corrosion or equipment damage.

Selecting an unsuitable material can lead to process inefficiencies, poor product quality, and costly downtime. Careful consideration of all these factors is vital for efficient and successful extrusion.

Q 20. How do you maintain consistent product quality during long production runs?

Maintaining consistent product quality during extended runs requires a multi-faceted approach:

- Precise Process Control: Monitoring and controlling key process parameters, such as temperature, pressure, screw speed, and die temperature, are critical. Automated control systems with feedback loops are often employed to maintain stability.

- Regular Die Cleaning and Maintenance: Regular cleaning of the die and screen packs prevents buildup of polymer residue and contaminants, which can affect product dimensions and quality. Scheduled maintenance helps ensure proper operation of all equipment.

- Raw Material Consistency: Ensuring consistent quality and properties of the raw material is crucial. Regular quality checks and supplier audits help guarantee consistent input material.

- Operator Training: Well-trained operators are vital for maintaining consistent process parameters and identifying deviations early on. Regular training and standardized operating procedures help prevent errors.

- Statistical Process Control (SPC): Implementing SPC techniques allows for ongoing monitoring of key quality parameters and helps identify potential trends or problems before they significantly impact the final product. This enables proactive adjustments and minimizes variability.

By implementing these strategies, a consistent product quality can be ensured, minimizing waste, optimizing production efficiency, and providing a reliable product to the customer.

Q 21. Describe your experience with different types of polymers used in extrusion.

My experience encompasses a broad range of polymers used in extrusion, including but not limited to:

- Polyethylene (PE): Extensive experience with both HDPE and LDPE, including various grades for film extrusion, pipe extrusion, and blow molding. I’ve worked on optimizing processes for different applications, ranging from thin-gauge films to heavy-duty pipes.

- Polypropylene (PP): Experience in extrusion of PP for various applications such as packaging, automotive parts, and fibers. I have expertise in dealing with the challenges associated with the higher melt viscosity of PP compared to PE.

- Polyvinyl Chloride (PVC): Significant experience in the extrusion of rigid and flexible PVC, primarily in pipe and profile applications. This includes managing the safety aspects associated with PVC processing and handling.

- Engineering Plastics: I’ve also worked extensively with engineering plastics like ABS, Nylon, and PET, specializing in precise dimensional control and handling of the more demanding rheological characteristics of these materials. This includes experience with coextrusion of multiple engineering polymers for complex applications.

This diverse experience allows me to adapt quickly to new challenges and optimize extrusion processes for various materials and applications. I am well-versed in the unique properties and processing challenges associated with each polymer, and how these properties are critical for designing and optimizing both the extrusion process and the final product.

Q 22. What safety precautions do you follow during extrusion operations?

Safety in extrusion is paramount. My approach is built on a layered safety system, encompassing preventative measures, emergency procedures, and continuous monitoring. This starts with rigorous adherence to lockout/tagout procedures before any maintenance or adjustments to the extruder. Personal Protective Equipment (PPE) is mandatory, including safety glasses, hearing protection, and heat-resistant gloves, depending on the material being processed. Regular machine inspections are crucial, checking for wear and tear, potential leaks, and ensuring all safety guards are in place and functioning correctly. We also conduct regular safety training for all operators to keep them up-to-date on best practices and emergency response protocols. For example, we have detailed emergency shutdown procedures posted prominently near the equipment and conduct drills to ensure everyone knows what to do in case of a malfunction or fire. Finally, we maintain meticulous records of all safety inspections, training, and incidents, allowing us to identify trends and improve our safety program continuously.

Q 23. How do you ensure the quality of the raw materials used in extrusion?

Ensuring raw material quality is fundamental to consistent extrusion results. We begin with selecting reputable suppliers who provide Certificates of Analysis (CoA) for each batch, verifying the material’s properties meet our specifications. This includes checking for factors like melt flow index (MFI), density, and color consistency. Upon arrival, we conduct incoming inspections, including visual checks for contaminants and random sampling for laboratory testing. These tests often include moisture content analysis, particle size distribution, and even rheological testing to determine the material’s flow behavior. Any discrepancies from the CoA or our internal standards trigger a thorough investigation, often involving contacting the supplier and potentially rejecting the batch. Maintaining a detailed history of each batch, including testing results and production performance data, helps us identify trends, potentially anticipate future issues, and fine-tune our raw material selection processes. For example, we experienced a batch of inconsistent resin that was impacting the quality of our film, and tracing this back to a change in the supplier’s processing technique allowed us to implement stricter quality control measures with them.

Q 24. How familiar are you with different types of extrusion equipment?

My experience spans a variety of extrusion equipment, from single-screw extruders for simpler applications to twin-screw extruders for more complex compounding and reactive extrusion processes. I’m proficient with both continuous and intermittent extrusion systems, and I understand the nuances of different screw designs, including barrier screws for coextrusion applications and mixing screws for achieving homogeneous blends. I’m also familiar with various downstream equipment, including die heads for film, sheet, pipe, and profile extrusion; chill rolls for cooling; and various winding and cutting systems. My experience extends to different control systems, ranging from older analog systems to more modern PLC-based automated controls. For example, I’ve worked extensively with both single-layer and multilayer coextrusion lines, where precise control of layer thickness and melt temperature is critical. I’ve also been involved in the selection, installation, and commissioning of new equipment, including a recent upgrade to a high-output twin-screw extruder for a specific, high-performance polymer application.

Q 25. Explain your experience with process optimization in extrusion.

Process optimization in extrusion is an iterative process focused on enhancing efficiency, product quality, and reducing waste. My approach starts with a thorough understanding of the process parameters, including screw speed, melt temperature, die pressure, and cooling rates. We then use Design of Experiments (DOE) methodologies, or statistical process control (SPC), to systematically evaluate the impact of these variables on key output parameters, such as output rate, product dimensions, and material properties. This data is used to refine the process settings, achieving better process stability and improved product consistency. For example, in one project, we used DOE to optimize the extrusion process for a medical-grade tubing application, resulting in a 15% increase in throughput and a reduction in material waste by 10%. Data analysis and visualization tools, like process capability studies (Cpk), allow us to track improvements and identify areas needing further attention. Continual monitoring and adjustment, incorporating feedback from production and quality control, is crucial for maintaining optimized performance.

Q 26. Describe your experience with troubleshooting extrusion process issues.

Troubleshooting extrusion issues requires a systematic approach. It begins with careful observation of the problem: Is there a change in output, dimensions, surface quality, or material properties? The next step involves examining process parameters, looking for deviations from established set points. We then check the raw materials for any inconsistencies and inspect the equipment for mechanical issues, such as wear and tear on the screws, die, or other components. Data analysis plays a critical role, as we analyze historical data and look for trends that may indicate the root cause. A common issue is die blockage, which requires immediate attention. We often use a combination of visual inspection, pressure readings, and temperature monitoring to determine the location of the blockage and implement a safe removal process. In one instance, we traced recurring defects to a problem with the cooling system, leading to an upgrade that eliminated the issue. A thorough understanding of the entire process, from raw material handling to final product inspection, is essential for efficient troubleshooting.

Q 27. How familiar are you with automation and control systems in extrusion?

I’m very familiar with automation and control systems in extrusion. My experience encompasses various systems, from basic analog controllers to sophisticated PLC-based systems with SCADA interfaces. I understand the role of sensors in monitoring key parameters like temperature, pressure, and flow rate. These systems allow for precise control of the extrusion process, leading to improved product quality and reduced variability. I’m also experienced with using data acquisition systems for real-time monitoring and data logging, which aids in process optimization and troubleshooting. This also includes experience with integrating these systems with enterprise resource planning (ERP) systems to optimize production planning and inventory control. For instance, I’ve successfully integrated a new automated system for real-time monitoring of melt pressure and temperature, leading to a significant decrease in production downtime caused by pressure fluctuations.

Q 28. How do you handle unexpected production issues during an extrusion process?

Handling unexpected production issues requires a calm and systematic approach. The first step is to ensure the safety of the operators and to immediately shut down the equipment if necessary. We then assess the situation, identifying the nature of the problem and its potential impact on production. This often involves coordinating with maintenance personnel, quality control, and management. Depending on the severity, we may implement temporary workarounds or initiate a full-scale investigation to identify the root cause and prevent future occurrences. For example, a sudden power outage required us to implement a controlled shutdown procedure to prevent damage to the equipment and material. Effective communication is crucial throughout this process, keeping all stakeholders informed about the situation and the planned actions. Detailed documentation of the event, including corrective actions and preventative measures, is essential for continuous improvement.

Key Topics to Learn for Extrusion and Coextrusion Interview

- Extrusion Fundamentals: Understanding the process, including material selection, screw design, and die design principles.

- Melt Rheology: Knowledge of polymer behavior under shear, its impact on extrusion parameters, and troubleshooting melt flow issues.

- Die Design and Optimization: Analyzing die geometry’s influence on product shape, dimensions, and surface finish. Understanding methods for optimizing die design for specific applications.

- Coextrusion Processes: Differences between single and multi-layer coextrusion, layer adhesion challenges, and managing different polymer melt flows.

- Process Control and Monitoring: Understanding and utilizing various sensors and control systems to maintain consistent product quality and troubleshoot production problems. This includes temperature, pressure, and flow rate control.

- Troubleshooting Common Extrusion Issues: Developing problem-solving skills to address issues like die swell, melt fracture, and gauge variations. Understanding root cause analysis techniques.

- Material Properties and their Impact on Extrusion: Knowing how material properties (e.g., viscosity, thermal stability) affect process parameters and final product quality.

- Safety Procedures and Regulations: Understanding and adhering to safety protocols within an extrusion environment.

- Quality Control and Testing: Familiarity with various quality control methods, including dimensional measurements, material testing, and visual inspection.

- Practical Applications: Understanding the wide range of applications for extrusion and coextrusion, including packaging films, pipes, profiles, and medical devices. Being able to discuss specific examples.

Next Steps

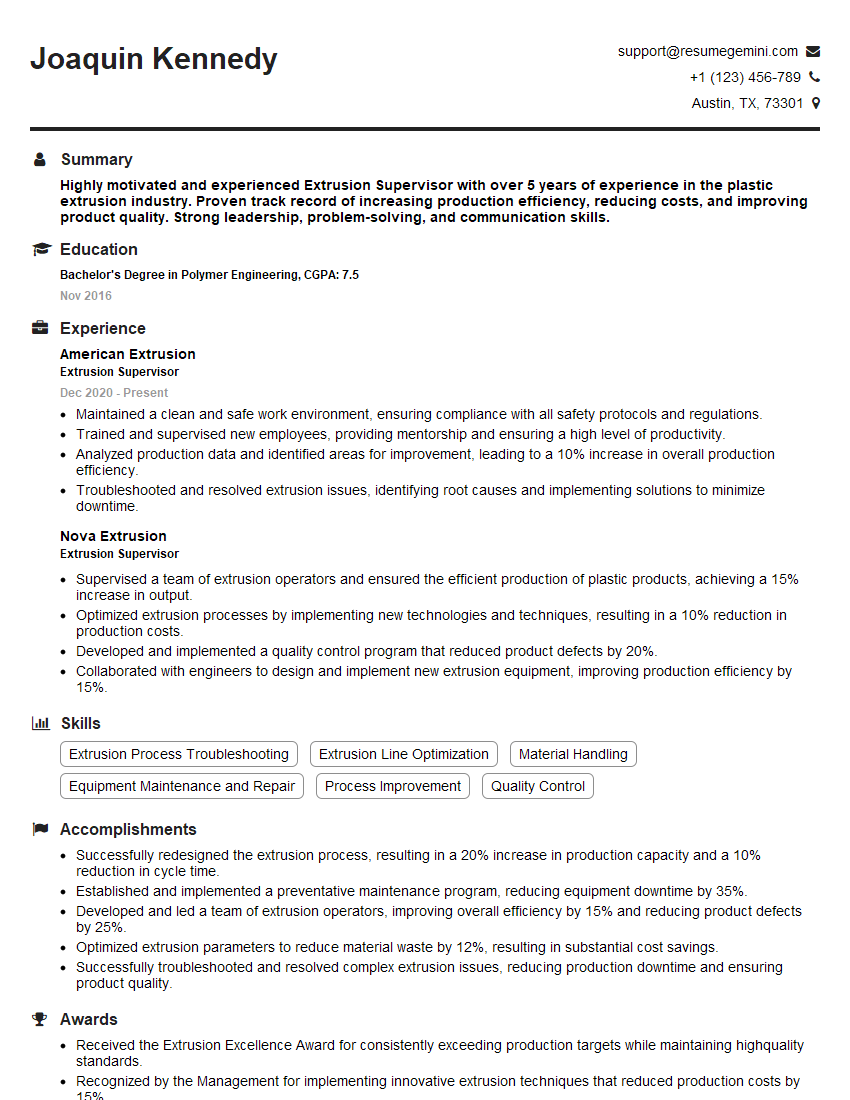

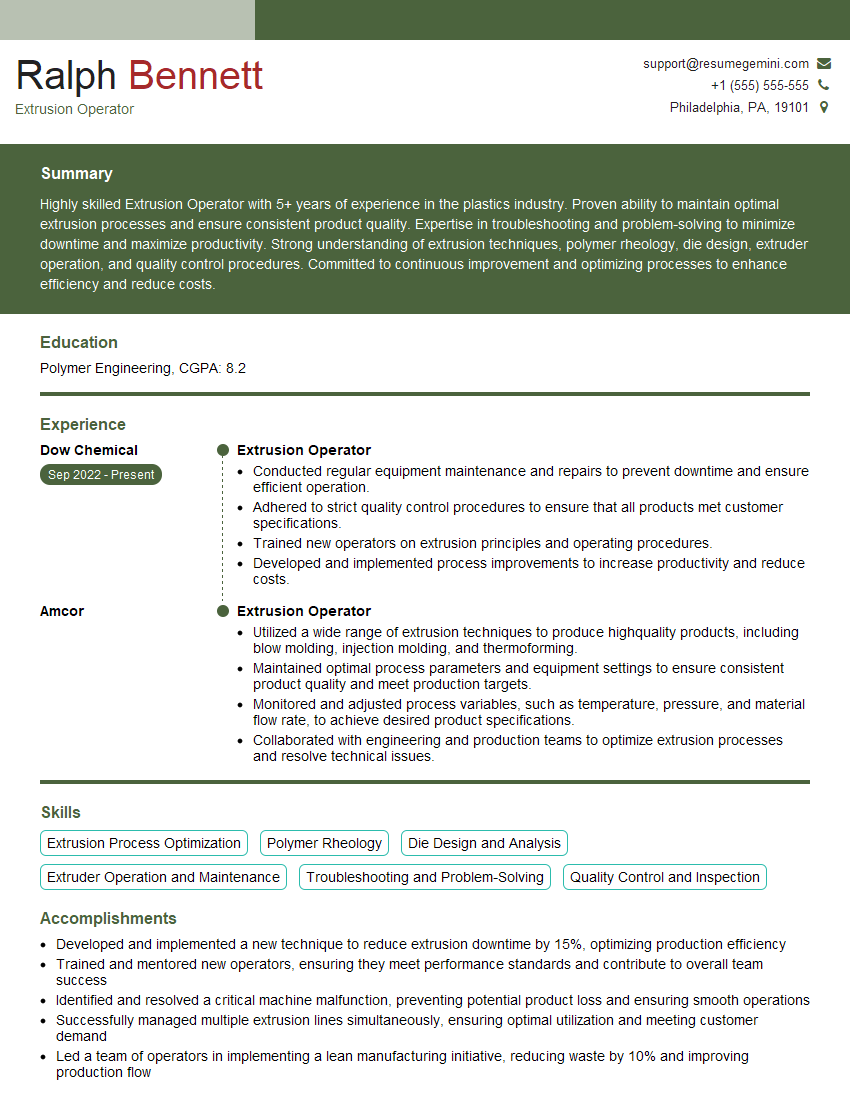

Mastering extrusion and coextrusion opens doors to exciting and rewarding careers in manufacturing, materials science, and engineering. A strong understanding of these processes is highly sought after in today’s competitive job market. To significantly boost your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific demands of the Extrusion and Coextrusion industry. Examples of resumes specifically designed for this field are available to help guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO