The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Water Treatment Technology interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Water Treatment Technology Interview

Q 1. Explain the difference between coagulation and flocculation in water treatment.

Coagulation and flocculation are crucial steps in water treatment, both aiming to remove suspended solids, but they achieve this through different mechanisms. Think of it like making a cake: coagulation is like adding ingredients (chemicals) to form clumps, while flocculation is like gently stirring to bring those clumps together into larger, easier-to-remove masses.

Coagulation involves adding a coagulant, typically aluminum sulfate (alum) or ferric chloride, to destabilize the negatively charged particles in the water. This destabilization allows the particles to collide and form microflocs. It’s a rapid process, occurring in seconds to minutes.

Flocculation is the subsequent slow mixing process that encourages these microflocs to grow larger, forming macroflocs. This gentle stirring brings the smaller particles together, forming larger, heavier flocs that readily settle out during sedimentation. This stage typically lasts for 20-40 minutes.

In essence, coagulation creates the initial clumps, while flocculation gently encourages those clumps to grow into larger, easily settleable aggregates. Without flocculation, the small particles formed during coagulation would remain dispersed, making sedimentation less effective.

Q 2. Describe the process of disinfection using chlorine and UV light.

Disinfection is the final stage of water treatment, aiming to eliminate harmful microorganisms like bacteria and viruses. Chlorine and UV light are two common disinfection methods, each with its own advantages and disadvantages.

Chlorine disinfection relies on the strong oxidizing power of chlorine to kill pathogens. Chlorine gas, hypochlorite solutions (liquid bleach), or chloramines are commonly used. The chlorine reacts with organic matter and microorganisms, rendering them harmless. However, chlorine can react with organic compounds to form disinfection byproducts (DBPs), some of which may be harmful. Careful monitoring and control are essential.

UV disinfection employs ultraviolet light to damage the DNA of microorganisms, preventing their reproduction and killing them. This method is environmentally friendly, producing no harmful byproducts. However, UV disinfection is less effective against some pathogens, like cryptosporidium, and requires clear water to be effective. Turbidity can significantly reduce the efficacy of UV disinfection.

In practice, many water treatment plants use a combination of these methods, for example, using chlorine for residual disinfection after UV treatment for higher efficacy and protection against regrowth.

Q 3. What are the different types of filtration used in water treatment?

Water treatment plants employ several filtration types to remove suspended solids, turbidity, and other contaminants. These can be broadly categorized as:

- Rapid Sand Filtration (RSF): This traditional method uses a bed of sand to filter out suspended particles. It’s cost-effective but requires regular backwashing to remove accumulated solids.

- Dual Media Filtration: Combines layers of anthracite coal and sand, offering improved efficiency compared to RSF, particularly for removing smaller particles.

- Multimedia Filtration: Uses multiple layers of progressively finer filter media (e.g., gravel, anthracite, sand) for enhanced filtration efficiency.

- Membrane Filtration: This advanced technique uses membranes with tiny pores to remove even smaller particles and microorganisms. Types include microfiltration, ultrafiltration, and nanofiltration.

- Diatomaceous Earth Filtration (DEF): Uses a filter aid made of diatomaceous earth (fossilized remains of diatoms) which is coated on the filter media to remove very fine particles and increase the filtration capacity. Common in swimming pool filtration.

The choice of filtration method depends on factors such as the water quality, treatment capacity requirements, and budget.

Q 4. How do you monitor and control pH levels in a water treatment plant?

pH control is crucial in water treatment, as it affects the efficiency of various processes, including coagulation, disinfection, and corrosion control. A slight change in pH can drastically alter the effectiveness of chemical treatment.

Monitoring is typically done using continuous online pH meters which provide real-time measurements. These meters utilize electrodes that measure the hydrogen ion concentration in the water. This data is then displayed and recorded, providing a continuous record of the pH level. Regular calibration of these meters is vital to ensure accuracy.

Control involves adjusting the pH using chemicals like lime (calcium hydroxide) to raise the pH or acid, such as sulfuric acid, to lower it. The amount of chemical added is determined based on the desired pH and the current measurement. This process is often automated using chemical feed systems, which adjust the chemical dosage based on the real-time pH readings. The entire process is closely monitored to maintain pH within the optimal range for the specific treatment process and to prevent corrosion in the pipes and equipment.

Q 5. Explain the importance of turbidity removal in water treatment.

Turbidity refers to the cloudiness or haziness of water caused by suspended solids like clay, silt, and microorganisms. Turbidity removal is essential for several reasons:

- Aesthetic Appeal: Clear water is more appealing to consumers and indicates higher water quality.

- Disinfection Efficiency: High turbidity can interfere with disinfection processes by shielding pathogens from the disinfectants.

- Membrane Protection: High turbidity can clog and damage filtration membranes, reducing their lifespan and efficiency.

- Public Health: Suspended solids can carry pathogens and other harmful substances.

Turbidity is typically removed through a combination of coagulation, flocculation, sedimentation, and filtration. Effective turbidity removal ensures that the water is safe and aesthetically pleasing.

Q 6. What are the common types of waterborne pathogens and how are they removed?

Waterborne pathogens pose a significant threat to public health. Common types include:

- Bacteria (e.g., E. coli, Salmonella): These single-celled organisms can cause various gastrointestinal illnesses. Removed through disinfection (chlorination, UV).

- Viruses (e.g., Norovirus, Rotavirus): These submicroscopic pathogens are more resistant to disinfection than bacteria. Removed through filtration (membrane filtration) and disinfection (chlorination, UV, ozonation).

- Protozoa (e.g., Giardia, Cryptosporidium): These single-celled parasites are resistant to disinfection and require advanced filtration methods (e.g., membrane filtration) for effective removal.

Removal strategies vary depending on the pathogen. Disinfection is highly effective against most bacteria and viruses, while advanced filtration is crucial for removing protozoa and other resistant organisms. Often, a multi-barrier approach is adopted, combining multiple treatment steps to achieve optimal pathogen removal.

Q 7. Describe the principles of reverse osmosis (RO) and its applications.

Reverse osmosis (RO) is a membrane filtration process that uses pressure to force water through a semi-permeable membrane. This membrane allows water molecules to pass through but rejects dissolved salts, minerals, and other impurities.

Principles: RO utilizes a pressure greater than the osmotic pressure to overcome the natural tendency of water to move from a less concentrated solution (pure water) to a more concentrated solution (saltwater) across the semipermeable membrane. This pressure difference forces the water molecules through the membrane, leaving behind the dissolved solids.

Applications: RO is widely used for:

- Desalination of seawater and brackish water: Producing potable water from saline sources.

- Water purification for industrial processes: Providing high-purity water for manufacturing, pharmaceuticals, and electronics.

- Treatment of wastewater: Removing dissolved contaminants from industrial wastewater and municipal effluents.

- Production of bottled water: Creating high-quality drinking water for consumers.

While highly effective, RO is energy-intensive and produces a concentrated brine stream as a byproduct, requiring careful management.

Q 8. Explain the process of membrane filtration, including microfiltration, ultrafiltration, and nanofiltration.

Membrane filtration is a crucial water treatment process that uses semi-permeable membranes to separate different components based on size and charge. It encompasses several techniques, with microfiltration, ultrafiltration, and nanofiltration differing primarily in pore size and target contaminants.

- Microfiltration (MF): MF membranes have the largest pore sizes (0.1 to 10 microns), effectively removing larger particles like suspended solids, bacteria, and protozoa. Think of it like a very fine sieve. An example is its use in treating surface water to remove sediment before further treatment.

- Ultrafiltration (UF): UF membranes possess smaller pores (0.001 to 0.1 microns), capable of removing dissolved organic matter (DOM), viruses, and some colloids. Imagine it as a much finer sieve that catches even smaller particles. It’s often employed in wastewater treatment to clarify effluent before discharge.

- Nanofiltration (NF): NF membranes have the smallest pore sizes (0.001 microns or less), removing multivalent ions (like calcium and magnesium), some organic molecules, and even some salts. It’s like having an extremely fine filter that separates molecules based on size and charge. NF finds application in softening water or pre-treating water for reverse osmosis.

The choice of membrane type depends on the specific water quality requirements and the types of contaminants present. Often, these processes are combined in a sequence for optimal water purification.

Q 9. How do you manage and dispose of sludge from water treatment processes?

Sludge management and disposal is a critical aspect of water treatment. Sludge, a byproduct of various treatment processes like coagulation, sedimentation, and filtration, contains concentrated pollutants and requires careful handling. The approach depends on several factors, including sludge characteristics, regulations, and economic viability.

- Thickening: Reducing the volume of sludge through gravity thickening or mechanical dewatering before further treatment.

- Digestion: Anaerobic digestion is a common method, breaking down organic matter in the sludge to produce biogas (methane and carbon dioxide) and a stabilized, less harmful byproduct. This is a sustainable approach that can generate energy.

- Stabilization: Chemical treatment (lime stabilization) or thermal drying can further reduce pathogens and odors before disposal.

- Disposal: Options include land application (as fertilizer if appropriate), incineration, landfilling, or beneficial reuse, such as in construction materials.

Proper sludge management is vital to minimize environmental impact. Strict adherence to regulations ensures safe and responsible disposal, protecting both human health and the environment.

Q 10. What are the key parameters used to assess water quality?

Assessing water quality involves a range of parameters, categorized broadly into physical, chemical, and biological indicators.

- Physical parameters: Temperature, turbidity (cloudiness), color, odor, taste, and pH. These provide an initial overview of water condition.

- Chemical parameters: Dissolved oxygen (DO), alkalinity, hardness, salinity, heavy metals (lead, mercury, etc.), nutrients (nitrogen and phosphorus), pesticides, and various organic compounds. These indicators reveal the chemical composition and potential toxicity.

- Biological parameters: Coliform bacteria (indicative of fecal contamination), other pathogens, and algal blooms. These are crucial for evaluating the microbiological safety of the water.

The specific parameters monitored depend on the intended use of the water. Drinking water requires far stricter standards than, say, irrigation water. Regulations provide guidelines for acceptable levels of each parameter to ensure safety and quality.

Q 11. Describe the role of aeration in water treatment.

Aeration is the process of introducing air into water, primarily to increase dissolved oxygen (DO) levels. This plays a vital role in various water treatment stages.

- Removal of volatile compounds: Aeration strips volatile organic compounds (VOCs) like trichloroethylene from the water, transferring them to the air phase.

- Oxidation of iron and manganese: Aeration facilitates the oxidation of dissolved iron and manganese, turning them into insoluble forms that are easily removed through sedimentation or filtration. This improves water clarity and prevents staining.

- Enhancement of biological processes: Increased DO supports the growth of aerobic microorganisms in activated sludge processes, crucial for the biological breakdown of organic pollutants in wastewater treatment.

- Removal of hydrogen sulfide: Aeration helps remove the unpleasant odor and toxicity associated with hydrogen sulfide by oxidizing it to less harmful substances.

Aeration methods include diffused aeration (using air diffusers), surface aeration (cascades or fountains), and forced draft aeration. The optimal method depends on the water treatment goals and the volume of water to be treated.

Q 12. Explain the concept of water hardness and its impact on water treatment.

Water hardness refers to the concentration of dissolved minerals, primarily calcium and magnesium ions, in water. These ions originate from the interaction of water with rocks and soil.

- Impact on water treatment: Hard water can cause scaling in pipes and equipment, reducing efficiency and lifespan. It also interferes with the effectiveness of soaps and detergents, requiring more to achieve the same cleaning power.

- Treatment methods: Water softening techniques include lime softening (adding lime to precipitate calcium and magnesium), ion exchange (using resins to replace hard ions with sodium), and reverse osmosis (removing ions through a semi-permeable membrane).

- Effects of hardness: While excessive hardness is undesirable, some level of hardness is beneficial, providing essential minerals. Very soft water can be corrosive to pipes and can leach heavy metals from pipes into the water.

Understanding water hardness is critical for selecting appropriate treatment strategies and managing the overall water quality. Striking a balance is key, ensuring safe and efficient water distribution.

Q 13. How do you troubleshoot common problems in water treatment processes?

Troubleshooting water treatment problems requires a systematic approach. It starts with identifying the issue, analyzing its root cause, and implementing appropriate corrective actions. This often involves examining key parameters and looking for trends.

- Identify the problem: Observe deviations from normal operating conditions, such as changes in water quality parameters (turbidity, pH, chlorine residual), equipment malfunction, or unexpected increase in energy consumption.

- Analyze the problem: Review operational data, inspect equipment, perform laboratory analyses of water samples, and check for any recent changes in the influent water quality or process operations. This is crucial for isolating the root cause.

- Implement corrective actions: Depending on the root cause, solutions could include cleaning or replacing filters, adjusting chemical dosages, repairing or replacing equipment, or modifying process parameters. Document the actions taken and their effectiveness.

- Preventative Maintenance: Regular preventative maintenance reduces the risk of equipment failure and process upsets. This includes regular inspections, cleaning, and lubrication of equipment.

Example: If chlorine residuals are low, one could check chlorine feed rates, examine the condition of the chlorination system, or analyze for the presence of reducing agents in the water that are consuming the chlorine.

Q 14. What are the different types of water treatment chemicals and their applications?

Various chemicals are employed in water treatment, each serving a specific purpose.

- Coagulants (e.g., alum, ferric chloride): Neutralize the charge of suspended particles, causing them to clump together for easier removal.

- Flocculants (e.g., polyacrylamide): Aid in the formation of larger flocs, improving sedimentation efficiency.

- Disinfectants (e.g., chlorine, ozone, UV): Eliminate harmful microorganisms, ensuring water safety.

- pH adjusters (e.g., lime, sulfuric acid): Control the water pH to optimize chemical reactions and prevent corrosion.

- Corrosion inhibitors (e.g., orthophosphates): Protect pipes and equipment from corrosion.

- Scale inhibitors: Prevent the formation of mineral scale in pipes and equipment.

- Activated carbon: Absorbs organic contaminants and improves taste and odor.

The selection of chemicals depends on water characteristics, treatment objectives, and regulatory requirements. Careful control of dosage is essential to achieve the desired results without introducing adverse effects.

Q 15. Explain the importance of regular maintenance and calibration of water treatment equipment.

Regular maintenance and calibration of water treatment equipment are crucial for ensuring the consistent delivery of safe and high-quality water. Neglecting this can lead to equipment failure, reduced treatment efficiency, and potential health risks. Think of it like regular servicing for your car – preventative maintenance avoids major breakdowns and keeps everything running smoothly.

Improved Efficiency: Regular maintenance keeps equipment operating at peak performance, reducing energy consumption and chemical usage.

Extended Equipment Lifespan: Preventative maintenance, like cleaning filters and lubricating moving parts, significantly extends the operational life of your equipment, saving you money on replacements.

Ensuring Regulatory Compliance: Many regulatory bodies require documented evidence of regular maintenance. This demonstrates your commitment to producing safe drinking water.

Enhanced Safety: Regular inspections identify potential hazards early, preventing accidents and ensuring the safety of plant operators and the public.

Accurate Data Collection: Calibration ensures that instrumentation provides accurate readings, allowing for precise control of treatment processes and optimal water quality.

For example, in a reverse osmosis (RO) system, regular cleaning of the membranes is essential to prevent scaling and fouling, which significantly reduces water production and necessitates expensive membrane replacements. Similarly, regular calibration of flow meters ensures accurate dosing of chemicals, preventing over- or under-dosing and maintaining the desired water quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the regulatory compliance requirements for water treatment plants.

Regulatory compliance for water treatment plants is paramount and varies depending on location and the type of water being treated (drinking water, industrial wastewater, etc.). These regulations are designed to protect public health and the environment. Key aspects include:

Water Quality Standards: These standards define the permissible limits for various contaminants in treated water (e.g., bacteria, turbidity, chlorine residuals). Agencies like the EPA in the US or equivalent bodies in other countries set these limits.

Treatment Process Requirements: Regulations often dictate specific treatment processes or technologies that must be employed to achieve the required water quality. This may include specific filtration methods, disinfection techniques, or chemical treatment protocols.

Operational Monitoring and Reporting: Plants must maintain detailed records of their operational parameters, including water quality data, chemical usage, and equipment maintenance. This data must be regularly submitted to the relevant regulatory authorities.

Operator Certification and Training: Operators often need to be certified and trained to ensure they possess the necessary expertise to safely and effectively operate the plant.

Emergency Response Plans: Plants are required to have plans in place to deal with potential emergencies, such as equipment failures or spills.

Non-compliance can result in significant penalties, including fines, operational shutdowns, and legal action. Therefore, it’s vital for water treatment plants to have robust systems in place to ensure ongoing compliance.

Q 17. How do you design a water treatment system for a specific application?

Designing a water treatment system is a multi-step process that begins with a thorough understanding of the source water quality and the desired treated water quality. It’s like building a house; you need a solid foundation and a detailed plan.

Source Water Assessment: This involves analyzing the source water for physical, chemical, and biological contaminants. This helps determine the necessary treatment processes.

Treatment Goals Definition: Establish the desired water quality parameters based on the intended application (e.g., drinking water, industrial process water). The required standards will be crucial here.

Treatment Process Selection: Based on the source water analysis and treatment goals, select the appropriate treatment technologies (e.g., coagulation, flocculation, sedimentation, filtration, disinfection). Some applications might necessitate more complex treatment trains.

System Design: Design the overall layout of the plant, including the arrangement of treatment units, piping networks, and instrumentation. This involves detailed engineering calculations and simulations.

Equipment Selection: Select appropriate equipment based on the design criteria, capacity requirements, and cost considerations.

Control System Design: Design a control system to monitor and control the treatment processes, ensuring consistent water quality.

Safety Considerations: Incorporate safety features throughout the design to protect plant operators and the environment.

For example, designing a water treatment system for a rural community with high turbidity might involve coagulation, flocculation, sedimentation, and filtration, followed by disinfection. In contrast, a system for an industrial process might require advanced treatments like reverse osmosis or ion exchange to remove specific contaminants.

Q 18. Explain your experience with different types of water treatment plant designs.

My experience encompasses a range of water treatment plant designs, including:

Conventional Treatment Plants: These utilize a series of processes such as coagulation, flocculation, sedimentation, filtration, and disinfection, suitable for many surface water sources.

Direct Filtration Plants: These omit the sedimentation step, ideal for sources with low turbidity and good coagulation characteristics.

Membrane Filtration Plants: These employ membrane technologies like microfiltration, ultrafiltration, nanofiltration, or reverse osmosis to remove a wide range of contaminants, often used for advanced water purification or desalination.

Decentralized Treatment Systems: Smaller, modular systems suitable for individual buildings or small communities.

I’ve worked on projects ranging from small-scale rural water treatment systems to large-capacity municipal plants, gaining experience in optimizing existing systems and designing new facilities to meet evolving water quality requirements. In one project, I successfully redesigned an aging conventional plant, improving efficiency by 15% and reducing chemical usage by 10% by incorporating advanced process controls and optimized chemical dosing strategies.

Q 19. Describe your experience with SCADA systems in water treatment plants.

SCADA (Supervisory Control and Data Acquisition) systems are essential for modern water treatment plants. They provide real-time monitoring and control of various plant parameters, allowing for efficient operation and improved water quality.

My experience with SCADA systems includes:

System Integration: Integrating SCADA systems with various plant equipment, including pumps, valves, chemical feeders, and analytical instruments.

Data Acquisition and Analysis: Using SCADA data to monitor plant performance, identify trends, and optimize treatment processes. This includes developing historical trend analysis and reporting capabilities.

Process Control: Implementing advanced control strategies to maintain optimal operating conditions and ensure consistent water quality. This might involve implementing PID controllers or more advanced model predictive control (MPC) strategies.

Alarm Management: Configuring alarm systems to alert operators to critical events and abnormal operating conditions, enhancing response times.

Remote Monitoring and Control: Utilizing remote access capabilities to monitor and control the plant from off-site locations.

In a recent project, I implemented a new SCADA system that resulted in a 5% reduction in energy consumption and improved the response time to operational anomalies by 20%. This enhanced the safety and overall efficiency of the plant significantly.

Q 20. What are the different types of pumps used in water treatment and their applications?

Various pump types are crucial in water treatment plants, each serving specific functions. The choice depends on factors like flow rate, head pressure, fluid characteristics, and budget constraints.

Centrifugal Pumps: These are the most common type, used for transferring large volumes of water at moderate pressures. They are reliable and relatively inexpensive.

Positive Displacement Pumps: These pumps displace a fixed volume of liquid with each stroke, providing a more consistent flow rate than centrifugal pumps. They are often used for dosing chemicals precisely.

Diaphragm Pumps: These pumps use a diaphragm to move the liquid, suitable for handling slurries or viscous fluids. They’re often used for transferring sludge or other thick materials.

Submersible Pumps: These pumps are submerged in the water source, ideal for pumping from deep wells or reservoirs.

For example, centrifugal pumps are commonly used to move water through various treatment stages, while positive displacement pumps ensure precise dosing of chemicals like coagulants or disinfectants. Submersible pumps are essential in deep well applications to draw water efficiently from the source.

Q 21. Explain your experience with water treatment plant safety protocols.

Water treatment plant safety protocols are paramount to protect both personnel and the environment. These protocols cover various aspects:

Lockout/Tagout Procedures: These procedures ensure that equipment is safely de-energized before maintenance or repairs, preventing accidental starts.

Personal Protective Equipment (PPE): Appropriate PPE, including gloves, eye protection, and respirators, must be used when handling chemicals or working near hazardous equipment.

Confined Space Entry Procedures: Strict protocols govern entry into confined spaces, such as tanks and basins, to prevent asphyxiation or other hazards.

Chemical Handling and Storage: Safe handling, storage, and disposal of chemicals are crucial to prevent spills, leaks, or exposure.

Emergency Response Plans: Comprehensive plans must be in place to handle emergencies such as spills, equipment failures, or power outages.

Regular Safety Training: Operators must receive regular training on safety procedures and emergency response protocols.

In my experience, I’ve been involved in developing and implementing safety programs for water treatment plants, resulting in a significant reduction in workplace incidents and improved overall safety culture. This includes conducting regular safety audits, providing hands-on training, and ensuring compliance with all relevant safety regulations.

Q 22. How do you handle emergency situations in a water treatment plant?

Emergency situations in a water treatment plant demand swift, decisive action. My approach is based on a well-rehearsed emergency response plan, which includes pre-defined roles and responsibilities for every team member. This plan is regularly reviewed and updated through drills and simulations.

For instance, if we experience a power outage, our emergency generator automatically kicks in, but we also have a tiered system of manual backups. Each team member knows their specific task during such an event – from isolating affected units to initiating alternative treatment processes. Detailed checklists and communication protocols ensure a coordinated response. We prioritize public safety and minimizing any service disruption. Post-incident analysis is crucial, allowing us to refine our response plan and identify potential weaknesses. This iterative approach helps to continuously improve our emergency preparedness.

Another example would be a chemical spill. Our plan dictates immediate containment and notification of relevant authorities. Depending on the nature of the spill, we may need to implement specific countermeasures, such as neutralizing agents. The priority is to prevent the spill from reaching the treated water supply. Real-time data monitoring and immediate communication are key to effective emergency response.

Q 23. Describe your experience with data analysis and reporting in water treatment.

Data analysis and reporting are fundamental to effective water treatment plant operation. I’m proficient in using SCADA systems (Supervisory Control and Data Acquisition) to monitor various parameters, such as flow rates, chemical dosages, turbidity, and pH levels. I then use this data to identify trends, detect anomalies, and optimize plant performance. I’m experienced with statistical process control (SPC) techniques to proactively identify potential issues before they escalate into problems.

For example, I recently used SPC charts to analyze chlorine residual data over a six-month period. By identifying a subtle upward trend in residual chlorine, I was able to preemptively adjust the dosage, preventing potential issues with disinfection and saving the plant money on chemical costs.

My reporting involves generating clear and concise reports for management and regulatory agencies. These reports summarize key performance indicators (KPIs), highlight any deviations from established norms, and propose corrective actions. I’m also familiar with creating visualizations like charts and graphs to easily communicate complex data. My experience includes using software such as Microsoft Excel, and specialized water quality data management programs.

Q 24. How do you stay updated on the latest advancements in water treatment technology?

Staying current in this rapidly evolving field requires a multi-faceted approach. I regularly attend industry conferences and workshops, such as those hosted by organizations like the American Water Works Association (AWWA). These events provide opportunities to network with peers and learn about the latest innovations. I also subscribe to relevant journals and online publications dedicated to water treatment technologies. These resources keep me informed about new research findings and technological breakthroughs.

Furthermore, I actively participate in online professional communities and forums. This allows me to engage in discussions with experts from around the world and stay abreast of emerging trends and best practices. Finally, I seek out opportunities for continuing education, attending webinars and online courses to enhance my technical skills and knowledge base.

Q 25. What are the challenges and opportunities in the water treatment industry?

The water treatment industry faces numerous challenges, but also presents exciting opportunities. A major challenge is ensuring access to clean, safe drinking water for everyone, particularly in underserved communities and developing nations. This requires innovative solutions that are cost-effective, sustainable, and adaptable to local conditions. Another challenge is adapting to climate change, which is impacting water sources through increased droughts, flooding, and contamination. Stricter regulations and increasing energy costs are also significant challenges.

However, there are significant opportunities as well. The increasing awareness of water scarcity and the need for sustainable water management is driving innovation. New technologies, such as advanced membrane filtration and water reuse systems, offer promising solutions. There’s also a growing demand for skilled professionals in the water treatment sector, creating a rewarding career path. The implementation of smart water management systems, using IoT and AI for efficient and predictive operation, is another area of significant opportunity.

Q 26. Explain your experience with different types of water testing methods.

My experience encompasses a wide range of water testing methods, both physical and chemical. I’m proficient in using standard methods for determining parameters like turbidity (using a nephelometer), pH (using a pH meter), and chlorine residual (using a colorimetric method). I’m familiar with microbiological testing techniques, including plate counts and membrane filtration methods to detect the presence of coliform bacteria and other pathogens.

I’ve also worked with more advanced analytical techniques, such as inductively coupled plasma mass spectrometry (ICP-MS) for determining the presence and concentration of heavy metals, and gas chromatography-mass spectrometry (GC-MS) for analyzing volatile organic compounds (VOCs). Quality control is crucial; I meticulously follow standardized procedures to ensure the accuracy and reliability of our test results, which are essential for maintaining regulatory compliance and protecting public health. Each technique has its own precision and sensitivity, and selecting the appropriate method is key to efficient and effective testing.

Q 27. Describe your experience with project management in water treatment projects.

I have extensive experience in managing water treatment projects, from initial planning and design to construction and commissioning. My approach involves meticulous planning, clear communication, and close collaboration with all stakeholders. I utilize project management methodologies like Agile or PRINCE2 to ensure projects are completed on time and within budget.

For example, I recently managed the upgrade of a water treatment plant’s filtration system. This involved coordinating with engineers, contractors, and regulatory agencies, developing a detailed project schedule, and managing the budget effectively. I used project management software to track progress, manage risks, and ensure timely completion. Regular meetings and progress reports kept all stakeholders informed, promoting transparency and accountability. Success in this project required strong communication and problem-solving skills, alongside a deep understanding of the technical aspects of water treatment.

Q 28. How would you approach optimizing the efficiency of a water treatment plant?

Optimizing a water treatment plant’s efficiency requires a holistic approach. It begins with a thorough assessment of the plant’s current operation, identifying areas for improvement. This might involve reviewing the plant’s design, assessing the efficiency of existing equipment, analyzing operational data, and evaluating the effectiveness of treatment processes.

Data analysis plays a crucial role. I would analyze historical data to identify trends and patterns, using this information to optimize chemical dosages, adjust flow rates, and improve energy consumption. For instance, I might implement advanced control systems that leverage real-time data to automatically adjust the treatment process based on changing water quality conditions. Another strategy would be to explore energy-efficient technologies, such as high-efficiency pumps and variable-frequency drives. Regular maintenance and proactive equipment replacement are also critical in minimizing downtime and maximizing efficiency. Finally, staff training and knowledge sharing contribute greatly to operational improvements.

Key Topics to Learn for Your Water Treatment Technology Interview

- Water Chemistry Fundamentals: Understanding pH, alkalinity, hardness, dissolved oxygen, and their impact on treatment processes. Practical application: Troubleshooting issues with chemical dosing and achieving desired water quality parameters.

- Coagulation and Flocculation: The principles behind removing suspended solids using coagulants and flocculants. Practical application: Optimizing the coagulation process to maximize particle removal efficiency in a clarifier.

- Filtration Technologies: Different types of filters (e.g., sand, gravel, membrane) and their applications. Practical application: Selecting the appropriate filter media and operating parameters for specific water quality challenges.

- Disinfection Methods: Chlorination, UV disinfection, ozonation – their mechanisms and effectiveness. Practical application: Calculating chlorine dose for effective disinfection while minimizing disinfection by-products.

- Membrane Processes: Reverse osmosis, microfiltration, ultrafiltration – their applications in water treatment and wastewater reuse. Practical application: Understanding membrane fouling and cleaning strategies.

- Water Quality Monitoring and Analysis: Proper sampling techniques and laboratory procedures for analyzing water quality parameters. Practical application: Interpreting laboratory results to identify and address water quality issues.

- Instrumentation and Control Systems: Understanding the role of sensors, controllers, and SCADA systems in automated water treatment plants. Practical application: Troubleshooting malfunctions in automated systems and ensuring optimal plant operation.

- Regulations and Compliance: Familiarity with relevant water quality regulations and standards. Practical application: Ensuring compliance with discharge permits and reporting requirements.

- Sustainable Water Treatment Practices: Energy efficiency, waste minimization, and resource recovery in water treatment. Practical application: Implementing strategies to reduce the environmental footprint of water treatment operations.

- Troubleshooting and Problem-Solving: Developing a systematic approach to identifying and resolving problems in water treatment systems. Practical application: Analyzing data, identifying root causes, and implementing corrective actions.

Next Steps

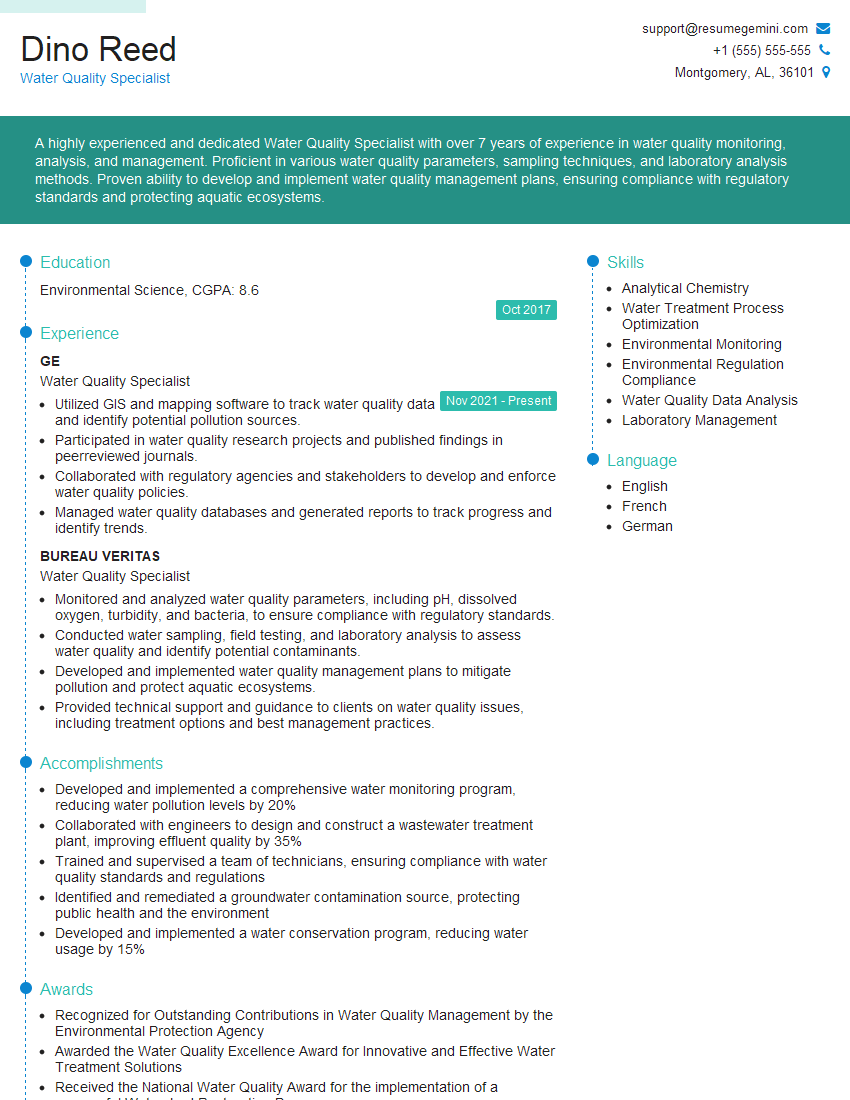

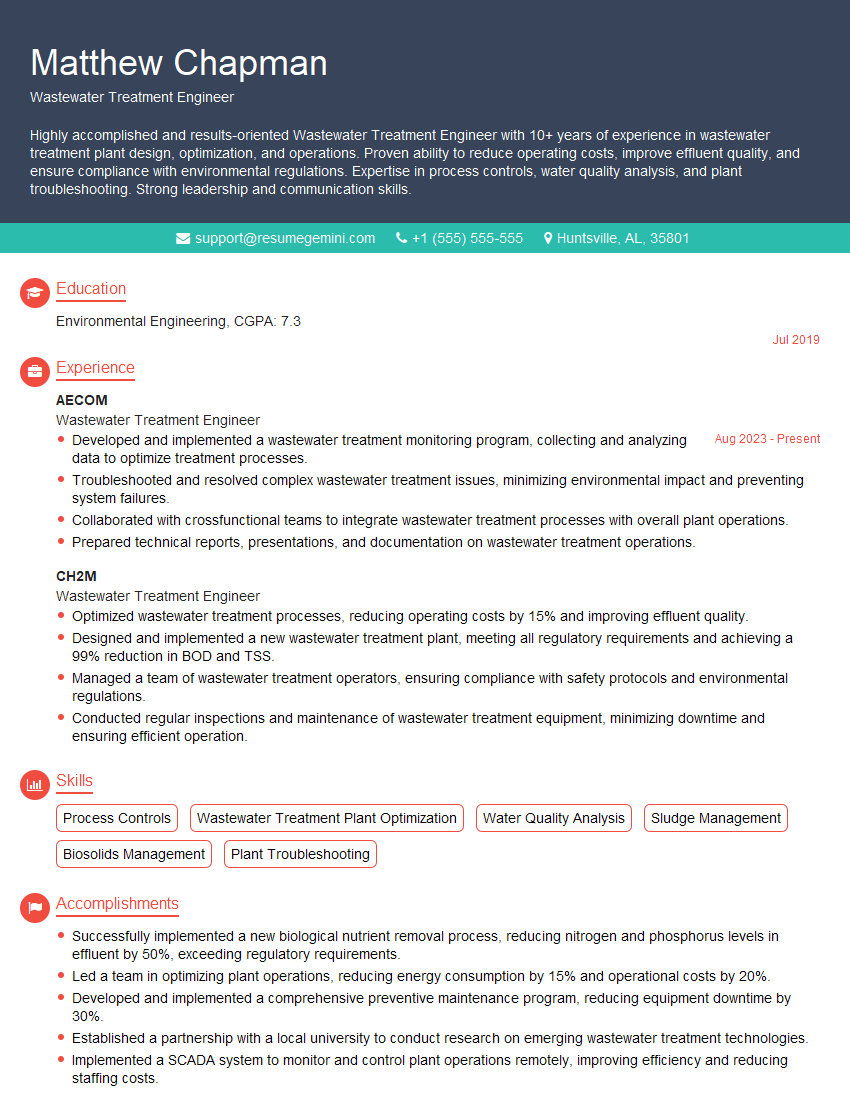

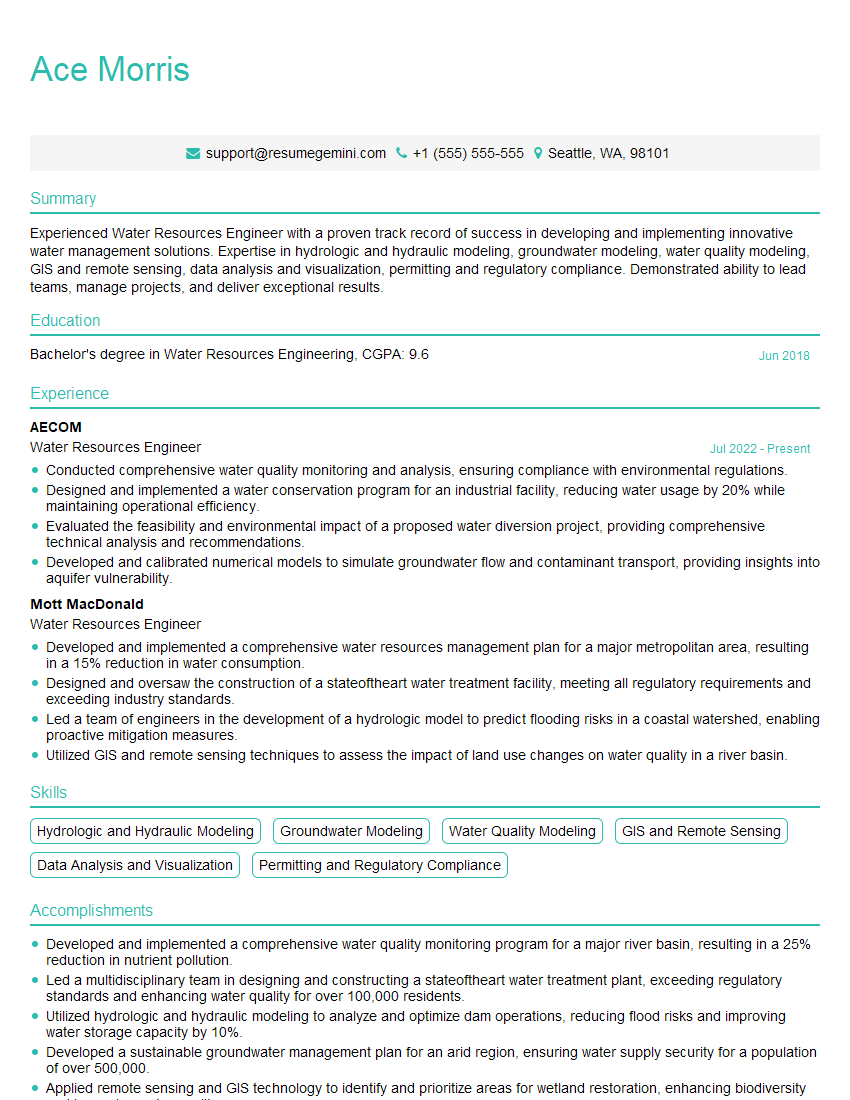

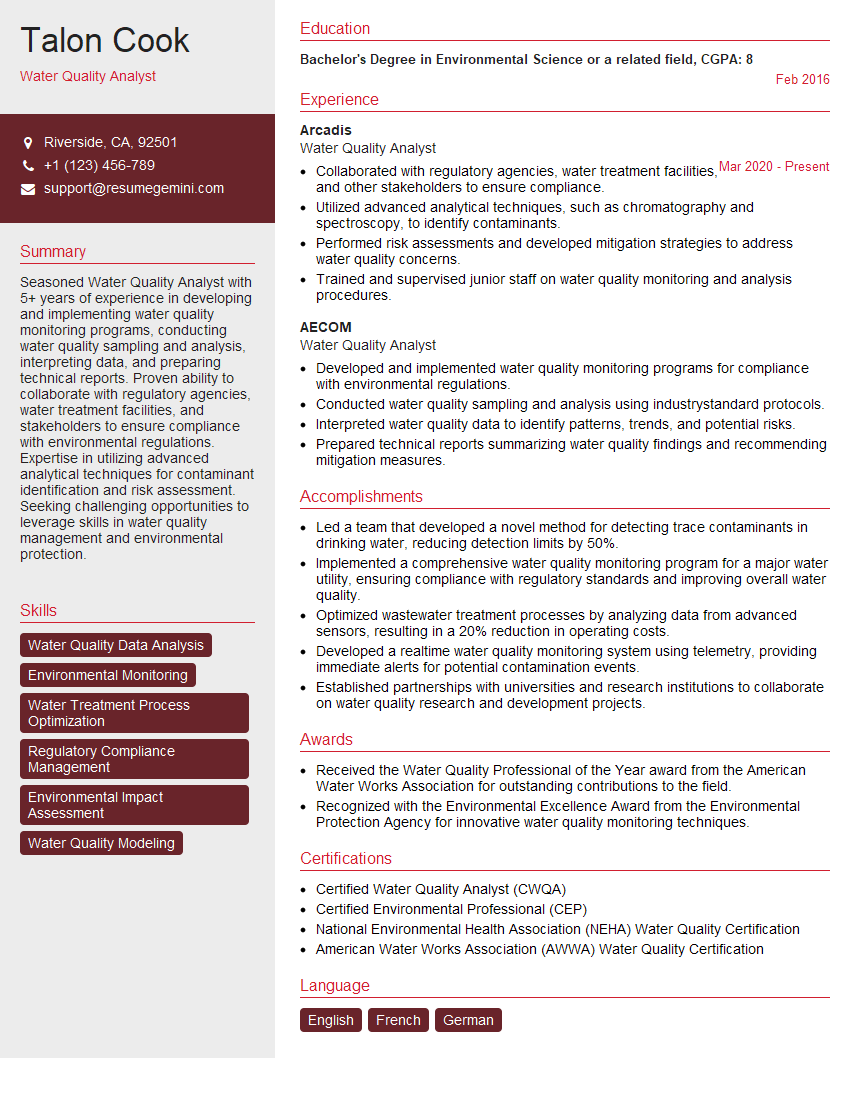

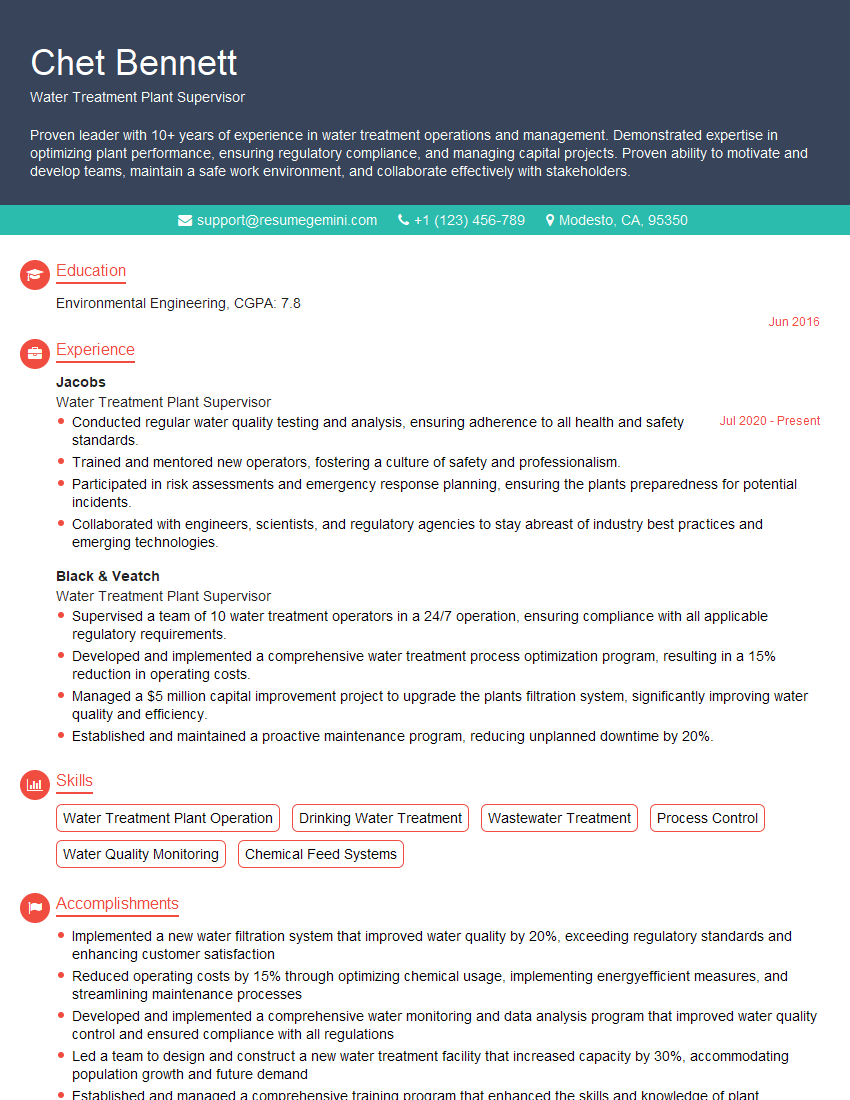

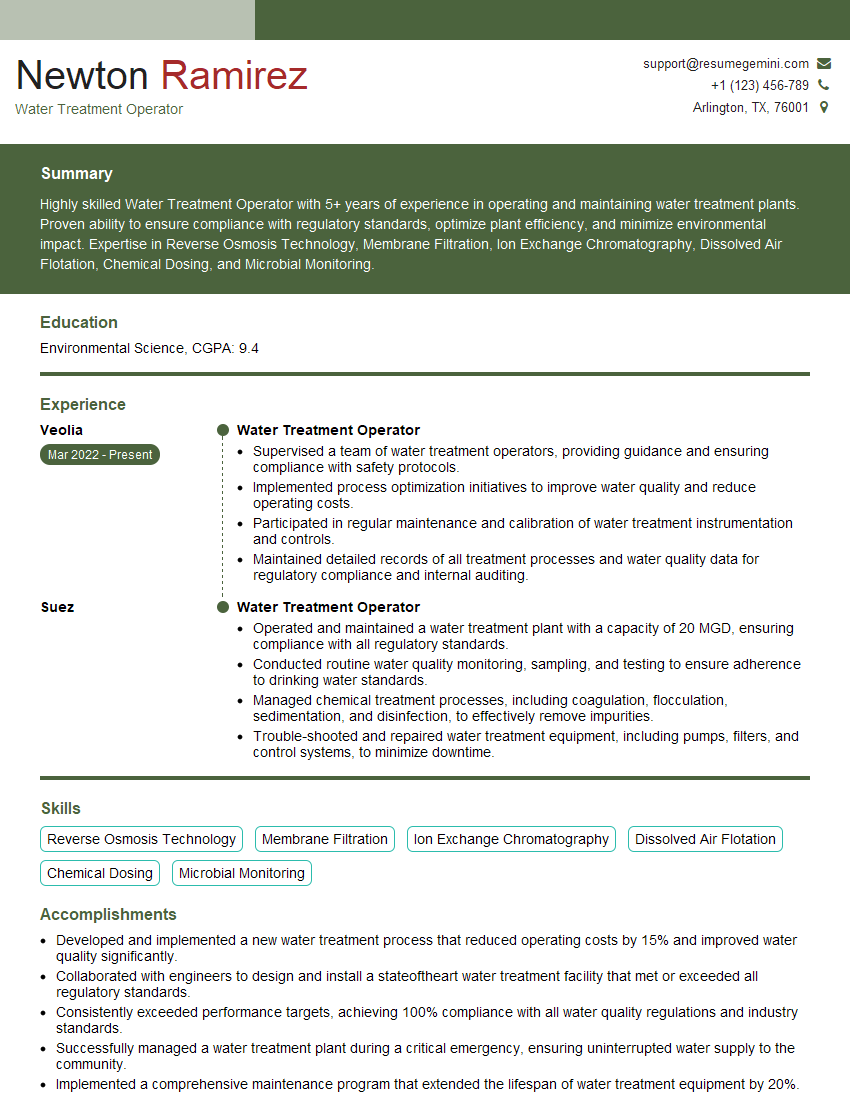

Mastering Water Treatment Technology opens doors to exciting and impactful careers, offering opportunities for professional growth and contributing to essential public services. To maximize your job prospects, create a resume that’s both impressive and easily scanned by Applicant Tracking Systems (ATS). ResumeGemini is a trusted resource that can help you build a professional, ATS-friendly resume that showcases your skills and experience effectively. Examples of resumes tailored to the Water Treatment Technology field are available to guide you. Invest in crafting a compelling resume – it’s your first step to landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO