The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience with cleaning chemicals and equipment interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience with cleaning chemicals and equipment Interview

Q 1. What safety precautions are necessary when handling cleaning chemicals?

Handling cleaning chemicals demands rigorous safety protocols. Think of it like handling potent medicine – a little goes a long way, and misuse can be dangerous. The core principles revolve around personal protective equipment (PPE) and proper ventilation.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves (nitrile or similar, chosen based on the chemical), eye protection (goggles or a face shield), and a respirator (if required by the chemical’s Safety Data Sheet, or SDS). Never underestimate the importance of this; a single splash can cause serious injury.

- Ventilation: Work in well-ventilated areas to minimize inhalation of fumes. If working indoors, open windows and use exhaust fans. For particularly strong chemicals, consider using a dedicated respirator with appropriate filters, as specified by the SDS.

- SDS Review: Before handling *any* chemical, meticulously read its Safety Data Sheet (SDS). This document provides crucial information on hazards, handling, storage, and first aid procedures. It’s your bible for safe chemical use.

- Spill Response Plan: Always have a spill response plan in place. Know how to neutralize spills safely and what absorbent materials to use. This will vary depending on the chemical, so refer to the SDS.

- Skin Contact: In case of skin contact, immediately flush the affected area with copious amounts of water for at least 15 minutes. Remove contaminated clothing.

For example, when handling bleach, I always wear gloves and eye protection, ensuring adequate ventilation, and keeping it separate from other chemicals (to prevent hazardous reactions).

Q 2. Describe your experience with different types of cleaning equipment (e.g., floor buffers, carpet extractors).

My experience with cleaning equipment is extensive, encompassing both small and large-scale applications. I’m proficient in operating and maintaining a range of equipment.

- Floor Buffers: I’m skilled in using various types of floor buffers – from single-disc machines for spot cleaning and polishing to larger, orbital buffers for high-volume cleaning. I understand the importance of selecting the appropriate pad type (e.g., polishing, scrubbing, stripping) for the floor type and cleaning task. I’m also trained in safe operating procedures to avoid accidents and damage to the floors.

- Carpet Extractors: I’ve operated both hot water extraction (steam cleaning) and dry cleaning carpet extractors. Understanding the different functionalities and their appropriate uses for various carpet types is critical. Proper pre-treatment, agitation, and extraction techniques ensure optimal cleaning results without damaging the carpet fibres. I’m familiar with maintenance, including cleaning and emptying the recovery tank and maintaining water temperature and pressure.

- Other Equipment: My experience also includes using vacuum cleaners (both upright and canister), pressure washers, and various other specialized cleaning tools. This diverse experience allows me to adapt to different cleaning scenarios and utilize the most appropriate equipment.

For instance, when tackling a heavily soiled carpeted area, I would use a hot water extraction carpet extractor, pre-treating stains and using appropriate agitation before extracting the dirty water. For regular floor maintenance in a high-traffic area, I’d utilize a floor buffer with a polishing pad to maintain shine and protect the floor.

Q 3. How do you determine the appropriate cleaning chemical for a specific surface or stain?

Selecting the right cleaning chemical is crucial for effective cleaning and preventing damage to the surface. This process involves careful consideration of several factors.

- Surface Type: Different surfaces (e.g., wood, tile, granite, glass) react differently to various chemicals. Using an abrasive cleaner on a delicate surface like marble can cause irreversible damage. For example, I would use a pH-neutral cleaner for granite and a specialized wood cleaner for hardwood floors.

- Stain Type: Different stains require different approaches. Grease stains necessitate degreasers, while biological stains might need enzymatic cleaners. Knowing the nature of the stain guides the choice of cleaning agent. For example, I’d use a specialized stain remover for bloodstains and a degreaser for kitchen grease.

- Chemical Compatibility: Certain chemicals react unpredictably when mixed; this necessitates careful assessment of each product’s compatibility with the surface and other chemicals.

- Safety Data Sheet (SDS): Before using any cleaning chemical, carefully consult its SDS for recommended application procedures, safety precautions, and compatible surfaces.

For example, if I encounter a coffee stain on a wooden table, I’d first test a small, inconspicuous area with a mild, wood-safe cleaner before applying it to the entire stain. For a stubborn grease stain on a ceramic tile, I would choose a degreasing cleaner designed for ceramic surfaces.

Q 4. Explain the proper dilution ratios for common cleaning chemicals.

Dilution ratios are critical for safety and effectiveness. Incorrect dilution can result in ineffective cleaning or damage to surfaces. Always refer to the product’s SDS for precise instructions, as ratios vary significantly between products and manufacturers.

However, a common example is all-purpose cleaner: many commercially available products suggest a dilution ratio of 1:10 (one part cleaner to ten parts water). This means that for every 100ml of water, you would add 10ml of cleaner. Always measure accurately; using a measuring cup or graduated cylinder is advisable.

It’s important to note that stronger concentrations aren’t always better; they may increase the risk of damage or leave residues. Following the manufacturer’s recommendations ensures optimal results and safety.

Example: 1:10 dilution = 10ml cleaner + 100ml water

Q 5. What are the potential hazards associated with mixing cleaning chemicals?

Mixing cleaning chemicals can be incredibly dangerous and should be strictly avoided. Mixing chemicals can create unpredictable reactions, generating toxic gases, flammable mixtures, or even explosive compounds. These reactions can lead to serious health consequences and even death.

For example, mixing bleach with ammonia produces chloramine gas, a highly toxic and potentially lethal gas. Similarly, mixing different acids or bases can result in exothermic reactions, generating heat and potentially causing burns or fires.

Never mix cleaning chemicals without first consulting the SDS for each product and having a thorough understanding of the potential chemical interactions. If you’re unsure, it’s best to use separate chemicals one after another, ensuring thorough rinsing between applications.

Q 6. How do you ensure the safe storage and disposal of cleaning chemicals?

Safe storage and disposal of cleaning chemicals are paramount. Improper handling can lead to spills, exposure, and environmental contamination.

- Storage: Cleaning chemicals should be stored in their original containers, tightly sealed, in a cool, dry, and well-ventilated area, away from heat sources and incompatible chemicals. Use appropriate shelving to prevent spills and keep containers clearly labeled. Keep chemicals out of reach of children and unauthorized personnel.

- Disposal: Always follow local regulations for the disposal of cleaning chemicals. Never pour chemicals down the drain unless specifically stated as acceptable on the SDS. Some chemicals may require special collection and disposal procedures through designated hazardous waste facilities. Contact your local waste management authority for guidelines.

For example, I would store bleach in its original container, away from acids and ammonia, and ensure that the area is well-ventilated. For disposal of spent cleaning solutions, I would follow local guidelines, possibly utilizing designated hazardous waste disposal services.

Q 7. Describe your experience with maintaining and troubleshooting cleaning equipment.

Maintaining and troubleshooting cleaning equipment is essential for ensuring efficient and safe operation. Regular maintenance extends equipment lifespan and prevents costly repairs.

- Regular Cleaning: Cleaning equipment after each use removes debris and prevents build-up, prolonging its operational life. This involves emptying tanks, cleaning filters, and wiping down exterior surfaces.

- Preventative Maintenance: Regularly checking belts, hoses, and other components helps identify potential issues before they become major problems. Lubricating moving parts as recommended by the manufacturer is crucial.

- Troubleshooting: I’m experienced in identifying and resolving common issues like clogged hoses, malfunctioning pumps, or motor problems. Understanding the basic mechanics of the equipment allows me to perform minor repairs or accurately assess when professional service is needed.

For example, if a floor buffer isn’t spinning correctly, I would first check the power cord and outlet. Then, I would inspect the belt for wear and tear and ensure proper tension. If necessary, I would replace the belt or seek professional help.

Q 8. How do you develop and implement a cleaning schedule for a large facility?

Developing a cleaning schedule for a large facility requires a systematic approach. It’s not just about listing tasks; it’s about optimizing efficiency, resource allocation, and ensuring consistent cleanliness. I begin by conducting a thorough assessment of the facility, identifying high-traffic areas, sensitive equipment, and specific cleaning needs for different zones (e.g., restrooms, offices, production areas).

Next, I create a master schedule, broken down into daily, weekly, monthly, and even quarterly tasks. Daily tasks might include emptying trash cans, wiping down surfaces, and vacuuming high-traffic areas. Weekly tasks might involve more thorough cleaning of restrooms, mopping floors, and cleaning windows. Monthly tasks could include deep cleaning of carpets, disinfecting equipment, and checking ventilation systems. Quarterly tasks might involve more extensive cleaning projects like stripping and waxing floors.

The schedule should also specify the cleaning products and equipment needed for each task, assigning responsibilities to specific cleaning personnel or teams. This detailed approach ensures accountability and avoids overlaps or omissions. Finally, regular review and adjustments are crucial; the schedule should be a living document adapting to changes in facility usage and emerging needs. For example, after a large event, the post-event cleaning schedule might need temporary adjustments to handle increased waste and spills.

Q 9. What are the key elements of a comprehensive cleaning safety program?

A comprehensive cleaning safety program is paramount. It’s not just about avoiding accidents; it’s about proactively protecting the health and well-being of cleaning staff and building occupants. Key elements include:

- Hazard Identification and Risk Assessment: This involves a detailed assessment of all potential hazards, including chemical exposure, ergonomic risks (lifting heavy equipment), slips, trips, and falls, and exposure to biohazards.

- Personal Protective Equipment (PPE): Providing and ensuring the proper use of PPE, such as gloves, eye protection, respirators, and protective footwear, is critical. Training on proper selection and use is essential.

- Chemical Safety Management: This involves proper storage, handling, and disposal of cleaning chemicals, including the use of Safety Data Sheets (SDS) and appropriate labeling.

- Training and Education: Regular training for all cleaning staff on safe work practices, hazard recognition, and emergency procedures is essential. This should cover topics ranging from chemical safety to proper lifting techniques.

- Emergency Response Plan: Developing and practicing emergency response plans for spills, injuries, or other incidents is crucial. This includes procedures for contacting emergency services and handling specific situations.

- Regular Inspections and Audits: Routine inspections of the workplace, equipment, and cleaning procedures help identify potential hazards and ensure compliance with safety regulations.

Think of it like this: a well-designed safety program is a proactive shield, preventing potential problems before they arise, rather than reacting to them after the fact.

Q 10. How do you handle spills and leaks of cleaning chemicals?

Handling spills and leaks of cleaning chemicals requires immediate and decisive action to minimize risks. The first step is always safety: evacuate the area if necessary and ensure everyone involved is wearing appropriate PPE, including gloves, eye protection, and respirators if the chemical warrants it. Never attempt to clean up a spill without proper training and equipment.

Next, refer to the SDS for the specific chemical spilled. The SDS will provide crucial information on the handling, cleanup, and neutralization of the spilled substance. This sheet will guide you on what absorbent materials (e.g., vermiculite, spill pads) to use, and whether any special neutralization techniques are required.

Once the spill is contained and cleaned up, the area should be thoroughly ventilated. Any contaminated materials should be disposed of according to local regulations. Finally, document the incident, including the type and quantity of chemical spilled, the steps taken for cleanup, and any injuries or other issues.

For example, if a bleach spill occurs, I would use a neutralizer like sodium thiosulfate to safely neutralize the bleach before cleaning up the area with absorbent materials. This is different from cleaning up a different chemical spill and highlights the importance of following the chemical’s SDS.

Q 11. What is your experience with using Personal Protective Equipment (PPE) while cleaning?

My experience with PPE is extensive. I understand that selecting the correct PPE is critical to preventing injuries and illnesses. I’m proficient in using various types of PPE, including:

- Gloves: I use nitrile, latex, or neoprene gloves depending on the chemicals being handled. I understand the limitations of different glove types and choose accordingly.

- Eye Protection: I consistently wear safety glasses or goggles to protect my eyes from splashes or fumes.

- Respiratory Protection: When working with chemicals that produce harmful vapors or dust, I use appropriate respirators. I’m familiar with different respirator types and know how to perform fit testing.

- Protective Clothing: Depending on the task, I may use aprons, coveralls, or other protective clothing to prevent skin exposure to chemicals or other hazards.

Furthermore, I emphasize proper PPE donning and doffing procedures to prevent cross-contamination. I regularly inspect my PPE for damage and replace it as needed. In my experience, proper use of PPE is not just a safety measure; it’s a demonstration of respect for oneself and one’s co-workers.

Q 12. How do you train new employees on the safe use of cleaning chemicals and equipment?

Training new employees on the safe use of cleaning chemicals and equipment is a crucial part of my responsibilities. My training program is multi-faceted and includes:

- Classroom Instruction: This covers topics such as chemical safety, SDS interpretation, proper use of equipment, emergency procedures, and relevant OSHA regulations.

- Hands-on Training: I provide supervised practical training where new employees practice using different cleaning chemicals and equipment in a controlled environment.

- Mentorship and Shadowing: Experienced cleaners mentor new employees, providing on-the-job guidance and answering questions.

- Regular Refresher Training: Periodic refresher training ensures that employees stay up-to-date on safety procedures and best practices.

- Written and Practical Examinations: I use both written and practical exams to assess the employee’s understanding of the training material and their ability to perform tasks safely.

I always emphasize the importance of following safety procedures and reporting any accidents or near misses. The goal is not only to meet compliance requirements, but to instill a strong safety culture where everyone feels responsible for their own safety and the safety of others.

Q 13. How do you monitor the effectiveness of cleaning procedures and chemicals?

Monitoring the effectiveness of cleaning procedures and chemicals involves a multi-pronged approach that combines visual inspection with objective measurement.

Visual Inspection: Regularly inspecting cleaned areas helps identify any areas needing extra attention or areas where the cleaning process is insufficient. This could include checking for visible dirt, grime, or stains.

ATP Bio-luminescence Testing: This method uses a device that measures Adenosine Triphosphate (ATP), an indicator of microbial contamination. A high ATP reading suggests inadequate cleaning. This is particularly important in areas requiring high levels of sanitation, such as food preparation areas or healthcare settings.

Microbial Testing: More involved testing involves taking samples to assess the presence of specific bacteria or microorganisms. This is essential for validating the effectiveness of disinfectants.

Feedback Mechanisms: Gathering feedback from building occupants or staff about cleanliness levels can also help identify areas for improvement.

By combining these methods, I can objectively assess the effectiveness of our cleaning procedures and chemicals, allowing for adjustments to improve efficiency and hygiene. For instance, if ATP testing consistently shows high readings in a specific area, it may indicate a need to adjust the cleaning process, change cleaning chemicals, or increase cleaning frequency.

Q 14. How familiar are you with OSHA regulations related to cleaning and sanitation?

I am very familiar with OSHA regulations related to cleaning and sanitation. My knowledge encompasses several key areas:

- Hazard Communication Standard (HazCom): I understand the requirements for properly labeling and handling hazardous chemicals, including the use of Safety Data Sheets (SDS).

- Personal Protective Equipment (PPE): I am knowledgeable about OSHA’s requirements for providing and using appropriate PPE in cleaning operations.

- Bloodborne Pathogens Standard: I’m familiar with procedures for handling and cleaning up blood and other potentially infectious materials.

- Occupational Safety and Health Regulations for General Industry: I understand the broader safety requirements relating to workplace safety, such as preventing slips, trips, and falls, and proper use of equipment.

Staying current with OSHA regulations is an ongoing process. I regularly review updates and attend relevant training sessions to maintain my understanding and ensure compliance. Understanding and complying with these regulations are not just about avoiding penalties; they’re about creating a safe and healthy working environment for everyone.

Q 15. Describe your experience with different types of cleaning solutions (e.g., disinfectants, degreasers).

My experience encompasses a wide range of cleaning solutions, categorized by their function. Disinfectants, like bleach solutions or quaternary ammonium compounds (quats), are crucial for eliminating bacteria and viruses. I’m proficient in understanding their concentration levels and appropriate contact times for effective sanitation. Degreasers, on the other hand, are specialized for removing grease and oil. I’ve worked extensively with both solvent-based and water-based degreasers, understanding their application based on the surface and type of grease involved. For example, a powerful solvent-based degreaser might be ideal for industrial kitchen equipment, while a gentler, water-based solution would be preferred for delicate surfaces. I also have experience with all-purpose cleaners, which are versatile solutions for general cleaning tasks. Proper selection always depends on the surface being cleaned, avoiding damage while ensuring efficacy.

- Example: In a previous role, I successfully implemented a new disinfection protocol using diluted bleach solution, reducing bacterial contamination in a high-traffic restroom by 80%, as verified by regular microbiological testing.

- Example: When dealing with a particularly stubborn grease buildup in a commercial kitchen’s ventilation system, I selected a heavy-duty solvent-based degreaser, following all safety protocols including proper ventilation and personal protective equipment (PPE).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with environmentally friendly cleaning products?

I have significant experience with environmentally friendly cleaning products. These products aim to minimize environmental impact by using biodegradable ingredients, reducing reliance on harsh chemicals, and often employing sustainable packaging. I’m familiar with various types, including those based on plant-derived ingredients, enzymes, and citric acid. The key is understanding their limitations compared to traditional cleaners; they may require longer contact times or more diligent scrubbing. However, the long-term benefits to human health and the environment justify their use. I understand the importance of reading and adhering to the product’s instructions to ensure effective cleaning. Proper dilution is key for both efficacy and safety.

Example: In one project, I successfully transitioned a large office building to an entirely green cleaning program, demonstrating that environmental responsibility does not compromise cleanliness. We monitored cleaning effectiveness using standardized cleanliness assessment tools, showing no reduction in cleanliness despite the switch.

Q 17. How do you ensure that all cleaning equipment is properly maintained and in good working order?

Proper equipment maintenance is paramount for safety and efficiency. My approach involves a structured system. Firstly, after each use, I thoroughly clean and rinse all equipment, removing any residue from cleaning solutions. Secondly, I conduct regular inspections, checking for wear and tear, damage to cords or hoses, and ensuring all safety features are functioning correctly. This includes checking for leaks, frayed wires, or any signs of malfunction. Any damaged or malfunctioning equipment is promptly reported and taken out of service until repaired or replaced. Lastly, I maintain detailed records of equipment maintenance, including cleaning dates, repairs, and replacements, ensuring traceability and compliance with safety regulations.

- Example: Regularly checking and changing the filters in our vacuum cleaners prevents clogging and maintains suction power, leading to more efficient cleaning and a longer equipment lifespan.

Q 18. Describe your experience with inventory management of cleaning supplies and chemicals.

Efficient inventory management of cleaning supplies is crucial. My experience includes using both manual and digital inventory systems. I’m proficient in tracking stock levels, placing timely orders to prevent shortages, and managing waste reduction initiatives. I use a system of regular stock checks, comparing actual quantities with minimum stock levels. This minimizes the risk of running out of essential supplies. I also ensure proper storage to maintain the quality and extend the shelf life of chemicals, following all safety guidelines for chemical storage including proper labeling and ventilation. I frequently analyze consumption patterns to optimize ordering quantities, avoiding unnecessary waste.

Example: By implementing a computerized inventory system, I reduced cleaning supply costs by 15% in my previous role, while maintaining a consistently sufficient stock.

Q 19. How do you prioritize cleaning tasks in a high-traffic area?

Prioritizing cleaning tasks in a high-traffic area requires a strategic approach. I prioritize areas that pose the highest risk of contamination or present immediate safety hazards. This typically involves a hierarchical approach: high-touch surfaces like doorknobs, light switches, and handrails are cleaned first and most frequently, followed by floors and other surfaces. High-traffic areas are addressed more frequently than less used areas. A visual inspection often helps me adjust the schedule as needed. This ensures a consistent level of cleanliness despite heavy use.

Example: In a busy shopping mall, I would prioritize cleaning restrooms, entrances, and escalator handrails multiple times a day, addressing other areas based on the perceived need and available time.

Q 20. What is your experience with specialized cleaning techniques (e.g., carpet cleaning, window washing)?

I’m experienced in specialized cleaning techniques. Carpet cleaning often involves hot water extraction (steam cleaning) or dry cleaning methods, depending on carpet type and soiling. I’m familiar with operating and maintaining the necessary equipment. Window washing requires techniques like squeegee cleaning or water-fed pole systems for high-reach windows. In both cases, I prioritize safety and efficiency, using appropriate safety measures and selecting the most effective technique based on the specific environment and task.

Example: I’ve successfully restored the appearance of heavily soiled carpets in several commercial spaces using hot water extraction techniques, extending the lifespan of the carpets and improving the overall environment.

Q 21. How do you address customer concerns or complaints regarding cleaning services?

Addressing customer concerns is critical. My approach involves active listening, empathetic understanding, and providing prompt solutions. First, I acknowledge the concern and validate the customer’s feelings. Then, I investigate the issue thoroughly, identifying the root cause. If the complaint is valid, I take immediate action to rectify the problem, offering appropriate apologies and ensuring the issue doesn’t reoccur. I maintain clear and professional communication throughout the process, keeping the customer informed of progress. I view each concern as an opportunity for improvement.

Example: A client once complained about streaks on their windows after a cleaning. After investigating, we discovered a problem with the squeegee blade. We replaced the blade, re-cleaned the windows, and followed up to ensure they were satisfied. The experience led to an improved quality check procedure for our cleaning equipment.

Q 22. How do you ensure compliance with all relevant health and safety regulations?

Ensuring compliance with health and safety regulations is paramount in the cleaning industry. It’s not just about following rules; it’s about protecting myself, my team, and the environment. My approach is multi-faceted:

- Regular Training: I stay updated on all relevant OSHA (Occupational Safety and Health Administration) guidelines and participate in regular training sessions on chemical handling, personal protective equipment (PPE) usage, and emergency procedures. This includes understanding Safety Data Sheets (SDS) for every cleaning chemical we use.

- Proper PPE Usage: This is non-negotiable. Depending on the task, this might include gloves (nitrile, latex, etc., depending on the chemical), eye protection, respirators, and appropriate footwear. I rigorously enforce PPE use within my team.

- Chemical Handling and Storage: Chemicals are stored securely, labeled correctly, and handled according to the manufacturer’s instructions. We use spill kits appropriately and practice proper disposal methods to prevent environmental contamination. We have a strict policy of never mixing cleaning chemicals, as this can create dangerous fumes or reactions.

- Incident Reporting: Any accidents, near misses, or unsafe conditions are immediately reported and thoroughly investigated. This helps prevent future incidents and identifies areas for improvement in our safety protocols.

- Regular Inspections: I conduct regular inspections of the workplace to ensure that all safety measures are in place and functioning correctly. This includes checking the condition of equipment and ensuring proper ventilation.

For example, in my previous role, we implemented a new color-coded system for chemical storage that significantly reduced the risk of accidental mixing, leading to a 20% reduction in minor incidents.

Q 23. What is your experience with budgeting and cost control related to cleaning supplies?

Budgeting and cost control are crucial for efficient cleaning operations. My experience involves a comprehensive approach:

- Supplier Negotiation: I actively negotiate contracts with cleaning supply vendors to secure the best prices and volume discounts. I leverage my knowledge of different products and their effectiveness to find cost-effective alternatives without compromising quality.

- Inventory Management: I implement inventory tracking systems to monitor usage and prevent waste. This involves regular stock checks and forecasting to avoid overstocking or running out of essential supplies. We use a just-in-time inventory system wherever feasible.

- Product Selection: I carefully evaluate the cost-effectiveness of different cleaning products. This includes considering factors like cleaning power, dilution ratios, and long-term usage costs. Sometimes, a slightly more expensive product can be more cost-effective in the long run due to its higher efficacy and longer lifespan.

- Waste Reduction: We actively seek ways to minimize waste, such as using concentrated cleaning solutions and reusable microfiber cloths instead of disposable ones. This significantly reduces both material costs and environmental impact.

- Equipment Maintenance: Proper maintenance of cleaning equipment extends its lifespan, reducing the need for frequent replacements. This also reduces downtime and maintains productivity.

In a previous role, by implementing these strategies, I managed to reduce cleaning supply costs by 15% within six months without sacrificing cleaning standards.

Q 24. How do you manage a team of cleaning personnel?

Managing a cleaning team requires strong leadership, communication, and organization skills. My approach focuses on:

- Clear Communication: I ensure clear communication of tasks, expectations, and safety procedures. Regular team meetings are held to address concerns, share best practices, and provide feedback.

- Training and Development: Providing ongoing training on new techniques, safety procedures, and equipment usage is essential for improving performance and efficiency. I also identify opportunities for professional development.

- Delegation and Empowerment: I delegate tasks effectively, empowering team members to take ownership and responsibility for their work. This fosters a sense of teamwork and collaboration.

- Performance Monitoring: I regularly monitor individual and team performance, providing constructive feedback and addressing any performance issues promptly. This includes tracking productivity and identifying areas for improvement.

- Motivation and Recognition: Recognizing and appreciating good work is crucial for maintaining high morale and motivation. This could involve verbal praise, team incentives, or employee recognition programs.

For example, I once mentored a new team member who initially struggled with time management. By providing personalized training and consistent feedback, I helped them improve their efficiency and boost their confidence significantly.

Q 25. Describe a time you had to troubleshoot a malfunctioning piece of cleaning equipment.

Troubleshooting malfunctioning equipment is a common occurrence. Once, our high-pressure floor cleaning machine suddenly stopped working mid-shift. Here’s how I approached the problem:

- Safety First: I immediately switched off the machine and secured the area to prevent any accidents.

- Visual Inspection: I carefully inspected the machine for any obvious issues like loose connections, frayed wires, or blockages.

- Check the Manual: I consulted the machine’s operating manual for troubleshooting steps. The manual suggested checking the power supply, water intake, and filters.

- Systematic Troubleshooting: I systematically checked each component mentioned in the manual. I discovered a clogged filter, which I cleaned carefully, following safety precautions.

- Testing and Retesting: After cleaning the filter, I tested the machine. It started working again. To be sure, I ran it through a test cycle before resuming normal operations.

- Preventative Maintenance: Following the incident, I implemented a regular maintenance schedule to check and clean filters and other vital parts proactively.

This incident highlighted the importance of having readily accessible manuals, a systematic troubleshooting approach, and proactive preventative maintenance to minimize downtime and improve equipment longevity.

Q 26. How do you adapt your cleaning techniques based on the type of surface or material being cleaned?

Adapting cleaning techniques to different surfaces is essential for effective and safe cleaning. Different materials have different sensitivities to cleaning chemicals and require specific techniques to avoid damage. For example:

- Wood: Wooden surfaces require gentle cleaning with pH-neutral cleaners. Aggressive chemicals can damage the finish. I would use a damp cloth or a specialized wood cleaner, avoiding excessive moisture.

- Marble and Granite: These natural stones are porous and sensitive to acidic cleaners. I would use a neutral cleaner and avoid abrasive scrubbers that could scratch the surface.

- Glass: Glass surfaces are typically cleaned with glass cleaners and a microfiber cloth to avoid streaks. I’d ensure the glass is clean and dry before using any cleaning agent.

- Stainless Steel: Stainless steel requires cleaning along the grain to avoid scratches. I would use a non-abrasive cleaner and a soft cloth.

- Fabric Upholstery: Fabric upholstery requires using appropriate upholstery cleaners and considering the fabric type to avoid damaging the material. Vacuuming is also essential to remove dust and debris.

Understanding the properties of various materials allows me to choose the right cleaning chemicals, tools, and techniques for optimal results while preventing damage. This requires continuous learning and staying up-to-date on best practices for various surfaces.

Q 27. What is your experience with using specialized cleaning equipment for hard-to-reach areas?

Experience with specialized cleaning equipment for hard-to-reach areas is critical. I’ve worked with a variety of such equipment including:

- Telescopic poles with various attachments: These are invaluable for cleaning high ceilings, light fixtures, and hard-to-reach corners. The versatility of attachments allows for dusting, washing, and even disinfection.

- Microfiber cleaning cloths and brushes with extended handles: These provide excellent reach while allowing for careful cleaning of delicate surfaces.

- Steam cleaners with specialized nozzles: Steam cleaners are effective for cleaning grout and other crevices, removing grime and eliminating bacteria. Using smaller nozzles allows access to tighter spaces.

- Rotary scrubbers and specialized wands: These are useful for cleaning tough stains on vertical surfaces like walls or hard to reach areas in large buildings.

- Vacuum systems with specialized attachments: Using vacuums with long wands and crevice tools effectively removes dust and debris from difficult-to-access areas, preventing dirt build-up.

The key is to select equipment appropriate for the task and the specific environment. Safety training on how to safely use these tools is also paramount. For example, when working at heights with telescopic poles, using appropriate safety harnesses and securing the area is vital.

Q 28. How do you maintain a clean and organized work environment?

Maintaining a clean and organized work environment is not just about aesthetics; it’s crucial for safety, efficiency, and professionalism. My approach includes:

- 5S Methodology: I utilize the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize our workspace. This involves regularly decluttering, storing supplies in designated areas, and keeping equipment clean and ready for use.

- Designated Storage Areas: We have designated areas for cleaning supplies, equipment, and waste materials, clearly labeled to prevent clutter and ensure items are easily accessible.

- Regular Cleaning: In addition to the cleaning work we do for clients, we also maintain a high level of cleanliness in our own workspace, regularly cleaning equipment, floors, and common areas.

- Regular Equipment Check: A regular check of equipment and supplies helps prevent problems and allows us to fix small issues promptly, before they become major disruptions.

- Waste Management: We employ a proper system for disposing of cleaning chemicals and other waste, following all relevant environmental regulations.

A well-organized workspace leads to improved efficiency, reduces the risk of accidents, and sets a professional example for our clients.

Key Topics to Learn for Experience with Cleaning Chemicals and Equipment Interview

- Understanding Chemical Safety: Knowing how to safely handle, store, and dispose of various cleaning chemicals, including understanding SDS sheets (Safety Data Sheets) and relevant safety regulations.

- Equipment Operation and Maintenance: Demonstrating proficiency in using various cleaning equipment such as floor buffers, vacuum cleaners, pressure washers, and carpet extractors; including their proper maintenance and troubleshooting basic malfunctions.

- Cleaning Techniques and Methods: Understanding different cleaning methods for various surfaces (e.g., tile, carpet, wood, glass) and selecting appropriate chemicals and equipment for optimal results. This includes knowledge of sanitation protocols.

- Effectiveness and Efficiency: Demonstrating an understanding of how to clean effectively and efficiently, minimizing chemical usage and maximizing results. This includes understanding time management and prioritization in a cleaning setting.

- Stain Removal and Treatment: Knowing how to identify and treat various stains using appropriate methods and chemicals, understanding the limitations of certain cleaning agents.

- Environmental Awareness: Demonstrating knowledge of environmentally friendly cleaning practices, including the selection of eco-friendly products and waste reduction strategies.

- Infection Control: Understanding and applying appropriate cleaning and disinfection procedures to prevent the spread of infections, especially relevant in healthcare or food service settings.

Next Steps

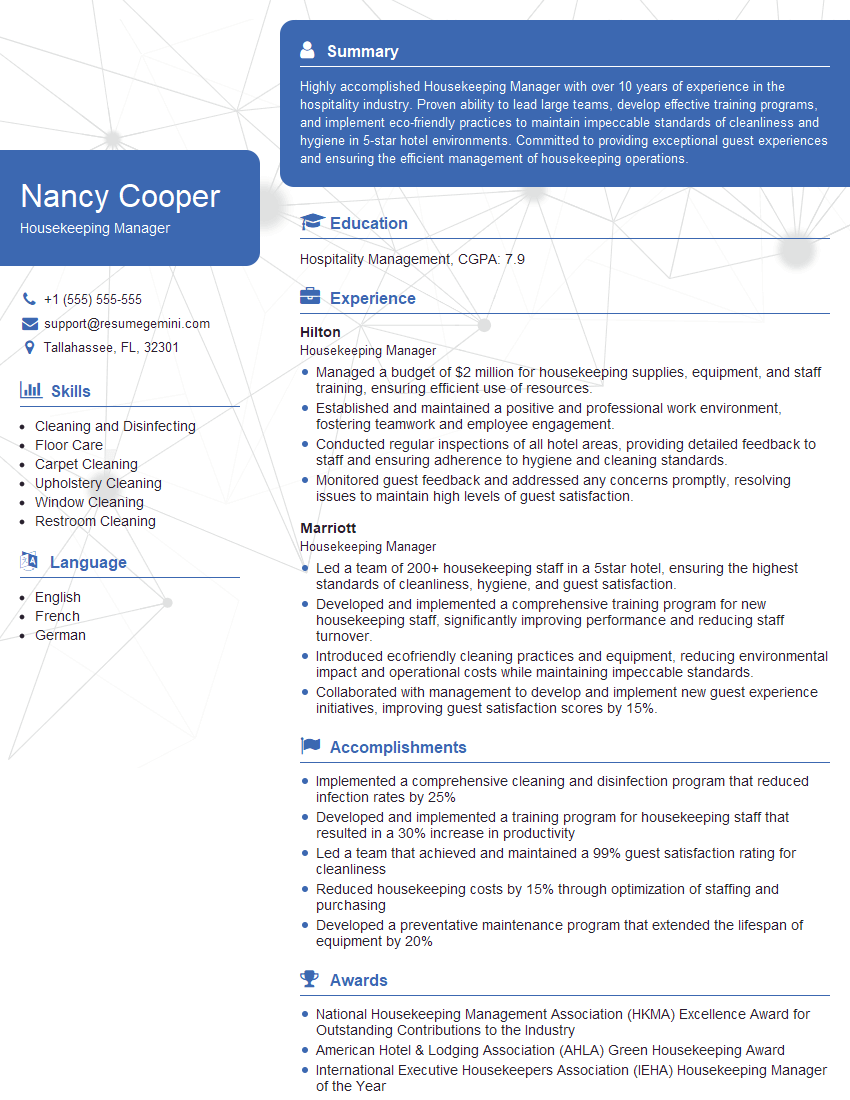

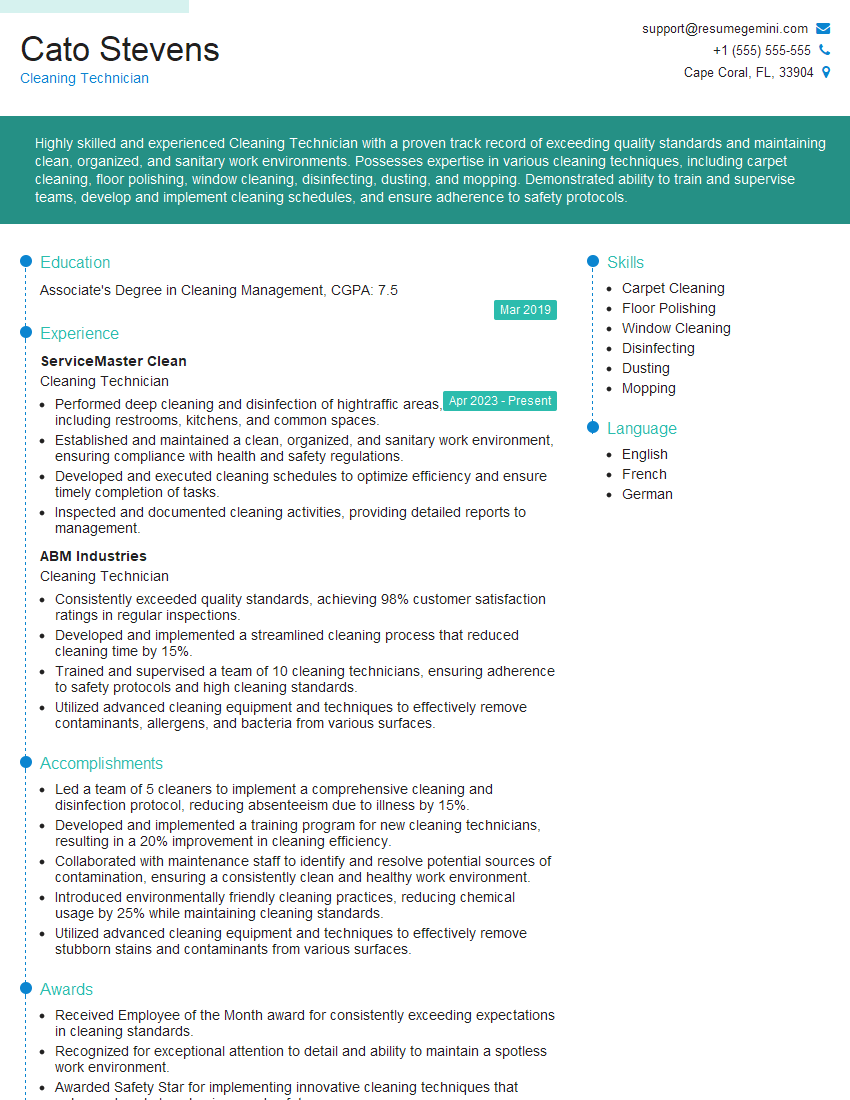

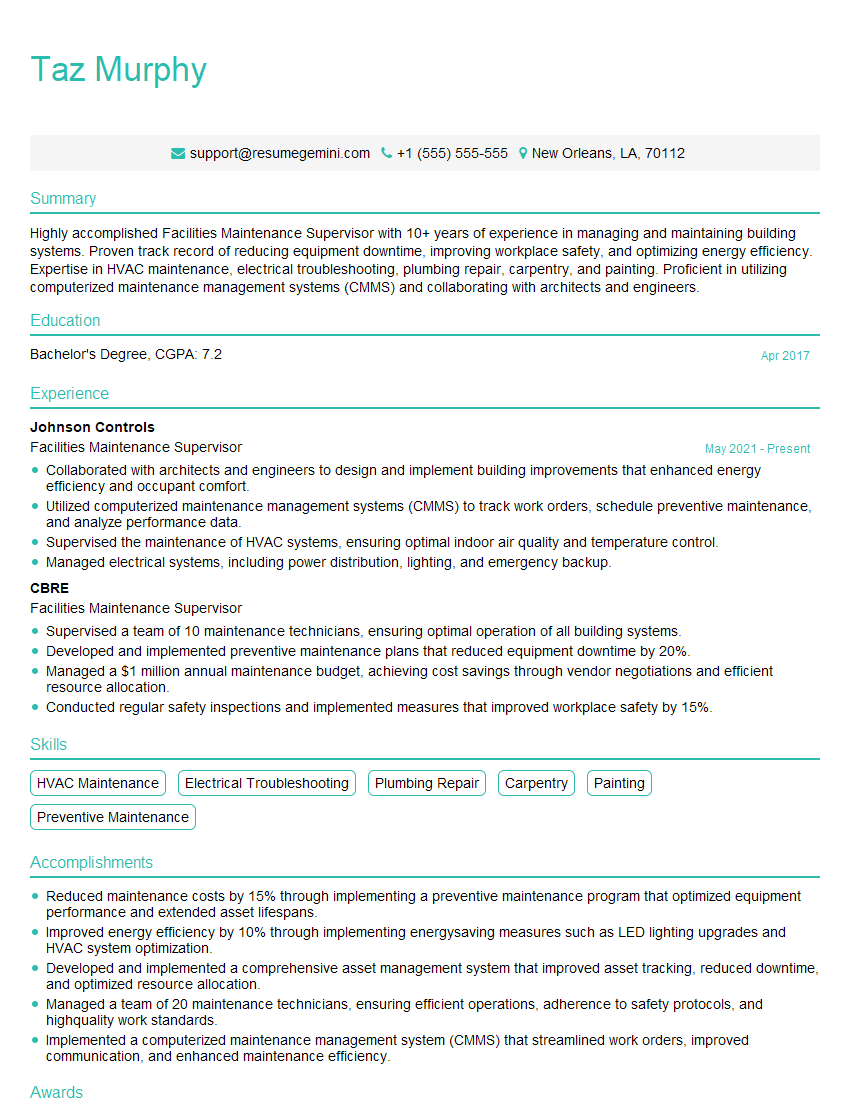

Mastering experience with cleaning chemicals and equipment significantly enhances your employability across various sectors, from hospitality and healthcare to commercial and industrial cleaning. A strong understanding of these topics demonstrates professionalism, safety awareness, and technical competence – all highly valued by employers. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to highlight your cleaning expertise. Examples of resumes specifically designed for roles emphasizing experience with cleaning chemicals and equipment are available to guide you. Invest in your future – build a winning resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO