Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Experience with using cleaning equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Experience with using cleaning equipment Interview

Q 1. What types of cleaning equipment are you proficient with?

My proficiency extends to a wide range of cleaning equipment, encompassing both manual tools and powered machinery. I’m experienced with various vacuum cleaners (upright, canister, backpack), floor buffers (both high-speed and low-speed), carpet extractors, pressure washers, high-reach pole systems, and various cleaning solutions application tools. I also have experience with specialized equipment like scrubbers and automatic floor sweepers, depending on the specific cleaning requirements of the job.

- Vacuum Cleaners: I can efficiently operate and maintain various types, adapting my technique to different floor surfaces and debris.

- Floor Buffers: I’m comfortable using different buffer pads (e.g., high-gloss, stripping, scrubbing) to achieve desired finishes.

- Carpet Extractors: I understand the intricacies of pre-treatment, extraction, and post-cleaning processes for optimal results.

- Pressure Washers: I’m adept at using these for both exterior and interior cleaning, following safety protocols diligently.

- High-Reach Equipment: I can safely and effectively clean hard-to-reach areas such as high ceilings and windows.

Q 2. Describe your experience with operating a floor buffer.

Operating a floor buffer requires precision and understanding of its capabilities. My experience involves using both rotary and orbital buffers, selecting the appropriate pad based on the floor type and the desired outcome. Before starting, I always inspect the buffer for any damage or loose parts. I begin with a low speed and gradually increase it as needed, ensuring even pressure and overlapping passes to avoid streaking. I’m mindful of the floor’s condition and adjust my technique accordingly to prevent damage. For example, I use a stripping pad with a low-speed buffer for removing old wax buildup, followed by a clean-up and polishing with a high-gloss pad and a high-speed buffer for a beautiful, reflective finish. Safety is paramount; I always ensure the area is clear of obstacles and individuals before operating the equipment.

In one instance, I used a floor buffer to restore the shine to a large marble floor in a high-traffic lobby. By carefully selecting the appropriate pads and adjusting the speed, I achieved a brilliant polish without damaging the delicate marble surface. This was achieved by first stripping the old wax layer, then cleaning thoroughly, before applying a new layer of wax and polishing.

Q 3. How do you maintain and troubleshoot a vacuum cleaner?

Maintaining and troubleshooting a vacuum cleaner is crucial for its longevity and efficiency. Regular maintenance includes emptying the dustbin or bag, checking and cleaning the filters (HEPA and pre-motor), and inspecting the belts and brushes for wear and tear. I also regularly check the hoses and attachments for blockages.

Troubleshooting common issues such as reduced suction often involves checking for blockages in the hose, dustbin, or filters. A clogged filter severely reduces suction. A faulty belt can also cause the brush roll to stop functioning correctly. In such cases, I’ll replace the belt or brush roll as needed. If the problem persists, I’d consult the vacuum cleaner’s manual or contact a repair technician.

For instance, in a previous role, I noticed a decrease in suction in one of our upright vacuums. After systematically checking all components, I identified a severely clogged filter that was restricting airflow. Replacing the filter restored the vacuum to full functionality. I always document maintenance and repairs to keep track of equipment performance and potential issues.

Q 4. What safety procedures do you follow when using cleaning chemicals?

Safety is my top priority when handling cleaning chemicals. I always read and follow the manufacturer’s instructions carefully, paying close attention to safety precautions, dilution ratios, and Personal Protective Equipment (PPE) requirements. This typically includes wearing gloves, eye protection, and sometimes a respirator, depending on the chemical and the environment. I ensure adequate ventilation in the area to prevent inhalation of fumes, and I never mix different cleaning chemicals as this can create dangerous reactions. I store chemicals properly, keeping them out of reach of unauthorized personnel and in their original containers with labels intact. Spills are immediately cleaned and neutralized according to the manufacturer’s guidelines, and all equipment used for cleanup is thoroughly rinsed. In case of accidental exposure or ingestion, I immediately follow established emergency procedures, seeking medical attention if necessary.

Q 5. Explain your experience with carpet extraction equipment.

My experience with carpet extraction equipment includes operating and maintaining both portable and truck-mounted extractors. I’m familiar with the entire process, from pre-treating the carpet with appropriate cleaning solutions to the extraction process itself. This involves carefully maneuvering the machine to ensure even saturation and thorough cleaning without over-wetting the carpet. I understand the importance of proper rinsing and using appropriate techniques to minimize drying time and prevent mildew. After each use, I thoroughly clean and maintain the machine, emptying the recovery tank, cleaning the filters, and inspecting the hoses for blockages. I always choose the right cleaning solutions based on the type of carpet and stain and properly adjust the settings of the machine for optimal performance. For example, in dealing with pet stains, a specialized enzyme cleaner would be employed followed by a thorough extraction.

Q 6. How do you safely operate a pressure washer?

Operating a pressure washer safely requires careful attention to detail. Before starting, I always inspect the machine for any damage or leaks. I ensure the nozzle is correctly attached and select the appropriate nozzle tip for the task. I always wear appropriate safety gear, including eye protection, gloves, and closed-toe shoes. I maintain a safe distance from the surface being cleaned to avoid damage or injury. I start with a lower pressure and gradually increase it as needed, working in controlled sweeps to prevent damage and ensure even cleaning. I never point the nozzle at myself or others. After use, I always shut off the power, release the pressure, and carefully store the equipment in a safe place, ensuring it is properly cleaned and maintained. Cleaning the nozzle and filters regularly prevents build-up.

For instance, I once used a pressure washer to clean a heavily soiled patio. I started with a low pressure and used a wide-angle nozzle to remove loose debris before switching to a higher pressure and a more focused nozzle to clean stubborn stains. This systematic approach ensured thorough cleaning while protecting the patio’s surface.

Q 7. Describe your experience with high-reach cleaning equipment.

My experience with high-reach cleaning equipment involves using telescopic poles and extension wands for cleaning high windows, ceilings, and other hard-to-reach areas. I am proficient in safely assembling and disassembling these systems, attaching appropriate cleaning tools such as brushes, squeegees, and microfiber cloths. I understand the importance of maintaining proper balance and stability when using these systems, avoiding overreach, and adhering to all safety regulations. Before starting, I carefully assess the area to identify potential hazards and plan my approach accordingly. I always use appropriate safety harnesses and fall protection when working at heights. Proper cleaning technique involves using overlapping strokes and maintaining even pressure to avoid streaks and ensure thorough cleaning. Regular inspection and maintenance of the equipment, including checking for loose parts and ensuring proper functionality, are crucial for safe and efficient operation.

Q 8. What are the different types of cleaning solutions and their applications?

Cleaning solutions are broadly categorized by their chemical composition and intended use. Choosing the right one is crucial for effective and safe cleaning.

- All-purpose cleaners: These are versatile solutions for general cleaning, often containing surfactants to lift dirt and grime. Think of your everyday kitchen cleaner – it’s designed to handle a range of surfaces but might not be powerful enough for heavy-duty tasks.

- Disinfectants: These solutions kill or inactivate microorganisms like bacteria and viruses. They’re essential in healthcare settings, food preparation areas, and anywhere hygiene is paramount. Bleach solutions are a common example, but others use different active ingredients like quaternary ammonium compounds.

- Degreasers: Specifically formulated to break down and remove grease and oil, these are vital in commercial kitchens, automotive workshops, and industrial settings. They often contain strong solvents.

- Acid cleaners: Used to remove mineral deposits, rust, and hard water stains. They’re powerful and should be used cautiously, always following manufacturer instructions. Examples include solutions containing phosphoric or citric acid.

- Alkaline cleaners: Effective at cutting through grease and grime, but gentler than acid cleaners. These are frequently used in dishwashing and laundry applications.

The choice depends on the specific cleaning task and the surface being cleaned. Always check the manufacturer’s recommendations for safe and effective use.

Q 9. How do you determine the appropriate cleaning solution for a given surface?

Determining the appropriate cleaning solution involves considering several factors:

- Surface material: Porous surfaces like wood or stone require different treatment than non-porous surfaces like glass or metal. Harsh chemicals can damage some materials.

- Type of soil: Grease, grime, dirt, or biological contaminants necessitate different cleaning approaches. A degreaser would be useless against a mold infestation.

- Desired level of cleanliness: General cleaning might require an all-purpose cleaner, whereas a sterile environment necessitates a disinfectant.

- Safety considerations: Always prioritize safety by selecting solutions appropriate for the environment and avoiding harmful chemical interactions.

For example, I’d use a mild, pH-neutral cleaner for delicate wood furniture, but a stronger degreaser for a heavily soiled kitchen floor. Always test any cleaning solution on an inconspicuous area first to check for compatibility.

Q 10. Describe your experience with industrial cleaning equipment.

My experience encompasses a wide range of industrial cleaning equipment, including:

- Floor cleaning machines: Automatic scrubbers, buffer polishers, and sweepers. I’m proficient in operating and maintaining these machines, ensuring optimal performance and efficiency.

- High-pressure washers: I have extensive experience using these for heavy-duty cleaning, adhering strictly to safety procedures to prevent injury and damage. Understanding water pressure and nozzle selection is crucial for effective cleaning without damaging surfaces.

- Vacuum cleaners: From standard wet/dry vacuums to specialized industrial models, I’m adept at selecting the right equipment for different tasks, such as removing dust, debris, or liquids.

- Steam cleaners: I’ve utilized steam cleaners for deep cleaning, disinfection, and removing stubborn stains, again emphasizing careful application to avoid damage.

I understand the importance of regular maintenance and proper operation of all equipment to maximize lifespan and safety.

Q 11. What is your experience with maintaining cleaning equipment logs?

Maintaining accurate cleaning equipment logs is critical for tracking maintenance, identifying potential issues early on, and ensuring compliance with safety regulations. My experience includes:

- Recording maintenance schedules: I meticulously document all preventative maintenance activities, such as filter changes, fluid replacements, and inspections, ensuring everything is completed on time.

- Tracking repairs and replacements: All repairs, part replacements, and service calls are documented, including dates, costs, and the nature of the repair. This allows for efficient budgeting and equipment lifecycle management.

- Maintaining inventory records: I keep track of cleaning solution stock levels and order new supplies proactively, avoiding disruptions to cleaning schedules.

- Using digital tools: I’m proficient in using various software and apps for logging and reporting. This streamlines the process and makes data easily accessible.

Thorough record-keeping allows for data-driven decision making related to equipment purchasing, maintenance budgeting, and overall operational efficiency.

Q 12. How do you ensure the safe storage of cleaning chemicals and equipment?

Safe storage of cleaning chemicals and equipment is non-negotiable. My approach includes:

- Designated storage areas: Chemicals are stored in clearly labeled, secure areas, away from incompatible substances and out of reach of unauthorized personnel. This prevents accidental mixing and minimizes safety risks.

- Proper labeling and hazard communication: All containers are clearly labeled with the chemical name, safety data sheet (SDS) information, and hazard warnings. This ensures everyone handling the chemicals is aware of the potential risks.

- Spill containment: Storage areas are designed to contain spills and prevent contamination. Absorbent materials are readily available.

- Equipment storage: Equipment is stored in a clean, dry location, protecting it from damage and ensuring it’s readily accessible when needed.

Compliance with all relevant safety regulations and company policies is paramount, and regular inspections ensure the effectiveness of our storage procedures.

Q 13. What is your experience with using specialized cleaning equipment (e.g., burnishing machines)?

I have experience operating specialized cleaning equipment such as burnishing machines. These machines are used to create a high-gloss finish on hard floor surfaces like vinyl or terrazzo. My experience includes:

- Proper machine setup: This involves selecting the appropriate pads and solutions for the specific floor type and desired finish. Incorrect setup can damage the floor.

- Safe operation: Burnishing machines are heavy and powerful; safe operation requires training and adherence to safety protocols.

- Maintenance: Regular maintenance, including pad changes and cleaning, is essential to ensure optimal performance and longevity of the machine.

- Achieving desired results: The skill lies in achieving a consistent, high-quality finish, requiring an understanding of floor preparation and the burnishing process itself.

I understand that achieving a superior, long-lasting shine requires attention to detail and precision in operation and maintenance.

Q 14. How do you handle equipment malfunctions?

Handling equipment malfunctions requires a systematic approach:

- Safety first: Always prioritize safety. If a malfunction presents a safety hazard, immediately turn off the equipment and report the issue.

- Assessment: Identify the nature of the malfunction. Is it a minor issue (e.g., clogged nozzle) or a more serious problem requiring professional repair?

- Troubleshooting: Attempt basic troubleshooting steps based on my knowledge and the equipment’s manual. This may involve checking power cords, cleaning filters, or addressing simple mechanical issues.

- Documentation: Record all aspects of the malfunction, including the date, time, problem description, troubleshooting steps, and outcome.

- Reporting: Report serious malfunctions promptly to the appropriate personnel for professional repair. This ensures the equipment is restored to safe operating condition as soon as possible.

Preventative maintenance plays a key role in reducing malfunctions. Regular checks and maintenance significantly reduce the likelihood of equipment failure.

Q 15. How do you prioritize cleaning tasks when using multiple pieces of equipment?

Prioritizing cleaning tasks with multiple equipment involves a strategic approach focusing on efficiency and safety. I use a method I call ‘Zone Cleaning,’ where I divide the area into manageable sections. First, I identify high-traffic areas requiring immediate attention (e.g., entrances, restrooms) and those with specific cleaning needs (e.g., spill cleanup). Then, I select the most appropriate equipment for each zone. For example, I might start with an industrial vacuum for large debris in a warehouse, followed by an auto scrubber for floor cleaning, and finally, a smaller, specialized vacuum for detailed cleaning of upholstery or delicate surfaces. This systematic approach ensures that I don’t waste time switching between tasks or equipment unnecessarily.

Think of it like a painter strategically selecting brushes – a large brush for broad strokes, a smaller one for details. I apply the same principle to cleaning, using the right tool for each job to maximize efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your knowledge of OSHA regulations related to cleaning equipment.

My understanding of OSHA regulations concerning cleaning equipment is extensive. I’m well-versed in regulations concerning personal protective equipment (PPE), including the mandatory use of safety glasses, gloves, and appropriate footwear to prevent injuries from chemical exposure or equipment malfunctions. I know the importance of proper training and certification before operating machinery like floor buffers or pressure washers, understanding lockout/tagout procedures to prevent accidental starts. Regular equipment inspections, proper maintenance, and adherence to manufacturer’s guidelines are critical aspects I always observe. OSHA’s emphasis on hazard communication is paramount, ensuring I’m familiar with the safety data sheets (SDS) for all cleaning chemicals I use, and understanding proper storage and handling procedures.

For instance, I’m acutely aware of the risks associated with using high-pressure equipment and the potential for serious injury if safety protocols aren’t followed. I routinely check for leaks, damaged hoses, and ensure the equipment is properly grounded to prevent electrical shocks.

Q 17. Describe your experience with training others on cleaning equipment safety.

I’ve had considerable experience training others in cleaning equipment safety. My approach is hands-on and emphasizes practical application. I start with a thorough review of relevant OSHA standards and manufacturer’s instructions. I then demonstrate proper equipment usage, highlighting key safety features and potential hazards. Trainees participate in simulated cleaning scenarios, allowing them to practice techniques under supervision. I use a combination of visual aids like diagrams and videos, and I encourage questions and feedback throughout the training process. Finally, I administer practical exams to assess their understanding and competence before allowing them to operate the equipment independently.

One example involved training new hires at a healthcare facility. I emphasized the importance of infection control and the proper use of disinfectants when using floor cleaning equipment in a hospital setting, making sure they understood the potential risks and how to mitigate them.

Q 18. What is your experience with using different types of floor cleaning machines?

My experience with floor cleaning machines is broad, encompassing various types. I’m proficient with both ride-on and walk-behind auto scrubbers, understanding the differences in their maneuverability and cleaning capacity. I’ve operated machines with different brush types (e.g., cylindrical, disc) and have experience adjusting cleaning solutions based on the type of floor and level of soiling. I’ve also used specialized floor cleaning equipment like carpet extractors and wet/dry vacuum cleaners for detailed cleaning.

For example, in a large warehouse setting, a ride-on auto scrubber is ideal for its speed and capacity, while a smaller, walk-behind model is more suitable for navigating tighter spaces and corners. Each machine requires a different level of skill and understanding of its operational parameters for safe and effective use.

Q 19. How do you inspect cleaning equipment for safety before use?

Before using any cleaning equipment, I conduct a thorough inspection, akin to a pre-flight check for an airplane. This involves visually checking for any visible damage to cords, hoses, or the machine’s casing. I verify that all safety guards are in place and functioning correctly. I test the functionality of switches and controls, ensuring they respond appropriately. I also check fluid levels (for machines using detergents or water) and make sure the equipment is properly grounded to prevent electrical hazards. Furthermore, I inspect for any leaks, especially in machines using high-pressure water or chemicals.

If I find any defects or issues during the inspection, I immediately report them to my supervisor and refrain from using the equipment until repairs are completed. Safety is my top priority.

Q 20. How familiar are you with various types of vacuum cleaners and their features?

I have extensive familiarity with various types of vacuum cleaners. This ranges from basic upright vacuums suitable for homes to heavy-duty industrial vacuums capable of handling large amounts of debris. I understand the differences between bagless and bagged systems, recognizing their advantages and disadvantages. I’m knowledgeable about different filtration systems, including HEPA filters for allergen removal, and understand how vacuum power and suction are affected by filter clogging. Furthermore, I’ve worked with specialized vacuums such as wet/dry vacs for handling spills and carpet extractors for deep cleaning carpets and upholstery.

Choosing the right vacuum depends heavily on the job. A powerful industrial vacuum is essential for a construction site, whereas a lightweight cordless model might be better suited for quick cleanup in an office.

Q 21. What is your experience with cleaning equipment in different environments (e.g., healthcare, industrial)?

My experience spans diverse environments, including healthcare, industrial, and commercial settings. In healthcare, I’ve worked with equipment designed for infection control, using disinfectants and specialized vacuums to maintain sterile environments. This involved adhering to strict protocols and using appropriate PPE. In industrial settings, I’ve dealt with heavy-duty equipment capable of handling large quantities of debris and potentially hazardous materials. Safety procedures are paramount in these settings. In commercial environments, I’ve adapted my cleaning strategies based on the type of business, considering factors such as foot traffic and specific cleaning requirements. For example, using specialized floor care equipment is crucial in retail spaces to maintain a polished image.

Adaptability is key. Each environment presents unique challenges and necessitates specialized knowledge and the ability to choose the right equipment and cleaning solutions.

Q 22. Explain your experience with using automated cleaning systems.

My experience with automated cleaning systems spans several years and various technologies. I’ve operated and maintained everything from robotic floor scrubbers and automated vacuum cleaners to high-pressure cleaning systems with integrated chemical dispensing. For instance, in my previous role at a large office complex, I was responsible for the daily operation and upkeep of three robotic floor scrubbers. These machines significantly increased cleaning efficiency, reducing cleaning time by approximately 40% compared to manual methods. I’m proficient in programming cleaning routes and optimizing cleaning parameters on various systems depending on floor type and soiling level. I also have experience troubleshooting these systems, diagnosing issues, and performing routine maintenance, such as changing brushes, filters, and batteries.

Another example involves the use of an automated window cleaning system. This involved precise calibration for optimal cleaning coverage while minimizing chemical usage. The ability to manage these systems efficiently allowed for significant time savings and improved the overall quality of cleaning.

Q 23. How do you maintain the cleanliness and hygiene of cleaning equipment?

Maintaining the cleanliness and hygiene of cleaning equipment is paramount for preventing cross-contamination and ensuring effective cleaning. My process involves a multi-step approach. After each use, I thoroughly rinse and clean all equipment parts that come into contact with cleaning solutions or surfaces. This includes mops, buckets, squeegees, and spray bottles. I then air dry or use clean cloths to dry the equipment, preventing mold and bacteria growth. For more intricate machinery, I follow the manufacturer’s instructions for cleaning and disinfection, often utilizing specialized cleaning solutions recommended for the specific equipment type. Regular checks and maintenance schedules are in place to prevent malfunctions and ensure optimal performance. This involves examining brushes, pads, and filters for wear and tear, replacing them as needed.

For example, when cleaning a restroom with a heavy-duty automatic scrubber, I’d follow a protocol of rinsing the machine, scrubbing the brushes, changing the solution tank and ensuring the dirty water tank is emptied completely. This ensures no residue is left that could contaminate subsequent cleaning cycles. Regular checks on the brushes’ effectiveness prevents inefficient and inadequate cleaning.

Q 24. Describe your process for disposing of cleaning chemicals and waste.

Disposal of cleaning chemicals and waste is handled strictly according to local regulations and safety guidelines. All chemical containers are clearly labeled, and I always adhere to the manufacturer’s instructions for storage and disposal. Spent cleaning solutions are disposed of appropriately, often through designated waste disposal systems. Solid waste, such as soiled mops and cloths, are disposed of in sealed bags, avoiding spills or contamination. I always wear appropriate personal protective equipment (PPE) during chemical handling and waste disposal, including gloves, eye protection, and protective clothing. Safety data sheets (SDS) for all cleaning chemicals are readily accessible and carefully reviewed before each use.

For example, in a large facility, we used a color-coded system to distinguish cleaning solutions and their appropriate disposal containers. This clear system helped to minimize the risk of accidental mixing or improper disposal. We also kept a detailed log of chemical use and disposal, which made it easy to monitor the usage of chemicals and maintain compliance with environmental regulations.

Q 25. How do you ensure the efficient use of cleaning supplies and equipment?

Efficient use of cleaning supplies and equipment is a key element of my approach. This involves careful planning and preparation. Before starting a cleaning task, I assess the area to determine the necessary supplies and equipment, avoiding overstocking or unnecessary material usage. I use the appropriate cleaning tools and chemicals for the specific task, ensuring targeted cleaning that minimizes waste. I measure and use the correct amount of chemicals as recommended by the manufacturer to prevent overuse and reduce environmental impact. I also regularly inspect equipment for optimal operation; well-maintained machinery reduces the amount of effort and supplies needed to achieve the best results.

For instance, when cleaning a large carpeted area, I would use a vacuum cleaner with appropriate attachments and select a cleaning solution tailored for carpets. This reduces the risk of damaging the carpet and prevents the use of unnecessary cleaning agents.

Q 26. What is your experience with troubleshooting common cleaning equipment problems?

Troubleshooting cleaning equipment problems is a regular part of my work. My approach is systematic, starting with a visual inspection to identify the source of the problem. If it’s a minor issue, such as a clogged filter or a loose part, I can usually fix it immediately. If the problem is more complex, I consult the equipment’s manual or contact the manufacturer for support. I keep a detailed log of equipment maintenance, repairs, and troubleshooting to proactively address recurring issues. My experience with various cleaning equipment types allows me to quickly diagnose and resolve most common problems.

For example, if a vacuum cleaner loses suction, I would first check the dust bag or filter for clogging, then examine the hoses for blockages. If the issue persists, I might check the motor or belts.

Q 27. What are some common safety hazards associated with cleaning equipment, and how do you mitigate them?

Cleaning equipment presents various safety hazards. Electrical shocks from faulty equipment are a significant concern, requiring regular inspection of cords, plugs, and the equipment itself. Chemical burns and inhalation hazards require careful handling of cleaning solutions, including the use of PPE, adequate ventilation, and following the manufacturer’s safety guidelines. Moving parts in machinery pose a risk of injury, necessitating careful operation and regular maintenance to prevent malfunctions. Sharp objects, such as broken glass or sharp edges on tools, can lead to cuts and injuries. To mitigate these risks, I always prioritize safety. I conduct thorough equipment inspections before use, wear appropriate PPE, and follow established safety protocols.

For example, when using a pressure washer, I would always ensure the area was clear of bystanders, wear protective eyewear and gloves, and use the equipment only as instructed by the manufacturer to prevent injury.

Q 28. How do you adapt your cleaning techniques and equipment choices to different types of surfaces and materials?

Adapting cleaning techniques and equipment choices to different surfaces and materials is crucial for effective and damage-free cleaning. I select cleaning solutions and tools that are compatible with the surface material. For example, I use different cleaning agents for delicate materials like marble compared to resilient materials such as sealed concrete floors. I also adjust the cleaning technique based on the surface texture and the level of soiling. Delicate materials require gentle cleaning methods, whereas more robust surfaces can withstand more aggressive cleaning. I avoid using abrasive tools or chemicals that could damage surfaces. My familiarity with various cleaning equipment and techniques allows me to achieve optimal results while protecting the surfaces I’m cleaning.

For example, cleaning a wooden floor would involve using a pH-neutral cleaner and a microfiber mop to avoid scratching the surface, while cleaning a tile floor might involve a more robust cleaning solution and a stronger scrubbing pad.

Key Topics to Learn for Experience with using cleaning equipment Interview

- Types of Cleaning Equipment: Understanding various equipment like vacuum cleaners (upright, canister, robotic), floor scrubbers, pressure washers, carpet cleaners, and specialized cleaning tools (e.g., window cleaning tools, detailing equipment). Knowing their applications and limitations is crucial.

- Safe and Effective Operation: Demonstrate knowledge of safety protocols, including proper use of personal protective equipment (PPE), safe handling procedures, and understanding potential hazards associated with each type of equipment. This includes maintenance and troubleshooting basics.

- Cleaning Agent Knowledge: Familiarity with different cleaning solutions, their appropriate uses (e.g., disinfectants, degreasers, all-purpose cleaners), and safe handling/storage practices. Understanding the environmental impact of different cleaning agents is a plus.

- Cleaning Techniques and Methods: Discuss various cleaning techniques for different surfaces (e.g., hardwood floors, carpets, tile, glass) and the best equipment choices for each. This includes understanding the importance of pre-treatment, appropriate cleaning solutions, and post-cleaning procedures.

- Maintenance and Troubleshooting: Show your understanding of routine equipment maintenance (e.g., emptying dust bags, changing filters, cleaning brushes) and basic troubleshooting skills (e.g., identifying common malfunctions, performing minor repairs).

- Efficiency and Productivity: Highlight your ability to work efficiently and productively, optimizing cleaning processes, and managing time effectively to meet deadlines. Demonstrate understanding of time management principles within a cleaning context.

- Environmental Awareness: Discuss your understanding of environmentally friendly cleaning practices, including the use of sustainable cleaning products and waste reduction strategies.

Next Steps

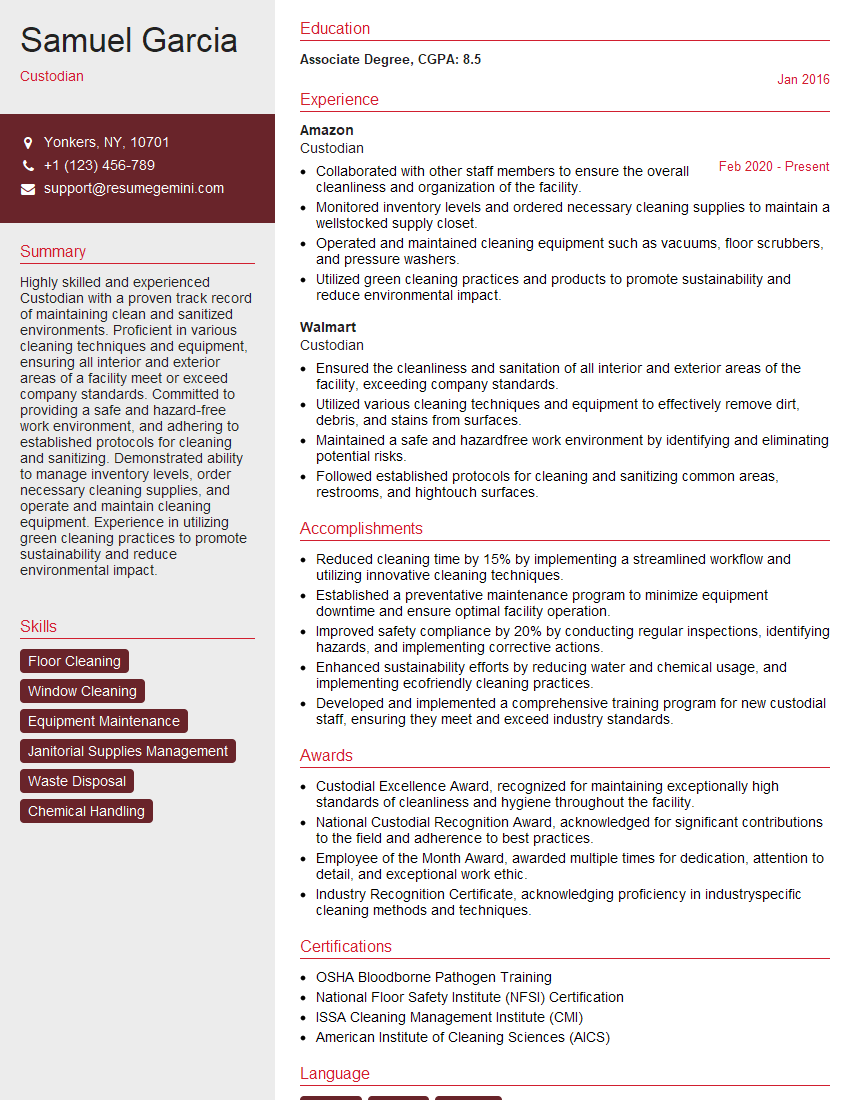

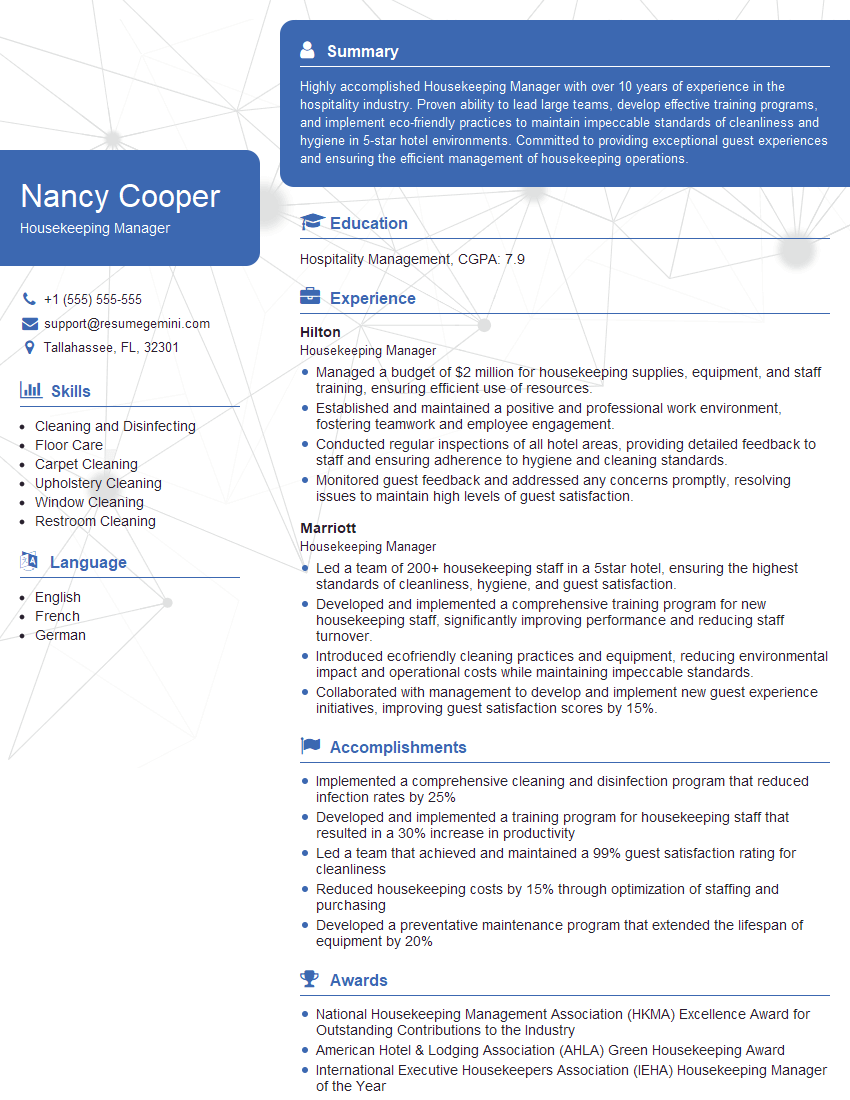

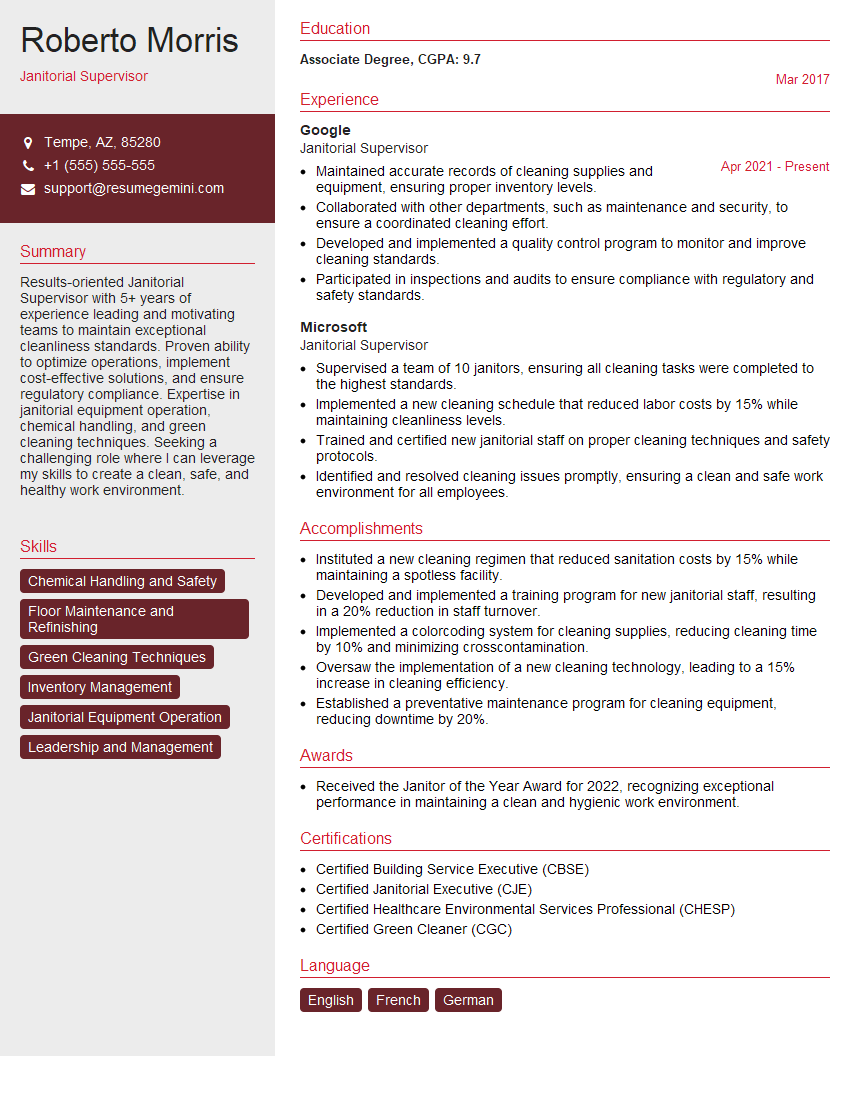

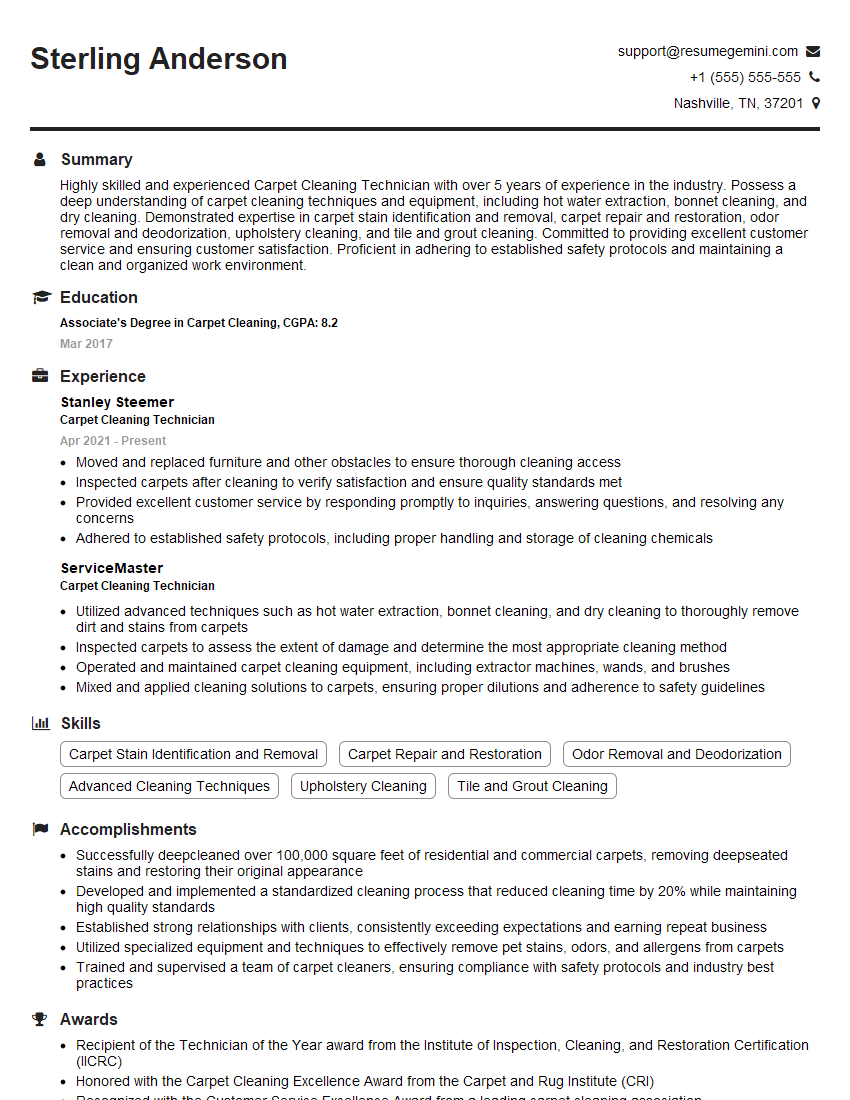

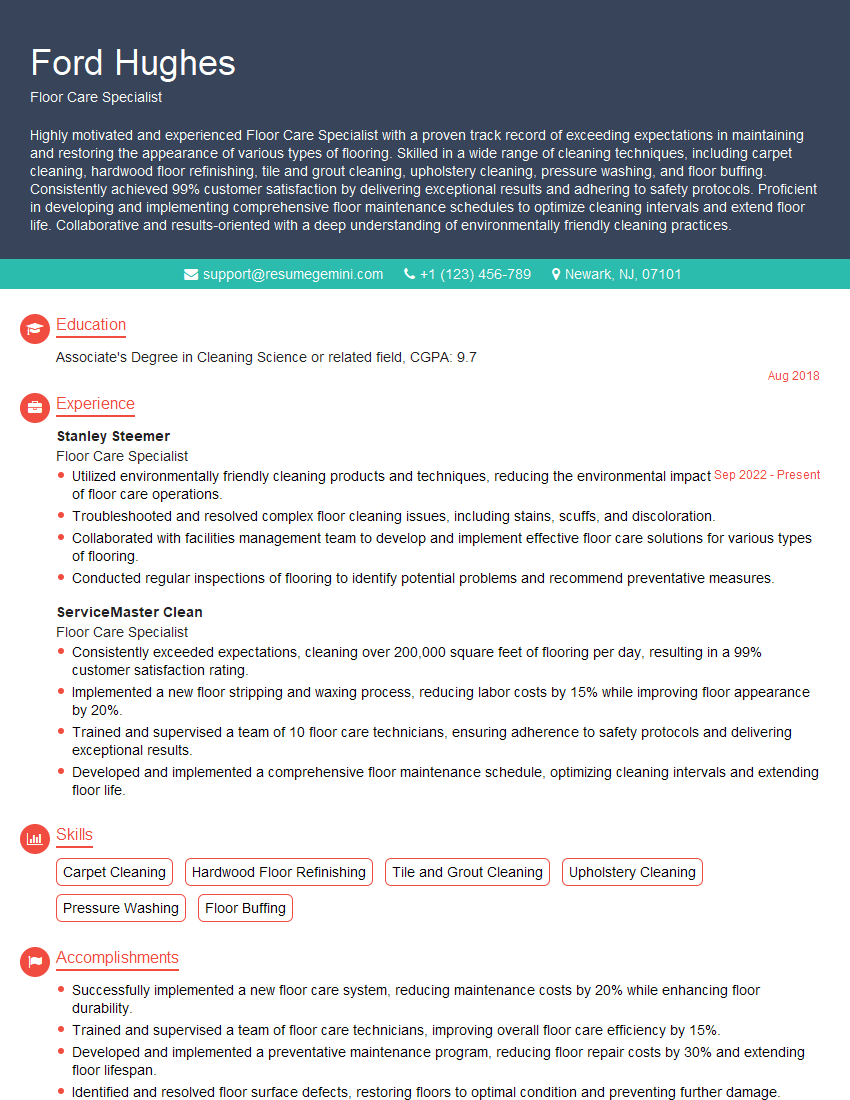

Mastering the use of cleaning equipment is vital for career advancement in various industries, from hospitality and healthcare to commercial cleaning and facilities management. A strong resume showcasing your skills and experience is essential for securing your ideal role. Creating an ATS-friendly resume significantly improves your chances of getting noticed by recruiters. To build a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini offers a powerful toolset and provides examples of resumes tailored to showcasing experience with using cleaning equipment, helping you present your qualifications effectively to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO