Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of aircraft cabin cleaning procedures interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of aircraft cabin cleaning procedures Interview

Q 1. What are the different types of cleaning agents used in aircraft cabin cleaning?

Aircraft cabin cleaning utilizes a variety of cleaning agents, carefully selected for their effectiveness and safety. The choice depends heavily on the surface being cleaned and the type of soil.

- Multi-purpose cleaners: These are typically diluted and used on many surfaces, but must be compatible with the materials in the cabin (e.g., avoiding harsh chemicals on leather or fabrics). They often contain disinfectants to kill germs.

- Specialized cleaners: For tougher stains on carpets and upholstery, specialized enzyme cleaners or stain removers are employed. These are formulated to break down organic matter like food and drinks.

- Glass cleaners: Streak-free glass cleaners are vital for maintaining clear windows and mirrors. These are usually ammonia-based but there are ammonia-free alternatives available that are safer for the environment and crew.

- Bathroom cleaners: Powerful disinfectants and deodorizers are used in lavatories to tackle the unique challenges posed by this high-traffic area. These are often chosen to combat bacteria and odors effectively.

- Degreasers: For removing grease and grime from galley areas and other high-traffic spots, specialized degreasers are necessary. These are typically powerful but require thorough rinsing.

It’s crucial that all cleaning agents are approved for use in aircraft cabins and meet the airline’s safety and environmental standards. Improper use can damage surfaces or harm passengers and crew.

Q 2. Explain the proper procedure for cleaning aircraft lavatories.

Cleaning aircraft lavatories is a critical task due to the high potential for contamination. It requires a meticulous and systematic approach.

- Preparation: Don personal protective equipment (PPE), including gloves and possibly a mask and eye protection. Ensure adequate ventilation if possible.

- Surface Cleaning: Begin by removing visible trash and waste. Use a suitable disinfectant cleaner (following manufacturer instructions) to thoroughly clean all surfaces: sinks, toilets, floors, walls, and counters. Pay close attention to frequently touched areas.

- Toilet Cleaning: Pay particular attention to disinfecting the toilet bowl and surrounding areas, using a dedicated toilet bowl cleaner. Allow sufficient contact time for effective disinfection.

- Waste Disposal: Empty waste receptacles, ensuring proper handling and disposal of sanitary waste and sharps, in accordance with biohazard protocols.

- Final Rinse & Dry: Rinse all surfaces thoroughly to remove all traces of cleaning agents. Wipe surfaces with clean cloths or paper towels. Use a vacuum cleaner to remove any debris or excess water from the floor.

- Deodorization: Use an approved deodorizer to eliminate odors. Avoid using strong perfumes that might trigger allergies.

- Inspection: Finally, inspect the lavatory for cleanliness and ensure all surfaces are disinfected.

Proper lavatory cleaning is essential for passenger hygiene and prevents the spread of illness.

Q 3. Describe your experience with handling biohazardous waste from aircraft cabins.

Handling biohazardous waste from aircraft cabins is a critical aspect of my job and requires strict adherence to regulations and safety procedures. I’ve undergone extensive training on proper identification, containment, and disposal of biohazardous materials.

My experience includes:

- Identification: Properly identifying biohazardous waste, such as blood, bodily fluids, and contaminated medical waste, as per the established guidelines.

- Containment: Using appropriate leak-proof containers and absorbent materials to securely contain and prevent leakage of any biohazardous substances.

- Segregation: Separating biohazardous waste from other types of waste to ensure appropriate handling and disposal.

- Documentation: Maintaining accurate records of all biohazardous waste collected, including the volume and nature of the waste, and when it was collected and disposed of.

- Disposal: Following all appropriate guidelines and regulations when handing the material over to licensed waste disposal companies.

The safety of the crew and the public is paramount. Any breach of procedure can have severe health consequences. I’ve also been involved in managing situations where there has been a spill or incident involving biohazardous material, ensuring the safety of other workers and the correct response is taken. This includes detailed reporting and potentially involving relevant authorities.

Q 4. How do you ensure compliance with safety regulations during aircraft cleaning?

Compliance with safety regulations is paramount during aircraft cleaning. We strictly adhere to guidelines set by the FAA (or equivalent regulatory body), the airline, and the cleaning product manufacturers.

These measures include:

- Use of approved cleaning agents: We only use cleaning agents that are specifically approved for use in aircraft cabins and meet all relevant safety and environmental regulations.

- PPE usage: We always use appropriate personal protective equipment (PPE), such as gloves, masks, and eye protection, to protect ourselves from potential hazards.

- Proper ventilation: We ensure adequate ventilation in the cabin during cleaning to minimize exposure to cleaning agents and other potential contaminants.

- Safe handling of equipment: We receive regular training on the safe use and maintenance of all cleaning equipment to prevent accidents.

- Emergency procedures: We are trained in emergency procedures to deal with any accidents or incidents that may occur during cleaning.

- Waste disposal: Adherence to stringent biohazard waste protocols and regulations is critical.

Regular safety briefings and training reinforce our commitment to these regulations. Failure to comply can lead to serious consequences and potentially endanger passengers and crew.

Q 5. What are the specific cleaning protocols for different aircraft surfaces (e.g., leather, fabric, metal)?

Different aircraft surfaces require specific cleaning protocols to avoid damage and maintain their appearance.

- Leather: Leather surfaces are cleaned using specialized leather cleaners that are gentle but effective. Harsh chemicals or abrasive cleaners can damage the leather’s finish. We often use a soft cloth and a gentle circular motion to clean leather seats and other surfaces.

- Fabric: Fabric surfaces require cleaning with appropriate fabric cleaners, avoiding excessive scrubbing or harsh chemicals which could cause discoloration or damage the fabric. Vacuuming is essential to remove loose debris before spot cleaning.

- Metal: Metal surfaces are typically cleaned with mild detergents and a non-abrasive cloth or sponge. Stainless steel requires special care to avoid scratches.

- Plastics and composites: Most plastics are cleaned using mild detergents and a soft cloth. Avoid abrasive materials or harsh chemicals as they can damage or discolor plastic.

- Windows: Dedicated glass cleaners are used and streak-free application is important to ensure clear visibility for passengers and crew.

Understanding these differences is crucial for preventing damage and extending the life of the aircraft’s interior.

Q 6. How do you prioritize cleaning tasks in a time-constrained environment?

In a time-constrained environment, prioritizing cleaning tasks is essential to ensure efficient turnaround times. We follow a structured approach:

- High-traffic areas first: Lavatories, galleys, and entryways are given priority, as these areas accumulate the most dirt and germs.

- Visible debris: Quickly removing large amounts of visible debris (trash, spills) improves the overall appearance and makes the subsequent cleaning more effective.

- High-touch surfaces: Armrests, seatbelts, tray tables, and handles are cleaned thoroughly as they are points of frequent contact.

- Systematic approach: We work systematically through the cabin, ensuring no area is missed. This helps prevent overlooking areas, particularly in the case of a large aircraft.

- Teamwork: Efficient teamwork and division of tasks is crucial, particularly during a tight turnaround.

Prioritization is based on hygiene, passenger experience, and regulatory compliance. We always aim to balance thorough cleaning with time constraints.

Q 7. Describe your experience with using specialized cleaning equipment (e.g., vacuum cleaners, carpet extractors).

I have extensive experience using various specialized cleaning equipment in aircraft cabin cleaning. This includes:

- Vacuum cleaners: We utilize high-powered HEPA-filtered vacuum cleaners designed for aircraft interiors to remove dust, dirt, and hair from carpets and upholstery. These are typically lightweight and maneuverable.

- Carpet extractors: For deep cleaning of carpets and upholstery, we use powerful extraction machines that inject cleaning solution and then remove it along with dirt and stains. Regular maintenance of these machines is crucial for optimal performance.

- Floor buffers: For routine floor maintenance, we may use floor buffers with appropriate pads to maintain a polished and hygienic surface.

- High-pressure cleaners: In certain areas or situations, high-pressure cleaners might be used (carefully and only on appropriate surfaces) for more intense cleaning.

Proper training and adherence to manufacturer’s instructions are essential for safe and effective operation of this equipment. Regular maintenance and inspections are equally important to ensure these machines remain functional and safe.

Q 8. How do you handle spills or other unexpected cleaning challenges in an aircraft cabin?

Handling spills in an aircraft cabin requires swift action and adherence to safety protocols. The first step is always to assess the spill – is it a simple liquid, something potentially hazardous (like bleach or a corrosive substance), or something biohazardous (blood or bodily fluids)?

For simple spills like water or soda, absorbent materials like paper towels or specialized spill kits are used. The area is thoroughly cleaned and dried to prevent slips and ensure passenger comfort. More significant spills might require specialized cleaning solutions depending on the nature of the spilled substance. Always wear appropriate personal protective equipment (PPE), including gloves and possibly eye protection.

For biohazardous spills, a completely different protocol is followed. This involves the use of designated cleaning solutions and procedures, potentially including the use of specialized equipment and the involvement of trained personnel. These procedures prioritize the safety of both cleaning staff and future passengers.

Remember, documentation is crucial. Any significant spill, regardless of its nature, should be recorded, along with the cleaning methods employed. This aids in tracking potential issues and maintaining safety records.

Q 9. What are your knowledge of various disinfectants and their appropriate use in aircraft cleaning?

Aircraft cleaning relies on a variety of disinfectants, each chosen for its effectiveness against specific types of germs and its compatibility with aircraft materials. Commonly used disinfectants include EPA-registered hospital-grade disinfectants containing quaternary ammonium compounds (quats), phenols, or chlorine-based solutions. The choice depends on the specific surface being cleaned and the type of contamination.

For example, quats are effective against a broad range of bacteria and viruses and are relatively safe for use on many surfaces. However, they might not be as effective against certain types of spores. Phenolic disinfectants are powerful but need to be handled carefully due to their potential toxicity. Chlorine-based solutions are powerful disinfectants but can be corrosive and should be used with caution and proper ventilation.

It’s critical to always follow the manufacturer’s instructions for dilution and application. Over-diluting can reduce effectiveness, while over-concentration can damage surfaces or pose health risks to cleaning personnel. Regular training on the safe and effective use of disinfectants is mandatory for all cabin cleaning staff.

Q 10. What safety precautions are crucial while using cleaning chemicals in an aircraft cabin?

Safety is paramount when using cleaning chemicals in an aircraft cabin. This necessitates the consistent use of personal protective equipment (PPE), including gloves, eye protection, and potentially respirators depending on the chemical being used. Good ventilation is crucial to minimize exposure to fumes. Cleaning staff should be trained to recognize the potential hazards associated with each cleaning solution and how to respond to spills or accidental exposure.

Proper storage of cleaning chemicals is also vital. They should be stored in designated areas, away from passenger areas and food preparation zones, and clearly labeled. The storage area must comply with all relevant safety regulations. Emergency procedures should be in place to handle spills or accidents involving chemicals. This includes knowing where to find safety data sheets (SDS) for each chemical and having access to emergency eye wash stations and showers.

Furthermore, regular safety training and refresher courses are indispensable. This ensures that cleaning personnel are aware of the latest safety protocols and can identify and mitigate potential risks effectively.

Q 11. Explain your understanding of aircraft cabin air filtration systems and their role in hygiene.

Aircraft cabin air filtration systems play a significant role in maintaining hygiene. These systems typically employ HEPA (High-Efficiency Particulate Air) filters, which are designed to remove a very high percentage of airborne particles, including dust, pollen, bacteria, and viruses. Fresh air is continuously circulated and filtered, reducing the concentration of contaminants in the cabin air.

The frequency of filter changes varies depending on the aircraft type and airline standards, but it’s typically done on a schedule to ensure optimal performance. The effectiveness of these systems contributes significantly to reducing the transmission of airborne illnesses among passengers and crew. While these systems are highly effective, they are not a substitute for proper cleaning and disinfection procedures.

Think of the HEPA filter as a highly sophisticated vacuum cleaner for the air. It significantly reduces the number of airborne particles, creating a cleaner and healthier environment. However, it’s still crucial to clean and disinfect surfaces to eliminate pathogens that are not airborne.

Q 12. How would you handle a situation where a passenger has left behind potentially hazardous materials?

Discovering potentially hazardous materials left behind by a passenger necessitates a careful and cautious approach. The first step is to secure the area and prevent any further exposure. This involves restricting access to the immediate vicinity and notifying relevant personnel, including potentially airport security or specialized hazmat teams if the substance is unknown or particularly dangerous.

The type of hazardous material dictates the next steps. For example, if it’s a suspicious package, airport security will handle it. If it’s a clearly identifiable chemical substance, the SDS (Safety Data Sheet) should be consulted to determine the appropriate handling and disposal procedures. Always wear appropriate PPE before handling any unknown substance. Documentation of the incident, including the location, the nature of the substance, and the actions taken, is crucial.

Passenger safety and the safety of the cleaning crew are paramount. Never attempt to handle a suspicious or unknown substance without proper training and equipment. The goal is to ensure the safety of everyone while adhering to all relevant safety regulations and procedures.

Q 13. What are your knowledge of OSHA and other relevant safety regulations pertaining to aircraft cleaning?

OSHA (Occupational Safety and Health Administration) regulations, along with other relevant aviation safety regulations, are paramount in aircraft cleaning. These regulations cover various aspects, including the use and handling of cleaning chemicals, proper ventilation, the use of personal protective equipment (PPE), hazard communication, emergency response procedures, and training requirements for cleaning personnel.

Specific regulations related to handling hazardous materials, biohazardous waste, and the disposal of contaminated items are also critical. Adherence to these regulations is non-negotiable and is essential to ensuring the safety of cleaning staff and the protection of the environment. Regular safety inspections and audits are often carried out to ensure compliance.

Failing to follow OSHA and other related regulations can result in serious penalties, including fines and legal action. Therefore, familiarity with these regulations is crucial for anyone involved in aircraft cabin cleaning.

Q 14. Explain the importance of following standard operating procedures (SOPs) in aircraft cleaning.

Following standard operating procedures (SOPs) is absolutely critical in aircraft cabin cleaning for multiple reasons. SOPs are detailed, step-by-step instructions designed to ensure consistency, efficiency, and, most importantly, safety. They provide a structured approach to cleaning, minimizing the risk of errors or omissions.

Following SOPs ensures that all areas of the cabin are cleaned thoroughly and consistently, reducing the spread of germs and improving hygiene standards. It also helps to maintain the structural integrity of the aircraft by preventing damage caused by incorrect cleaning methods. Furthermore, SOPs help to streamline the cleaning process, optimizing time and resource allocation.

SOPs are not merely guidelines; they are the foundation of a safe and efficient cleaning operation. Deviation from SOPs increases the risk of accidents, injuries, and potential damage to the aircraft. Regular training and refresher courses are crucial to ensure that all cleaning personnel are familiar with and understand the SOPs completely.

Q 15. How do you ensure the proper disposal of waste materials generated during aircraft cleaning?

Proper waste disposal during aircraft cleaning is crucial for hygiene and environmental compliance. We follow strict protocols, segregating waste into different categories: biohazardous waste (like used medical supplies), recyclable materials (plastic bottles, aluminum cans), and general waste. Biohazardous waste is double-bagged and sealed according to IATA regulations, clearly labeled, and handed over to authorized waste disposal companies. Recyclables are collected separately and sent to recycling facilities. General waste is disposed of in designated bins on the ground, following airport regulations. All disposal records are meticulously documented, including the type and quantity of waste, the date, and the disposal company’s confirmation.

For example, if we find a used syringe, it’s immediately placed into a puncture-resistant container, double-bagged, labeled with biohazard stickers and registered in our waste log before being handed off to the airport’s designated waste management team. This stringent process ensures safety and environmental responsibility.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience in maintaining detailed cleaning logs and records.

Maintaining detailed cleaning logs is a non-negotiable part of our process. We use a digital system that allows for real-time updates and easy access to records. Each cleaning session is documented, including the flight number, date, time, crew involved, cleaning products used, areas cleaned, any issues encountered, and the time taken. We track the effectiveness of cleaning agents and identify any trends that might indicate a need for process improvement. These logs are vital for quality control, auditing, and traceability. They also help us ensure that all cleaning procedures have been followed correctly, reducing the risk of oversight.

For instance, if a particular section of the cabin consistently shows signs of staining, the cleaning log helps us identify the type of stain, the cleaning agents used, and the result, thereby allowing us to optimize our cleaning approach for that specific area. The data gathered also helps to inform future training for the cleaning crew.

Q 17. How would you manage a team of aircraft cleaners during a busy period?

Managing a team during a busy period requires clear communication, delegation, and efficient task allocation. I use a combination of pre-planning and on-the-spot coordination. Before the rush, we establish a clear cleaning schedule based on flight arrival times and turnaround priorities. Each team member is assigned specific tasks and areas of responsibility. During peak times, I use a visual management system, like a whiteboard, to track progress, identify any bottlenecks, and quickly re-allocate resources as needed. Regular briefings ensure that everyone is updated on priorities and any changes in the schedule. Open communication fosters collaboration and a sense of shared responsibility, ensuring that we work effectively under pressure.

For example, during a major weather disruption, I’ll prioritize cleaning high-priority aircraft first, assigning my most experienced cleaners to those planes, while the others handle less urgent tasks. I’ll also communicate regularly with the ground crew and airport authorities to keep updated on flight schedules, minimizing delays and disruptions.

Q 18. What is your understanding of the different types of aircraft cabin surfaces and their specific cleaning needs?

Different aircraft cabin surfaces have distinct cleaning requirements. Galley surfaces, for instance, often require more stringent sanitation due to food preparation. These areas typically need to be disinfected regularly using EPA-registered disinfectants. Leather seats require specialized cleaners to prevent damage and maintain their finish. Carpet cleaning needs vacuuming and potentially spot treatment. The lavatories require extra attention to disinfection. For example, the use of high-pressure cleaners for removing stubborn soil, and the use of specialized toilet bowl cleaners. We need to carefully select cleaning agents based on the material to avoid damage and to maintain the aircraft’s interior aesthetics and hygiene standards. Training includes material safety data sheets (MSDS) on every chemical used to ensure the safety of my staff.

We always refer to the aircraft manufacturer’s cleaning guidelines to ensure that we use appropriate products and techniques for each surface. This understanding ensures that our cleaning protocols are not only effective but also protect the aircraft’s integrity.

Q 19. How do you identify and address potential sources of contamination in an aircraft cabin?

Identifying and addressing contamination sources is paramount. We inspect the cabin thoroughly before cleaning, looking for spills, biohazardous materials, or anything that might pose a health risk. Areas like lavatories, galleys, and seat pockets receive extra scrutiny. We also train our staff to recognize potential biohazards. Any contamination is addressed using the appropriate cleaning agents and disposal methods. We adhere to strict infection control protocols, ensuring that contaminated areas are cleaned and disinfected thoroughly, and used cleaning equipment is appropriately sanitized.

For instance, if we discover a blood spill, we follow strict biohazard procedures, using specialized cleaning solutions and personal protective equipment (PPE) to ensure complete sanitization and safe disposal of the contaminated materials. All involved crew then document the procedure in the cleaning log and report it to the relevant aviation authority.

Q 20. Describe your problem-solving skills in handling unexpected issues during aircraft cabin cleaning.

Unexpected issues are a part of the job. My approach focuses on quick assessment, problem-solving, and communication. If we encounter a major spill or equipment malfunction, I immediately assess the situation, prioritize safety, and then determine the best course of action. I involve the necessary team members, communicate any potential delays to relevant authorities, and find creative solutions to overcome the obstacle. This might involve improvising with available resources, contacting maintenance for equipment repair, or requesting additional assistance. Documentation of the issue and its resolution is essential for future reference and potential improvement in our procedures.

For example, if a cleaning machine malfunctions mid-clean, I would first ensure the safety of my team. Then I would contact maintenance, report the malfunction, and find an alternative method to clean the affected area – perhaps using manual cleaning methods until the machine is repaired. The incident and its resolution would then be documented in the cleaning logs for future review.

Q 21. What is your experience with quality control checks in aircraft cleaning?

Quality control is integral. We use a multi-layered approach. First, each cleaner is responsible for a thorough self-check of their assigned area. Then, team leads conduct random spot checks, verifying the cleanliness and adherence to procedures. Finally, a supervisor conducts a final inspection before the aircraft is released for the next flight. We utilize checklists to ensure consistency and completeness. Discrepancies or issues identified during these checks are immediately addressed, and retraining or procedural adjustments are implemented as needed. Our aim is to consistently deliver high standards of hygiene and cabin cleanliness, adhering to regulatory requirements and industry best practices.

For example, if a spot check reveals an area that needs additional cleaning, we immediately rectify the issue and follow up with the cleaner to address any training gaps or procedural misunderstandings. This continuous monitoring process helps to maintain high standards of quality and consistency in our aircraft cleaning service.

Q 22. How do you prioritize cleaning tasks based on aircraft type and flight schedule?

Prioritizing cleaning tasks hinges on understanding the aircraft type and its flight schedule. Larger aircraft like a Boeing 777 naturally require more time and resources than a smaller regional jet. A short turnaround flight (e.g., a 1-hour hop) demands speed and efficiency, focusing on high-traffic areas like lavatories, galleys, and seat areas. Conversely, an overnight flight allows for a more thorough deep clean, including detailed upholstery cleaning and carpet shampooing.

- High-Priority (All Aircraft Types): Lavatories (disinfection is paramount), galleys (food waste removal and sanitation), and seat areas (seatbelt cleaning, tray table sanitization).

- Medium-Priority (Turnaround Flights): General cabin wipe-down, trash collection, and floor vacuuming.

- Medium-Priority (Overnight Flights): Detailed upholstery cleaning, carpet shampooing, more thorough wiping and disinfecting of surfaces.

- Low-Priority (Overnight Flights): Window cleaning, more in-depth cleaning of less-used areas.

Think of it like this: a short flight is like a quick tidy-up of a room, while an overnight flight allows for a full spring cleaning. We always follow the airline’s specific cleaning checklists tailored to their aircraft and operational requirements.

Q 23. What are your knowledge of the use of personal protective equipment (PPE) during aircraft cleaning?

Personal Protective Equipment (PPE) is non-negotiable in aircraft cabin cleaning. Our safety is paramount. We always wear appropriate PPE, which typically includes:

- Gloves: Nitrile gloves are standard, offering protection against cleaning chemicals and potential biological hazards.

- Eye Protection: Safety glasses are worn to protect against splashing chemicals or debris.

- Respiratory Protection: Depending on the cleaning agent used, a respirator might be needed to protect against airborne particles or fumes. For example, when using strong disinfectants.

- Aprons: Protective aprons prevent soiling of clothing and provide an extra layer of protection.

Failing to wear appropriate PPE puts us at risk of chemical burns, exposure to infectious diseases, or even eye injuries. It’s a critical part of our job and company policy.

Q 24. How would you communicate effectively with other ground crew members and airline staff during the cleaning process?

Effective communication is the backbone of a smooth cleaning process. We use a combination of methods:

- Pre-Flight Briefing: Before commencing cleaning, the team receives clear instructions, outlining tasks, timelines, and any specific requirements from the airline. This briefing helps avoid confusion and ensures everyone is on the same page.

- Visual Communication: Whiteboards or designated communication areas are often used to track progress and communicate any challenges encountered.

- Two-Way Radios: Constant communication via two-way radios keeps the team connected, allowing for quick updates on task completion, problems, and changes in schedule.

- Post-Flight Debrief: After completion, we often conduct a short debrief to highlight successes, address challenges, and improve future cleaning operations.

Imagine a well-oiled machine – every part needs to work in sync for optimal results. Clear communication is that oil.

Q 25. What is your understanding of the importance of maintaining a clean and sanitary aircraft cabin for passenger health?

Maintaining a clean and sanitary aircraft cabin is crucial for passenger health and well-being. It’s about preventing the spread of infectious diseases, reducing allergies, and creating a pleasant environment for everyone onboard. Germs thrive in unsanitary conditions, and airplanes, with their recirculated air and numerous passengers, create the perfect breeding ground if not properly cleaned. We use hospital-grade disinfectants to eliminate pathogens and allergens, following strict protocols that ensure cleanliness in all areas.

Think about it: you wouldn’t want to sit on a dirty seat or touch a grimy tray table. A clean cabin provides peace of mind and contributes to a positive passenger experience.

Q 26. How do you adapt your cleaning strategies based on different levels of aircraft soiling?

Adapting cleaning strategies to varying levels of soiling is essential. A quick turnaround flight after a short domestic route requires a different approach than a long-haul flight from a busy international hub.

- Light Soiling: A quick wipe-down of high-touch surfaces, trash removal, and vacuuming is sufficient.

- Moderate Soiling: This might involve more thorough cleaning of seats and carpets, along with deeper disinfection of lavatories and galleys. We might use specialized cleaning solutions for tougher stains.

- Heavy Soiling: This requires a more extensive cleaning protocol, including possibly spot cleaning or shampooing carpets, deep cleaning of upholstery, and potential use of specialized equipment for stubborn stains.

We assess the soiling level upon entering the aircraft and adjust our cleaning schedule and technique accordingly. It’s about being adaptable and efficient, while always maintaining the highest standards of hygiene.

Q 27. Explain your process for reporting any damaged equipment or unsafe conditions found during aircraft cabin cleaning.

Reporting damaged equipment or unsafe conditions follows a strict procedure to ensure safety and accountability. We use a standardized reporting system, usually a digital log or a paper-based form, depending on the airline. This form typically requires us to detail:

- Location of the damage or hazard (e.g., ‘broken seat armrest in row 12, seat 3B’).

- Nature of the damage or hazard (e.g., ‘sharp edge on broken armrest poses risk of injury’).

- Photographs or videos (visual documentation is crucial for clarity).

- Time of discovery

The report is then immediately submitted to our supervisor or the designated ground crew contact. This immediate reporting allows for prompt action, preventing accidents and ensuring the safety of future passengers and cleaning personnel. Safety is our top priority, and this reporting system plays a key role in upholding that.

Key Topics to Learn for Aircraft Cabin Cleaning Procedures Interview

- Safety Regulations and Procedures: Understanding and adhering to all relevant safety regulations, including the use of Personal Protective Equipment (PPE) and hazardous material handling.

- Cleaning Agent Knowledge: Familiarity with different cleaning agents, their appropriate uses, and safe handling practices. This includes understanding environmental impact and proper disposal methods.

- Cleaning Methods and Techniques: Mastering efficient and effective cleaning techniques for various surfaces within the aircraft cabin, including upholstery, lavatories, and galleys. This also includes understanding the importance of disinfection and sanitation.

- Equipment Operation and Maintenance: Proficiency in operating and maintaining cleaning equipment, such as vacuum cleaners, floor polishers, and specialized cleaning tools. Knowing basic troubleshooting is crucial.

- Waste Management: Understanding procedures for handling and disposing of waste materials generated during the cleaning process, in accordance with airline and regulatory guidelines.

- Quality Control and Inspection: Knowledge of quality control checks and inspection procedures to ensure a consistently high standard of cleanliness and hygiene.

- Time Management and Efficiency: Demonstrating an understanding of how to efficiently clean an aircraft cabin within the allocated timeframe, prioritizing tasks effectively.

- Problem-solving and Adaptability: The ability to identify and resolve unexpected issues or challenges that may arise during the cleaning process, demonstrating flexibility and resourcefulness.

Next Steps

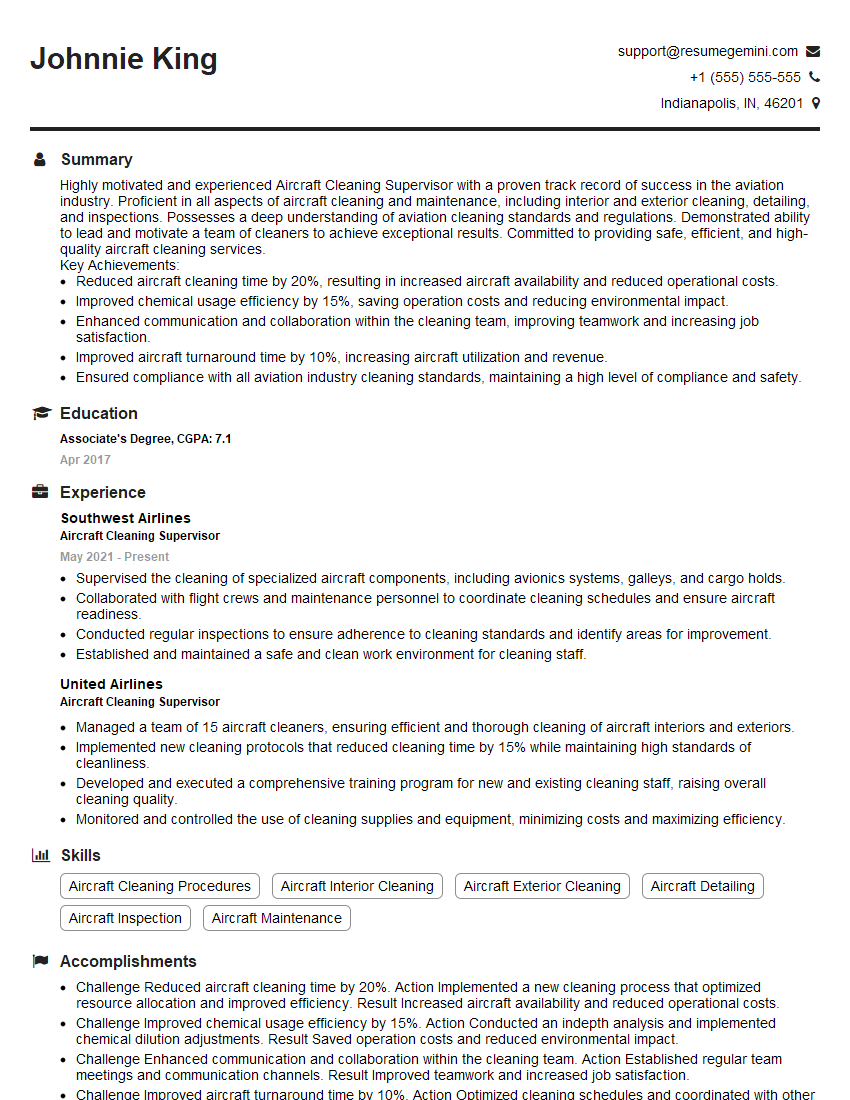

Mastering aircraft cabin cleaning procedures is vital for career progression in the aviation industry. It demonstrates your commitment to safety, efficiency, and providing a positive passenger experience. To significantly enhance your job prospects, crafting a strong, ATS-friendly resume is key. ResumeGemini can help you build a professional and impactful resume tailored to highlight your skills and experience in this specialized field. We provide examples of resumes specifically designed for candidates with Knowledge of aircraft cabin cleaning procedures to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO