The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Hazard Communication and Safety Protocols interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Hazard Communication and Safety Protocols Interview

Q 1. Explain the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon system created by the United Nations to bring consistency to the classification and communication of chemical hazards worldwide. Before GHS, different countries had vastly different systems, leading to confusion and potential safety issues when dealing with chemicals across borders. GHS aims to standardize how chemicals are classified based on their health, environmental, and physical hazards, and how that information is communicated through labels and Safety Data Sheets (SDSs).

Think of it like this: imagine trying to understand traffic signs in different countries. Some might use pictures, others words, and the meanings could vary wildly. GHS is like creating a universal set of traffic signs for chemicals, making it easier to understand the risks associated with them regardless of where you are.

- Classification: Chemicals are categorized into hazard classes (e.g., flammable, toxic, corrosive) based on standardized criteria. This involves testing and evaluating the chemical’s properties.

- Labelling: GHS specifies the elements required on chemical labels, including pictograms (symbols), signal words (Danger or Warning), hazard statements, and precautionary statements. This provides a clear and consistent warning to users about the potential hazards.

- Safety Data Sheets (SDS): GHS dictates a standardized format for SDSs, providing comprehensive information on the chemical’s properties, hazards, safe handling procedures, and emergency response measures. This detailed information allows for informed use and reduces risks.

The implementation of GHS has significantly improved chemical safety globally by creating a common language for hazard communication and reducing the likelihood of accidents and misinterpretations.

Q 2. Describe the process of developing a Safety Data Sheet (SDS).

Developing a Safety Data Sheet (SDS) is a rigorous process requiring a detailed understanding of the chemical’s properties and potential hazards. It’s not simply a matter of filling out a form; it requires thorough testing and evaluation.

- Chemical Identification: Begin by precisely identifying the chemical, including its chemical name, synonyms, CAS number (Chemical Abstracts Service Registry Number – a unique identifier), and relevant chemical formulas.

- Hazard Identification: Conduct thorough testing and evaluation to determine the chemical’s hazards. This often involves using standardized test methods and referencing existing toxicological data. This step identifies the physical, health, and environmental hazards.

- Composition/Information on Ingredients: List all the ingredients in the chemical, including their concentrations. This is crucial for understanding potential synergistic effects or interactions between components.

- First-Aid Measures: Outline the appropriate first-aid procedures in case of exposure, detailing specific actions for different routes of exposure (e.g., inhalation, skin contact, ingestion).

- Fire-Fighting Measures: Describe the appropriate fire-fighting techniques and extinguishing agents suitable for the chemical.

- Accidental Release Measures: Outline procedures to handle spills or leaks, including containment and cleanup methods.

- Handling and Storage: Provide guidelines on the safe handling, storage, and transportation of the chemical, including any special precautions.

- Exposure Controls/Personal Protection: Detail necessary engineering controls (e.g., ventilation) and personal protective equipment (PPE) needed to minimize exposure.

- Physical and Chemical Properties: Include relevant physical properties like boiling point, melting point, flammability, and reactivity data.

- Stability and Reactivity: Describe the chemical’s stability and reactivity under various conditions, including potential hazards from incompatible materials.

- Toxicological Information: Summarize the toxicity data for the chemical, indicating acute and chronic health effects.

- Ecological Information: Provide information on the environmental fate and effects of the chemical.

- Disposal Considerations: Detail procedures for the safe disposal of the chemical and its waste.

- Transport Information: If applicable, provide information on the safe transport of the chemical, according to relevant regulations.

- Regulatory Information: Include relevant regulatory information and compliance requirements.

- Other Information: Include any other relevant information, such as references and the date of preparation.

The completed SDS must be reviewed and approved by a qualified person before distribution. Regular updates are required if new information becomes available.

Q 3. What are the key elements of a comprehensive Hazard Communication Program?

A comprehensive Hazard Communication Program (HCP) is a cornerstone of workplace safety. It ensures employees are informed about the hazards present in their work environment and trained on how to handle them safely. A robust HCP encompasses several key elements:

- Hazard Identification and Assessment: This involves systematically identifying all chemical and physical hazards in the workplace through a thorough hazard assessment. This includes identifying potential exposure routes and evaluating the severity of the risks.

- Inventory of Hazardous Chemicals: Maintaining an accurate list of all chemicals used in the workplace, their locations, and relevant safety information.

- Labeling: Ensuring all containers of hazardous chemicals are properly labeled according to GHS standards.

- Safety Data Sheet (SDS) Access and Training: Providing readily accessible SDSs for all hazardous chemicals and conducting regular training on how to interpret and utilize this information.

- Employee Training: Implementing comprehensive training programs for all employees on hazard recognition, safe handling practices, and emergency procedures. This should be tailored to specific job roles and the hazards involved.

- Communication Methods: Establishing clear and effective communication channels to convey hazard information to employees. This may include meetings, written materials, and online resources.

- Record Keeping: Maintaining accurate records of chemical inventories, SDSs, training records, and any incidents involving hazardous chemicals. This provides a crucial audit trail.

- Program Review and Updates: Regularly reviewing and updating the HCP to reflect changes in the workplace, new chemicals, or regulatory updates. This ensures the program remains relevant and effective.

Think of a HCP as a comprehensive safety manual that equips your employees with the knowledge and tools to work safely. The program’s effectiveness depends on consistent implementation and active employee engagement.

Q 4. How do you ensure compliance with OSHA’s Hazard Communication Standard (HCS)?

Compliance with OSHA’s Hazard Communication Standard (HCS) is crucial for maintaining a safe work environment and avoiding penalties. It requires a multi-faceted approach:

- Implementing a Comprehensive HCP: Developing and implementing a detailed HCP that addresses all the key elements mentioned above. This is the foundation of compliance.

- GHS Compliance: Ensuring that all chemical labels and SDSs are compliant with the GHS standards. This includes using standardized pictograms, hazard statements, and precautionary statements.

- Training: Providing thorough training to all employees on hazard recognition, safe work practices, and emergency procedures. This training must be documented.

- SDS Access: Making SDSs readily accessible to all employees. This might involve a central location, online access, or a combination of both.

- Inventory Management: Maintaining an up-to-date inventory of all hazardous chemicals used in the workplace. This helps track potential exposures and facilitates accurate reporting.

- Regular Audits and Inspections: Conducting regular inspections to ensure ongoing compliance with the HCS. This includes checking labels, SDS availability, and the effectiveness of safety procedures.

- Incident Reporting and Investigation: Establishing procedures for promptly reporting and investigating any incidents involving hazardous chemicals. This allows for corrective actions to prevent future occurrences.

- Staying Updated: Staying informed about changes and updates to the HCS and GHS standards. OSHA’s website is an excellent resource for this.

OSHA compliance isn’t a one-time effort; it’s an ongoing commitment to maintaining a safe and healthy workplace. Proactive measures, consistent monitoring, and employee engagement are essential for successful compliance.

Q 5. Explain the different types of Personal Protective Equipment (PPE) and their applications.

Personal Protective Equipment (PPE) is crucial for mitigating workplace hazards. Different types of PPE are designed for specific hazards:

- Eye and Face Protection: This includes safety glasses, goggles, face shields, and welding helmets. They protect against flying particles, chemicals splashes, and intense light.

- Head Protection: Hard hats protect against falling objects, impact, and electrical hazards.

- Hearing Protection: Earplugs and earmuffs reduce noise exposure to prevent hearing loss in noisy environments.

- Respiratory Protection: Respirators protect against airborne hazards like dust, fumes, gases, and vapors. Different types of respirators offer varying levels of protection.

- Hand Protection: Gloves provide protection against cuts, abrasions, chemicals, and biological hazards. The choice of glove material depends on the specific hazard.

- Foot Protection: Safety shoes or boots protect feet from falling objects, punctures, and crushing hazards. Steel-toe boots are commonly used.

- Body Protection: This includes coveralls, aprons, and other garments that protect the body from chemical splashes, cuts, and abrasions.

Example: A worker handling corrosive chemicals would need to wear chemical-resistant gloves, eye protection, and a lab coat. A construction worker working at heights would need a hard hat and appropriate fall protection equipment.

It’s crucial to remember that PPE is a last line of defense. Engineering controls and administrative controls (e.g., ventilation, safe work procedures) should always be prioritized to minimize hazards before relying on PPE.

Q 6. What are the different types of hazards found in a workplace?

Workplace hazards are diverse and can be broadly categorized into several types:

- Physical Hazards: These are hazards that can cause physical harm, such as noise, vibration, radiation, extreme temperatures (heat or cold), slips, trips, and falls.

- Chemical Hazards: These hazards are caused by exposure to hazardous chemicals, including gases, liquids, solids, and dusts. These can cause acute or chronic health effects.

- Biological Hazards: These hazards involve exposure to biological agents like bacteria, viruses, fungi, and parasites. They can cause infections and diseases.

- Ergonomic Hazards: These hazards relate to the design of the workplace and work processes that can lead to musculoskeletal disorders. This includes repetitive movements, awkward postures, and forceful exertions.

- Psychosocial Hazards: These hazards involve workplace stressors that can affect mental health, such as workplace violence, harassment, bullying, and excessive workload.

- Fire Hazards: These involve the potential for fire or explosions due to flammable materials or faulty equipment.

- Electrical Hazards: Exposure to electrical currents can cause shocks, burns, or electrocution.

Understanding the different types of hazards is essential for conducting effective risk assessments and implementing appropriate control measures.

Q 7. How do you conduct a workplace hazard assessment?

Conducting a workplace hazard assessment is a systematic process to identify and evaluate potential hazards. A common approach involves these steps:

- Walkthrough Survey: Conduct a physical walkthrough of the workplace to visually identify potential hazards. Take photos and document observations.

- Interviews: Interview workers to gather information about their experiences and perceptions of workplace hazards. This provides valuable insights from those who work directly with the hazards.

- Review of Records: Review existing safety records, incident reports, and previous assessments. This helps identify recurring hazards and trends.

- Hazard Identification: Based on the survey, interviews, and record review, create a comprehensive list of identified hazards. Categorize them according to hazard type (as discussed in the previous answer).

- Risk Assessment: Evaluate the likelihood and severity of each hazard. This might involve a matrix or scoring system. Consider factors such as the frequency of exposure, the duration of exposure, and the potential consequences.

- Control Measures: Develop and implement appropriate control measures to eliminate or reduce the risks. Prioritize using engineering controls (e.g., machine guards), followed by administrative controls (e.g., safe work procedures), and finally, personal protective equipment (PPE) as a last resort.

- Documentation: Thoroughly document the entire hazard assessment process, including findings, risk assessments, and implemented control measures. This documentation serves as a valuable record and helps track progress.

- Review and Update: Regularly review and update the hazard assessment to reflect changes in the workplace or new information. This should be done at least annually or whenever significant changes occur.

A well-conducted hazard assessment is a proactive measure that helps prevent workplace incidents and promotes a safer working environment. Remember that employee involvement in the assessment process is key to its success.

Q 8. Describe your experience with Lockout/Tagout procedures.

Lockout/Tagout (LOTO) procedures are critical safety protocols designed to prevent the unexpected energization or startup of machinery and equipment during maintenance or servicing. My experience encompasses developing, implementing, and auditing LOTO programs across diverse industrial settings. This includes training employees on proper procedures, conducting regular inspections to ensure compliance, and investigating incidents involving LOTO violations.

For instance, in a previous role at a manufacturing plant, I oversaw the implementation of a new LOTO system for a high-speed packaging line. This involved detailed risk assessments, the creation of procedure-specific lockout devices, and comprehensive training for all maintenance personnel. We transitioned from a largely informal system to a standardized, documented process, resulting in a significant reduction in near-miss incidents. A key element was creating visually appealing, step-by-step checklists, ensuring even those with limited literacy could understand and adhere to the procedures. Each step in the process, from identifying energy sources to verifying isolation and applying lockout devices, was clearly illustrated. The system also incorporated a robust ‘challenge’ process, ensuring that only authorized personnel could release the lockouts.

My experience extends beyond simple implementation. I’ve also investigated LOTO-related incidents, identifying root causes and recommending corrective actions to prevent recurrence. This includes reviewing existing procedures, updating training materials, and implementing new safety controls. I am proficient in various lockout device types and their appropriate applications, from simple padlocks to more complex energy isolating devices.

Q 9. Explain the importance of emergency preparedness and response planning.

Emergency preparedness and response planning are paramount for minimizing the impact of unforeseen events, protecting employees, and ensuring business continuity. A robust plan anticipates various hazards, establishes clear communication channels, and outlines step-by-step procedures for handling emergencies. My experience includes developing and implementing comprehensive emergency response plans for various industries, including manufacturing, healthcare, and construction.

Imagine a scenario where a chemical spill occurs in a manufacturing facility. A well-defined emergency response plan dictates immediate actions: evacuation procedures for affected areas, containment strategies for the spill, emergency medical services notification, and communication to regulatory agencies. The plan also includes regular drills and training to familiarize employees with their roles and responsibilities during an emergency. This isn’t just about theoretical preparation; it’s about instilling a culture of safety and preparedness.

My approach focuses on a proactive, risk-based approach. We begin by identifying potential hazards through risk assessments and then develop tailored response strategies. This includes establishing clear communication protocols (e.g., using a dedicated emergency notification system), designating trained emergency response teams, and ensuring ready access to essential emergency equipment. Regularly reviewing and updating the plan based on lessons learned from incidents, drills, and changes in the workplace environment is critical. Post-incident reviews are invaluable for identifying areas for improvement and ensuring the plan’s effectiveness.

Q 10. How do you train employees on hazard communication and safety protocols?

Training employees on hazard communication and safety protocols is a continuous process that goes beyond simply delivering information; it’s about building a safety-conscious culture. My approach involves a multi-faceted strategy incorporating diverse learning methods to cater to various learning styles.

Initially, I conduct thorough needs assessments to identify specific training requirements based on job roles and potential hazards. Then, I develop training programs incorporating a mix of methods: interactive lectures, hands-on demonstrations, videos, and simulations. For example, when training on chemical handling, we might use virtual reality simulations to allow employees to safely practice emergency response procedures in a risk-free environment. We also utilize online modules for self-paced learning, allowing employees to review material at their own convenience and reinforce key concepts.

Furthermore, I emphasize practical application. Following classroom instruction, employees participate in practical exercises and drills, such as mock emergency responses or hazard identification walkthroughs. These exercises solidify their understanding and build confidence in applying their newly acquired knowledge. Regular refresher training and competency assessments ensure the ongoing effectiveness of the training. Crucially, the training includes methods for reporting hazards and near misses, fostering open communication and a collaborative safety culture.

Q 11. What is your experience with incident investigation and reporting?

Incident investigation and reporting are crucial for identifying root causes, preventing recurrence, and improving overall workplace safety. My experience includes leading investigations into various incidents, ranging from minor injuries to major accidents, adhering to rigorous investigative methodologies.

My approach follows a systematic process: First, secure the scene, ensuring the safety of all personnel. Then, I gather evidence meticulously, including witness statements, documentation, photos, and any physical evidence. Next, I analyze the gathered information to identify contributing factors, focusing on both direct and indirect causes. This is not about finding blame but about understanding the sequence of events that led to the incident. A thorough analysis might reveal systemic weaknesses in safety procedures or training gaps.

The final step involves creating a comprehensive report detailing the findings, recommendations for corrective actions, and preventative measures. This report is then used to update safety protocols, improve training programs, and implement engineering controls to mitigate similar risks in the future. For example, if an incident was caused by inadequate machine guarding, the report would recommend improvements to the guarding system and additional training on machine safety procedures. I also utilize data analysis techniques to identify trends in incidents and to proactively address emerging risks.

Q 12. Describe your experience with conducting safety inspections and audits.

Conducting safety inspections and audits is a vital aspect of proactive hazard management. My experience involves planning and executing comprehensive safety inspections and audits across various industries, identifying potential hazards, and ensuring compliance with relevant regulations and standards.

Before conducting an inspection, I develop a detailed checklist based on industry-specific regulations and the unique hazards of the worksite. The checklist covers aspects like machine guarding, personal protective equipment (PPE) usage, emergency exits, housekeeping, and chemical handling. During the inspection, I meticulously examine the workplace, noting any deviations from established safety standards and documenting findings with photos and detailed descriptions.

Following the inspection, I prepare a comprehensive report detailing identified hazards, their severity, and recommendations for corrective actions. These recommendations might range from minor adjustments to major modifications. I then follow up to ensure that corrective actions are implemented and verified. Audits are a more in-depth process, involving a systematic review of safety management systems and their effectiveness. I’m experienced in conducting audits against standards like ISO 45001, ensuring that the organization’s safety management system is robust and efficient.

Q 13. How do you identify and mitigate workplace hazards?

Identifying and mitigating workplace hazards is a continuous cycle requiring a proactive approach. My experience involves utilizing various techniques to identify hazards, assess their risks, and implement appropriate control measures.

I utilize a combination of methods, including regular safety inspections, job hazard analyses (JHAs), and hazard and operability studies (HAZOPs). JHAs systematically examine each step of a task, identifying potential hazards and the likelihood and severity of associated risks. HAZOPs are more comprehensive, involving a team-based approach to identify potential hazards in complex systems. Regular safety meetings and employee feedback also play a critical role in identifying hazards.

Once hazards are identified, I implement control measures using a hierarchy of controls, prioritizing the most effective methods. This hierarchy starts with elimination of the hazard, followed by substitution, engineering controls, administrative controls, and lastly, personal protective equipment (PPE). For instance, if a machine poses a crushing hazard, I would first explore whether the machine could be replaced with a safer alternative (substitution). If not, I would implement engineering controls like installing robust guarding (engineering controls). Administrative controls like establishing safe work procedures would complement this. PPE, like safety gloves, would be the last resort and is considered less effective than other controls because it protects the worker rather than eliminating the hazard itself.

Q 14. What is your experience with developing and implementing safety policies and procedures?

Developing and implementing safety policies and procedures requires a comprehensive understanding of relevant regulations, industry best practices, and organizational needs. My experience encompasses creating and implementing safety programs tailored to various organizations and work environments.

The process begins with a thorough risk assessment, identifying all potential hazards within the workplace. This assessment considers factors such as the likelihood and severity of each hazard, providing a basis for prioritizing control measures. Then, I develop comprehensive safety policies and procedures based on the risk assessment and relevant legal and regulatory requirements. These documents clearly define roles, responsibilities, and procedures for various aspects of safety, including emergency response, hazard reporting, and PPE usage.

Crucially, these policies and procedures need to be easily accessible and understandable to all employees. I often incorporate visual aids, simple language, and multiple communication channels to ensure understanding. Implementation involves training employees on the new policies and procedures, monitoring their adherence, and providing ongoing support. Regular review and updates are essential, incorporating feedback from employees and lessons learned from incident investigations and audits. My goal is to create a robust safety management system that integrates seamlessly into the organizational culture, fostering a proactive and safety-conscious work environment.

Q 15. How do you communicate safety information effectively to employees?

Effective hazard communication relies on a multi-faceted approach, ensuring information reaches every employee in a way they understand and can act upon. It’s not just about posting signs; it’s about creating a safety culture.

Training: Regular, engaging training sessions, tailored to different job roles and literacy levels, are crucial. We use interactive modules, videos, and hands-on demonstrations to reinforce learning. For example, I developed a training program using virtual reality simulations to demonstrate the consequences of ignoring safety procedures in a chemical handling scenario.

Clear and Concise Signage & Documentation: Safety data sheets (SDS) must be readily available and easy to understand. Signage should use clear, simple language and pictograms, especially in multilingual workplaces. I’ve personally translated SDS into several languages to enhance comprehension.

Regular Communication: Safety updates, toolbox talks, and team meetings provide opportunities for ongoing communication and address specific hazards. We use a combination of emails, posters and even informal chats to keep safety top of mind.

Feedback Mechanisms: Establishing open communication channels, such as suggestion boxes or anonymous reporting systems, empowers employees to voice concerns and contribute to a safer work environment. I implemented a system where employees could anonymously report near misses without fear of repercussions.

Personal Protective Equipment (PPE) Training: Correct PPE use is paramount. Employees must receive training on selection, fit testing, donning, doffing, and maintenance of appropriate PPE. I’ve conducted numerous fit-testing sessions for respirators, ensuring a proper seal for optimal protection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using different types of safety equipment.

My experience encompasses a wide range of safety equipment, from basic PPE to more specialized apparatus. I’m proficient in the use, maintenance, and inspection of various items.

Personal Protective Equipment (PPE): I’m experienced with all standard PPE, including safety glasses, gloves (various types for chemical resistance, cut protection, etc.), hard hats, safety shoes, hearing protection, and high-visibility clothing. I’ve frequently conducted PPE audits to ensure compliance and proper fit.

Respiratory Protection: I am trained in the selection, fit testing, and use of various respirators, including N95 masks, half-mask respirators, and full-face respirators. I’ve managed respirator programs, including proper storage, maintenance, and training on their appropriate use.

Fall Protection Equipment: I’m familiar with harness systems, lanyards, lifelines, and anchor points, ensuring their correct usage and regular inspection. I’ve led training sessions on fall protection techniques and risk assessments for working at heights.

Emergency Equipment: I am trained in the use of fire extinguishers, emergency showers, eyewash stations, and first aid kits. I am also experienced in conducting emergency drills and evacuation procedures.

Q 17. How do you manage and handle hazardous waste?

Hazardous waste management is crucial for environmental protection and worker safety. It involves a rigorous, multi-step process adhering strictly to all relevant regulations.

Segregation and Containment: Hazardous waste must be segregated according to its properties (flammable, corrosive, toxic, etc.) and stored in appropriately labeled containers. This prevents cross-contamination and potential reactions.

Proper Labeling and Documentation: Each container must be clearly labeled with the waste’s identity, hazards, and date of generation. Detailed records of waste generation, storage, and disposal must be maintained. We use a barcode system to streamline tracking.

Disposal: Disposal methods vary depending on waste type. We utilize licensed hazardous waste disposal companies for proper treatment, neutralization, and disposal according to all local, state and federal regulations. I have extensive experience in completing all the necessary paperwork and ensuring compliance.

Emergency Response: A plan should be in place to address spills and leaks promptly. This includes having appropriate absorbent materials, personal protective equipment (PPE), and trained personnel ready to respond to any incident. I’ve successfully managed several waste spills, implementing containment and cleanup procedures safely and efficiently.

Q 18. Explain your experience with different types of respiratory protection.

Respiratory protection is critical in environments with airborne hazards. Selecting the right respirator depends on the specific hazard and requires careful consideration.

Air-Purifying Respirators (APR): These filter out contaminants from the air. N95 masks are common APRs, effective against certain particles, but not all gases or vapors. I’ve led training sessions specifically on the limitations of N95 respirators.

Supplied-Air Respirators (SAR): These provide clean air from an external source, such as a compressed air tank or blower. SARs are essential when dealing with high concentrations of hazardous substances. I have experience with both airline and self-contained breathing apparatus (SCBA) systems.

Fit Testing: Ensuring a proper seal is vital for effective respiratory protection. I regularly conduct qualitative fit tests (QNFT) and quantitative fit tests (QNFT) to verify the respirator fits each employee correctly. We use a variety of methods, including the negative and positive pressure tests.

Maintenance and Inspection: Regular cleaning, inspection, and maintenance of respirators are necessary to ensure their effectiveness and longevity. I have created and implemented a detailed respirator maintenance program ensuring compliance with all relevant regulations and standards.

Q 19. What is your understanding of confined space entry procedures?

Confined space entry is inherently dangerous and requires strict adherence to established procedures. It involves potential hazards like oxygen deficiency, toxic gases, and engulfment. These spaces must be thoroughly assessed and prepared before entry.

Permit-Required Confined Space Program: A comprehensive permit system is crucial, documenting every step of the process, from pre-entry testing to post-entry monitoring. I’ve developed and managed such programs.

Atmospheric Monitoring: Before entry, the confined space’s atmosphere must be tested for oxygen levels, flammable gases, and toxic substances. Appropriate meters are used, and readings are recorded on the permit.

Ventilation: Adequate ventilation is essential to dilute or remove hazardous gases. This might involve using blowers or other ventilation equipment.

Entry Procedures: Entry teams follow a detailed procedure, including the use of appropriate PPE, standby personnel, and communication systems. Entry and exit procedures must be closely monitored.

Rescue Plan: A detailed rescue plan must be in place, outlining procedures for rescuing workers in case of an emergency. Regular rescue drills are vital.

Q 20. Explain your experience with fall protection systems.

Fall protection systems are critical for preventing injuries from falls. They need to be carefully designed, implemented, and maintained.

Fall Arrest Systems: These systems aim to stop a fall before it becomes a serious injury. They include harnesses, lanyards, shock absorbers, and anchor points. I have personally inspected and certified a variety of fall protection equipment on numerous job sites.

Fall Restraint Systems: These systems prevent falls from happening in the first place. They consist of guardrails, safety nets, and other barriers. I have been directly involved in the planning, implementation and regular inspections of these systems.

Anchor Points: Reliable anchor points are crucial to the effectiveness of fall protection systems. I’ve evaluated and approved countless anchor points, ensuring their strength and suitability for the intended use.

Inspection and Maintenance: Regular inspection and maintenance are crucial for ensuring the integrity of fall protection systems. I’ve conducted numerous inspections and ensured that damaged equipment is promptly replaced. We use a barcode system to track equipment inspections.

Training: Comprehensive training on the proper use and inspection of fall protection equipment is essential for all workers. I frequently provide hands-on training and refresher courses.

Q 21. Describe your experience working with contractors and ensuring their safety.

Working with contractors requires a proactive approach to ensure their safety aligns with our standards. Communication and collaboration are key.

Pre-qualification: Before engaging a contractor, we verify their safety records, insurance coverage, and qualifications. We require them to submit their safety plans for review.

Safety Orientation: Contractors receive a thorough orientation covering our site-specific hazards, safety rules, emergency procedures, and PPE requirements. I’ve personally conducted these orientations countless times.

Joint Safety Inspections: Regular joint safety inspections with contractors help identify potential hazards and ensure compliance with safety protocols. This fosters a collaborative approach to safety.

Incident Reporting: Contractors are required to report all incidents, near misses, and injuries promptly. We investigate all incidents to identify root causes and prevent recurrences. I’ve managed many incident investigations involving contractors.

Communication: Open and clear communication channels are maintained throughout the project. Regular meetings ensure any safety concerns are addressed immediately.

Q 22. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations requires a multifaceted approach. It starts with a thorough understanding of all applicable laws and permits relevant to the organization’s operations. This involves staying updated on changes in legislation and industry best practices.

Next, we need robust waste management procedures. This includes proper segregation, handling, storage, and disposal of hazardous materials, according to the specific regulations. Regular audits and inspections are crucial to verify adherence to these procedures. We use a checklist-based system to ensure consistency. For example, we track waste generation, ensuring proper documentation for each type of waste and the methods used for its disposal.

Furthermore, regular employee training on environmental regulations and best practices is paramount. This isn’t a one-time event; it’s an ongoing process to ensure everyone understands their responsibilities and the potential consequences of non-compliance. We utilize interactive training modules and regular refresher courses to maximize effectiveness. Finally, proactive environmental monitoring and reporting are essential to identify and address any potential issues before they become major problems. This may include regular water quality testing or air emission monitoring, depending on the specific operations.

Q 23. What is your experience with safety management systems (SMS)?

My experience with Safety Management Systems (SMS) is extensive. I’ve been involved in the implementation and management of SMS across several industries, including manufacturing and construction. I understand that a robust SMS is not just a collection of documents; it’s a living, breathing system that requires continuous improvement and adaptation.

I’m proficient in developing and implementing SMS frameworks aligned with international standards, such as ISO 45001 (Occupational health and safety management systems). This involves hazard identification and risk assessment, developing and implementing control measures, emergency preparedness planning, and regular internal audits to ensure effectiveness.

In a recent project, we implemented a new SMS in a manufacturing plant. This involved a comprehensive hazard identification and risk assessment process, leading to the implementation of new safety protocols and training programs. We tracked key performance indicators (KPIs) like incident rates and near-miss reports to measure the effectiveness of the implemented changes. The result was a significant reduction in workplace accidents and a noticeable improvement in employee morale.

Q 24. How do you measure the effectiveness of a safety program?

Measuring the effectiveness of a safety program is not simply about the number of accidents. It’s a comprehensive evaluation of the program’s impact on various aspects of safety performance. We use a variety of metrics to achieve this.

Key performance indicators (KPIs) play a central role. These include leading indicators, which predict future performance (e.g., the number of safety training hours completed, the frequency of safety inspections), and lagging indicators, which reflect past performance (e.g., the number of accidents, lost-time injuries).

We also analyze near-miss reports and employee feedback to identify areas for improvement. For instance, a consistently high number of near misses in a specific area might indicate a need for additional safeguards or retraining. Employee satisfaction surveys can reveal concerns or suggestions about safety practices. By combining quantitative data (KPIs) with qualitative data (near misses, surveys), we obtain a holistic understanding of the program’s effectiveness.

Q 25. Describe your experience with near-miss reporting and analysis.

Near-miss reporting is crucial for proactive safety management. A near miss, while not resulting in an injury, highlights potential hazards and weaknesses in the system. My experience involves establishing a robust near-miss reporting system that encourages employees to report incidents without fear of retribution.

This involves creating a clear and accessible reporting mechanism, emphasizing the importance of learning from near misses rather than blaming individuals. We use a simple online form and ensure confidentiality.

Once reports are collected, we perform a thorough analysis to identify root causes. This often involves using techniques like root cause analysis (RCA) or fault tree analysis (FTA) to determine the underlying factors that contributed to the near miss. The findings are then used to implement corrective actions, such as improving safety procedures, providing additional training, or modifying equipment. For instance, a series of near misses involving a specific piece of machinery might lead to the installation of additional safety guards or the development of a new operating procedure.

Q 26. How do you handle situations where employees are not following safety procedures?

Addressing situations where employees aren’t following safety procedures requires a multi-step approach focusing on both correction and prevention.

First, we investigate the situation to understand the reasons behind non-compliance. Is it due to lack of training, unclear procedures, inadequate equipment, or something else? Open communication with the employee is critical.

Once the root cause is identified, we take corrective action. This might involve additional training, clarification of procedures, provision of necessary personal protective equipment (PPE), or improvement of workplace conditions. If the non-compliance is due to willful disregard, progressive disciplinary action may be necessary, following established company policies. The focus is on education and correction, but consistent disregard for safety mandates requires firm action.

Finally, it’s important to update procedures or training based on the findings. This ensures that similar incidents are less likely to happen again. Regular reinforcement of safety rules and recognition of safe behaviors is key to a positive safety culture.

Q 27. Explain your approach to promoting a safety-conscious culture in the workplace.

Promoting a safety-conscious culture is paramount. It’s not just about rules and regulations; it’s about creating a workplace where safety is everyone’s responsibility. My approach is multifaceted.

Firstly, visible leadership commitment is essential. Management needs to actively demonstrate their commitment to safety by participating in safety training, leading safety meetings, and addressing safety concerns promptly.

Secondly, fostering open communication and a culture of reporting is key. Employees must feel comfortable reporting hazards or near misses without fear of reprisal.

Thirdly, we use various engagement methods – safety campaigns, team meetings, and safety newsletters. These help keep safety top-of-mind and reinforce the importance of safe work practices. We also celebrate success stories and recognize employees who demonstrate exceptional safety performance.

Regular training and reinforcement are essential for maintaining safety awareness and competency. Finally, continuous improvement is vital. Regularly reviewing safety performance data, and actively soliciting feedback from employees ensures that our safety culture remains dynamic and relevant.

Q 28. Describe your experience with data analysis related to safety performance.

Data analysis is crucial for evaluating the effectiveness of safety programs and identifying areas for improvement. My experience involves using data to inform decision-making and drive continuous improvement.

We collect data from various sources: accident reports, near-miss reports, safety inspections, and employee surveys. This data is then analyzed to identify trends, patterns, and potential root causes of incidents.

Statistical methods like trend analysis and regression analysis are used to identify correlations between different variables and predict future safety performance. For example, we might analyze the relationship between the number of training hours and the accident rate. Data visualization tools like charts and dashboards are used to communicate findings effectively to stakeholders.

Data analysis also helps us track the effectiveness of interventions and adjustments made to safety procedures. We can measure the impact of new training programs, changes in equipment, or modifications to safety protocols on key safety indicators. This data-driven approach ensures that our safety initiatives are evidence-based and yield tangible improvements.

Key Topics to Learn for Hazard Communication and Safety Protocols Interview

- Hazard Identification and Assessment: Understanding methods for identifying and evaluating workplace hazards, including chemical, biological, and physical hazards. This includes practical application of risk assessment methodologies.

- Hazard Communication Standard (HCS): Deep understanding of OSHA’s HCS, including the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), Safety Data Sheets (SDS), and proper labeling requirements. Practical application involves interpreting SDS information and applying it to real-world scenarios.

- Personal Protective Equipment (PPE): Knowledge of different types of PPE, their selection criteria based on identified hazards, proper use, limitations, and maintenance. Practical scenarios might involve selecting appropriate PPE for various tasks and explaining the rationale.

- Emergency Response Procedures: Familiarity with emergency action plans, spill response procedures, first aid and CPR, and evacuation routes. Problem-solving could involve designing a response plan for a specific workplace scenario or troubleshooting a flawed existing plan.

- Training and Education: Understanding the importance of comprehensive safety training programs for employees, including the development and delivery of effective training materials. This includes practical knowledge of various training methods and assessment techniques.

- Regulatory Compliance: Knowledge of relevant safety regulations and standards (e.g., OSHA, EPA) and the methods for ensuring compliance within a workplace. This requires understanding how to interpret and apply regulations to specific situations.

- Recordkeeping and Documentation: Understanding the importance of maintaining accurate records of safety training, incidents, and inspections. Practical applications might involve creating and maintaining compliance documentation.

Next Steps

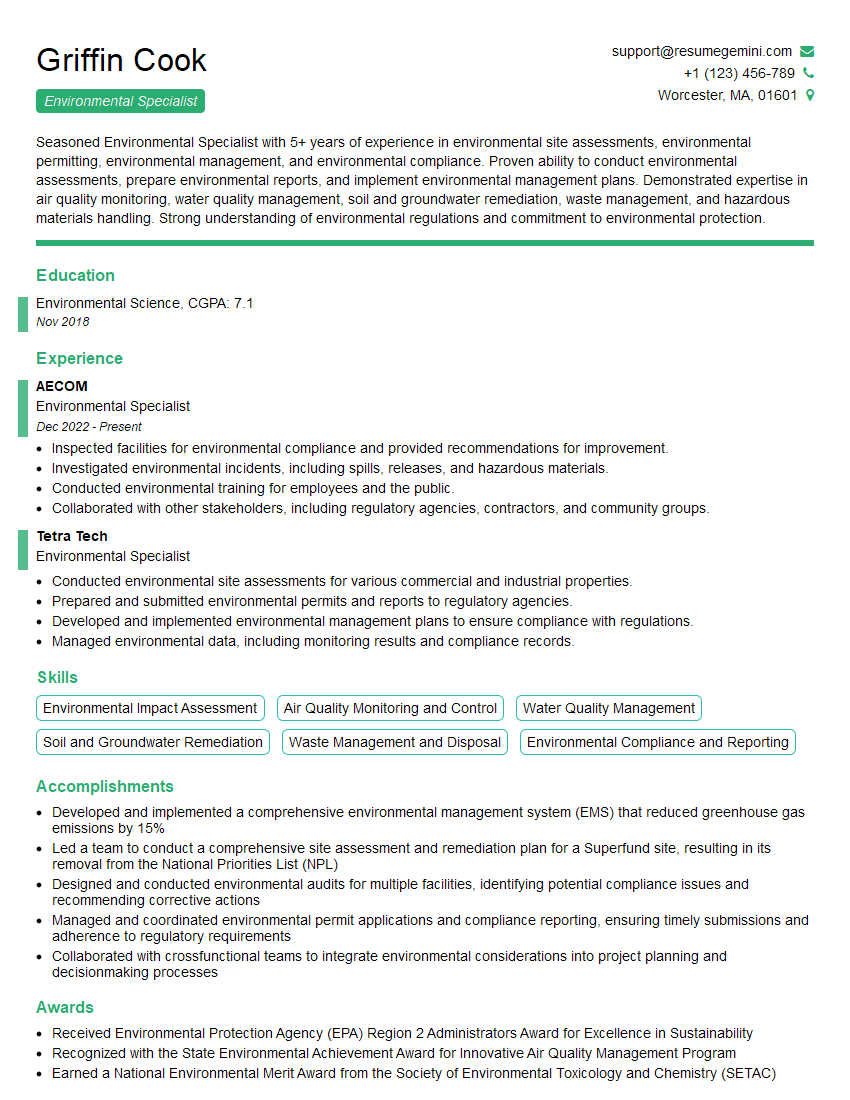

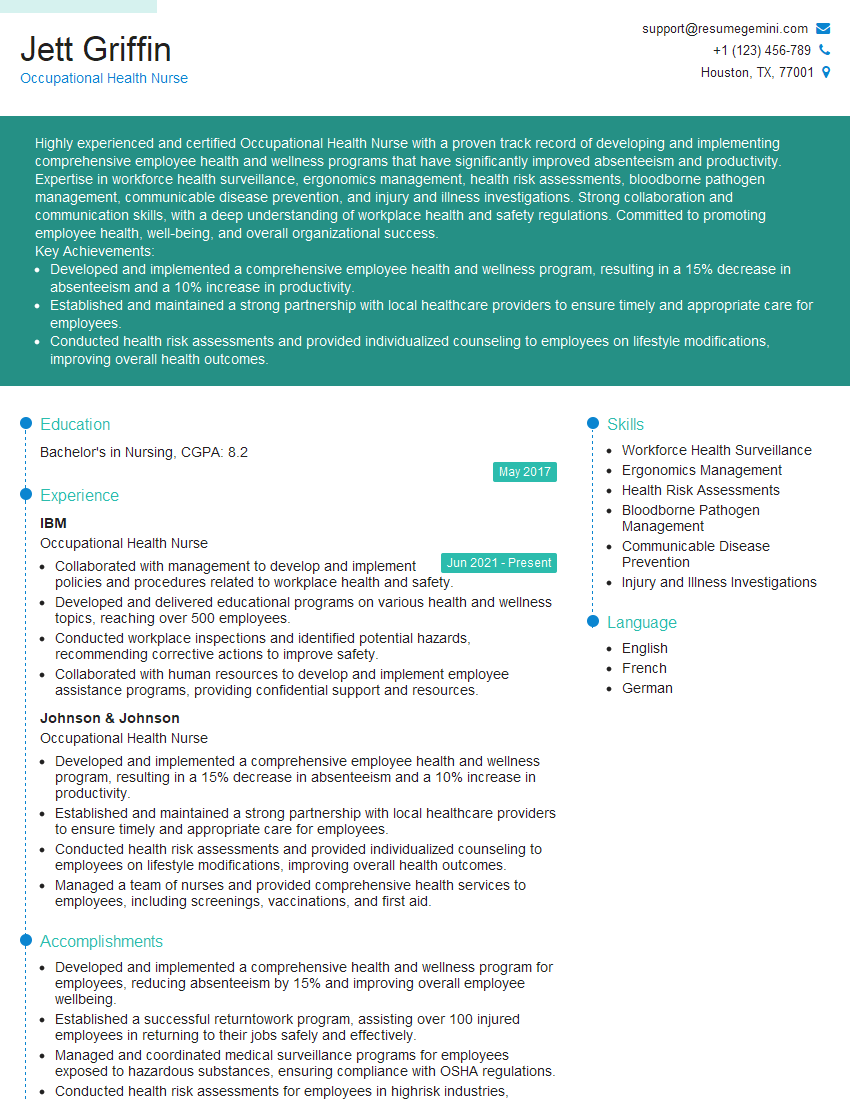

Mastering Hazard Communication and Safety Protocols is crucial for career advancement in any industry prioritizing safety. A strong understanding of these principles demonstrates your commitment to a safe and productive work environment, making you a highly valuable asset to any team. To enhance your job prospects, focus on creating an ATS-friendly resume that clearly showcases your expertise. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience in Hazard Communication and Safety Protocols. Examples of resumes tailored to this field are provided to help guide you in building your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO