Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential MIG (Metal Inert Gas Welding) interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in MIG (Metal Inert Gas Welding) Interview

Q 1. What are the different types of MIG welding processes?

MIG welding, or Metal Inert Gas welding, encompasses several variations, each tailored to specific applications and materials. The key differences lie in the type of power source used and the transfer mode of the welding wire.

- Short-Circuiting Transfer (Spray Transfer): This is the most common method for thin materials. The wire touches the workpiece, creating a short circuit and a small, controlled transfer of molten metal. Think of it like gently placing tiny droplets of metal onto the joint.

- Globular Transfer: Larger droplets are transferred to the weld pool, resulting in a more spatter-prone process. This method is suitable for thicker materials and often uses less refined shielding gas mixtures.

- Spray Transfer: This process uses higher current and wire feed speeds, leading to a smooth, even weld with minimal spatter. It’s ideal for thicker materials requiring high deposition rates. Imagine a finely atomized mist of metal being applied to the joint.

- Pulsed Spray Transfer: A variation of spray transfer, this method uses a pulsed current to control the droplet size and reduce spatter, making it versatile for a range of thicknesses.

The choice of process depends on factors such as material thickness, type of metal, desired weld quality, and the skill of the welder.

Q 2. Explain the role of shielding gas in MIG welding.

The shielding gas in MIG welding plays a crucial role in protecting the molten weld pool from atmospheric contamination, primarily oxygen and nitrogen. These gases can react with the molten metal, causing undesirable effects like porosity (holes in the weld) and embrittlement (making the metal weaker). The shielding gas forms a protective blanket around the weld, preventing these reactions and ensuring a high-quality weld.

Common shielding gases include Argon (Ar), Carbon Dioxide (CO2), and mixtures of both. Argon is an inert gas, meaning it doesn’t react chemically with the molten metal, making it ideal for most applications. CO2 is less expensive but can lead to more spatter and a less visually appealing weld. Gas mixtures offer a balance between cost and weld quality.

For example, a common mixture is 75% Argon and 25% CO2, offering improved arc stability and penetration compared to pure Argon while being more economical than using pure Argon alone.

Q 3. Describe the relationship between wire feed speed and welding parameters.

Wire feed speed is intrinsically linked to other welding parameters, primarily voltage and amperage. Increasing the wire feed speed generally increases the metal deposition rate. However, this needs to be balanced with the amperage (current) and voltage settings. Too high a wire feed speed with insufficient current can result in inadequate fusion, while too low a speed with excessive current might lead to excessive heat input and burn-through.

Imagine a water faucet: the wire feed speed is like the rate at which the water flows, while amperage is like the water pressure. You need to adjust both to get the desired flow and pressure at the tap. Voltage affects the arc length and thus the heat input, making it another crucial variable in achieving a proper weld.

In practice, you’d typically adjust the voltage to control the arc length and penetration, and then adjust the wire feed speed to match the amperage and achieve the desired weld bead profile. Proper adjustments require experience and understanding of the material properties.

Q 4. How do you adjust for different metal thicknesses in MIG welding?

Adjusting for different metal thicknesses in MIG welding requires careful consideration of several parameters. Thicker materials require higher current and penetration, while thinner materials need lower settings to prevent burn-through.

- Current (Amperage): Higher amperage for thicker materials to provide sufficient heat for fusion, lower amperage for thinner materials to avoid burning through.

- Voltage: Adjust voltage to control arc length and heat input. Higher voltage generally leads to deeper penetration, but needs to be balanced with current.

- Wire Feed Speed: Increase the feed speed for faster deposition in thicker materials, decrease it for thinner ones to prevent excessive heat input.

- Travel Speed: Reduce travel speed for thicker sections to allow for complete fusion and heat distribution. Increase travel speed for thinner sections.

Example: Welding a 1/8″ steel sheet would require considerably lower amperage and a slower travel speed compared to welding a 1/2″ steel plate. It’s crucial to use appropriate settings and practice on scrap pieces before welding the actual components.

Q 5. What are the common causes of porosity in MIG welds?

Porosity, the presence of small holes in the weld, is a common defect in MIG welding. Several factors can contribute to it:

- Insufficient Shielding Gas Coverage: Poor gas flow, improper nozzle-to-workpiece distance, or drafts can allow atmospheric gases to contaminate the weld pool.

- Moisture in the Shielding Gas: Moisture in the gas can create hydrogen pores in the weld.

- Contaminated Base Metal: Oil, grease, or rust on the base metal can introduce gases into the weld.

- Improper Welding Parameters: Excessive current or travel speed can trap gases in the weld pool.

- Out-of-Spec Wire: Using wire with contaminants or incorrect material can introduce impurities that cause porosity.

Preventing porosity requires attention to detail: ensuring clean base metal, using a dry shielding gas, maintaining proper gas coverage, and using appropriate welding parameters.

Q 6. How do you identify and correct weld spatter?

Weld spatter is the ejection of molten metal droplets during the welding process, leaving unsightly bumps on the weld. It can be addressed through several methods:

- Adjust Welding Parameters: Reducing the amperage or optimizing the wire feed speed can reduce spatter. Switching to pulsed spray transfer can also help significantly.

- Shielding Gas Composition: Using a gas blend with a higher Argon content reduces spatter compared to pure CO2.

- Cleanliness: Clean base materials free from oil, grease and rust. A clean nozzle is essential to prevent spatter sticking to it.

- Proper Technique: Consistent travel speed and proper arc length control minimizes spatter.

- Spatter Removal: After welding, carefully remove spatter using a wire brush or other appropriate tools.

For instance, if you observe excessive spatter, try reducing the amperage by 10-15 amps and re-assess. If the spatter persists, a different gas mix or pulsed spray transfer might be necessary.

Q 7. Explain the importance of proper joint preparation in MIG welding.

Proper joint preparation is paramount in MIG welding for achieving strong, consistent, and aesthetically pleasing welds. It ensures complete penetration, proper fusion, and minimizes weld defects.

This includes:

- Cleaning: Removing any dirt, oil, grease, paint, or rust from the surfaces to be welded.

- Beveling: Preparing the edges of the materials to be joined by beveling or chamfering, creating a V-groove or other suitable joint profile to achieve appropriate penetration for the selected thickness. This is especially crucial for thicker materials.

- Fixturing: Using jigs or clamps to hold the components firmly in place during welding to maintain proper alignment and avoid distortion.

- Gap Control: Maintaining a consistent gap between the joint surfaces is essential for ensuring proper weld penetration and minimizing voids. This gap is critical to achieving proper fusion. Too much or too little gap can create problems.

Think of it as preparing the ground before building a house; without proper foundation, the structure will be weak and unstable. Similarly, improper joint preparation leads to weak, inconsistent and potentially dangerous welds.

Q 8. What are the safety precautions you take when MIG welding?

MIG welding, while incredibly versatile, presents inherent safety risks. My approach to safety is multifaceted and prioritizes prevention. Before even starting, I always ensure I’m wearing the appropriate personal protective equipment (PPE), including a welding helmet with a shade appropriate for the process (typically shade 10-12 for MIG), heavy-duty gloves, a long-sleeved shirt and pants made of flame-resistant material, and closed-toe shoes. I inspect the welding area for any potential hazards, ensuring the workspace is clean, well-ventilated, and free from flammable materials. I also check my equipment to make sure all cables are properly insulated and connected, ensuring there’s no risk of electrical shock or short-circuiting. During welding, I maintain a safe distance from other workers and avoid working in confined spaces without proper ventilation. Furthermore, I always be aware of the intense UV light produced by the welding arc, and take necessary precautions to protect my eyes from harmful radiation.

After completing the welding work, I ensure the equipment cools down before handling it, and I properly dispose of any slag or other welding byproducts, following all safety regulations.

Q 9. How do you select the appropriate wire diameter and type for a specific application?

Wire diameter and type selection in MIG welding is crucial for achieving high-quality welds. The choice depends heavily on the base material’s thickness, the welding position (flat, vertical, overhead), and the desired weld penetration. Thicker materials generally require larger diameter wires to achieve sufficient penetration. For example, a 0.035-inch wire is suitable for thin sheet metal, while a 0.045-inch or even 0.062-inch wire might be necessary for thicker materials like 1/4-inch steel.

The wire type is determined by the base material’s composition. Steel, stainless steel, aluminum, and various other metals each require specific wire compositions to ensure proper fusion and minimize porosity. For instance, using a solid steel wire (ER70S-6) is common for mild steel, while stainless steel would require an appropriate stainless steel wire (e.g., ER308LSi). The flux-cored wires offer self-shielded welding without the need for an external shielding gas, beneficial in outdoor settings with wind. Careful consideration of these factors ensures the optimal selection of wire diameter and type to produce robust, reliable welds.

Q 10. What are the signs of a defective MIG weld?

Identifying a defective MIG weld requires a keen eye and understanding of weld characteristics. Several visual indicators can point to a problem. Porosity, characterized by small holes within the weld bead, indicates gas entrapment during the welding process, possibly caused by poor shielding gas coverage or moisture contamination. Incomplete penetration, where the weld doesn’t fully fuse the base materials, results in a weak joint, easily discernible visually. Undercutting, a groove along the edges of the weld, suggests excessive heat input or improper travel speed. Excessive spatter, indicating inconsistent arc control, can create a rough, uneven weld surface. Cracks within the weld bead or the heat-affected zone are critical defects, suggesting a metallurgical issue.

Beyond visual inspection, mechanical tests such as tensile testing might be needed to verify the weld’s strength and reliability. A well-executed MIG weld should exhibit a smooth, uniform bead with good fusion and no visible defects.

Q 11. Describe the different types of MIG welding equipment.

MIG welding equipment comes in various forms, catering to different needs and scales of operation. At the core, you have the power source, which provides the electrical energy to create the welding arc. These range from simple, compact units for occasional hobbyists to larger, more sophisticated industrial units with advanced control systems. Beyond the power source, you’ll find wire feeders, either integrated into the power source or separate units that control the wire feed speed. The gas cylinder, providing the shielding gas, is also a crucial component, as is the welding gun itself, responsible for delivering the wire and shielding gas to the weld zone. Accessories like a welding cart for increased mobility and safety, and various consumables like contact tips and drive rolls, add to the overall equipment setup.

For example, industrial applications might use a multi-process welder capable of handling various welding processes including MIG, TIG and stick welding, while smaller shops may favor a dedicated MIG welder designed for specific material types and thicknesses.

Q 12. Explain the function of each component in a MIG welding power source.

The MIG welding power source comprises several key components, each playing a vital role in generating the stable arc required for welding. The power supply’s function is to provide the welding current, typically DC (Direct Current) for most MIG applications. This current is regulated to maintain a stable arc, and the amount is directly related to the weld penetration. A wire feeder is responsible for smoothly delivering the consumable electrode (wire) at a consistent speed, affecting the weld bead characteristics. The voltage control in the power source helps regulate the arc length and stability. Without proper voltage control, the arc can become erratic, resulting in inconsistent weld quality. The wire feed speed control, often linked to the current control, regulates the amount of wire fed into the weld, thus affecting the weld bead size and penetration. The gas control system regulates the flow of shielding gas, preventing oxidation of the weld pool.

All these components must work in perfect harmony to produce a high-quality weld. For instance, if the wire feed speed is too slow, you might get insufficient weld metal deposition; if the current is too low, insufficient penetration will result. Proper calibration and monitoring of these parameters are crucial for producing consistent and high-quality welds.

Q 13. How do you perform a visual inspection of a MIG weld?

Visual inspection is the first and often most important step in evaluating a MIG weld’s quality. I start by examining the weld bead’s overall appearance. A good weld should exhibit a smooth, uniform bead with consistent width and height along its length. I check for the presence of defects like porosity (small holes), undercutting (grooves at the weld edges), cracks, or excessive spatter. I also examine the fusion between the weld bead and the base metal, ensuring complete penetration. The weld should show a clean, smooth transition between the bead and the parent material. Using a magnifying glass can help in detecting small imperfections not easily visible to the naked eye. I also ensure that the weld bead is free from any foreign inclusions like slag or other contaminants. Proper lighting is crucial for a detailed assessment. By systematically checking these aspects, I ensure that the weld meets the required standards of quality and integrity.

Documentation of the visual inspection is usually performed with photos and detailed notes, for potential further analysis.

Q 14. What are the limitations of MIG welding?

Despite its versatility, MIG welding has some limitations. It’s not ideal for all materials; joining dissimilar metals successfully can be challenging. The quality of the weld is highly dependent on operator skill and consistent control of process parameters. Inconsistent wire feed, improper gas shielding, or variations in welding speed can lead to significant defects. Furthermore, MIG welding can be susceptible to spatter, which can be aesthetically undesirable and sometimes requires additional cleaning. While versatile, MIG welding may not be appropriate for applications requiring extremely high precision or for work in environments with significant wind conditions, unless using self-shielded flux-cored wire. Finally, the high heat input can lead to distortion of the base material, especially in thin sections. Understanding these limitations helps determine when MIG welding is the most appropriate choice and when other welding processes might be preferable.

Q 15. How do you troubleshoot common MIG welding problems, such as lack of penetration or excessive burn-through?

Troubleshooting MIG welding issues like lack of penetration or excessive burn-through involves systematically checking several key parameters. Lack of penetration, where the weld doesn’t fully fuse the base materials, often points to insufficient heat input. Excessive burn-through, on the other hand, indicates too much heat. Let’s break down the troubleshooting steps:

- Lack of Penetration:

- Increase amperage: More current means more heat.

- Increase wire feed speed: More filler metal means a larger weld pool.

- Reduce travel speed: Slower travel allows more time for heat transfer.

- Check for wire sticking or birdnesting: This can disrupt the consistent flow of filler metal.

- Verify gas flow: Inadequate shielding gas leads to oxidation and poor fusion.

- Inspect the contact tip: A worn or damaged contact tip can affect wire feed and arc stability.

- Excessive Burn-Through:

- Decrease amperage: Reduce the heat input.

- Decrease wire feed speed: Less filler metal deposited per unit time.

- Increase travel speed: Less time to melt the base materials.

- Use a smaller diameter filler wire: This reduces the heat input per unit length.

- Adjust your technique: Avoid lingering too long in one spot.

- Check for gas flow: Excessive gas flow can affect arc stability.

Example: I once had a job where we were welding thin sheet metal, and we were experiencing excessive burn-through. By systematically reducing the amperage and increasing the travel speed, we were able to eliminate the problem and produce high-quality welds.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the difference between pulsed MIG welding and standard MIG welding?

Pulsed MIG welding is an advanced technique that offers superior control over the welding process compared to standard MIG welding. In standard MIG, a consistent current flows, resulting in a continuous weld pool. Pulsed MIG, however, utilizes a rapidly alternating current, switching between high and low current levels repeatedly. Think of it like a rapid tap-tap-tap instead of a constant flow.

- Standard MIG: Provides a continuous arc and weld pool, best suited for thicker materials and applications requiring high deposition rates.

- Pulsed MIG: Offers better control over heat input, minimizing burn-through and spatter on thinner materials. It produces a narrower and more precisely controlled weld bead, ideal for applications requiring high quality and fine detail.

Key Differences Summarized:

| Feature | Standard MIG | Pulsed MIG |

|---|---|---|

| Arc | Continuous | Intermittent (pulsed) |

| Heat Input | Higher | Lower & more controlled |

| Weld Bead | Wider | Narrower, more precise |

| Spatter | More | Less |

| Applications | Thicker materials, high deposition rate | Thinner materials, precise control needed |

Example: Pulsed MIG is frequently used in automotive body repair due to its ability to produce clean welds on thin sheet metal without causing distortion or burn-through.

Q 17. Explain the importance of maintaining your MIG welding equipment.

Maintaining your MIG welding equipment is crucial for ensuring consistent weld quality, operator safety, and prolonging the lifespan of the machine. Think of it like regular car maintenance – neglecting it leads to bigger, more expensive problems down the line.

- Regular Cleaning: This includes cleaning the contact tip, liner, and drive rolls regularly to prevent wire feed issues and maintain arc stability.

- Gas Flow Check: Ensuring the shielding gas flow is properly regulated and the gas is of high purity is essential for achieving quality welds.

- Wire Feed System Inspection: The drive rolls and wire feed motor should be inspected for wear and tear. Proper adjustment is vital to prevent wire birdnesting or jams.

- Grounding: Maintaining a good ground connection is critical to prevent inconsistent arc and potential electrical hazards.

- Scheduled Maintenance: This includes regular checks of all components and periodic professional servicing. This will help catch potential problems before they become major issues.

Example: A clogged liner can cause the wire to feed inconsistently, resulting in poor weld quality and potentially dangerous situations. Regular cleaning prevents this.

Q 18. Describe your experience with different types of filler metals used in MIG welding.

My experience encompasses a wide range of filler metals used in MIG welding, each suited to specific applications and base materials. The choice of filler metal is crucial for achieving the desired weld properties.

- Solid Wire: This is the most common type, available in various compositions and diameters, such as mild steel, stainless steel, aluminum, and others. The choice depends on the base material being welded and the desired mechanical properties of the weld.

- Flux-cored Wire: These wires contain a flux core that provides shielding and deoxidizing properties, making them useful for welding in outdoor environments or on rusty materials where consistent shielding gas might be challenging.

- Aluminum Wire: Welding aluminum requires special considerations due to its high thermal conductivity and reactivity with oxygen. Aluminum filler wires are formulated to address these challenges.

- Stainless Steel Wire: Different grades of stainless steel filler wires are chosen based on the base metal’s composition and the desired corrosion resistance of the weld.

Example: When welding mild steel, I typically use ER70S-6 solid wire, which provides good strength and weldability. For stainless steel, I’d select a filler wire that matches the base material’s composition to maintain corrosion resistance.

Q 19. How do you interpret welding symbols?

Welding symbols are a standardized way to communicate complex welding requirements on engineering drawings. They provide concise information about the type of weld, its location, dimensions, and other specifications. Understanding these symbols is essential for accurate fabrication.

A welding symbol typically includes:

- Reference Line: The horizontal line extending from the weld symbol.

- Arrow Side: The side of the joint to which the symbol applies.

- Other Side: The opposite side of the joint, indicated by a similar symbol but mirrored.

- Weld Symbol: Indicates the type of weld (e.g., fillet, groove, spot).

- Dimensions: Specify the size and length of the weld.

- Process Designation: Identifies the welding process to be used (e.g., MIG, TIG).

Example: A symbol showing a triangle pointing towards the arrow side along the reference line might indicate a fillet weld on one side of the joint. Dimensions would then specify the leg length of that fillet weld.

Note: Proficiency in interpreting welding symbols requires dedicated study and practical application of welding codes and standards. There are many resources available for detailed explanation and practice.

Q 20. How do you ensure the quality of your MIG welds?

Ensuring the quality of MIG welds involves several key considerations, from preparation to post-weld inspection. It’s a holistic approach rather than a single step.

- Proper Joint Preparation: Clean, properly fitted joints are essential for good fusion. This includes removing any dirt, grease, or paint and ensuring proper fit-up.

- Consistent Welding Parameters: Maintaining consistent amperage, wire feed speed, and travel speed is crucial for uniform weld penetration and bead appearance.

- Adequate Shielding Gas Coverage: Ensuring the weld pool is completely shielded from atmospheric contamination prevents oxidation and porosity.

- Post-Weld Inspection: Visual inspection is crucial to check for defects like cracks, porosity, or incomplete fusion. Additional techniques like radiographic inspection (RT) or ultrasonic testing (UT) may be used for more critical applications.

- Documentation: Maintaining records of welding parameters and inspection results ensures traceability and accountability.

Example: I always conduct a visual inspection after each weld, using a magnifying glass to check for any imperfections, before moving onto the next joint.

Q 21. Describe your experience with different types of metal and their weldability.

My experience covers a range of metals and their weldability characteristics. Each metal presents unique challenges that influence welding technique and parameter selection.

- Mild Steel: Relatively easy to weld with MIG, offering good weldability and strength. ER70S-6 is a commonly used filler metal.

- Stainless Steel: Requires careful control of heat input to avoid distortion and cracking. Specialized stainless steel filler wires are essential to maintain corrosion resistance.

- Aluminum: Challenges include its high thermal conductivity and oxide layer. Special techniques and filler wires are needed, often requiring higher amperage and pre-cleaning.

- Magnesium: High reactivity with oxygen demands stringent cleanliness and specialized shielding gas mixtures.

Example: Welding aluminum requires a cleaner process compared to steel, often necessitating specific cleaning procedures to remove the oxide layer. Poor cleaning will always result in porosity.

Note: Different grades of each metal have varying weldability characteristics. Detailed knowledge of the material’s composition and properties is crucial for successful welding.

Q 22. Explain your experience with different joint configurations.

My experience encompasses a wide range of MIG welding joint configurations, crucial for ensuring structural integrity and weld quality. These configurations are chosen based on factors like the application, material thickness, and desired strength.

- Butt Joints: These are the simplest, joining two pieces of metal end-to-end. Preparation is key; proper edge preparation (beveling or squaring) is vital for penetration and a strong weld. I’ve extensively used butt joints in fabricating pipelines and structural components.

- Lap Joints: Overlapping two pieces, lap joints are easy to assemble, often used in sheet metal fabrication. However, the weld needs to be strong enough to handle the potential shear stresses. I’ve worked with lap joints in automotive bodywork and thin-gauge stainless steel applications.

- T-Joints: These join two pieces at a 90-degree angle, requiring careful attention to penetration into both pieces. Proper joint fit-up is critical, and I’ve found that using backing plates can help improve weld quality in thicker materials, as seen in my work on heavy machinery frames.

- Corner Joints: Used to join two pieces at a corner, these are often used in box-section fabrication. Achieving full penetration in both members is vital to ensure strength; I usually employ specific techniques like weaving or multiple passes.

- Edge Joints: These join the edges of two overlapping pieces. They’re efficient but require careful attention to ensure full fusion. I often employ this type of joint when welding thin sheets together, for instance, during the construction of enclosures.

Understanding the strengths and weaknesses of each joint type allows me to select the most suitable configuration for the specific application, ensuring the final product meets the required specifications.

Q 23. What are your preferred techniques for achieving consistent weld quality?

Consistent weld quality is paramount, and my approach involves a multi-faceted strategy. It’s not just about technique, but a holistic approach.

- Proper Preparation: This includes meticulous cleaning of the base materials to remove any contaminants such as oil, grease, or rust which can severely compromise weld integrity. This preparation is as much a part of the process as the welding itself.

- Consistent Welding Parameters: I carefully control parameters like voltage, amperage, wire feed speed, and travel speed. Slight variations can significantly impact the weld’s quality. For example, too much amperage can lead to burn-through, while too little can result in insufficient penetration. I meticulously adjust these based on the material thickness and type.

- Proper Shielding Gas Coverage: The shielding gas prevents atmospheric contamination of the weld puddle, critical for ensuring a smooth, sound weld. I ensure consistent gas flow and proper shielding by using appropriate gas nozzles and maintaining the correct distance between the nozzle and the workpiece.

- Regular Equipment Maintenance: Consistent checks on the MIG welder, including wire feed rollers, contact tip, and gas flow, prevent unexpected issues that could affect weld quality. A well-maintained machine is a crucial component of a quality weld.

- Post-Weld Inspection: Visual inspection is crucial. I look for porosity, undercutting, cracks, and incomplete penetration. I also may employ non-destructive testing (NDT) methods depending on the application’s criticality.

By combining these techniques, I consistently produce high-quality welds that meet or exceed project specifications.

Q 24. Describe a time you had to troubleshoot a complex welding problem.

During a project involving the fabrication of a large stainless steel pressure vessel, we encountered significant porosity in the welds. This was unacceptable given the vessel’s intended use. Initial troubleshooting focused on the obvious – checking gas flow, wire feed, and voltage settings. However, these checks yielded nothing conclusive.

I systematically investigated other potential causes. I discovered the problem stemmed from poor surface preparation. Although the parts seemed clean, microscopic analysis revealed a thin layer of oil residue from the manufacturing process which we’d overlooked. The oil was interfering with the welding process, leading to the porosity.

Our solution involved a more rigorous cleaning process, implementing a degreasing and meticulous wire brushing procedure before welding. We re-welded the affected sections, and subsequent inspections revealed significant improvement. The problem highlighted the importance of thorough surface preparation and the need to consider less obvious factors when troubleshooting welding problems.

Q 25. How do you manage your time effectively while working on multiple projects?

Managing multiple projects effectively requires organization and prioritization. I use a combination of techniques to stay on schedule and deliver quality work.

- Prioritization Matrix: I use a matrix to prioritize tasks based on urgency and importance. This helps me focus my efforts on the most critical aspects of each project.

- Detailed Project Planning: Before starting a project, I create a detailed plan outlining all tasks, timelines, and resource requirements. This allows for better allocation of time and resources.

- Time Blocking: I dedicate specific blocks of time to work on particular projects, minimizing distractions and maximizing productivity. I treat each block as a dedicated session.

- Regular Progress Reviews: I regularly review my progress against the project plan, identifying and addressing any potential delays early on. This keeps everything on schedule.

- Effective Communication: Maintaining open communication with project managers and team members helps to coordinate efforts and address potential challenges promptly.

By implementing these strategies, I effectively juggle multiple projects while maintaining a high standard of work.

Q 26. How do you stay current with the latest advancements in MIG welding technology?

Staying current in MIG welding technology is essential. I actively pursue several methods to keep my knowledge and skills up-to-date.

- Industry Publications: I regularly read industry journals and publications to learn about new welding techniques, materials, and equipment. These resources offer insights into the latest advancements and best practices.

- Professional Development Courses: I participate in workshops and training sessions offered by welding equipment manufacturers and industry associations. These courses provide hands-on experience with the latest technologies.

- Online Resources: I utilize online forums, webinars, and technical papers to stay informed about ongoing developments in the field. This complements my other learning methods.

- Networking: I engage with other welding professionals at industry events and conferences, exchanging knowledge and insights. Learning from peers and experts is invaluable.

- Manufacturer Websites and Documentation: I regularly consult manufacturer websites and equipment documentation for the latest updates on welding equipment and recommended procedures.

By utilizing a variety of resources, I ensure that my skills and knowledge remain relevant and cutting-edge, allowing me to implement the most efficient and effective welding techniques in my work.

Q 27. What is your experience with different types of MIG welding applications?

My MIG welding experience spans various applications, reflecting the versatility of the process.

- Automotive Repair and Fabrication: I have extensive experience in automotive body repair and custom fabrication, working with various steel grades and thicknesses. This requires precision and attention to detail.

- Structural Steel Fabrication: I have been involved in the fabrication of structural steel components for buildings and industrial facilities. This involves working with heavier gauge materials and requires adherence to strict safety and quality standards.

- Pipeline Welding: I have experience in the welding of pipelines, demanding consistent weld quality and adherence to stringent codes and regulations. The demands for precision and strength are very high in this sector.

- Stainless Steel Fabrication: I’ve worked extensively with various grades of stainless steel, requiring specialized techniques and knowledge to avoid issues like sensitization and cracking. Maintaining high-quality surface finishes is also important.

- Aluminum Welding: I’m proficient in aluminum MIG welding, needing to use specific parameters and techniques to prevent porosity and achieve strong, corrosion-resistant welds.

This varied experience has provided a strong foundation in understanding different material properties and the best techniques for each application.

Q 28. Describe your approach to workplace safety and compliance.

Workplace safety is non-negotiable. My approach prioritizes proactive measures and strict adherence to all safety regulations.

- Personal Protective Equipment (PPE): I consistently and correctly use all required PPE, including welding helmets with appropriate shade lenses, welding gloves, long-sleeved shirts, and safety glasses. This is my first line of defense against hazards.

- Proper Ventilation: I ensure adequate ventilation is available to prevent exposure to harmful fumes and gases generated during the welding process. This is particularly crucial when working in enclosed spaces.

- Fire Prevention: I maintain a clean and organized workspace, keeping flammable materials away from the welding area. I regularly check for fire hazards and have appropriate fire extinguishers readily available.

- Safe Handling of Materials: I always use appropriate lifting and handling techniques for materials to avoid injuries. I ensure the safe storage of materials to prevent accidents.

- Regular Equipment Inspections: I conduct regular inspections of welding equipment to ensure it’s in safe working order and free from defects that could cause hazards. This is a preventative safety measure.

- Awareness of Surroundings: I always maintain awareness of my surroundings and potential hazards, ensuring I’m not working in unsafe conditions.

Safety is an integral part of my welding practices. I believe proactive measures and a commitment to safe work habits are essential for a productive and hazard-free working environment.

Key Topics to Learn for MIG (Metal Inert Gas Welding) Interview

- MIG Welding Processes: Understand the different types of MIG welding (short-circuiting, globular, spray transfer) and their applications. Consider the impact of varying voltage, amperage, and wire feed speed.

- Gas Selection and Shielding: Discuss the role of shielding gas (e.g., Argon, CO2, mixtures) in protecting the weld from atmospheric contamination. Explain how gas flow rate affects weld quality.

- Metal Transfer Modes: Describe the characteristics of different metal transfer modes and their suitability for various materials and thicknesses. Be prepared to discuss the advantages and disadvantages of each.

- Weld Joint Design: Understand different weld joint preparations (e.g., butt, lap, T-joints) and their impact on weld strength and integrity. Know how to choose the appropriate joint design for a given application.

- Welding Parameters and Control: Explain the relationship between welding parameters (voltage, amperage, wire feed speed, travel speed) and weld bead geometry, penetration, and overall quality. Be prepared to troubleshoot common welding defects.

- Material Compatibility and Selection: Discuss the considerations for welding different base materials (e.g., steel, aluminum, stainless steel) using MIG welding. Understand the importance of filler metal selection.

- Safety Procedures and Practices: Demonstrate a thorough understanding of safety precautions related to MIG welding, including PPE, fire safety, and electrical hazards.

- Troubleshooting Common Defects: Be ready to discuss common MIG welding defects (e.g., porosity, spatter, lack of fusion) and their causes and remedies. Demonstrate problem-solving skills.

- Weld Inspection and Testing: Explain different methods used to inspect and test welds for quality and integrity (e.g., visual inspection, destructive and non-destructive testing methods).

Next Steps

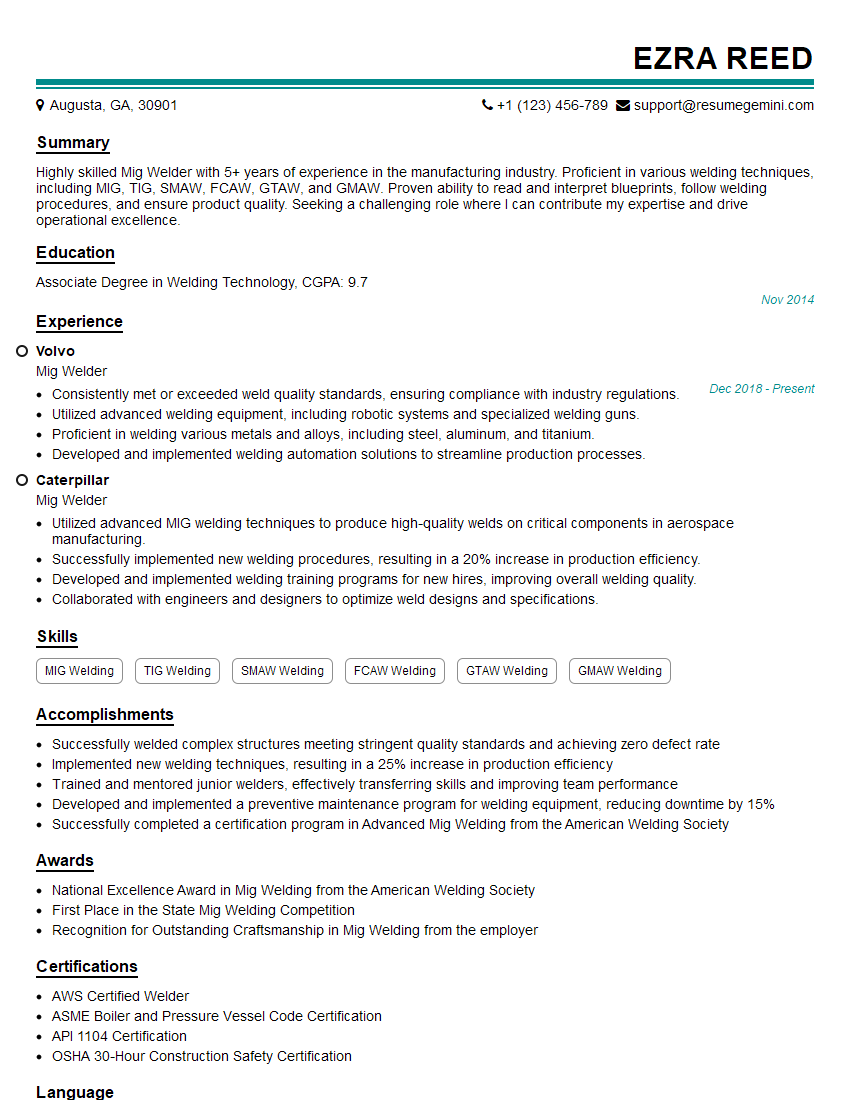

Mastering MIG welding opens doors to a wide range of rewarding careers in manufacturing, construction, and other industries. A strong understanding of this skill will significantly boost your job prospects. To maximize your chances of landing your dream job, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is essential in today’s competitive job market. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that catches the recruiter’s eye. ResumeGemini provides examples of resumes tailored to MIG (Metal Inert Gas Welding) roles, to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO