Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Countertops interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Countertops Interview

Q 1. Describe your experience with various countertop materials (granite, quartz, laminate, etc.).

My experience spans a wide range of countertop materials, each with its unique properties and challenges. Granite, a natural stone, offers unparalleled beauty and durability but requires careful sealing and is prone to staining if not properly maintained. I’ve worked extensively with various granite types, from the classic black galaxy to more exotic variations, understanding their inherent characteristics to advise clients on the best choice for their needs. Quartz, an engineered stone, provides exceptional durability and low maintenance, making it a popular choice. I’m familiar with numerous quartz brands and their varying performance levels, helping clients select the optimal balance of aesthetics and practicality. Laminate, a cost-effective option, is surprisingly versatile, mimicking the look of natural stone or offering unique patterns. My experience includes working with various laminate grades and understanding their limitations in terms of heat resistance and durability. I’ve also worked with other materials like marble, butcher block, and solid surface, each presenting unique installation and maintenance considerations.

For example, I once worked on a project where the client desired a high-end look on a budget. We carefully selected a high-quality laminate that realistically mimicked the veining of Calacatta marble, achieving a luxurious look without the hefty price tag.

Q 2. Explain the process of countertop installation, from template creation to final sealing.

Countertop installation is a precise process requiring meticulous attention to detail. It begins with template creation. We carefully measure the countertop area, accounting for sinks, cooktops, and other features, creating a precise template using specialized materials. This template is then used to fabricate the countertop in the shop. Next comes fabrication, where the countertop is cut, shaped, and polished according to the template. This step requires specialized tools and expertise to ensure accuracy. Installation involves carefully positioning the countertop, securing it with adhesive and mechanical fasteners. Finally, sealing is crucial, particularly for natural stone countertops like granite and marble. We apply a high-quality sealant to protect the surface from stains and moisture damage. The entire process necessitates a high level of precision, proper safety measures, and attention to detail throughout each stage.

Q 3. What are the common challenges encountered during countertop fabrication?

Common challenges include inaccurate measurements leading to ill-fitting countertops, unexpected issues with existing cabinetry or plumbing, and material defects like cracks or inconsistencies in natural stone. Dealing with complex sink or cooktop cutouts also presents a challenge, requiring precise planning and execution. In one instance, a hidden plumbing issue was discovered during installation, requiring quick problem-solving to adapt the installation plan without compromising the quality of the finished product. Effective communication with clients throughout the process helps mitigate many of these challenges.

Q 4. How do you handle edge profiling and finishing on different countertop materials?

Edge profiling and finishing are critical for aesthetics and functionality. Different materials require different techniques. Granite and quartz are often finished with eased, bevelled, or ogee edges, using specialized tooling. Laminate edges require careful finishing to prevent chipping or peeling, often using edge banding and sealing. For natural stone, I use specialized tools like diamond grinders and polishers to create smooth, seamless edges. The choice of edge profile significantly affects the overall look and feel of the countertop; a simple eased edge provides a clean, modern look, while a more ornate ogee edge adds a touch of elegance.

Q 5. What safety measures do you implement during countertop installation?

Safety is paramount. We always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and dust masks. When working with power tools like saws and grinders, we ensure the work area is clear and safe, using appropriate safety guards. We carefully handle heavy materials using proper lifting techniques and equipment to prevent injury. Furthermore, we adhere to all relevant workplace safety regulations and guidelines to ensure a safe working environment for our team and those around us.

Q 6. How do you measure and cut countertops accurately to ensure a perfect fit?

Accurate measurement and cutting are essential for a perfect fit. We use a combination of digital measuring tools and traditional techniques to ensure precision. For complex shapes, we utilize templates created from precise measurements taken on-site. We employ high-precision cutting tools like CNC routers for engineered stone and specialized saws for natural stone, ensuring clean, accurate cuts. Double-checking measurements at every stage minimizes errors and ensures the countertop fits perfectly.

Q 7. Explain your experience with different countertop joining techniques.

I have experience with several countertop joining techniques. For seamless joints in engineered stone like quartz, we use specialized adhesives and techniques that ensure minimal visibility. With natural stone, matching the veining pattern is a key challenge, and we carefully select and align slabs to minimize discrepancies. In some cases, we employ invisible seaming techniques to create virtually seamless joints, even with large countertops. Different materials and their inherent properties dictate the best joining approach; the goal is always to create a strong, aesthetically pleasing, and durable joint.

Q 8. How do you repair common countertop damage, such as chips or cracks?

Repairing countertop chips and cracks depends heavily on the material. For minor chips in materials like granite or quartz, epoxy resin is often the solution. It’s crucial to choose a resin that closely matches the countertop’s color. The process involves carefully cleaning the damaged area, applying the resin, and then allowing it to cure completely according to the manufacturer’s instructions. For larger cracks, a more involved process might be needed, potentially involving filling the crack with resin and then grinding and polishing the area to restore the surface finish. Laminate countertops, on the other hand, may require replacing the damaged section completely, often needing to cut out the affected area and glue in a new piece, paying close attention to matching patterns.

For example, I once repaired a small chip in a client’s granite countertop using a high-quality epoxy resin. The color match was almost perfect, and after curing and polishing, the repair was virtually invisible. A different situation called for repairing a deep crack in a quartz countertop. This required careful crack filling with resin, followed by a multi-step grinding and polishing process using progressively finer grit diamond pads to achieve a seamless finish.

Q 9. What are the different types of countertop sinks and how are they installed?

Countertop sinks come in various materials and installation methods. Undermount sinks, popular for their sleek look, are installed from below the countertop, creating a seamless surface. They typically require a precisely cut opening and strong adhesive to secure them. Topmount (drop-in) sinks are simpler to install, resting on top of the countertop with a visible rim; installation involves simply sealing the edges against leaks. Integrated sinks are a more sophisticated option. These are typically crafted from the same material as the countertop, providing a unified, high-end aesthetic. They require precise fabrication and seamless integration during the countertop manufacturing process. Lastly, farmhouse sinks are larger, apron-front sinks often made from porcelain, cast iron, or composite materials. Their installation may need custom framing and support structures.

The choice of installation method affects not only the look but also the complexity of installation. An undermount sink installation requires more precision and skill because an improper cut can lead to significant damage. I’ve personally dealt with installation challenges ranging from fitting an undermount sink into a particularly intricate countertop curve to ensuring a watertight seal for a topmount sink using high-quality silicone.

Q 10. Describe your experience with using various power tools for countertop fabrication.

My experience with power tools in countertop fabrication is extensive. I’m proficient in using a variety of tools, including CNC routers for precise cutting and shaping, especially when working with templates, bridge saws for cutting slabs of natural stone, and various hand-held tools like angle grinders and polishers for finishing and edge detailing. I also have experience with oscillating tools for intricate cuts and removing material in tight spaces. Safety is paramount. I always use the appropriate safety gear, including eye protection, dust masks, and hearing protection, when operating these tools. Regular maintenance is also key to ensuring tools remain accurate and efficient.

For example, when creating a custom radius edge on a granite countertop, I rely on my knowledge of using a CNC router and specialized edge profiling bits to create a precisely shaped edge. In contrast, using an angle grinder equipped with a diamond blade allows for quick and effective removal of excess material while shaping the edges of more rigid materials such as quartz or granite. Correct use and speed management of these tools is essential for achieving the desired outcome.

Q 11. How do you ensure the proper sealing and maintenance of different countertop materials?

Proper sealing and maintenance are vital to preserving the longevity and aesthetic appeal of countertops. Natural stone, like granite or marble, benefits from periodic sealing to protect against staining and water damage. Engineered stones typically require less frequent sealing, but a sealant can still enhance their stain resistance. Laminate countertops usually require less maintenance but should be cleaned with mild detergents to prevent scratches. The type of sealant used should be specific to the countertop material. For example, a penetrating sealant is ideal for natural stone, while a topical sealant is often sufficient for engineered stone.

In my experience, failing to properly seal natural stone can lead to permanent staining and etching. One client had a marble countertop that was stained due to lack of sealing. The solution involved using a specialized stone cleaner to remove surface stains as much as possible and then applying a new layer of sealant, which dramatically improved the countertop’s appearance and its resistance to future staining.

Q 12. What is your experience with templating countertops for complex installations?

Templating countertops for complex installations requires precision and attention to detail. It involves carefully measuring the countertop area, taking into account any obstacles or features like sinks, cooktops, and backsplashes. Accurate measurements are critical to ensure a perfect fit. I use both manual measuring techniques and digital templating tools, including laser measuring devices for complex curves and angles to capture the precise dimensions. These templates are then used to guide the cutting and fabrication process in the shop. Complex installations may involve multiple templates to account for different sections and levels.

One challenging templating project involved a curved island countertop with an integrated sink and waterfall edge. Precise measurements were essential to ensure the sink’s proper installation and the seamless flow of the waterfall edge. Using a combination of manual and digital templating tools, and creating multiple templates for the different sections of the countertop, I was able to achieve a perfect fit and a stunning final product.

Q 13. Describe your knowledge of countertop edge profiles and their applications.

Countertop edge profiles refer to the shape of the countertop’s edge. A wide variety of profiles exist, each offering a distinct aesthetic. Common profiles include straight edges, eased edges (slightly rounded for comfort), bevel edges (angled edges for a more modern look), ogee edges (a classic, S-shaped profile), and bullnose edges (a rounded profile). The choice of edge profile depends on the countertop material, the overall kitchen design, and personal preference. For example, a sharp, straight edge may be suitable for a contemporary kitchen with sleek lines, while a more ornate profile like an ogee edge might complement a more traditional style.

Understanding the nuances of various edge profiles is key to achieving the desired aesthetic for a project. For instance, a bullnose edge is often preferred for softer, more tactile feel and is commonly used with natural stones which have a more natural or organic appearance. Choosing an appropriate profile for a specific countertop material is also a consideration, as some edges are more difficult to achieve on certain materials. For example, very sharp profiles are challenging on softer stones.

Q 14. What are the differences between natural stone and engineered stone countertops?

Natural stone countertops, like granite, marble, or quartz, are mined directly from the earth. Each slab is unique in its pattern and veining, offering a natural, luxurious look. They are durable but can be prone to staining and etching if not properly sealed. Engineered stone, such as quartz, is a manufactured material made from ground natural stone, resins, and pigments. It offers consistent color and patterning throughout the slab, greater stain resistance and uniformity, and often greater durability. While natural stone offers the unique beauty of nature, engineered stone offers more predictable outcomes and consistency.

The choice between natural and engineered stone is often a matter of budget and desired aesthetics. Natural stone often commands a higher price, while engineered stone is often more cost-effective and maintains a consistent look throughout the countertops. Both materials require proper care and maintenance, although engineered stone typically requires less sealing and offers greater stain resistance. I have worked with many clients who weighed these considerations and ultimately made informed decisions.

Q 15. How do you manage a challenging or unexpected issue during a countertop installation?

Encountering unexpected issues during countertop installation is par for the course. My approach prioritizes problem-solving and communication. For example, if I discover unforeseen structural damage during demolition, I immediately document it with photos and discuss the necessary repairs with the client, outlining the impact on the timeline and budget. This transparency is crucial. I’ve had instances where unexpected plumbing issues were discovered – in such cases, I collaborate closely with the plumber to resolve the issue efficiently, maintaining open communication with the client throughout the process. My strategy always involves:

- Assessment: Carefully evaluate the problem, identifying its root cause and potential impact.

- Documentation: Photograph the issue and keep detailed records of all communication.

- Collaboration: If specialist expertise is needed (plumbing, electrical, etc.), I immediately involve them.

- Communication: I keep the client informed at every stage, providing realistic solutions and adjusting the timeline as needed.

- Contingency Planning: I always build some buffer into my schedule and budget to accommodate unexpected situations.

Ultimately, a calm, methodical response, coupled with clear communication, is key to resolving unexpected challenges smoothly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience working with different types of adhesives and sealants?

My experience with adhesives and sealants is extensive, encompassing a wide range of materials suitable for various countertop materials. I’m proficient with epoxies, silicones, and polyurethane-based adhesives, understanding their properties and applications. For example, I know that epoxy is ideal for bonding natural stone due to its strength and durability, while silicone is better suited for sealing joints where flexibility and water resistance are paramount, like seams between countertops and backsplashes. I meticulously select the right adhesive based on the material, the application, and the specific environment. I also understand the importance of proper surface preparation for optimal adhesion. Failing to prepare the surface properly can lead to premature failure of the adhesive or sealant, and I am meticulous in following manufacturer guidelines for every product.

Furthermore, I understand the nuances of different sealant types. For instance, I know to use a food-safe sealant in kitchen applications to ensure hygiene. The choice of sealant isn’t just about bonding; it’s about ensuring longevity and maintaining the integrity of the countertop installation.

Q 17. How do you handle customer inquiries and concerns regarding countertop choices?

Addressing customer inquiries and concerns is a vital part of my work. I believe in proactive and empathetic communication. When a client expresses concern about countertop choices, I start by actively listening to their doubts and anxieties. I then use this information to guide them towards the most suitable option, offering visual aids, samples, and comparing pros and cons of various materials based on their lifestyle, budget, and aesthetic preferences. For instance, if a client is concerned about the maintenance of natural stone, I will explain the sealing process and the level of care required, contrasting this with the low-maintenance aspects of engineered stone. I also offer realistic expectations – nothing is completely maintenance-free, and I want to set the client up for success.

I find that providing well-researched information and demonstrating a genuine interest in their needs significantly reduces anxieties and fosters trust. My goal is to ensure the client feels fully informed and confident in their final decision.

Q 18. What are the most common mistakes to avoid during countertop installation?

Avoiding mistakes during countertop installation is crucial for a successful project. Some common pitfalls include:

- Inadequate measurements: Inaccurate measurements lead to misfits and wasted material. Always double-check measurements, using precise tools and techniques.

- Poor surface preparation: Failure to properly clean and prepare the substrate before installation leads to poor adhesion and potential failure.

- Incorrect adhesive selection: Choosing the wrong adhesive for the countertop material will lead to weak bonding and potential damage.

- Improper sealant application: Inadequate sealing allows water penetration, leading to staining and damage. Always ensure complete and even sealant application.

- Ignoring manufacturer’s instructions: Each material has specific installation requirements, ignoring these can have devastating consequences.

- Rushing the process: Taking shortcuts or rushing the installation increases the likelihood of mistakes.

By meticulously following best practices and taking the time to do things correctly, these common errors can be easily avoided.

Q 19. Explain your understanding of countertop design principles.

Countertop design principles revolve around functionality, aesthetics, and durability. Functionality considers the intended use of the space – a kitchen countertop needs to withstand heavy use and heat, while a bathroom countertop prioritizes water resistance. Aesthetics involve integrating the countertop with the overall design scheme, considering factors like color, texture, and pattern. Durability refers to choosing materials that can withstand daily wear and tear, considering factors like stain resistance, scratch resistance, and longevity.

For example, a modern kitchen might benefit from a sleek, minimalist quartz countertop, while a rustic farmhouse kitchen might be complemented by a warm, textured granite. The design process always involves considering the client’s style, budget, and the practical requirements of the space. The goal is to create a beautiful and functional space that meets the client’s vision and lasts for years.

Q 20. Describe your experience with working from blueprints or designs.

I have extensive experience working from blueprints and designs. This involves carefully reviewing the plans to understand the scope of work, the specific materials required, and the overall layout. I verify measurements, check for potential issues or conflicts, and identify any special considerations like complex cuts or unique features. I often use the blueprints as a guide to create detailed templates for cutting and fitting the countertop. I’m proficient with various software programs to interpret digital designs and translate them into real-world installations. Any discrepancies or ambiguities in the blueprints are immediately brought to the client’s attention to ensure we’re all on the same page. This proactive approach prevents costly mistakes down the line.

For example, I once worked on a project with intricate curves and cutouts specified on a 3D model. My experience allowed me to accurately translate the digital design into a precise countertop installation.

Q 21. How do you estimate the time and materials required for a countertop project?

Estimating time and materials requires a detailed understanding of the project scope. I begin by carefully reviewing the blueprints, noting the size and complexity of the countertop, the type of material, and any special features. I then factor in the time required for each stage of the process, including templating, cutting, fabrication, polishing (if applicable), and installation. I use historical data from past projects to refine my estimates, factoring in potential challenges and unforeseen delays. The material estimation is equally crucial; I account for waste and always order a small surplus to prevent delays due to material shortages.

For example, a simple laminate countertop installation requires significantly less time and material compared to a complex natural stone installation with intricate edge details and cutouts. My estimates always include a contingency buffer to account for unexpected events and ensure the project stays within budget and timeline.

Q 22. What is your experience with working within budget constraints?

Working within budget constraints is crucial in the countertop industry. It requires a multifaceted approach combining careful planning, material selection, and efficient labor management. My process starts with a detailed initial consultation to understand the client’s budget and desired aesthetic. Then, I explore various countertop materials, considering their price points and availability. For instance, if a client desires the look of granite but has a limited budget, I might suggest a more affordable engineered stone option like quartz that mimics the granite’s appearance. I also optimize the fabrication process by minimizing waste and utilizing efficient cutting techniques. Finally, I maintain transparent communication with the client throughout the project, providing regular updates and cost breakdowns to ensure that we stay on track. One memorable project involved a tight budget for a large kitchen remodel. By suggesting a beautiful laminate countertop with a custom edge profile, we achieved a stunning result without exceeding the allocated funds. This approach not only satisfied the client but also demonstrated my ability to deliver high-quality results even under budget limitations.

Q 23. Describe your process for quality control during fabrication and installation.

Quality control is paramount in countertop fabrication and installation. My process begins with meticulous template creation, ensuring an accurate representation of the countertop’s dimensions and features. During fabrication, I inspect each slab for imperfections, using quality tools to ensure precision cutting and polishing. I pay particular attention to seam alignment and edge details. For instance, if a seam needs to be created, I use advanced techniques to minimize its visibility and maintain a seamless aesthetic. Before installation, I conduct a final quality check to verify the countertop’s dimensions and confirm that it aligns perfectly with the existing cabinetry. During installation, I take extra care to protect the countertop from scratches or damage. After installation, I perform a final walkthrough with the client, addressing any concerns and ensuring their complete satisfaction. This meticulous approach has earned me a reputation for delivering flawless countertops that stand the test of time.

Q 24. What software or tools are you proficient in using for countertop design or fabrication?

Proficiency in design and fabrication software is essential for efficient and accurate countertop production. I’m highly proficient in using AutoCAD for precise template creation and 3D modeling, allowing for detailed visualization and accurate measurements. I also utilize SketchUp for rendering designs and creating visual representations for clients. In addition, I am familiar with various fabrication-specific software packages used to program CNC machines for precise cutting and shaping. This expertise helps me to translate client visions into accurate, detailed fabrication plans, minimizing errors and waste.

Q 25. How do you maintain a safe and organized work environment?

Maintaining a safe and organized work environment is non-negotiable. I prioritize safety by ensuring that all team members wear appropriate personal protective equipment (PPE), such as safety glasses, dust masks, and gloves. The workspace is kept clean and clutter-free, with tools and materials organized for efficient workflow and to prevent accidents. Hazardous materials are stored properly, following all safety regulations. Regular equipment maintenance is performed to prevent malfunctions and potential injuries. A clear system of communication and responsibility is in place, ensuring everyone is aware of safety procedures and potential hazards. For instance, before starting any operation involving power tools, a thorough safety briefing and verification of safe working conditions are always carried out.

Q 26. Explain your experience with handling different types of countertop backsplashes.

My experience encompasses a wide range of countertop backsplash materials. I’ve worked extensively with ceramic tile, glass tile, natural stone, and engineered stone backsplashes. Each material presents unique installation challenges and considerations. For instance, installing a natural stone backsplash requires precise cutting and careful grouting to maintain the stone’s integrity and beauty. Glass tiles, on the other hand, require a different approach, focusing on the precise placement and alignment of each tile. I’m adept at matching the backsplash material to the countertop material, creating a harmonious and aesthetically pleasing design. I always consult with the client to understand their preferences and provide recommendations based on their budget and the overall design aesthetic.

Q 27. How do you prioritize tasks and manage multiple projects simultaneously?

Managing multiple projects effectively requires a well-organized approach. I use project management software to track deadlines, budgets, and materials. I prioritize tasks based on urgency and dependency, ensuring that critical tasks are completed first. I also maintain open communication with clients, providing regular updates and addressing any concerns proactively. Using a combination of project management tools and detailed planning allows me to effectively juggle several projects, ensuring each one receives the necessary attention and is completed to a high standard. A well-defined workflow, coupled with timely and transparent communication, is key to successful multitasking in this industry.

Q 28. What are your career goals related to the countertop industry?

My career goals center around continued growth and expertise in the countertop industry. I aim to enhance my knowledge of new materials and technologies, staying at the forefront of industry trends. I’m eager to expand my leadership skills and mentor other professionals, contributing to the overall quality and professionalism of the industry. Ultimately, my goal is to establish myself as a recognized expert in high-end countertop design and fabrication, delivering exceptional results for clients and contributing to the growth and innovation within the field.

Key Topics to Learn for Countertops Interview

- Countertop Materials: Understanding the properties, advantages, and disadvantages of various countertop materials (e.g., granite, quartz, marble, laminate, butcher block). This includes knowledge of their durability, maintenance requirements, and aesthetic qualities.

- Installation Techniques: Familiarity with different installation methods, including proper measuring, cutting, and securing techniques for various materials. Understanding the importance of precision and attention to detail.

- Fabrication Processes: Knowledge of the processes involved in creating custom countertops, including templating, edge profiling, and finishing. Understanding the tools and equipment used in these processes.

- Design Considerations: Ability to advise clients on countertop selection based on their needs and preferences, considering factors like style, budget, and practicality. Understanding design principles and trends in kitchen and bathroom design.

- Maintenance and Repair: Knowledge of proper maintenance procedures for different countertop materials and techniques for repairing common damages, such as chips, cracks, and stains.

- Safety Procedures: Understanding and adhering to safety regulations and best practices when working with various tools, materials, and equipment. This includes personal protective equipment (PPE) usage.

- Client Communication: Effective communication skills to understand client needs, manage expectations, and provide professional advice and solutions.

- Project Management: Ability to manage time, resources, and projects effectively, ensuring projects are completed on time and within budget.

Next Steps

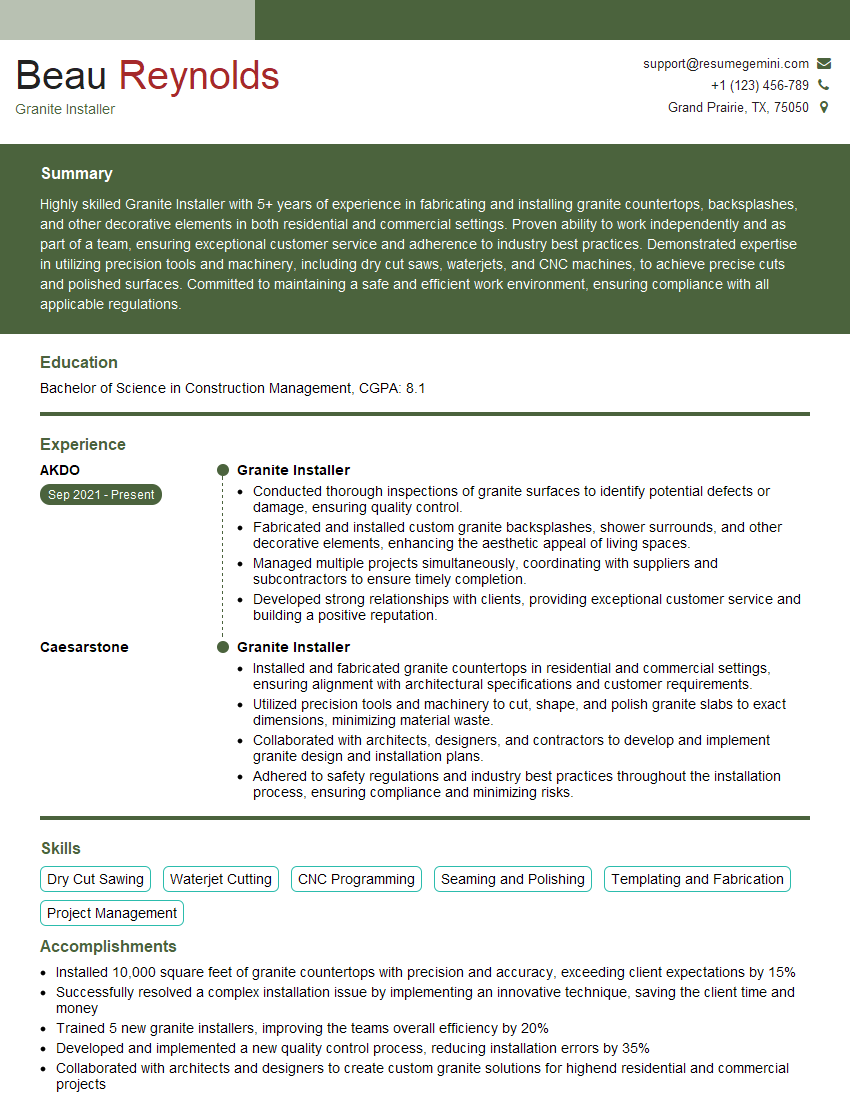

Mastering the intricacies of countertops opens doors to exciting career opportunities in a dynamic and growing industry. Your expertise in material selection, installation, and client communication will be highly valued. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to the countertops industry are available within ResumeGemini to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO