Unlock your full potential by mastering the most common Label Inspection interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Label Inspection Interview

Q 1. What are the key aspects of a label inspection checklist?

A comprehensive label inspection checklist ensures consistent quality control. It’s like a recipe for perfect labels – following it meticulously guarantees a consistently high-quality product. Key aspects include verifying:

- Print Quality: Checking for sharpness, clarity, and the absence of smudges, streaks, or color variations. This includes verifying the accuracy of barcodes and other critical markings.

- Registration/Alignment: Ensuring all elements (text, images, barcodes) are precisely positioned as per the design. Misalignment can render labels unreadable or unusable.

- Color Accuracy: Verifying that colors match the approved design specifications. This often involves using colorimeters or spectrophotometers for precise measurements.

- Material Integrity: Assessing the label material for defects like wrinkles, tears, creases, or inconsistencies in thickness. The material should adhere properly and withstand handling.

- Adhesive Performance: Evaluating the label’s ability to adhere correctly to the product. Insufficient or excessive adhesive can cause problems.

- Barcode Readability: Testing the scannability of barcodes using a barcode scanner to ensure accurate data capture. This is crucial for logistics and inventory management.

- Text Accuracy: Checking for correct spelling, font, and size of text. This is essential for product information and regulatory compliance.

A well-structured checklist allows for easy tracking of defects and facilitates consistent inspection across different batches and operators.

Q 2. Describe your experience with different types of label inspection equipment.

My experience encompasses a wide range of label inspection equipment, from basic manual inspection tools to sophisticated automated systems. I’ve worked with:

- Manual Inspection Magnifiers: Used for detailed visual checks of small defects and fine print. These are essential for initial assessments and verifying specific areas.

- Barcode Scanners: Crucial for verifying the readability and accuracy of barcodes, ensuring seamless integration with supply chain systems.

- Colorimeters/Spectrophotometers: These precision instruments are vital for objective color accuracy measurement, comparing printed labels against design specifications. I’m proficient in using these to quantify color differences and ensure compliance.

- Automated Vision Inspection Systems: These advanced systems offer high-throughput inspection capabilities, automatically detecting defects such as misalignment, missing elements, print defects, and inconsistencies in color. I have experience programming and operating various vision systems, including those from Cognex and Keyence.

- Dimensional Measurement Systems: These devices, often integrated into automated systems, precisely measure label dimensions to ensure consistency and conformance to specifications. This is particularly relevant for ensuring labels fit product packaging correctly.

My experience allows me to select and effectively utilize the most appropriate equipment for specific inspection tasks, optimizing efficiency and accuracy.

Q 3. How do you identify and classify different label defects?

Identifying and classifying label defects involves a systematic approach. I typically categorize defects into these major groups:

- Print Defects: These include blurry text, missing ink, smudging, streaks, uneven color distribution, and incorrect color reproduction.

- Registration/Alignment Errors: This involves misalignment of elements on the label, such as text, images, or barcodes. The degree of misalignment influences the severity of the defect.

- Material Defects: These comprise wrinkles, creases, tears, holes, and inconsistencies in material thickness or texture.

- Adhesive Defects: This category includes issues with insufficient adhesion (labels peeling), excessive adhesive (messy application), or improper adhesion to specific substrates.

- Barcode Defects: This covers unreadable or damaged barcodes due to poor print quality, misalignment, or damage to the label material.

Each defect is further classified by severity based on its impact on product usability, readability, and compliance. For example, a minor smudge might be acceptable, while a completely unreadable barcode is a critical defect.

Q 4. What are the common causes of label misalignment?

Label misalignment, a frequent issue, stems from various sources within the printing and labeling process. Common causes include:

- Mechanical Issues: Problems with the printing press’s mechanical components, such as worn gears, misaligned rollers, or improper tension on the web.

- Incorrect Setup: Errors in the initial setup of the printing press, involving incorrect registration marks or improper calibration of print heads.

- Material Issues: Variations in the label material itself, such as inconsistent thickness or stretch, can lead to misalignment.

- Operator Error: Human error during press operation, such as incorrect adjustments or failure to follow standard operating procedures.

- Environmental Factors: Changes in temperature and humidity can affect the label material and contribute to misalignment.

Troubleshooting misalignment often requires a systematic approach, checking each potential cause sequentially. Analyzing the pattern of misalignment can provide crucial clues about the root cause.

Q 5. Explain your experience with color accuracy measurement in label inspection.

Color accuracy is paramount in label inspection, impacting brand identity and product appeal. My experience includes using colorimeters and spectrophotometers to objectively measure and compare label colors to design specifications. This involves:

- Defining Color Standards: Establishing accurate color standards using Pantone, CMYK, or other color systems, ensuring consistent color representation across batches.

- Instrumental Measurement: Using colorimeters and spectrophotometers to measure the color values of printed labels, obtaining precise numerical data representing color characteristics (L*a*b*, Delta E).

- Data Analysis: Comparing measured values to target values to quantify color differences (Delta E). Acceptable Delta E values are established based on industry standards and client requirements.

- Color Correction: Working with printing operators to adjust press settings and ink formulations to achieve the desired color accuracy when discrepancies exceed tolerance levels.

I am experienced in interpreting color data, understanding the implications of color differences, and guiding corrective actions to ensure consistently accurate color reproduction.

Q 6. How do you handle discrepancies found during label inspection?

Discrepancies found during label inspection are handled systematically, prioritizing prompt corrective action and preventing further defects. The process involves:

- Defect Identification and Classification: Clearly identifying and classifying the nature and severity of each defect found.

- Root Cause Analysis: Investigating the root cause of the discrepancies. This may involve examining the printing process, label material, or other contributing factors. It’s like detective work, finding the source of the problem.

- Corrective Actions: Implementing appropriate corrective actions to address the root cause, which may involve adjusting machine settings, replacing faulty components, or retraining operators.

- Verification: Verifying the effectiveness of the corrective actions through repeat inspections. This ensures the problem is resolved and doesn’t recur.

- Documentation: Thoroughly documenting the discrepancies, root cause analysis, corrective actions, and verification results. This creates a history for future reference and process improvement.

- Communication: Communicating findings and corrective actions to relevant stakeholders, including production management, quality control, and potentially clients.

This structured approach minimizes production downtime, maintains quality, and ensures compliance with standards.

Q 7. What are your methods for documenting inspection results?

Detailed and accurate documentation is crucial for maintaining quality control and traceability. My methods include:

- Inspection Reports: Generating detailed reports that include the date, time, lot number, number of labels inspected, types of defects found, their severity, and the overall pass/fail rate. I use software to generate these reports automatically.

- Data Logging: Using automated inspection systems to record inspection data electronically, which allows for easy analysis and trend identification. This data may be integrated into a larger quality management system (QMS).

- Image Capture: Capturing images of critical defects to visually illustrate the issues and provide clear evidence for future reference. This is particularly useful for complex defects.

- Statistical Process Control (SPC) Charts: Employing SPC charts to track defects over time, identifying trends and potential areas for process improvement. This is a proactive approach to continuous improvement.

This comprehensive documentation ensures transparency, supports process improvement initiatives, and provides a readily available audit trail.

Q 8. Describe your experience with statistical process control (SPC) in label inspection.

Statistical Process Control (SPC) is crucial in label inspection for maintaining consistent quality and identifying potential problems before they become major issues. It involves using statistical methods to monitor and control a process, in this case, the label printing and application process. My experience includes implementing and interpreting control charts, such as X-bar and R charts, to track key parameters like label dimensions, color consistency, and barcode scannability. For instance, I’ve used X-bar and R charts to monitor the print registration of labels on a particular roll. By setting upper and lower control limits, we could quickly identify when the process drifted outside acceptable tolerances, allowing for timely intervention and preventing a large batch of defective labels. This proactive approach significantly reduced waste and improved overall efficiency. I’m also proficient in analyzing control chart data to identify trends and patterns, indicating the root cause of variations and guiding corrective actions. Furthermore, I’ve utilized capability analysis (Cp and Cpk) to assess the process’s ability to meet specifications, providing data-driven insights for process improvement initiatives.

Q 9. How familiar are you with different label printing technologies?

My familiarity with label printing technologies is extensive. I have hands-on experience with various methods, including:

- Flexography: I’m well-versed in understanding the nuances of flexographic printing, including plate making, ink selection, and press operation. I can troubleshoot common issues like misregistration and ink consistency problems.

- Digital Printing: I’m proficient with various digital label printing technologies, such as inkjet and toner-based systems. This includes understanding image resolution, color management, and media compatibility. I’ve worked with various digital printing platforms, allowing me to quickly diagnose and resolve issues like banding or image artifacts.

- Offset Printing: I understand the principles of offset lithography as applied to label printing, including plate preparation, ink-water balance, and press operation. I’m familiar with the unique challenges of this technology for label production, such as longer setup times and higher minimum order quantities.

- Screen Printing: I have experience with screen printing, particularly for specialized labels requiring high-opacity inks or unique textures. I understand the intricacies of stencil creation and screen maintenance.

This broad understanding allows me to effectively diagnose problems arising from any of these printing technologies and recommend appropriate solutions.

Q 10. How do you ensure the accuracy of barcodes and other data on labels?

Ensuring the accuracy of barcodes and other data is paramount. We employ a multi-pronged approach. This begins with rigorous pre-press checks, verifying the accuracy of the artwork and data before printing. During the printing process, we use automated verification systems, including barcode scanners and Optical Character Recognition (OCR) software, to check for errors. We also employ 100% verification methods for high-value labels or those with stringent accuracy requirements, which involves scanning every single label. Furthermore, we establish clear acceptance criteria for barcode quality, based on industry standards like ISO/IEC 15416, ensuring the barcodes are easily readable by scanners. Out-of-tolerance labels are immediately identified and rejected. Any discrepancies are thoroughly investigated, and the root cause is identified and corrected to prevent recurrence. Regular calibration of scanning equipment and software updates are also critical for maintaining accuracy.

Q 11. Explain your experience with label adhesion testing.

Label adhesion testing is crucial to ensure the label will remain securely attached to its substrate under various conditions. My experience encompasses a range of test methods, including:

- Peel adhesion tests: Using a tensile testing machine to measure the force required to peel a label from its substrate, quantifying the bond strength.

- Roll peel adhesion test: Assessing the adhesion of labels on a roll, simulating the conditions encountered during high-speed dispensing.

- Environmental testing: Exposing labels to various conditions (temperature, humidity, UV exposure) to evaluate their adhesion over time. This helps predict long-term performance and identify potential failures.

I’ve used these methods to assess the effectiveness of various adhesives and substrate combinations, ensuring that the labels meet the required adhesion specifications for the intended application. For example, a recent project involved testing the adhesion of labels intended for outdoor use, requiring rigorous environmental testing to ensure they remained affixed despite exposure to extreme weather conditions.

Q 12. How would you handle a large batch of defective labels?

Handling a large batch of defective labels requires a structured approach. First, we would quarantine the affected batch to prevent its entry into the supply chain. Next, a thorough investigation would be launched to identify the root cause of the defects. This could involve analyzing the control charts, examining the printing process, and checking the raw materials. Once the root cause is identified, corrective actions would be implemented to prevent recurrence. Depending on the nature of the defect and its severity, we might consider several options:

- Rework: If the defects are minor and easily correctable (e.g., minor misalignment), rework might be feasible.

- Scrap: If the defects are significant and cannot be corrected economically, the labels would be scrapped.

- Partial Use: In some cases, parts of the batch might be usable, depending on the type and location of the defect.

Throughout this process, detailed documentation is maintained, including the number of defective labels, the cause of the defect, the corrective actions taken, and the resulting disposition of the batch. This information is used for continuous improvement efforts.

Q 13. Describe your experience with root cause analysis in label inspection.

Root cause analysis is critical for preventing recurring defects. I’m proficient in various techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Pareto analysis. For example, if we consistently observed barcode scannability issues, we would use these methods to drill down to the underlying causes. The 5 Whys would help uncover the chain of events leading to the problem. A Fishbone diagram would help us systematically brainstorm potential causes, categorized by factors such as materials, machinery, methods, and manpower. Pareto analysis would help us prioritize the most significant causes based on their frequency and impact. This structured approach ensures that we address the root cause, preventing future occurrences and improving the overall efficiency and reliability of the label production process.

Q 14. How familiar are you with industry standards and regulations related to labeling?

I’m very familiar with industry standards and regulations related to labeling. My knowledge encompasses:

- GS1 Standards: I understand the importance of adhering to GS1 standards for barcode symbology, data structures, and Global Trade Item Numbers (GTINs).

- FDA Regulations: I’m knowledgeable about FDA regulations for food and drug labeling, including requirements for ingredient lists, nutritional information, and warnings.

- Hazardous Materials Labeling: I’m familiar with regulations like GHS (Globally Harmonized System) for labeling hazardous materials, including the proper use of hazard pictograms and signal words.

- Industry-Specific Regulations: I understand the labeling requirements for various industries, such as cosmetics, pharmaceuticals, and automotive.

This understanding ensures that the labels we produce comply with all relevant regulations, minimizing the risk of non-compliance and potential legal issues.

Q 15. What are your methods for preventing label defects?

Preventing label defects starts long before the inspection stage. It’s a proactive, multi-faceted approach involving careful planning and execution at every step of the label production process. My methods focus on three key areas:

- Upstream Process Control: This involves rigorously monitoring and controlling the printing press, ensuring consistent ink levels, accurate die-cutting, and proper material handling. For example, regularly scheduled maintenance on the printing press, including cleaning the rollers and checking ink viscosity, minimizes print defects. Implementing a robust quality control system at the raw material stage, verifying the quality of the adhesive, paper stock and inks, is crucial.

- Operator Training and Skill Development: Well-trained operators are key. Comprehensive training programs focusing on proper machine operation, quality checks at each stage, and troubleshooting common defects are essential. We can use checklists and visual aids to reinforce best practices. For instance, we provide training on identifying misalignment, color inconsistencies and other subtle imperfections.

- Environmental Control: Maintaining a stable production environment is crucial. Factors like temperature, humidity, and cleanliness can significantly impact label quality. We use climate-controlled environments where necessary, and implement strict cleanliness protocols to prevent dust and debris from affecting the labels.

By focusing on these preventative measures, we significantly reduce the number of defects needing attention during the inspection phase, improving efficiency and reducing waste.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize label inspection tasks?

Prioritizing label inspection tasks is crucial for efficiency and effectiveness. My approach involves a combination of factors:

- Urgency: Labels destined for time-sensitive products or shipments are prioritized. This might include products with short shelf lives or those awaiting urgent delivery.

- Criticality: Labels with crucial information, like warnings or dosage instructions on pharmaceuticals, or traceability information on food products, take precedence. A misprint on these labels can have serious consequences.

- Volume: High-volume orders are often given priority to meet production deadlines. But a systematic approach of sample sizes is crucial even in high-volume orders to check for consistent quality.

- Risk Assessment: We assess the potential risk associated with each label type. Labels for products with a higher risk of safety or regulatory violations are inspected more thoroughly.

I often utilize a weighted scoring system to combine these factors, allowing for a data-driven approach to prioritization. This system ensures that resources are allocated effectively to those labels needing the most immediate attention.

Q 17. Explain your experience working with automated label inspection systems.

I have extensive experience working with various automated label inspection systems, including vision systems and laser-based solutions. I’m proficient in setting up and configuring these systems, interpreting results, and troubleshooting issues. For example, I’ve worked with Cognex and Keyence systems, which use sophisticated image processing algorithms to detect even minor defects like scratches, smudges, and misprints.

My experience extends to programming simple scripts to customize the inspection parameters based on specific label requirements and integrating these systems with existing production line management software for real-time data analysis and reporting. I understand the importance of calibrating these systems regularly to maintain accuracy and minimizing false positives or negatives. I’m also familiar with different types of cameras, lighting configurations and the importance of optimized image acquisition for effective defect detection.

Q 18. How do you ensure the traceability of label inspection results?

Ensuring traceability of label inspection results is paramount for accountability and quality control. Our system utilizes a unique identification number (UID) assigned to each batch of labels. This UID is tracked throughout the entire production process, from raw material sourcing to finished goods inspection. The inspection results, including images of defects and a summary report, are then linked to this UID in our database.

This allows for complete traceability, enabling us to easily identify the specific batch if issues arise with the final product. The system generates comprehensive audit trails, documenting all actions taken during the inspection process. This ensures transparency and facilitates efficient problem-solving and corrective actions. We also maintain a record of the specific inspection equipment used, ensuring we can pinpoint any potential problems with the machinery itself.

Q 19. Describe your experience with different types of label materials.

My experience encompasses a wide range of label materials, including paper (coated, uncoated, and specialized papers), various films (polyester, polypropylene, vinyl), and even fabric labels. Each material presents unique challenges in terms of printability, durability, and inspection techniques. For instance, glossy films can cause glare during inspection, requiring adjustments to the lighting configuration of the automated systems.

I’m familiar with the properties of each material type and how those properties affect the inspection process, and I adapt my techniques accordingly. This includes adjusting the sensitivity settings on inspection equipment, choosing appropriate lighting, and using different image processing algorithms to optimize defect detection for each material. Understanding material specifications and their potential for defects is crucial for effective inspection and preventing downstream problems.

Q 20. How do you handle label inspection discrepancies with different departments?

Handling discrepancies effectively requires clear communication and a collaborative approach. When discrepancies arise, my first step is to thoroughly review the inspection data, comparing findings from different departments. This involves a careful analysis of the images captured during automated inspection and a physical verification of a sample of the labels.

I then initiate a meeting with the relevant departments (printing, packaging, quality control, etc.) to discuss the findings, and collaboratively determine the root cause. We will use data analysis to identify patterns and trends. Once the root cause is identified, we collaboratively develop a corrective action plan, including preventative measures to avoid similar discrepancies in the future. All agreed-upon actions are documented and tracked to ensure effective resolution and accountability.

Q 21. What are your problem-solving skills in label inspection?

My problem-solving approach in label inspection is systematic and data-driven. When a problem arises, I follow these steps:

- Identify the Problem: Clearly define the defect, noting its type, frequency, and location on the label.

- Gather Data: Collect data from various sources, including inspection reports, production logs, and operator feedback. I would analyze images from the inspection system, looking for patterns or trends.

- Analyze the Data: Use statistical analysis and root-cause analysis tools (like the 5 Whys or Fishbone diagram) to identify the underlying cause of the defect.

- Develop and Implement Solutions: Based on the root cause analysis, propose and implement corrective actions. These might involve adjusting machine settings, improving operator training, or modifying the production process.

- Monitor and Evaluate: After implementing the solution, continuously monitor the process to ensure the defect is resolved and prevent recurrence.

For example, if we experience recurring misalignment issues, I might investigate the printing press settings, check for wear and tear on the components, and evaluate the operator’s technique. By applying this structured approach, I can effectively and efficiently resolve label inspection challenges.

Q 22. How do you maintain accurate records in label inspection?

Maintaining accurate records in label inspection is crucial for traceability, regulatory compliance, and continuous improvement. We employ a multi-faceted approach.

- Digital Record Keeping: We utilize a dedicated software system to log every inspection. This includes the date, time, product batch number, inspector’s name, the number of units inspected, and a detailed description of any discrepancies found, including photographic evidence. This system automatically generates reports and allows for easy data analysis.

- Clear and Standardized Reporting: Our reports follow a standardized format, ensuring consistency and clarity. This includes specific codes for different types of label errors (e.g., missing information, incorrect text, damaged label) to facilitate quick identification of trends.

- Audit Trails: Every change or update to the inspection records is logged, creating an audit trail that ensures data integrity and accountability. This helps us identify and rectify any errors in record-keeping promptly.

- Regular Data Backups: Regular backups of our digital records are performed to prevent data loss and ensure business continuity in case of unforeseen circumstances. We use both on-site and off-site backups.

For example, if a batch of labels is found to have an incorrect expiration date, the system records this finding, along with images of the affected labels, allowing for immediate recall and prevention of further distribution.

Q 23. Explain your knowledge of GMP (Good Manufacturing Practices) related to labeling.

GMP (Good Manufacturing Practices) for labeling are paramount to ensuring product safety and consumer trust. My understanding encompasses several key areas.

- Accuracy of Information: Labels must accurately reflect the product’s contents, including ingredients, net weight, manufacturer details, and any relevant warnings or precautions. Any deviation is a critical GMP violation.

- Label Integrity: Labels should be durable, clearly legible, and free from defects that could compromise product safety or mislead the consumer (e.g., smudging, tearing, incorrect barcodes).

- Traceability: Each label should be linked to the production batch, facilitating quick identification and recall in case of a problem. This often involves batch numbers printed directly on the label or linked through a tracking system.

- Labeling Materials: GMP guidelines also govern the materials used for labeling, ensuring that they are food-safe or pharmaceutically compliant, depending on the product. This includes avoiding materials that could leach chemicals into the product.

- Change Control: Any changes to the label design or information require a formal change control process to ensure that all aspects are validated and meet GMP standards before implementation.

For instance, a pharmaceutical label’s accuracy is paramount because incorrect dosage instructions could have serious health consequences. My experience includes rigorous adherence to GMP standards during label inspections for both food and pharmaceutical products.

Q 24. How do you adapt to changing priorities in a fast-paced label inspection environment?

Adapting to changing priorities in a fast-paced environment involves flexibility, strong communication, and prioritization skills. My approach involves:

- Clear Communication: Maintaining open communication with my supervisor and team members about changing priorities and workload is vital. This ensures that everyone is on the same page and can adjust their tasks accordingly.

- Prioritization: I use a prioritization framework to identify the most critical tasks based on their urgency and impact. This ensures that time-sensitive inspections receive the necessary attention.

- Flexibility: I am comfortable shifting between different types of inspections and adjusting my workflow to meet changing demands. This includes handling unexpected issues and prioritizing accordingly.

- Proactive Problem-Solving: Identifying and addressing potential bottlenecks proactively minimizes disruptions. For example, anticipating potential delays in a new product launch and adjusting inspection schedules accordingly.

Imagine a scenario where a new product needs urgent inspection before launch. I would immediately prioritize this, informing my team and coordinating resources to ensure timely completion while maintaining the quality of the inspection process.

Q 25. Describe your experience with image analysis software used for label inspection.

I have extensive experience using image analysis software for label inspection. This technology significantly enhances speed and accuracy. I’m proficient in software that allows for:

- Automated Defect Detection: The software automatically detects discrepancies such as missing text, blurry images, incorrect barcodes, and color variations, which significantly speeds up the inspection process compared to manual inspection.

- Data Analysis and Reporting: The software generates detailed reports with quantifiable data on the number and types of defects found, which aids in identifying trends and areas for improvement in the manufacturing process.

- Customization: Many systems allow customization of inspection criteria to meet specific product and regulatory requirements. For example, setting tolerance levels for color variations or specific text elements.

- Integration with Other Systems: The software can be integrated with other systems, such as production tracking and quality management systems, to improve overall traceability and efficiency.

For example, I’ve used software that identifies subtle color variations that might be missed by the human eye, ensuring consistent branding and preventing the release of products with substandard labels. My experience includes proficiency in [mention specific software names, e.g., Cognex VisionPro, Halcon] and I am comfortable learning and adapting to new image analysis tools.

Q 26. How do you communicate effectively about label inspection findings to management?

Effective communication of label inspection findings is key to preventing product recalls and ensuring regulatory compliance. My approach includes:

- Clear and Concise Reporting: I use clear and concise language in my reports, avoiding technical jargon whenever possible. I focus on presenting the findings in a way that is easily understandable for management, regardless of their technical expertise.

- Data Visualization: I use charts and graphs to visually present key findings, making it easier for management to quickly grasp the overall picture. This highlights trends and critical issues.

- Prioritization of Issues: I prioritize the findings based on their severity and potential impact, focusing on critical issues that require immediate attention.

- Recommendations: I provide clear and actionable recommendations for addressing the identified problems. This could include process improvements, equipment upgrades, or retraining of personnel.

- Regular Updates: I provide regular updates on the status of ongoing inspections and any significant findings.

For example, I would present a report showing a significant increase in misprinted labels with a clear explanation of the root cause and suggest potential solutions like recalibrating printing equipment.

Q 27. What are your strategies for improving efficiency in label inspection?

Improving efficiency in label inspection requires a holistic approach combining technology, process optimization, and teamwork. My strategies include:

- Automation: Leveraging automated inspection systems, as discussed earlier, significantly reduces inspection time and improves accuracy.

- Process Optimization: Streamlining the inspection workflow by eliminating unnecessary steps and improving the organization of the inspection area can improve efficiency.

- Training and Development: Investing in training and development for inspectors ensures they possess the necessary skills and knowledge to perform their tasks effectively and efficiently.

- Preventive Maintenance: Regular preventive maintenance of inspection equipment minimizes downtime and ensures consistent performance.

- Data Analysis: Analyzing inspection data to identify trends and patterns can help in proactively addressing potential issues and preventing future problems.

For instance, by implementing a new automated system, we reduced inspection time by 50%, allowing for increased throughput and reducing labor costs. Continuous analysis of our data revealed a recurring issue with label alignment, allowing for timely adjustments to the printing process.

Q 28. Explain your experience with different types of label applications (e.g., food, pharmaceuticals)

My experience encompasses label inspection across diverse applications, including food, pharmaceuticals, and cosmetics. The key differences lie in regulatory requirements and the criticality of label accuracy.

- Food Labels: Food label inspection is rigorous, focusing on accuracy of ingredient lists, allergen information, nutritional facts, and expiration dates. Compliance with FDA regulations is paramount. I have experience inspecting labels for various food products, from packaged goods to fresh produce.

- Pharmaceutical Labels: Pharmaceutical label inspection is the most stringent due to the potential health consequences of inaccuracies. Precision and accuracy are critical in ensuring correct dosage information, warnings, and batch numbers. My experience includes inspecting labels for various pharmaceutical products, including tablets, capsules, and injectables.

- Cosmetics Labels: Cosmetic label inspection focuses on accuracy of ingredient lists, warnings, and net weight. Compliance with relevant regulations is crucial. I’ve inspected labels for a range of cosmetic products, including skincare, makeup, and hair care products.

Each industry has its specific requirements and challenges. For example, the need for high-resolution imaging is more critical in pharmaceutical label inspection to ensure legibility of small print, while food label inspection often involves checking for signs of tampering or damage to packaging.

Key Topics to Learn for Label Inspection Interview

- Regulations and Compliance: Understanding relevant industry regulations (e.g., FDA, GMP) and their impact on label accuracy and compliance.

- Labeling Best Practices: Familiarizing yourself with established best practices for label design, content, and placement to ensure clarity and accuracy.

- Inspection Techniques: Mastering visual inspection methods, including techniques for detecting errors in text, graphics, and barcodes.

- Technological Applications: Understanding the role of automated inspection systems and software in improving efficiency and accuracy.

- Quality Control Procedures: Becoming proficient in implementing and following established quality control processes during label inspection.

- Data Analysis and Reporting: Knowing how to analyze inspection data to identify trends, root causes of errors, and suggest improvements.

- Problem-Solving and Troubleshooting: Developing the ability to quickly identify and resolve label inspection issues, escalating when necessary.

- Documentation and Record Keeping: Understanding the importance of accurate and detailed documentation of inspection findings and corrective actions.

- Communication and Collaboration: Practicing effective communication with production teams, supervisors, and other stakeholders to ensure label quality.

- Continuous Improvement: Demonstrating a commitment to continuous improvement and identifying opportunities to optimize label inspection processes.

Next Steps

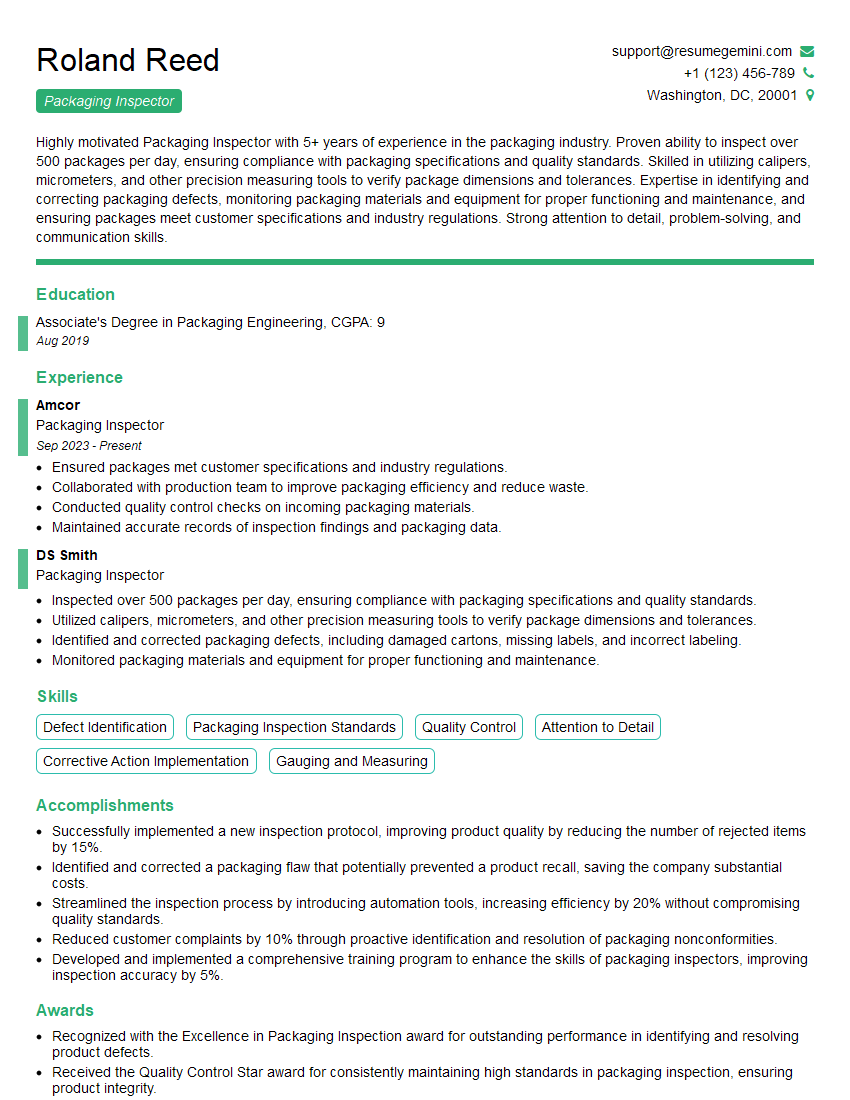

Mastering label inspection skills opens doors to rewarding careers in quality control, manufacturing, and related fields, offering opportunities for advancement and specialization. To significantly boost your job prospects, it’s crucial to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Label Inspection are available to further guide your preparation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO